BE AC2020 User Manual

AC2020

PORTABLE AIR

COMPRESSOR

USER MANUAL

2 3

Introduction

4 Using the Operator’s Manual

4 Specifications

Product Identification

5 Record Identification Numbers

Safety

6 Receipt and Inspection

7 Safety Instructions

7 Hazard Symbols and Meanings

8 Air Tank Warning

8 Fire Warnings

8 Breathable Air Warning

9 Electric Shock Warning

9 Air Tools and Accessories Warning

10 General Safety Information

11 Spraying Precautions

11 Hose Precautions

Installation & Grounding

12 Installation and Location

12 Grounding Instructions

13 Extension Cords

Air Compressor Components

14 Air Compressor Breakdown

Assembly

15 Assembly Instructions

Operation

16 Preparation for Starting

17 Operation and Adjustment

Maintenance

18 Maintenance

18 Daily

18 Weekly

19 Monthly

19 3 Months or 500 Operating Hours

19 12 Months or 1000 Operating Hours

Caution

19 Caution

Exploded View

20 Exploded View Diagram

21 Exploded View List

List of Goods

22 List of Goods

Troubleshooting

23 Troubleshooting Chart

4 5

Item Data

Model AC2020

Power 1.5HP/2HP/2.5HP

Voltage 230V/240V 120V/220v

Frequency 50Hz 60Hz

Motor Poles 2P

Rated Speed 2850 r/min 3450 r/min

Current 7.5~15A

Delivery 5.0 CFM@40psi 4.3 CFM@90psi

Discharge Pressure 125 PSI

Restart Pressure 95 PSI

Tank Capacity 10 GAL 12 GAL 15 GAL 20 GAL

Air Outlet Size 1/4”

Using the Operator’s manual

Thank you for purchasing a our compressor. Your machine is designed for

long life, dependability, and industry-leading performance. Please take time

now to read through this manual so you better understand the machine’s

operation, maintenance and safety precautions.

Everyone who operates this machine must read and understand this manual.

The time you take now will prolong your machine’s life and prepare you for its

safe operation.

The manufacturer reserves the right to make improvements in design and/or

changes in specifications at any time without incurring any obligation to install

them on units previously sold.

Attention: Read through the complete manual

prior to the initial use of your compressor.

Record Identification Numbers

COMPRESSOR

If you need to contact an Authorized Dealer or Customer Service line

(1-866-850-6662) for information on servicing, always provide the

product model and identification numbers.

You will need to locate the model and serial number for the machine and

record the information in the places provided below.

Date of Purchase:

Dealer Name:

Dealer Phone:

Product Identification Numbers

Model Number:

Serial Number:

SPECIFICATIONS

6 7

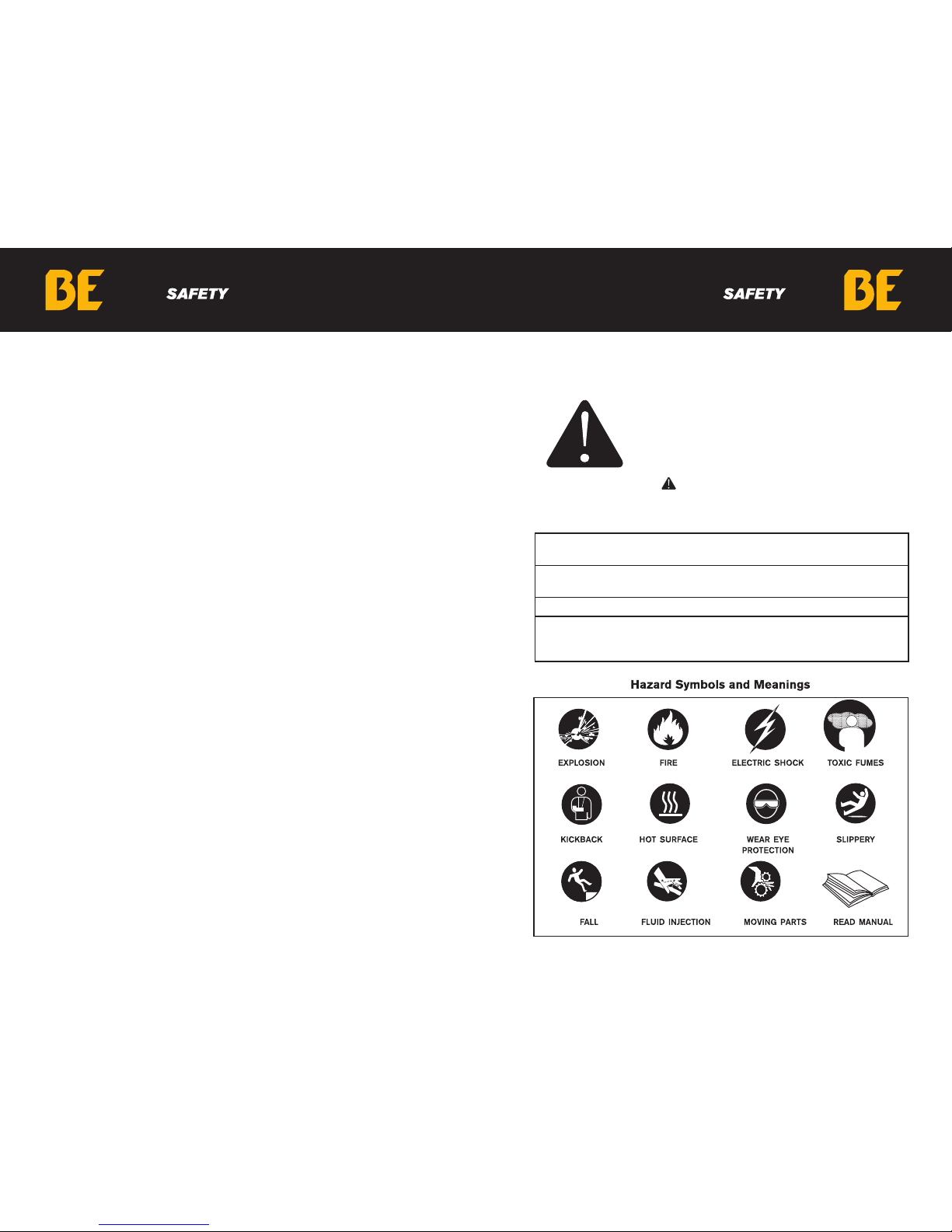

The safety alert symbol ( ) is used with a signal word (DANGER,

CAUTION, WARNING), a pictorial and/or a safety message to alert you

to hazards.

DANGER WILL cause DEATH, SEVERE INJURY or substantial

property damage.

WARNING CAN cause DEATH, SEVERE INJURY or substantial

property damage.

CAUTION WILL or CAN cause MINOR INJURY or property damage.

NOTICE indicates a situation that could result in equipment damage.

Follow safety messages to avoid or reduce the risk of injury or

death.

Save these Instructions

SAFETY RULES

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey

all safety messages that follow this symbol to

avoid possible injury or death.

Receipt and Inspection

Before signing the delivery receipt, inspect for damage and missing parts.

If damage or missing parts are apparent, make the appropriate notation

on the delivery receipt, then sign the receipt. Immediately contact the

carrier for an inspection. All material must be held in the receiving

location for the carrier’s inspection. Delivery receipts that have been

signed without a notation of damage or missing parts are considered

to be delivered “clear.” Subsequent claims are then considered to

be concealed damage claims. Settle damage claims directly with the

transportation company.

If you discover damage after receiving the air compressor (concealed

damage), the carrier must be notified within 15 days of receipt and an

inspection must be requested by telephone with confirmation in writing.

On concealed damage claims, the burden of establishing that the

compressor was damaged in transit reverts back to the claimant.

Read the compressor nameplate to verify it is the model ordered, and

read the motor nameplate to verify it is compatible with your electrical

conditions. Make sure electrical enclosures and components are

appropriate.

8 9

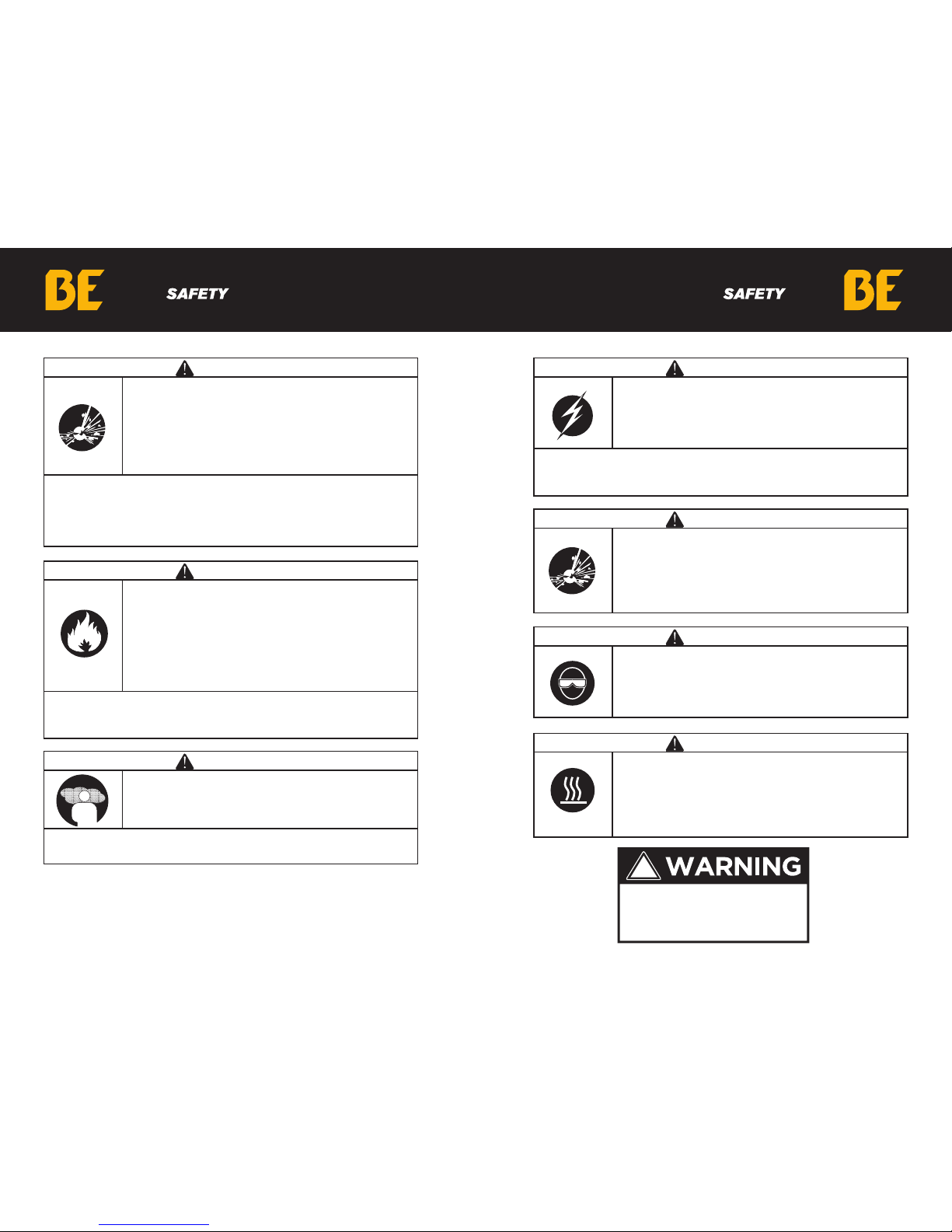

WARNING

AIR TANK WARNING: Drain liquid from air tank daily,

or after each use, using the drain valve located on the

bottom of the lower air tank. Failure to properly drain

liquid from the tank will cause rust from moisture buildup, which weakens the tank and could lead to a violent

tank explosion, Periodically inspect the tanks for unsafe

conditions such as corrosion.

Never attempt to repair or make modifications to the tank or its attachments. Welding, drilling or any other modifications may weaken

the tank, which may result in damage from rupture or explosion. Never

remove or attempt to adjust the pressure switch, safety valve, or other

factory set operating pressures.

WARNING

FIRE WARNING: Avoid dangerous environments. Do

not use compressor near gasoline or other flammable

materials. Keep work area well lit. Normal sparking of

a motor or sparking from grinding metal could ignite

fumes. Do not spray flammable materials in the vicinity

of an open flame or other ignition source, including the

air compressor itself. Do not direct paint or other spray

material towards the compressor.

Read and follow all safely instructions for the material you are spraying. Be sure to use an approved respirator designed for use with your

specific application.

WARNING

BREATHABLE AIR WARNING: This air compressor in

not designed, nor intended for the supply of breathable

quality air. Air produced by this unit may contain carbon

monoxide or other toxic vapors.

Do not inhale air from the compressor or from a breathing device

connected to it.

WARNING

ELECTRIC SHOCK WARNING: When using electric

powered tools, machines or equipment, basic safety

precautions should always be followed to minimize the

risk of electrical shock or personal injury to yourself and

others.

This air compressor is powered by electricity and should never be used

without properly grounded electrical connections. Do not use in wet or

damp locations or expose to rain.

WARNING

AIR TOOLS AND ACCESSORIES WARNING: Do

not exceed the pressure rating of any air tools, spray

guns, air accessories, or inflatables. Excess pressure

can cause them to explode, resulting in serious injury.

Follow the manufacturers recommended pressure settings for all air tools and air accessories.

WARNING

Do not direct compressed air stream at people or pets.

The powerful compressed air stream can damage

exposed skin and easily propel loose dirt and other

small objects. Always wear eye protection that meets

ANSI Z28.1 specifications.

WARNING

Keep hands and fingers away from exposed metal parts

on a running air compressor. Air compressors generate significant heat during normal operation, which can

cause serious burns. The compressor will remain hot for

some time after operation and should not be touched or

moved until cool.

This product can expose you to chemicals

including lead, which is known to the State

of California to cause cancer and birth

defects or other reproductive harm. For more

information, go to www.P65Warnings.ca.gov.

Wash hands after handling.

!

10 11

GENERAL SAFETY INFORMATION

Do not operate unit if damaged during shipping, handling or use. Damage

may result in bursting and cause injury or property damage.

Since the air compressor and other components (filters, lubricators,

hoses, etc.) used, make up a high pressure pumping system, the

following safety precautions must be observed at all times:

1. Read all manuals included with this product carefully. Be thoroughly

familiar with the controls and the proper use of the equipment.

2. Follow all local electrical and safety codes

3. Only persons well acquainted with these rules of safe operation

should be allowed to use the compressor.

4. Keep visitors away and NEVER allow children in the work area.

5. Wear safety glasses and use hearing protection when operating the

pump or unit.

6. Do not stand on or use the pump or unit as a handhold.

7. Before each use, inspect compressed air system and electrical

components for signs of damage, deterioration, weakness or leakage.

Repair or replace defective items before using.

8. Check all fasteners at frequent intervals for proper tightness.

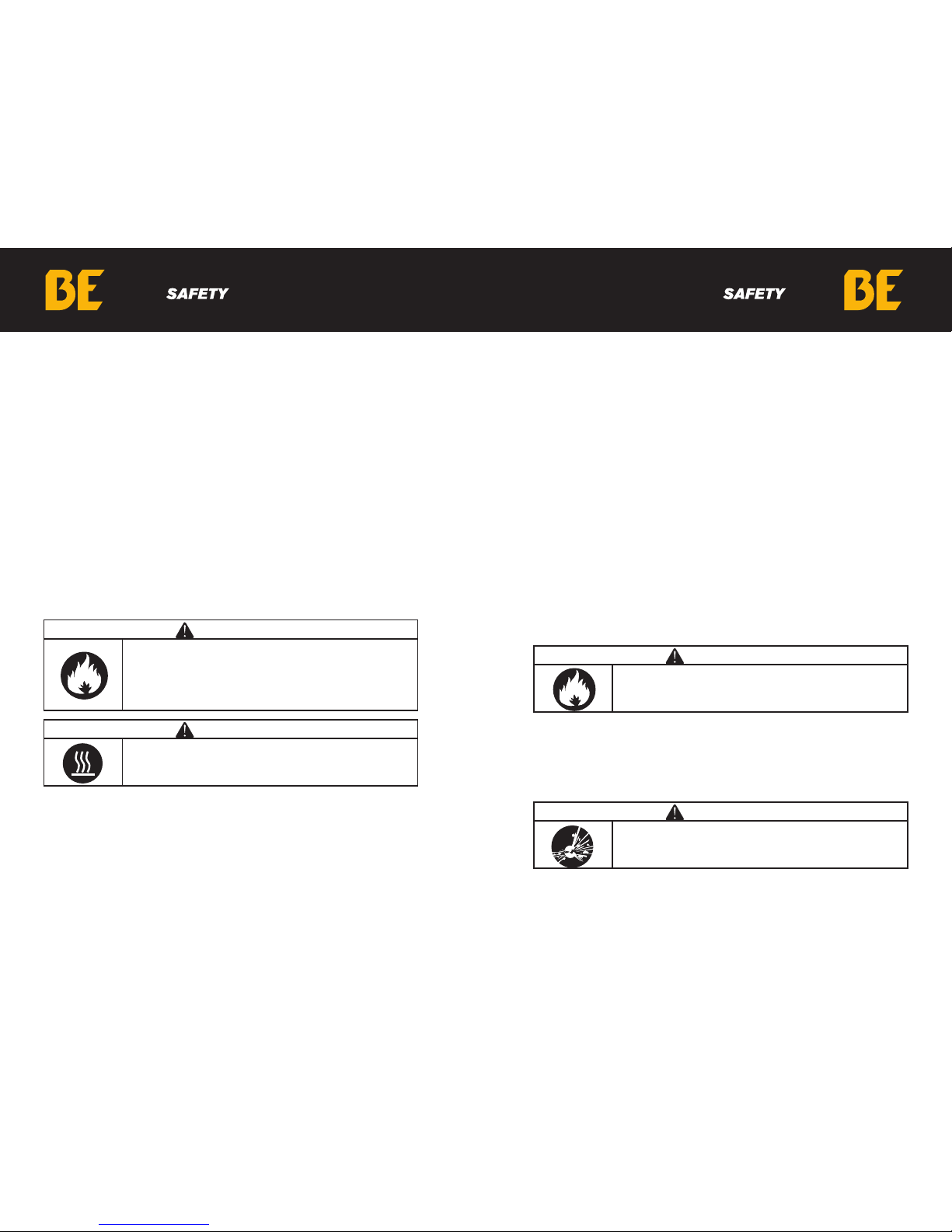

WARNING

Compressor parts may be hot even if the unit is

stopped.

9. Keep fingers away from a running compressor; fast moving and hot

parts will cause injury and/or burns.

10. If the equipment should start to abnormally vibrate, STOP the engine/

motor and check immediately for the cause. Vibration is generally a

warning of trouble.

11. To reduce fire hazard, keep engine/motor exterior free of oil, solvent,

or excessive grease. Never remove or attempt to adjust safety valve.

Keep safety valve free from paint and other accumulations.

WARNING

Motors, electrical equipment and controls can cause

electrical arcs that will ignite a flammable gas or vapor.

Never operate or repair in or near a flammable gas or

vapor. Never store flammable liquids or gases in the

vicinity of the compressor.

WARNING

Do not spray flammable materials in vicinity of open

flame or near ignition sources including the compressor

unit.

12. Never attempt to repair or modify a tank! Welding, drilling or any

other modification will weaken the tank resulting in damage from

rupture or explosion. Always replace worn or damaged tanks. Drain

liquid from tank daily.

13. Tanks rust from moisture build-up, which weakens the tank. Make

sure to drain tank daily and inspect periodically for unsafe conditions

such as rust formation and corrosion.

14. Fast moving air will stir up dust and debris which may be harmful.

Release air slowly when draining moisture or depressurizing the

compressor system.

SPRAYING PRECAUTIONS

15. Do not smoke when spraying paint, insecticides, or other flammable

substances.

16. Use a face mask/respirator when spraying and spray in a well

ventilated area to prevent health and fire hazards.

17. Do not direct paint or other sprayed material at the compressor.

Locate compressor as far away from the spraying area as possible to

minimize overspray accumulation on the compressor.

18. When spraying or cleaning with solvents or toxic chemicals, follow

the instructions provided by the chemical manufacturer.

HOSE PRECAUTIONS

19. Inspect hose before use. Do not exceed working pressure marked

on hose. Do not twist, bend knot, or abrade hose. Do not wrap hose

around body.

20. Keep away from hot surfaces and chemicals.

WARNING

Arcing Parts. Keep the compressor/motor at least 6m

away from explosive vapour.

12 13

Installation and Grounding

NSTALLATION AND LOCATION

The compressor must be used on a stable level surface. The air compressor must be used in a clean and well-ventilated area. The compressor

requires an unobstructed airflow and must be located a minimum of 18

inches from any walls or other obstructions.

GROUNDING INSTRUCTIONS

This product should be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape

wire for the electric current. This product is equipped with a cord having

a grounding wire with an appropriate grounding plug. The plug must be

plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

This product is for use on a nominal 120-volt circuit and has a threeprong grounding plug that looks like the plug illustrated in Figure 1. Make

sure that the product is connected to an outlet having the same

configuration as the plug. No adapter should be used with this product.

The use of a GFCI outlet is strongly recommended. The third prong is to

be used ground the tool and provide protection against electrical shock.

Never remove the third prong.

Check with a qualified electrician or serviceman if the grounding instructions are not completely understood, or if In doubt as to whether the

product is properly grounded. Do not modify the plug provided; if it will

not fit the outlet, have the proper outlet installed by a qualified electrician.

DANGER

ELECTRIC SHOCK: Improper installation of the ground-

ing plug can result in a risk of electric shock. If repair or

replacement of the cord is necessary, do not connect the

grounding wire to either flat blade terminal. The wire with

insulation having an outer surface that is green with or

without yellow stripes is the grounding wire.

Figure 1

EXTENSION CORDS

We do not recommend the use on an extension cord with this product as

this may result in the loss of power and overheating of the motor. An

additional air hose should be used instead of an extension cord. However,

if the use of an extension cord is unavoidable, use only UL listed wire

extension cords that have three-pronged grounding type plugs and three

prong receptacles that accept the tool’s plug. Improper use of extension

cords may cause inefficient operation of you tool, which can result an

overheating.

Be sure your extension cord is rated to allow sufficient flow to motor.

Refer to the guide for minimum gauge required for extension cords.

Use of an extension cord heavy enough to carry the current the tool will

draw is very important. Especially when the power source is of great

distance. An extension cord that is insufficient will cause a drop in line

voltage, resulting in power loss and causing the motor to overheat.

Guard against electrical shock. Avoid body contact with grounded services such as pipes, radiators, ovens, stoves, and refrigerator enclosures.

If not properly grounded, this power tool can incur the potential hazard of

light trickle shock, particularly when used in damp locations. If an electrical shock occurs, there is the potential of a secondary hazard such as

your hands contacting an operating air tool.

Extension Cord Length Wire Size (A.W.C.)

Up to 25 Feet 14

26 to 50 Feet 12

51 to 100 Feet 10

Grounding Pin Grounded Outlet

14 15

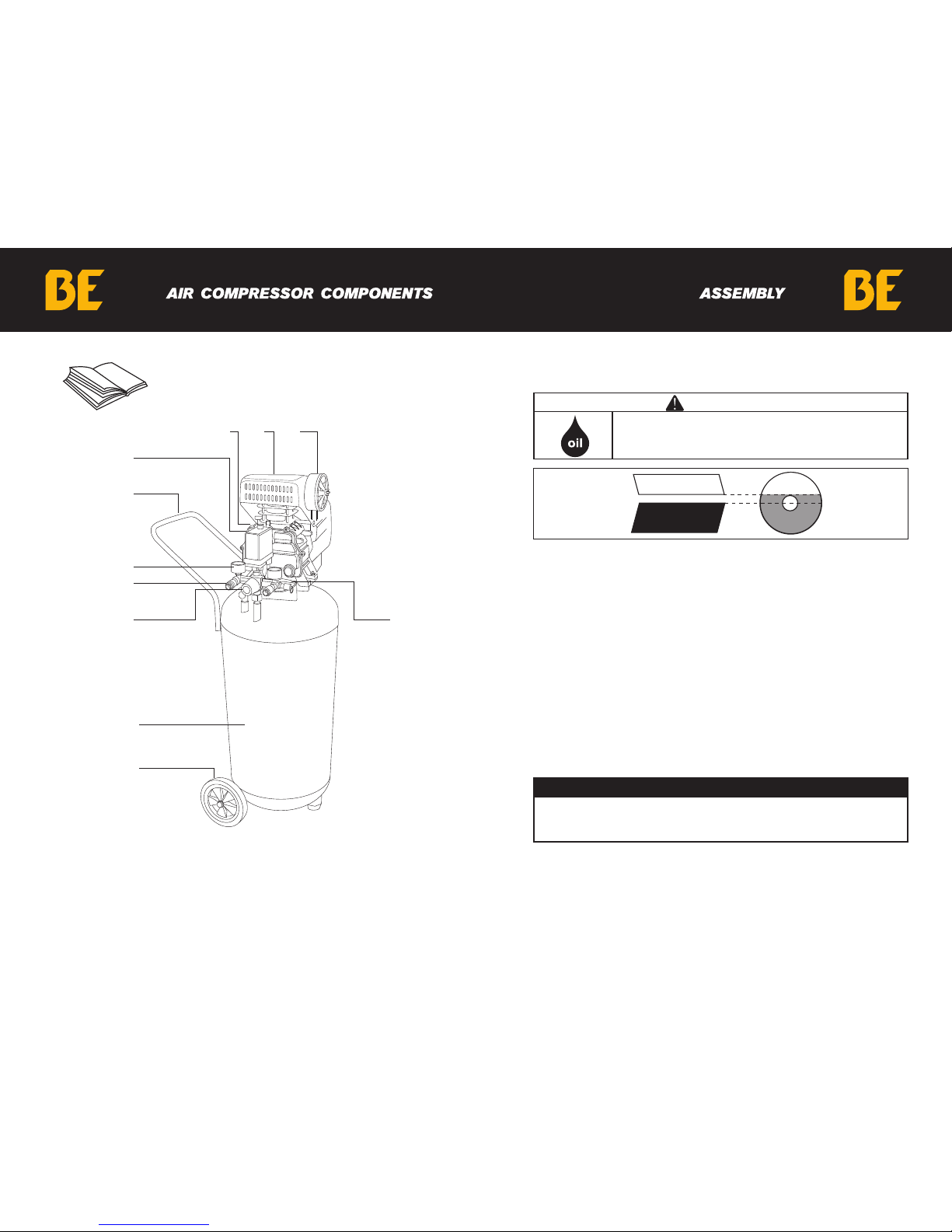

Read this operator’s manual and safety rules

before operating your compressor.

WARNING

The compressor is shipped without oil in the crankcase.

Add oil as indicated below.

Assembly

Read all safety instructions before using air compressor.

1. After opening the carton, please remove all parts and check

against photograph on carton. If any parts are missing, please call at

1-866-850-6662.

2. Place air compressor on a flat, level surface.

3. Pour supplied oil into crankcase until the oil level reaches the red dot in

the oil level sight glass. Be careful not to overfill.

4. Install oil fill plug, supplied for compressor operation, before starting

compressor.

5. Close tank drain valve on the bottom of the air tank by turning the valve

clockwise until fully closed.

6. Attach the air coupler to the compressor regulator valve. Use Teflon

thread-sealing tape on the threads to make sure you have an airtight

connection. Do not over tighten fittings.

7. Attach the supplied air filter to the air intake port on the pump head.

8. Attach air hose and any desired air accessories (which are not

included). Use Teflon thread-sealing tape on the threads to make sure

you have an airtight connection. Do not over tighten fittings.

Refill Oil

Immediately

Check Oil

Level Daily

Oil Level OK

NOTICE

Do not operate the compressor without lubricant or with low lubricant

level. We are not responsible for damage caused to the compressor

due to operation without proper lubrication.

1. Air Filter

2. Fan Cover

3. Pump

4. Pressure Switch

5. Hand

6. Pump

1.2.3.

4.

5.

6.

7.

8.

10.

9.

11.

7. Quick Couplers

8. Unit Support

9. Safety Valve

10. Tank

11. Wheel

Loading...

Loading...