BC Biomedical ULT-2000 Owners Manual

ULT-2000 Series Product Overview

Are your TEE and other types of “invasive”

ultrasound transducers safe?

Sonosite TEE Transducer

Courtesy of Sonosite, Inc.

Bothell, WA

www.sonosite.com

Or are you putting your patients

needlessly at risk?

Copyright May, 2007 by BC Group International, Inc.

1 Revision 1 – May 25, 2007

Author: Michael R. Erwine

INDEX

The Next Generation in TEE Transducer Testing is Here...........................................................3

Why Should You Test Your Transducers Anyway?....................................................................3

How Can Ultrasound Transducers Be Easily Tested?................................................................8

Can Non-Technically Oriented Personnel Perform These Tests?............................................10

Can Technically-Oriented Personnel Get Important Measurement Data?................................ 10

Competitive Product Comparison.............................................................................................11

The Difference Starts with the Bath Conductivity Test..............................................................11

Dealing With Real World Parameters.......................................................................................13

Why Test With AC Voltages Instead of DC Voltages?..............................................................14

Can Test Results Be Archived for Legal Liability Purposes?....................................................14

PC Utility Software Makes It Easy............................................................................................14

Ultrasound Transducer Adapter Compatibility..........................................................................14

Available Transducer Adapters.................................................................................................15

Advanced Features for Advanced Users..................................................................................15

Competitive Product Cost Comparison.....................................................................................15

Conclusion................................................................................................................................16

ULT-2000 Series Product Specifications..................................................................................17

Technical References...............................................................................................................18

About the Author.......................................................................................................................19

APPENDICES

APPENDIX A (Siemens DALE 800A Instrument Specifications)..............................................21

APPENDIX B (Fluke Biomedical ULT-800 Instrument Specifications)......................................22

APPENDIX C (Dale Technology DALE800 Instrument Specifications) ....................................23

APPENDIX D (Sonosite TEE Electrical Safety Test Description).............................................24

APPENDIX E (Sonosite TEE Bite Hole Inspection Test – 1st page) .........................................25

APPENDIX F (Sonosite TEE Bite-Hole Inspection Test – 2nd page).........................................26

APPENDIX G (GE Healthcare Simplified Leakage Current Setup) ..........................................27

APPENDIX H (Voltaic Cells).....................................................................................................28

APPENDIX I (Sample Printout of Test Results form ULT-2000)...............................................29

APPENDIX J (History of BC Group International, Inc.).............................................................30

Copyright May, 2007 by BC Group International, Inc.

2 Revision 1 – May 25, 2007

Author: Michael R. Erwine

The Next Generation in TEE Transducer Testing is Here

Until now, commercially available dedicated electrical leakage current testing systems for TEE and other types of

“invasive” diagnostic ultrasound transducers have been limited to red light / green light testing

according to the manufacturer of the test device, a green LED lights up. If the test results in a Failure, a red LED

lights up. So what constitutes this Pass or Fail criteria? You have to dig into the product specifications of the

particular test instrument to find that out, and once you find the information, you will notice that the exact same

test protocol (test voltage, test voltage frequency, lower leakage current limit, and upper leakage current limit) is

used for ALL types of ultrasound transducers tested, totally regardless of clinical application or the level of risk to

the patient.

But what if the user really wants to know if the TEE or other type of diagnostic ultrasound transducer is “safe by a

long shot” or if it passes just marginally? Is it getting worse or staying the same? Is it leaking more electrical

current this time vs. the last time it was tested? Is the insulation barrier holding up or breaking down? Does the

transducer display higher leakage values when flexed or strained in a particular way? Can the test results be

printed out with a time and date stamp for formal documentation purposes? Until now, there was no real way to

get the answers to these important questions with existing commercially available dedicated ultrasound electrical

leakage current testing systems.

The BC Biomedical ULT-2000 Series of Ultrasound Transducer Leakage Current Testers (the ULT-2010 and ULT-2020

instruments)

2

changes all of this and delivers the “next generation” in dedicated test devices for TEE and other diagnostic

ultrasound transducers, with added functionality and flexibility never before seen in a commercially available and

affordable tester.

1

. If the test Passes

Why Should You Test Your Transducers Anyway?

Many types of diagnostic ultrasound transducers come into “intimate” contact with the patient and should be

tested regularly to evaluate the integrity of the insulation barrier between the inner wiring of the transducer and

the outside world. But because of their proximity to the heart during typical clinical application, TEE

(Transesophageal Echocardiography) ultrasound transducers are of paramount concern regarding electrical

safety and the containment of potentially harmful electrical leakage currents. A tiny bite hole from a previous TEE

procedure can leave the next patient at risk to elevated and potentially harmful levels of electrical leakage

currents, with such currents actually being introduced by the TEE transducer into the patient’s thoracic cavity,

within a few centimeters of the heart muscle.

1

This methodology commonly refers to the Dale Technology DALE800, the Fluke Biomedical ULT-800, and the Siemens Medical Solutions DALE800A

product that is purchased under private label agreement with Fluke Biomedical.

2

Commercial availability scheduled for July/August 2007.

3 Revision 1 – May 25, 2007

Copyright May, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Major diagnostic ultrasound system manufacturers such as GE Healthcare, Philips Medical Systems, Siemens

Medical Solutions, Sonosite, Inc. and Toshiba America Medical Systems highly recommend electrical

leakage current testing of TEE transducers prior to each clinical application (or at least between clinical

applications). TEE transducers such as the Acuson V510B and V705B,

GE Healthcare 6T, Philips Medical

Systems miniMulti, OmniPlane III, S7-3t, MPT- 7-4, Siemens Medical Solutions V5M, V5Ms, V7M, Sonosite

TEE/8-3, and Toshiba America Medical Systems PEF 510SB are just a few examples of transducers that should

be regularly tested for electrical leakage currents per manufacturer recommendations.

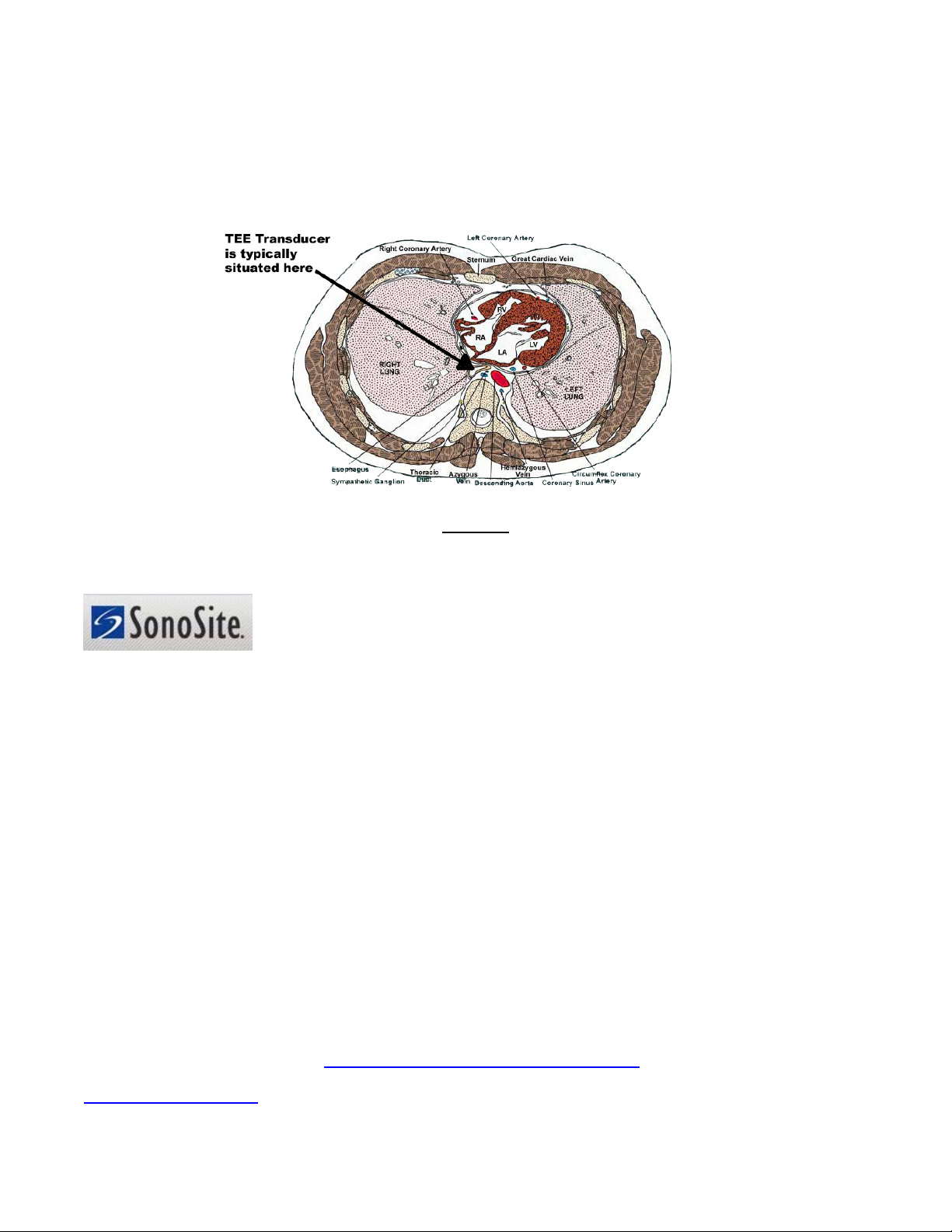

Figure 1

for TEE transducers since the introduction of their own TEE transducer. In their TEE Transducer User Guide

(pages 31-33) they highly recommend periodic electrical safety testing. Language from this publication (top of

page 31) is as follows:

Cross-Section of the Human Thoracic Cavity Showing Proximity of a TEE Transducer to the Heart

Sonosite, Inc. (Bothell, WA) has been an advocate of electrical leakage current testing

“The electrical leakage current test should be performed on the TEE transducer after

taking it out of the box and prior to each exam, alternatively, if the bite-hole inspection

test is done prior to each exam, then the electrical leakage current test should be done

yearly at a minimum.”

The “bite hole inspection test” referred to in the Sonosite, Inc. TEE Transducer User Guide publication involves

setting up a water bath with a liquid medium that is electrically conductive to a specified level (water mixed with

50g NaCl/liter of water), using a Digital Multimeter calibrated to NIST traceability, and a copper or aluminum sheet

with an area of at least 25 cm

shaft placed into the liquid up to the 40 cm mark. Readings are taken and compared to desired results. This test

is recommended as a possible alternative to the electrical safety test (described in detail below using the BC

Biomedical ULT-2000 Series), but it would actually be more time consuming than the electrical safety test

described below, and could not be combined with the normal cleaning and disinfection process. Also, because

this test utilizes a simple digital multimeter, it is a DC-only low voltage test, and it will not capture capacitive

electrical leakage currents that may be present during normal use of the ultrasound transducer with the

ultrasound system powered by a customary AC power system at 50 or 60 Hz.

The Sonosite TEE Transducer User Guide publication can be downloaded from the Sonosite, Inc. company

website at the following location:

the page to find it. You can also see Appendices D, E. and F of this document for detailed information, or simply

follow this embedded link to access the file at the Sonosite web site.

4 Revision 1 – May 25, 2007

2

. The TEE transducer is then submersed in the water bath with the endoscopic

http://www.sonosite.com/content/view/55/439/ . Simply scroll to the bottom of

Copyright May, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Since early 2006, Sonosite, Inc. has purchased and offered for resale to their customers as an accessory item to

their TEE transducers, the Fluke ULT-800 instrument for electrical safety testing.

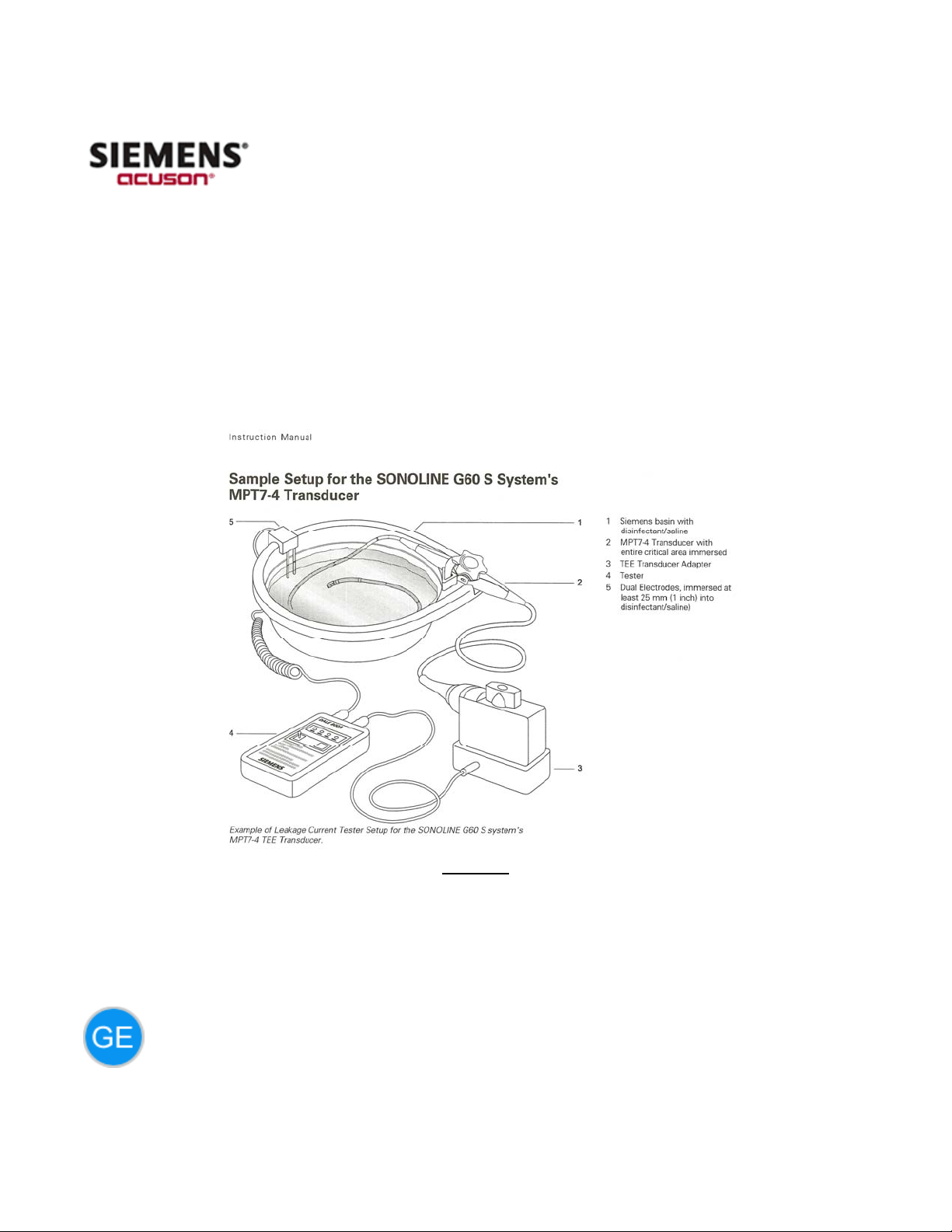

Siemens Medical Solutions is probably the most pro-active diagnostic ultrasound

manufacturer in the market today when it comes to advocating TEE transducer electrical leakage current testing.

Since April, 1993, Siemens Medical Solutions (Mountain View, CA) has been offering the DALE 800A TEE

Transducer Leakage Current Tester to its TEE transducer customers as an accessory item, under the Siemens

Medical Solutions brand label. In the Siemens DALE 800A TEE Transducer Leakage Current Tester

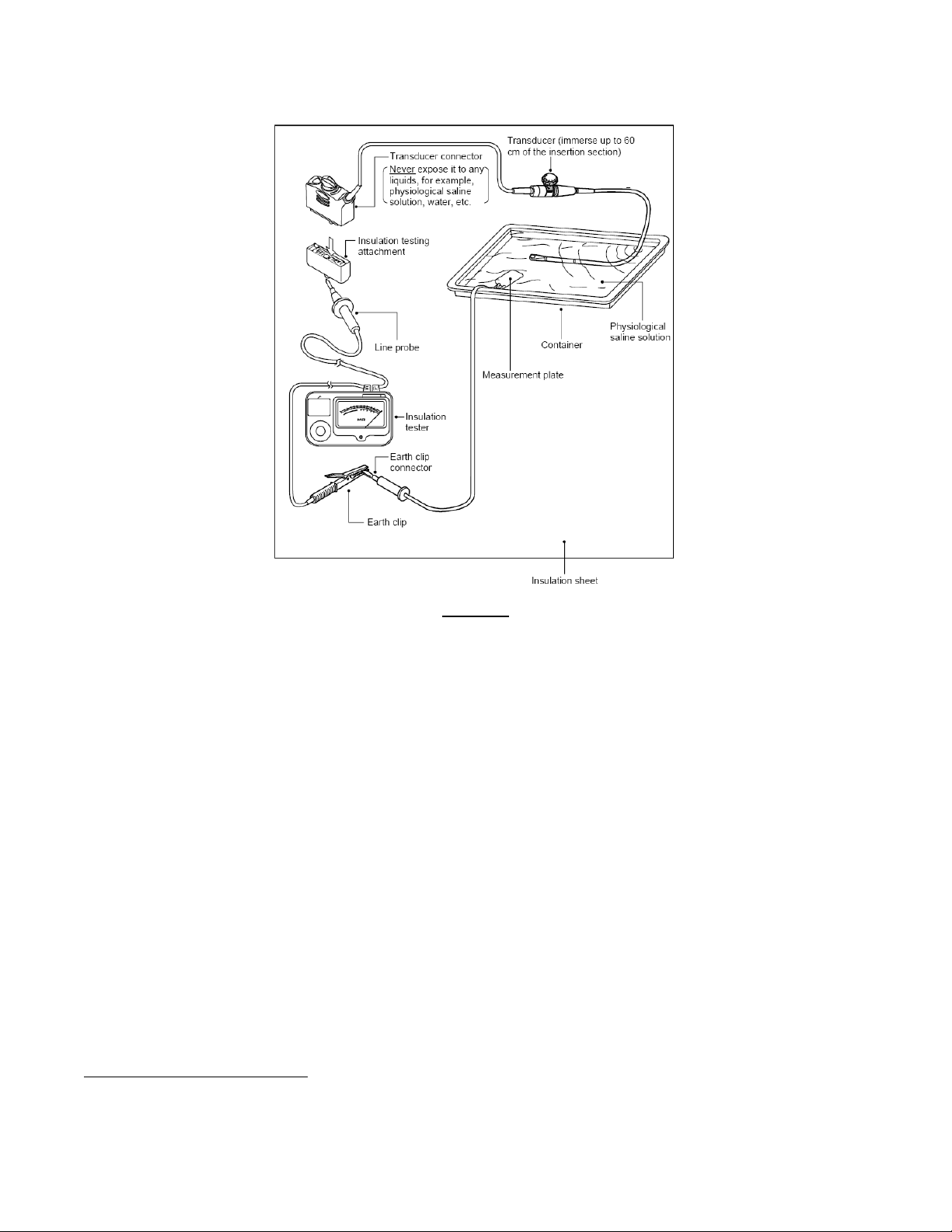

Instruction Manual, the testing method outlined is exactly the same as that shown in Figure 2 below. The

following language appears in the Siemens manual:

“The hand-held battery-operated Tester is designed for use during the routine transducer

cleaning procedure conducted between patient examinations.”

The illustration in Figure 2 below is the recommended test setup that Siemens Medical Solutions gives to their

customers in the DALE 800A TEE Transducer Leakage Current Tester Instruction Manual:

Figure 2

As of the release date of this document, Siemens Medical Solutions markets the DALE800A TEE Transducer

Leakage Current Tester on a worldwide basis and strongly endorses TEE electrical leakage current testing with

its customers, as well as the specific testing methodology outlined in this document. See Appendix A for product

specifications on the Siemens Medical Solutions DALE 800A instrument.

GE Healthcare is another pro-active ultrasound system manufacturer when it comes to advocating

electrical leakage current testing of their TEE transducers. For example, in the GE Service Note # SN76018

(October 2, 2000), they outline an electrical safety testing protocol that is very similar to the one described in

detail in this document. On page 2 of this service note, the following is stated:

5 Revision 1 – May 25, 2007

Recommended TEE Transducer Test Setup Specified by Siemens Medical Solutions

Copyright May, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

“The electrical leakage current in the probe can alternatively be measured in a

simplified test without the access to the ultrasound scanner, by using the procedure

described below. The test described below is not a complete safety test. It is focused on

the most important insulation test for this product”.

The test setup outlined in this GE service note can be seen in Appendix G of this document. In this same service

note, GE Healthcare states the following on page 4 relative to electrical leakage current testing on TEE

transducers in general:

“GE Vingmed Ultrasound AS recommends that leakage current testing be carried out on

a regular basis to obtain the best possible patient safety. Also, a leakage current test

should be conducted prior to the use of the probe in any surgical procedure.”

Philips Medical Systems has a history of recommending routine electrical leakage current

testing of their TEE transducers that dates back to the Hewlett Packard and Agilent days. It was Hewlett Packard

that initially established a working relationship with Dale Technology, Inc. of Thornwood, NY in the late 1990’s

regarding the use and recommendation of the DALE800 to their ultrasound customers. At that time, the DALE800

was the only commercially available dedicated ultrasound transducer electrical leakage current testing solution.

Currently, Philips continues to advocate electrical leakage current testing on their TEE transducers with their

customers, as part of an ultrasound “system” approach. In their TEE Proper Care and Handling Manual

(Publication # 4535 611 90271 Rev B), they have the following comments regarding electrical safety concerns

with TEE transducers:

“Cuts in the transducer cable or cracks in the housing can destroy the electrical safety

features of the transducers.”

“Bites can cause electrical hazards or mechanical malfunction.”

“Cuts in the transducer insulation can result in current leakage and may lead to serious

patient electrical hazards. In addition, fluid that enters the gastroscope via the cut will

cause electrical and mechanical operational problems.”

In some of their latest ultrasound system user manuals (specifically, manuals that are involved with systems that

utilize TEE or other “invasive” types of ultrasound transducers), Philips Medical Systems includes detailed

electrical safety testing instructions that are highly recommended to help determine of there is a hole of any kind

in the transducer outer insulating barrier. Bite holes or cuts in this insulation barrier could lead to elevated levels

of electrical leakage currents, consequently putting the patient at risk. Philips Medical Systems also warns

against conducting transducer electrical safety tests by making simple DC measurements on their transducers,

and further claims that such testing procedures yield inaccurate results regarding electrical leakage currents in

transducers. The prescribed testing method offered by Philips Medical Systems involves the immersion of the

TEE and/or other type of “invasive” ultrasound transducer in a saline solution, typically described within this

document.

Toshiba Medical America is yet another advocate of routine electrical leakage current

testing of their TEE transducers with their customers. In their TEE transducer Operation Manuals, Toshiba

recommends an electrical leakage current test prior to each clinical procedure involving the transducer. They

have an electrical leakage current testing solution in place (the Hioki Model 3451 Digital Megohm Insulation

Copyright May, 2007 by BC Group International, Inc.

6 Revision 1 – May 25, 2007

Author: Michael R. Erwine

HiTester

3

) and they include this tester with each TEE transducer that they sell. A diagram of the recommended

test setup for the Toshiba line of TEE transducers, utilizing the Toshiba supplied tester appears in Figure 3 below.

Figure 3

Recommended TEE Transducer Test Setup for Toshiba TEE Transducers Using the Toshiba Tester

(Hioki Model 3451 Digital Megohm Insulation HiTester)

Toshiba Medical lists the following safety recommendation in their Operation Manual For Multiplane

Transesophageal Transducer Model PET-510MB (2B701-591E*G):

3

“Checks Before Use… Checks before system power ON… Electrical Safety Inspection

(inspection using the safety kit)… Perform electrical safety inspection using the safety kit

to check for damage to the transducer which may not be visible.”

In general, this level concern over transducer electrical leakage currents is slowly but surely expanding to other

types of “invasive” ultrasound transducers such as those used during laparoscopic procedures. Other major

medical device manufacturers in the ultrasound arena are also beginning to make such recommendations to their

customers concerning not only TEE but other types of invasive ultrasound transducers, and the need for electrical

leakage current testing on them. Once again, the typical clinical application of these types of transducers finds

them having been inserted at least several inches into a body cavity or through some type of an incision in the

body, thus violating the human body’s natural protection (the outer layers of otherwise dry skin) from electrical

macroshock and microshock conditions.

The effects of even the smallest levels of electrical leakage currents on the heart muscle and other internal

organs has been studied for over thirty years, and the potential risks are still viewed as critical ones, especially

with such currents in close proximity to the heart, as in the typical application of a TEE transducer.

3

The Hioki 3451 Digital Megohm HiTester is a DC Insulation Tester and it tests the transducer insulation barrier with DC voltage only. It will not pick up

any capacitive electrical leakage currents that may exist in the transducer during actual use on a conventional AC power systems running at 50 or 60 Hz.

Copyright May, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

7 Revision 1 – May 25, 2007

How Can Ultrasound Transducers Be Easily Tested?

TEE and other types of diagnostic ultrasound transducers can be easily tested as part of the routine cleaning and

disinfection process following each clinical procedure

there are no elaborate test setups required. There are two basic approaches that can be taken, depending on the

method commonly used to clean and disinfect ultrasound probes at the medical facility in question.

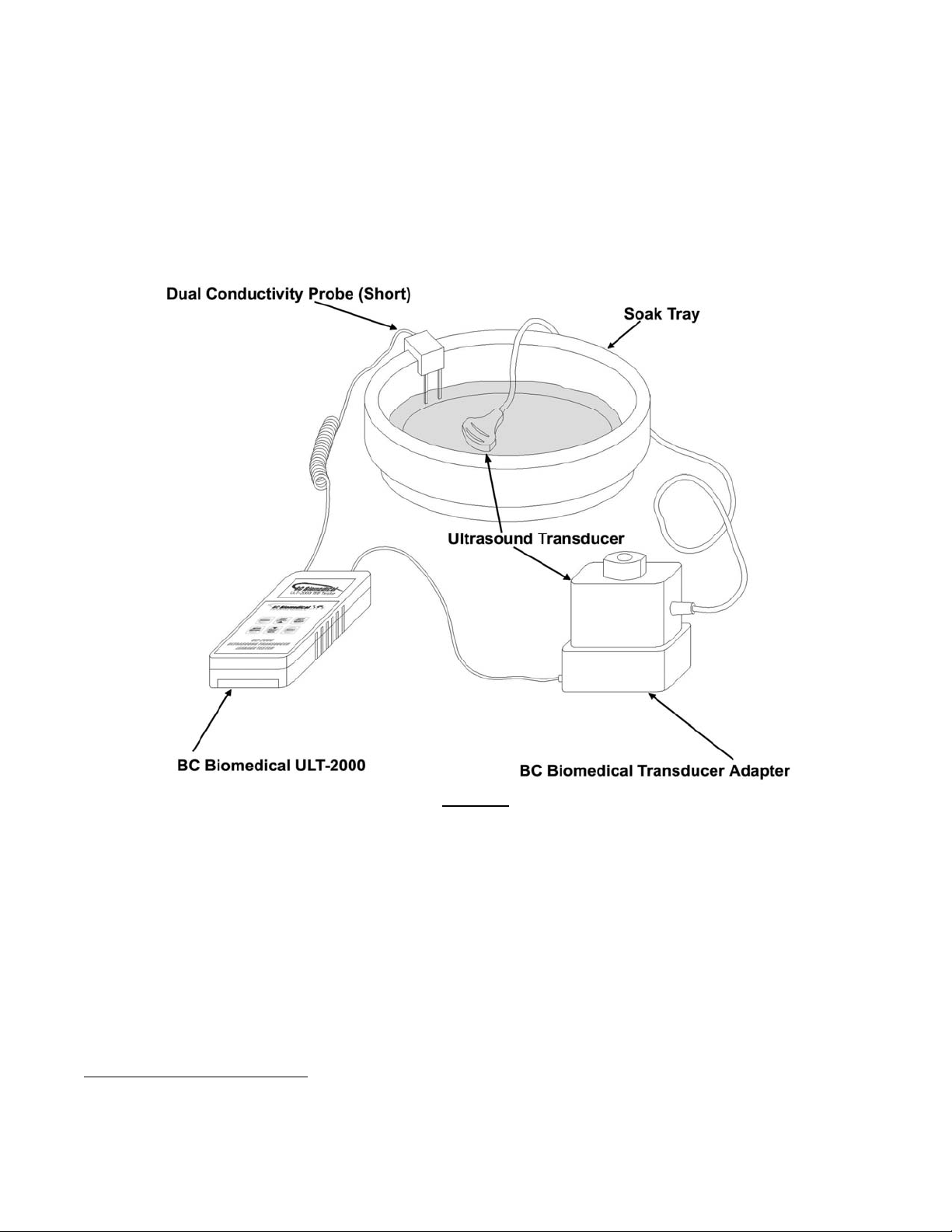

Facilities that utilize a cleaning agent such as Cidex® in a “soak tray” can use this same setup to test the

ultrasound transducer for electrical safety during the cleaning and disinfecting process. A typical test setup is

illustrated in Figure 4 below. The most commonly used soak tray has historically been a Cidex

®

Cidex

2032 compatible tray is available from BC Group International (BC Part # BC20-42200).

4

. There is no need to make a big deal over testing and

®

2032 Tray. A

Figure 4

Cidex® is characteristically an electrically conductive medium that works extremely well for electrical leakage

testing of ultrasound transducers, including TEE transducers. If Cidex

the setup above, a Cidex

This same test setup can be used as a simple test procedure (without the disinfecting function) by using a saline

solution or a mixture of tap water with dissolved table salt. The bath conductivity test function of the BC

Biomedical ULT-200 Series will assist in setting up a bath solution that is suitably conductive to electrical currents

for this test. In such a test, a Cidex

Biomedical #BC20-42210 Generic Soak Tray may be used.

The BC Biomedical # BC20-42100 Dual Conductivity Probe is typically used in the soak tray testing solution as

pictured above. This is the shorter of the two dual conductivity probe types available from BC Group International

for the ULT-2000 Series.

4

The soak tray and commercial cleaning system immersion test procedure outlined in this document should only be conducted on those types of transducers

that are approved by the original medical device manufacturer for immersion in a cleaning agent bath. Consult with the manufacturer of your transducer to

see what transducers are applicable to this procedure.

8 Revision 1 – May 25, 2007

Typical Electrical Leakage Test Setup Using a Soak Tray

®

®

compatible soak tray such as the BC Biomedical # BC20-42200 must be used.

®

compatible soak tray is not required. A less costly tray such as the BC

or another disinfecting agent is used in

Copyright May, 2007 by BC Group International, Inc.

4

Author: Michael R. Erwine

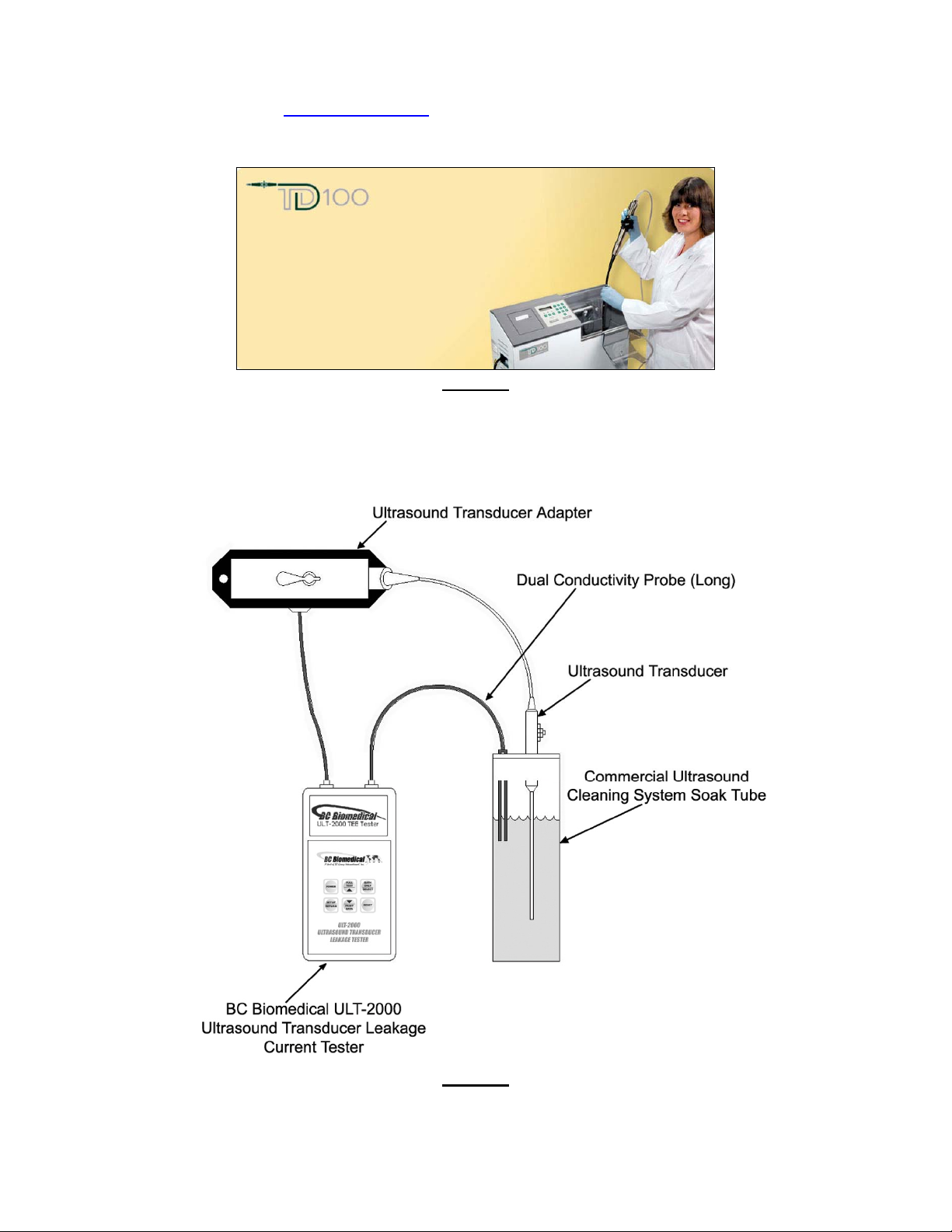

Where a commercially available ultrasound transducer cleaning system such as the TD-100 TEE Probe

Disinfector by PCI Medical (

www.pcimedical.com) is used (shown in Figure 5 below), the BC Biomedical ULT-

2000 Series can also be easily utilized as part of the enzymatic pre-cleaning process, for a combination

cleaning/disinfecting and electrical leakage current testing process with such systems.

Figure 5

The special-purpose BC Biomedical # BC20-42101 Dual Conductivity Probe is typically used in this type of

application. A generic setup using a commercially available disinfecting and cleaning station is illustrated in

Figure 6 below.

PCI Medical TD100 Cleaning System

Figure 6

Generic Functional Diagram of a Typical Electrical Leakage Test Setup Using a Commercial Cleaning Station

Copyright May, 2007 by BC Group International, Inc.

9 Revision 1 – May 25, 2007

Author: Michael R. Erwine

Loading...

Loading...