Page 1

www.bdsensors.de

EN

Operating Manual

Electronic OEM Pressure Switch Pneumatics with IO-Link

Interface

iS4

Headquarters

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Deutschland

Tel.: +49 (0) 9235-9811-0

Fax: +49 (0) 9235-9811-11

Eastern Europe

BD SENSORS s.r.o.

Hradištská 817

CZ - 687 08 Buchlovice

Tschechische Republic

Tel.: +42 (0) 572-4110 11

Fax: +42 (0) 572-4114 97

The addresses of our overseas offices can be found at

www.bdsensors.de. Data sheets, user manuals, ordering

codes and certificates are al so available for you to download

from our website.

1. Generals

1.1 General and safety-related information on this

operating manual

This operating manual enables safe and proper handling of

the product, and forms part of the device. It should be kept in

close proximity to the place of use, accessible for staff

members at any time.

All persons entrusted with the mounting, installation, putting

into service, operation, mai ntenance, removal from service,

and disposal of the device must have read and understood

the operating manual and in particular the safety-rel ated

information.

– Technical modifications reserved –

1.2 Symbols Used

Warning word

- Type and source of danger

- Measures to avoid the

danger

Warning word Meaning

DANGER

- Imminent danger!

- Non-compliance will result in

death or serious injury.

WARNING

- Possible danger!

- Non-compliance may result in

death or serious injury.

CAUTION

- Hazardous situation!

- Non-compliance may result in

minor or moderate injury.

NOTE – draws attention to a po ssibly hazardous situation

that may result in property damage i n case of noncompliance.

1.3 Staff Qualification

Qualified persons are persons that are familiar with the

mounting, installation, putting into service, operation,

maintenance, removal from service, and disposal of the

product a nd have the a ppropriate qualification for their

activity.

All work with this product must be carried out by qualified persons!

1.4 Limitation of Liability and Warranty

Failure to observe the instructions or technical regulations,

improper use and use not as intended, and alteration of or

damage to the device will result in the forfeiture of warranty

and liability claims.

1.5 Intended Use

- The Pressure switch iS4 with IO-Li nk interface has been

developed for pressure measuring applications depending

on the particular model. Depending on mechanical connection, they are suitabl e for a wide range of applications.

The press ure switch is intended for installation in a machine or system. It is the responsibility of the user to check

whether the device is suitable for the chosen application. If

in doubt, please contact our sales office. BD SENSORS

cannot, however, assume any liability for an incorrect

choice or any consequences arising from this!

- Media that can be measured compressed air and nonaggressive gases which are compatible with the materials

that contact the medium. These are described in the data

sheet. Furthermore, it must be ensured in each individual

case that the medium is compatible with the parts they

come in contact with it.

- The technical data listed in the current data sheet are

engaging. If the data sheet is not available, please order

or download it from our homepage.

WARNING

Danger of death through incorrect

use

- In order to avoid accidents, use the

device only in accordance with its

intended use.

1.6 Package contents

Check that all of the li sted parts are included in the delivered

package and have been supplied in accorda nce with your

order:

- Electronic OEM Pressure Switch iS4

- Operating Manual

2. Product Identification

The type plate serves to identify the device. The most

important data can be taken from this. The order code is

used for unique identification of your product.

.

Fig. 1 Type plate

The type plate must not be removed from the device!

3. Installation

3.1 Installation and safety instructions

DANGER

Danger of death from electric shock

-

Install the device only when the machine

is depressurized and the power supply

has been switched off!

WARNING

Danger of death from improper install

a-

tion

- Installation must be performed only by

appropriately qualified specialist personnel

who have read and understood the user

manual.

General information for oxygen use

DANGER

Danger of death from explosion

through improper use of devices intended for use with oxygen

- The following points must be observed

in order to ensure safe handling:

- Make sure that a special version of yo ur device has

been ordered for use with oxygen and that the expected

device has been delivered. The easiest way for you to

verify this is by checking the type plate (see Fig. 1 regarding this). If your order code ends with the digits

"007", then your devi ce is suitable for oxygen applications.

- When it is delivered, the device is packaged in a plastic

bag to protect it from contamination. Take note of the

advice sticker with the text "Device for oxygen; unpack

immediately before installation"! Also note that contact

with skin should be avoided when unpacking and installing the device so as to a void leaving grease resi dues on the device.

- The relevant provisions concerning explosion protection

must be met during installation. Also check whether approval as intrinsically safe equipment is required in addition to suitability for oxygen. (This is not the case for the

device as supplied!)

- Please note that the entire system must comply with the

requirements of the BAM (German Federal Institute for

Materials Research and Testing, DIN 19247).

- Pressure transmitters designed for use wi thout seal s

are recommended for oxygen applications > 25 bar.

- Pressure transmitters with FKM (Vi 567) sealing rings:

Maximum permitted values: 25 bar / 150° C

(BAM approval).

Please treat this highly sensitive electronic measuring

instrument caref ully, both when packed and when unpacked!

No modifications or alterations may be made to the

device.

Do not throw or drop the device!

Only remove the packaging and, if applicable, the

protective cap from the device shortl y before its installation, so as to avoid damaging the diaphragm. Be sure to

retain the supplied protective cap!

Fit the protective cap back over the diaphragm immedi-

ately after dismounting the device.

Treat the unprotected diaphragm wi th extreme care; it

can be damaged very easily.

Do not apply any force to install the devi ce so as to

avoid damaging the device and the system!

When installing outdoors or in humid environments, the

following points should be noted:

- The device should be electrically connected immediately after installation to ensure that no moisture is able to

penetrate into the plug connector, if this is not possible,

the ingress of moisture must be prevented by using a

suitable protective cap. (T he protection class specified

in the data sheet applies to the connected device.)

- Select an installation position that allows spl ashed water

and condensation to drai n away. Ensure that sealing

surfaces are not exposed to standing liquid!

- Install the device such that it is protected from direct

sunlight. In the worst case, direct sunlight may result in

the maximum permissible operating temperature being

exceeded, which ca n then damage the device or affect

its ability to function correctly. If the internal pressure in

the device rises, this could also cause temporary measurement errors.

Take care that the pressure connector is not subjected

to any mechanical stresses higher than that permitted,

since this could cause the characteristic to shift or result

in damage. This applies especially to very small pressure ranges, as well as to devices wi th a pressure connector made of plastic.

In t he case of hydraulic systems, ori ent the device such

that the pressure connector faces upwards (for venting).

Provide a cooling section when using the device in

steam lines.

If there is a risk that a device installed outdoors mig ht

be damaged by lightning stri ke or overvol tage, we recommend the provisi on of overvoltage protection between the power supply unit or control cabinet and t he

device.

If the device is installed with the pressure connector

facing upwards, make sure that no liquid runs do wn the

housing. This could result i n moisture and dirt blocking

the gauge reference i n the housing and cause malfunctions. If necessary, remove any dust and dirt from the

edge of the screw joint of the electrical connector.

3.2 General installation instructions

- Carefully remove the device from i ts packaging and

dispose of the packaging properly.

- Then proceed as described in the following installation

instructions.

3.3 Installation steps for internal thread G1/8"

- Use a suitable seal for sealing, e. g. Teflon strip, flat

gasket or O-ring, on the screwed end of the counterpart.

- Ensure that the surface of the taking part is perfectly

smooth and clean.

- Tighten the counterpart with a wrench (max. torque

3 Nm).

3.4 Installation steps for internal thread M5

- For sealing use an O-ring that fits properl y into the

groove. (O-ring is not included in the scope of delivery)

- Ensure that the surface of the counterp art is perfectly

smooth and clean.

- Screw the counterpart (e.g. screw connection, quick

coupling) by hand into the pressure switch.

- Tighten the counterpart with a wrench (max. torque

1 Nm).

4. Electrical Installation

WARNING

Danger of death from electric shock

- Switch off the power supply before

installing the device.

Electrically connect the device in accordance with t he

specifications given on the type plate, the following pi n

assignment table and the connection diagram.

Pin configuration:

Electrical connection

M8x1

(4-pin)

(L+)

(L-)

C/Q

Supply +

Supply –

IO-Link (COMx) / SIO

1

3

4

Shield housing

Wiring diagram:

SIO / IO-Link (COMx)-System

If possi ble, use a shielded and twisted multicore cable

for the electrical connection.

5. Commissioning

Before using the device for the first time, check that it

has been properly installed, and make sure that it does

not show any visible defects.

The device may by commissioned only by appropriately

qualified specialist personnel who have read and understood the user manual.

The transmitter shall be supplied by Limited Energy

Source (per UL 61010) or NEC Class 2 Power Source.

6. IO-Link Interface

6.1 General device information

Baud rate COM2 (38,4 kbit/s)

Input process data length 2 byte

Minimum cycle time 5 ms

IO-Link version0000000000 V 1.1

SIO-Mode yes

6.2 SIO mode (standard IO mode)

In this mode the sensor operates like a normal pressure

sensor with standard output signals. The digital output is

always on Pin 4 of the connector plug or over green cable.

6.3 IO-Link mode (communication mode)

The pressure sensor switches to the IO-Link communication

mode, when it operates under an IO-Link master. IO-Link

communication is only possible over Pin 4 of the connector

plug or over green cable.

6.4 Process data

The process data length of the sensor is 16 bits. The switch

state (BCD1) as well as the current me asured values are

transmitted. The 14 bits of the measured val ue are scaled

according to the measuring range.

15 bit 14…2 1 0

Signed

Bit

Measured

value

0 BDC1 / Output 1

6.5 Error codes

Error Code Description

0x8011 Index not available

0x8012 Subindex not available

0x8023 Access Denied

0x8030 Parameter Value out of Range

0x8033 Parameter length overrun

0x8034 Parameter length under run

6.6 Event codes

Event-

Codes

IO-Link

1.1

EventCodes

IO-Link

1.0

Device

status

Type

No malfunction

0x0000 0x0000 0 Noti fica-

tion

General

malfunction.

Unknown

error

0x1000 0x1000 4 Erro r

Process

variable range

over-run.

Process Data

uncertain

0x8C10 0x8C10 2 Warning

Process

variable range

under-run.

Process Data

uncertain

0x8C30 0x8C10 2 Warning

6.7 Parameter data

The parameter data of the pressure switch correspond to the

Smart Sensor Profile. The data can be found in the product

data sheet or parameter overview, see section 13.

7. Decommissioning

WARNUNG

Danger of injury from media escaping under pressure

- Dismount in an orderly fashion when

the machine is depressurized and the

power supply has been switched off.

-

Check whether the medium needs to

be drained before dismounting!

WARNUNG

Danger of injury from the measured

medium

- Depending on the measured medium, suitable precautions should be

taken, e.g. protective gloves, goggles.

8. Maintenance

The device is, in principle, maintenance free. If necessary,

the housing of the device may be cleaned with a damp cloth

and a non-aggressive cleaning solution while it is switched

off.

With certain media may, however, deposits or contamination

may accumulate on the diaphragm. The specification of

appropriate maintenance intervals for inspection is recommended in this case. Once the device has been properly

decommissioned, the diaphragm can normally be cleaned

with a non-aggressive cleaning solution and a soft brush or

sponge. Care should be taken while doing so. If the diaphragm is covered in lime scale, decalcification by BD

SENSORS is recommended. See the Servicing/Repair

section with regard to this.

Incorrect cl eaning can result in irreparable damage to

the measuri ng cell. For this reason, you should never

use sharp objects or compressed air to clean the diaphragm.

9. Servicing/Repair

9.1 Recalibration

It is possible that the offset value or the scaling value may

shift during the lifetime of the device. This is indicated by a

deviation in the output signal value with reference to the set

measurement range start or end values re spectively. If either

of these two phenomena should occur after a prolonged

period of use, recalibration is recommended in order to

ensure a continued high level of accuracy.

9.2 Return

Whenever the device i s returned, no matter whether for

recalibration, decalcification, modification or repair, it must be

carefully cleaned and packed such that there is no risk of

breakage. The device must be accompanied by a notice of

return giving a detailed description of the fault. If your device

has come i nto contact with pollutants, then a notice of

decontamination will also be needed. You can find the

relevant templates o n our website at www.bdsensors.de.

Should you send i n your device without a notice of decontamination and do ubts with regard to the medium used

should arise in our service department, repair work will

commence only once an appropriate notice has been received.

CAUTION

Danger of injury from pollutants

- If the device has come into contact with

pollutants, wear suitable protective clothing, e.g. gloves, goggles, when cleaning

it.

10. Disposal

The device must be di sposed of in accordance with European Directives 2002/96/EC

and 2003/108/EC (Waste Electrical and

Electronic Equipment). W aste electrical

products may not be disposed of with

household waste!

Depending on the medi um used, residues

on the devi ce may constitute a hazard to

the environment. You should therefore ta ke

appropriate precautions if necessary and

dispose of the device properly.

11. Guarantee Conditions

The guarantee conditions are subject to the statutory warranty period of 24 months, starting from t he date of dispatch. No

warranty claims will be accepted i f the device has been used

improperly, modified or damaged. The warranty does not

cover damaged diaphragms. Warranty cover also excludes

any claims for defects that have arisen as a result of normal

wear.

12. Declaration of conformity / CE

The suppl ied device fulfills the statutory requirements. The

relevant directives, harmonized standards and documents

are listed in the EU Declaration of Conformity applicable to

the product. This can be found at http:// www.bdsensors.de.

In addition, the operational safety of the device i s confirmed

by the CE mark on the type plate.

Order code

Pin configuration

Type designation

Supply

Measure range

Signal

Serieal number

ID: BA_IS4_E | Version: 08

.2017.0

Page 2

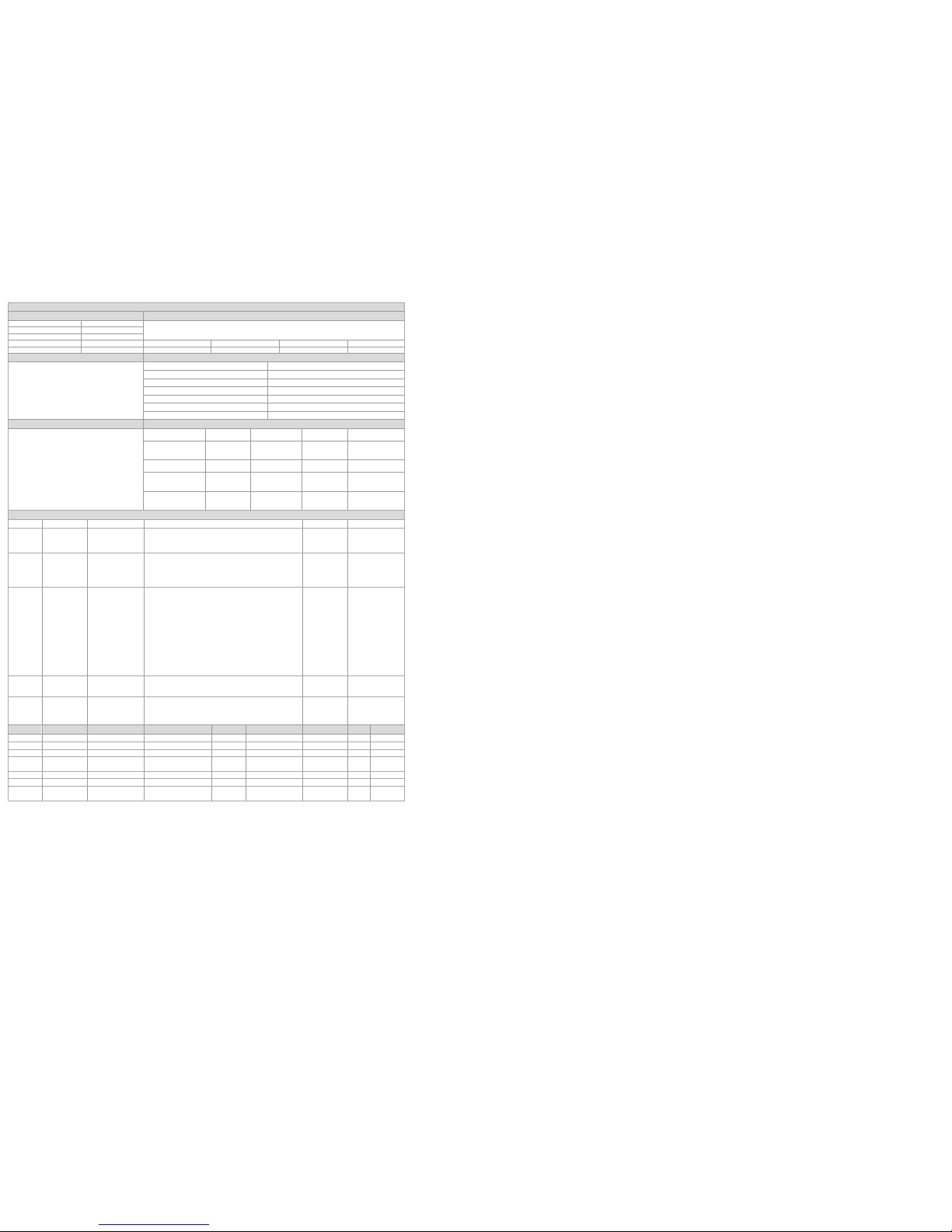

13. Parameter overview

IO-Link interface

1. General device information 4. Process data

Baud rate COM2 (38.4 kbit/s) The process data length of the sensor is 16 bits. The switch state (BCD1) as well as the current measured

values are transmitted. The 14 bits of the measured value are scaled according to the measuring range.

Input process data length 2 byte

Minimum cycle time 5 ms

IO-Link version V 1.1 15 bit 14 … 2 1 0

SIO mode yes Signed Bit measurement 0 BDC1 / output 1

2. SIO mode (standard IO mode) 5. Error message

In this mode the sensor operates like a normal pressure

sensor with standard output signals. The digital output is

always on Pin 4 of the connector plug.

Error Codes Description

0x8011 Index not available

0x8012 Subindex not available

0x8023 Access Denied

0x8030 Parameter Value out of Range

0x8033 Parameter length overrun

0x8034 Parameter length underrun

3. IO-Link mode (communication mode) 6. Event codes

The pressure sensor switches into IO-Link communication mode when operating under an IO-Link master. IOLink communication is only possible via Pin connector.

Event-Codes

IO-Link 1.1

Event-Codes

IO-Link 1.0

Device status

Type

No malfunction

0x0000

0x0000

0 Notification

General malfunctionunknown error

0x1000 0x1000 4 Error

Process variable

range over-run -

Process Data uncertain

0x8C10 0x8C10

2

Warning

Process variable

range under-run.

Process Data uncertain

0x8C30

0x8C10

2

Warning

7. Parameter data (The parameter data for the pressure sensor correspon d to the Smart Sensor profile.)

Index hex Subindex hex Object name Single Value Default Comment

0x02 0x00 System Commands

0x81 = delete Min-/Max-Wert

0x82 = res

0xA0 = Set0

The action

is executed

by writing

in the subindex

0x03 0x00 Data Storage Index

0x01: Upload Start

0x02: Upload End

0x03: Download Start

0x04: Download End

0x05: Datastorage Break

0x0C 0x00 Device Access Lock

0x00: Unlocked

0x01: IO-Link Lock

0x02: Datastorage Lock

0x04: Parameterization Lock

0x08: User Interface Lock

0x03: IO-Link Lock + Datastorage Lock

0x05: IO-Link Lock + Parameterization Lock

0x09: IO-Link Lock + User Interface Lock

0x06: Datastorage Lock + Parameterization Lock

0x0A: Datastorage Lock + User Interface Lock

0x07: Datastorage Lock + IO-Link Lock + Parameterization Lock

0x0B: Datastorage Lock + IO-Link Lock + User

Interface Lock

0x00:

Unlocked

0x24 0x00 Device Status

0x00 Device is operating properly

0x02 Out-of-Specification

0x04 Failure

0x3D 0x02 Switch Point mode

0x80: Hysteresis NO

0x81: Hysteresis NC

0x82: Window NO

0x83: Window NC

0x80: HNo

Index hex Subindex hex Object name Access Length Value Range Gradient Unit Default

0x3C 0x01 SetPoint 1 = SP R/W 2 Byte Process Data 100%

0x3C 0x02 SetPoint 2 = rP R/W 2 Byte Process Data 0%

0xD0 0x00 Delay Switching Time R/W 2 Byte 0 ... 500 0.1 sec 0

0xD1 0x00 Delay Back Switching

Time

R/W 2 Byte 0 ... 500 0.1 sec 0

0xD5 0x00 Min Pressure Value R 2 Byte Process Data

0xD6 0x00 Max Pressure Value R 2 Byte Process Data

0xD7 0x00 Measure damping R/W 2 Byte 0…1000 in 10 ms

steps

1 ms 0

Loading...

Loading...