Page 1

10GL1200R / 10GL1200SR

1 Description

BEA’s Gate-Lock provides an effective magnetic

bond (1200 lbs.) to keep sliding or swing gates

locked for your security needs. The attractive,

weather resistance stainless steel housing makes

this lock suitable for external applications.

UL GATE LOCKS

USER’S GUIDE

MAGNETIC UL LOCK FOR GATES

FRONT MOUNT

10GL1200R

2 Specications

DESCRIPTION SPECIFICATION

Input Voltage: 12 or 24 VDC

Current: 500 mA @ 12 VDC

Contact Rating: 0.250 A @ 12 V

Dimensions: 8.750”L X 2.500”H X 1.625”D

Conduit ftting:

(10GL1200R only)

Cerication: UL/CUL

250 mA @ 24 VDC

0.125 A @ 24 V

3/4 inch NPS conduit tting

14 Threads per inch

3 Precautions

Shut off all power before attempting any wiring procedures.

Maintain a clean and safe environment when working in public areas.

Constantly be aware of pedestrian trafc around the door area.

Always stop pedestrian trafc through the doorway when performing tests that may result in unexpected reactions by the

door.

ESD electrostatic discharge: Circuit boards are vulnerable to damage by electrostatic discharge. Before handling any board

ensure you dissipate your body’s charge.

Always check placement of all wiring before powering up to insure that moving door parts will not catch any wires and cause

damage to equipment.

Ensure compliance with all applicable safety standards (i.e. ANSI A156.10) upon completion of installation.

DO NOT attempt any internal repair of the sensor. All repairs and/or component replacements must be performed by BEA,

Inc. Unauthorized disassembly or repair:

1. May jeopardize personal safety and may expose one to the risk of electrical shock.

2. May adversely affect the safe and reliable performance of the product will result in a voided product warranty.

LZ BRACKET

10LZBRGATE1200

FRONT MOUNT

10GL1200R

4 Pre Installation Check

1. When preparing to wire multiple devices together for a ‘system’ conguration, it is best to ensure the correct operation of each device

independently before starting to help reduce troubleshooting time later in the event of a discrepancy.

2. Prior to installing any equipment, ensure the correct line voltage and stability. When applying equipment on a new installation utilizing new

electrical supply circuits, always ensure that correct line voltage exists and is stable. Remember to shut the power back off after this is

checked and before performing any wiring to the system.

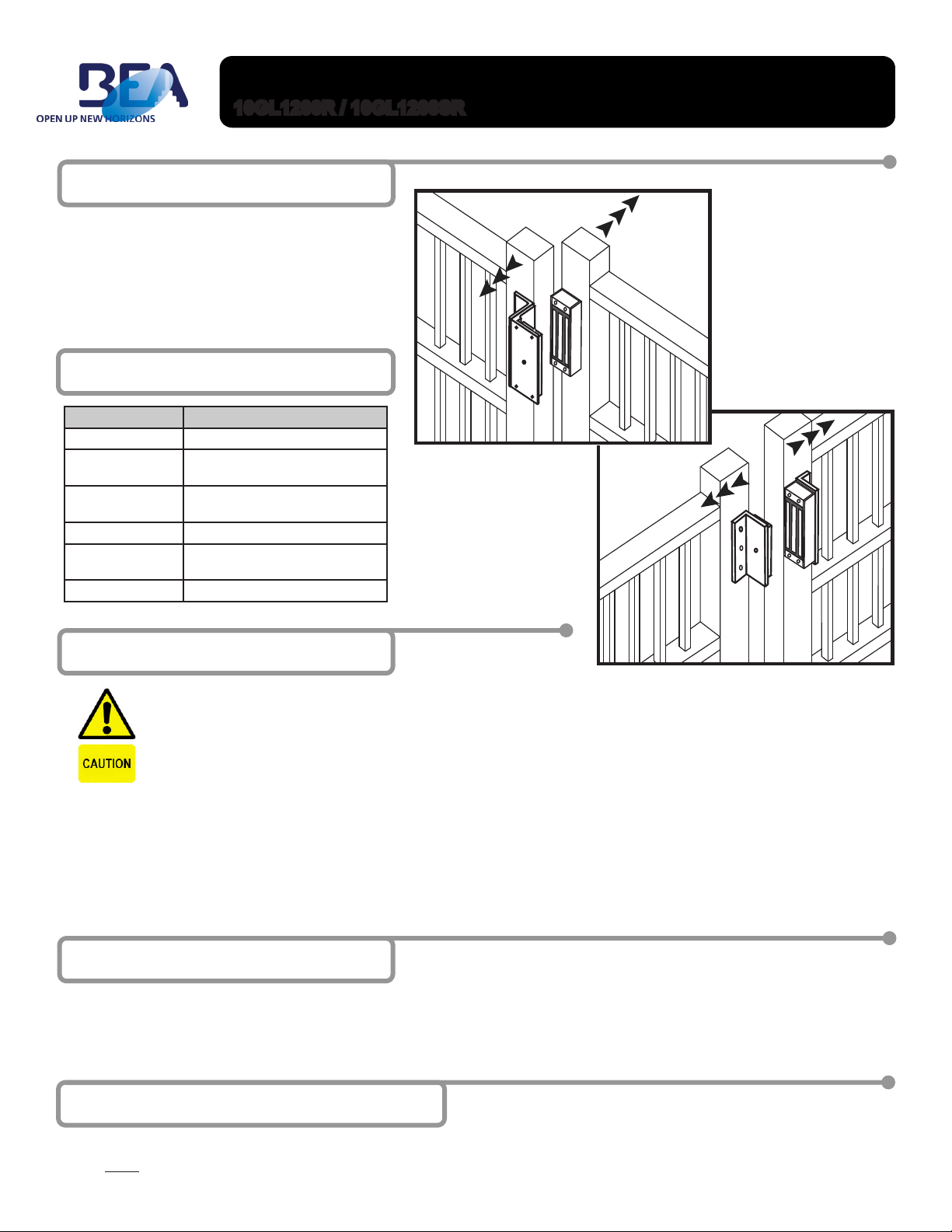

5 Installation

1. Determine the desired location for mounting the Gate-Lock assembly on the gate and/or post.

NOTE: Position the maglock end with the conduit tting (3/4” female) relative to the location of electrical wiring.

75.5668.05 20160915 Page 1 of 2

Page 2

5 Installation (Continued)

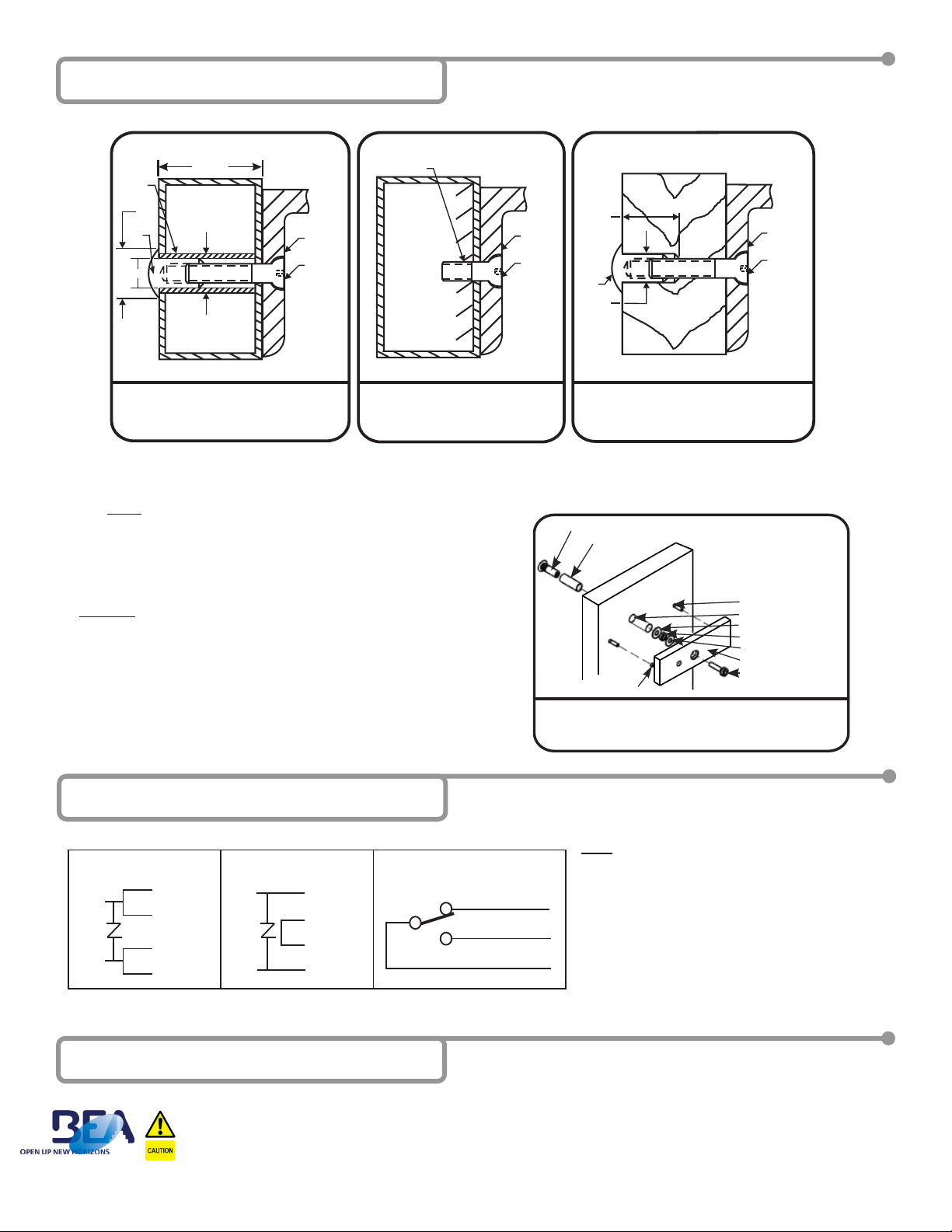

2. Drill the mounting holes for the bracket (armature and/or magnet, depending on conguration) per FIGURE 1.

DOOR

SPACER

7/8"

SEX

NUT

1/2"

1. Drill an 5/16" diameter hole through gate.

2. Enlarge the 5/16” hole to 5/8” from sex

nut side only.

1-3/4"

5/8"

GATE LOCK

BRACKET

MOUNTING

SCREW

HOLLOW TUBE SOLID CORE

FIGURE 1A

M8-1.25 THREAD

1. Drill an 17/64" diameter hole and

tap for M8-1.25 thread.

REINFORCED TUBE

FIGURE 1B

NOTE: If applicable, drill two (2) 1/4” holes, 9/16” deep, 3 1/4” from

armature mounting screw hole for anti-spin pin locations.

Drive anti-spin pins into armature holes using a rubber mallet.

3. Attach bracket(s) rmly with mounting machine/sheet metal screws.

To reduce the effects of excessive vibrations on bracket attachment,

apply Locktite/Threadlocker (not included) to screws during installation.

CAUTION: FAILURE TO PROPERLY SECURE THE ARMATURE COULD

RESULT IN SERIOUS INJURY OR SECURITY BREACH.

4. With washers and spacers included (See FIGURE 2), rmly tighten

armature mounting screws to bracket with hex wrench.

5. Attach magnet assembly to bracket or post with four (4) socket head

screws or self taping screws with anti-tamper plugs.

6. Close the gate and verify magnet face and

armature are making full contact over entire

surface. Make adjustments as required.

ARMATURE PLATE

ASSEMBLY

FIGURE 2

GATE LOCK

BRACKET

MOUNTING

SCREW

1 1/2"

SEX

NUT

15/32"

1. Drill an 5/16" diameter hole through gate.

2. Enlarge the 5/16” hole to 15/32” to a depth

of 1 1/2” from sex nut side only.

GATE LOCK

BRACKET

MOUNTING

SCREW

FIGURE 1C

NUT

SPACER (11/16”)

POST

HOLE FOR GUIDE PIN

HOLE FOR NUT

STEEL WASHER

RUBBER WASHER

STEEL WASHER

ARMATURE PLATE

GUIDE PIN

NOTE: DO NOT over-tighten armature plate. Rubber washer is designed

to allow the armature plate to automatically adjust position

for best mating position between lock and armaure plate.

SCREW M8 (35MM)

6 Wiring

NOTE: For 12V source; connect RED/BLACK

12VDC

+

BLACK

TVS TVS

GREEN

RED

-

ORANGE

+

-

24VDC LOCK STATUS

RED

(NON-BONDED STATE)

BLUE (NC)

BLACK

YELLOW (NO)

GREEN

ORANGE

BROWN (COM)

wires and connect GREEN/ORANGE wires.

For

24V source; short BLACK/GREEN wires

and connect RED and ORANGE wires .

Lock Status contacts change status when

the bonding occurs.

Transient voltage suppressor (TVS) should

be placed as directed.

BEA recommends a UL Power Supply.

7 Company Contact

24/7 Tech Support: 1-800-407-4545 | Customer Service: 1-800-523-2462 | General Tech Questions: Tech_Services@beainc.com | Tech Docs: www.beasensors.com

Page 2 of 2 75.5668.05 20160915

Loading...

Loading...