B.David Company

9333

World Health Through Water Purication Systems

INSTALLATION AND OPERATING INSTRUCTION MANUAL

RS-90 RC-93 RP-100

Nanotechnology Under Counter Water Purification System

FOR SYSTEMS, FILTERS & SERVICE t: 952.884.8417 e: info@bdavidwater.com w: bdavidwater.com

Rev: 12/01/2015

B.David Company

9333

World Health Through Water Purication Systems

Important – Set Eective Life

Indicator to 1000 Gallons

PECIFICATIONS:

S

Pressure Range: 2.1-8.62 bar (20-115 psi)

Temperature Range: 4.4-38.8°C (40-102°F)

Service Flow Rate @60 psi (4.1 bar): 2.3 lpm at 4.1 bar 0.6 gpm

Rated Service Life: 3,785 L (1000 gallons)

Dimensions: 394 mm x 133 mm x 356 mm (15.5 in. x 5.25 in. x 14 in.)

Weight (lled with water): 8.6 kg (19 lbs.)

Nanotechnology Under Counter Water Purification System

B.David

Specic Filter

Placement

RS-90 RC-93 RP-100

FOR SYSTEMS, FILTERS & SERVICE t: 952.884.8417 e: info@bdavidwater.com w: bdavidwater.com

PARTS INCLUDED:

Filter system with lter cartridges

•

Installation hardware (mounting screws, saddle valve, ttings)

•

6.35 mm (1/4-inch) tubing

•

Lead-free faucet

•

Tools and Materials Required:

Safety Glasses

•

Hand or electric drill

•

(cordless recommended)

File

•

Phillips head screwdriver

•

2 adjustable wrenches

•

Tube cutters or utility knife

•

If sink does not have hole for separate faucet:

Center punch – 19mm (3/4-inch) drill bit

•

PRECAUTIONS:

Protect lters against freezing, which can cause cracking of the lter and water leakage.

•

The rubber O-ring provides the water-tight seal between the cap and the bottom of the housing.

•

It is important that the O-ring be properly seated in the groove below the threads of the housing or a

water leak could occur.

To prevent costly repairs or possible water damage, the sump of plastic housings must be replaced

•

every ve years for clear, and ten years for opaque. If sump is older than recommended, replace

immediately. Date sump for reference and indicate replacement date.

NOTE:

For cold water use only.

•

Make certain that installation complies with all local laws and regulations.

•

After prolonged periods of non-use (such as during a vacation) it is recommended that the system be

•

ushed thoroughly. Let water run for 5-6 minutes before using.

The lter cartridges used with this system have a limited service life. Changes in taste, odor, and/or

•

ow of the water being ltered indicate that the cartridges should be replaced.

9333 Nanotechnology Under Counter Water Purification System 2

INSTALLATION

For standard under-sink installation on 10 mm (3/8-inch) cold water line.

•

Please read all instructions and precautions before installing and using your ltration System.

•

Numbered diagrams correspond with numbered steps.

•

1. Installing the Saddle Valve (diagram 1)

Use of a hand drill is recommended. To protect

yourself from serious injury or fatal shock when

using an electric drill, be sure the drill and the out-

let it is plugged into are properly grounded. When

using a drill, follow the manufacturer’s guidelines

and procedures.

NOTE: Saddle valve must be installed on a 51 mm

(2-inch) long, straight-walled section of 10-22 mm

(3/8-inch to 7/8-inch) steel, brass, copper, or

PVC pipe.

(A) Turn o cold water supply and turn on nearest

faucet before starting installation. Place a tray or

towels under the cold water line to catch excess

water.

(B) Drill a 3 mm (1/8-inch) hole in cold water line.

Remove any burrs with sandpaper or le.

(C) Turn handle on the saddle valve to expose

lance no more than 5 mm (3/16-inch) beyond

black rubber gasket.

(D) Place valve body over hole in cold water line

so lance ts into hole.

(E) Attach back plate of clamp and tighten bolts

evenly and rmly so brackets are parallel.

(F) Turn valve handle clockwise to closed position

and leave closed until installation is complete.

2. Selecting the Faucet Location (diagram 2)

NOTE: The drinking water faucet should be posi-

tioned with function, convenience, and appear-

ance in mind. An adequate at area is required

to allow faucet base to rest securely. The faucet

ts through a 19mm (3/4-inch) hole. Most sinks

have pre-drilled 35 or 38mm (1-inch) diameter

holes that may be used for faucet. If installation of

these pre-drilled holes cannot be used or are in an

inconvenient location, it will be necessary to drill a

19mm (3/4-inch) hole in the sink to accommodate

the faucet.

9333 Nanotechnology Under Counter Water Purification System 3

DO NOT ATTEMPT TO DRILL THROUGH AN ALL-

PORCELAIN SINK. If you have an all-porcelain sink,

mount the faucet in pre-drilled sprayer hole or drill through

countertop next to sink.

When drilling through a countertop make sure the

area below the drilled area is free of wiring and piping.

Make certain there is ample room to make the proper con-

nections to the bottom of the faucet. Do not drill through a

countertop that is more than 25mm (1-inch) thick.

DO NOT ATTEMPT to drill through a tiled, marble,

granite or similar countertop. Consult a plumber or the

countertop manufacturer for advice or assistance.

(A) Line bottom of sink with newspaper to prevent metal

shavings, parts, or tools from falling down drain.

(B) Place masking tape over the area to be drilled to pre-

vent scratches if drill bit slips.

(C) Mark hole with center punch. Use a 6mm (l/4-inch)

drill bit for a pilot hole, then, using a 13mm (3/4- inch) drill

bit or hole saw, drill a hole completely through the sink.

Smooth rough edges with a le.

3. Mounting the Faucet (diagram 3)

(A) Remove wing nut (C) and metal washer (B) from the

threaded shaft of the faucet. Leave the black rubber

washer (A) on the threaded shaft.

(B) Slide the threaded shaft of the faucet into drilled hole.

(C) From under the sink, slide the metal washer on and

thread on the wing nut. Tighten wing nut by hand until

tight. It may be necessary to have a second person hold

the faucet while tightening the wing nut.

NOTE: Do not over tighten the wing nut. Hand tighten

only. Do not use pliers or wrench to tighten.

4. Mounting the System (diagram 4)

(A) Center system between water supply adapter and

drinking water faucet.

NOTE: Allow 38 mm (1.5 inches) clearance below system

to enable lter cartridge changes.

(B) Install mounting screws at least 380 mm (15-inches)

from cabinet oor and 235 mm (9 1/4 inches) apart. Leave

enough space [approximately 13 mm (l/2-inch) between

the head of the screw and the wall to slip system onto

screws.

(C) Place system over screws on wall and slide sideways.

Tighten screws.

9333 Nanotechnology Under Counter Water Purification System 4

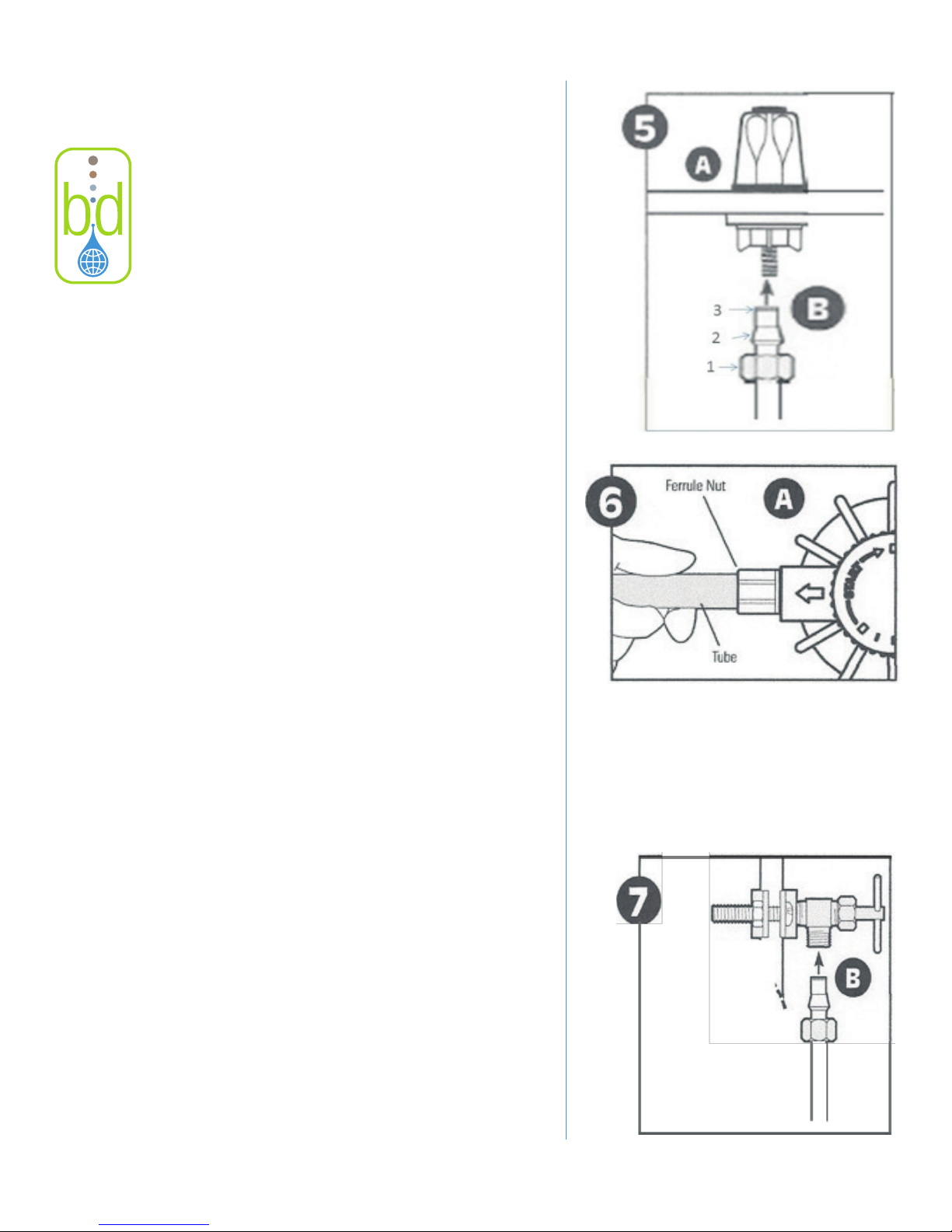

5. Connecting the Faucet (diagram 5)

CAUTION: Do not over-tighten compression nut. Use

caution not to bend or crimp tubes when securing.

(A) Locate compression nuts in installation kit and fau-

cet package.

(B) Attach compression nuts to faucet stem and Eec-

tive Life Indicator (ELI) and hand tighten. Then loosen

compression nut one full turn.

NOTE: If the compression nut should come apart, refer-

ence diagram 5A for correct reassembly.

6. Attaching Tube (diagram 6)

(A) Attach tube to compression nut on faucet stem by

inserting tube into the compression nut opening. Gently

push the tubing until it comes to a stop.

CAUTION: Tube must be fully inserted in the compress

on tting base to the tube stop on the faucet stem and

on the outlet stem of the ELI.

(B) Turn the nut hand tight.

(C) Wrench tighten the nut 1 ½ to 2 turns.

NOTE: All nuts must be retightened when the system

reaches projected operating temperature.

NOTE: A squeaking sound when tightening the nut is

normal. If ttings are removed, Teon® tape must be

used for pipe threaded connections.

NOTE: Compression nut should come preassembled

with ferrules inside. If nut should come apart,

see gure 5A for proper reassembly.

(D) Determine the length of tubing needed from the fau-

cet to the ELI and cut the tubing. A slight sag in the lines

will allow for some ease in installation. Insert the tubing

into the compression nut on the ELI. Repeat steps 6B

and 6C.

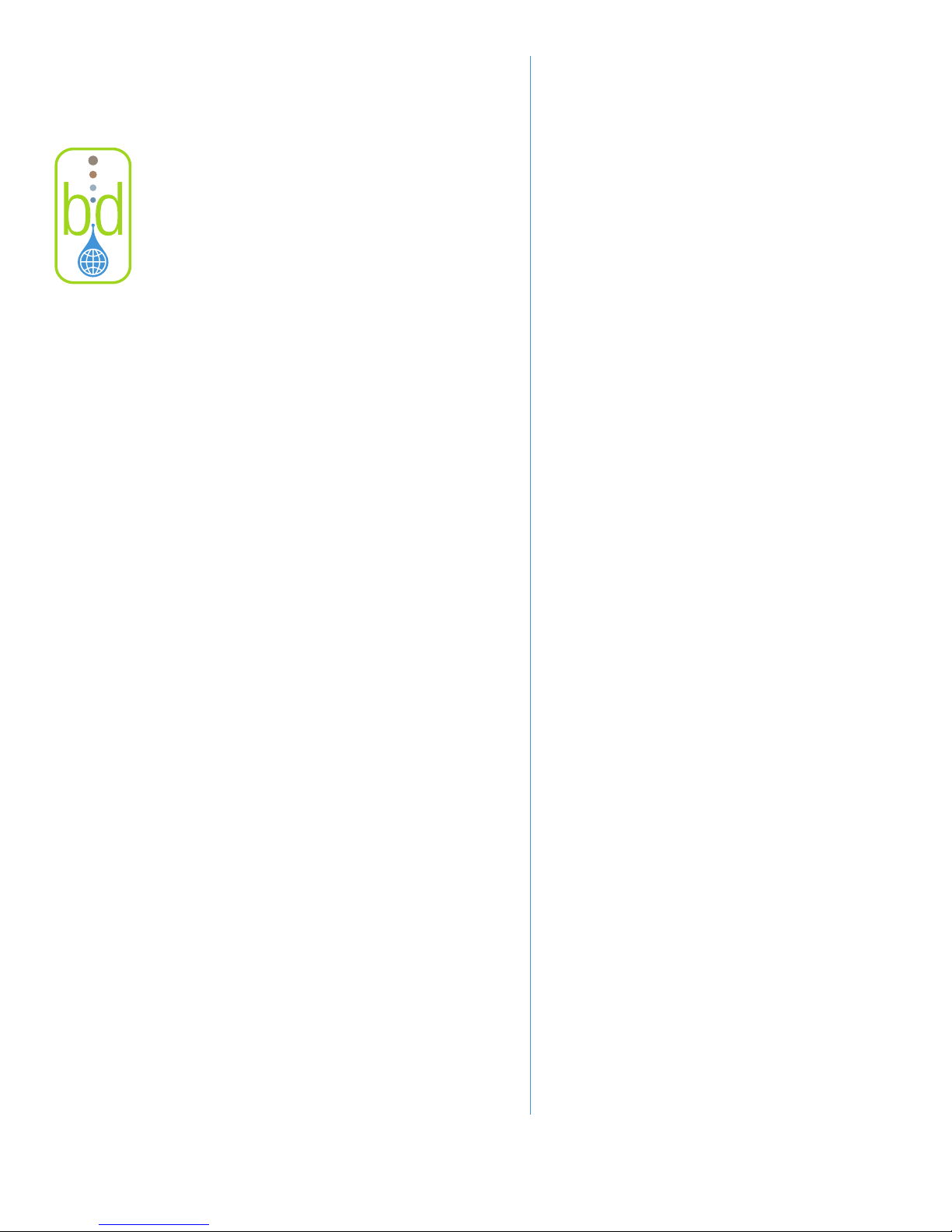

7. Connecting the Saddle Valve (diagram 7)

(A) Determine the length of plastic tubing needed to

connect the inlet (left) side of the lter with the saddle

valve. Be sure to allow enough tubing to prevent kinking

and cut the tubing squarely. Slide brass compression

nut onto tubing, followed by plastic ferrule. The long,

tapered end of the ferrule should face towards the end

of the tubing. Place insert into end of tubing.

(B) Insert tubing into saddle valve and hand-tighten

compression nut. Using a wrench tighten nut

1 to 1 ½ turns.

9333 Nanotechnology Under Counter Water Purification System 5

8. Connecting the Saddle Valve (diagram 8)

(A) Locate Compression Nut in installation kit pack-

age and attach to inlet tting. Tighten the nut hand

tight and then loosen one full turn.

(B) Repeat steps 6B and 6C.

9. Connecting Inlet Line to System (diagram 9)

(A) Locate Compression Nut in installation kit pack-

age and attach to inlet tting. Tighten the nut hand

tight and then loosen one full turn.

(B) Repeat steps 6B and 6C.

10. Setting the Eective Life Indicator

The Eective Life Indicator is the black dial located

on the center of the mounting bracket. Each white

mark on the dial represents 378.5L (100 gallons).

The START mark represents 4542.5L (1,200 gal-

lons); however, the lter cartridges have an eective

life of 3785.4L (1,000 gallons), so you will need to

move the dial clockwise so that the indicator arrow

lines up with the 3785.4L (1,000 gallons) mark

(2 marks past The START mark). Important – set

Eective Life Indicator to 1000 gallons after

each new lter replacement.

NOTE: To prevent indicator malfunctions, only

move the dial when the system is depressurized.

11. Putting the System into Operation

(A) Slowly turn on cold water supply.

(B) Press red pressure-relief button on top

of system.

C) Make sure Eective Life Indicator is set at

3785.4L (1,000 gallons).

(D) Rotate base of drinking water faucet count-

er-clockwise to “ON” position. Allow water to run

for 5 minutes to ush air and carbon nes from lter

cartridges. Check system for leaks before leaving

installation.

NOTE: A drinking water cartridge may contain car-

bon nes (very ne black powder). After installation,

ush the cartridge for 5 minutes to remove the nes

before using the water. It is recommended that you

run the tap at least 20 seconds prior to using water

for drinking or cooking purposes.

9333 Nanotechnology Under Counter Water Purification System 6

NOTE: Initially, ltered water may appear cloudy.

If you set a glass of water on a level surface, you

should be able to watch the cloudiness disappear

from the bottom of the glass upwards. This harm-

less cloudiness results from the release of trapped

air within the cartridge and will disappear within a

few weeks after installation.

INSTALLATION IS NOW COMPLETE.

Filter Cartridge Replacement

Filter cartridges will last about 3785 liters (1,000

gallons) or twelve months before they need to be

replaced. Filter cartridge life varies depending on

lter life, usage, and/or water conditions. Changes

in taste, color, and ow of the water being ltered

indicate that the cartridge should be replaced.

Read all instructions before replacing lter car-

tridges.

1. Turn o cold water supply to system and press

red pressure-relief button.

2. Unscrew and remove bottom of lter housing.

Locate and remove large O-ring, wipe clean of

lubricant, and set aside. Repeat for second and

third housings.

3. Discard used lter cartridges. Using a

non-abrasive sponge or cloth, scrub the bottom

of lter housings, O-ring grooves, and caps with

dish soap and warm water. Rinse thoroughly. Fill

bottom of each housing 1/3 full with water. Add

14.7ML (1 tablespoon) of household bleach and

scrub to disinfect.

CAUTION: Read “WARNING” information on the

bleach container before using its contents.

4. Lubricate O-ring with clean silicone grease.

Insert each O-ring in groove and press into place.

NOTE: This step is important to ensure a proper

housing seal. Make certain each O-ring is seated

level in its groove or a leak may occur.

5. Screw bottom of housings with bleach water

onto caps without lter cartridges and hand-tight-

en. DO NOT OVER-TIGHTEN.

6. Turn on water supply. Let faucet run for about

10 seconds, then turn o faucet and let stand for

20-30 minutes.

7. Turn on faucet and allow bleach water to run

out (about 3-5 minutes).

8. Turn o water supply to system and press pres-

sure-relief button. Remove bottom of housings

and empty out water.

9. Insert each lter cartridge in bottom of appro-

priate lter housing.

10. Screw bottom of housings onto caps and

hand-tighten. DO NOT OVER-TIGHTEN. Make

certain cap standpipe slips into cartridge.

11. Reset Eective Life Indicator to 1000 gallons

(see instructions under “Setting the Eective Life

Indicator” on Page 6).

12. Turn on water to system and press pres-

sure-relief button. Let faucet run for 5 minutes

to remove trapped air and carbon nes. Check

system for leaks before leaving installation.

NOTE: A drinking water cartridge may contain

carbon nes (very ne black powder). After instal-

lation, ush the cartridge for 5 minutes to remove

the nes before using the water. It is recommend-

ed that you run the tap at least 20 seconds prior

to using water for drinking or cooking purposes.

NOTE: Initially, ltered water may appear cloudy.

If you set a glass of water on a level surface, you

should be able to watch the cloudiness disappear

from the bottom of the glass upwards. This harm-

less cloudiness results from the release of trapped

air within the cartridge and will disappear within a

few weeks after installation.

9333 Nanotechnology Under Counter Water Purification System 7

Troubleshooting:

Leaks between cap and bottom of lter housing:

•

Turn o water supply and turn on drinking water

faucet to release pressure in system. Remove bot-

tom of housing. Clean O-ring and O-ring groove

(located directly beneath threads of housing). Lu-

bricate O-ring with silicone grease and replace se-

curely into groove. Screw bottom of housing onto

cap and hand-tighten. DO NOT OVER TIGHTEN.

Turn on water supply and check for leaks.

Leaks on system inlet /outlet connections:

•

Turn o water supply and turn on drinking water

faucet to release pressure in system. Remove

tubing from tting and make sure end of tubing is

cut squarely and free of burrs. Reinsert tubing into

tting, making sure to push tubing to a hard stop.

Hand tight compression nut rst, then tighten 1 to

1 1/2 turns for new compression nut. Tighten only

1/2 to 1 turn with wrench for previously tightened

compression nut.

Leaks on faucet / tubing connection:

•

Turn o water supply, then turn on drinking water

faucet to release pressure in system. Loosen and

remove compression nut tting on faucet stem.

Make sure tubing is inserted rmly into end of

faucet stem, then retighten compression nut with

ngers until secure. Turn on saddle valve, then

turn o faucet to check for leaks.

NOTE: If leaks persist, or if there are other leaks

on system, turn o water supply.

Low Water Flow:

1. Check ow at faucet. The # 9333 system

should ll a gallon jug in approximately 2 minutes.

Flow rates will vary with individual household

water pressure.

2. Check lter cartridge installation. Make certain

all lter cartridges are properly oriented in lter

housings.

B. David specic / Replacement Filter Cartridges

1. Stage # 1: RS-90

2. Stage # 2: RC-93

3. Stage # 3: RP-100

Complete System

# 9333 Nano ltration system

B. David LIMITED WARRANTY

B. David warrants to the original owner (under normal use): all products

and parts to be free from defects in material and workmanship for a

period of one (1) year. Not withstanding the foregoing, (a) the warranty

period for sumps shall be a period of ve (5) years. Any replacement

products furnished will be free from defects in material and/or work-

manship for the remainder of the original warranty period or 30 days,

whichever is longer. This warranty does not cover: (1) cartridges and

accessories (2) defects not reported within the above time period, (3)

items manufactured by other companies, (4) problems arising from fail-

ure to comply with B. David instructions, (5) problems and/or damage

arising from acts of nature. abuse. misuse, negligence or accident by

any party other than B. David, (6) problems and/or damage resulting

in whole or in part from alteration. Modication, repair or attempted

alteration. modication or repair by any party other than B. David, (7)

noncompliance with applicable codes/ordinances.

If a defect in workmanship and/or material in a product or part covered

by the warranty should a rise, B. David, at its sole discretion, will repair

or replace the defective product or part B. David may consider in good

faith, the customer’s preference).

All claimed defective product must: (1) be authorized for return by B.

David with an RGA number (2) include proof of the purchase date of

the product or part (3) returned to B. David prior to the expiration of the

warranty date at the customer’s expense. shipment pre-paid,

(4) be accompanied by a letter detailing the Model Number, Serial Num-

ber (if any), and a brief description of the problem.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW. B

DAVID DISCLAIMS ALL OTHER WARRANTIES, WHETHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO. THE IMPLIED WAR-

RANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, WITH REGARD TO THE PRODUCTS. PARTS AND ANY

ACCOMPANYING WRIT TEN MATERIALS.

To the maximum extent permitted by applicable law, B. David shall not

be liable for any damages whatsoever (including, but not limited to, loss

of time, inconvenience, expenses, labor or material charges incurred in

connection with the removal or replacement of the products or parts,

special. Incidental, consequential, or indirect damages for personal

injury, loss of business prots, business interruption, loss of business

information, or any other pecuniary loss) arising out of the use of or

inability to use the defective products or parts even if B. David has been

advised of the possibility of such damages.

B. David’s maximum liability under any provision of this limited Warranty

shall be limited to the amount actually paid for the products or parts.

NOTE: Because some states do not allow the exclusion or limitation of

incidental or consequential damages, the above limitations or exclu-

sions may not apply.

THIS WARRANTY GRANTS SPECIFIC LEGAL RIGHTS, ANO OTHER

RIGHTS MAY APPLY. SUCH RIGHTS VARY FROM STATE TO STATE.

9333 Nanotechnology Under Counter Water Purification System P/N 161131 Rev C 8

MAINTENANCE

Date Activity/Service Performed Installation Date

B.David Company

World Health Through Water Purication Systems

Tel: (952) 884-8417

Email: info@bdavidwater.com

Visit our website: www.bdavidwater.com

Loading...

Loading...