Page 1

BEAM Alliance

Operation Manual

Page 2

IMPORTANT SAFEGUARDS

When using an electronic appliance, basic safety precautions should always be followed, including those listed

below.

READ ALL INSTRUCTIONS BEFORE USING THIS VACUUM SYSTEM.

WARNING

To reduce the risk of re, electric shock or injury:

• This vacuum cleaner is intended for dry pick up only. Do not use on wet surfaces or pick up any

liquids, hot debris or any ammable items that would cause harm to the vacuum cleaner.

• Keep cord away from heated surfaces.

• Do not allow vacuum to be used as a toy. Close supervision is necessary when this vacuum is used

by or near children.

• Use this vacuum only for its intended use as described in this manual. (Use of attachments not

recommended by manufacturer may cause re, electric shock, injury or damage to system

• components.)

• Connect to a properly grounded (earthed) outlet only. See grounding (earthing) instructions.

• Mount unit at least 30 cm (12 inches) from the oor, ceiling and corner sidewall to insure adequate

ventilation for motor.

• Never operate this vacuum if it has a damaged cord or plug, if it is not working properly, or if it has

been dropped or damaged. Return to authorized dealer/distributor for repair.

• Never disconnect plug by pulling cord. To disconnect from outlet, grasp the plug, not the cord.

• Do not put any object into openings. Do not use with any opening blocked. Keep free of dust, lint, hair

and anything that may reduce air ow/suction. Lack of air ow will cause the motor to overheat.

• This vacuum cleaner creates suction. Keep hair, face, ngers, all body parts and loose clothing away

from any openings.

• Never operate without dust bag and/or lter in place.

• Turn off all controls before unplugging.

• Never handle plug, cord or power unit with wet hands.

• Use extra care when cleaning on stairs.

• Do not locate the power unit in a high temperature area or where it is inaccessible, for example, an

attic or crawl space.

• Do not use extension cords or outlets with inadequate current carry capacity.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches or hot ashes.

• Do not use on wet surfaces.

• Do not vacuum drywall dust or baking our as it may cause damage to your vacuum.

• This appliance is not intended for use by persons, (including children), with reduced physical,

sensory, or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

• If the power cord is damaged, it must be replaced by a special cord available from the authorized

local dealer/distributor.

• Keep your work area well lit.

• Unplug electrical appliances before vacuuming them.

• Do not pick up ammable or combustible liquids such as gasoline, or use in areas where they may be

present.

SAVE THESE INSTRUCTIONS

2

Page 3

Dear Beam Customer;

Congratulations on your new Beam Alliance Central Vacuum! You have just purchased Beam’s most innovative

and intuitive Central Vacuum. Thank you for your support. For maximum benet, please read this instruction

manual before installing and operating your central vacuum. You will want to keep these instructions for future

reference.

To purchase or inquire about accessories and installation services, please contact your local dealer or visit our

website at www.beam.com.

We recommend you register your Central Vacuum at our website www.beam.com.

For your convenience, write down the model number and serial number and model number located on your

power unit below. You will nd these numbers on the rating plate located on the back top of the unit.

Model Number _______________________

Serial Number _______________________

Purchase Date _______________________

Opening the Package

Your Central Vacuum and its accompanying hardware and accessories are carefully packed in a cardboard

package designed to protect it from transportation damage. You will nd the pieces needed to hook up your

central vacuum packaged in the dirt bucket.

Installation of your Central Vacuum

If you are planning to install your central vacuum yourself, there is an excellent installation manual and

installation video available to you online at www.beam.com. If you want a professional to install your central

vacuum, please contact your local dealer or call 1-800-369-2326 in the United States and 1-800-282-2886 in

Canada. We will be happy to direct you to the professional installer in your area.

GENERAL INFORMATION

The central vacuum system is designed for dry pick up of household dirt and dust and is not intended to pick

up liquids. Avoid picking up hard or sharp objects with the system to prevent hose and plastic pipe damage or

clogs. This central vacuum system is intended for household use only.

Service Information

The instructions in this booklet serve as a guide to routine

maintenance. For additional information, contact your local

authorized dealer/distributor.

Rating Plate

The style, model and serial numbers are indicated on the

rating plate located on back left side of power unit. For

prompt and complete service information, always refer

to these numbers when inquiring about service (refer to

Figure 1.)

Figure 1.

3

Page 4

GROUNDING INSTRUCTIONS

This vacuum must be grounded (earthed). If it should malfunction or breakdown, grounding (earthing)

provides a path of least resistance for electric current to reduce the risk of electric shock. This vacuum is

equipped with a cord having an equipment-grounding conductor and grounding (earthing) plug. The plug

must be inserted into an appropriate outlet that is properly installed and grounded (earthed) in accordance

with all local codes and ordinances.

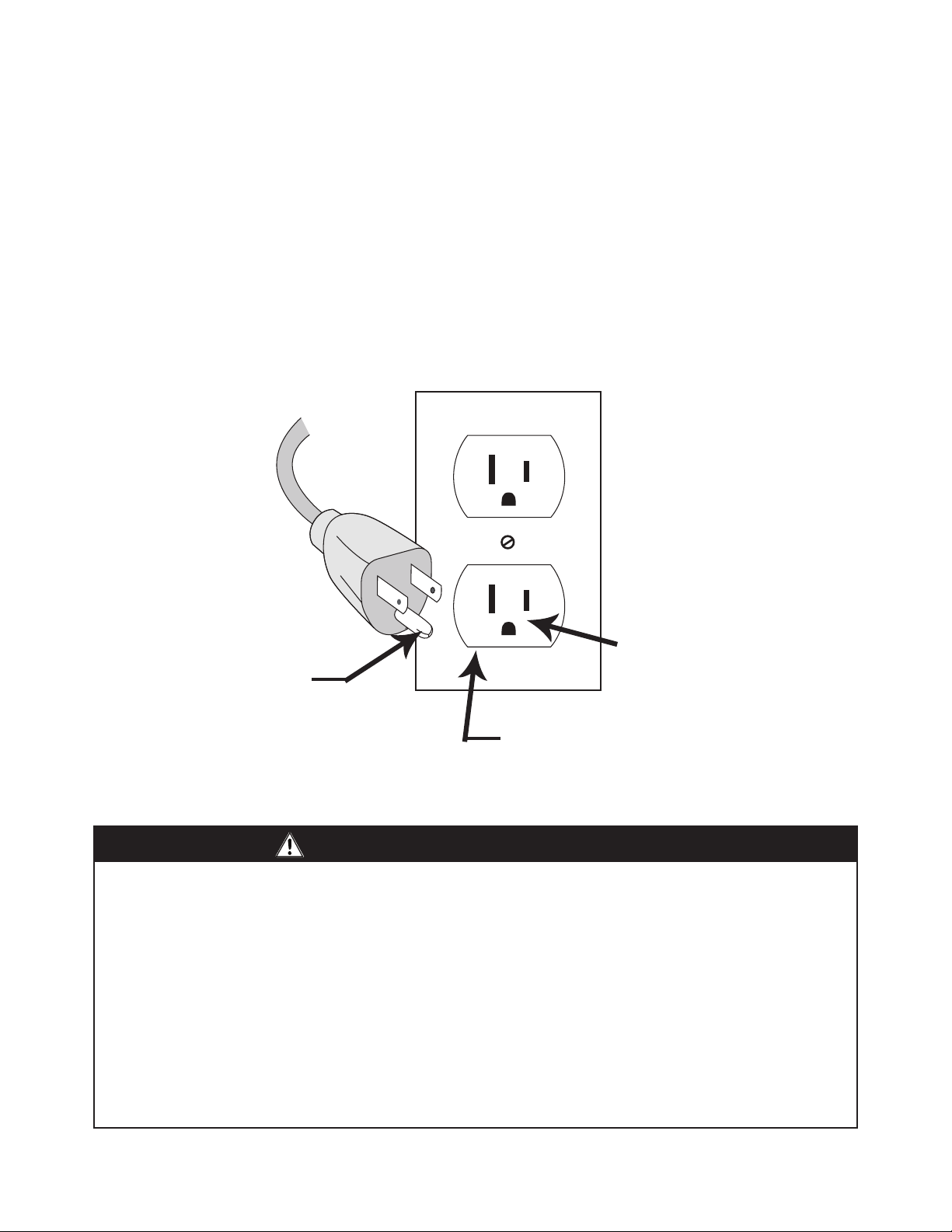

110/115/120V Models

This vacuum is for use on a nominal 110/115/120 volt circuit, and has a grounded plug like the one shown

below. Make sure the appliance is connected to an outlet having the same conguration as the plug. No

adaptor should be used with this vacuum.

Grounded Pin Receptacle

Grounding Pin

Grounded Outlet

WARNING

Improper connections of the equipment-grounding (earthing) conductor can result in risk of electric shock.

Check with qualied electrician or service person if you are in doubt as to whether the outlet is properly

grounded (earthed). Do not modify the plug provided with the appliance. If it will not t the outlet, have the

proper outlet installed by a qualied electrician. This appliance is for use on a nominal 120 volt (see rating

plate for correct voltage) circuit and has a ground (earth) plug that looks like the plug illustrated Make sure

the appliance is connected to an outlet having the same conguration as the plug.

• No adapter should be used with this appliance.

• Do not use an extension cord with this appliance.

• If the power cable is damaged, use only OEM replacement cable.

• Check the power unit on/off button and all inlet valves for operation.

• This power unit is intended for household and commercial use only.

4

Page 5

INSTALLATION

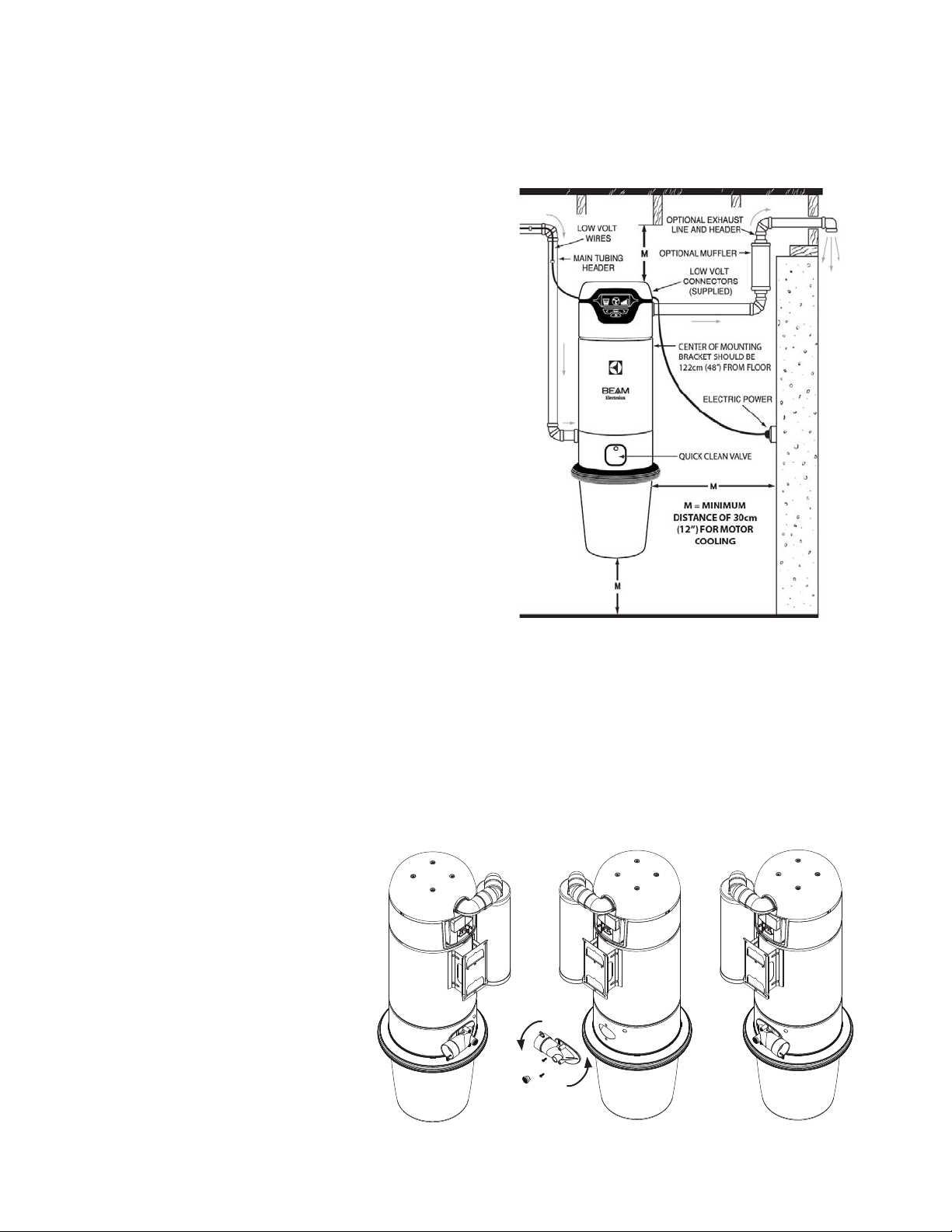

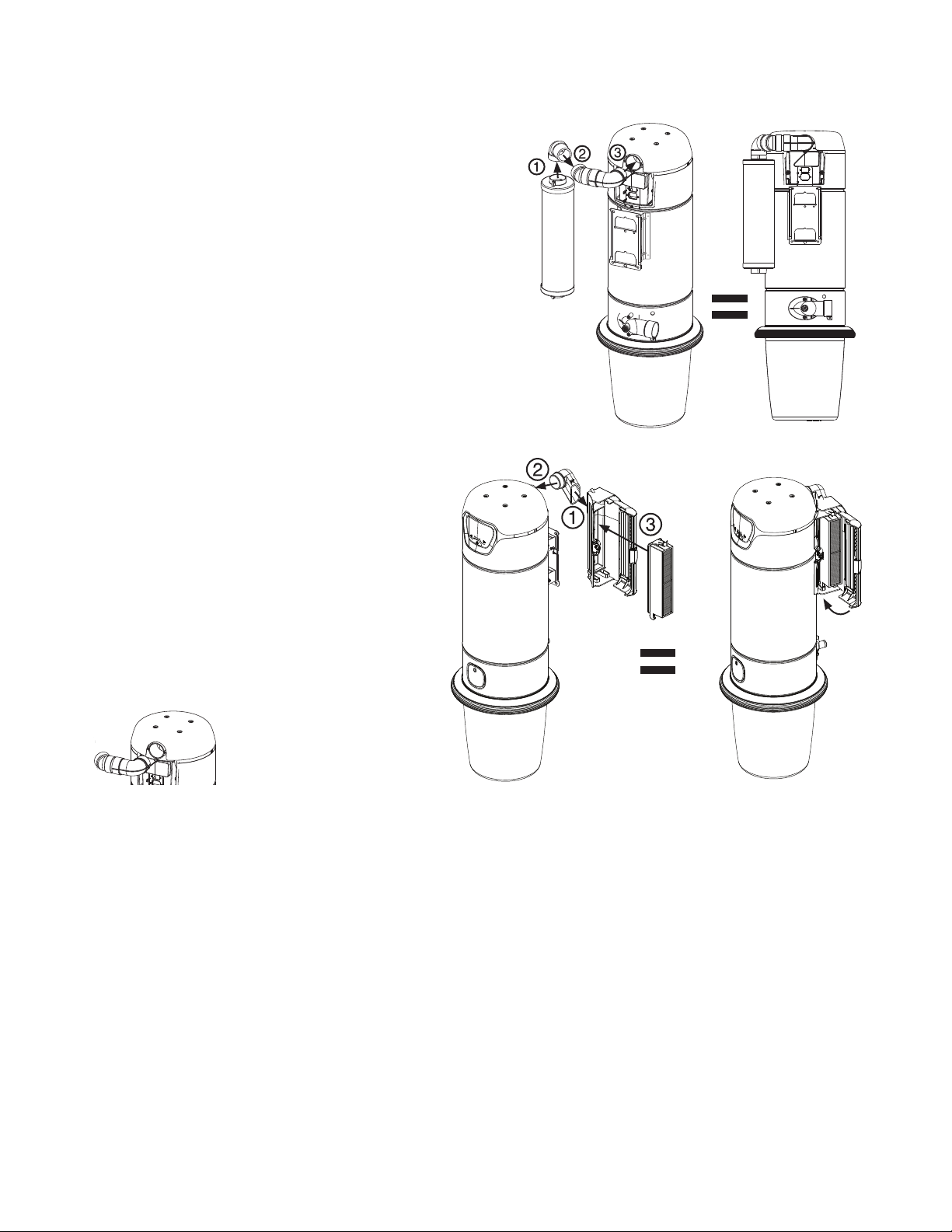

Installation of Power Unit

The power unit hangs on the mounting bracket which is

screwed to the wall. The bottom screws of the mounting

bracket should be about 48” (122 cm) up from the oor

to allow convenient removal of the dirt bucket. For proper

motor cooling, there must be at least 12” (31 cm) between

unit and the ceiling. If mounting on plaster or panel walls,

be sure mounting screws enter studs. If mounting on

concrete wall, drill the wall with a masonry bit and insert the

appropriate wall anchors. Strip the low-voltage wires that

were installed with the main trunk line. (Figure 2)

With optional “Quick Clean” Inlet on the power unit, connect

trunk line wires to wire harness on back of unit before

connecting to the spring loaded connectors on the back

side of the power unit. If you do not have the “Quick Clean”

valve option, simply connect the trunk line wires directly to

the spring loaded connectors on the back side of the power

unit. Connect the main tube line to the tube intake on the

power unit with the connector and clamp provided.

Do not glue the connection to the power unit in case you

wish to remove at a future date. This unit may be vented

outside. Do not exceed a run of over 20 feet off of exhaust,

Do not vent power unit into a wall, ceiling or concealed

space of a building.

NOTE: Power Unit On/Off button is used when unit is not equipped with “Quick Clean” inlet or as an over ride

switch in the event your trunk line wiring becomes damaged. All other inlets operate automatically when hose

end is inserted into inlet valve. The power cable has a three-prong female connector on one end. This connector

must be plugged into the mating connector on the power unit. Plug the other end of the power cable into the

wall electrical outlet.

WIRING: Check local codes, but use not less than #12-2 wires with ground. Plug power unit cord into

appropriate electrical outlet. Be sure line voltage is sufficient to handle 20 amp loads.

Figure 2

Intake Flange

Your power unit has been designed

for either a left or right pipe intake.

This is to give you more exibility

when choosing the location you

wish to hang your power unit. To

change the direction of the intake

ange, you simply remove the two

Torx 20 screws located on the

intake ange and turn the intake

ange 180 degrees. Secure the

intake ange with the same two

Torx 20 screws. (Figure 3)

Figure 3

5

Page 6

Muffler Installation

The muffler is installed to the exhaust located at the rear

of the power unit using the 3 ttings provided and Torx 20

screws provided. We suggest you install your muffler as

shown, prior to hanging your Power Unit (Although some

modication to this is acceptable), (Figure 4).

NOTE: Do not install muffler on the same side as the

intake ange so as to not interfere with pipe intake. Insert

the 90 degree tting into the muffler and screw into place.

Glue the next two ttings in place before connecting to the

power unit. Use the Torx 20 screws provided to connect

muffler to Power Unit.

NOTE: Do not glue the muffler pipe to the central vacuum

unit.

HEPA Filter Installation (optional)

Use the Torx 20 screws to secure the 90 degree

elbow provided to the HEPA lter. Use screws

to connect HEPA lter to Power Unit. We

recommend you install the HEPA lter before

hanging your Power Unit. (Figure 5a)

Figure 4

NOTE: Do not glue the HEPA lter to the

central vacuum unit.

NOTE: One elbow must be installed if the

muffler or the HEPA lter is not used. (Figure 5b)

Figure 5aFigure 5b

BASIC OPERATION FOR BEAM ALLIANCE POWER UNIT

To operate, simply plug the hose into one of the handy wall inlet valves. The metal ring on the hose cuff will

complete a low-voltage electrical circuit, which in turn activates a relay and turns on the system’s power unit. To

turn off the power unit, simply unplug the hose from the inlet.

Note: When unplugging the hose, it is recommended to hold the inlet door open for a few seconds until the

suction pressure has sufficiently decreased.

For safety purposes, a low-voltage circuit is utilized at the wall inlet. The power unit functions on a standard

110/120-volt circuit. There are optional hoses available with an on/off switch located on the handle.

Note: When using one of these optional hoses, it is important to properly align the hose with the wall inlet when

plugging it in to prevent damage to the unit.

6

Page 7

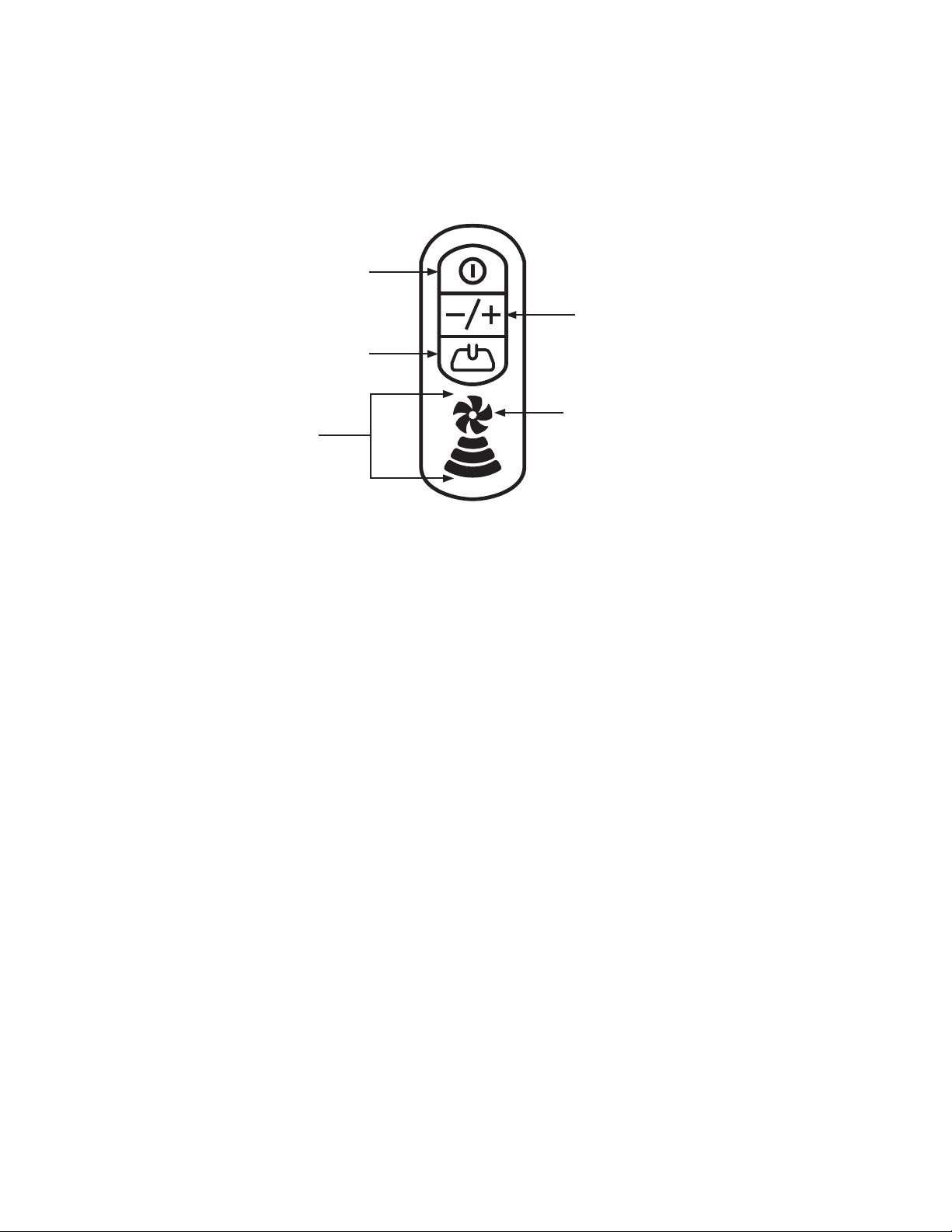

BASIC OPERATION FOR BEAM ALLIANCE HOSE

The BEAM Alliance hose is designed to work as an integrated system with the BEAM Alliance Power Unit. It

will not work with any other Central Vacuum System. The BEAM Alliance Hose System brings more options to

your ngertips!

Power Button

Variable Speed

Controls

ON/OFF

Brush Roll

Low

Variable Speed

Indicator

High

System Light:

Blue pulsating light

= system ready/stand-by

Red ashing light

= check power unit

Power Button

The Power button located on Alliance hose handle allows you to conveniently turn the Power Unit off and on at

the handle. For those 110V/24V hoses needed to power an electric powerhead, you will nd a powerhead icon

button conveniently located on the handle that allows you to turn the powerhead off and on.

Variable Speed Control

The BEAM Alliance Hose Handle is equipped with variable speed control allowing you to decrease or increase

the speed of the motor and in effect the end of hose suction. You now can dene how much suction you need

to do the specic job at hand! Decrease suction by pressing the (-) button, and increase suction press the (+)

button. When the system is turned on the suction defaults to highest and so all Variable Speed Indicator bars

will be lit. Decreasing suction decreases the number of indicator bars lit.

System Indicator

When the Alliance hose is connected to an inlet valve the fan blade image on hose handle will pulsate with

a glowing blue light. This conrms communication between the hose handle and power unit. When the fan

blades are solid blue, all systems are GO. When the fan blades are RED, you should empty your bucket or

check for other performance issue. If the fan blades begin FLASHING and are RED, you should turn off your

vacuum immediately. Check over your power unit and if you are unable to diagnose issue, call your local dealer

for service.

CARE AND MAINTENANCE

Your Beam Built-in Vacuum comes with a lifetime limited warranty (see complete warranty details in this

pamphlet). It will give you a lifetime of trouble-free service by following some simple guidelines.

7

Page 8

The BEAM Alliance central vacuum system is equipped with a ow-thru motor and will never need lubrication.

Should you experience any problems with your motor, please contact your local authorized dealer/distributor.

• Power unit can be dusted off with a clean, soft cloth. Caution: do not use liquid cleaners or water as an

electrical shock may occur.

• Do not tamper with power unit. Do not place anything on top of power unit as this could restrict cooling air

to the motor, causing the motor to overheat.

• Do not attempt to pick up anything that will not go through the cleaning tool or hose end. Do not use the

system to pick up construction debris.

• Do not attach anything else to the system’s electrical power source. Be sure that a properly- sized protected

circuit is used for your unit’s electrical requirements. Consult your authorized Beam dealer for the correct

size.

• After removing the hose from the inlet, hold the inlet door open for a few seconds to help clear dirt from the

vacuum tubing and make sure the power unit has been turned off.

• To ensure proper cleaning, use only one inlet at a time.

• If service is ever required, have it performed by your authorized Beam dealer.

Dirt Bucket Cleaning and Maintenance

All of the dirt vacuumed from your home is captured in the dirt bucket located on the bottom of your power unit.

It is important that you remember to empty it on a regular basis to ensure optimal performance. The frequency

required is dependent on many factors in your home (i.e. type of oor coverings, number of people living in the

home and how many pets). A general rule is to empty the dirt receptacle twice a year… in spring and in fall. It

is ideal to empty the dirt bucket when it is half full.

To remove the bucket simply press the Release Ring in

any two opposing positions and pull down. Empty the

debris into a garbage can or bag and reinstall the bucket.

You will hear a click when it is properly reinstalled. It is

important to note that the system will not operate properly

if the bucket is not installed properly (Figure 6).

While the dirt receptacle is off, check that the cloth lter

is free from debris, tears or puncture holes. A clean lter,

free from holes gives your motor maximum protection and

ensures optimal performance.

Figure 6

HEPA Filter Maintenance

It is recommended that you change the HEPA lter annually, (more regularly if you vacuum more than twice a

week).

1. Open HEPA lter door with button located on the side, center

of door.

2. Press down on the tab at top of lter and pull outwards,

(discard lter).

3. Insert New HEPA lter aligning and leading with the two plastic

tabs at bottom of cavity.

4. Snap upright into place.

5. Close HEPA door without force. If the door does not close

easily, remove and reinstall lter (Figure 7).

Figure 7

8

Page 9

Hose Care

For optimum benet, the hose should be used and stored at temperatures above 40˚F (5˚C). Always hang up

the hose when not in use using the hose hanger supplied. If hose should become clogged, insert the wand

end into the utility inlet on the power unit. Seal connection. Turn on the power unit with the manual switch. The

obstruction should be quickly vacuumed out. If, however, the hose remains clogged, insert an electrician’s sh

tape (wire) or garden hose through the hose to remove the obstruction, being careful not to puncture the hose.

Disconnect hose handle from wands before storing. DO NOT store hose in direct sunlight.

TROUBLE-SHOOTING

Automatic Shut-Off

The Alliance Central Vacuum comes equipped with a timed automatic shut off set to automatically turn your

power unit off if your vacuum is left to run for 30 minutes. The shut off is to protect you in the event the vacuum

is inadvertently left on. The shut-off timer is easily reset by turning the power unit on by way of the on/off button

on your hose handle or on the power unit.

The system is also equipped with a thermal protection shut-off to protect the power unit from overheating, In the

event a thermal shut-off occurs, a motor fault icon will be displayed on the screen of the power unit and a red

ashing fan blade will show on the Alliance hose handle. Please allow for the unit to cool for approximately 30

minutes. If the unit does not restart after the 30 minutes, please contact your local authorized dealer/distributor.

Partial Loss of Suction

1. Clean out dirt receptacle. Ensure lter is free from debris, tears and or punctures. If this does not resolves

issue, see step 2.

2. Turn ON vacuum at Power Unit. Check suction at Power Unit. If strong, check the suction at each inlet. If it

is not the same suction at each one, the line may be partially clogged. To locate a clog, compare the suction

at each inlet. First check the inlet closest to the power unit then continue to check each successive inlet until

you locate inlet with loss of suction.. The obstruction will be located between this inlet and the one previously

checked. To remove clog, carefully insert electrician’s sh tape into the inlet and push obstruction through. Or,

If you have a secondary vacuum, you can put vacuum hose into inlet, turn on secondary vacuum and draw out

obstruction. If this fails to remove the clog, call your local authorized dealer/distributor.

Total Loss of Suction (with motor running)

1. Check power, light on screen.

2. If you have good suction at the unit, but no suction in the hose then there is a clog in the pipes or hose. To

remove the clog, refer to step 2 above or call your local authorized dealer/distributor. If obstruction is in your

hose, take your hose to local dealer.

Motor Refuses to Start

1. Check to ensure central vacuum is plugged into an electrical outlet.

2. Check fuses or breakers in your homes electrical panel

3. If power unit has power but your inlets turn on vacuum, the problem will be in your low voltage wiring to the

wall inlets.

4. If you are unable to resolve your issue, call your local authorized dealer/distributor.

9

Page 10

SERVICE INFORMATION

Status OK

Power Nozzle Button

(2G)

Power Button

(Phoenix & 2G)

Left Scroll

Right Scroll

Enter

Attention Needed

Status OK

Status OK

Power Level Button

(2G)

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Motor Running

Screensaver

Call for Service

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Status OK

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Status OK

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Status OK

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Motor Running

Call for Service

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Motor Running

Screensaver

(2G)

(2G)

(2G)

Status OK

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Call for Service

Power Nozzle Button

(2G)

The instructions in this booklet serve as a guide for routine operation and maintenance. For further

Information contact your local authorized dealer/distributor

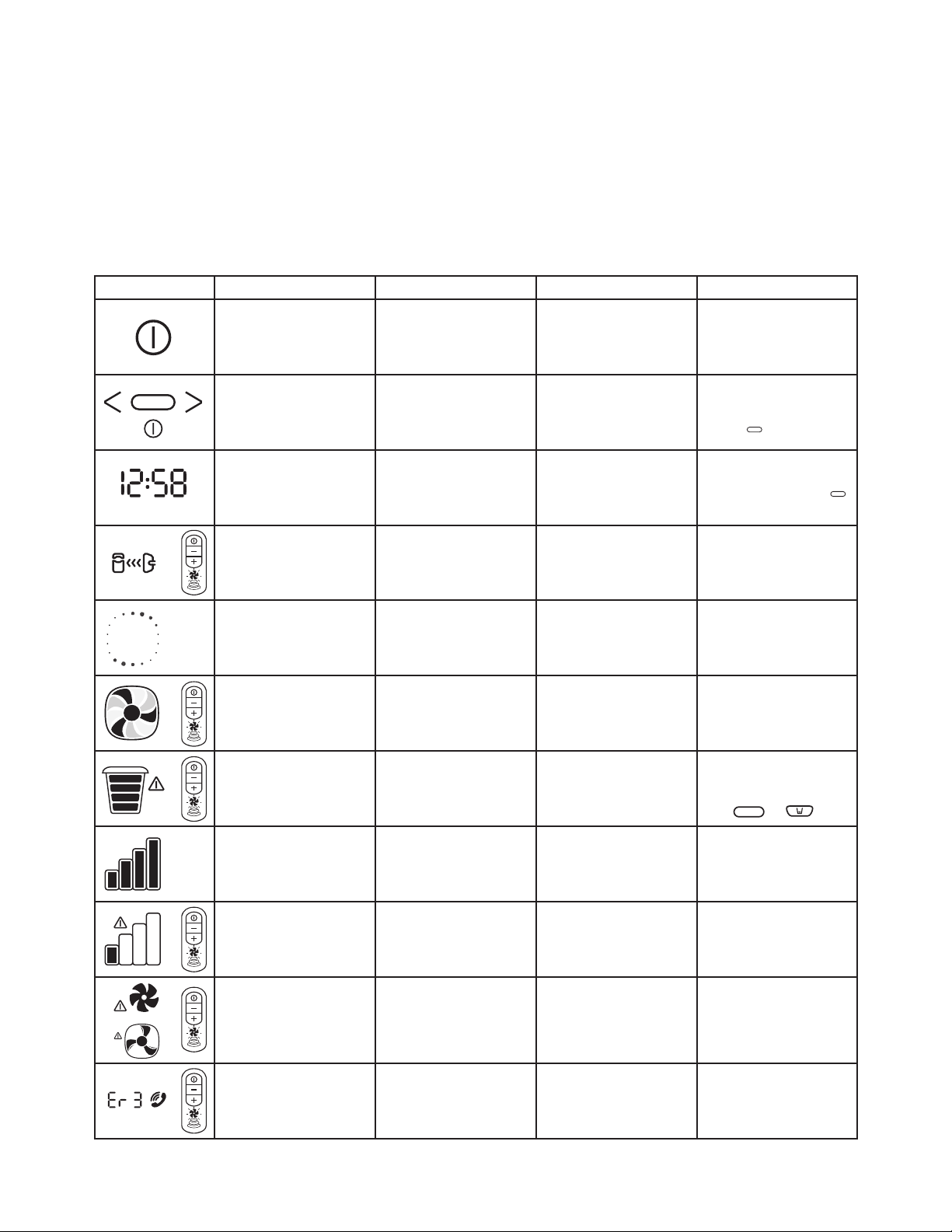

BEAM ALLIANCE LED/LCD ICON CHART

SYMBOL DESCRIPTION AVAILABILITY MEANING ACTION REQUIRED

ON/OFF Button Standard Turns power unit on or off None

10

or

Navigation Buttons On select models These buttons are located below

Clock On select models A digital clock is located on the top

Communication Link On select models The communication link icon

Screen Saver On select models When the power unit wakes from

Variable Speed Indicator On select models When the power unit is on, the

Empty Bucket Indicator On select models The empty bucket indicator is

Performance Bars On select models 3 - 4 bars indicate the system is

Flashing Performance Bars Alert On select models When 2 bars or less are illuminated,

Motor Fault Indicators Standard Indicates a system fault or

Error Codes On select models Error codes dened:

the display screen. Use to modify

time or reset empty bucket indicator

left corner of the display screen of

the power unit

appears at the top of the power

when the hose connection into the

inlet valve is complete and the hose

handle is communicating with the

sleep mode, the screen saver icon

will appear for 2-3 seconds before

timed to remind you to empty your

communicate with the hose handle

exceptionally restricted. The power

unit will communicate to the hose

handle and ashing red fan blades

exceeded; 2) Electronics problem;

3) Power surges; 4) Motor failure; 5)

power unit

disappearing and other icons will

spin relative to the speed/suction

appear

fan blades on the screen will

indicated on the hose handle

dirt bucket. The power unit will

signalling fan blades to ash red

performing at the optimum level.

Performance levels will change

depending on the variable speed

settings and during the use of

specialty attachments

the airow of your power unit is

will display

malfunction. This symbol may

occur due to one of the following:

1) Maximum system run time

Mechanical failure

ER 1: Under current

ER 2: Over current short

ER 3: 30-minute time out

ER 4: Over current long

ER 5: Line error or off current

Scroll through using Left ( < ) or

Right ( > ) buttons to appropriate

icon. When the appropriate

selection is highlighted, hold the

Enter ( ) button down for 5

seconds

You can choose from either a 12

or 24 hour clock. To set time, use

the (<) and (>) buttons to arrive at

the correct time. Press Enter ( )

when your selections are complete

None

None

None

Empty dirt bucket and reset the

system by pushing one of the two

reset buttons and holding for 5

seconds

or

Check for blockage if performance

bars uctuate under normal

vacuuming conditions

Check to ensure the dirt bucket

is not overloaded. Check for

blockages in the system. Check for

motor wear (contact an authorized

service technician)

Turn on and off the power unit. This

may reset the system. If this fails,

unplug the power unit and call an

authorized technician

Turn off and unplug power unit

and call an authorized technician.

For further detail on error codes,

contact your authorized service

dealer

Page 11

WARRANTY

Lifetime Limited Warranty

Electrolux Central Vacuum Systems is protected by a limited lifetime warranty. This warranty is valid from the

date of purchase, for as long as you are the original owner, and the system remains at its original place of

installation.

• Limited lifetime warranty on metal body and self cleaning lter.

• Motors, electrical components and dirt receptacle in BEAM Alliance power units are warranted for 15 years.

• BEAM Alliance cleaning sets carry a 5 year warranty.

• Labor on all warranted items is covered for 1 year.

This warranty does not apply to consumable items requiring normal replacement such as belts, replacement

lter bags and lights.

THIS IS THE SOLE AND EXCLUSIVE WARRANTY OF ELECTROLUX CENTRAL VACUUM SYSTEMS.

IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN DURATION OF LIMITED WARRANTY PERIOD.

Should any defect in material or workmanship appear within the time of the above warranty, the selling BEAM

Dealer should be contacted. The Dealer shall repair or replace (at BEAM’s sole option), or credit, such part or

parts in accordance with the applicable warranty period stated above. BEAM shall not be responsible for such

service unless provided by an authorized BEAM Dealer utilizing authentic BEAM replacement parts.

This warranty does not apply to loss or damage resulting from (at BEAM’s sole option) normal wear and tear,

commercial use, vacuum of drywall dust, neglect, abuse acts of God, accidents, improper installation, improper

modication or alteration, improper use and operation or failure to provide proper maintenance.

Some States or Provinces do not allow exclusion of warranties or limitations of damages, so the above

limitations and exclusions may not apply to you. This warranty gives you specic legal rights. You may have

additional rights, which vary from State to State, or Province to Province. This limited warranty applies to USA

and Canada installations only. For specic warranty information for your Country, consult your authorized Beam

Dealer.

Other warranties apply to other parts of this equipment and optional accessories. Please contact the material

accompanying the individual items.

BEAM SHALL NOT BE RESPONIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR SPECIAL DAMAGES

ARISING FROM THE USE OF THIS SYSTEM.

Keep all payment records (bill of sale/delivery slip). The date on these records establishes the warranty period.

Should warranty service be required, you must show proof of purchase. If proof of purchase cannot be supplied,

the warranty period will be determined from the date of manufacture of the product.

In the event of a product recall, register your products at www.beam.com.

United States

10200 David Taylor Drive

Charlotte, NC 28262

1-800-369-2326

Canada

5855 Terry Fox Way

Mississauga, ON L5V 3E4

1-800-282-2886

11

Page 12

12

Sold and serviced by:

© 2013 Electrolux Home Care Products Ltd. #87238-R2

Page 13

BEAM Alliance

Manuel d’utilisation

Page 14

IMPORTANTES DIRECTIVES DE SÉCURITÉ

Lors de l’utilisation d’un appareil électronique, des précautions de base devraient toujours être prises, incluant celles

indiquées ci-dessous.

LISEZ TOUTES LES DIRECTIVES AVANT D’UTILISER CET ASPIRATEUR CENTRAL.

AVERTISSEMENT

An de réduire les risques d’incendie, de décharges électriques ou blessures :

• Cet aspirateur est conçu pour le ramassage de débris secs seulement. Ne l’utilisez pas sur des surfaces

mouillées ou pour ramasser des liquides, des débris chauds ou des matières inammables, lesquelles peuvent

endommager l’aspirateur.

• Tenez le l loin des surfaces chauffées.

• Ne permettez pas que l’aspirateur soit utilisé comme un jouet. Une surveillance étroite est nécessaire lorsque

cet aspirateur est utilisé par des enfants ou près d’eux.

• N’utilisez cet aspirateur que pour l’usage pour lequel il a été conçu et tel que décrit dans ce manuel. (L’utilisation

d’accessoires non recommandés par le fabricant peut être une cause d’incendie, de décharge électrique, de

blessures ou de dommages aux composantes du système.)

• Branchez-le seulement dans une prise de courant correctement mise à la terre. Voir les instructions de mise à la

terre.

• Installez l’unité motrice à au moins 30 cm (12’’) du plancher, du plafond et des murs adjacents pour permettre

une ventilation adéquate du moteur.

• N’utilisez pas cet aspirateur si le cordon ou la che sont endommagés, s’il ne fonctionne pas correctement ou s’il

a été échappé ou endommagé. Apportez-le à un détaillant/distributeur autorisé pour réparation.

• Ne débranchez pas la che en tirant sur le cordon. Pour débrancher de la prise de courant, prenez et tirez la

che, et non le cordon.

• N’insérez aucun objet dans les prises d’aspiration. N’utilisez pas l’appareil si une des prises d’aspiration est

obstruée. Gardez les prises d’aspiration exemptes de toute accumulation de poussière, charpie, cheveux ou

toutes autres choses qui peut réduire le débit d’air/d’aspiration. La réduction du débit d’air entraînera une

surchauffe du moteur.

• Cet aspirateur crée une succion. Gardez les vêtements amples, les cheveux, le visage, les doigts et toutes les

autres parties du corps loin de toutes les prises d’aspiration.

• Ne faites jamais fonctionner cet appareil si le sac à poussière et/ou le ltre ne sont pas en place.

• Fermez toutes les commandes avant de débrancher.

• Ne manipulez pas la che, le cordon ou l’unité motrice avec des mains mouillées.

• Redoublez de prudence lorsque vous nettoyez les escaliers.

• Ne placez pas l’unité motrice dans un endroit où la température est élevée ou dans un endroit où il sera difficile

d’y accéder comme un comble ou un vide sanitaire.

• N’utilisez pas de rallonges ni de prises électriques dont l’intensité de courant admissible n’est pas adéquate.

• Ne ramassez rien qui vient de brûler ou dont une fumée s’échappe, comme des cigarettes, des allumettes ou

des cendres chaudes.

• N’utilisez pas cet appareil sur des surfaces mouillées.

• N’aspirez pas de poussière de placoplâtre ou de farine parce que cela peut endommager votre aspirateur.

• Cet appareil n’est pas destiné à être utilisé par des personnes (incluant les enfants) ayant des capacités

physiques, sensorielles ou mentales réduites, ou manquant d’expérience ou de connaissances, à moins qu’une

personne responsable de leur sécurité ne leur ait donné des directives sur l’utilisation de l’appareil ou ne les

supervise.

• Si le cordon d’alimentation est endommagé, il doit être remplacé par un cordon spécique que vous trouverez

chez le détaillant ou le distributeur autorisé local.

• Gardez votre aire de travail bien éclairé.

• Débranchez les appareils électriques avant de les nettoyer.

• N’utilisez pas cet aspirateur pour ramasser des liquides inammables ou combustibles, comme de l’essence, ou

pour nettoyer des endroits où des produits de ce genre peuvent être présents.

14

CONSERVEZ CES DIRECTIVES

Page 15

Cher client Beam;

Félicitations pour votre nouvel aspirateur central BEAM Alliance! Vous venez juste d’acheter l’aspirateur central le plus

novateur et le plus intuitif de Beam. Merci de votre appui. Pour proter au maximum de tous les avantages, veuillez lire

ce manuel d’instructions avant d’installer et d’utiliser votre aspirateur central. Nous vous recommandons de conserver ce

manuel d’instructions pour référence ultérieure.

Pour acheter des accessoires et des services d’installation ou vous informer sur ceux-ci, veuillez communiquer avec votre

détaillant local ou visitez notre site Web à www.beam.com.

Nous vous recommandons d’enregistrer votre aspirateur central en ligne à www.beam.com.

Pour plus de commodité, inscrivez ci-dessous le numéro de modèle et le numéro de série qui se trouvent sur votre unité

motrice, ainsi que la date d’achat. Vous trouverez ces numéros sur la plaque signalétique apposée sur la partie supérieure

arrière de l’unité motrice.

Numéro de modèle _______________________

Numéro de série _______________________

Date d’achat _______________________

Ouverture de l’emballage

Votre aspirateur central ainsi que la quincaillerie et les accessoires qui l’accompagnent sont soigneusement emballés dans

une boîte de carton conçue pour les protéger contre les dommages pouvant survenir durant le transport. Vous trouverez les

pièces nécessaires pour suspendre votre aspirateur central dans la cuve à poussière.

IInstallation de votre aspirateur central

Si vous planiez installer vous-même votre aspirateur central, vous trouverez si notre site www.beam.com un excellent

guide d’installation ainsi qu’une vidéo d’installation. Si vous désirez que l’installation de votre aspirateur central soit faite par

un professionnel, communiquez avec votre détaillant local ou téléphonez au 1-800-369-2326 (pour les États-Unis) ou au

1-800-282-2886 (pour le Canada). Nous serons heureux de vous diriger vers un installateur professionnel de votre région.

INFORMATION GÉNÉRALE

Ce système central d’aspiration est conçu pour le ramassage des débris domestiques secs et n’est pas conçu

pour ramasser des liquides. Évitez de ramasser des objets durs, coupants ou pointus avec le système pour ne

pas endommager ou obstruer le boyau et les tuyaux en plastique. Ce système central est destiné à un usage

domestique seulement.

Information concernant l’entretien/réparation

Les directives contenues dans ce livret servent de guide pour l’entretien de routine. Pour de plus amples

informations, communiquez avec votre détaillant/distributeur autorisé local.

Plaque signalétique

Le style ainsi que les numéros de modèle et de série

sont indiqués sur la plaque signalétique qui se trouve du

côté gauche à l’arrière de l’unité motrice. Pour obtenir des

informations de service après-vente rapides et complètes,

donnez toujours ces numéros lors des appels de service

après-vente (voir la gure 1.)

Figure 1.

15

Page 16

INSTRUCTIONS DE MISE À LA TERRE

Cet aspirateur doit être mis à la terre. En cas de mauvais fonctionnement ou de panne, la mise à la terre

procure une voie de moindre résistance pour le courant électrique an de réduire le risque de décharge

électrique. Cet aspirateur est équipé d’un cordon électrique doté d’une che avec conducteur de mise à la terre.

La che doit être insérée dans une prise électrique appropriée qui est correctement installée et mise à la terre

conformément aux codes et règlement locaux.

Modèles 110/115/120 V

Cet aspirateur doit être utilisé sur un circuit nominal de 110/115/120 volts et est doté d’une che de mise à la

terre semblable à celle montrée ci-dessus. Assurez-vous que l’appareil est branché dans une prise électrique

ayant la même conguration que la che. Aucun adaptateur ne doit être utilisé avec cet aspirateur.

Alvéole de la broche de mise à la terre

Broche de mise à la terre

Prise de courant mise à la terre

AVERTISSEMENT

Des branchements inadéquats de l’équipement de mise à la terre entraînent des risques de décharges électriques. Si

vous n’êtes pas certain que la prise soit convenablement mise à la terre, consultez un électricien ou un technicien de

service qualié. Ne modiez pas la che fournie avec l’appareil. Si elle n’adapte pas à la prise de courant, faites installer

une prise de courant adéquate par un électricien qualié. Cet appareil est conçu pour un circuit nominal de 120 volts

(consultez la plaque signalétique pour savoir quelle est la tension appropriée) et est doté d’une che avec mise à la terre

qui ressemble à celle montré ci-dessous. Assurez-vous que l’appareil est branché dans une prise de courant ayant la

même conguration que la che.

• Aucun adaptateur ne doit être utilisé avec cet appareil.

• N’utilisez pas de l de rallonge avec cet appareil.

• Si le câble d’alimentation est endommagé, utilisez seulement un câble de rechange d’origine.

• Assurez-vous que le bouton marche/arrêt de l’unité motrice et que toutes les prises d’admission d’air fonctionnent

bien.

• Cette unité motrice a été conçue pour un usage domestique ou commercial seulement.

16

Page 17

INSTALLATION

Installation de l’unité motrice

L’unité motrice doit être suspendue à un support de xation vissé au

mur. Les vis allant au bas du support de xation doivent être vissées

à environ 122 cm (48’’) au-dessus du plancher an de pouvoir

enlever aisément la cuve à poussière. Un espace d’au moins 31 cm

(12’’) doit également être laissé entre l’unité motrice et le plafond an

de permettre un refroidissement adéquat du moteur. Si l’installation

du support de xation se fait sur des murs de plâtre ou des panneaux

muraux, assurez-vous que les vis soient insérées dans les montants

du mur. Si l’installation se fait sur un mur de béton, percez le

mur avec un foret à maçonnerie et insérez les ancrages muraux

appropriés. Dénudez les ls à basse tension qui ont été installés

avec la ligne de tuyauterie principale (gure 2).

Fils à basse

tension

Collecteur de la

ligne de tuyauterie

principale

Ligne et collecteur

d’évacuation

optionnels

Silencieux optionnel

Connecteurs à

basse tension

(fournis)

Le centre du support de

montage doit être à 122 cm

(48’’) du plancher

Prise de courant murale

Prise d’aspiration

Quick Clean

Si l’unité motrice est dotée de la prise d’aspiration optionnelle

« Quick Clean » pour nettoyage rapide, reliez les ls de la ligne

principale au faisceau de ls électriques qui se trouvent à l’arrière de

M = Distance minimum

de 30 cm (12’’)

pour permettre le

refroidissement du moteur

l’unité motrice avant de les relier aux connecteurs à ressort à l’arrière

de l’unité motrice. Si vous n’avez pas la prise d’aspiration optionnelle

« Quick Clean » pour nettoyage rapide, vous n’avez qu’à relier

directement les ls de la ligne principale aux connecteurs à ressort

qui se trouvent à l’arrière de l’unité motrice. Raccordez ensuite la

ligne de tuyauterie principale au tuyau de la prise d’admission d’air à

Figure 2

l’aide du raccord et du collier de serrage fournis.

Ne collez pas le raccord à l’unité motrice au cas où vous voudriez enlever celle-ci ultérieurement. Cette unité motrice peut

avoir un système d’évacuation à l’extérieur; le parcours d’évacuation ne doit toutefois pas être de plus de 6,1 m (20’).

La sortie du système d’évacuation ne doit pas donner à l’intérieur d’un mur, d’un plafond ou d’un espace dissimulé d’un

bâtiment.

NOTE : Le bouton marche/arrêt placé sur l’unité motrice sert uniquement lorsque l’unité motrice n’est pas dotée d’une prise

d’aspiration « Quick Clean » ou est utilisé comme interrupteur prioritaire si le lage de la ligne principale est endommagé.

Toutes les autres prises d’aspiration fonctionnent automatiquement lorsque l’extrémité du boyau y est insérée. Le cordon

d’alimentation a une che femelle tripolaire à une des extrémités. Cette che doit être branchée dans le connecteur

homologue de l’unité motrice. Branchez l’autre extrémité du cordon d’alimentation dans la prise de courant murale.

FILAGE : Vériez les codes locaux, mais n’utilisez pas de lage moindre de #12-2 avec mise à la terre. Branchez le cordon

d’alimentation de l’unité motrice dans une prise de courant appropriée. Assurez-vous que le circuit électrique peut supporter

une charge de 20 ampères.

Bride d’admission d’air

Votre unité motrice a été conçue

pour recevoir un tuyau d’admission

d’air gauche ou droit. Ceci a pour

but de vous donner plus de exibilité

pour choisir l’emplacement désiré

pour suspendre votre unité motrice.

Pour changer la direction de la bride

d’admission d’air, vous n’avez qu’à

retirer les deux vis Torx 20 qui se

trouvent sur la bride d’admission d’air,

puis tournez la bride d’admission d’air

à 180 degrés. Fixez fermement la

bride d’admission d’air avec les deux

mêmes vis Torx 20. (Figure 3)

Figure 3

17

Page 18

Installation du silencieux

Le silencieux s’installe au niveau de l’orice d’évacuation qui

se trouve à l’arrière de l’unité motrice en utilisant les 3 raccords

fournis et les vis Torx 20 fournies. Nous vous suggérons d’installer

le silencieux, tel qu’indiqué, avant de suspendre votre unité

motrice (bien que certains modications à cette méthode soient

acceptables). (Figure 4)

NOTE : Installez le silencieux du côté opposé à la bride

d’admission an qu’il ne nuise pas au raccordement de la

tuyauterie d’admission. Insérez le raccord à 90 degrés dans le

silencieux et vissez-le. Placez les deux autres raccords et collezles avant de les raccorder à l’unité motrice. Utilisez les vis Torx 20

fournies pour raccorder le silencieux à l’unité motrice.

NOTE : Ne collez pas le tuyau du silencieux à l’unité motrice de

l’aspirateur central.

Installation du ltre HEPA

(optionnelle)

Utilisez les vis Torx 20 pour xer fermement le coude

à 90 degrés fournis au ltre HEPA. Utilisez des vis

pour xer le ltre HEPA sur l’unité motrice. Nous vous

recommandons d’installer le ltre HEPA avant de

suspendre l’unité motrice. (Figure 5)

Figure 4

NOTE : Ne collez pas le ltre HEPA à l’unité motrice

de l’aspirateur central.

NOTE : Un coude large doit être installé si le

silencieux ou le ltre HEPA n’est pas utilisé.

(Figure 5b)

Figure 5

Figure 5b

RÈGLES D’UTILISATION DE BASE POUR L’UNITÉ MOTRICE

BEAM ALLIANCE

Pour faire démarrer l’unité motrice, vous n’avez qu’à brancher le boyau dans l’une des pratiques prises d’aspiration murale.

L’anneau métallique sur l’embout du boyau complétera le circuit électrique à basse tension, ce qui activera un relais et fera

démarrer l’unité motrice du système. Pour arrêter l’unité motrice, il suffit de débrancher le boyau de la prise d’aspiration

murale.

Note : Lorsque vous débranchez le boyau, il est recommandé de tenir le clapet ouvert pendant quelques secondes, jusqu’à

ce que la pression d’aspiration ait suffisamment diminué.

Pour des raisons de sécurité, un circuit à basse tension est utilisé au niveau des prises d’aspiration murales. L’unité motrice

fonctionne sur un circuit électrique standard de 110/120 volts. Des boyaux dotés d’un interrupteur sur la poignée sont offerts

en option.

18

Note : Si vous utilisez un des ces boyaux optionnels, il est important de bien aligner le boyau avec la prise d’aspiration

Page 19

murale lorsque vous l’y branchez pour éviter d’endommager le système.

RÈGLES D’UTILISATION DE BASE POUR LE BOYAU BEAM

ALLIANCE

Le boyau BEAM Alliance est conçu pour fonctionner comme un système intégré avec l’unité motrice BEAM Alliance. Il ne

fonctionnera pas avec un autre système central d’aspiration. Le boyau BEAM Alliance offre plusieurs options qui se trouvent

au bout de vos doigts!

Bouton marche/arrêt

Interrupteur pour le

rouleau-brosseur

Indicateur de

vitesse variable

Basse

Élevée

Commande de

vitesse variable

Indicateur lumineux du système

Lumière pulsatoire bleue =

système prêt/en attente

Lumière clignotante rouge =

unité motrice à vérier

Bouton marche/arrêt

Le bouton marche/arrêt, placé sur la poignée du boyau Alliance, vous permet de mettre en marche et d’arrêter aisément

l’unité motrice. Sur les boyaux de 110/24 V, nécessaires pour utiliser une brosse motorisée électrique, il y a également un

bouton icône, placé de façon pratique sur la poignée du boyau, qui vous permet de mettre en marche et d’arrêter la brosse

électrique.

Commande de vitesse variable

La poignée du boyau Alliance est également dotée d’une commande de vitesse variable qui vous permet de diminuer ou

d’augmenter la vitesse du moteur et, par conséquent, la puissance d’aspiration au bout du boyau. Vous pouvez maintenant

dénir la puissance d’aspiration dont vous avez besoin pour accomplir une tâche spécique! Pour diminuer la puissance

d’aspiration, appuyez sur le bouton (-) et pour l’augmenter, appuyez sur le bouton (+). Lorsque le système est mis en

marche, il offre, par défaut la puissance d’aspiration la plus élevée et, par conséquent, toutes les barres de l’indicateur de

vitesse variable seront allumées. Si vous diminuez la puissance d’aspiration, le nombre de barres allumées de l’indicateur

diminuera.

Indicateur lumineux du système

Lorsque le boyau Alliance est branché dans une prise d’aspiration, l’icône « pales de ventilateur » affichera une lumière

pulsatoire bleue. Cela conrme que la communication est établie entre la poignée du boyau et l’unité motrice. Lorsque

les pales de ventilateur sont d’un bleu constant, cela signie que tous les systèmes sont PRÊTS. Lorsque les pales de

ventilateur sont ROUGES, cela signie que vous devez vider la cuve à poussière ou vérier s’il y a un autre problème

de rendement. Si les pales de ventilateur commencent à CLIGNOTER et qu’elles sont ROUGES, vous devez arrêter

immédiatement l’aspirateur. Vériez ce qui est affiché sur votre unité motrice et si vous êtes incapable de diagnostiquer le

problème, faites un appel de service auprès de votre détaillant local.

19

Page 20

ENTRETIEN ET MAINTENANCE

Votre aspirateur central BEAM est couvert par une garantie à vie limitée (voir les détails complets de la garantie dans ce

manuel). En suivant les quelques directives simples qui suivent, vous proterez des avantages de celui-ci sans problèmes

et durant de très nombreuses années.

Le système central d’aspiration BEAM Alliance est équipé d’un moteur à circulation d’air directe et il n’aura jamais besoin

de lubrication. Si vous avez des problèmes avec votre moteur, veuillez communiquer avec votre détaillant/distributeur

autorisé local.

• L’unité motrice doit être époussetée avec un chiffon doux propre. Avertissement : n’utilisez pas de nettoyants

liquides ou d’eau parce que cela peut causer une décharge électrique.

• Ne manipulez pas l’unité motrice. Ne mettez rien sur le dessus de l’unité motrice parce que cela pourrait nuire au

refroidissement du moteur et, de ce fait, entraîner une surchauffe du moteur.

• N’essayez pas d’aspirer quelque chose qui ne passera pas à travers l’accessoire de nettoyage ou l’embout du boyau.

N’utilisez pas ce système d’aspiration pour ramasser des débris de construction.

• Ne reliez rien d’autre à la source d’alimentation électrique du système. Assurez-vous qu’un circuit protégé d’un calibre

adéquat est utilisé pour répondre aux besoins électriques de votre unité motrice. Consultez votre détaillant autorisé

Beam pour savoir quel est le calibre requis.

• Après avoir retiré le boyau de la prise d’aspiration, tenez le clapet de la prise ouvert pendant quelques secondes pour

aider à dégager les tuyaux de la saleté qui s’y trouve et assurez-vous que l’unité motrice est bien arrêtée.

• Pour un nettoyage adéquat, n’utilisez qu’une prise d’aspiration à la fois.

• Si jamais votre système a besoin d’entretien ou de

réparation, assurez-vous que le service sera effectué par

votre détaillant autorisé BEAM.

Nettoyage et entretien de la cuve à poussière

Toutes les saletés et poussières aspirées sont emprisonnées

dans la cuve à poussière placée au bas de votre unité motrice.

Il est important de ne pas oublier de la vider sur une base

régulière pour que votre système offre une performance

optimale. La fréquence requise dépend de plusieurs facteurs (c.à-d. le type de revêtements de sol, le nombre de personnes et

d’animaux de compagnie qui vivent dans votre maison). La règle

générale est de vider la cuve à poussière deux fois par année...

au printemps et à l’automne. Par contre, l’idéal est de vider la cuve à poussière lorsqu’elle est à moitié pleine.

Pour retirer la cuve, appuyez simplement sur la bague de déverrouillage en deux points opposés et tirez vers le bas.

Videz les débris dans une poubelle ou un sac et réinstallez la cuve. Vous entendrez un clic lorsqu’elle sera correctement

réinstallée. Il est important de noter que le système ne fonctionnera pas correctement si la cuve n’est pas installée

correctement. (Figure 6)

Pendant que la cuve à poussière est retirée, assurez-vous que le ltre en toile est exempt de débris, de déchirures ou de

perforations. Un ltre propre, exempt de trous, protège le moteur de votre unité motrice de façon maximale et permet à votre

système d’avoir une performance optimale.

Figure 6

Entretien du ltre HEPA

Il est recommandé de changer le ltre HEPA sur une base annuelle (plus

fréquemment si vous passez l’aspirateur plus de deux fois par semaine).

1. Ouvrez la porte du ltre HEPA en appuyant sur le bouton placé sur le

côté au centre de la porte.

2. Appuyez sur la languette qui se trouve au haut du ltre et tirez le ltre

vers l’extérieur (jetez le ltre).

3. Insérez le nouveau ltre HEPA en l’alignant avec les deux languettes

de plastique au bas de la cavité.

Figure 7

20

Page 21

4. Enclenchez-le en position verticale.

5. Fermez doucement la porte du ltre HEPA. Si la porte ne se ferme pas facilement, retirez le ltre et réinstallez-le.

(Figure 7)

Entretien du boyau

Pour que le boyau offre un rendement optimal, il doit être utilisé et rangé à des températures supérieures à 5 ˚C (40˚F).

Suspendez toujours le boyau sur le support à boyau fourni lorsqu’il n’est pas utilisé. Si le boyau est obstrué, insérez

l’extrémité du tube dans la prise d’aspiration utilitaire qui se trouve sur l’unité motrice. Scellez l’ouverture de la prise.

Démarrez l’unité motrice en appuyant sur l’interrupteur manuel. Ce qui crée l’obstruction devrait être rapidement aspiré.

Toutefois, si le boyau demeure obstrué, insérez un ruban de tirage ou un boyau d’arrosage dans le boyau pour retirer ce qui

obstrue le boyau, en prenant soin de ne pas percer le boyau. Retirez les tubes du boyau avant de ranger celui-ci. NE rangez

PAS le boyau à la lumière directe du soleil.

DÉPANNAGE

Arrêt automatique

L’aspirateur central Alliance est équipé d’un dispositif d’arrêt automatique qui arrête automatiquement l’unité motrice

après 30 minutes. Ce dispositif d’arrêt vise à vous protéger si votre aspirateur est laissé en fonction par inadvertance. La

minuterie peut facilement être remise à zéro en appuyant sur le bouton marche/arrêt qui se trouve sur la poignée du boyau

ou sur celui qui se trouve sur l’unité motrice.

Le système est également équipé d’une protection thermique d’arrêt pour protéger l’unité motrice contre la surchauffe. En

cas d’arrêt thermique, un icône de défaillance du moteur sera affiché sur l’écran de l’unité motrice et l’icône de pales de

ventilateur clignotera en rouge sur la poignée du boyau Alliance. Laissez l’unité motrice refroidir pendant environ 30 minutes.

Si l’unité motrice ne redémarre pas après 30 minutes, communiquez avec votre détaillant/distributeur autorisé local.

Perte partielle de la puissance d’aspiration

1. Videz la cuve à poussière. Assurez-vous que le ltre est exempt de débris, de déchirures ou de trous. Si le problème

n’est pas réglé, allez à l’étape 2.

2. Faites démarrer le système en utilisant l’interrupteur qui se trouve sur l’unité motrice. Vériez la puissance d’aspiration

au niveau de l’unité motrice. Si elle est forte, vériez la puissance d’aspiration à chaque prise d’aspiration murale. Si

elle n’est pas constante à chaque prise d’aspiration, cela signie qu’il y a une obstruction partielle dans les conduits.

Pour trouver où se trouve l’obstruction, comparez la puissance d’aspiration à chaque prise. Pour le faire, vériez

d’abord la prise d’aspiration qui se trouve le plus près de l’unité motrice, puis continuer la vérication de chaque prise

suivante jusqu’à ce que vous trouviez la prise où la perte de puissance d’aspiration se fait sentir. L’obstruction devrait

être située entre cette prise et celle vériée juste avant. Pour débloquer, insérez délicatement un ruban de tirage dans

la prise d’aspiration et poussez sur ce qui cause l’obstruction; ou, si vous avez un autre aspirateur, vous pouvez insérez

le boyau de cet aspirateur dans la prise d’aspiration, démarrez cet aspirateur an d’aspirer ce qui obstrue le conduit. Si

aucune de ces méthodes ne réussit, communiquez avec votre détaillant/distributeur autorisé local.

Perte totale de la puissance d’aspiration (lorsque le moteur tourne)

1. Vériez la puissance – lumière sur l’écran.

2. Si vous avez une bonne puissance d’aspiration au niveau de l’unité motrice, mais aucune au niveau du boyau, c’est

qu’il y a obstruction dans les conduits ou le boyau. Pour débloquer, suivre les directives de l’étape 2 précédente (perte

partielle) ou communiquez avec votre détaillant/distributeur autorisé. Si l’obstruction est dans le boyau, apportez votre

boyau chez un détaillant autorisé.

Moteur qui refuse de démarrer

1. Vériez si l’aspirateur central est bien branché dans une prise de courant.

2. Vériez les fusibles ou les disjoncteurs du panneau électrique de votre maison.

3. Si l’unité motrice est sous tension, mais que l’insertion du boyau dans les prises d’aspiration murales ne fait pas

démarrer l’aspirateur, c’est qu’il y a un problème avec le câblage à basse tension au niveau des prises d’aspiration

murales.

4. Si vous n’arrivez pas résoudre le problème, communiquez avec votre détaillant/distributeur autorisé.

21

Page 22

INFORMATION SUR L’ENTRETIEN

Status OK

Power Nozzle Button

(2G)

Power Button

(Phoenix & 2G)

Left Scroll

Right Scroll

Enter

Attention Needed

Status OK

Status OK

Power Level Button

(2G)

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Motor Running

Screensaver

Call for Service

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Status OK

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Status OK

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Status OK

2G-to-Unit Connection

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Power Nozzle Button

Status OK

Time

Error Code

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Motor Running

Call for Service

Power Nozzle Button

(2G)

Power ON/Power Level

(2G)

Performance Level

Bucket Level

Motor Running

Screensaver

(2G)

(2G)

(2G)

Les instructions contenues dans ce manuel servent de guide pour l’utilisation et l’entretien de routine. Pour des plus amples

informations, communiquez avec votre détaillant/distributeur autorisé.

TABLEAU EXPLICATIF DES ICÔNES DE L’AFFICHAGE DEL/ACL

ICÔNE DESCRIPTION DISPONIBILITÉ SIGNIFICATION ACTION REQUISE

Bouton MARCHE/ARRÊT Sur tous les modèles Sert à faire démarrer ou à arrêter l’unité

motrice

Aucune

Boutons de navigation Sur certains modèles Ces boutons se trouvent sous l’écran

Horloge Sur certains modèles Une horloge numérique se trouve dans le

Lien de communication Sur certains modèles L’icône du lien de communication

Économiseur d’écran Sur certains modèles Lorsque l’unité motrice quitte le mode

Indicateur de vitesse variable Sur certains modèles Lorsque l’unité motrice fonctionne, les

Indicateur de cuve à vider Sur certains modèles L’indicateur de cuve à vider est temporisé

et sont utilisés pour changer l’heure ou

remettre à zéro l’indicateur de cuve à vider.

coin supérieur gauche de l’écran de l’unité

apparaît dans le haut de l’écran de l’unité

motrice lorsque boyau est branché dans

une prise d’aspiration murale et que la

communication se fait entre la poignée du

veille, l’icône de l’économiseur d’écran

apparaît pendant 2 à 3 secondes avant de

disparaître et de laisser la place à d’autres

pâles de ventilateur apparaissant sur

l’écran tournent selon la vitesse/puissance

d’aspiration indiquée sur la poignée du

pour vous rappeler de vider votre cuve

à poussière. L’unité motrice enverra un

message à la poignée du boyau qui fera

clignoter les pales du ventilateur en rouge.

motrice.

boyau et l’unité motrice.

icônes.

boyau.

Faites déler à l’aide des boutons

gauche (< ) ou droit ( > ) jusqu’à

l’icône appropriée. Lorsque la sélection

appropriée est affichée en surbrillance,

maintenez le bouton « entrée » ( )

enfoncé pendant 5 secondes.

Vous pouvez choisir une horloge de 12 ou

24 heures. Pour régler l’heure, utilisez les

boutons (<) et (>) jusqu’à ce que atteigniez

l’heure exacte. Appuyez sur « entrée »

( ) lorsque vos sélections sont

terminées.

Aucune

Aucune

Aucune

Videz la cuve à poussière et remettez le

système à zéro en appuyant sur un des

deux boutons de remise à zéro et en le

maintenant enfoncé pendant 5 secondes

( ) ou ( )

22

ou

Barres de performance Sur certains modèles L’affichage de 3 ou 4 barres indique que

Voyant clignotant – Baisse

de performance

Indicateurs de défaillance

du moteur

Sur certains modèles Lorsque 2 barres ou moins sont allumées,

Sur tous les modèles Ils indiquent une défaillance ou un

Codes d’erreur Sur certains modèles Dénition des codes d’erreur :

le système offre un niveau de performance

optimal. Les niveaux de performance

varieront en fonction des réglages de

vitesse variable et lorsque des accessoires

de nettoyage spéciaux sont utilisés.

cela signie que le débit d’air de votre

unité motrice est exceptionnellement

réduit. L’unité motrice enverra un message

à la poignée du boyau et les pales de

ventilateur clignoteront en rouge.

mauvais fonctionnement du système.

Ces icônes apparaissent dans l’une des

situations suivantes : 1) dépassement

de la durée maximale de fonctionnement

du système; 2) problème électronique; 3)

surtension; 4) défaillance du moteur; 5)

défaillance mécanique.

ER 1 : Sous-intensité

ER 2 : Surintensité - courte

ER 3 : Temps d’arrêt de 30 minutes

ER 4 : Surintensité – longue

ER 5 : Problème de communication ou

absence de courant

Si les barres de performance uctuent

dans des conditions normales d’aspiration,

vériez s’il y a une obstruction.

Assurez-vous que la cuve à poussière

n’a pas besoin d’être vidée. Vériez s’il

y a des obstructions dans les conduits.

Faites vérier l’état d’usure du moteur

(communiquez avec un technicien de

service autorisé).

Arrêtez et redémarrez l’unité motrice. Cela

peut réinitialiser le système. Si cela ne

fonctionne pas, débranchez l’unité motrice

et appelez un technicien de service

Arrêtez et débranchez l’unité motrice, puis

appelez un technicien de service autorisé.

Pour des plus amples détails sur les

codes d’erreur, communiquez avec votre

autorisé.

détaillant autorisé.

Page 23

GARANTIE

Garantie limitée à vie

Les systèmes centraux d’aspiration Electrolux sont couverts par une garantie à vie limitée. Cette garantie est valide à

compter de la date d’achat pour aussi longtemps que vous êtes le propriétaire initial du système et que le système demeure

à son emplacement d’installation initial.

• Garantie à vie limitée sur le corps en métal de l’unité motrice et sur le ltre autonettoyant.

• Les unités motrices BEAM Alliance sont couvertes par une garantie de 15 ans sur le moteur, les composants

électriques et la cuve à poussière.

• Le boyau et les ensembles de nettoyage BEAM Alliance sont couverts par une garantie de 5 ans.

• Les frais de main-d’œuvre pour tous les articles garantis sont couverts pour une période d’un (1) an.

Cette garantie ne s’applique pas aux articles consommables qui demandent un remplacement normal comme les courroies,

les sacs ltrants de rechange et les ampoules.

CECI EST LA SEULE ET UNIQUE GARANTIE ACCORDÉE POUR LES SYSTÈMES CENTRAUX D’ASPIRATION

ELECTROLUX. LES GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE

OU D’ADAPTATION POUR UN USAGE PARTICULIER, SONT LIMITÉES EN EN TEMPS À LA DURÉE DE LA PÉRIODE

DE GARANTIE LIMITÉE.

Advenant l’apparition d’un défaut de matériau ou de fabrication à l’intérieur de la période couverte par la présente

garantie, le détaillant BEAM qui a vendu le produit devrait être contacté. Le détaillant réparera ou remplacera (au seul

choix de BEAM), ou créditera, la ou les pièces jugée(s) défectueuse(s) conformément à la période de garantie applicable

mentionnée ci-dessus. BEAM ne sera en aucun cas responsable d’un tel service à moins qu’il n’ait été offert par un

détaillant autorisé BEAM utilisant des pièces de rechange authentiques BEAM.

Cette garantie ne s’applique pas aux pertes ou dommages résultant (à la seule discrétion de BEAM) d’une usure normale,

d’un usage commercial, de l’aspiration de poussière de cloison sèche, de négligence, d’abus, d’un événement de force

majeure, d’accidents, d’une installation inappropriée, d’une modication ou d’une altération inappropriée, d’une utilisation

inappropriée ou d’un défaut de faire un entretien approprié.

Certains états ou certaines provinces ne permettent pas les exclusions de garanties ou les restrictions des dommages, par

conséquent, les restrictions et exclusions mentionnées ci-dessus peuvent ne pas s’appliquer dans votre cas. Cette garantie

vous confère des droits légaux spéciques. Il se peut que vous ayez d’autres droits qui varient d’un état à l’autre ou d’une

province à l’autre. Cette garantie s’applique aux installations faites aux É.-U. et au Canada seulement. Pour obtenir des

renseignements sur la garantie spécique pour votre pays, veuillez consulter votre détaillant autorisé BEAM.

D’autres garanties s’appliquent aux autres pièces de cet équipement et aux accessoires optionnels. Veuillez consulter le

matériel écrit qui accompagne chaque article.

BEAM NE POURRA ÊTRE TENUE RESPONSABLE DE TOUS DOMMAGES INDIRECTS, ACCESSOIRES OU

PARTICULIERS DÉCOULANT DE L’UTILISATION DE CE SYSTÈME.

Assurez-vous de conserver toutes les preuves de paiement (facture ou contrat de vente/bon de livraison). La date

apparaissant sur ces documents sert à établir la période de garantie. Advenant le cas où un service au titre de la garantie

serait requis, vous devrez fournir la preuve d’achat. Si la preuve d’achat ne peut être fournie, la période de garantie sera

établie à compter de la date de fabrication du produit.

Nous vous recommandons d’enregistrer vos produits à www.beam.com an que nous puissions vous joindre advenant un

rappel de produits.

États-Unis

10200 David Taylor Drive

Charlotte, NC 28262

1-800-369-2326

Canada

5855 Terry Fox Way

Mississauga, ON L5V 3E4

1-800-282-2886

23

Page 24

24

Vente et service assurés par :

© 2013 Electrolux Home Care Products Ltd. #87238-R2

Page 25

BEAM Alliance

Manual de operaciones

Page 26

MEDIDAS DE SEGURIDAD IMPORTANTES

Al utilizar un aparato electrónico, siempre deben seguirse las precauciones básicas de seguridad, incluyendo

las que se mencionan a continuación.

LEA TODAS LAS INSTRUCCIONES ANTES DE UTILIZAR EL SISTEMA DE ASPIRACIÓN.

ADVERTENCIA

Para reducir el riesgo de incendio, descarga eléctrica o lesión:

• Esta aspiradora está diseñada para recoger residuos secos únicamente. No utilice en supercies húmedas

o para recoger líquidos, desperdicios calientes o cualquier artículo inamable que pueda causar daño a la

aspiradora.

• Mantenga el cordón alejado de supercies calientes.

• No permita el uso de la aspiradora como un juguete. Es necesario supervisar de cerca cuando la aspiradora

sea utilizada por niños o cerca de ellos.

• Utilice esta aspiradora únicamente para el uso que se describe en este manual. (El uso de aditamentos no

recomendados por el fabricante puede ocasionar incendios, descargas eléctricas, lesiones o daños a los

componentes del sistema).

• Conecte únicamente a una toma a tierra apropiada. Vea las instrucciones de tomas a tierra.

• Arme la unidad a una distancia mínima de 30 cm (12 pulgadas) del suelo, el techo y esquinas de paredes para

asegurar una ventilación adecuada para el motor.

• Nunca opere esta aspiradora si el cordón o el enchufe está dañado, si no funciona adecuadamente o si ha

caído o esta dañada. Devuelva al vendedor/distribuidor autorizado para reparación.

• Nunca desconecte el enchufe jalando del cordón. Para desconectar del tomacorriente, sujete el enchufe, no el

cordón.

• No coloque objetos en las aberturas. No utilice la aspiradora si tiene alguna abertura bloqueada.

• Mantenga la aspiradora libre de polvo, pelusa, cabellos y cualquier cosa que pueda reducir la succión/ujo de

aire. La falta de ujo de aire causará que el motor se sobrecaliente.

• Esta aspiradora crea succión. Mantenga el cabello, rostro, dedos y todas las partes corporales y ropa holgada

lejos de cualquier abertura.

• Nunca opere la aspiradora sin que el ltro/bolsa para polvo se encuentre en su lugar.

• Apague todos los controles antes de desenchufar.

• Nunca manipule el enchufe, el cordón o la unidad de poder con las manos húmedas.

• Tenga mucho cuidado al limpiar escaleras.

• No coloque la unidad de poder en un área de temperatura alta o inaccesible, por ejemplo, un ático o cámara.

• No utilice enchufes o cordones con extensión cuya capacidad de corriente no sean las adecuadas.

• No recoja artículos que se estén incendiando o estén humeando, como cigarrillos, cerillos o cenizas calientes.

• No utilice la aspiradora en supercies húmedas.

• No aspire polvo de paneles de yeso o harina para hornear ya que puede dañar su aspiradora.

• Este artefacto no fue diseñado para ser utilizado por personas, (incluso niños), con capacidades físicas,

sensoriales o mentales reducidas, o con falta de experiencia y conocimiento, a menos que reciban supervisión

o instrucción con respecto al uso del artefacto por una persona responsable de su seguridad.

• Si el cordón de poder se daña, debe ser reemplazado por un cordón especial disponible en el local de venta o

distribución autorizado.

• Mantenga en área de trabajo bien iluminada.

• Desenchufe los artefactos eléctricos antes de aspirarlos.

• No recoja líquidos combustibles o inamables como gasolina, o utilice este artefacto en áreas en las que

puedan estar presentes

26

GUARDE ESTAS INSTRUCCIONES

Page 27

Estimado cliente de Beam:

¡Felicitaciones por la adquisición de su nueva aspiradora Beam Alliance! Usted acaba de adquirir la

aspiradora central más innovadora e intuitiva de Beam. Le agradecemos su apoyo. Para obtener el máximo

benecio, por favor lea este manual de instrucciones antes de instalar y operar su aspiradora central. Usted

deseará conservar estas instrucciones para futuras referencias.

Para compras o consultas acerca de accesorios y servicios de instalación, sírvase contactar a su vendedor

local o visite nuestro sitio web en www.beam.com.

Recomendamos que registre su Aspiradora central en nuestro sitio web en www.beam.com.

Para su conveniencia, escriba a continuación el número de modelo y número de serie ubicado en su unida de poder. Usted

encontrará estos números en la placa de calicación ubicada en la parte superior trasera de la unidad.

Número de modelo_______________________

Número de serie _______________________

Fecha de compra _______________________

Al abrir el paquete

Su aspiradora central y el hardware y los accesorios que la acompañan son empacados cuidadosamente en un empaque

de cartón diseñado para proteger el producto de cualquier daño durante el transporte. Encontrará las piezas necesarias

para equipar su aspiradora central empacadas en el depósito para polvo.

Instalación de su aspiradora central

Si está planeando instalar la aspiradora central usted mismo, cuenta con un excelente manual y un video de instalación

disponible en línea en www.beam.com. Si desea que un profesional instale su aspiradora central, sírvase contactar a

su vendedor local o llame al 1-800-369-2326 en los Estados Unidos y al 1-800-282-2886 en Canadá. Nos complacerá

comunicarlo con un profesional de instalación en su área.

INFORMACIÓN GENERAL

El sistema de aspiradora central está diseñado para recoger residuos secos de suciedad y polvo del hogar y

no para recoger líquidos. Evite aspirar objetos duros o losos con el sistema para evitar que las mangueras y

las tuberías de plástico se dañen o se obstruyan. Este sistema de aspiradora central está diseñado sólo para

uso doméstico.

Información de servicio

Las instrucciones en este folleto sirven como una guía

para el mantenimiento de rutina. Para obtener información

adicional, comuníquese con su vendedor/distribuidor local

autorizado.

Placa de calicación

El estilo, modelo y número de serie se indican en la placa

de calicación situada en la parte posterior izquierda de la

unidad de poder. Para obtener información sobre servicio

rápido y completo, siempre reérase a estos números cuando

solicite dicha información (véase la gura 1).

Figure 1.

27

Page 28

INSTRUCCIONES PARA CONEXIÓN A TIERRA

Esta aspiradora debe estar conectada a tierra (puesta a tierra). Si deja de funcionar correctamente o tiene

una avería, la conexión a tierra (puesta a tierra) proporciona una ruta de menor resistencia para la corriente

eléctrica a n de reducir el riesgo de descarga eléctrica. Esta aspiradora está equipada con un cordón que

tiene un conductor del equipo a tierra y enchufe conectado a tierra (puesta a tierra). El enchufe debe insertarse

en un tomacorriente apropiado que esté correctamente instalado y conectado a tierra (puesta a tierra) de

acuerdo con todos los códigos y ordenanzas locales.

Modelos 110/115/120V

Esta aspiradora es para uso en un circuito nominal de 110/115/120 voltios y tiene un enchufe de conexión

a tierra como el que se muestra a continuación. Asegúrese de que el artefacto esté conectado a un

tomacorriente que tenga la misma conguración que el enchufe. No debe utilizar adaptador con esta

aspiradora.

Receptor de

punta a tierra

Punta a tierra

Salida

a tierra

ADVERTENCIA

Conexiones inapropiadas del conductor del equipo a tierra pueden ocasionar riesgos de descarga eléctrica.

Consulte con un electricista o persona de servicio calicada si tiene dudas acerca de la correcta conexión a tierra

del tomacorriente. No modique el enchufe provisto con el artefacto. Si no encajara en el tomacorriente, haga que un

electricista calicado instale el tomacorriente apropiado. Este artefacto está diseñado para ser utilizado con un circuito

nominal de 120 voltios (vea la placa de calicación para ubicar el voltaje correcto) y cuneta un enchufe para conexión a

tierra que se asemeja al que aparece en la ilustración. Asegúrese de que el artefacto esté conectado a un tomacorriente

que tenga la misma conguración que el enchufe.

• No debe utilizar un adaptador con este artefacto.

• No utilice un cordón de extensión con este artefacto.

• Si el cable de poder se daña, utilice únicamente un cable de reemplazo del equipo original del fabricante (OEM, por

sus siglas en inglés).

• Revise la unidad el botón de encendido/apagado de la unidad de poder y todas las válvulas de entrada para el

funcionamiento.

• Esta unidad de poder ha sido diseñada únicamente para uso comercial y el hogar.

28

Page 29

INSTALACIÓN

Instalación de la unidad de poder

La unidad de poder cuelga del soporte del montaje atornillado en

la pared. Los tornillos de la base del soporte de montaje deben

ubicarse aproximadamente a 48 pulgadas (122 cm) del suelo para

permitir el conveniente retiro del depósito para polvo. Para lograr

el enfriamiento adecuado del motor, debe haber por lo menos 12

pulgadas (31 cm) de distancia entre la unidad y el techo. Si se monta

la unidad en paredes de escayola o yeso, asegúrese de que los

tornillos de montaje ingresen en los pernos. Si se monta la unidad en

una pared de concreto, taladre la pared con una broca de albañilería

e inserte los tacos para pared apropiados. Retire el recubrimiento

de los cables de bajo voltaje instalados con la línea troncal principal.

(Figura 2)

Cables de voltaje

bajo

Cabezal de

tubería principal

Cabezal y linea de

escape opcional

Silenciador opcional

Conectores

de bajo voltaje

(suministrados)

El centro del gancho de

montaje debe estar a

122cm.

Energía eléctrica

Válvula de limpieza

rápida

Con el ingreso de “Limpieza rápida” opcional en la unidad de poder,

conecte los cables de la línea troncal al arnés de cable en la parte

M = Distancia minima de

30cm (12”) para enfriar el

trasera de la unidad antes de conectarla a los conectores con

resortes en el lado posterior de la unidad de poder. Si no cuenta con

la opción de válvula de “limpieza rápida”, simplemente conecte los

cables de línea troncal directamente a los conectores con resortes

en el lado posterior de la unidad de poder. Conecte la línea de tubo