BD Diesel Performance X-monitor 2 Installation Manual

19 November 2008 BD X-Monitor 2 # 1080500 1

B

D

B

D

Digital Gauge Monitoring Package

*** READ THIS MANUAL & DISCLAIMER COMPLETELY BEFORE INSTALLING THIS PR ODUCT ***

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

X--

X

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

M

M

Installation Instructions

P/N#

Installation Manual P/N#: I1080500

O

O

BD Engine Brake Inc

N

N

1080500

I

I

T

T

O

O

R

R

2

2

19 November 2008 BD X-Monitor 2 # 1080500 2

TABLE OF CONTENTS

Accessories......................................................................................................................4

Pillar Mounts.............................................................................................................4

Others.......................................................................................................................4

Tools Needed....................................................................................................................4

Pre-Installation.................................................................................................................4

Installation........................................................................................................................5

Thermocouple Installation ..............................................................................................6

Vehicle Specific Placement.......................................................................................6

Dodge 1998-2006............................................................................................6

Ford 1999-2006...............................................................................................6

GM 2001-2006.................................................................................................7

Generic Installation of the Thermocouple.................................................................7

Pre-Turbo Installation ......................................................................................7

Post-Turbo Installation.....................................................................................8

Wiring Installation............................................................................................................8

Dodge 1998-2002 5.9L.............................................................................................8

Dodge 2003-2006 5.9L...........................................................................................12

Optional Ram Xpower Control #1800505...............................................................15

X-Power Control Wiring Diagram...................................................................16

Optional Ram Fuel Pressure Monitoring Kit #1080150...........................................17

Rail Pressure Sensor (3rd Gen Dodge Only 2003-06) ...................................17

Auxiliary Fuel Pressure..................................................................................17

Wiring Diagram (Fuel Pressure)....................................................................18

Ford 1999-2003 7.3L ..............................................................................................19

Ford 2003-2006 6.0L ..............................................................................................22

Duramax 2001-06...................................................................................................25

Universal Wiring Diagram .............................................................................................28

Display Functions..........................................................................................................29

Main Menu..............................................................................................................29

Display Menu.................................................................................................30

Alerts Menu....................................................................................................30

Defueling Settings ................................................................................30

Warnings..............................................................................................31

Setup .............................................................................................................31

Backlight...............................................................................................33

Technical Support..........................................................................................................33

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 3

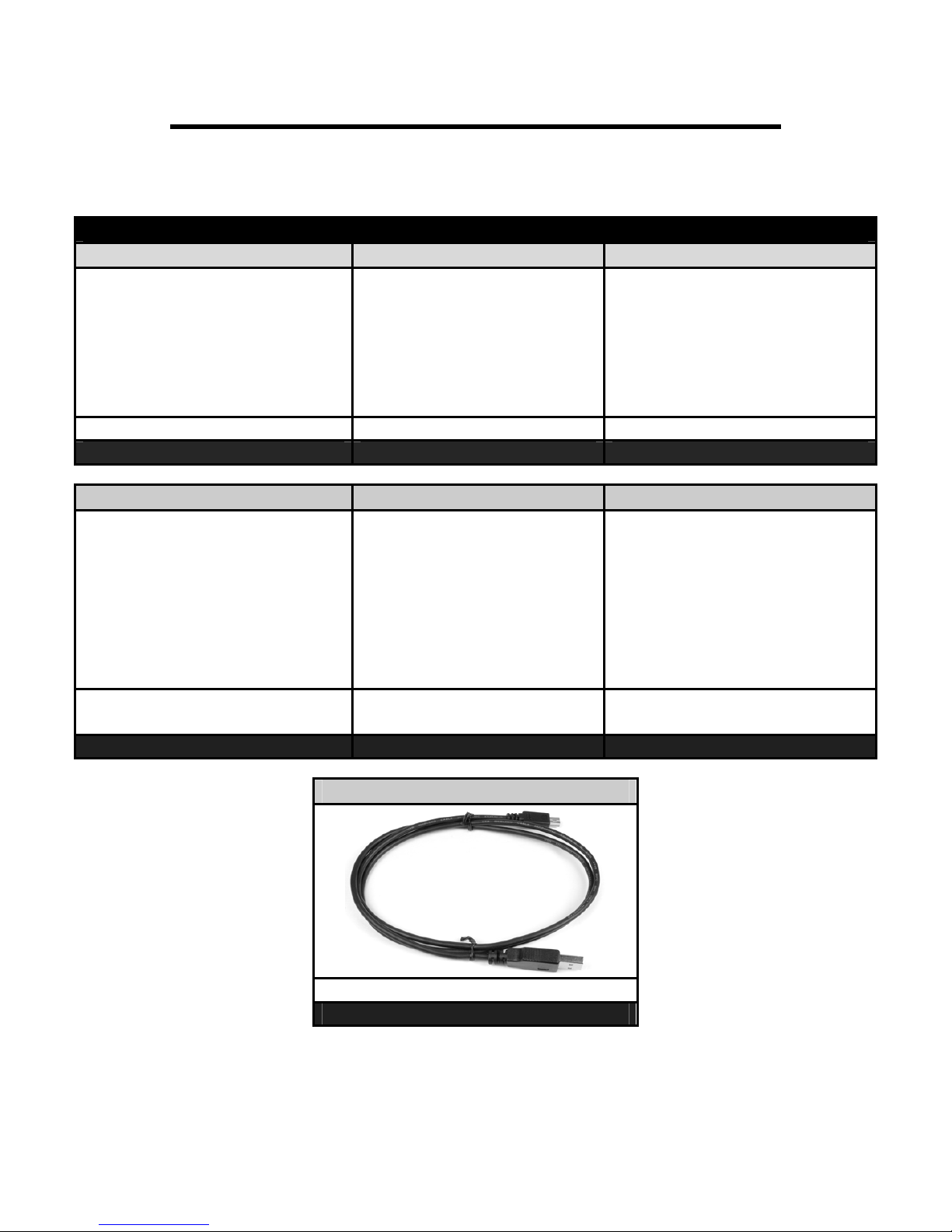

KIT CONTENTS:

Please check to make sure that you have all the parts listed in this kit before you start

the disassembly your truck.

1080500 – BD X2 Monitor

1805000 1800508 1800502

X2 Monitor Assembly

Qty: 1 Qty: 1 Qty: 3

Monitor Holder

Thermocouple w/ Harness

1800503 1800504 1800506

Sensor Fitting Adapters

Qty: 3 Qty: 1 Qty: 1

Main Harness

(includes oil sensor)

X2 Installation Care Kit

1800507

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

USB Cable (for internet updates)

Qty: 1

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 4

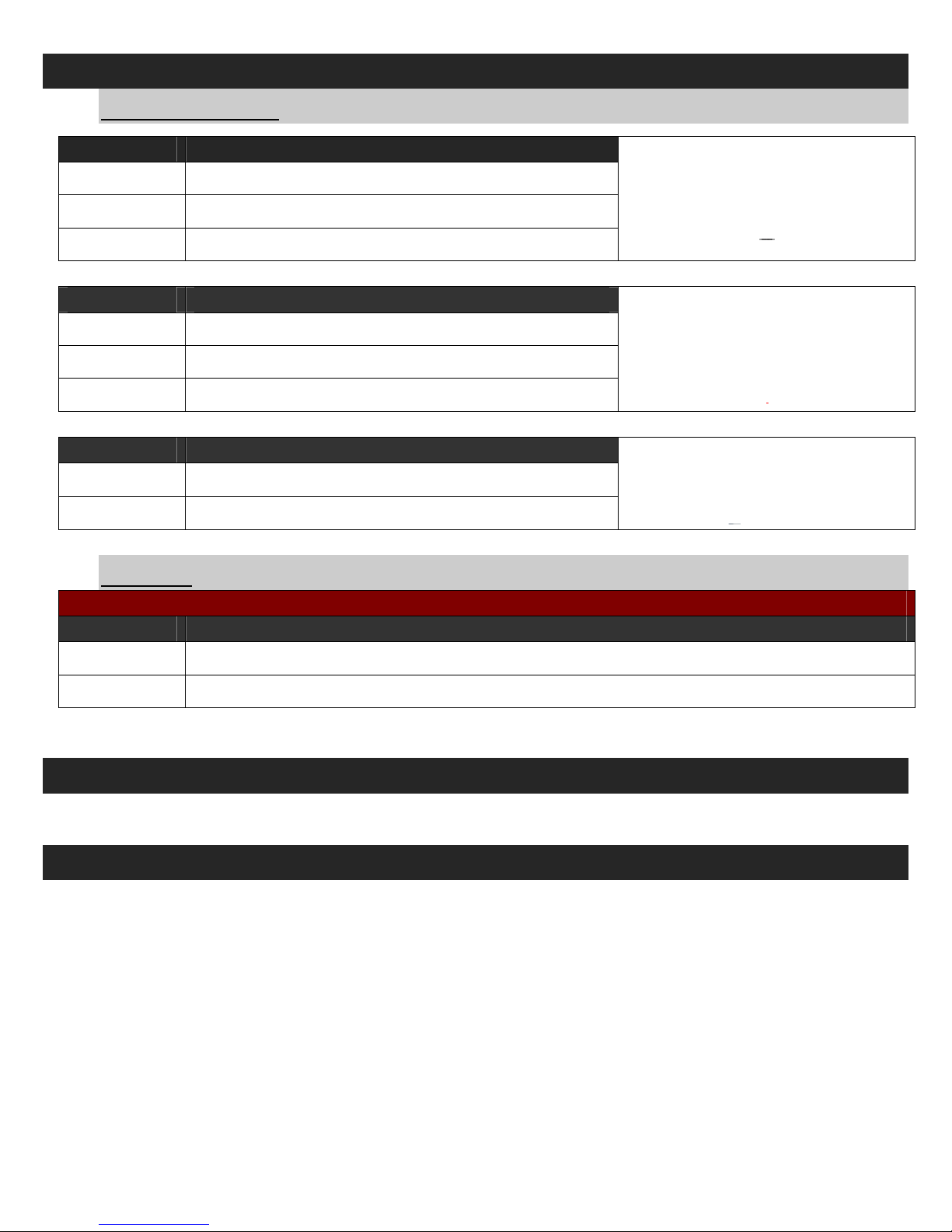

Accessories

Pillar Mounts

P/N# Application

1080570

1080571

1080572

P/N# Application

1080551

1080553

1080552

P/N# Application

1080560

1080561

Powerstroke 1999-2002 7.3L

Powerstroke 2003-2007 6.0L

Powerstroke 2007-2008 6.4L

Cummins 1998½-2002 24V w/ Speaker

Cummins 1998½-2002 24V w/o Speaker

Cummins 2003-2007 24V HPCR

Duramax 6.6L 2001-2007 w/o Speaker

Duramax 6.6L 2001-2007 w/ Speaker

Others

Fuel Pressure Monitoring Kit

P/N# Application

1080150

1800505

All

Ram Xpower Control

Tools Needed

Power Drill, 21/64” Drill Bit, 1/8” NPT Tap, Teflon Tape

Pre-Installation

The BD X2 Monitor is a powerful monitor that has the ability to monitor up to 7 engine

parameters, with up to 4 displaying at a time. However, the X2 still monitors up to all 7

parameters simultaneously with the option to set warnings for up to 6 parameters. Defueling options are available based upon 4 of these parameters. While monitoring these

parameters, the X2 also records the highest/lowest value of all parameters being

monitored. In addition to recording the min/max readings you also have the ability to data

log these parameters. The X2 also has the ability to control multiple power modules.

There are many more features to the X2 which will be explained in detail further on in the

manual.

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 5

Installation

Choose a location in your vehicle where you want to mount the X2. It is important to do a

test fitting to make sure that is plainly visible while driving, but not an obstruction of your

driving view. We recommend beside the A-Pillar on the driver’s side. The rest of these

instructions assume that you chose this location. If you choose a different location, you

may have to use different techniques to route the cable harness under the dash.

Loosen or remove the A-Pillar. You need the pillar to be loose enough to route the

connectors down the pillar and beside the dash. The ultimate goal is to get the 3

connectors on the end of the cable harness under the dash and below the steering

wheel. Most A-Pillars have plenty of room to route the cable and still install the A-Pillar

back in the factory position without any modifications. It is okay for the pillar to be tight

against the cable as long as it doesn’t have enough pressure to damage the harness.

Once the cable is routed, pull any slack down

under the dash, but leave enough room to stand

the X2 up in the mounted position.

Clip the assembled base onto the X2. Hold the

X2 with the base i

ntact in the posit

to mount it. Make sure the viewing angle is

correct for the location. If the base needs to be

adjusted, you may do so by using a #2 Phillips

head screwdriver. Simply loosen the 2 screws

holding the base onto the adjustable disk. Do not

remove the screws completely; just loosen them

enough to move the X2’s position. Once you

have your desired angle, tighten the screws.

There are two ways to secure the base to your dash. You may permanently mount it with

the 2 supplied screws or you can use the supplied double sided 3M Tape. This tape is

strong enough to hold your gauge in position and is also removable.

If Using Screws: Holding the X2 in place, carefully mark a spot on the dash on both sides

of the disk where the screw slots are located. Carefully drill a 1/8” hole in these spots for

a pilot hole. You want to make sure to try and drill in the center of the provided slots so

that you leave some room for adjustment. Holding the gauge back into place, carefully

install the screws into the pilot holes. Although the dashes are fairly thick it is important to

not over tighten the screws and strip the plastic material.

If Using Tape: Clean the desired mounting area and the bottom of the mount with the

provided alcohol wipe. Apply the double sided tape to the bottom of the mount. It is best

ion you want

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 6

to only peel one side of the tape protector off at a time. Once you are ready to mount it,

carefully stick it to the dash. Once it is in its desired location, press down firmly onto the

dash. It is best to apply pressure on all parts of the base that has the tape on so it takes a

good hold.

Thermocouple Installation

Vehicle Specific Placement

Please review the recommended positioning for the thermocouple for your specific

vehicle.

Dodge 1998-2006

On the passenger side of the

vehicle locate the exhaust

manifold. On the top side of the

manifold between cylinders #2

and #3 is the ideal location for the

thermocouple.

Ford 1999-2006

On the driver’s side of the

vehicle, locate the exhaust

manifold. You will need to drill

from underneath the vehicle. The

ideal location for the

thermocouple is located just as

the manifold turns up to the turbo

inlet pipe. Make certain that you

drill at an angle that will accept

the length of the thermocouple.

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 7

GM 2001-2006

Remove the passenger side

fender well. Once this is removed,

you will see the exhaust manifold.

Towards the rear of the manifold

there is a flange that the manifold

bolts to. Just in front of this flange

is the ideal place to drill for the

thermocouple.

Generic Installation of the Thermocouple

This section provides instructions for the generic installation of the thermocouple.

Pre-Turbo Installation

You must drill a 21/64 hole in your exhaust manifold. There are 2 ways to do this – the

best way is the way that makes you most comfortable. You can remove the manifold to

do this or you can do it on the vehicle while the engine is idling. It is also desirable to drill

a 1/8” pilot hole. Leaving the engine idling will allow any small shavings to safely exit the

exhaust. It is recommended to apply a small amount of grease to the drill bit before

drilling.

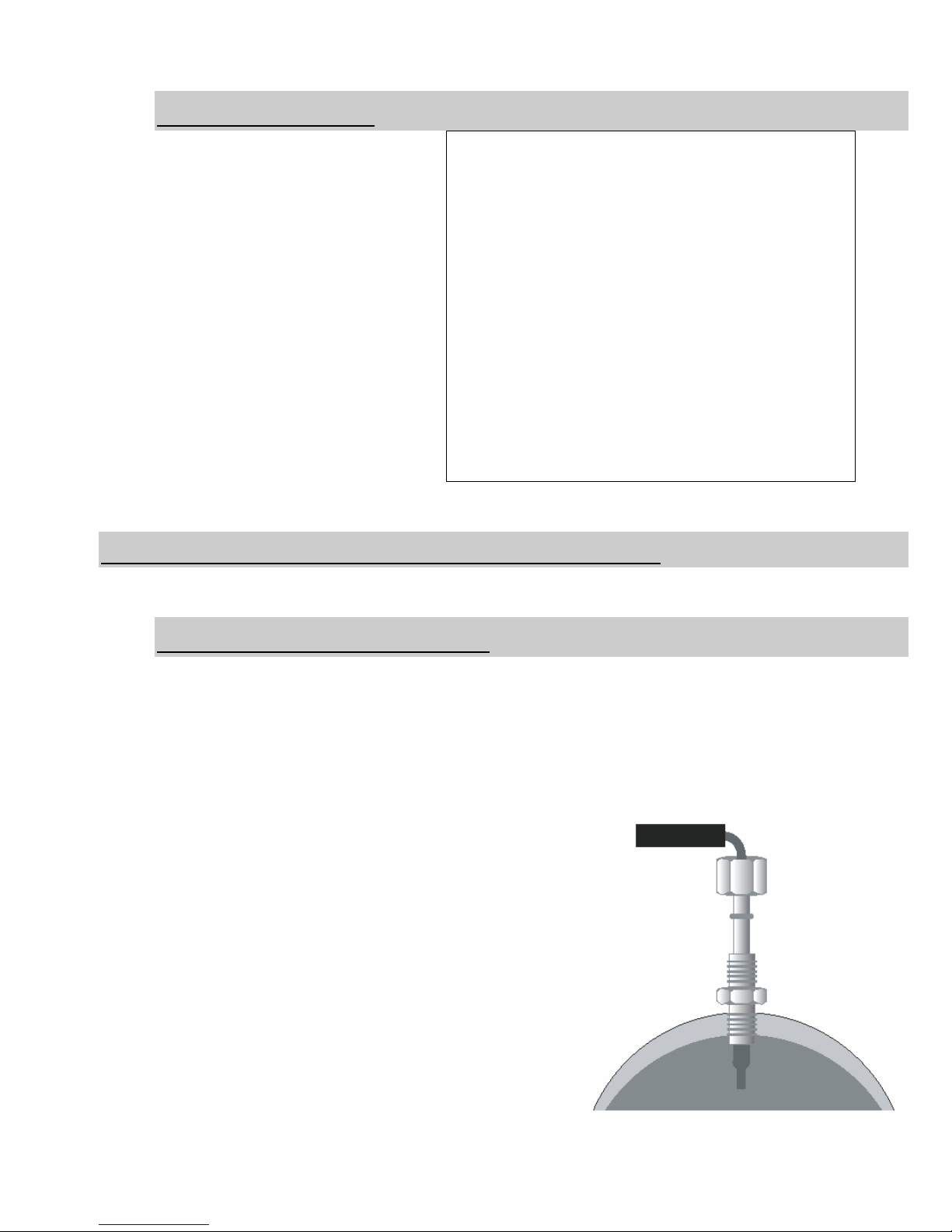

Use a 1/8-27 or 1/8NPT tap to make threads in the

hole you just drilled. You will not want to run the tap all

the way into the manifold. This is a tapered tap so the

threads at the top are larger than the ones on the

bottom. You need to tape it far enough to screw the

thermocouple bushing into the manifold.

Screw the thermocouple bushing into the manifold. Be

careful not to over tighten it.

Insert the supplied thermocouple into the bushing and

tighten the locking nut.

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 8

Post-Turbo Installation

Drill a 21/64 hole into your turbo down pipe. There is no need for the engine to idle or to

remove the exhaust piece from the truck. The metal shavings will simply exit the exhaust

system when you run the engine.

Use a 1/8-27 or 1/8NPT tap to make threads in the hole you just drilled. You will not want

to run the tap all the way into the manifold. This is a tapered tap, meaning that the

threads at the top are larger than the ones on the bottom. You need to tap it far enough

to screw the thermocouple bushing into the exhaust pipe.

Screw the thermocouple bushing into the pipe. Be careful not to over tighten because it is

easy to strip the threads in the thin exhaust pipe.

Insert the supplied thermocouple into the bushing and tighten the locking nut.

Wiring Installation

Dodge 1998-2002 5.9L

1. Find the lead wire. This is a 2-wire harness with an orange and black wire. The

larger connector needs to be connected to the thermocouple.

2. Route the lead wire across the engine bay to the driver’s side. Tie the lead wire out

of the way of any moving or hot parts to avoid damage to the wires.

3. On the driver’s side firewall there is a rubber plug. Cut a slit in the outer portion of

the plug to route the small connector and wire into the cab.

4. Plug the small 2-wire plug into the corresponding plug on the cable harness.

5. Lay wiring harness #1 out on your engine. The green plug will go inside the cabin

using the same location you routed the lead wire through.

6. Locate the engine’s MAP sensor. This is on the driver’s side of the engine and

behind the fuel filter canister. The year model determines the shape of the

connector.

a. For 1998-2000 trucks, the MAP sensor is round (triangle). There are 2 wires

in the top of the plug and 1 wire in the bottom of the plug. Connect the

supplied T-Tap to the wire that is on the bottom of the plug. This should also

be labeled pin “C” on the connector.

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 9

b. For 2001 trucks, the

MAP sensor is an

oval shape. It also

has 3 wires. Connect

the supplied wire tap

to pin “C” on the

plug. To locate pin C,

look at the back of

the plug where the

wires go into the plug

and the retaining clip

is on top, pin “C” is

on the right side.

c. For 2002 trucks, the MAP sensor is also an oval shape, but it also has a

plastic red lock that you m

ust remove to remove the sensor. It also has 3

wires. Connect the supplied T-Tap to the wire that is in the center of the plug.

If you have a power module installed,

you will need to connect to the same

wire on the module’s wiring harness to

receive an accurate reading. Only tap

the wire of the plug that is going into

the sensor. Do not tap the wire on the

factory plug when you are using a

power module. This will result in a

false reading.

7. Connect the blue wire to the TTap.

8.

Locate the Engine Coolant Temperature Sensor (ECT) on the front of the engine.

This is a 2-wire connector located on the top of the engine, in front of the valve

cover.

9. Connect the orange wire to the T-Tap.

10. Find the 1/8” male x ¼” female and the ¼” male x 1/8” female brass fittings supplied

in the kit.

11. Screw the ¼” male end of the brass fitting into the ¼” female fitting. Use Teflon tape

to make sure that it will not leak.

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

19 November 2008 BD X-Monitor 2 # 1080500 10

12. Screw the supplied 1/8” temperature sensor into the 1/8” female side of the brass

connector.

13. Locate test port #2 on your transmission.

This port is on the passenger side of the

vehicle. The transmission is round on the

front passenger side corner. Moving

towards the rear of the transmission you

will see an inset part of the transmission.

There is a small plug in the test port.

Remove the plug.

14. Using Teflon tape, screw the temperature

probe and fittings into the test port. Do

not over tighten.

Route the purple wire from the wiring harness to the temperature sensor.

15.

16. Remove the nut and washers from the sensor and install the purple wire. Replace

the washers and tighten the nut to secure the wire.

17. Go over the wiring harness and secure it to the vehicle, out of harms way using the

supplied wire ties. Keep all wires as far away from moving parts and hot parts of the

engine as possible.

18. Slide the green plug through the rubber grommet where you ran the lead wire. Pull

enough of the wire harness inside the cab so that the switch port connection (white

and black wires) and the black wire with the ring terminal and the red wire with the

fuse tap are inside the cab.

19. Find the bolt located by the firewall and remove it. Place the bolt through the ring

terminal of the black wire and screw it back into its location.

20. Open the fuse box, located on the inside of the truck on the driver’s side of the

dash. You will be required to open the driver’s side door to access the fuse

compartment.

21. Remove fuse #17 and install the fuse tap over the leg of the fuse. Re-install the

fuse.

22. Once everything is secure and installed, you will want to start your engine. The X2

comes pre-set for these 4 parameters. To make sure everything is installed

correctly, use these basic guidelines:

BD Engine Brake Inc

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

19 November 2008 BD X-Monitor 2 # 1080500 11

EGT temperatures should be in the 250-350°F (120-175°C) ranges, depending on

engine temperature and outside temperature. Boost pressure should read 0psi at

idle and up to 5psi while revving the engine at the idle position. ECT should be

similar to your factory gauge. If the vehicle is cold, it should read close to ambient

temperature and slowly rise.

Transmission temperature will most likely read ~100°F (35°C). It can take up to 20

miles, depending on the outside temperature, driving style and load to reach

temperatures above 100°F (35°C). Operating temperatures range from 110-180°F

(40-80°C) dependant upon load and driving style.

23. Using the supplied wire ties, tie up the wire and cable harness under the dash.

A10 – 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

Ship: #88 – 446 Harrison St, Sumas, WA 98295 Mail: PO Box 231, Sumas, WA 98295

Ph: 604.853.6096 Fax: 604.853.8749 Internet: www.bd-power.com

BD Engine Brake Inc

Loading...

Loading...