BBK LT1703s Service Manual

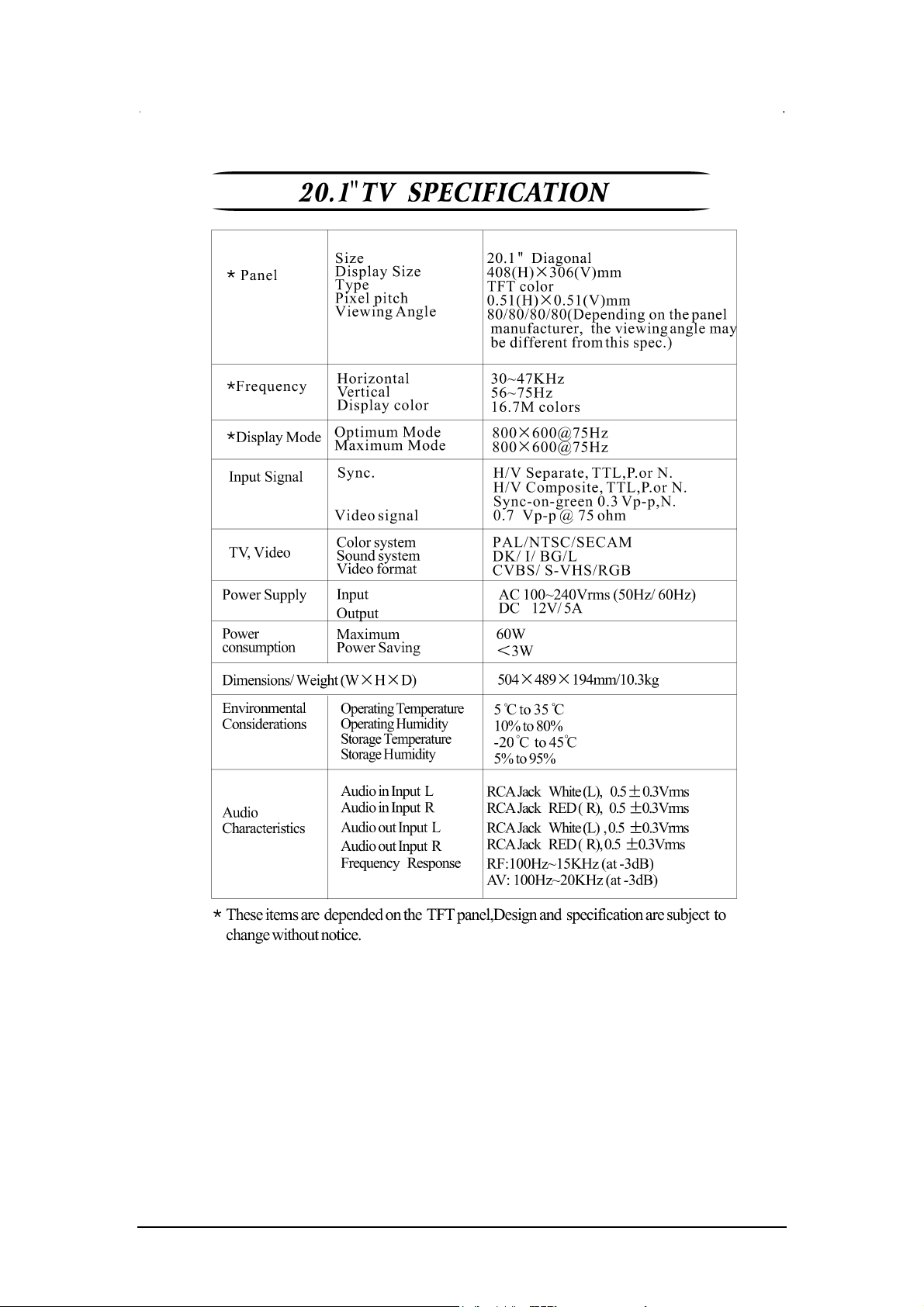

LT1703S/LT2003S

SERVICE

MANUAL

LT1703S/LT2003S

SERVICE MANUAL

Version:1.00

Author(s):Flat Panel TV Department of

BBK AV ELETRONICS CORP.,LTD

Keywords:

LT1703S/LT2003S SERVICE MANUAL

Number of pages:58

Date:2005-3-26

1

NOTICE

THIS DOCUMENT IS BASED ON THE LCD TV WITH INTERNAL

MODEL : LT1703S(RU) AND LT2003S(RU).

2

1. SAFETY PREAUTIONS 4

2. PREVENTION OF ELECTRO---STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES)DEVICES 5

3. CONTROL BUTTON LOCATIONS AND EXPLANATIONS 6

4. ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT 14

5. TEST SCHEME FOR LT1703/LT2003 15

6. IC BLOCK DIAGRAM & DESCRIPTION 18

7. SCHEMATIC & P.C.B WIRING DIAGRAM 39

8. MATERIAL LIST 50

3

1. SAFETY PREAUTIONS

4

2. PREVENTION OF ELECTRO---STATIC

DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES)DEVICES

5

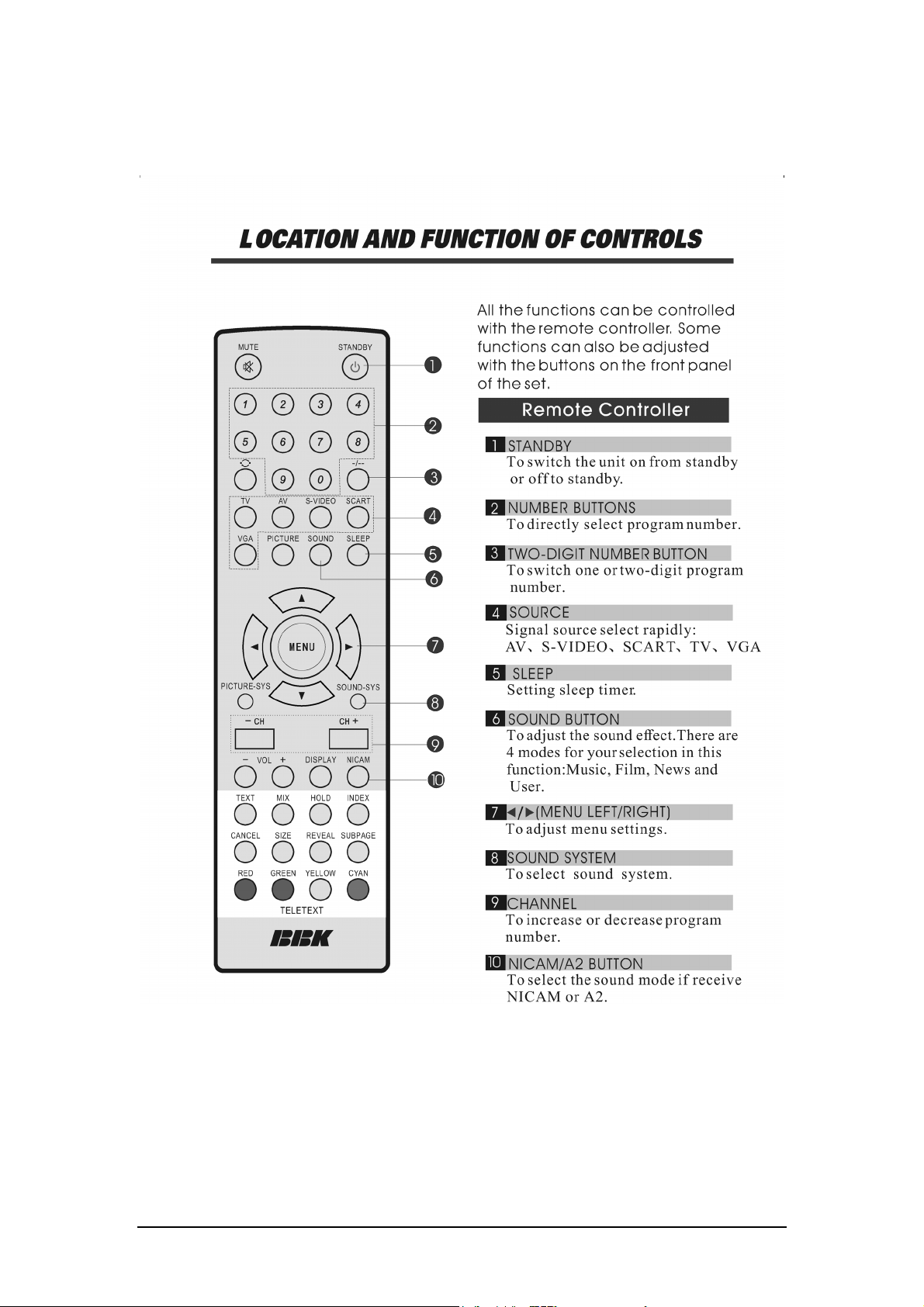

3. Control Button Locations and Explanations

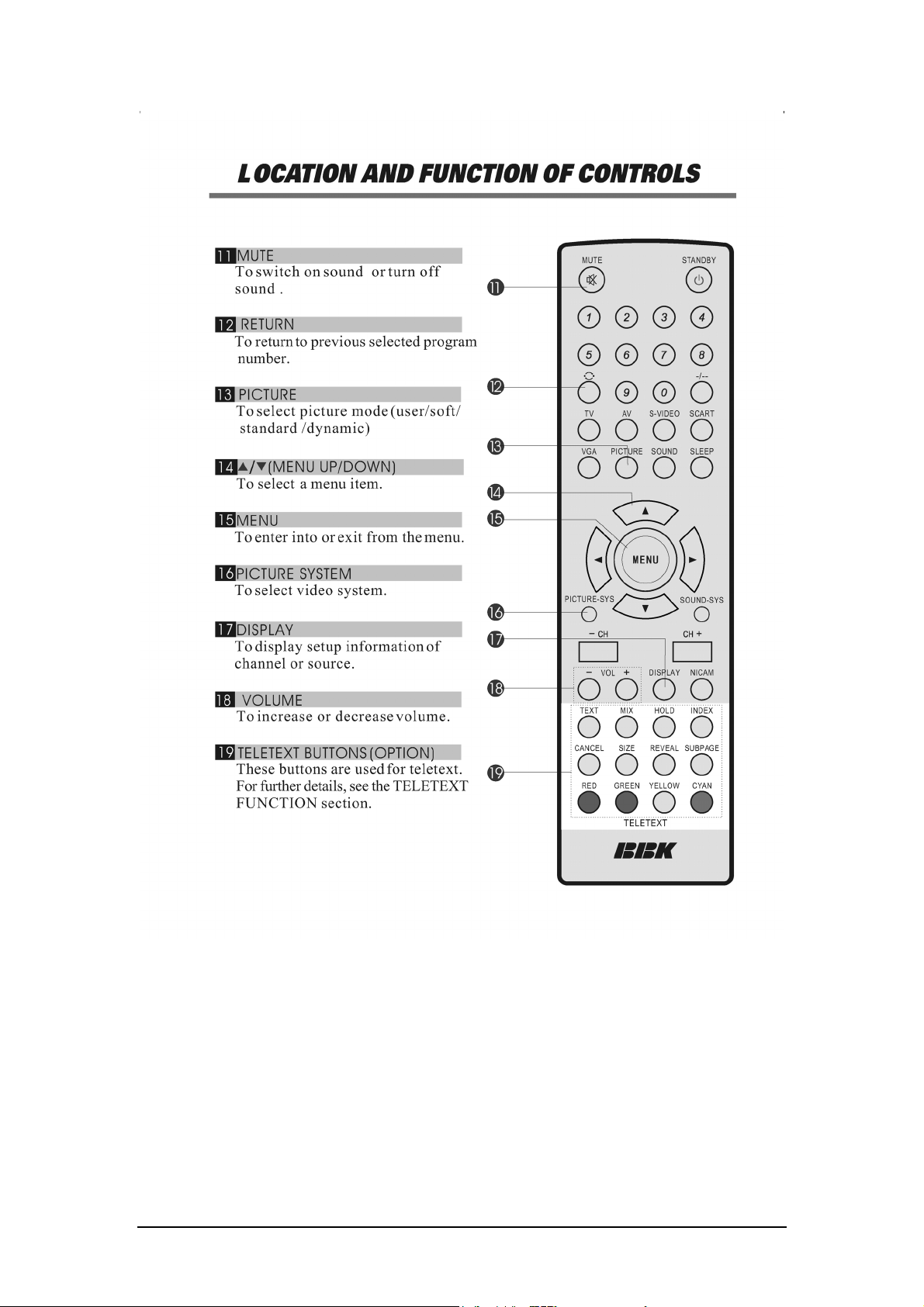

Remote Control Illustration

6

7

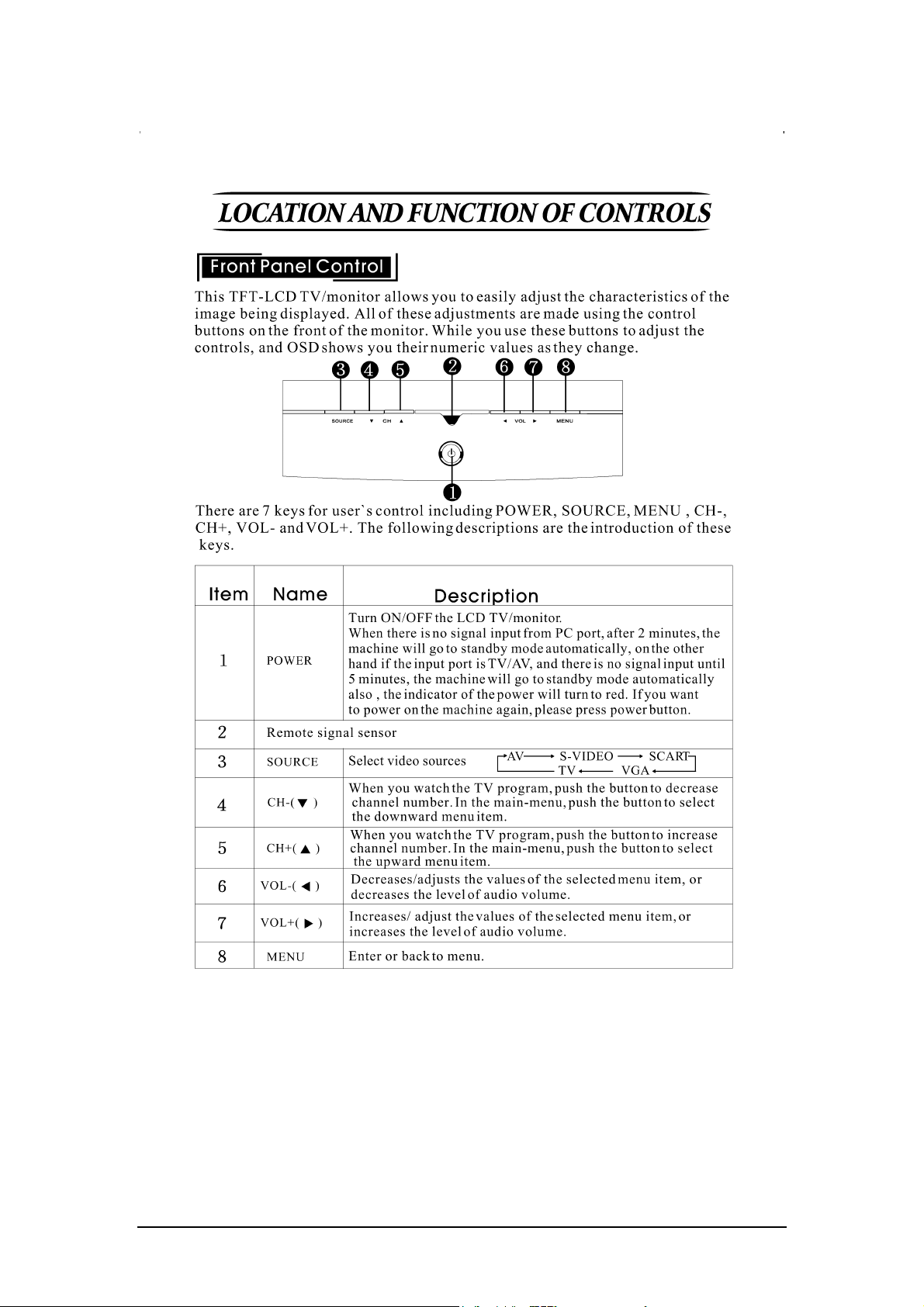

Front Panel Illustration

8

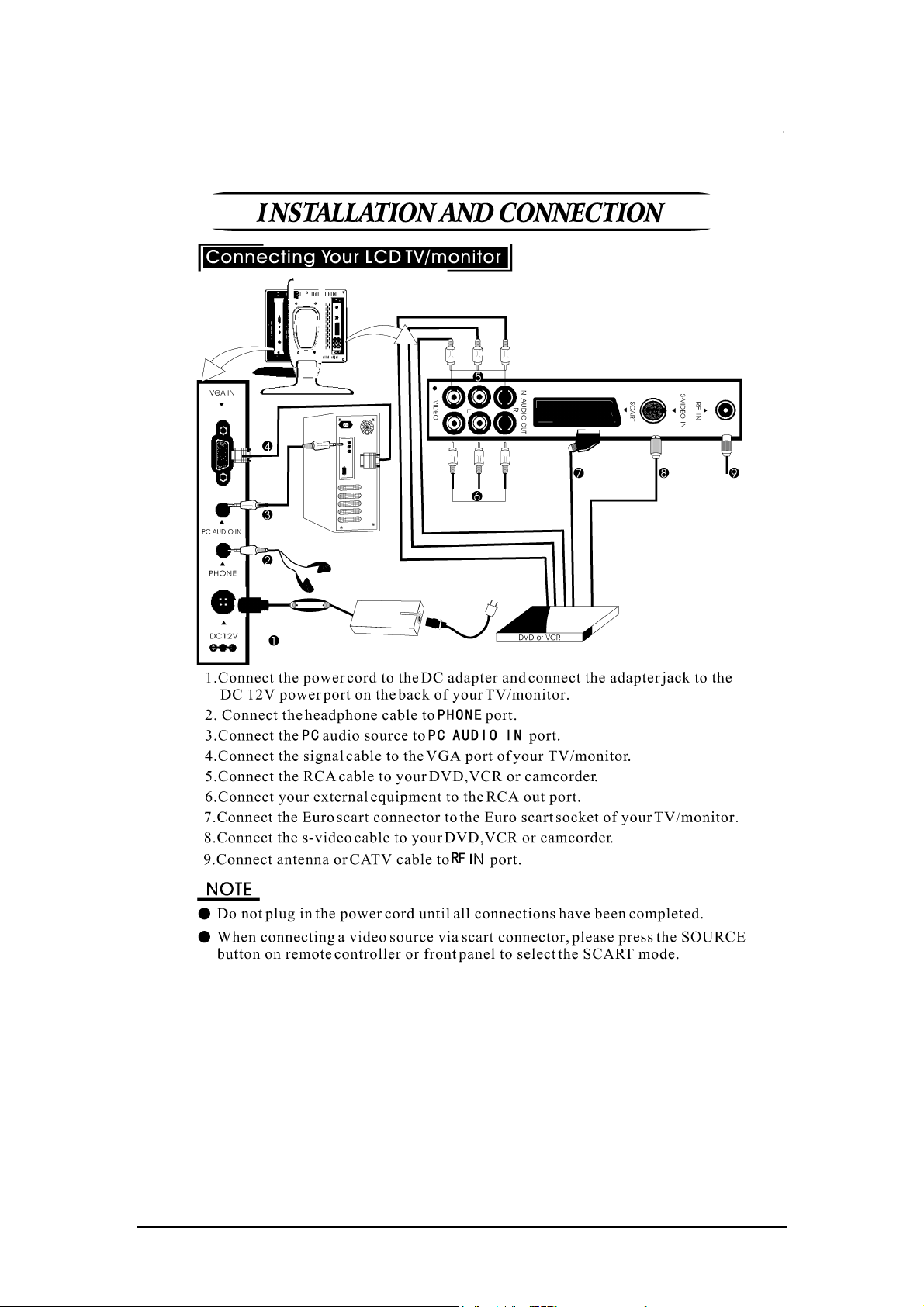

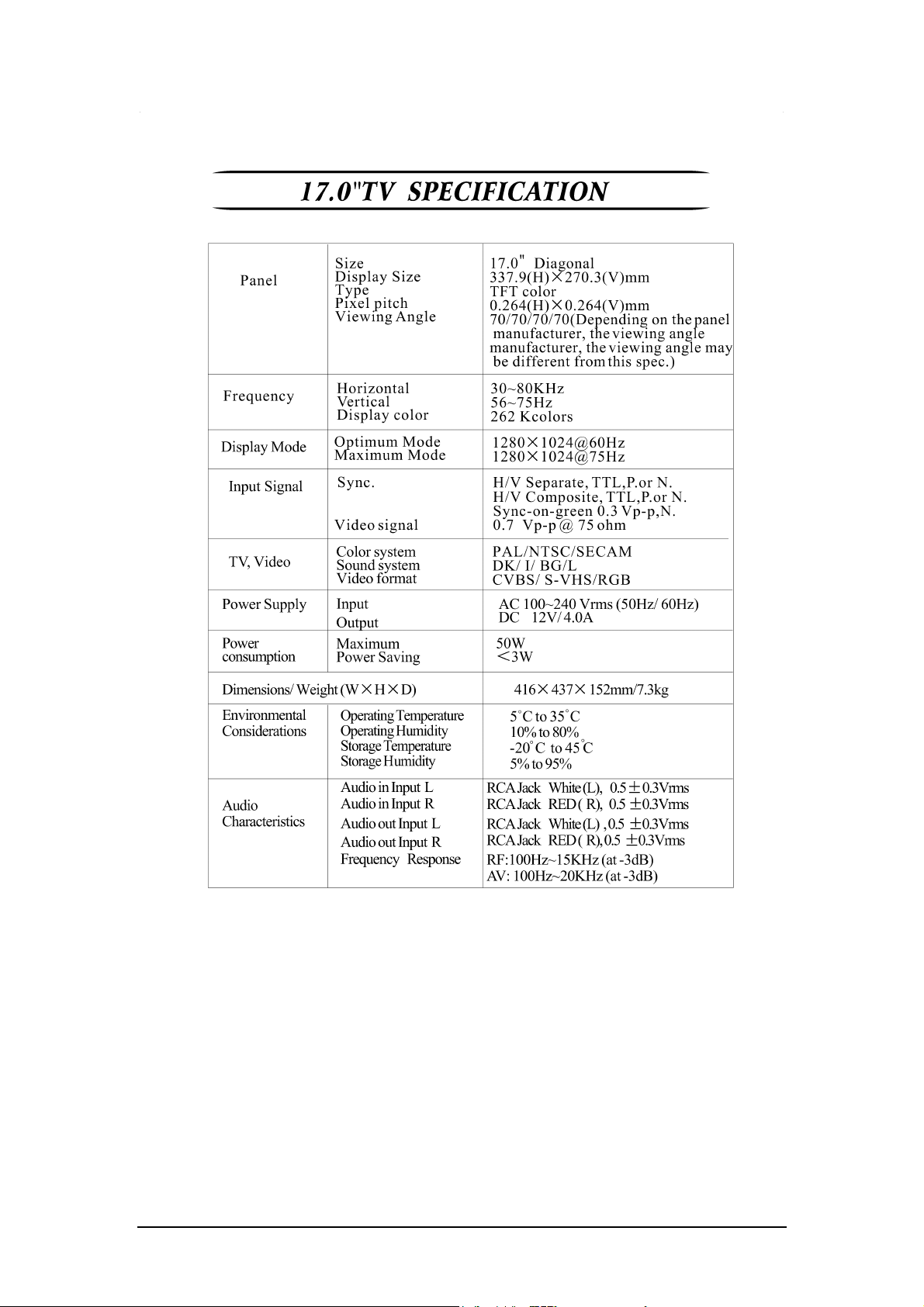

OTHER INFORMATION

9

10

11

12

13

4. Assembling and disassembling the mechanism unit

SEE THE PIECE OF PAPER COME WITH THE MENUAL.

14

5. Test Scheme for LT1703S/LT2003S

Description of purpose of the test scheme:

The electric functional part of LT1703S/LT2003S LCD color TV set is

composed of driving board, audio and video board, control key board and

backlight power supply board. The backlight power supply is a bought module

and the supplier and IQC of our company will check its function and

consistency together; the other functional boards are designed and

manufactured by us. This test scheme will make a guiding criterion of test

method for these modules machined and manufactured by us.

After testing of all the functional modules, the assembled machine will be

tested completely so as to confirm the indexes of all performance to be

qualified or not.

This test scheme is only a guiding document which can not replace the

operating manual book for the production. The test scope of the operating

manual book shall be adjusted according to the real practice. However, the key

technique index must reach the requirement prescribed by this test scheme.

2. The test scheme for driving board and control key board

1) Testing equipments

A. FLUKE45 multimeter one set

B. Special test host computer one set

C. DVD player with SCART terminal one set

D. Audio-board in perfect condition one set

E. Testing frock one piece

F. Remote controller one piece

2) Testing flow

A. Tested driving board into clamp and connect the control key board, then

fulfill and affirm the related testing set-ups.

B. Switch on power, check the power supply voltage of +5、+3.3V、+2.5V

boards by multimeter so as to affirm they are in normal status or not, then

press key “POWER” on the control key board to start the machine.

C. Link the VGA signal outputted from computer to the tested driving board (or

linked by the thimble of clamp), then switch to “VGA” state by remote controller

or “SOURCE” key on the control key board.

D. Check the display quality of all display modes under VGA mode, the

character shall be clear and without distinct jamming.

E. Activate the special “DisplayMate for Windows” test software and select the

“Set up Display”, the exact requirements as follow ① There isn’t distinct

jamming. on the tested pictures; ② All colors are in normal status; ③ The

brightness and definition of pane picture of horizontal lines should be

consistent with that of vertical lines; ④ The color of color stripe is correct and

transition edge is clear; ⑤ The tested picture of DisplayMate Utilities is clear

and arranged properly, focalized normally without distinct jamming.

F. Switch signal source to “AV” mode, start DVD Player and play the

Panasonic demonstration disc so as to check the picture display quality under

AV state, it is required that picture is stable, clear without distinct transverse

and netted striation jamming.

G. Switch signal source to “S-Video” state, the items to be checked and

requirements are as same as that of “AV” state.

15

H. Switch signal source to “SCART” mode, test the Video mode outputted by

“SCART” under “CVBS” mode and “RGB” mode respectively. It is required that

the picture is stable and clear without any jamming. At the same time, test the

picture under RGB mode and it shall have advantage over that of CVBS mode.

The identification of RGB of the machine is in normal state.

3) The qualified criterion and others

Only if the functions of all tested signal source channels have reached their

related standards, the tested board shall be affirmed to be qualified, as to the

board not qualified will be maintained and retested.

3. Testing of audio & video board

1) Testing equipments

A. FLUKE 54200 television signal generator one set

B. HITACHI VC-6545 oscillograph one set

C. Testing frock one piece

D. Driving board in perfect condition one piece

E. CATV antenna one piece

F. TV set with AV input port one set

G. 5MHz Twin channel audio oscillograph one set

H. Remote controller one piece

2) Testing flow

A. Put the tested audio & video board into clamp and link well signal

connections of AV In/Out、S- Video 、TV、SCART (or linked by thimble of

clamp). Install the related instruments and equipments and mark the often

used fixed devices with symbol strip codes.

B. Switch LCD TV to TV receiving mode, set Pattern as “MULTI

BURST”+“GREY SCALE”+“COLOR BAR”, test respectively the watching

situation on the three frequency points of 48.25、168.25、471.25MHz. It is

required that under any Pattern mode, it can reach to the following statuses

that the layer of Pattern is distinct, each grayscale is clear; the color of color

strip is real and transition edge is clear; the brightness of each section of

0.5MHZ/1.0/2.0/4.0MHz of the multi-wave are consistent with each other, they

are so clearly that the vertical lines inside pane can be identified, and so do

4.8MHZ (this section shall be a little darker under that of TV mode).

C. Set the sound mode as BG under TV mode, activate NICAM option as well,

then adjust RF level to 45dB, test respectively the sound quality of FM

MONO/DUAL/STEREO on 48.25、168.25、471.25MHZ, it is required that

sound is clear without distinct noise,for example crack.

D. Set Pattern as “MULTI BURST”, select one channel and input modes of

AV、S-VIDEO、SCART, measure the wave profile between R908 and 7

th

-contact by oscillograph, as indicated in the attached chart hereafter, it is

required that the synchronizing header pulse wave profile of CVBS signal is

square wave and its range of amplitude is 0.3+0.05/-0.1V

amplitude of whole video frequency signal is 1.0±0.2V

P-P; the

The range of

pmp.

range of amplitude

of multi-wave at 4.0MHZ is as same as that of 1.0MHZ, the difference shall be

≤2dB(calculated according to 20lg V

4.0/V1.0

shall be prescribed by the project office.

), the value of amplitude at 4.0MHz

E. Under TV mode, set RF level as 50dBµV and receive anyone of the above

mentioned three frequencies. Awaiting until the normalization of pattern, then

press “TEXT” key on remote controller, the related information of picture will

appear; again press “INDEX” key to let picture return to the menu page; press

16

“CHANNEL+”key to select picture’s 101 pages, it will be refreshed page by

page. Please observe the character or graphics of each refreshed page so as

to confirm any imperfect character or image, it is required that less two pictures

with imperfect character or image in each 10 pictures; please test respectively

the functions of keys including “MIX”、“HOLD”、“CANCEL”、“SIZE”、“REVEAL”

and “RED”、“GREEN”、“YELLOW”、“CYAN” and confirm them normal or not.

F. Under SCART mode, use 54200 “Video” edit key to enter edit menu of

Video, select CVBS and RGB from “SCAROUT” column in order to observe

the image quality of picture, the transition edge of RGB’s COLOR BAR shall be

clear and frequency spectrum of multi-wave are clear and bright under the two

modes of CVBS and RGB., the image quality in CABS mode is consistent with

that of AV state, in the same time, please note that there is any sound

outputted and the receiving status of TEXT in CABS mode.

G. Link 5MHz audio oscillograph to the output ports of loudspeaker, adjust

RF signal with 1KHz audio frequency, tune up volume and let audio outputting

wave profile be distorted just, then measure the peak value of wave profile, it is

required that the value is not less than 10Vp-p.

H. Turn on /off the machine with “POWER” key on remote controller or control

key board and confirm there is any “POP” noise while turning on/off it, there

isn’t any abnormal color block, flashing and astigmatism on picture as well.

4. The test scheme for machine

1) Testing equipment

A. FLUKE 54200 one set

B. FLUKE 5418 one set

C. Special test host computer one set

D. DVD Player one set

E. TV set with AV input port one set

F. CATV antenna 4 pieces

G. Remote controller several pieces

2) Testing requirement

The testing requirement for the related functions of PC and audio & video are

consistent with that of above mentioned boards; the switch testing shall be

done between all modes under PC mode (the display mode of 640×480、800

×600、1024×768(LT1703S)、1280×1024(LT1703S) ), and there will be no

any abnormal grating during the switching. The project office may arrange

reasonably the testing stations according to exact status and change of

capacity of the production line.

In addition, the color sensitivity and FM sound sensitivity also shall be tested

while testing the receiving station of RF signal. The color sensitivity is ≤37db

and FM sound sensitivity is≤30db.

As to the qualified finished products, the related indexes of at least two

machines adopted in accordance with the sample standard shall be tested.

The testing form, please refer to the attached page.

As to those products largely for exportation, it is suggested herein that a

related placement test EMC should be done.

17

Loading...

Loading...