Page 1

BOLLARD MOUNTING POST

USER’S GUIDE

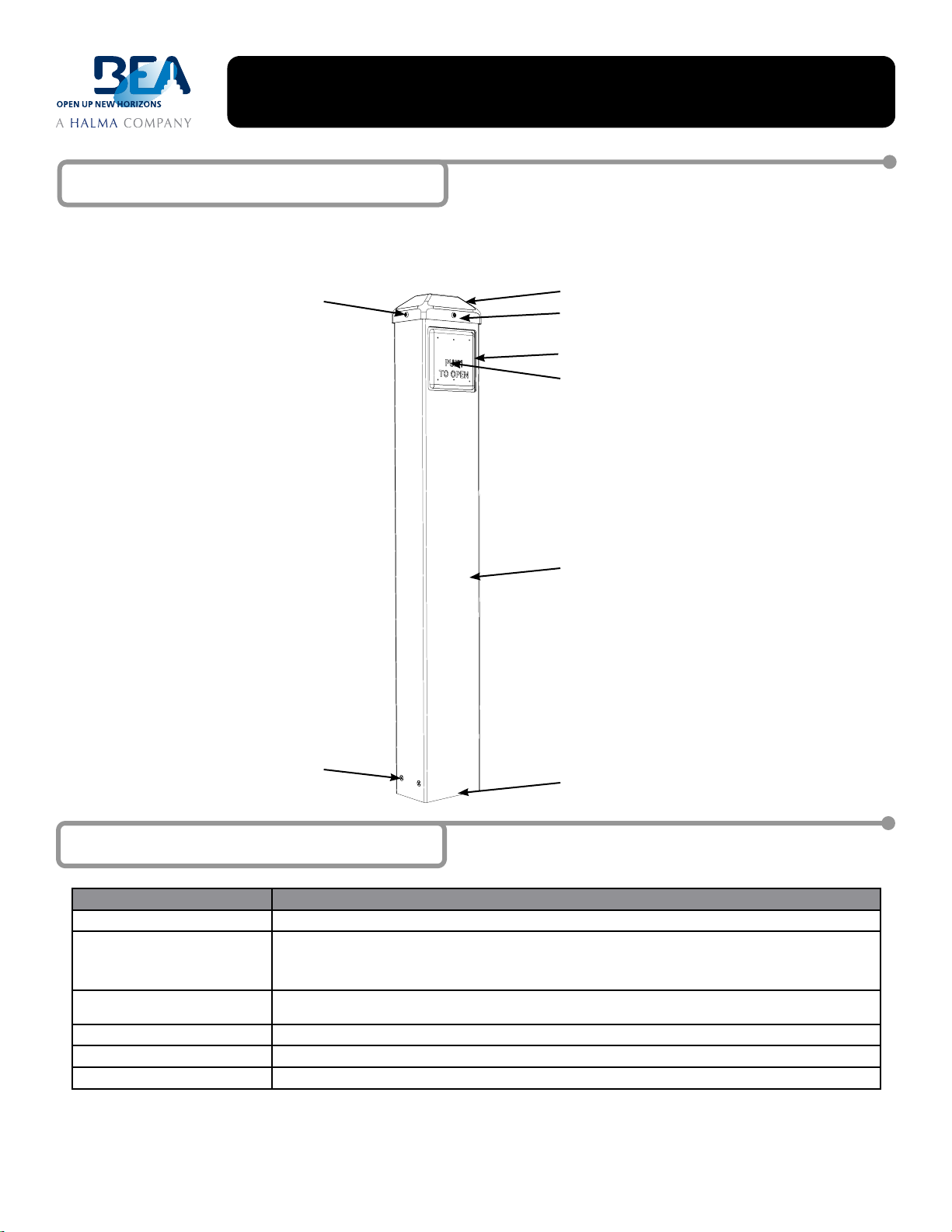

MOUNTING POST FOR PUSHPLATES

1 Description

The Bollard (Black-10BOLLARDBLK, Bronze-10BOLLARDBRZ & Silver-10BOLLARDSLV) is used for mounting pushplates that activate automatic

doors. It will accept BEA’s 4 ½” Square Pushplate, 4 ¾” Square Pushplate, 4 ¾” Panther Pushplate, Dual Vestibule Pushplate and 4 ½” Round

Pushplate. The post is made of durable carbon steel and the mounting bracket is made of stainless steel for strength. It can be mounted on either

existing concrete or newly poured concrete.

CAP MOUNTING SCREWS (3)

PLASTIC CAP

TRANSMITTER MOUNTING TRAY (HIDDEN)

NOT USED WITH PANTHER APPLICATION

PUSHPLATE MOUNTING BOX (HIDDEN)

PUSHPLATE (NOT INCLUDED)

WILL ACCEPT:

4 1/2” SQUARE PUSHPLATE

(10PBS45X)

4 3/4” SQUARE PUSHPLATE

(10PBS, 10PBS1, 10PBS10)

4 3/4” SQUARE PANTHER PUSHPLATE

(10EMSQ475X)

DUAL VESTIBULE PUSHPLATE

(10PBDGP1)

4 1/2” ROUND PUSHPLATE

(10PBR45X)

POST ASSEMBLY

POST MOUNTING SCREWS (4)

POST MOUNTING BRACKET (HIDDEN)

2 Specications

DESCRIPTION SPECIFICATION

Dimensions (with cap attached) 41 ½”H x 6 ¼” W x 4 ¼”D

Material

• Post

• Cap

• Mounting Bracket

Pushplate Options 4 ½” Square Pushplate, 4 ¾” Square Pushplate, 4 ¾” Square Panther Pushplate, Dual Vestibule Pushplate

Weight 35 lbs (16 kilos)

Color Black, Bronze, Silver

Mounting Hardware L-anchor, Expansion Anchor, Split Washer and Nut (Included)

75.0131.05 20080606 Page 1 of 4

Powder-Coated (Inside and Out) Carbon Steel

UV-Resistant ABS Plastic

Stainless Steel

and 4 ½” Round Pushplate

Page 2

3 Precautions

2.19 in

55.58 mm

1/4-20

53.95 mm

2.12 in

3.65 in

25.40 mm

143.51 mm

5.65 in

0.44 in

11.11 mm

92.71 mm

1.00 in

39.37 mm

1.55 in

3.55 in

92.10 mm

Shut off all power before attempting any wiring procedures.

Maintain a clean & safe environment when working in public areas.

Constantly be aware of pedestrian trafc around the door area.

Always stop pedestrian trafc through the doorway when performing tests that may result in unexpected reactions by the door.

Always check placement of all wiring before powering up to insure moving door parts will not catch any wires and cause

damage to equipment.

Ensure compliance with all applicable safety standards (i.e. ANSI A156.19 / A156.10) upon completion of installation.

DO NOT attempt any internal repair of the sensor. All repairs and/or component replacements must be performed by BEA, Inc.

Unauthorized disassembly or repair:

1. May jeopardize personal safety and may expose one to the risk of electrical shock.

2. May adversely affect the safe and reliable performance of the product resulting in a voided warranty.

4 Pre Installation Check

1. When preparing to wire multiple devices together for a ‘system’ conguration, it is best to ensure the correct operation of each device

independently before starting to help reduce troubleshooting time later in the event of a discrepancy.

2. Prior to installing any equipment, ensure correct line voltage and stability. When applying equipment on a new installation utilizing new

electrical supply circuits, always ensure correct line voltage exists and is stable. Remember to shut the power back off after this is checked

and before performing any wiring to the system.

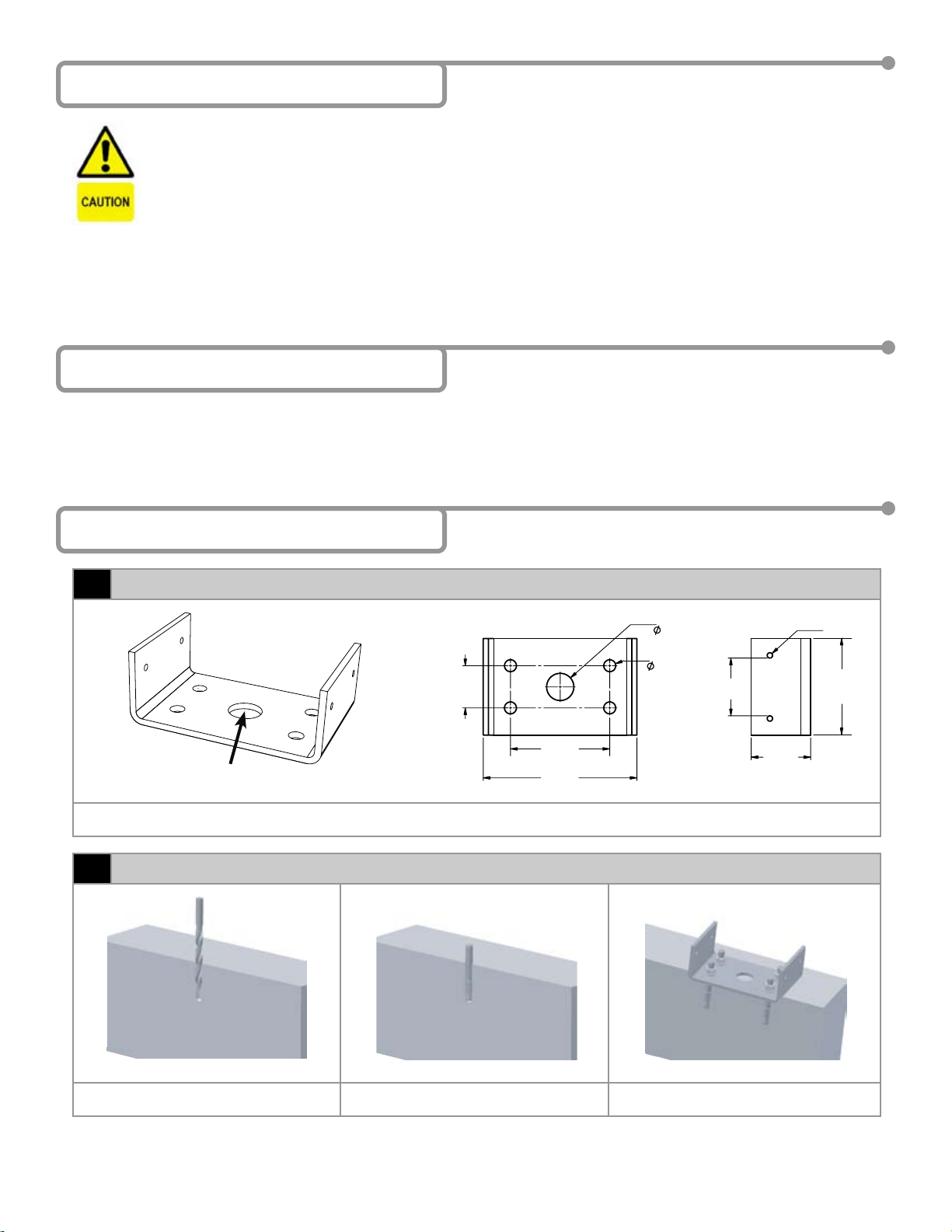

5 Installation

Hardwire Bracket - Optional

1

FOR HARDWIRING RUN WIRE

THROUGH 1” DIAMETER HOLE

1. The Bollard is designed to house a pushplate used to activate a door by either a remote controlled transmitter or hardwired directly to the

door control. If the door is hardwired, pass the wire through the 1 inch diameter hole in the mounting bracket.

Attach Mounting Bracket Using Expansion Anchors - Existing Concrete

2

1. Mark and drill 3/8” diameter hole in four

locations.

Page 2 of 4 75.0131.05 20080606

2. Hammer in and set anchor in four hole

locations.

3. Install and tighten nuts to secure mounting

bracket.

Page 3

5 Installation (Continued)

Attach Mounting Bracket Using ‘L’ Shaped Anchors - New Concrete

3

1” EXPOSED

6”

1. Pour concrete at least 6 inches deep. 2. Insert anchors into curing concrete. Leave

Attach Post to Mounting Bracket

4

1. Align post to mounting bracket and attach post to mounting bracket with four post mounting screws.

Install Pushplate

5

at least 1 inch exposed.

3. Once concrete has cured attach anchor and

tighten nuts onto mounting bracket.

PUSHPLATE INSTALLATION DUAL PUSHPLATE INSTALLATION PANTHER PUSHPLATE INSTALLATION

1. Thread the pushplate screws into the mounting box leaving a majority of the screw exposed. Attach the pushplate to the mounting screws,

then use the hex key provided to fully tighten the screws. Refer to the appropriate Pushplate User’s Guide for detailed installation and setup

instructions.

75.0131.05 20080606 Page 3 of 4

Page 4

5 Installation (Continued)

Attach Transmitter

6

TRANSMITTER MOUNTING TRAY

ATTACH TO PUSHPLATE

NOTE: PANTHER PUSHPLATES DO NOT

REQUIRE A TRANSMITTER.

ATTACH

TRANSMITTER

HERE

CAUTION: IF THE TRANSMITTER IS ALLOWED TO HANG DOWN INSIDE THE BOLLARD, ERRATIC OPERATION MAY OCCUR.

1. If using the transmitter for this application, attach transmitter to mounting tray with velcro pad included in the package. Hardwired systems do

not require this step.

2. Attach plastic cap to top of the post with three cap mounting screws. Tighten screws with hex key included in the pushplate package.

6 Company Contact

Do not leave problems unresolved. If a satisfactory solution cannot be achieved after troubleshooting a problem, please

call BEA, Inc. If you must wait for the following workday to call BEA, leave the door inoperable until satisfactory repairs

can be made. Never sacrice the safe operation of the automatic door or gate for an incomplete solution.

The following numbers can be called 24 hours a day, 7 days a week. For more information visit www.beasensors.com.

West:

South-East:

US and Canada:

1-888-419-2564

1-800-407-4545

1-866-249-7937

Mid-West:

North-East:

Canada:

1-888-308-8843

1-866-836-1863

1-866-836-1863

Page 4 of 4 75.0131.05 20080606

Loading...

Loading...