Page 1

LINEA

SHELVING

INSTRUCTION MANUAL

™

5801(A)/5802(A)

LET’S GET STARTED.

DESIGN MATTHEW WEATHERLY

Page 2

Page 3

Congratulations on purchasing your Linea Shelving 5801(A) / 5802(A) from BDI. Your

shelving has been designed to provide a lifetime of enjoyment. This manual will provide

you with assembly instructions and other helpful information to ensure that you get the

most out of your shelving. Please save it for future reference.

Your Linea shelving has been engineered for simple assembly. Please follow these

directions carefully to prevent any damage.

Should you need further assistance, contact BDI at customerservice@bdiusa.com.

ENJOY!

BDIUSA.COM | 3NEED ASSISTANCE? customerservice@bdiusa.com

Page 4

HARDWARE AND COMPONENTSHARDWARE AND COMPONENTS

Unpack and identify the parts listed below. Note that some components are shipped inside the

cabinet. The assembly workspace should be a non-marring surface such as carpet. For missing

hardware pieces, please contact BDI Customer Service at customerservice@bdiusa.com.

Do not use power tools for the assembly of this product.

For all other concerns, please contact your BDI retailer.

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

TI

Phillips Screwdriver

1

C3

Cabinet Block

2 per unit

H3

Wooden Dowel

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

T2

Hex Driver

1

H1

M6 x 30mm Screw

12 per unit

H4

Barrel Nut

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

T3

Leveler Wrench

1

H2

Cam Bolt

4 per unit

H11

Shelf Pin

QUANTITY

4 | BDIUSA.COM LINEA 5801(A) / 5802(A)

8 per unit

QUANTITY

4 per unit

QUANTITY

16 per unit

Page 5

HARDWARE AND COMPONENTS

Holes on 1 side Holes on 2 sides

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

End Panel

2 per Base Unit

5801/5801A

5802/5802A

Top Panel

C1

C4

PART #

DESCRIPTION

QUANTITY

1 per extension unit

C2

Inner Panel

5801/5801A 5802/5802A

PART #

DESCRIPTION

C5

Cabinet

QUANTITY

PART #

DESCRIPTION

QUANTITY

1 per unit

C6

Outer Glass Shelf

3 per unit

QUANTITY

PART #

DESCRIPTION

QUANTITY

1 per unit

C7

Inner Glass Shelf

1 per unit

BDIUSA.COM | 5NEED ASSISTANCE? customerservice@bdiusa.com

Page 6

HARDWARE AND COMPONENTSHARDWARE AND COMPONENTS

Wall Mounting Kit

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

QUANTITY

H5

Wall Bracket

2

H8

Sheetrock Anchor

4

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

QUANTITY

H6

Cabinet Bracket

2

H9

Plaster/Block Anchor

4

PART #

DESCRIPTION

QUANTITY

PART #

DESCRIPTION

QUANTITY

H7

Fastener Screw

4

H10

Bracket Screw

2

6 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 7

SINGLE OR MULTIPLE UNITS

Linea can be configured as stand-alone units or multiple combinations of narrow and wide units.

GO TO PAGE 8 GO TO PAGE 20

5801 5802

5801/5802 + 5801A/5802A

or other multi-unit combinations

BDIUSA.COM | 7NEED ASSISTANCE? customerservice@bdiusa.com

Page 8

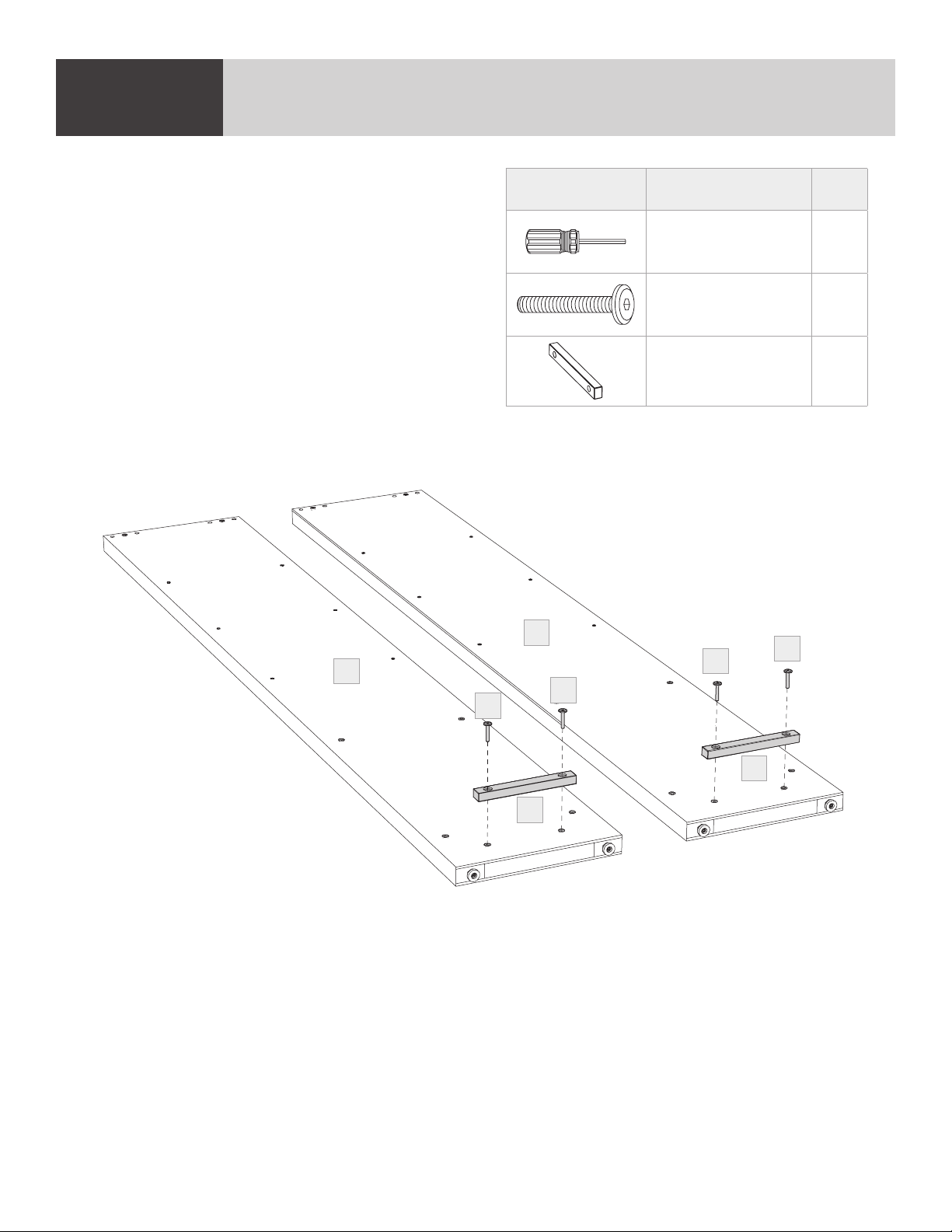

STEP 1. ATTACH CABINET BLOCKS TO END PANELSASSEMBLY

Attach 1 (C3) Cabinet Block to each (C1) End

Panel using (H1) Screws and (T2) Hex Driver.

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H1-SCREW 4

C3-CABINET BLOCK 2

C1

H1

C3

C1

H1

Lower End

H1

H1

C3

8 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 9

STEP 2. INSTALL CAMS AND DOWELS

ASSEMBLY

Find the sets of 3 holes near the top edge of the

(C1) Side Panels. Screw (H2) Cam Bolts into the

threaded holes using (T1) Phillips Screwdriver and

push (H3) Wooden Dowels into the outer holes.

Lower End

C1

C1

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

H2-CAM BOLT 4

H3-WOODEN DOWEL 8

H3

H2

H3

H3

H2

H3

BDIUSA.COM | 9NEED ASSISTANCE? customerservice@bdiusa.com

Page 10

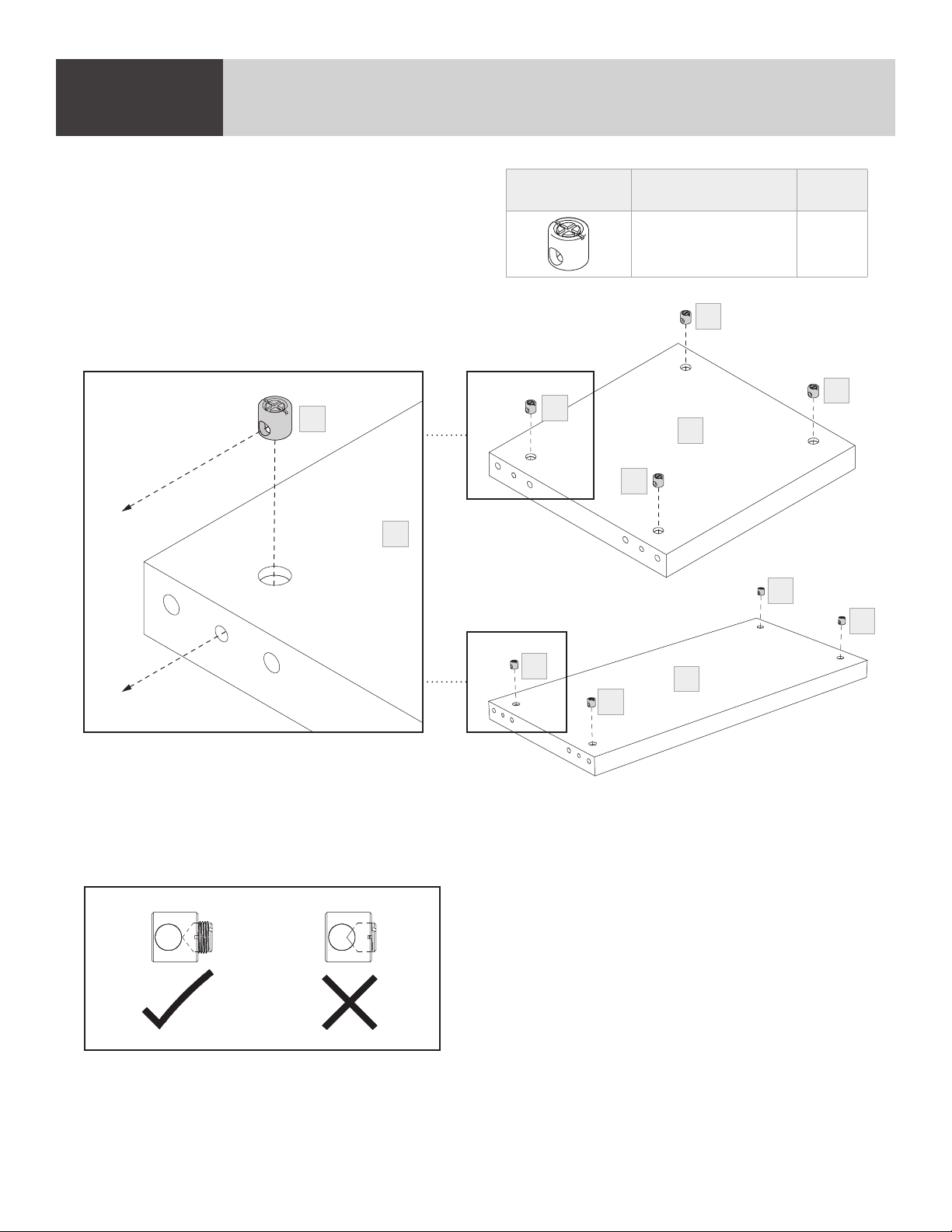

STEP 3. INSERT BARREL NUTSASSEMBLY

Insert 4 (H4) Barrel Nuts into the holes on the

top of the (C4) Top Panel, making sure that the

hole on the side of the barrel nuts align with the

holes on the edges of the panel.

H4

Align hole

C4

PART/DESCRIPTION QTY

H4-BARREL NUT 4

H4

H4

H4

C4

H4

5801

H4

H4

H4

H4

NOTE: Look into the side hole of the barrel nuts and

make sure, the set screw is not blocking the hole.

If the hole is blocked, unscrew set screw a few turns until

the hole is clear, which will allow the cam bolts to enter.

C4

5802

10 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 11

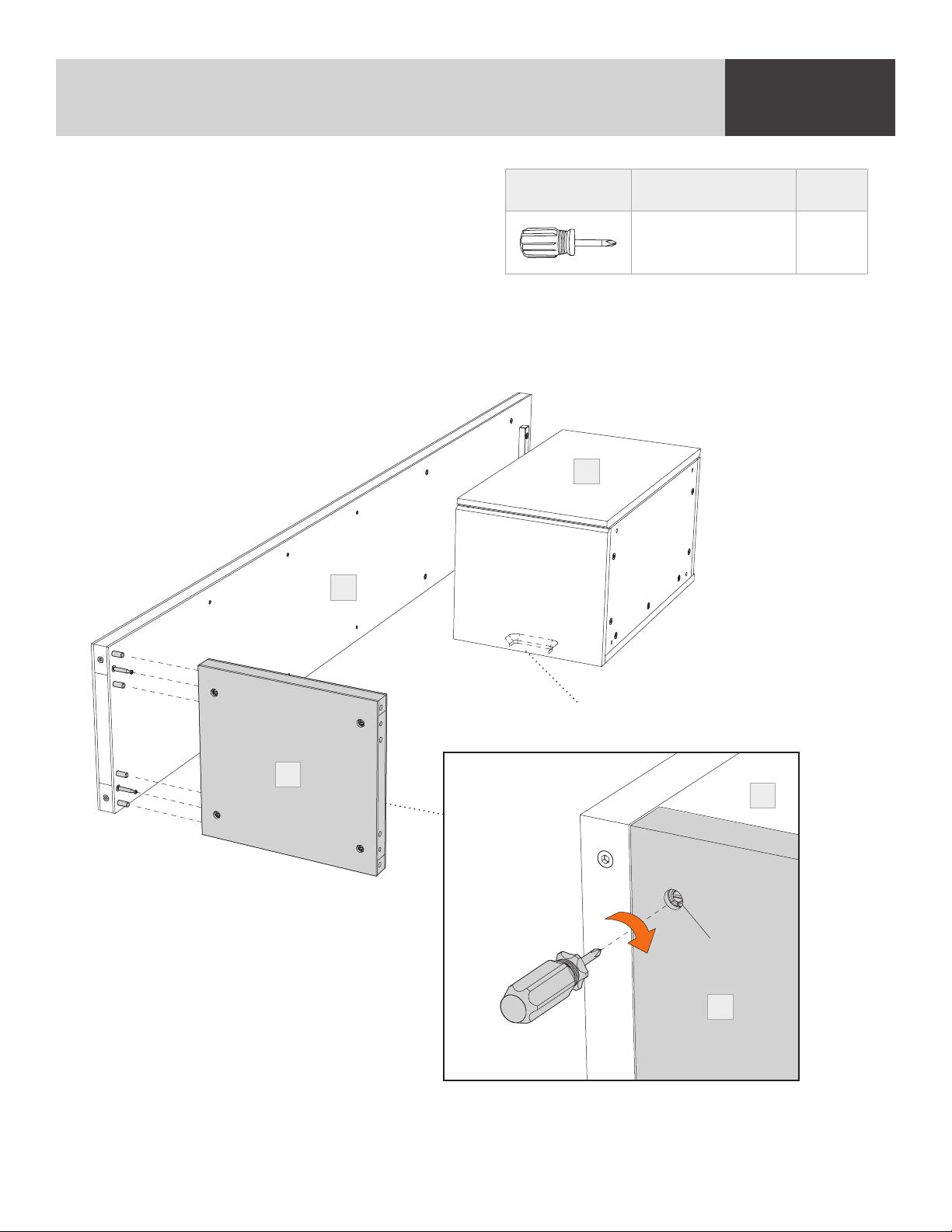

STEP 4. ATTACH TOP PANEL TO SIDE PANEL

ASSEMBLY

Attach (C4) Top Panel to (C1) End Panel by

sliding dowels and cam bolts into the holes on the

PART/DESCRIPTION QTY

edge of (C4) Top Panel. If cams don’t go into

barrel nuts, check to make sure the barrel nut is

aligned with the side hole and make sure the set

T1-PHILLIPS

SCREWDRIVER

1

screw is loosened before insertion of the cam bolts.

Tighten barrel nuts using (T1) Phillips Screwdriver with a clockwise turn. Position (C5) Cabinet as

shown. Make sure rectangular opening on back of cabinet is facing upward towards (C4) Top Panel.

Make sure the door is facing upward.

Door(s) up

C5

C1

C4

Holes on this side

Rectangular opening here

C1

Barrel nut

C4

BDIUSA.COM | 11NEED ASSISTANCE? customerservice@bdiusa.com

Page 12

STEP 5. ATTACH SECOND END PANELASSEMBLY

Attach the next (C1) End Panel to the other side of

(C4) Top Panel by sliding dowels and cams into the

holes on the side of (C4) Top Panel. Tighten barrel

nuts using (T1) Phillips Screwdriver.

C1

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

C4

12 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 13

STEP 6. ATTACH CABINET TO END PANELS

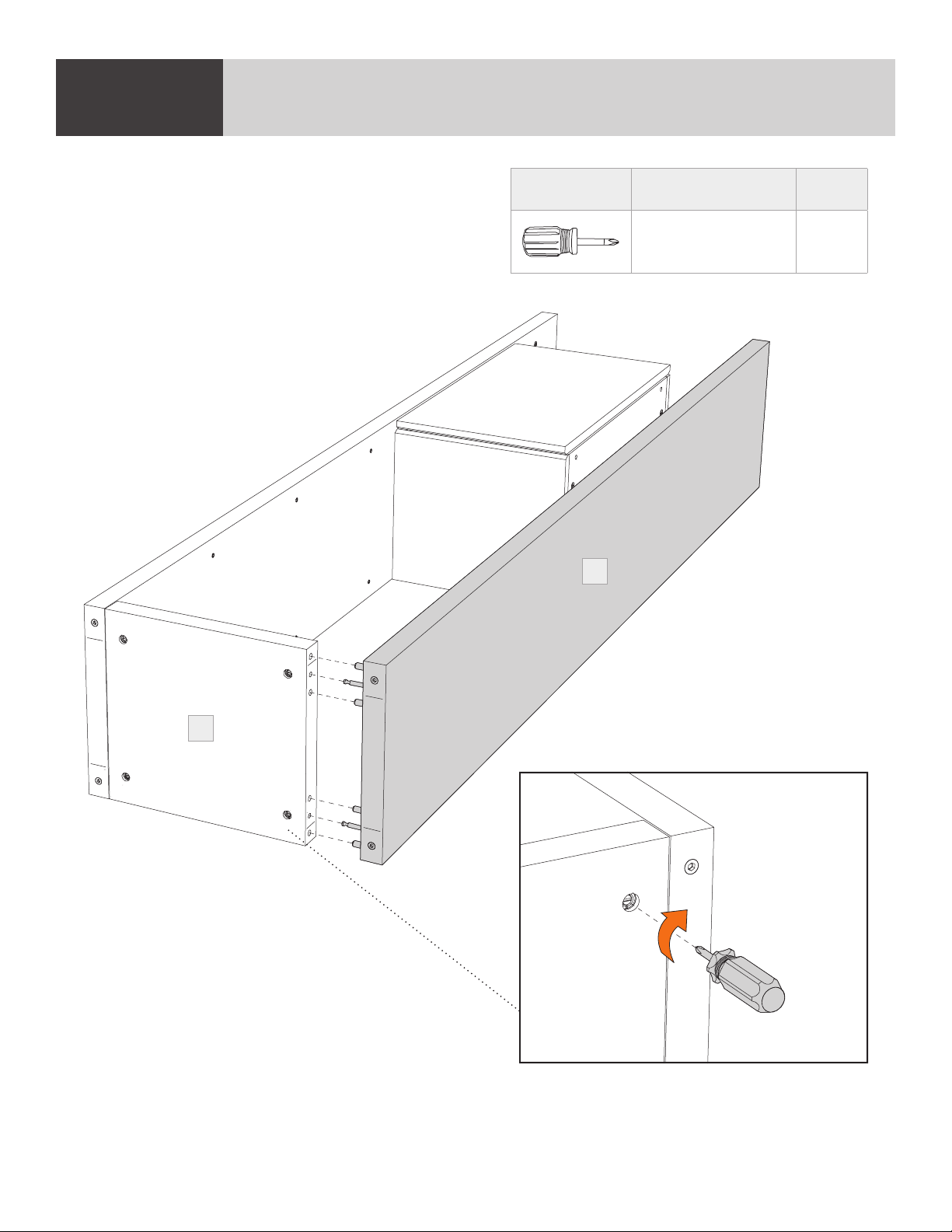

ASSEMBLY

Making sure the bottom of the cabinet is against

the (C3) Cabinet Blocks, carefully open the

cabinet door and attach the (C5) Cabinet to

(C1) End Panels using 8 (H1) Screws and tighten

with (T2) Hex Driver.

C1

C1

C5

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H1-SCREW 8

C3

H1

H1

H1

C5

C1

H1

H1

C1

H1

BDIUSA.COM | 13NEED ASSISTANCE? customerservice@bdiusa.com

Page 14

2 PERSON TASK

STEP 7. STAND UP / WALL CONNECTIONASSEMBLY

With help from another person, carefully stand the cabinet onto its base. Carefully walk it into position.

Attaching your Linea shelving to the wall is required to ensure your safety. Use painter’s tape to

mark both upper back corners of the unit, as shown.

Painter’s tape

14 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 15

STEP 8. WALL CONNECTION (continued)

ASSEMBLY

Move the cabinet to the side. Place (H5) Wall

Brackets on the wall (flush with top and 1/4"

(7mm) away from the edge) and mark hole

locations on the wall using a pencil. Drill holes at

these locations for wall inserts.

Choose (H8) or (H9) Wall Anchors appropriate

for your wall type.

H5

1/4"

7mm

PART/DESCRIPTION QTY

H5-WALL BRACKET 2

H7-SCREW 4

H8-ANCHOR 4

H9-ANCHOR 4

Choose wall anchors based on your walls:

H8

H9

Sheetrock Anchor

Plaster/Brick/Block Anchor

Insert (H8) or (H9) Wall Anchors into the holes and attach (H5) Wall Brackets to the wall using

(H7) Anchor Screws.

H8/H9

H7

H5

H8/H9

H7

BDIUSA.COM | 15NEED ASSISTANCE? customerservice@bdiusa.com

Page 16

2 PERSON TASK

STEP 9. WALL CONNECTION (continued)ASSEMBLY

Re-position your Linea cabinet in front of the

(H5) Wall Brackets. Stand on a step ladder and

slide (H6) Cabinet Brackets down into the slot in

(H5) Wall Brackets and tighten using (H10) Bracket

Screws and (T2) Hex Driver.

H10

H6

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H6-CABINET BRACKET 2

H10-BRACKET SCREW 2

H10

H6

16 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 17

STEP 10. INSTALL SHELVES AND LEVEL

ASSEMBLY

Attach 16 (H11) Shelf Pins into the threaded holes

using a (T1) Phillips Screwdriver—choose preferred

interior shelf height. Install (C6) Outer Glass

Shelves on the shelf pins, tilting the glass slightly

to avoid hitting side panels. Tilt and install (C7)

Inner Glass Shelf inside the cabinet.

Use (T3) Leveler Wrench to level the cabinets.

H11

T1

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

T3-LEVELER WRENCH 1

H11-SHELF PIN 16

C6

C6

T3

C6

C7

BDIUSA.COM | 17NEED ASSISTANCE? customerservice@bdiusa.com

Page 18

CHOOSE DOOR POSITIONFINE TUNING

The door on your Linea 5801 Cabinet can be

attached to the opposite side (if desired), allowing

the door to swing to the right. Remove the 2 screws

holding each hinge plate to the side of the cabinet

using (T1) Phillips Screwdriver and flip the door

(top becomes bottom) and attach to the threaded

holes on the opposite side using the same screws.

Proceed to page 30.

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

ASSEMBLY

18 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 19

CONFIGURATIONS

Endless Possibilities

Linea can be configured in endless ways. Below are a few examples. Configurations up to 3 units

wide may be assembled on the floor, stood up and carefully positioned. It is also possible to

assemble 1 unit, stand it up, and add additional units to it. Every configuration requires 1 base unit

and then additional units. Base units come with 2 end panels, and each add on unit always includes

1 inner panel.

5801 + 5802A +5801A

5801 + 5801A 5802 + 5802A

5801 + 5802A 5802 + 5801A

BDIUSA.COM | 19NEED ASSISTANCE? customerservice@bdiusa.com

Page 20

HARDWARE AND COMPONENTSHYBRID KIT

Hybrid Assembly

The following pages will show how to assemble a kit of 2 units shown below—which is a 5802 and a

5801A. Your configuration may differ, but the assembly method will be the same.

End Panel

Inner Panel

End Panel

5802 (Base) + 5801A (Add-on)

20 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 21

STEP 1. ATTACH CABINET BLOCKS TO PANELS

ASSEMBLY

Attach (C3) Cabinet Blocks to a (C1) End Panel

and a (C2) Inner Panel using (H1) Screws and

(T2) Hex Driver.

C2

C1

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H1-SCREW 4 per unit

C3-CABINET BLOCK 2 per unit

H1

H1

C3

H1

H1

H1

C3

C3

H1

BDIUSA.COM | 21NEED ASSISTANCE? customerservice@bdiusa.com

Page 22

STEP 2. INSTALL CAMS AND DOWELSASSEMBLY

Find the sets of 3 holes near the top edge of the

(C1) End Panel and (C2) Inner Panel. Screw

(H2) Cam Bolts into the threaded holes using (T1)

Phillips Screwdriver and push (H3) Wooden

Dowels into the outer holes.

C2

C1

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

H2-CAM BOLT 4 per unit

H3-WOODEN DOWEL 8 per unit

H2

H3

H3

H2

H3

H3

22 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 23

STEP 3. INSERT BARREL NUTS

ASSEMBLY

Insert 4 (H4) Barrel Nuts into the holes on the

top of the (C4) Top Panel, making sure that the

hole on the side of the barrel nuts align with the

holes on the edges of the panel.

H4

Align hole

C4

PART/DESCRIPTION QTY

H4-BARREL NUT 4

H4

H4

H4

C4

H4

5801

H4

H4

H4

H4

NOTE: Look into the side hole of the barrel nuts and

make sure, the set screw is not blocking the hole.

If the hole is blocked, unscrew set screw a few turns until

the hole is clear, which will allow the cam bolts to enter.

C4

5802

BDIUSA.COM | 23NEED ASSISTANCE? customerservice@bdiusa.com

Page 24

STEP 4. ATTACH TOP PANEL TO PANELSASSEMBLY

Attach (C4) Top Panel to (C1) End Panel and

(C2) Inner Panel by sliding dowels and cam bolts

into the holes on the edge of (C4) Top Panel.

If cams don’t go into barrel nuts, check to make

sure the barrel nut is aligned with the side hole

and make sure the set screw is loosened before

insertion of the cam bolts.

Tighten barrel nuts using (T1) Phillips Screwdriver with a clockwise turn. Position cabinets as

shown. Make sure the door is facing upward.

Doors up

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

C1

1

C2

Barrel nut

C4

Holes on this side

C4

24 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 25

STEP 5. ATTACH CABINET

ASSEMBLY

Making sure the bottom of the cabinet is against

the (C3) Cabinet Blocks, carefully open the

cabinet doors and attach the (C5) Cabinet to

(C1) End Panels and (C2) Inner Panels using

8 (H1) Screws per cabinet and tighten with

(T2) Hex Driver.

C1

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H1-SCREW 8

C2

H1

H1

C5

H1

H1

H1

C3

BDIUSA.COM | 25NEED ASSISTANCE? customerservice@bdiusa.com

Page 26

2 PERSON TASK

STEP 6. STAND UP / CONNECT TO WALLASSEMBLY

Painter’s

tape

6A-1: Inline Against Wall

Option A: With help from at least 1 other

person, carefully stand the cabinets onto

their base. Carefully lift and slide into

position flat along a wall.

6A-2: Inline Against Wall

Option A: Attaching your Linea Cabinet to

the wall is required to ensure your safety.

Use painter’s tape to mark at least 1 upper

back corner of the unit, as shown. It is

recommended to attach the 2 outer

corners of multiple units.

Painter’s

tape

6B-1: Perpendicular Variation

Option B: With help from at least 1 other

person, carefully stand the cabinets onto

their base. Carefully lift and slide into

position as a peninsula extending

perpendicular to a wall.

Option B: Attaching your Linea Cabinet to

Use painter’s tape to mark at least 1 upper

6B-2: Perpendicular Variation

the wall is required to ensure your safety.

back corner of the unit, as shown. It is

recommended to attach the 2 outer

corners of multiple units.

26 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 27

STEP 7. WALL CONNECTION (continued)

ASSEMBLY

Move the cabinet to the side. Place (H5) Wall

Brackets on the wall (flush with top and 1/4"

(7mm) away from the edge) and mark hole

locations on the wall using a pencil. Drill holes at

these locations for wall inserts.

Choose (H8) or (H9) Wall Anchors appropriate

for your wall type.

H5

1/4"

7mm

PART/DESCRIPTION QTY

H5-WALL BRACKET 2

H7-SCREW 4

H8-ANCHOR 4

H9-ANCHOR 4

Choose wall anchors based on your walls:

H8

H9

Sheetrock Anchor

Plaster/Brick/Block Anchor

Insert (H8) or (H9) Wall Anchors into the holes and attach (H5) Wall Brackets to the wall using

(H7) Anchor Screws.

H8/H9

H7

H5

H8/H9

H7

BDIUSA.COM | 27NEED ASSISTANCE? customerservice@bdiusa.com

Page 28

2 PERSON TASK

STEP 8. WALL CONNECTION (continued)ASSEMBLY

Re-position your Linea cabinet in front of the

(H5) Wall Brackets. Stand on a step ladder and

slide one (H6) Cabinet Bracket down into the slot

in (H5) Wall Brackets and tighten using (H10)

Bracket Screws and (T2) Hex Driver. Save the

second (H5) Wall Bracket for the final unit in the

inline assembly.

Inline Against Wall

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H6-CABINET BRACKET 2

H10-BRACKET SCREW 2

H10

H6

H10

H6

H10

H6

Perpendicular

Variation

28 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 29

STEP 9. ATTACH CABINET BLOCK(S) TO PANEL(S)

ASSEMBLY

Attach (C3) Cabinet Block to the next panel in

the series using (H1) Screws and (T2) Hex Wrench.

Note: If you assemble the final unit in the series,

this will be a (C1) End Panel. If you are attaching

additional units, this will be a (C2) Inner Panel.

Attach (C3) Cabinet Blocks and (H1) Screws to

both sides of the (C2) Inner Panel.

C1 or C2

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H1-SCREW 4 per unit

C3-CABINET BLOCK 2 per unit

H1

H1

C3

BDIUSA.COM | 29NEED ASSISTANCE? customerservice@bdiusa.com

Page 30

ASSEMBLY

STEP 10. INSTALL CAMS AND DOWELS

Find the sets of 3 holes near the top edge of the

panel. Screw (H2) Cam Bolts into the threaded

holes using (T1) Phillips Screwdriver and push

(H3) Wooden Dowels into the outer holes.

C1 or C2

H2

H3

H2

H3

H3

H3

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

H2-CAM BOLT 4 per unit

H3-WOODEN DOWEL 8 per unit

ASSEMBLY

STEP 11. ATTACH TOP PANEL

Attach (C4) Top Panel to the (C1) End Panel by

sliding dowels and cam bolts into the holes on the

edge of (C4) Top Panel.

If cams don’t go into barrel nuts, check to make

sure the set screw is loosened before insertion of

the cam bolts. (See page 23.)

Tighten barrel nuts using (T1) Phillips Screwdriver

with a clockwise turn.

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

C1 or C2

C4

30 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 31

2 PERSON TASK

STEP 12. ATTACH TOP PANEL TO DIVIDER PANEL

ASSEMBLY

With help from at least 1 other person, carefully stand the top panel and end panel assembly onto its

base and connect it to the (C2) Inner Panel by sliding the dowels and cam bolts into the holes on

the edge of the (C4) Top Panel.

BDIUSA.COM | 31NEED ASSISTANCE? customerservice@bdiusa.com

Page 32

STEP 13. CONNECT TO WALLASSEMBLY

If this is the final unit in the series, follow steps 13–15 to connect to the wall. If you will be attaching

additional units, skip to step 16.

Use painter’s tape to mark at least 1 upper back corner of the last unit in the series, as shown.

Painter’s

tape

Remove add on panel.

32 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 33

STEP 14. WALL CONNECTION

ASSEMBLY

Move the cabinet to the side. Place (H5) Wall

Brackets on the wall (flush with top and 1/4"

(7mm) away from the edge) and mark hole

locations on the wall using a pencil. Drill holes at

these locations for wall inserts.

Choose (H8) or (H9) Wall Anchors appropriate

for your wall type.

H5

1/4"

7mm

PART/DESCRIPTION QTY

H5-WALL BRACKET 2

H7-SCREW 4

H8-ANCHOR 4

H9-ANCHOR 4

Choose wall anchors based on your walls:

H8

H9

Sheetrock Anchor

Plaster/Brick/Block Anchor

Insert (H8) or (H9) Wall Anchors into the holes and attach (H5) Wall Brackets to the wall using

(H7) Anchor Screws.

H8/H9

H7

H5

H8/H9

H7

BDIUSA.COM | 33NEED ASSISTANCE? customerservice@bdiusa.com

Page 34

2 PERSON TASK

STEP 15. ATTACH TOP PANEL TO DIVIDER PANELASSEMBLY

With help from at least 1 other person, carefully

stand the top panel and end panel assembly onto

its base and connect it to the (C2) Inner Panel by

sliding the dowels and cam bolts into the holes on

the edge of the (C4) Top Panel.

Install second wall bracket if this is the final unit.

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H6-CABINET BRACKET 1

H10-BRACKET SCREW 1

H10

H6

34 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 35

2 PERSON TASK

STEP 16. INSTALL CABINET

ASSEMBLY

With the help of at least 1 other person, carefully slide the (C5) Cabinet onto the (C3) Cabinet

Blocks. Slide the cabinet back until the door is flush with the front edges of the (C1) End Panel and

(C2) Inner Panel.

C5

C2

C1 or C2

BDIUSA.COM | 35NEED ASSISTANCE? customerservice@bdiusa.com

Page 36

STEP 17. ATTACH CABINETASSEMBLY

Carefully open the cabinet door(s) and attach the

(C5) Cabinet to (C1) End Panel and (C2) Inner

Panel using 8 (H1) Screws and tighten with

(T2) Hex Driver.

PART/DESCRIPTION QTY

T2-HEX DRIVER 1

H1-SCREW 8

H1

H1

H1

36 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 37

STEP 18. INSTALL SHELVES AND LEVEL

ASSEMBLY

Attach 16 (H11) Shelf Pins into the threaded holes

of each cabinet section using a (T1) Phillips

Screwdriver—choose preferred interior shelf

height. Install (C6) Outer Glass Shelves on the

shelf pins, tilting the glass slightly to avoid hitting

side panels. Tilt and install (C7) Inner Glass Shelf

inside the cabinet.

Use (T3) Leveler Wrench to level the cabinets.

To change 5801 door hinges, see page 18.

H11

T1

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

T3-LEVELER WRENCH 1

H11-SHELF PIN

C6

1

16 per

unit

C6

T3

C6

C6

C7

C6

C6

C7

BDIUSA.COM | 37NEED ASSISTANCE? customerservice@bdiusa.com

Page 38

ADJUST DOOR HINGES (IF NEEDED)FINE TUNING

The doors on your cabinet should be evenly

spaced, and the doors should open and close

freely without rubbing against the door frame.

If the cabinet’s doors appear out of alignment,

this condition can be corrected with minor

adjustments to the European hinges on each

door. Because these hinges are adjustable, adjusting one hinge can sometimes cause the need for

adjustments to other hinges. But with a few adjustments, you can modify the orientation of the

cabinet doors to make sure that they hang perfectly within your cabinet.

Use a (T1) Phillips Screwdriver to adjust the door hinges:

n By adjusting Screw 1, the door will move LEFT or RIGHT within the frame. Make minor

adjustments at both top and bottom hinges for best results.

n By loosening both Screws 2 on both hinges, the door can move UP or DOWN. Retighten the screws.

n By adjusting Screw 3 the entire door will move IN or OUT, opening or closing the gap between

the door frame and cabinet. (This screw rarely needs adjustment.)

PART/DESCRIPTION QTY

T1-PHILLIPS

SCREWDRIVER

1

1 2 3

38 | BDIUSA.COM LINEA 5801(A) / 5802(A)

Page 39

CARE & MAINTENANCE

GLASS

Glass surface is maintained using household glass cleaner and a paper towel or cloth.

SATIN-ETCHED GLASS

This uniquely smooth-to-the-touch glass surface can be regularly maintained using household glass

cleaner and a paper towel or cloth. Minor scratches or scuffs not eliminated using paper towel or cloth

can usually be removed by using a ‘Magic Eraser’. Magic Eraser is a melamine foam product available

at any grocery store or home improvement center. Dampen the entire glass surface as well as the

Magic Eraser, then rub the entire glass surface in broad, even strokes using moderate pressure. Clean

and dry the surface with a paper towel. Check for results and repeat as necessary.

Any scratches or scuffing not eliminated by one of the above methods can often be addressed by

‘refreshing’ the glass. This is a process that should not be required more than once per 6-12 months.

See this brief video for the simple method: www.bdiusa.com/glass

WOOD

Wood surfaces should be cleaned with a slightly damp (not saturated) cloth or paper towel. Do not

use glass cleaner on wood. If moisture remains, dry the surface with another cloth. If needed, a gentle

non-abrasive cleanser may be used, but be sure to wipe away all cleaner residue and dry the surface

with a cloth.

BDI’s wood finishes feature natural hardwood solids and veneers. Wood is a product of nature and—

unlike man-made materials that can be manufactured to strict and consistent specifications—has

natural imperfections that are part of its appeal and character. Every piece of wood differs from every

other, even when coming from the very same tree. As such, variation in grain, texture and tone should

be expected from one panel or piece of furniture to the next.

While BDI’s stained wood finishes are stable in tone & appearance, all finishes are subject to some

degree of discoloration with prolonged exposure to direct sunlight. Please take care to avoid

positioning your BDI cabinet in any area with extensive direct sunlight. To learn more about the

features of natural wood, visit www.bdiusa.com/wood

METAL & PAINTED SURFACES

Surfaces should be cleaned with a slightly damp (not saturated) cloth or paper towel. If moisture

remains, dry the surface with another cloth. If needed, a gentle non-abrasive cleanser may be used,

but be sure to wipe away all cleaner residue and dry the surface with a cloth.

BDIUSA.COM | 39NEED ASSISTANCE? customerservice@bdiusa.com

Page 40

WARRANTY

BDI warrants to the original purchaser that for the below stated warranty term, BDI will repair or

replace any product, part, or component covered by this warranty which fails under normal use as a

result of a defect in material or workmanship. BDI will repair or replace the aforementioned product,

part or component with a comparable product, part or component. The decision to repair or replace

will be at BDI’s sole discretion.

BDI Home Theater Furniture, Office Furniture, Modular Systems, Tables and other furniture pieces

are warranted for three (3) years from the date of purchase as shown on your sales receipt. The

warranty period starts from the date of purchase. This warranty extends only to the original

purchasers who acquire new product from BDI Authorized Resellers. Any product, part, or

component must have been assembled, installed, used, and maintained according to BDI’s published

instructions in order to be eligible for warranty coverage. Any modification to the original product

voids the warranty.

To view BDI’s complete warranty information, visit www.bdiusa.com/warranty

PRODUCT REGISTRATION

Registering your new BDI product allows us to send you important product updates, service

information and helpful hints related to your BDI products. Register today, and you will be entered

to win free a BINK table from BDI: www.bdiusa.com/register

WARNING

SERIOUS OR FATAL CRUSHING INJURIES CAN OCCUR FROM FURNITURE TIP-OVER. TO HELP

PREVENT TIP-OVER:

nDO NOT allow children to hang on the open doors

n DO NOT allow children to climb on the cabinets

nA LWAYS attach your Linea shelving to a wall

nFAILURE to secure your Linea shelving to a wall can lead to SERIOUS INJURY OR DEATH

USE OF TIP-OVER RESTRAINT MAY REDUCE—BUT NOT ELIMINATE—THE RISK OF TIP-OVER.

These distinctive product configurations are protected by US and international patents, trade

dress, and/or copyright laws. Linea & BDI are trademarks of Becker Designed, Inc. All rights

reserved. ©2021, BDI | V.08.27.2021

Made in China.

Loading...

Loading...