E

EUROPE

ASIA

nal +

DS 400

Operating Manual

Electronic Pressure Switch DS 4XX

DS 400, DS 400 P, DS 401, DS 401 P

www.bdsensors.com

Headquarter Western Europe / International

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Germany

Tel: +49 (0) 92 35 / 98 11-0

Fax: +49 (0) 92 35 / 98 11-11

Headquarter Eastern Europe

BD SENSORS s.r.o.

Hradištská 817

CZ - 687 08 Buchlovice

Czech Republic

Tel: +42 (0) 5 72 / 4 11-0 11

Fax: +42 (0) 5 72 / 4 11-4 97

further agencies in:

• Belgium

• Denmark

• France

• Greece

• Italy

• Lithuania

• Luxemburg

• Netherlands

• Norway

The addresses of our distribution partners are listed on our

homepage www.bdsensors.com. It is possible to download

data sheets, operating manuals, ordering codes and certificates, as well.

Table of contents

1. General information

2. Product identification

3. Mechanical installation

4. Electrical Installation

5. Initial start-up

6. Operation

7. Placing out of service

8. Maintenance

9. Service / Repair

10. Disposal

11. Warranty conditions

12. Declaration of conformity

1. General information

1.1 Information on the operating manual

This operating manual contains important information on

proper usage of the device. Read this operating manual

carefully before installing and starting up the pressure

measuring device.

Adhere to the safety notes and operating instructions which

are given in the operating manual. Additionally applicable

regulations regarding occupational safety, accident prevention as well as national installation standards and engineering rules must be complied with!

Russia

BD SENSORS RUS

39a, Varshavskoe shosse

RU - Moscow 117105

Russia

Tel: +7 (0) 9 59 81 / 09 63

Fax: +7 (0) 9 57 95 / 07 21

• Poland

• Romania

• Sweden

• Switzerland

• Slovakia

• Spain

• Turkey

• UK

• Ukraine

• Iran

• Israel

• Kazakhstan

• Taiwan

• Thailand

AUSTRALIA

This operating manual is part of the device, must be kept

nearest its location, always accessible to all employees.

This operating manual is copyrighted. The contents of this

operating manual reflect the version available at the time of

printing. It has been issued to our best knowledge. However,

errors may have occurred. BD SENSORS is not liable for any

incorrect statements and their effects.

– Technical modifications reserved –

1.2 Symbols used

DANGER! – dangerous situation, which may result in

death or serious injuries

WARNING! – potentially dangerous situation, which

may result in death or serious injuries

CAUTION! – potentially dangerous situation, which may

result in minor injuries

!

CAUTION! – potentially dangerous situation, which may

result in physical damage

NOTE – tips and information to ensure a failure-free

operation

1.3 Target group

WARNING! To avoid operator hazards and damages of

the device, the following instructions have to be worked

out by qualified technical personnel.

1.4 Limitation of liability

By non-observance of the operating manual, inappropriate

use, modification or damage, no liability is assumed and

warranty claims will be excluded.

1.5 Intended use

- The electronic pressure switch DS 4XX has been

developed, according to the type for applications, for

absolute, vacuum and overpressure measurement. It is

equipped with a 4-digit LED-display to show the current

system pressure. Depending on the device and the mechanical connection it is suitable for various areas of

use.

- It is the operator's responsibility to check and verify the

suitability of the device for the intended application. If

any doubts remain, please contact our sales department

in order to ensure proper usage. BD SENSORS is not

liable for any incorrect selections and their effects!

- Permissible media are gases or liquids, specified in the

data sheet. In addition it has to be ensured, that this

medium is compatible with the media wetted parts.

- The technical data listed in the current data sheet are

engaging and must be complied with. If the data sheet is

not available, please order or download it from our

homepage. (http://www.bdsensors.com/products/download/datasheets)

WARNING! – Danger through improper usage!

1.6 Package contents

Please verify that all listed parts are undamaged included in

the delivery and check for consistency specified in your

order:

- electronic pressure switch, series DS 4XX

- for mechanical pressure ports DIN 3852: o-ring

(pre-assembled)

- sheet of unit labels

- mounting instructions

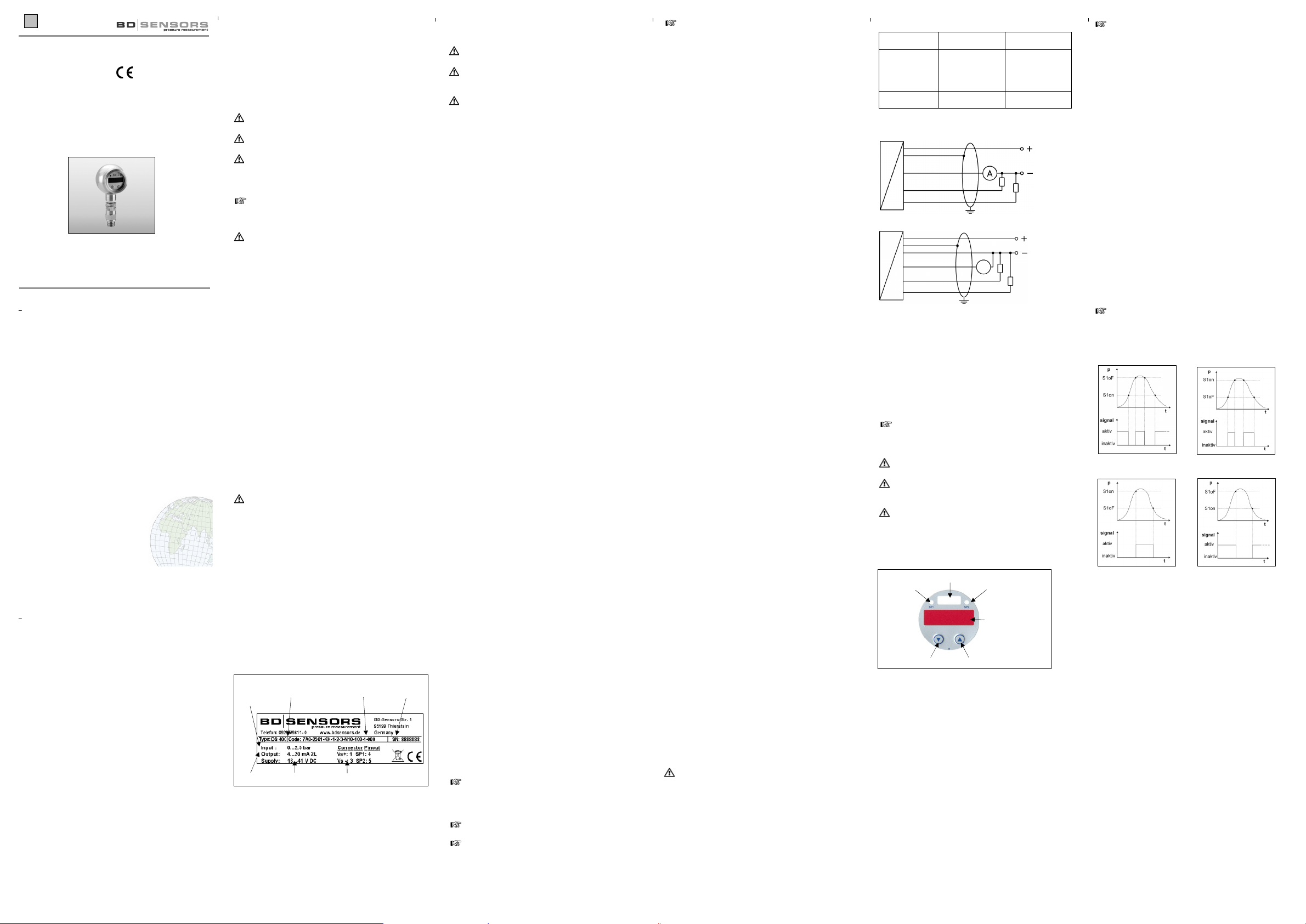

2. Product identification

The device can be identified by its manufacturing label. It

provides the most important data. By the ordering code the

product can be clearly identified. The programme version of

the firmware, (e. g. P07) will appear for about 1 second in the

display after starting up the device. Please hold it ready for

inquiry calls.

nominal

pressure

range

signal

Fig. 1 manufacturing label

!

The manufacturing label must not be removed from the

device!

type

designation

supply

ordering

code

connector pinout

serial

number

3. Mechanical installation

3.1 Mounting and safety instructions

WARNING! Install the device only when depressurized

and currentless!

WARNING! This device may only be install ed by

qualified technical personnel who has read and understood the operating manual!

DANGER! Explosion hazard, with devices for oxygen

applications, when used improperly. To ensure a usage

without danger, the following points must be adhered to:

- Make sure, your device has been ordered and delivered as a special version for oxygen applications. You can check the manufacturing label (see

figure 1). If the ordering code ends with "007", then

the device is suitable for oxygen applications.

- At time of delivery the device is packed into a plastic bag in order to prevent it from impurity. Please

observe the indication label "Device for oxygen,

unpack only directly before assembling". Also,

avoid any skin contacts during unpacking and assembly, in order to prevent greasy residues on the

device.

- During installation, the respective explosion protection regulations have to be met. Check, if ATEXapproval is necessary for this type (oxygen) device.

(the delivered device has no ATEX-approval)

- Note the entire design requirements meet the

standard demand of BAM (DIN 19247).

- For devices with oxygen capability up to 50 bar, orings V747-75 with BAM-approval are being used.

The max. capabilities allowed, are 40 bar/130° C

and 50 bar/100° C.

- For devices with oxygen capability over 50 bar, orings FKM 90 are being used. These have been

tested up to 95° C and 215 bar in the scientific coal

research institute in Ostrava – CZ.

!

Handle this high-sensitive electronic precision

measuring device with care, both in packed and

unpacked condition!

!

There are no modifications/changes to be made on the

device.

!

Do not throw the package/device!

!

To avoid damaging the diaphragm, remove packaging

and protective cap only directly before starting up the

device. A delivered protective cap must be stored!

!

Place the protective cap on the pressure port again

immediately after disassembling.

!

Handle the unprotected diaphragm very carefully - it is

very sensitive and may be easily damaged.

!

Do not use any force when installing the device to prevent damage of the device and the plant!

!

For installations outdoor and in damp areas following

these instructions:

- To prevent moisture admission in the plug the device should be installed electrically after mounting,

at once. Otherwise a moisture admission has to be

blocked e.g. by using a suitable protection cap.

(The ingress protection in the data sheet is valid for

the connected device.)

- Choose an assembly position, which allows the

flow-off of splashed water and condensation. Avoid

permanent fluid at sealing surfaces!

- When using a cable gland device, turn the outgoing

cable downwards. If the cable has to be turned

upwards, then point it downward so the moisture

can drain.

- Install the device in such a way that it is protected

from direct solar irradiation. Direct solar irradiation

can lead to the permissible operating temperature

being overstepped in the worst case. By this the

operability of the device can be affected or damaged. If the internal pressure i ncreases due to solar irradiation, measurement errors may be caused.

!

For devices with gauge reference in the housing (small

hole next to the electrical connection), install the device

in such a way, that the gauge reference is protected

from dirt and moisture. Should the device be exposed to

fluid admission, the functionality will be blocked by the

gauge reference. An exact measurement in this condition is not possible. Furthermore this can lead to damages on the device.

Take note that no assembly stress occurs at the

pressure port, since this may cause a shifting of the

characteristic curve. This is especially important for very

small pressure ranges as well as for devices with a

pressure port made of plastic.

In hydraulic systems, position the device in such a way

that the pressure port points upward (ventilation).

Provide a cooling line when using the device in steam

piping.

If installing the device outdoor and there is any danger

of lightning or overpressure we suggest putting a

overpressure protection unit between the supply/switch

cabinet and the device to prevent damage.

3.2 General installation steps

- Carefully remove the pressure measuring device from

the package and dispose of the package properly.

- Go ahead as detailed in the specific instructions below.

3.3 Installation steps for DIN 3852

- Check to ensure the proper groove fitting of the o-ring

and additionally to ensure no damage to the o-ring.

- Ensure that the sealing surface of the taking part is

perfectly smooth and clean.

- Screw the device into the corresponding thread by

hand.

- If you have a device with a knurled ring, the transmitter

has to be screwed in by hand only.

- Devices with a spanner flat have to be fully tightened

with an open-end wrench (wrench size of steel: G1/4":

approx. 5 Nm; G1/2": approx. 10 Nm; G3/4": approx. 15

Nm; G1": approx. 20 Nm; wrench size of plastic: max. 3

Nm).

3.4 Installation steps for EN 837

- Use a suitable seal, corresponding to the medium and

the pressure input (e. g. a cooper gasket).

- Ensure that the sealing surface of the taking part is

perfectly smooth and clean.

- Screw the device into the corresponding thread by

hand.

- Tighten it with a wrench (for G1/4": approx. 20 Nm; for

G1/2": approx. 50 Nm).

3.5 Installation steps for NPT

- Use a suitable seal, corresponding to the medium and

the pressure input (e. g. a PTFE-strip).

- Screw the device into the corresponding thread by

hand.

- Tighten it with a wrench (for 1/4" NPT: approx. 30 Nm;

for 1/2" NPT: approx. 70 Nm).

3.6 Installation steps for dairy pipe

- Check to ensure that the O-ring fits properly into the

intended groove in the mounting part.

- Centre the dairy pipe connection in the counterpart.

- Screw the cup nut onto the mounting part.

- Then tighten it with a hook wrench.

3.7 Installation steps for Clamp and Varivent

- Use a suitable seal corresponding to the medium and

the pressure input.

- Put the seal onto the corresponding mounting part.

- Centre the Clamp or Variventconnection on the fitting

counterpart with seal.

- Then fit the device with a suitable fastening element

(e. g. semi-ring or retractable ring clamp) according to

the supplier’s instructions.

3.8 Positioning of the display module

The display and operating module is continuously rotatable

so that clear readability i s guaranteed even in unusual

installation positions. To change the position, go ahead as

follows:

- Screw off the metal cap by hand.

- Turn the display and operating module carefully into the

desired position by hand. The module is equipped with

a rotational limiter.

- Before screwing on the cap again, the o-ring and sealing surfaces of the housing have to be checked for

damage and if necessary have to be changed!

- Afterwards screw the metal cap on by hand and make

sure that the housing is firmly locked again.

!

Pay attention that no moisture can enter the device.

Moreover, the seals and the sealing surfaces should not

get dirty, as this may cause a reduction of the degree of

protection depending on the case of application or place

of installation. This can lead to a breakdown of the devices or to irreparable damages on the device.

4. Electrical Installation

WARNING! Install the device only when depressurized

and currentless!

Establish the electrical connection of the device according to

the technical data shown on the manufacturing label, the pin

configuration and the respective wiring diagram shown

below.

Pin configuration:

Electrical

connections

Supply +

Supply –

3-wire: Sig

Contact 1

Contact 2

Shield

Wiring diagrams:

2-wire-system (current)

supply +

p

supply –

contact 1

I

contact 2

3-wire-system (current/voltage)

supply +

p

supply –

signal +

contact 1

I/U

contact 2

!

For the installation of a device with cable outlet following

bending radiuses have to be complied with:

cable without ventilation tube:

static installation : 5-fold cable diameter

dynamic application: 10-fold cable diameter

cable with ventilation tube:

static installation : 10-fold cable diameter

dynamic application: 20-fold cable diameter

!

Prevent the damage or removal of the PTFE filter which

is fixed over the end of the air tube on devices with

cable outlet and integrated air tube.

For the electrical connection a shielded and twisted

multicore cable is recommended.

M12x1, metal

(5-pin)

1

3

2

4

5

plug housing /

pressure port

A/V

cable colours

(DIN 47100)

wh (white)

bn (brown)

gn (green)

gr (grey)

pn (pink)

(green/yellow)

VS

R

L

R

L

V

S

R

L

R

L

gn/ye

5. Initial start-up

WARNING! Before start-up, the user has to check for

proper installation and for any visible defects.

WARNING! The device can be started and operated by

authorized personnel only, who have read and understood the operating manual!

WARNING! The device has to be used within the

technical specifications, only (check the technical data

in the data sheet)!

6. Operation

6.1 Operating and display elements

LED

contact 1

▼-button ▲-button

Fig. 2 touchpad for device with two contacts

The device has, according to the order max. two LEDs which

are allocated to the resp. contacts. The LEDs will light up

when the respective set point has been reached and the

contact is active. The display of the measured value as well

as the configuration of the individual parameters occurs

menu-driven via the seven-segment display.

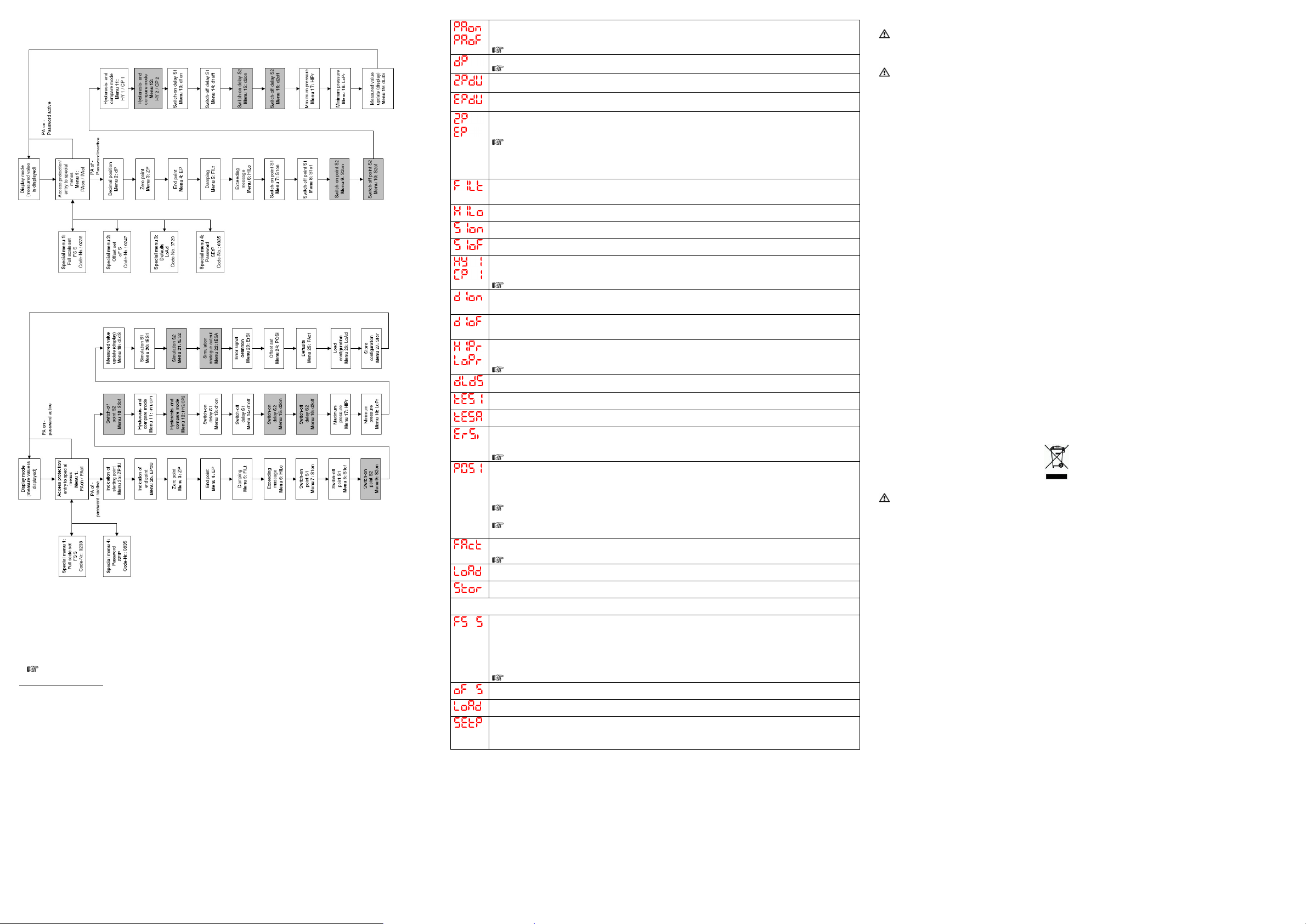

6.2 Configuration

The menu system is a closed system allowing you to scroll

both forward and backward through the individual set-up

menus to navigate to the desired setting item. All settings are

permanently stored in an EEPROM and therefore available

again even after disconnecting from the supply voltage. The

structure of the menu system is the same for all types of

devices, regardless of the number of contacts. However,

they only differ by the number of menus. Following figure and

the menu list shows all possible menus. On devices with

3-wire output 4 ... 20 mA and 0 ... 20 mA, the menus ZP and

EP have special functions. The menu DP is not applied, as

the decimal point is already factory set during production.

unit

LED-contact 2

4-digit seven

segment display

Please follow the manual meticulously and remember

that changes of the adjustable parameters (switch-on

point, switch-off point, etc.) become only effective after

pushing both buttons simultaneously and leaving the

menu item.

!

Pay attention that no moisture can enter the device

during configuration. Moreover, the seals and the sealing surfaces should not get dirty, as this may cause a

reduction of the degree of protection depending on the

case of application or place of installation. This can lead

to a breakdown of the device or to irreparable damages

on the device. Right after configuration, the metal cap

has to be screwed on again.

6.3 Password system

To avoid a configuration by unauthorized persons, the

possibility is given to lock the device by an access protection.

More information is given in menu 1 of the menu list.

6.4 Configuration example of the analogue output for

3-wire devices

By the menus ZP and EP, the analogue output for 3-wire

devices (4...20 mA and 0...20 mA) can be configured. In the

following, the function of these menus shall be made clear by

an example: assuming you have a pressure switch with a

nominal pressure range 0 ... 400 bar with an analogue signal

of 4...20 mA / 3-wire. By factory the following performance is

set:

0 bar = 4.00 mA 200 bar = 12.00 mA 400 bar = 20 mA

If you change the value in the menu ZP from 0 to 20 and the

value in the menu EP from 400 to 300, the following performance will appear:

20 bar = 4.00 mA 160 bar = 12.00 mA 300 bar = 20 mA

The values of ZP and EP are adjustable up to 1:6 of the

nominal pressure range.

6.5. Description of hysteresis and compare mode

To invert the respective modes, you have to exchange the

values for the switch-on and switch-off points.

Fig. 3 compare mode Fig. 4 compare mode

inverted

Fig. 5 hysteresis mode Fig. 6 hysteresis mode

inverted

6.6. Structure of the menu system

menu 1

–

access protection

menus 3 and 4

– set zero point / end point

menu 5

–

set damping

menu 6

–

exceeding message

menus 7and 9

– set switch

-

on points

menus 8 and 10

– set switch

-

off points

menus 11 and 12

– select hysteresis or compare mode

menus 13 and 15

– set switch

-

on delay

menus 14 and 16

– set switch

-

off delay

menus 17 and 18

–

maximum / minimum pressure display

menu 19

– measured value update (display)

men

us 20 and 21

– simulate contacts (only 3

-

wire-system)

menu 22

–

simulate analogue output (only 3

-

wire-system)

menu 23

– error signal definition (only 3

-

wire-system)

menu 24

– offset compensation / position correction (only 3

-

wire-system)

menu 25

– load

defaults (only 3

-

wire-system)

menu 26

– load configuration (only 3

-

wire-system)

menu 27

– store configuration (only 3

-

wire-system)

special menus

special menu 1

– full scale compensation

special menu 2

– offset compensation / position correction (only 2

-

wire-system)

special menu 3

– load defaults (only 2

-

wire-system)

special menu 4

– set password

2-wire-version P07

3-wire-version P07

6.7 Menu list

- ▲-button: move in the menu system (forward) or increase the displayed value; it will also lead you to the operating mode

(beginning with menu 1)

- ▼-button: move in the menu system (backward) or decrease the displayed value; it will also lead you to the operating mode

(beginning with the last menu)

- both buttons simultaneously: confirm the menu items and set values

to increase the counting speed, when setting the values: keeping the respective button pushed for more than 5 seconds

Execution of configuration:

- set the desired menu item by pushing the ▲- or ▼-button

- activate the set menu item by pushing both buttons simultaneously

- set the desired value or select one of the offered settings by using the ▲- or ▼-button

- store the set value / selected setting and exit the menu by pushing both buttons simultaneously

PAon password active to deactivate: set password

PAof password inactive to activate: set password

default setting for the password is "0005"; modification of the password is described in special menu 4

menu 2 – set decimal point position (only 2-wire-system)

for devices with 3-wire output 4 ... 20 mA and 0 ... 20 mA the decimal point was already set during production

menu 2a – indication of the starting point, which was defined with the order (only 3-wire-system)

no configuration is possible

menu 2b – indication of the end point, which was defined with the order (only 3-wire-system)

no configuration is possible

the device has been configured correctly before delivery, so a later setting of a 2-wire device is only necessary, if a

differing displayed value is desired (e. g. 0 ... 100 %)

For devices with 3-wire output 4 ... 20 mA and 0 ... 20 mA this menu has a different meaning: The configuration of the zero point causes a changing of the analogue output, whereas the display value remains unchanged. (zero and end point can be configured within the limits of the nominal pressure range, according to

the manufacturing label); for more information see "6.4 Configuration example of the analogue output for 3wire-devices"

this function allows getting a constant display value although the measuring values may vary considerably; the time

constant for a simulated low-pass filter can be set (0.3 up to 30 sec permissible)

set "on" or "off"

set the particular values, for the activation of contact 1 (S1on) or 2 (S2on)

set the particular values, for the deactivation of contact 1 (S1oF) or 2 (S2oF)

select the hysteresis mode (HY 1/2) or compare mode (CP 1/2) for the contacts 1 or 2

(no. corresponds to the contact)

compare "6.5. Description of hysteresis and compare mode"

set the particular value of the switch-on delay after reaching contact 1 (d1on) or 2 (d2on)

(0 up to 100 sec permissible)

set the particular value of the delay after reaching the switch-of point 1 (d1oF) or 2 (d2oF)

(0 up to 100 sec permissible)

view high pressure (HIPr) or low pressure (LoPr) during the measurement process

(the value will not remain stored if the power supply is interrupted)

to erase: push both buttons again within one second

set the length of the update cycles for the display (0.0 up to 10 sec permissible)

with the ▲- or ▼-button the contacts 1 (tES1) or 2 (tES2) can be activated or deactivated

select one of the following settings: "oi 4" (4 mA or 2 V), "oi12" (12 mA or 6 V) and "oi20" (20 mA or 10 V)

(to access a special menu, select the menu item "PAof" with the ▲- or ▼-button and confirm it; "1" appears in the display)

set the desired error signal (this is given out in case of a defect); permissible settings are "OFF" (no error signal

output), "C 0" (0 mA or 0 V), "C L0" (3.5 mA or 1.75 V) and "C HI" (23 mA or 11.5 V)

an output of the error signal is only given when menu 6 is set on "on"

confirm menu item "P0SI"; if offset ≠ ambient pressure it is necessary to place the device under pressure (pressure

reference has to corresponding to the zero point of the pressure measuring range); push both buttons to store the

signal being emitted from the pressure switch as offset; in the display the set zero point will appear although the

sensor signal in the offset is displaced

a position correction is necessary, if the installation position differs from the calibration position (otherwise this

can cause a little deviation of the signal, which gives a wrong value indication)

the analogue output signal (for devices with analogue output) is not affected by this change;

when displacing the offset, the full scale will also be displaced

to load the defaults, push both buttons simultaneously, after confirming the menu item

any changes carried out will be reset (password will be set on "0005")

to load a stored configuration (via menu 39), set the desired number 1 up to 5

to store a configuration, set the desired number 1 up to 5

for full scale compensation, which is necessary if the indicated value for full scale differs from the real full scale

value in the application (a compensation is only possible with a respective reference source, if the deviation of the

measured value is within defined limits); set "0238"; confirm with both buttons; "FS S" will appear in the display; now

it is necessary to place the device under pressure (the pressure must correspond to the end point of the pressure

measuring range); push both buttons, to store the signal being emitted from the pressure switch as full scale; in the

display the set end point will appear although the full scale sensor signal is displaced.

the analogue output signal (for devices with analogue output) is not affected by this change

set "0247"; the menu description is identical with menu "P0SI" (menu 24) for 3-wire-devices

set "0729"; the menu description is identical with menu "FAct" (menu 25) for 3- wire-devices

set "0835"; confirm with both buttons; "SEtP" appears in the display; set the password using the ▲- or ▼-button

(0 ... 9999 are permissible, the code numbers 0238, 0247, 0729, 0835 are exempt); confirm the password by

pushing both buttons simultaneously

7. Placing out of service

WARNING! When dismantling the device, it must

always be done in the depressurized and currentless

condition! Check also if the medium has to be drained

off before dismantling!

WARNING! Depending on the medium, it may cause

danger for the user. Comply therefore with adequate

precautions for purification.

8. Maintenance

In principle, this device is maintenance-free. If desired, the

housing of the device can be cleaned when switched of

using a damp cloth and non-aggressive cleaning solutions.

Depending on the measuring medium, however, the diaphragm may be polluted or coated with deposit. If the medium is known for such tendencies, the user has to set

appropriate cleaning intervals. After placing the device out of

service correctly, the diaphragm can usually be cleaned

carefully with a non-aggressive cleaning solution and a soft

brush or sponge. If the diaphragm is calcified, it is recommended to send the device to BD SENSORS for decalcification. Please read therefore the chapter “Service/Repair”

below.

!

An incorrect cleaning can cause irreparable damages

on diaphragm. Never use spiky objects or pressured air

for cleaning the diaphragm.

9. Service / Repair

9.1 Recalibration

During the life-time of the device, the value of offset and

span may shift. As a consequence, a deviating signal value

in reference to the nominal pressure range starting point or

end point may be transmitted. If one of these two phenomena occurs after prolonged use, a recalibration is recommended to ensure furthermore high accuracy.

9.2 Return

Before every return of your device, whether for recalibration,

decalcification, modifications or repair, it is necessary to

contact us to ensure a fast handling of your request. Please

inform us by sending an email to: return@bdsensors.de.

Include the number of devices sent and request a RMA.

Then clean the device and pack it shatterproof before send it

to BD SENSORS indicating the RMA.

10. Disposal

The device must be disposed according to the

European Directives 2002/96/EG and

2003/108/EG (on waste electrical and electronic

equipment). Waste of electrical and electronic

equipment may not be disposed by domestic

refuse!

WARNING! Depending on the measuring medium,

deposit on the device may cause danger for the user

and the environment. Comply with adequate precautions for purification and dispose of it properly.

11. Warranty conditions

The warranty conditions are subject to the legal warranty

period of 24 months from the date of delivery. In case of

improper use, modifications of or damages to the device, we

do not accept warranty claims. Damaged diaphragms will

also not be accepted. Furthermore, defects due to normal

wear are not subject to warranty services.

12. Declaration of conformity / CE

The delivered device fulfils all legal requirements.

The applied directives, harmonised standards and documents are listed in the EC declaration of conformity, which is

available online at: http://www.bdsensors.com/products/

download/certificates.

Additionally, the operational safety is confirmed by the CE

sign on the manufacturing label.

DS4XX_E_110310

Loading...

Loading...