B + B Thermo-Technik DSI 820-LC-2M, DSI 820-LC-5M, DS 1820-LC-IOM, DS 1820-LC-15M, DS 1820-LC-20M User guide

...

OPERATION MANUAL

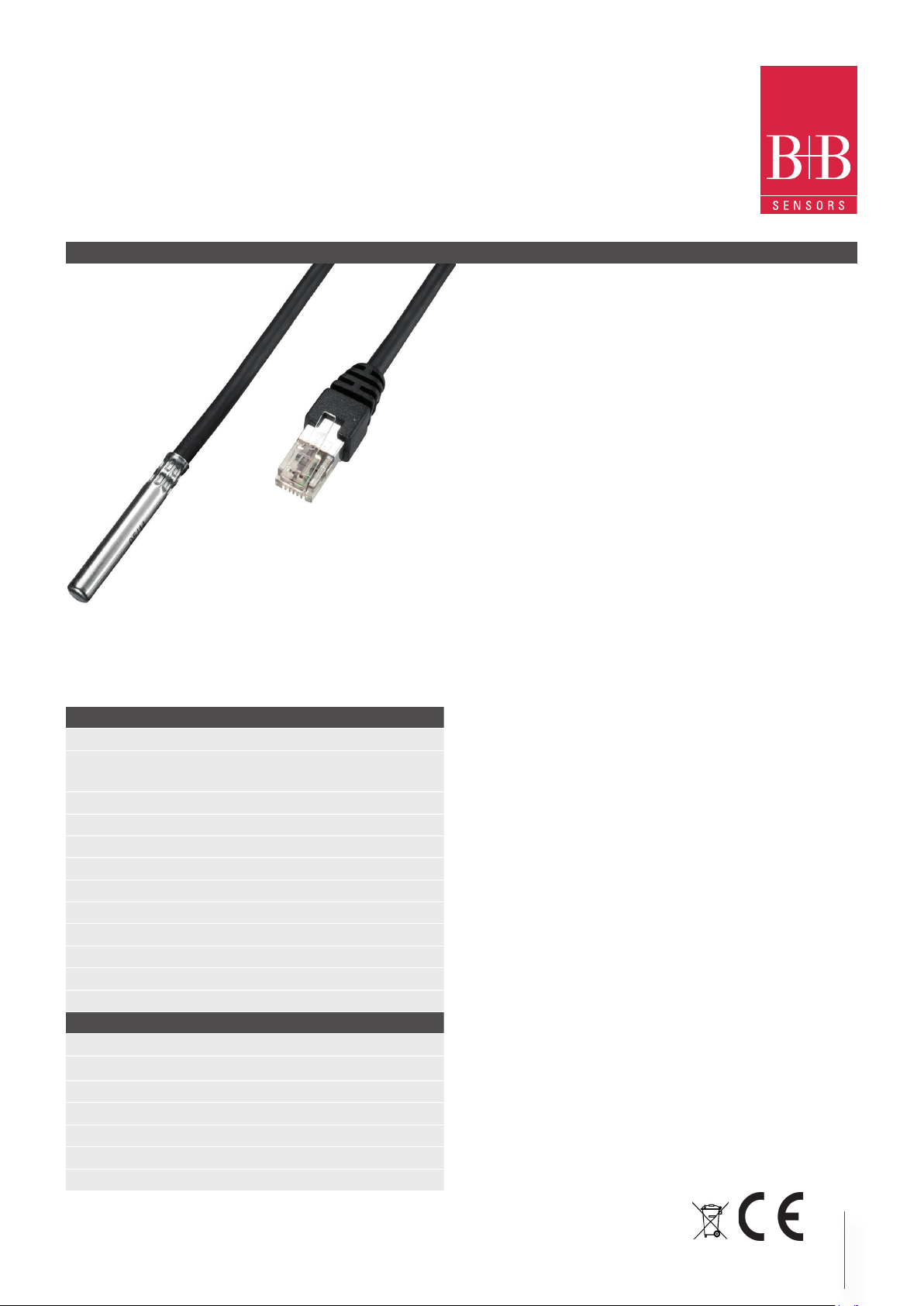

Temperature probe DS18S20 with

connection cable and RJ11 plug

DescriptionDescription

Characteristic features

• Ready made, plug-in type temperature probe

with DALLAS semi-conductor sensor DS18S20

• Sensor in stainless steel protective sleeve

• Splash waterproof

• Connection black PVC at cable

• RJ11 plug connector with breakage protection

• Continuous operating temperature –10...+60 °C,

stationery –40...+80 °C, short time 100 °C

(see Temperature range on page 2)

• Resolution 0.06 °C

• Accuracy ±0.5 °C nominal (from -10...+85 °C),

as per data sheet of manufacturer

• Scratchpad memory for probe identication

Technical data

Measuring range -55...+125 °C

Operating range

Accuracy ±0,5 °C at -10...+85 °C

Nominal length 40 mm

Diameter probe Ø 6 mm

Material probe Stainless steel 1.4571

Model with decoupling capacitor

Connection cable PVC-at cable, unshielded

Plug connector RJ11, 6P4C

CE-conformance 2004/108/EG

EMV-noise emission EN 61000-6-3:2011

EMV-noise withstanding EN 61000-6-1:2007

Article Art. No

Temperature probe DS 1820

connection cable 2 m DS1820-LC-2M

connection cable 5 m DS1820-LC-5M

connection cable 10 m DS1820-LC-10M

connection cable 15 m DS1820-LC-15M

connection cable 20 m DS1820-LC-20M

connection cable 30 m DS1820-LC-30M

-10...+60 °C, more detailed

information on page 2

Areas of application

• Monitoring of frozen goods as per cold storage regulations

• Building instrumentation

• Air conditioning systems

• Quality assurance

• Science and research laboratories

• Industrial temperature logging

Available probes

The reasonably priced probes with PVC connection cable are meant for

measurement in open atmosphere, on surfaces or in non-aggressive

gas medium. The probes are sealed and can bear water contact for

some time. However, long term immersion in liquid is not recommended.

Temperature range

The Dallas temperature sensors are semiconductor sensors. The unhoused sensors are suitable for temperature measurement in the range

of –55…+125 °C. These temperature values are the nal limits and

operating above these values is not at all recommended, otherwise

the component can get damaged. In addition, the allowable application

temperature also depends on the connection cable and type of protection sleeve used. PVC insulated cable gets hard and brittle below

–10 °C and hence should not used at these lower temperatures otherwise the insulation may crack. Above 60 °C continuous operating temperature, the PVC becomes soft and can get deformed. At approx. 80

°C, the material becomes plastic and the insulation gets damaged under pressure.

Technical changes reserved

0141 0316-143 21.08.2015

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

Fon +49 771 83160 | Fax +49 771 8316-50 | info@bb-sensors.com | bb-sensors.com

1 / 2

OPERATION MANUAL

Temperature probe DS18S20 with

connection cable and RJ11 plug

Installing and conguration

The Dallas temperature sensor of type 1820 has an internal identica-

tion (serial number) and can be operated in parallel together with several other components on a three-wire bus. After wiring all the sensors,

the PC adapter must be individually congured for the connected sensors. Operation is not possible without prior conguration of the system.

Since the conguration is stored in the internal EEPROM of adapter,

this process is to be done only once. Only if an additional sensor is to be

used on the existing network, the conguration needs to be repeated.

The sorting of probes, found on the network, is done on the basis of

binary serial number.

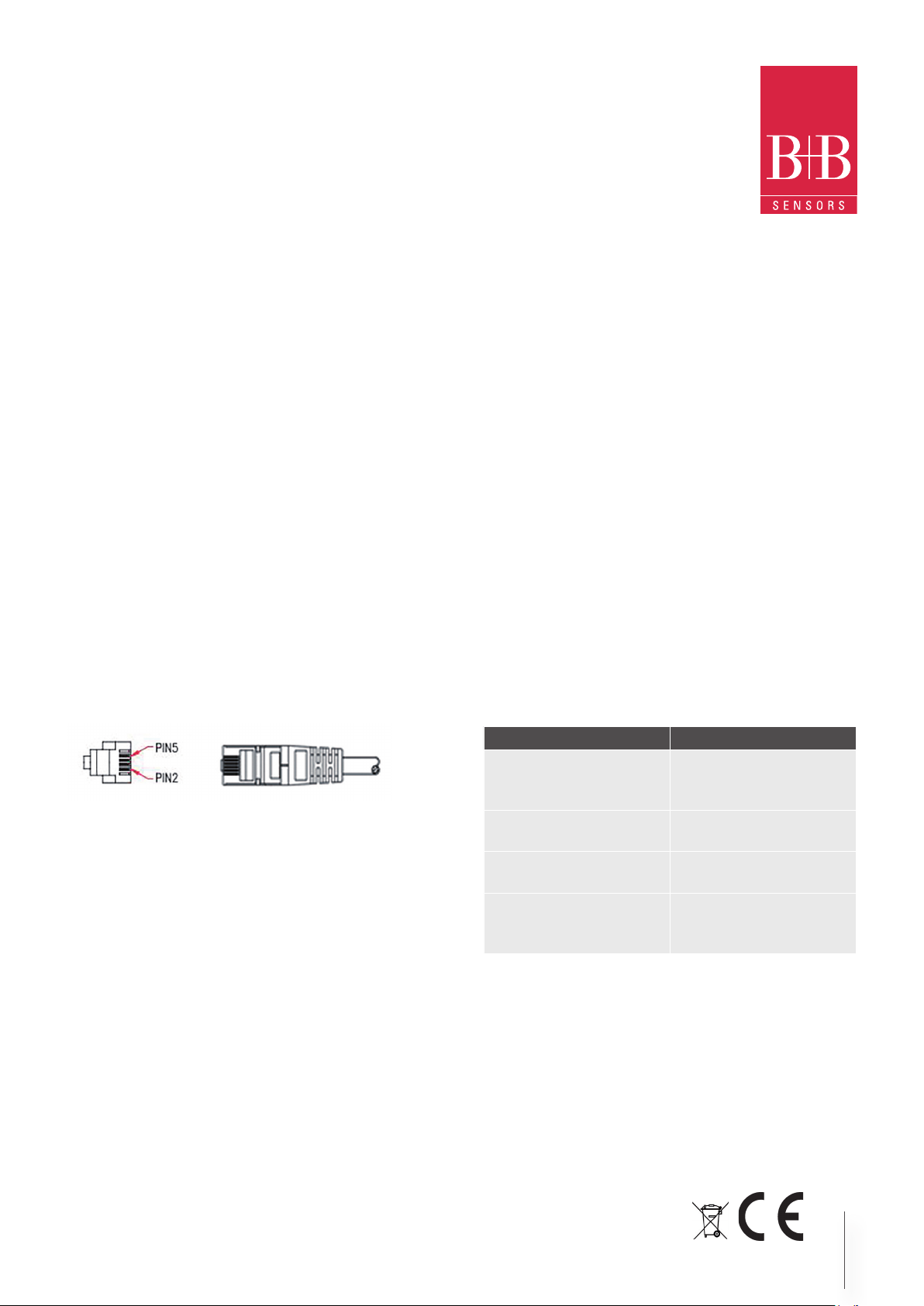

Pin conguration of RJ11-plug connector

The Western-plug connector is congured as follows (View on the

cable, i.e. contact surfaces of the plug!):

1 Unoccupied

2 Ground

3 Dallas Data or unoccupied

4 Dallas Data

5 +5 V

6 Unoccupied

In 4-core at cable, PIN 1 and PIN 6 are not occupied. PIN 3 and 4 are

bridged together at the PC-adapter. Only PIN4 is needed to connect

the data line of the sensor.

Measuring accuracy

The sensors are calibrated during manufacture and have a typical

measuring accuracy of ±0.5 °C at 23 °C application temperature. At

the upper and lower limit of measuring range, the accuracy is somewhat on the lower side. Further information is available in the data

sheet of component at the website of manufacturer.

During all temperature measurements, the physical conditions are also

to be taken care of in order to avoid measuring error, which mainly

decides the precision of measuring arrangement.

Thermal transition resistance of

measuring objectsensor

This is the main measuring error which occurs during surface measurements. This can be eliminated by providing good thermal contact

through mounting in a tube, applying thermal conducting paste or thermal conducting adhesive.

Thermal heat transfer of sensor-ambient temperature

During surface measurements, the measuring arrangement should

be thermally insulated from the surroundings, for example, with some

foam material or mineral wood.

Thermal heat transfer of sensor-connecting wires

This measuring error can be minimised by itself, for example, if the

connecting lead used is as thin as possible and the connecting material

is a bad thermal conductor or if the connecting wire is tempered with

the measuring object.

In principle the highest measuring accuracy is achieved through immersion in liquids or in a mounting tube. However, an additional measuring

error should be included while taking measurements on surfaces.

Accessories

Accessories Articleno.

Distribution box for temperature

measuring system, 10 sockets

RJ12

Temperature measuring system

TLOG with RS232-Interface

Temperature measuring system

TLOG with USB-Interface

Humidity/temperature measuring system with USB-interface

Hytelog Multisensor USB

VERT-GEH

0567 0002

0567 0004

0567 0001

Attention

Please avoid extreme mechanical and inappropriate exposure.

The device/product is not suitable for potential explosive areas and

medical-technical applications.

Technical changes reserved

0141 0316-143 21.08.2015

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

Fon +49 771 83160 | Fax +49 771 8316-50 | info@bb-sensors.com | bb-sensors.com

2 / 2

Loading...

Loading...