Page 1

75.5984.01 LZR-H100 20181221 Page 1 of 175.5984.01 LZR-H100 20181221 Page 1 of 1

LZR®-H100

EN

LASER SCANNER FOR BARRIERS & GATES

with max. detection range of 32’ × 32’

User’s Guide

Visit website for available

languages of this document.

Page 2

Page 2 of 6 75.5984.01 LZR-H100 20181221Page 2 of 6 75.5984.01 LZR-H100 20181221

The device contains IR and visible laser diodes.

IR laser: wavelength 905nm; max. output pulse power 75W

(Class 1 according to IEC 60825-1)

Visible laser: wavelength 650nm; max. output CW power 3mW

(Class 3R according to IEC 60825-1)

The visible laser beams are inactive during normal functioning.

The installer can activate the visible lasers if needed.

CAUTION!

Use of controls, adjustments or performance of procedures other than those specified herein may result

in hazardous radiation exposure.

Avoid condensation on

the laser windows.

Avoid extreme vibrations. Do not cover the laser

windows.

Avoid moving objects

and light sources in front

of the laser window.

Avoid the presence of

smoke and fog in the

detection field.

Avoid exposure to

sudden and extreme

temperature changes.

Keep the sensor

permanently powered in

environments where the

temperature can drop

below 35 °F.

Do not use aggressive

products to clean the

laser windows.

Avoid direct exposure to

high pressure cleaning.

Do not look into the laser

emitter or the visible red

laser beams.

The warranty is void if

unauthorized repairs are

made or attempted by

unauthorized personnel.

Only trained and qualified

personnel may install and

adjust the sensor.

After installation, enter

an access code by remote

control.

This sensor is designed to be used as a movement and presence sensor to control the opening and the closing process

of a gate or a barrier. The installer of the system is responsible for installing the sensor and the system in compliance

with applicable national and international standards on safety. The manufacturer of the sensor cannot be held

responsible for incorrect installations or inappropriate adjustments of the sensor.

This device is not intended for use in with any automatically activated doors. US Pat. No. 7,084,388, which is not

owned by BEA, covers automatic doors comprising, among other things, a scanning detector. The LZR-H100 is not

sold with consent, implied or otherwise, for use with automatically activated doors, as set forth in the aforementioned

patent.

Clean the laser window

with compressed air. If

needed, wipe only with

a soft, clean and damp

microfibre cloth.

INSTALLATION & MAINTENANCE

SAFETY

Page 3

75.5984.01 LZR-H100 20181221 Page 3 of 675.5984.01 LZR-H100 20181221 Page 3 of 6

1

2

3

4

5

6

8

9

7

R1

R2

E P

no detection

detection

error

power

Caution!

Laser radiation

= LED flashes quickly

= LED flashes

= LED is off

1. laser window – emission

2. laser window – reception

3. LED signals

4. screws for position lock

5. connector

R1: Relay 1 - detection in opening field

R2: Relay 2 - detection in safety field

Important remote control

sequence

Possible remote control

adjustments

Factory values

All 4 LEDs can be switched off and on again by remote control.

This can be useful in cases where the sensor should not draw any attention.

Important Good to know

DESCRIPTION

LED-SIGNALS

SYMBOLS

= LED is on

no error

no power

E: Error status

P: Power status

LED-signal at power-on

6. protection cover

7. visible laser beams

8. notch for tilt angle adjustment

9. adjustable bracket

Page 4

Page 4 of 6 75.5984.01 LZR-H100 20181221Page 4 of 6 75.5984.01 LZR-H100 20181221

6"

0°

45°

90°

0°

0°

0°

0°

The sensor and detection field position are very important

for the good functioning of the barrier.

In order to position the sensor correctly, use the 3 visible

red laser beams.

The visible laser beams are also used to determine the

reference of the sensor in order to ensure the safety of the

barrier.

It is important to understand some basic principles before installing the sensor.

The sensor has to learn a reference when the safety field

is the only protection against contact between the vehicle

and the boom.

The reference can be adjusted on any type of object

already present on site (wall, tree, barrier boom support)

or on a post.

Always make sure the object on which the reference is

adjusted:

• is positioned in the continuity of the 0° laser beam

• is positioned min. at the end of the barrier or farther

away than the end of the barrier

• has a surface of at least 6 inches

• is firmly fixed to floor and not subject to vibrations

Use reflective sticker when the distance

between sensor and reference is higher

than 16.5 feet.

If the safety field is the only protection against contact

with the barrier, the safety field of the sensor must be

situated directly below the barrier.

This is only possible when the sensor is positioned

correctly and the reference has been learned.

If the reference is situated at the end of the barrier,

the detection field width is the same as the reference

distance.

If the reference is farther away, you need to adjust the

detection field width to the width of the barrier.

In order to maximize safety for mixed traffic (vehicles

and trucks), an additional vertical detection zone is

recommended (LZR-I30).

BASIC PRINCIPLES

REFERENCE

VISIBLE RED LASER BEAMS

SAFETY FIELD

Page 5

75.5984.01 LZR-H100 20181221 Page 5 of 675.5984.01 LZR-H100 20181221 Page 5 of 6

A

B

B

A

A

B

A

B

B

A

0°

45°

90°

0°

45°

90°

These requirements ensure optimal safety of the barrier in order to protect against contact with the barrier.

• 2 LZR-H100

• 2 references, 1 for each sensor

SAFETY FIELD

OPENING FIELD

DOUBLE ACCESS LANE

APPLICATION REQUIREMENTS

• 2 LZR-H100

• 1 reference

SINGLE ACCESS LANE

Page 6

Page 6 of 6 75.5984.01 LZR-H100 20181221Page 6 of 6 75.5984.01 LZR-H100 20181221

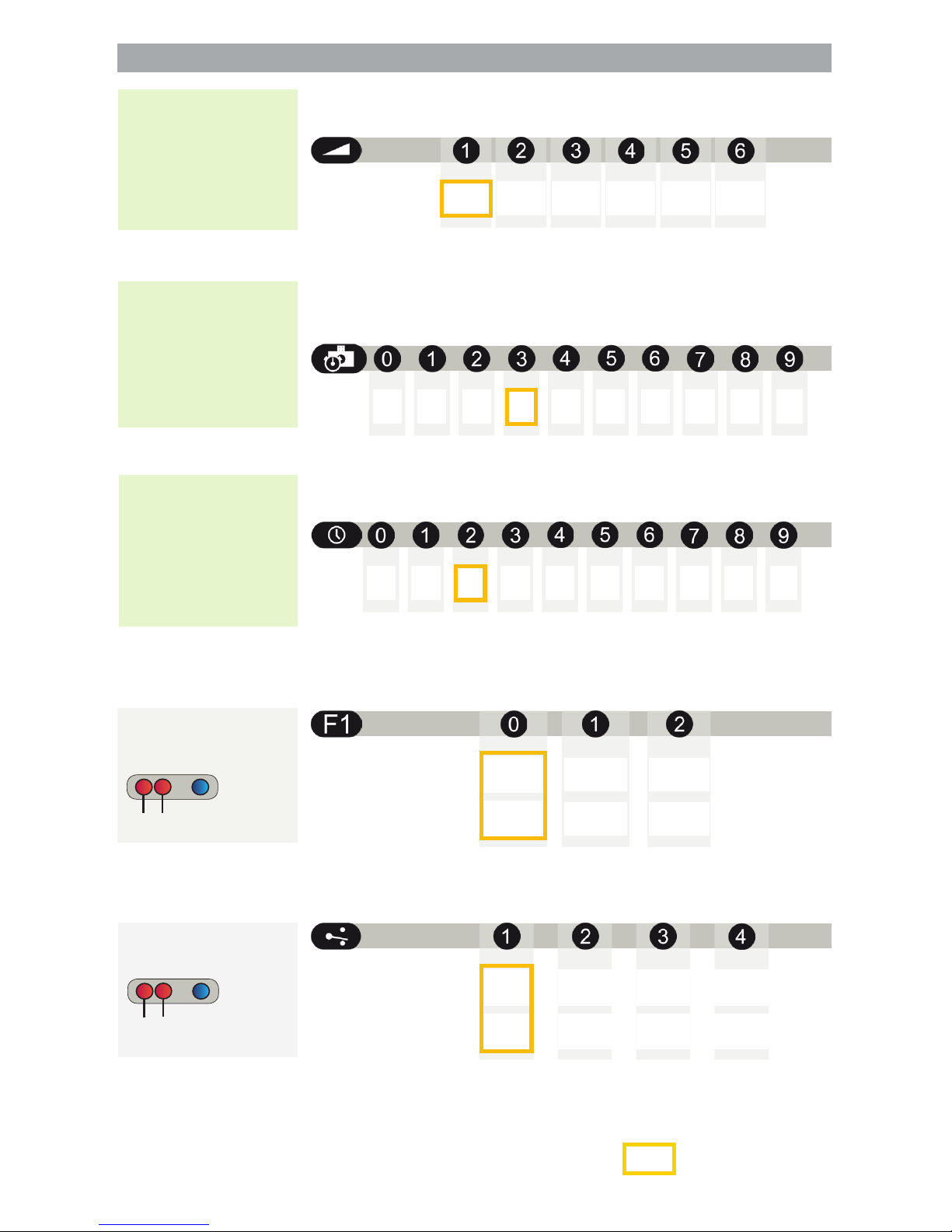

HOW TO USE THE REMOTE CONTROL

x

4 21

3

x

The access code is recommended for sensors installed close to each other.

After unlocking, the first LED

flashes red and the sensor

can be adjusted by remote

control.

If the red LED flashes quickly after unlocking, you

need to enter an access code from 1 to 4 digits.

X = NUMBER OF FLASHES = VALUE OF THE PARAMETER

= field width: 4.2 m

red red red

redredred

red

red

red

red

red

red

red red

red

red

green

green orange

orange

green

off

off

off

green

off

off

= field width is defined by teach-in

To end an adjustment session,

always lock the sensor.

Enter the existing code

ADJUSTING ONE OR MORE PARAMETERS

CHECKING A VALUE

RESTORING TO FACTORY VALUES

SAVING AN ACCESS CODE

DELETING AN ACCESS CODE

DELETING AN UNKNOWN ACCESS CODE

Page 7

75.5984.01 LZR-H100 20181221 Page 7 of 1675.5984.01 LZR-H100 20181221 Page 7 of 16

Lmin (in)

hmin (in)

2 9.5 2

4 14 2.3

6 19 2.5

d (in)

14 – 17 in

B

A

RECOMMENDED MOUNTING

Ensure there are no obstructions in front of the

sensor!

Do not position the detection field as shown.

When using the safety, place the sensor just

behind the barrier to ensure that the safety field

protects the area around the barrier.

When using the safety, do not place the sensor

before the barrier (A) or more than 15 inches after

the barrier (B). The area around the barrier is not safe.

Install the sensor at a mounting height between

14 – 17 inches. If the barrier is only used by

trucks, the mouting height may be increased.

Do not cover the front face of the sensor with

glass or plastic.

Ensure that the detection field is parallel to the

barrier.

If the reference beam is too low or too high,

contact with the barrier may occur.

Page 8

Page 8 of 16 75.5984.01 LZR-H100 20181221Page 8 of 16 75.5984.01 LZR-H100 20181221

1

1 2 3

IN LOCK

4 5 6

No test function:

Connect BLUE (DC+) and BLUE/WHITE

(DC-) to power supply.

(no polarity)

RELAY 1 - OPENING FIELD

RELAY 2 - SAFETY FIELD

NOT USED

RED

BLACK

WHITE

GREEN

WHITE/BLACK

GREEN/WHITE

BLUE

BLUE/WHITE

ORANGE

ORANGE/BLACK

TEST +

TEST -

POWER SUPPLY +

MOUNTING & WIRING

LED signal at power-on:

Correct positioning is needed

Carefully read the application requirements and tips before mounting the sensor.

Mounting position of the sensor is crucial for proper functioning of the barrier.

Power on without test signal:

Connect blue/white and blue

wires to test or power supply.

No detection

Safety and opening detection

POWER SUPPLY -

Use a mounting post or a mounting

accessory (e.g. LBA accessory) to

secure the sensor to the pole.

Position the bracket and secure

using the 4 screws to avoid

vibrations.

Firmly close the protection cover. Turn the sensor until the two

triangles are aligned.

Position the housing on the

bracket.

Open the protection cover, plug

the connector and position the

cable in the slit.

Page 9

75.5984.01 LZR-H100 20181221 Page 9 of 1675.5984.01 LZR-H100 20181221 Page 9 of 16

2

0°

45°

90°

1

2

3

0°

0°

0°

4

FIELD POSITIONING

Activate the visible laser beams by remote control

to position the sensor correctly.

The detection field and reference position are very important for proper functioning of the barrier.

Turn the sensor slightly on its axis to

adjust the lateral angle of the sensor to

place the 0° laser spot on the reference.

Adjust the tilt angle of the detection

field with the hex key if necessary.

To finish, lock the sensor position.

Use a sheet of white paper to verify that the laser beam

is positioned at 0°.

The reference point can be adjusted on any object at the

end of the barrier or farther away. Its surface should be

at least 6 inches wide and it must be secured.

Use the reflective sticker when the distance between

sensor and reference is higher than 16 feet (see page 4).

- The 0° spot must be parallel to the barrier.

- The beginning of the opening field should be

approximately 15 inches above the ground.

To turn off the beams, use the same

sequence. After 15 minutes, the beams

turn off automatically.

REFERENCE

Page 10

Page 10 of 16 75.5984.01 LZR-H100 20181221Page 10 of 16 75.5984.01 LZR-H100 20181221

3 MOUNTING SIDE & REFERENCE

Select the correct mounting side with or without reference.

WITH REFERENCE

(RECOMMENDED)

LEFTRIGHT

WITHOUT REFERENCE

By default, the sensor automatically adjusts the

width of the safety field based on the reference.

The safety field secures the area around the barrier

and protects against contact with the barrier.

The safety field detects the presence of a car, but

the area around the barrier is not secured.

For best detection performance, use

teh sensor with the reference point.

Page 11

75.5984.01 LZR-H100 20181221 Page 11 of 1675.5984.01 LZR-H100 20181221 Page 11 of 16

4

30 s

-

-

MIN

MAX

Once the sensor has finished the teach-in,

make sure that the safety field is correctly

configured and that the area around the barrier

or gate is safe.

You can also increase or decrease the field by 10 cm:

SAFETY FIELD

Always launch a new teach-in after adjusting the field dimensions.

If the safety field is the only protection against contact with the boom, the safety field of the sensor must be

situated right under the boom. This is only possible when the sensor is positioned correctly and the reference has

been learned.

The safety field is necessary for the correct functioning of the installation. If the safety field is badly adjusted,

the manufacturer of the sensor cannot be held responsible for inappropriate functioning of the installation.

Always verify the correct functioning of the safety field before leaving the premisses.

WIDTH

DEPTH

EX:

for a field depth of 1.5 m

Before launching a teach-in, the field dimensions can be adjusted by remote control.

Dimensions must be entered using the metric system - convert if necessary.

Value C must be adapted to the width of the barrier:

• when the reference point is farther away than the desired detection field width

• when a mounting side without reference has been selected

auto-set to

reference*

Launch a teach-in by remote control. You have 3 seconds to step out of the detection field.

Then wait for the sensor to learn its environment (30 seconds).

During the teach-in, the detection field must be free of snow buildups, heavy rain, snowfall, fog or other moving

objects.

If you walk along the detection area while the teach-in function is active, the sensor memorizes the outline of the

walk path and stores this as a new detection field. The shortest distance measured by each laser beam is stored by

the sensor and determines the field limit.

0.5 m 9.6 m

0.5 m 9.6 m

* without reference, the width will be automatically set to 9.9 m

FIELD DIMENSIONS

TEACH-IN

2.0 m

Page 12

Page 12 of 16 75.5984.01 LZR-H100 20181221Page 12 of 16 75.5984.01 LZR-H100 20181221

-

MIN

MAX

5

45 s

-

EX:

for a field depth of 5 m

same width as

safety field

OPENING FIELD

WIDTH

DEPTH

If the 1st red LED stays ON and no moving

objects are in the detection field, reduce the

opening field size or launch a new teach-in.

You can also increase or decrease the field by 10 cm:

0.5 m 9.6 m

Always launch a new teach-in after adjusting the field dimensions.

TEACH-IN

FIELD DIMENSIONS

0.5 m 9.6 m

if no opening

field is

needed

Before launching a teach-in, the field dimensions can be adjusted by remote control.

Dimensions must be entered using the metric system - convert if necessary.

Launch a teach-in by remote control. You have 3 seconds to step out of the detection field.

Then wait for the sensor to learn its environment (45 seconds).

During the teach-in, the detection field must be free of snow buildups, heavy rain, snowfall, fog or other moving

objects.

If you walk along the detection area while the teach-in function is active, the sensor memorizes the outline of the

walk path and stores this as a new detection field. The shortest distance measured by each laser beam is stored by

the sensor and determines the field limit.

Page 13

75.5984.01 LZR-H100 20181221 Page 13 of 1675.5984.01 LZR-H100 20181221 Page 13 of 16

cm

ms

R1 R2

R1 R2

A – NO

P – NC

P – NC

A – NO

P – NC

P – NC

A – NO

A – NO

PEDESTRIAN FILTER

opening field

OUTPUT CONFIGURATION

approximate values

approximate values

DETECTION DELAY

opening field

OUTPUT FUNCTION

RE L AY 1

RE L AY 1

RE L AY 2

RE L AY 2

MAX. PRESENCE TIME

opening field

STANDSTILL IN OPENING FIELD:

Select the amount of time R1 should stay active after an object becomes still in the opening

field.

presence presence presence

motion

motion or

presence

motion +

presence

REMOTE CONTROL ADJUSTMENTS (OPTIONAL)

Select value 3 or higher to reject pedestrians. All objects wider than the chosen setting will be

detected.

ENVIRONMENT FILTER:

Increase value in case of heavy rain, snow, or moving objects in the environment.

FACTORY VALUE

off 50

off

off

100

65 72 100 120

5

sec10sec30sec1min2min5min10min2hour

∞

200 300 400 500 600 700 800 900

Page 14

Page 14 of 16 75.5984.01 LZR-H100 20181221Page 14 of 16 75.5984.01 LZR-H100 20181221

teach-in

safety field

teach-in

opening field

factory

values

visible

laser beams

MAGIC WAND

DETECTION TRAJECTORY

opening field

BIDIRECTIONAL bidirectional detection

approaching + departing

UNI 400% unidirectional detection

only approaching

in any direction

UNI 200% unidirectional detection

only approaching

towards the barrier/gate

UNI 100% unidirectional detection

only approaching

within width of barrier/

gate

UNI 50% unidirectional detection

only approaching

towards central zone of

barrier/gate

UNI CENTER unidirectional detection

only approaching

towards centre of barrier/gate

UNI RIGHT unidirectional detection

only approaching

towards right side

UNI LEFT unidirectional detection

only approaching

towards left side

NOTE: Select "high" if fog is

causing unwanted detections.

standard high

IMMUNITY

REMOTE CONTROL ADJUSTMENTS (OPTIONAL)

Page 15

75.5984.01 LZR-H100 20181221 Page 15 of 1675.5984.01 LZR-H100 20181221 Page 15 of 16

TROUBLESHOOTING

No blue LED No power Check cable and connection.

Polarity of power supply is

inverted

Check the polarity of the power supply.

All LEDs have been deactivated

by remote control

Activate LEDs using remote control.

Only blue LED is on Test input is not connected Check wiring. The blue and blue/white

cable must be connected to the test input

or the power supply.

Detection LED remains

green

Detection field too small or

deactivated

Check size of fields.

Launch a teach-in.

Object size is too small Decrease minimum onject size.

Detection LED remains red Someone/Something is in the

detection field

Step out of the field and/or remove the

any object(s) from the field.

Field is touching floor/wall/door

– this leads to detection

Activate the 3 red beams and check if the

position of the sensor is correct. If not,

adjust the hex screws.

Verify the field size.

Launch a teach-in.

Orange LED flashing and

detection LEDs are red

No background (reference

point) is found

Check position of sensor.

Check the mounting side setting. If no

reference point is found, set the mounting

side to value 3 to 5.

Launch a new teach-in.

Sensor is masked Verify and clean the front screens with a

damp cloth.

Orange LED is on

Both detection LEDs are

orange

Power supply voltage exceeds

acceptable limits

Check power supply voltage.

Sensor exceeds temperature

limits

Verify the temperature of the environment.

Protect the sensor from sunlight using a

cover, if necessary.

Internal error Wait a few seconds.

If the LED remains ON, reset the power

supply.

If the LED turns on again, replace the

sensor.

Sensor does not respond

to the remote control

30 minutes after last use,

sensor locks access to RC

Cut and restore power supply. RC is

accessible again for 30 minutes.

Remote control batteries not

installed properly or are dead

Check battery orientation or replace the

batteries.

Remote control not pointed

correctly

Point the remote control towards the

sensor, but with a slight angle. The RC

should not be pointed in a right angle in

front of the sensor.

Reflective object is close to the

sensor

Avoid highly reflective material in proximity

to the sensor.

Sensor does not unlock Access code needs entered or

an incorrect code was used

Cycle power supply.

No code is required to unlock during the

first minute after powering.

Page 16

Page 16 of 16 75.5984.01 LZR-H100 20181221Page 16 of 16 75.5984.01 LZR-H100 20181221

Technology LASER scanner, time-of-flight measurement (4 laser curtains)

Detection mode motion and presence

Max. detection field 32’ × 32’

Remission factor >2%

Angular resolution 0.3516°

Emission characteristics

IR laser:

Red visible laser:

wavelength 905 nm; max. output pulse power 75 W (CLASS 1)

wavelength 650 nm; max. output CW power 3 mW (CLASS 3R)

Supply voltage 10 – 35 VDC @ sensor side

Power consumption <5 W

Peak current at power-on: 1.8 A (max. 80 ms @ 35 V)

Cable length: 33’

Response time

Motion detection:

Presence detection:

typ. 200 ms (adjustable)

typ. 20 ms (max. 80 ms)

Output:

Max. switching voltage:

Max. switching current:

Switching time:

Output resistance:

Voltage drop on output:

Leakage current:

2 electronic relays (galvanic isolated – polarity free)

35 VDC / 24 VAC

80 mA (resistive)

tON=5 ms; tOFF=5 ms

typ 30 Ω

<0.7 V @ 20 mA

<10 µA

Test input:

Max. contact voltage:

Voltage threshold:

1 optocoupler (galvanic isolated - polarity free)

30 VDC (over-voltage protected)

Log. H: >8 VDC

Log. L: <3 VDC

LED-signal: 1 blue LED: power-on status

1 orange LED: error status

2 bi-colored LEDs: detection/output status (green = no detection, red = detection)

Dimensions: 3 5⁄8”× 2 3⁄4”× 5”(W × H × D) mounting bracket: + 1⁄2”

Material / Colour: PC/ASA, black

Mounting angles on bracket: -45°, 0°, 45°

Rotation angles on bracket: -5 – 5° (lockable)

Tilt angles on bracket: -3 – 3°

Protection degree: IP65

Temperature range: powered: -22 – 140 °F unpowered: 14 – 140 °F

Humidity: 0 – 95% non-condensing

Vibrations: <2 G

Pollution on front screens: max. 30%; homogenous

Norm conformity: IEC 61000-6-2; IEC 61000-6-3; IEC 60950-1; IEC 60825-1

ISO 13849-1 (Pl “d” CAT 2); IEC 62061 (SIL 2); IEC 61496-1 (Type 2)

TECHNICAL SPECIFICATIONS

BEA, the sensor manufacturer, cannot be held responsible for incorrect installations or inappropriate adjustments of the sensor/device; therefore, BEA

does not guarantee any use of the sensor outside of its intended purpose.

BEA strongly recommends that installation and service technicians be AAADM-certifi ed for pedestrian doors, IDA-certifi ed for doors/gates, and factorytrained for the type of door/gate system.

Installers and service personnel are responsible for executing a risk assessment following each installation/service performed, ensuring that the sensor

system installation is compliant with local, national, and international regulations, codes, and standards.

Once installation or service work is complete, a safety inspection of the door/gate shall be performed per the door/gate manufacturer recommendations

and/or per AAADM/ANSI/DASMA guidelines (where applicable) for best industry practices. Safety inspections must be performed during each service

call – examples of these safety inspections can be found on an AAADM safety information label (e.g. ANSI/DASMA 102, ANSI/DASMA 107).

Verify that all appropriate industry signage and warning labels are in place.

BEA INSTALLATION/SERVICE COMPLIANCE EXPECTATIONS

PLEASE KEEP FOR FURTHER USE – DESIGNED FOR COLOR PRINTING

Tech Support: 1-800-407-4545 | Customer Service: 1-800-523-2462

General Tech Questions: Tech_Services@beainc.com | Tech Docs: www.BEAinc.com

©BEA | Original Instructions | 75.5984.01 LZR-H100 20181221

Specifications are subject to change without prior notice.

All values measured in specific conditions.

Loading...

Loading...