Page 1

STANCE® 6650/6651/6652

LIFT DESK

OWNER’S MANUAL

bdiusa.com

customerservice@bdiusa.com

Product Registration

Registering your new BDI product allows us to send you important

product updates, service information and helpful hints related to your BDI

products. Register today, and you will be entered to win free a BINK table

from BDI: www.bdiusa.com/register

Placement and Maintenance

Stance® Lift Desk is designed for indoor use on level floors. Clean glass

with glass cleaner, and steel parts and wood veneer with a damp cloth.

Your Stance® Lift Desk is engineered for easy assembly. Carefully

follow this procedure to prevent any damage. Do not use power tools

for assembly of this product.

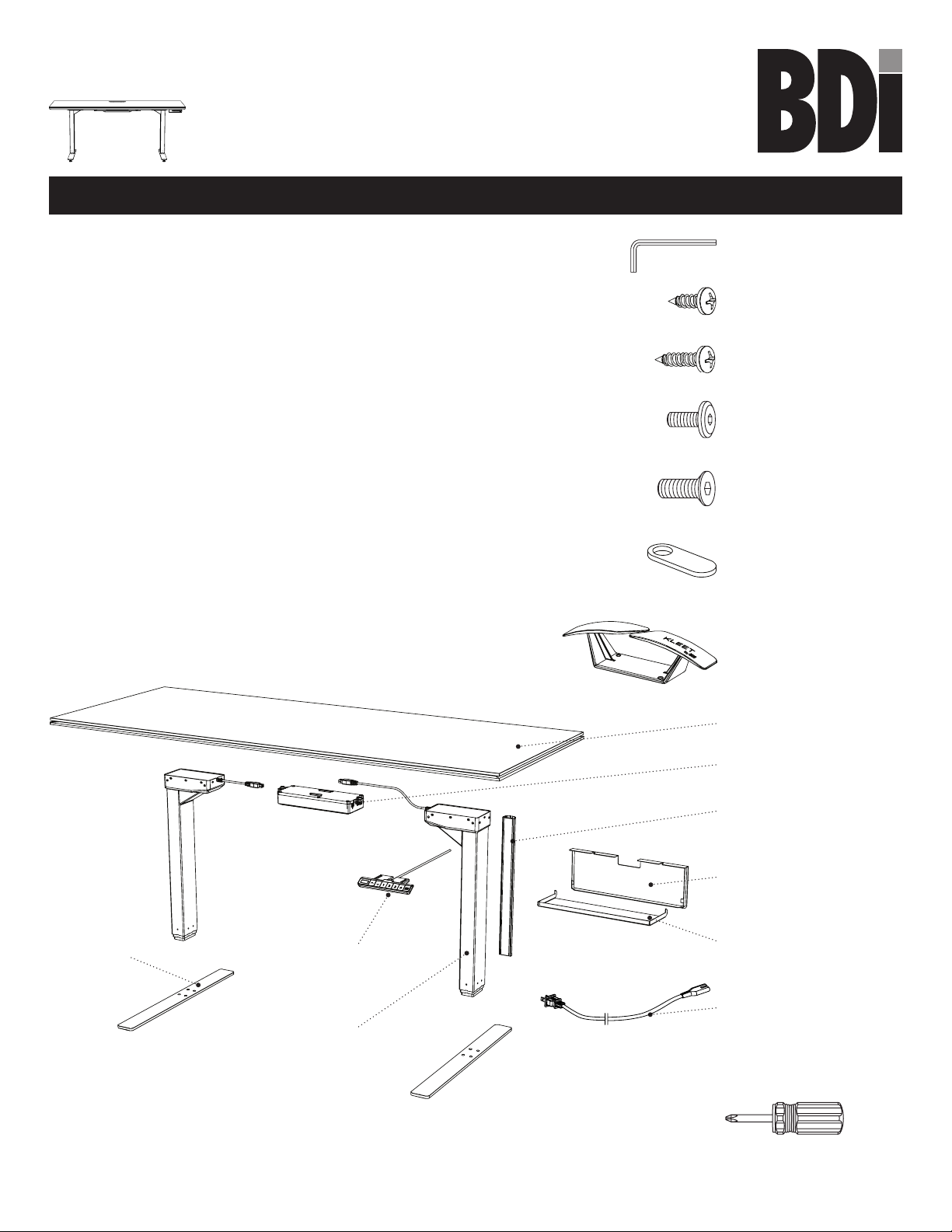

Step 1

Unpack and identify the parts listed below. The assembly workspace

should be a non-marring surface such as carpet. For missing hardware

pieces, please contact BDI Customer Service at customerservice@bdiusa.

com. For all other concerns, please contact your BDI retailer.

T1 4mm Hex Wrench

H1 Wood Screw x 12

H2 Long Wood Screw x 2

H3 M6 x 12mm Screw x 10

H4 M6 x 16mm Flathead

Screw x 8

H6 Wire Clip x 6

H8 Cord Wrap x 2

C5 Foot x 2

Designed by BDI Studio

These distinctive product configurations are protected by US and international patents, trade dress, and/or

copyright laws. Stance & BDI are trademarks of Becker Designed, Inc. All rights reserved. ©2019, BDI

Made in Turkey & China. 12.03.2019 V4

C2 Keypad x 1

C3 Leg x 2

A1 Main Panel x 1

C1 Control Module x 1

C7 Cord Conduit x 1

C8 Wire Tray Panel x 1

C9 Wire Tray Shelf x 1

C6 Power Cord x 1

Tool Required:

Phillips Screwdriver

Page 2

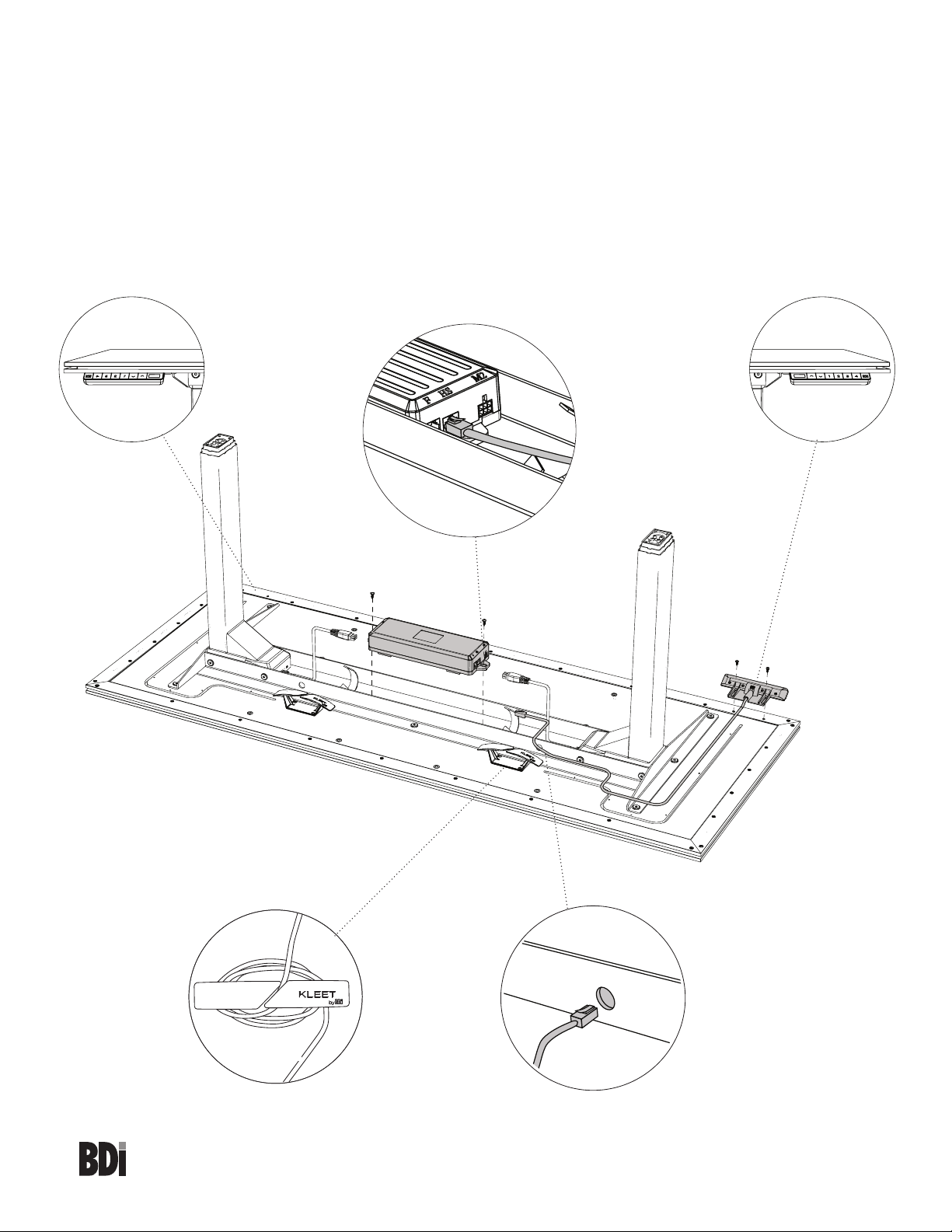

Step 2 - Lay main panel upside down on a soft surface (like carpet). Position 2 legs C3 into the corners inside

the metal frame with cords facing inward. Attach the 2 legs to the metal frame using screws H3 and tighten

with hex wrench T1. Start all screws before tightening the screws.

H3

C3

T1

H2 x 8

C3

H3

H3

Step 3 - Attach 2 cord wraps H8 using wood screws H1 going into the 2 sets of pilot holes located as

shown. Tighten with a Phillips screwdriver.

H3

H8

H1

H1

H8

H8

2

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 3

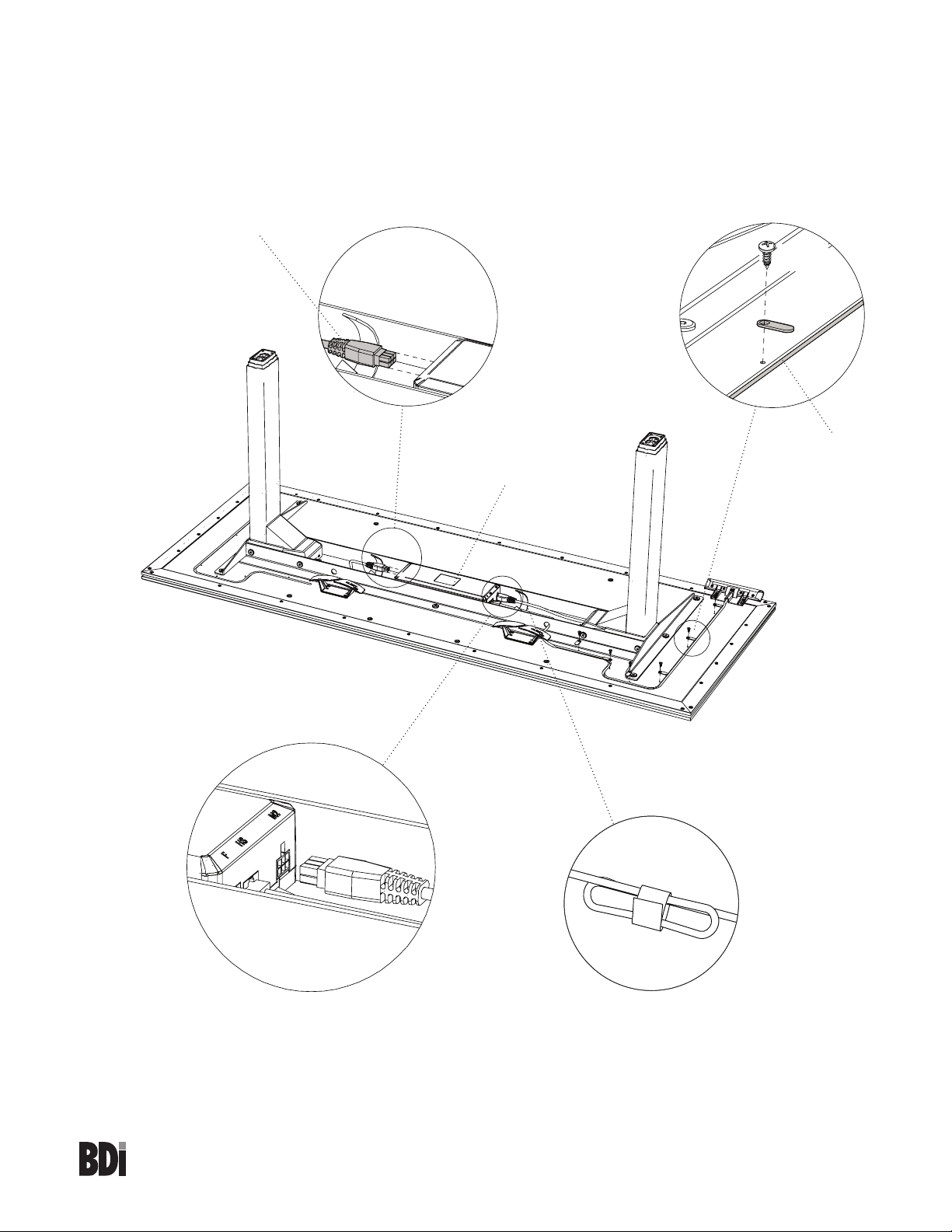

Step 4 - Attach Keypad C2 on the desired side (left or right) with 2 wood screws H1 going into pre-drilled

pilot holes. Tighten with a Phillips screwdriver.

Step 5 - Position the control module C1 so that the keypad socket (labeled HS) is facing the keypad and

secure between the 2 steel rails with 2 long wood screws H2 as shown going into the pre-drilled pilot holes.

Tighten with a Phillips screwdriver.

Step 6 - Route the keypad cord into the groove in the panel and through the hole in the metal frame. Plug the

end of the keypad cord into the HS socket on the control module C1. Use the cord wrap (Kleet) H8 to

secure loose cords.

User’s left

hand side

H2

C1

H2

H1

User’s right

hand side

H1

C2

Cord Wrap

Hole in

metal frame

3

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 4

Step 7 - Secure the keypad cord into the groove using cord clips H6 and wood screws H1.

Step 8 - Connect the leg cords into the control module sockets labeled M1 and M2. Use the hook and loop

ties provided to gather loose cords.

leg cord

H1 x 6

H6 x 6

control

module

cord inside

groove

Hook & Loop Tie

4

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 5

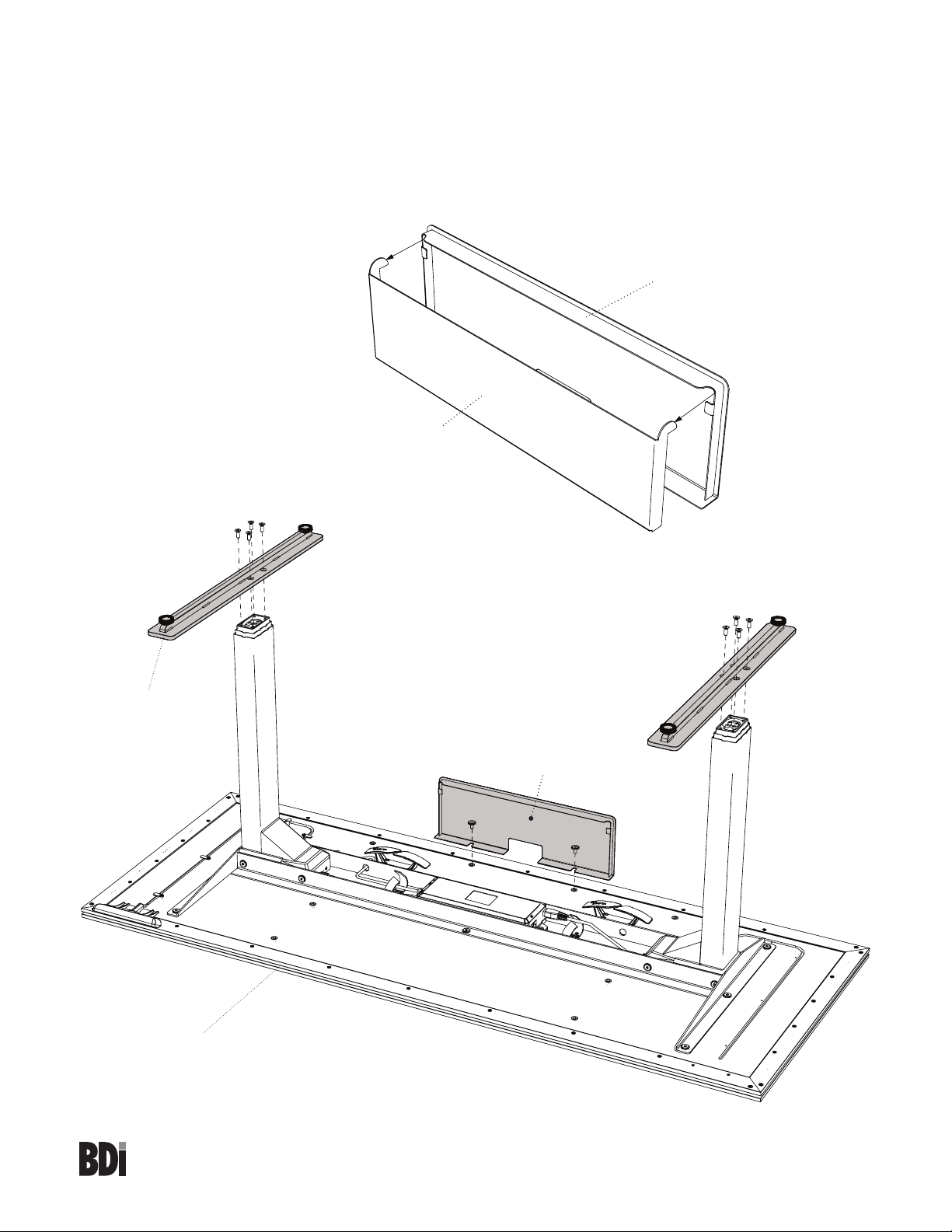

Step 9 - Making sure the long end of the foot is facing towards the front of the desk, attach each foot C5 with

flathead screws H4 and hex wrench T1.

Step 10 - Separate wire tray panel C8 from wire tray shelf C9. Note: they will only separate when rotated

to a closed position as shown. Attach wire tray panel C8 to the middle of the back edge of the desk using

screws H3 going into 2 threaded inserts. Tighten with Hex Wrench T1.

C8

wire tray

panel

C9

wire tray

shelf

C5H4 x 4

long end

forward

front edge

of desk

H3

C8

H3

H4 x 4

C5

5

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 6

Step 11 -Drawer (optional accessory)

If you did not purchase a drawer or modesty panel, proceed to step 13. Using the 4 screws and hex wrench

that came with your drawer, install the drawer as shown with front of drawer facing the front edge of the desk.

Start threading all 4 screws before tightening.

Step 12 - Modesty Panel (optional accessory)

Attach the 2 metal brackets to the modesty panel as shown with the 8 wood screws provided going into the 8

pilot holes located towards the top, inside edge of the panel. DO NOT over tighten the screws, otherwise they

will strip. DO NOT attach the modesty panel until after the desk is positioned on its feet.

6

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 7

Step 13 - Plug the Power Cord C5 into the power port (labeled AC) on the Control Module C3.

Step 14 - With the help of another person, carefully turn the desk on to its feet. Plug the other end of the

Power Cord into the nearest wall socket. Refer to the User Manual on Page 12 and follow the Reset

Procedure. You may now adjust the height of your desk.

2 Person Ta sk

7

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 8

Step 15 - Reattach wire tray shelf C9 to wire tray panel C8 and open so the shelf is flat. Use the shelf to

hold power strips or power modules and gather the excess cords using cord wraps H8.

Step 16 - Modesty Panel [continued (optional)]

Find the 2 threaded holes on either side of the metal tray. Thread screws (provided with the modesty panel)

half way into the threaded holes. Hook the modesty panel bracket notches onto the screw heads, slide

backward and then tighten the 2 screws with the hex wrench provided.

C9

2

C8

1

1) Insert screws half way

2) Slide bracket notch

backwards and onto

screw heads

3) Tighten screws with

hex wrench provided

bracket notch

8

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 9

Attach the Cord Conduit (optional)

Remove adhesive film and attach the Cord Conduit C6 to the back of the top section of the leg nearest the wall

outlet. Insert power cord(s) into the Cord Conduit.

C6

Remove excess lubricant from legs

When new, the legs may have excess lubricant. Extend the legs to their highest position and wipe off excess

lubricant with a clean, dry cloth or rag.

9

STANCE 6650/6651/6652

LIFT DESK

customerservice@bdiusa.com

bdiusa.com

Page 10

Install the Drawer liner (optional)

Open the drawer. Place the drawer liner into the drawer. Use the notches on the back of the drawer to route

cords. The front of the drawer can swing down to accommodate keyboard use.

Drawer liner

Cord management

notch

Flip down front

Adjust levelers

Levelers are integrated into each leg assembly and are accessed at the bottom of each leg. If your floor is

uneven, you may extend one or more levelers to attain a level, stable position.

10

STANCE 6650/6651/6652

LIFT DESK

Levelers

bdiusa.com

customerservice@bdiusa.com

Page 11

Attach a monitor arm (optional)

The Stance Lift Desk is compatible with most third party monitor arms. Attach your monitor arm on either side

of the metal wire tray, or on either side of the modesty panel as indicated by the arrows below.

For Model #6650, a monitor arm will not fit if the modesty panel is installed.

Caution! Do not push a metal bracket directly onto the edge of the glass. Leave a few mm (1/16”) between

the monitor arm and the edge of the glass to prevent the glass from breaking.

Do not over tighten the monitor arm.

Optional Monitor Arm

(NOT INCLUDED)

Monitor Arm Range

With wire tray only

Monitor Arm Range

With wire tray and

modesty panel installed

Wire tray

Modesty panel

11

STANCE 6650/6651/6652

LIFT DESK

bdiusa.com

customerservice@bdiusa.com

Page 12

User Manual

Caution!

• Make sure there are no obstacles under or over the path of the desk.

• Make sure the desk top is not touching any walls.

• Make sure all the cords are long enough to reach lowest and highest desk positions.

!

!

Important:

• You must reset the desk prior to use.

Reset Procedure:

1. Press and hold the DOWN button on the keypad until the desk reaches its lowest height.

2. Release the DOWN button.

3. Press and hold the DOWN button again until the LED sidplay reads “RST”.

4. Release the DOWN button.

5. Press and hold the DOWN button again until the desk lowers a little bit more, slightly rises and stops.

6. Release the DOWN button. Your desk is now ready for use.

“Reset”

looks like this

UP Down Memory

12

STANCE 6650/6651/6652

LIFT DESK

bdiusa.com

customerservice@bdiusa.com

Page 13

Height Adjustment

The desk base can be adjusted by pressing and holding either the UP or DOWN button until the desired

height is reached.

To program up to four presets, use the up/down buttons to find a desired height, then press “BDI” followed

by a number 1-4. To Change the Movement Program (explained below) follow the Reset Procedure to

step 4. The display should be flashing “RST”. Press and hold the “1” button (about 5 seconds) until the

display flashes “10.1” or “10.2”. You can press and hold the “1” button again to switch to the other setting.

Once the chosen setting is selected finish the Reset Procedure steps 5 and 6.

One Touch (Default) - 10.1:

Once a preset button is pushed, the desk will move to the programmed height. To stop movement, press any

number on the keypad.

Constant Touch - 10.2:

A preset button must remain pressed for the desk to move to the programmed height. To stop movement,

release the button.

Trouble Shooting

If your desk is not functioning properly it may need to be reset. Follow the RESET procedure above.

If your LED readout displays an error message Er1 confirm that all wired connections are secure. Then

perform the reset procedure above.

Keypad Lock

To lock the keypad:

Press and hold the “BDI” button for about 8 seconds until the LED display reads “LOC”. The keypad is now

locked and cannot be used to move the desk.

To unlock the keypad:

Press and hold the “BDI” button for about 8 seconds until the LED display switches from “LOC” to the height

display. The keypad is now unlocked and can be used as normal.

Height Display: Inches or Centimeters

To change unit of height measurements (inches or centimeters) follow the Reset Procedure to step 4. The

display should be flashing “RST”. Press and hold the “2” button (about 5 seconds) until the display flashes

“10.3” or “10.4”. You can press and hold the “2” button again to switch to the other setting. Once the chosen

setting is selected, finish the Reset Procedure steps 5 and 6.

Centimeters - 10.3

Inches (Default) - 10.4

13

STANCE 6650/6651/6652

LIFT DESK

bdiusa.com

customerservice@bdiusa.com

Page 14

Setting the Upper and Lower Limits

The base is designed to go to its minimum and maximum heights, allowing for the widest possible range. If you

prefer to change the settings to a more narrow range, follow these steps:

To set the Lower-limit position:

Use the UP/DOWN buttons to move the base to the desired minimum height position. Press and release the

“BDI” button and the LED display should read “S”. Next, press and release the DOWN button. Now, press

and hold the “BDI” button (for about 2 seconds) until the LED display changes to “000” and then automatically

returns to show the selected height. The new lower limit is now set.

To set the Upper-limit position:

Use the UP/DOWN buttons to move the base to the desired maximum height position. Press and release the

“BDI” button and the LED display should read “S”. Next, press and release the UP button. Now, press and

hold the “BDI” button (for about 2 seconds) until the LED display changes to 999 and then automatically returns

to show the selected height. The new upper limit is now set.

Note:

• You can set just the upper limit or just the lower limit or both.

• After the upper and lower limits are set, the previous memory positions (1,2,3,4) may be outside the new

range of movement. If so, simply reset the momory positions.

• If you attempt to revise a previously set upper or lower limit and it is outside of the existing range, you will

need to remove the previously set upper/lower limits first.

A Reset Procedure requires the desk to be fully lowered (beyond any lower limit set). Please ensure that you

have the proper clearance below the desk!

To remove the upper/lower limit positions:

Press and release the “BDI” button and the LED display should read “S”. Within 5 seconds, press and hold the

“BDI” button until the display flashes “555”. The upper and lower limits are now removed.

Technical Specifications

Height Range 24.75”–49.75” (63–126 cm)

Travel Speed 1.5" per second

Weight Capacity 150 lbs (68 kg)

Duty Cycle 10%, Max 2 minutes with 18 minutes off

Memory 4 position presets

Monitor Arm Compatible Yes

14

STANCE 6650/6651/6652

LIFT DESK

bdiusa.com

customerservice@bdiusa.com

Page 15

Trouble Shooting

If your desk is not functioning properly it may need to be reset. Follow the RESET procedure above.

If your LED readout displays an error message Er1 confirm that all wired connections are secure. Then

perform the reset procedure above.

15

STANCE 6650/6651/6652

LIFT DESK

bdiusa.com

customerservice@bdiusa.com

Loading...

Loading...