Page 1

LET US MAKE YOUR GROUND SOURCE HYDRONICS

SYSTEM EASIER AND MORE EFFICIENT

www.bdmfginc.com

HYDRONIC BUFFER TANK

1

Page 2

IT’S FINALLY HERE A HYDRONIC BUFFER TANK WITH THE PUMPS, CONTROLS AND VALVES

ALL IN ONE. NO MORE HASSLES OF TRYING TO MOUNT EVERYTHING. ALL YOU HAVE TO DO

IS PLUMB THE LINES, WIRE THE THERMOSTATS, AND HEAT PUMP, THEN FILL THE SYSTEM.

THE NON PRESSURIZED TANK KEEPS AIR OUT OF YOUR SYSTEMS SO YOU DON’T HAVE TO.

Pressure Relief Valve

Manual Relief Valve

Control Box w/ transformer

and Printed Circuit Board

115V Hydronic Side w/ 3/4” or 1” Ball Valve

230V Pump Ground Source HP

Thermostat Wire Entrance

AVAILABLE SIZES:

HSS®-12, HSS®-20, HSS®-30, HSS®-40, HSS®-60, HSS®-80

2” inlet & 3/4”or 1” Ball Valve outlets

Water temperature not to exceed 150 degree max. Designed for 6 to 10 gallons

per ton of buffer volume. (Tank is not designed to be a hot/chilled water storage

device) 115V Pump on Hydronic Heat Side & 230V Pump W/ Water Side.

Hydronic Pump Relay standard Sensor for One Stage Heat, Two Stage Heat or

Heating & Cooling built in.

***CUSTOM TANKS MADE TO ORDER***

***CUSTOM TANKS MADE TO ORDER***

***CUSTOM TANKS MADE TO ORDER******CUSTOM TANKS MADE TO ORDER***

2

Page 3

Installation Guidelines and Procedures for B & D MFG

.,

INC.

SAFETY INSTRUCTIONS

This safety alert symbol will be used in this manual to draw attention to safety related instructions.

When used, the safety alert symbol means: ATTENTION! BECOME ALERT! YOUR SAFETY

IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A

SAFETY HAZARD.

HSS® Series Hydronic Buffer Tank

TANK PLACEMENT REQUIREMENTS

A level location with 36" of clearance on the front of tank required. This

allows enough room to hook-up the manifolds for the Hydronic Zone and

Water-to-Water Heat Pump. An allowance for 36" of clearance on the top of

the tank (between lid and ceiling) for insertion of an optional flow meter tool,

which is recommended. Buffer Tank location shall be in a conditioned air

space to prevent condensation.

WARNING: Electrical Shock and potential circuit damage. Disconnect power supply before beginning installation.

Failure to follow these instructions could result in serious personal injury or death and property damage.

Improper wiring and wire can cause electrical shock and fires. Wiring connections must be made in

accordance with all applicable electrical codes and ordinances. Use copper wire only. Failure to follow these

instructions could result in serious personal injury or death and property damage.

Potential electrical overload. Each circuit is limited to a maximum of 3 amps and 1/3 HP. The

combined load for the controller is limited to 15 amps and 1 HP maximum. Failure to follow these instructions

could result in serious personal injury or death and property damage.

ELECTRICAL SERVICE & CONNECTIONS

The HSS® Buffer Tank requires a dedicated 20 amp, 120 volt circuit. The

primary wiring must be in accordance with Local Codes and that of the

National Electric Code. Low voltage wiring must be isolated from primary

voltage lines and connections.

The individual circulator pumps for the Hydronic Zones are pre-wired and

labeled at the control panel for field connections, these pumps are factory

assembled for 120 volts. The Water to Water (load side) circulator pumps shall

be wired to the heat pump’s control box; (see heat pump manufacturers wiring

diagram for proper wiring connections) and are typically wired with the

compressor contactor load side. Follow the color-coded schematic of low

voltage wiring. (see page 7)

WARNING: Load side circulator pumps are 220 volts. It is important to tag the Buffer Tank as having

separate power sources for servicing.

WARNING: HSS® Buffer Tank is a non-pressurized unit and should never be pressurized.

3

Page 4

THERMOSTAT WIRING

The HSS® can provide heating/cooling control and heating only control

depending on the system requirements. Any terminal block located on the

HSS® control board can be used for heating and/or cooling however the

HO/HC jumper must be on HC to enable cooling control for its corresponding

zone. (See schematic on page 7)

Heating & Heating Cooling- Connect thermostat wire R to its corresponding

pump zone on the HSS® Control R terminal. Connect thermostat wire Y to its

corresponding pump zone on the HSS® Control Y terminal. If the zone

thermostat requires 24V power connect thermostat wire C to its corresponding

pump zone on the HSS® Control C terminal.

Master Heating/Cooling- The Heat/Cool master thermostat determines the

system Heat/Cool setting. Connect thermostat wire R to its corresponding

pump zone on the HSS® Control R terminal. Connect thermostat wire Y to its

corresponding pump zone on the HSS® Control Y terminal. Connect

thermostat wire O to its corresponding pump zone on the HSS® Control O

terminal. If the zone thermostat requires 24V power connect thermostat wire

C to its corresponding pump zone on the HSS® Control C terminal.

PIPING HOOKUP

The HSS® Buffer Tank has Stainless Steel unions and pipe connections. It is

recommended when using transition fittings between steel and PVC, CPVC or

PE style plastic pipe. Extreme caution must be used when inserting steel into

plastic fittings or plastic into steel fittings. The HSS® Buffer Tank does

experience a wide range of temperature and over tightening of plastics fittings

can lead to fitting failures, water loss with in the HSS® Buffer Tank and

extreme cases, pump failure due to lack of water. It is recommended on plastic

style threaded joints the joint be snugged only and a good grade of thread

sealant be used. The system, once filled and purged, has capabilities of having

air handlers approximately 30' higher than the lid of the Buffer Tank and the

(see schematic page 7)

lid may be removed without water spilling out of the tank. All threaded fittings

on the HSS® Buffer Tank should be backed up with and additional wrench to

ensure damage does not occur to the Buffer Tank from twisting of fittings. All

lines should be insulated to prevent condensation forming on lines.

4

Page 5

PURGING HSS® BUFFER TANK

The HSS® Buffer Tank can have several loops or circuits and each one

should be purged separately. The HSS Buffer Tank shall be filled with water

prior to running any of the circulator pumps. Keep a water source nearby to

fill the tank as necessary. As air is relieved from the system piping water will

need to be added. Prior to running any of the pumps except the 15-58

pumps, the large metal screw on the back of the Grundfos pump shall be

removed, and the pump shaft turned by hand to allow air to be purged from

the pump. ( Check 3– speed pump for right setting.)

Turn on the 1st zone pump, by jumper or thermostat, and monitor the water

level in the HSS® Buffer Tank, as the water level drops in the Buffer Tank,

add water to maintain a minimum level of water in the tank. A minimum

level would be just below the return line pipe discharge point. The reason for

a low water level while filling is to allow air to vent without splashing water

out of the Buffer Tank. When the water level rises, 1-2" above the discharge

point in the Buffer Tank then shut off the 1st zone circuit and start the 2nd

zone circuit process. Repeat this process until all zones have been purged.

It is important to note the arrow on the pump should be pointing up this will

ensure proper flow direction. The isolation pump flanges should be turned

on. This is accomplished when the line on the valve is parallel with the pipe

direction. There may be occasions when a pump for an air handler is located

two stories above the HSS® Buffer Tank and will not have enough head to

purge the air out of the line. In those cases turn the isolation valve shut and

pull out the smaller pump and bolt in a larger pump and open the isolation

flanges. Once the air handler has been purged, then shut off the isolation

valves on the flanges. Unbolt the temporary pump and bolt in the permanent

pump, open the isolation flanges while pump is running open bottom flange

first. Once the pump runs and pushes a small amount of air out of the system

the pump will maintain the prime. If you should loose prime on this circuit

you would need to re purge as described above. When all the hydronic zones

are purged then move to the water-to-water heat pump manifold and start the

purging process as started with the zone pumps. Be sure to purge the air out

of the pumps first.

WARNING: HSS® Buffer Tank is a non-pressurized unit and should never be pressurized.

5

Page 6

PROGRAMMING OF THE B&D TEMPERATURE CONTROLLER

1. Power needs to be applied to the HSS Buffer Tank, the Temperature controller display will turn on.

2. Press and hold the MODE button for 5 seconds and it will enter programming mode. After 2 seconds the

temperature scale will show on the LCD display. By pressing the up or down button allows you to change

from “FAR” or “CEN”.

3. Press mode button once and enter the control type. The display will show “TY1”. After 2 seconds the

LCD will show “HEA” or “COL”, by pressing the up and down button allows the setting change from

“HEA” or “COL”. The setting must be “COL”.

4. Press the mode button again to change to temperature differential “SP1”. After 2 seconds the LCD will

display a number, by pressing up and down button allows the setting change the number setting.

5. Press the mode again and the LCD displays “HS1”, after 2 seconds the LCD will show current setting.

The hysteresis time, would be a built in time delay. By pressing the the up and down button to set the

desired time. Change to zero to disable.

6. Press mode button once and enter the control type. The display will show “TY2”. After 2 seconds the

LCD will show “HEA” or “COL”, by pressing the up and down button allows the setting change from

“HEA” or “COL”. The setting must be “HEA”.

7. Press the mode button again to change to temperature differential “SP2”. After 2 seconds the LCD will

display a number, by pressing up and down button allows the setting change the number setting.

8. Press the mode again and the LCD displays “HS2”, after 2 seconds the LCD will show current setting.

The hysteresis time, would be a built in time delay. By pressing the the up and down button to set the

desired time. Change to zero to disable.

The controller includes a locking function that will prevent accidental reprogramming. The soft lock is enabled

and disabled by pressing both the UP and DOWN buttons for five seconds. The LCD will show “LOC” to

indicate the controller is locked. The LCD will show “UNL” to indicate that the controller is now unlocked. The

soft lock will retain its setting through power interruptions.

Step Annunciator Description Display

1 F – C Fahrenheit or Celsius Scale F

2 ty1 Heating or Cooling Col or HEA

3 Sp1 Set Point Temperature #

4 ds1 Differential Temperature #

5 HS1 Timer for Delay #

6 Repeat steps 2-5 for stage 2

*Note the B & D Temperature control will automatically end programming if no keys are depressed for a

period of fifteen seconds. Any settings that have been input to the control will be accepted at that point.

6

Page 7

7

Page 8

DIAGNOSTICS

Water runs out of the top of the HSS® Buffer Tank

1. Air in zones will cause water to over flow when pumps are shut off.

2. A water line leak above the height of the Buffer Tank could cause air

to enter and allow the water to run out.

3. If the HSS

®®®®

Buffer Tank was filled during the air conditioning season

and then operating in the heating season, the water level can rise and

overflow.

4. A properly purged system will result in less than 2"of water level

movement between pumps running and pumps not running. If

movement is greater than 2" air is still present in the system.

Water level continues to drop in the Buffer Tank

1. If it is a new install as air continues to purge the water level will

drop. This process should not last much over a few days of operation.

2. During the heating season and going into the cooling season the

water level may drop but should remain near that level.

3. Possible leak in the hydronic loop or in the heat pump loop.

Water will not circulate on the hydronic zone side

1. Check that all isolation valves are turned on.

2. Check that all pumps are set with the arrow up.

3. Power is at the HSS

®®®®

Flow Control.

4. Air has been purged out of all air handlers.

5. Pumps have a sufficient pump curve to meet the needs of the zone.

6. A zone thermostat may not be calling for heat.

The lid will not come off of the Buffer Tank

1. The lid was installed to tight originally.

2. The purge valve was not opened to the atmosphere.

The Heat Pump will not run but the zone pumps are operating

1. The Digital Aqua Stat not programmed correctly.

2. The water temperature is at a point that all temperatures are satisfied.

Note: When filling a HSS

®®®®

Buffer Tank with 40°F – 60ºF water

the cooling set point may need to be lowered to start the heating

cycle. Once water temperature is above 70ºF the cooling set point

should be reset to original setting.

be pressurized.

Warning: HSS® Buffer Tank is a non-pressurized unit and should never

8

Page 9

®

Non-Pressurized STAINLESS STEEL Hydronic Buffer Tank

GT Stainless Steel Tank

Tank Size

Total Hydronic Circuits

Total W/W Circuits

B-B&G; G-Grundfos

Voltage (1-115; 3-230)

*Hydronic circuit ball valve 3/4”on 15/58, 1” on 26/99-3 speed pump.

W /W Side 1-1/4” Ball Valve

Tank Water Level is 3” to 4” Down on Main Tank

Control Board Electrical Data:

115V/Single Phase 15 amp Circuit

HSS60-3-1-G-13

1 1/4” FPT

w/ Ball Valve

HSS

®

GT BUFFER TANK Flow Center Physical Dimensions (in.)*

Max Gal

Storage

12 21” 7 1/2” 7” 9” 24” 49” 57 1/2” 10” 17” 1 1/4” MPT 1 1/4” U 30#

20 21” 7 1/2” 7” 9” 24” 49” 57 1/2” 13” 20” 1 1/4” MPT 1 1/4” U 38#

30 21” 7 1/2” 7” 9” 24” 49”

40 21” 7 1/2” 7” 9” 24” 49”

60 21” 7 1/2” 7” 9” 24” 49”

80 21” 7 1/2” 7” 9” 24” 49” 54” 25” 31” 2” FPT 2” U 97#

Max

Hydronic

Circuits

3

6

9

12

12

12

9

G

H I J K L M N O P

54” 16” 23” 1 1/2” FPT 1 1/4” or 2” U 52#

54” 18” 25” 2” FPT 1 1/4” or 2”U 60#

54” 22” 29” 2” FPT 2” U 84#

* Dimensions are approximate

Q

Wt

Tank

Page 10

HSS® BUFFER TANK WARRANTY

15-58

B & D Mfg., Inc. warrants for a period of three (3) years from date of purchase that all HSS® Buffer Tank pumps and circuit boards are

free from defects in materials and workmanship. B & D Mfg., Inc. warrants for a period of five (5) years from date of purchase that all

HSS® Buffer Tank, stainless steel tanks only, are free from defects in materials and workmanship. B & D Mfg., Inc. warrants for a

period of one (1) year from date of purchase that all other parts are free from defects in materials and workmanship. Defective parts will

be repaired or replaced at the Manufacturer’s discretion. No allowance for labor or property damage is implied.

ALL WARRANTY PRODUCTS MUST BE RETURNED WITHIN 30 DAYS OF

RECEIPT OF REPLACEMENT TO RECEIVE CREDIT.

Seller's liability for any breach of this Warranty shall be limited solely to replacement or repair, and the sole option of seller, of any part

or parts found to be defective during the Warranty period provided the Product is properly installed and is being used as originally

intended. Buyer must notify Seller of any breach of this Warranty within the aforementioned Warranty period: defective parts must be

shipped by Buyer to Seller with transportation charges prepaid.

It is expressly agreed that this shall be the sole and exclusive remedy of the buyer. Under no circumstances shall seller be liable for any

costs, loss expenses damages, special damages, incidental damages of manufacture, sale, use or repair of the product whether based

upon warranty, contract, negligence or strict liability. In no event will liability exceed the purchase price of the product.

The warranty and limits of liability contained herein are in lieu of all other warranties and liabilities, expressed or implied. All implied

warranties of merchantability and fitness for a particular purpose are hereby disclaimed by seller and excluded from this warranty.

Seller neither assumes nor authorizes any person to assume for it, any other Warranty obligation in connection with the sale of the

Product. This Warranty shall not apply to any Product or parts of Products which (a) have been repaired or altered outside of seller’s

facilities: or (b) have been subject to misuse, negligence or accidents: or (c) have been used in a manner contrary to seller’s instructions.

FORM lws

REV 2006/Replaces All previous Warra nty Statements

Warning: HSS

®

Buffer Tank should never be used with an outdoor

wood boiler. Outdoor wood boilers can produce water temperatures

above 150 degrees and will void ALL WARRANTIES.

901 9th Street Scranton, IA 51462

B & D Mfg., Inc.

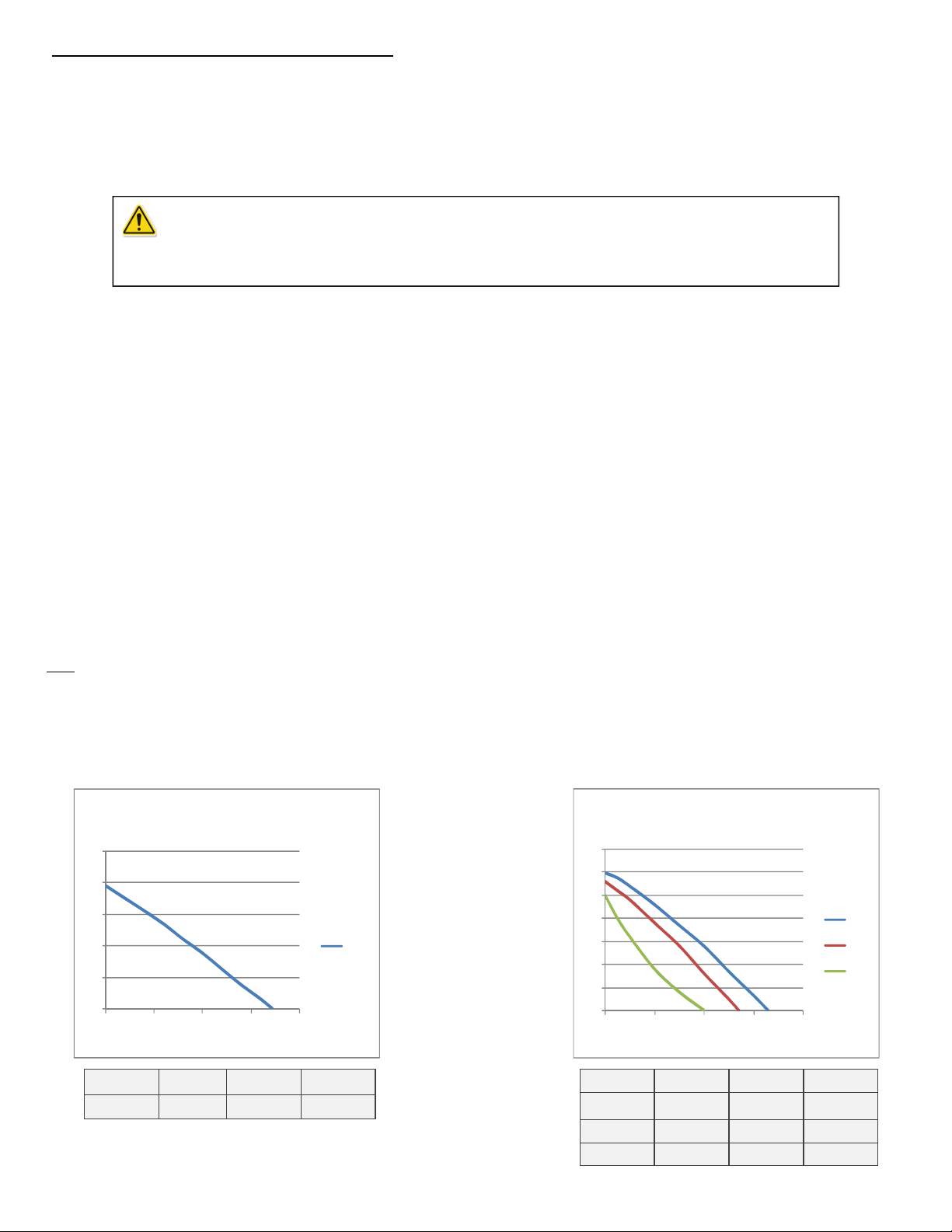

Hydronic 115V pump curves.

15-58

25

20

15

10

5

0

0 5 10 15 20

Volts Speed Amps Was

115 1 .75 89

35

30

25

20

15

10

5

0

0 10 20 30 40

Volts Speed Amps Was

115 1 1.8 197

115 2 1.5 179

115 3 1.3 150

© e.g. 2009-2012 B & D Mfg., Inc. all rights reserved

26-99

HI

MED

Low

Loading...

Loading...