Page 1

SERVICE MANUAL

DL373D

Page 2

CONTENTS

1. SAFETY PRECAUTIONS

1

2. PREVE NTION OF ELE CTR O STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENS ITIVE(ES)DEVICES

3. CONTROL BUTTON LOCATIONS AND E XPLANATIONS

4. PREVE RTION OF STATIC ELE CTRICITY DISCHARGE

5. E LE C TR IC AL C ONFIR MATION

5.1 VIDE O OUTP UT (LUMINANC E S IG NAL) C ONFIR MATION

5.2 VIDE O OUTP UT(C HR OMINANC E S IG NAL) C ONFIR MATION

6. MP E G BOAR D C HE C K WAVE FOR M

7.2 MT1389

1

2

4

5

5

6

7

8

7.3 U214 HY29F800 11

7.4 HY57V641620HG

14

8. S C HE MATIC & P C B WIR ING DIAG R AM

17

9. S P AR E P AR TS LIS T 33

Page 3

1.1 GENERAL GUIDELINES

1. SAFETY PREAUTIONS

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO

ELECTROSTATICALLY SENSITIVE(ES)DEVICES

1

1. When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barrier, insulation papers

shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD).

notice (1885x323x2 tiff)

Page 4

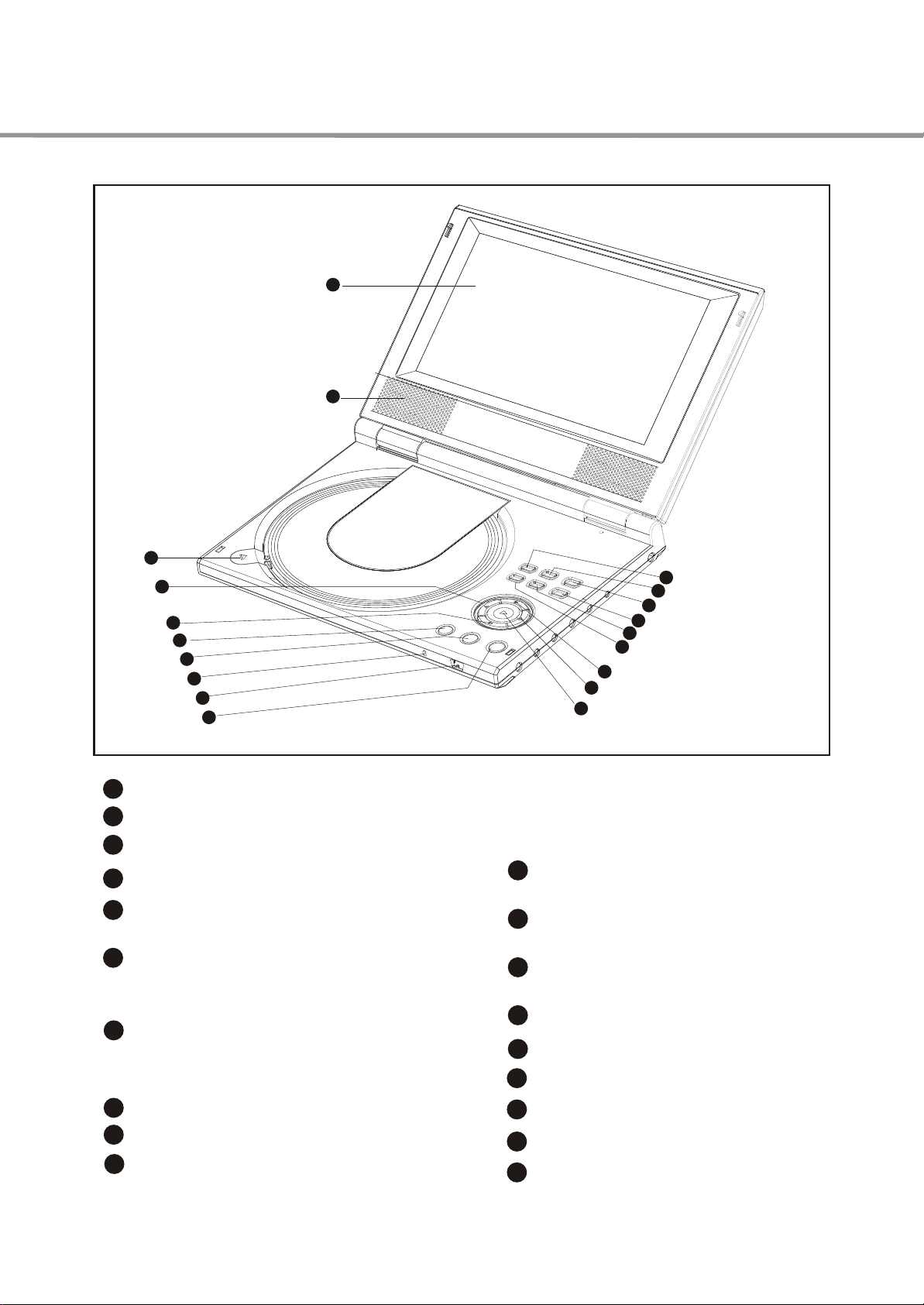

3.Control Button Locations and Explanations

2

1

2

3

4

5

6

7

8

9

10

1

Color TFT LCD

2

Speakers

3

OPEN/CLOSE button

4

PREV button / LEFT direction arrow

5

PAUSE button / DOWN

direction arrow

6

Vol-

Adjust the volume of headphone an

d speaker.

7

Vol+

Adjust the volume of headphone

and speaker.

8

Power indicator

9

IR sensor

10

Panel/Switch Button

19

18

17

16

15

14

13

12

11

Press once to switch to Direction

Buttons function

Press twice to switch to Virtual

Keyboard function

11

PLAY button / SELECT

button

12

NEXT button / RIGHT

direction arrow

13

STOP button / UP direction

arrow

14

SET button

15

PICTURE button

16

DVD/AUXIN button

17

POWER button

18

MENU button

19

Browser Button

Page 5

Control Button Locations and Explanations(Continued)

3

Page 6

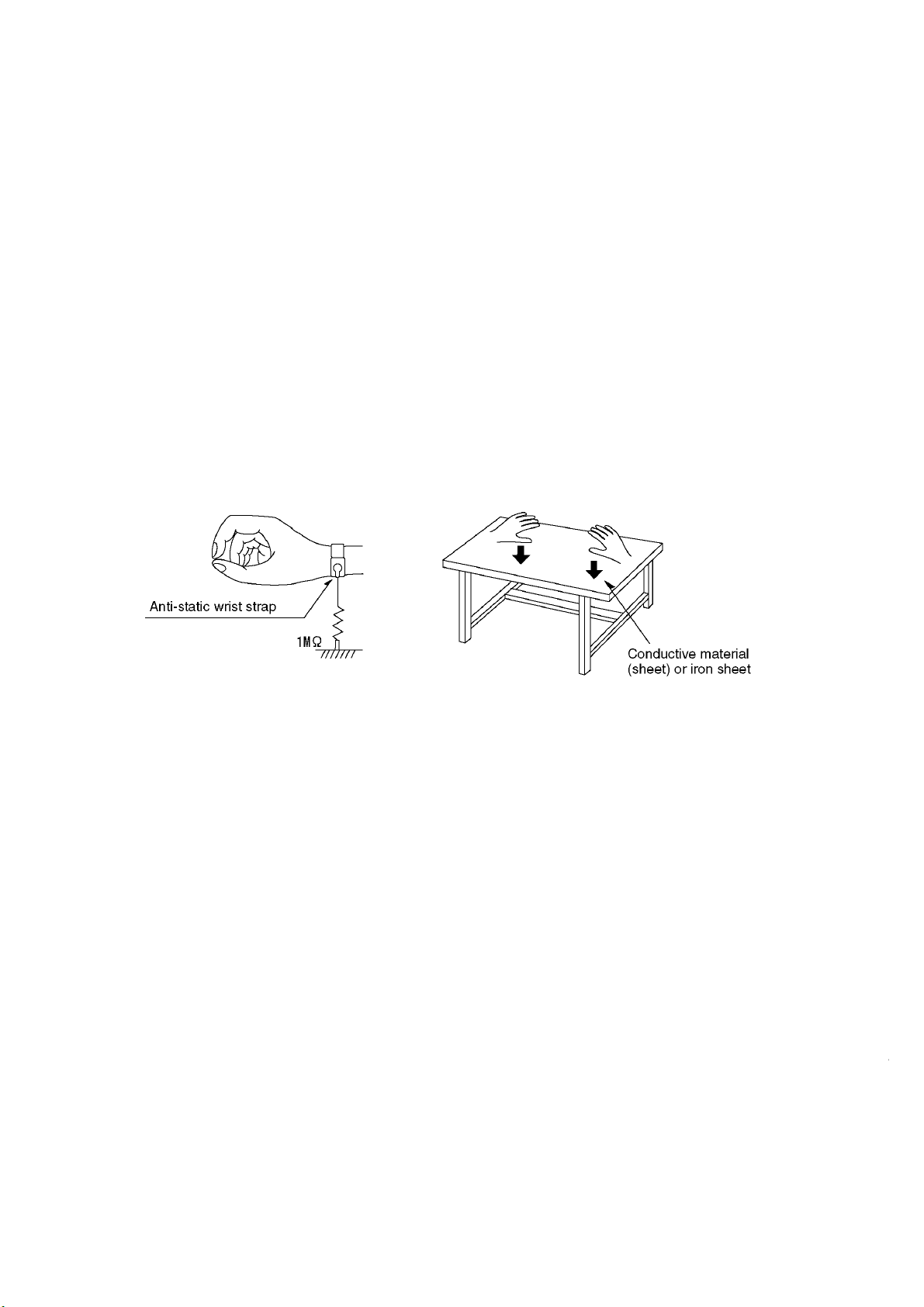

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1. Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the

3. The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

4

4.PREVENTION OF STATIC ELECTRICITY DISCHARGE

4.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

4.1.1. Worktable grounding

sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

4.1.3.Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before

installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure. (See this Technical Guide).

2. Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2. When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the

optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

Page 7

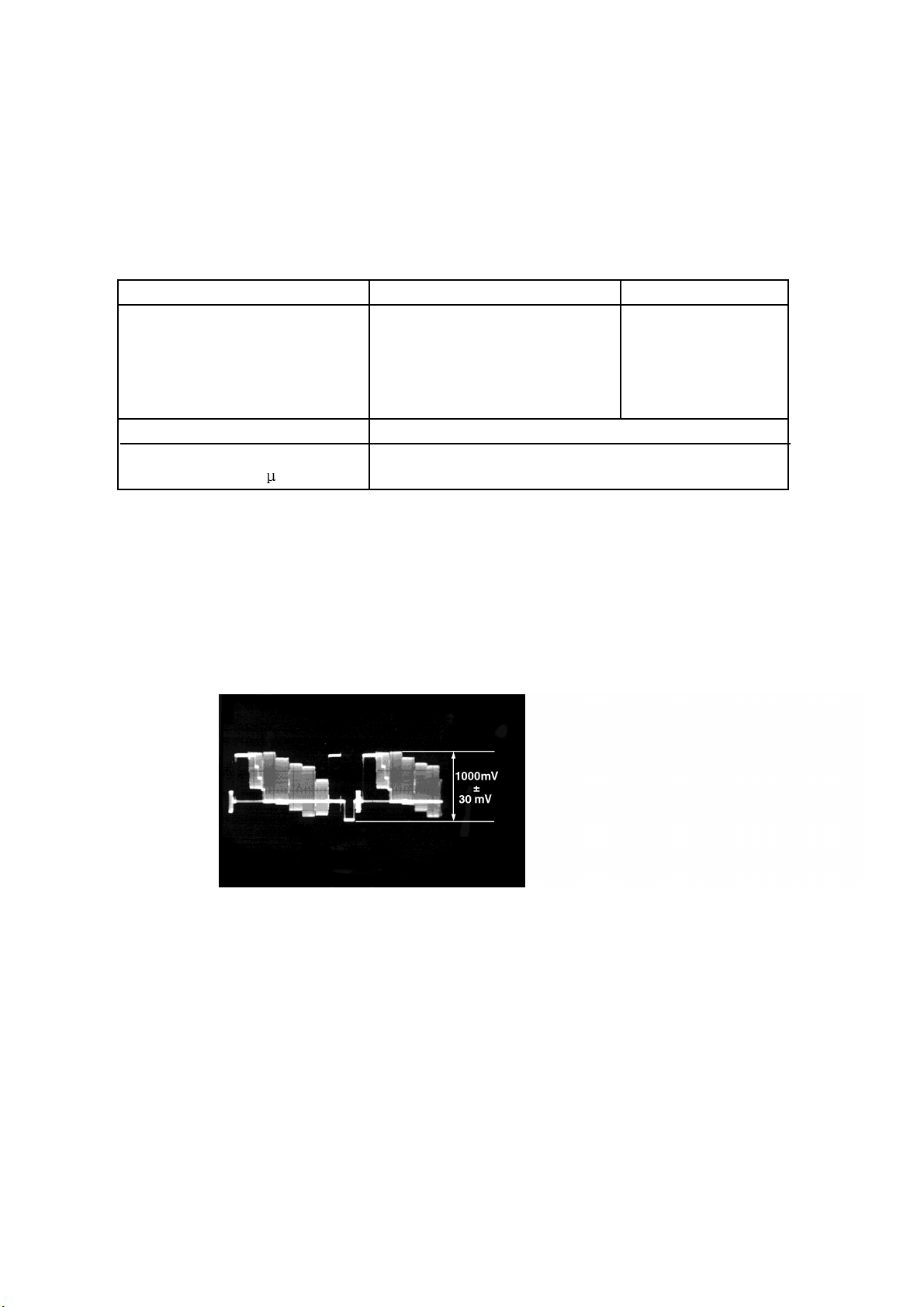

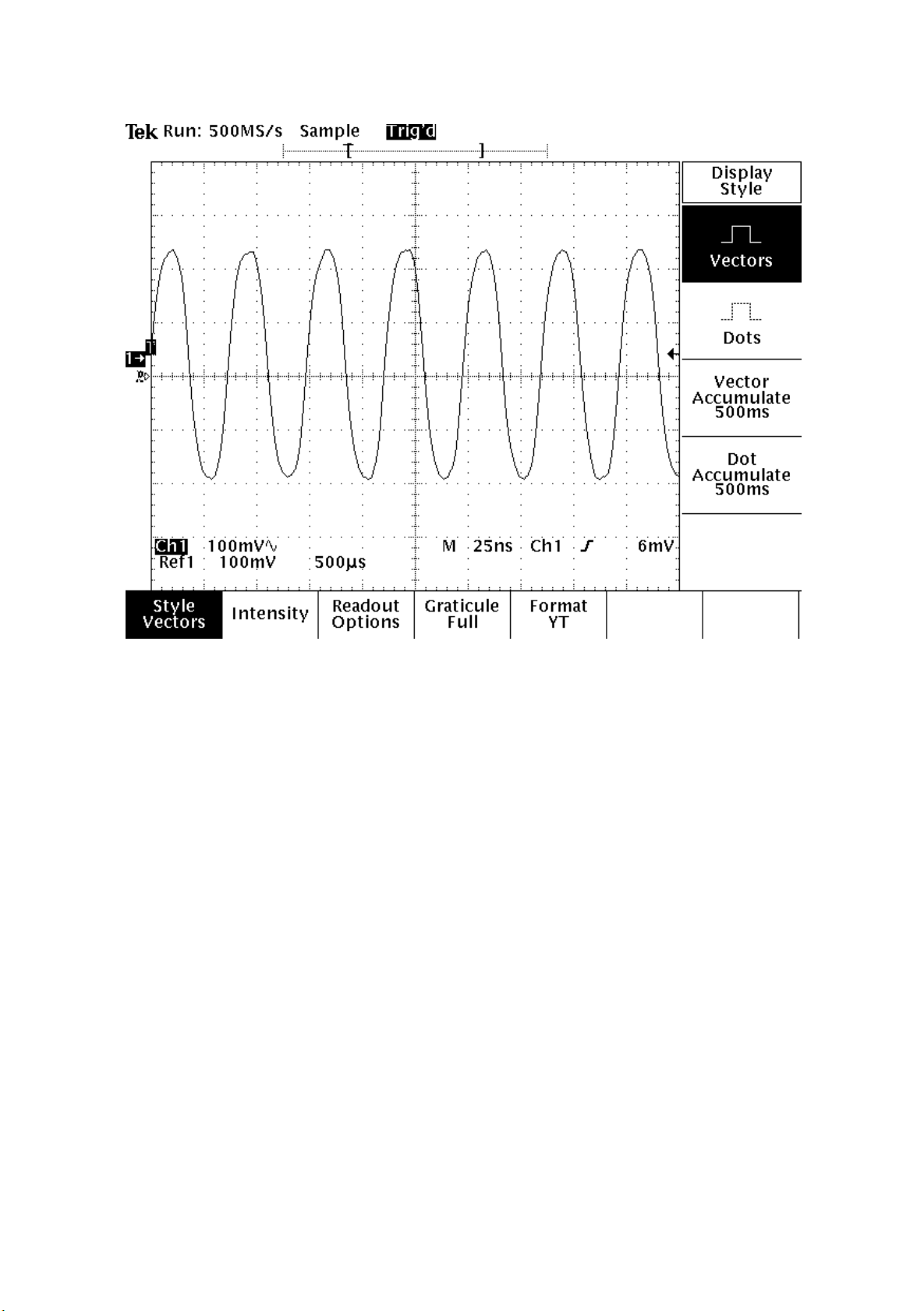

5.1. Video Output (Luminance Signal) Confirmation

5

5.Electrical Confirmation

DO this confirmation after replacing a P.C.B.

Measurement point

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 8

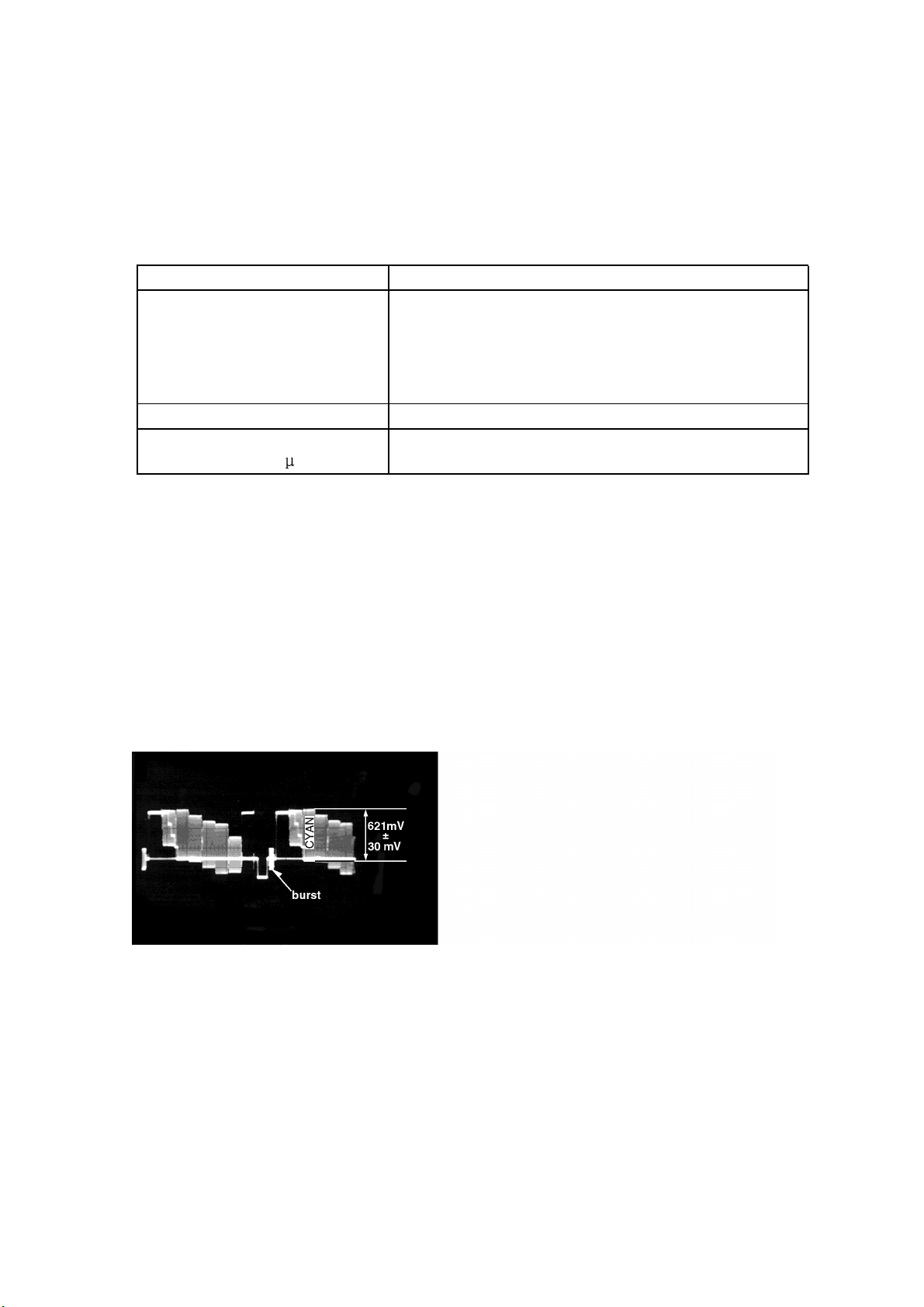

Do the confirmation after replacing P.C.B.

Screwdriver,Oscilloscope

5.2 Video Output(Chrominance Signal) Confirmation

6

Measurement point

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 9

6.MPEG BOARD CHECK WAVEFORM

6.1 27MHz WAVEFORM

7

Page 10

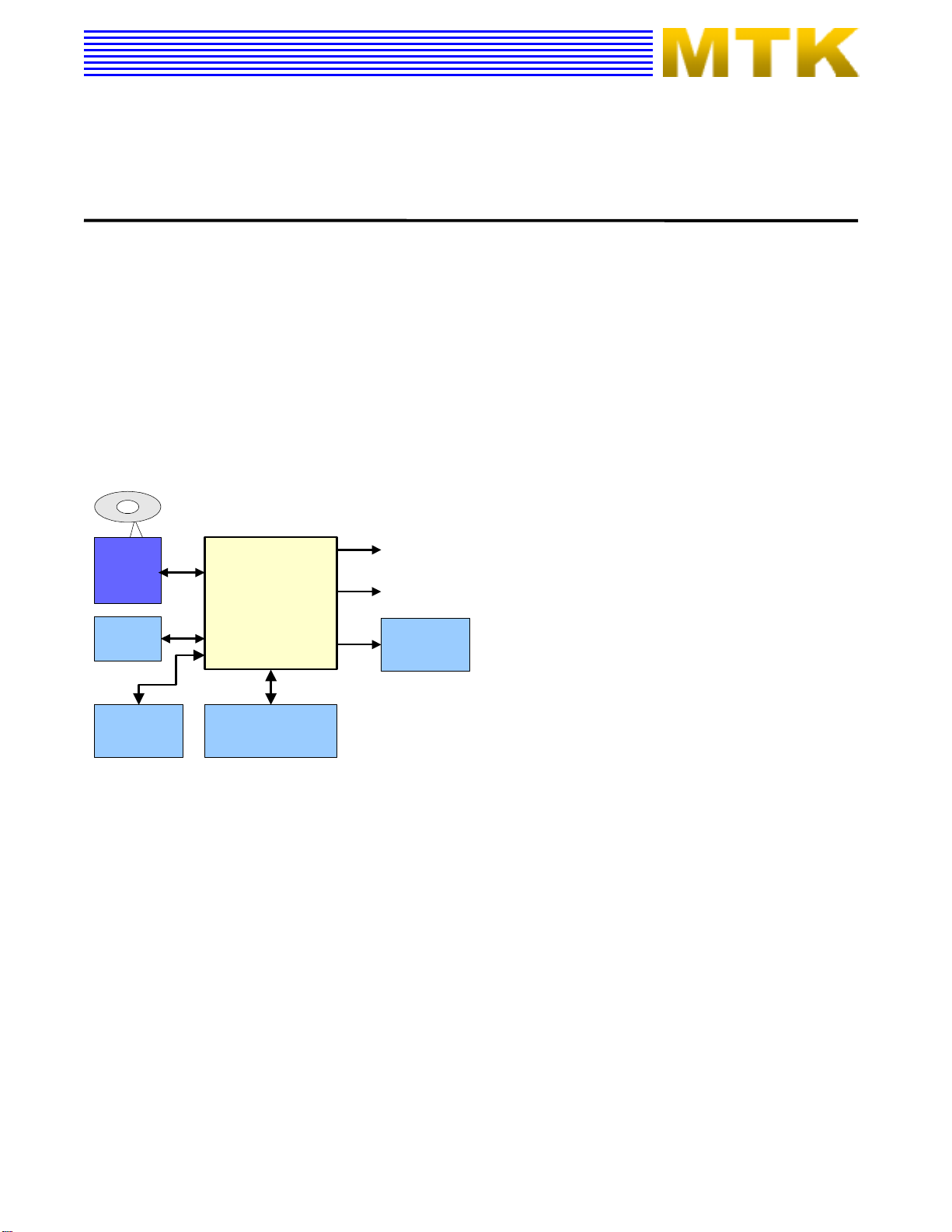

7.2 MT1389

8

MT1389

Specifications are subject to change without notice

Progressive-Scan DVD Player SOC

MediaTek MT1389 is a DVD player system-on-chip (SOC) which incorporates advanced features like high

quality TV encoder and state-of-art de-interlace processing. The MT1389 enables consumer electronics

manufacturers to build high quality, cost-effective DVD players, portable DVD players or any other home

entertainment audio/video devices.

rd

Based on MediaTek’s world-leading DVD player SOC architecture, the MT1389 is the 3

player SOC. It integrates the MediaTek 2

decoder.

The progressive scan of the MT1389 utilized a proprietary advanced motion-adaptive de-interlace algorithm to

achieve the best movie/video playback. It can easily detect 3:2/2:2 pull down source and restore the correct

original pictures. It also supports a patent-pending edge-preserving algorithm to remove the saw-tooth effect.

nd

generation front-end analog RF amplifier and the Servo/MPEG AV

generation of the DVD

Key Features

RF/Servo/MPEG Integration

High Performance Audio Processor

Motion-Adaptive, Edge-Preserving De-interlace

108MHz/12-bit, 6 CH TV Encoder

DVD

PUH

Module

CVBS, Y/C,

Component

SDPIF

MT1389L

Applications

FLASH

Front-panel

Remote

DRAM

Audio DAC

Standard DVD Players

Portable DVD Players

DVD Player System Diagram Using MT1389

Page 11

9

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1389

General Feature List

1024-bytes on-chip RAM

Super Integration DVD player single chip

High performance analog RF amplifier

Servo controller and data channel processing

MPEG-1/MPEG-2/JPEG video

Dolby AC-3/DTS/DVD-Audio

Unified memory architecture

Versatile video scaling & quality

enhancement

OSD & Sub-picture

2-D graphic engine

Built-in clock generator

Built-in high quality TV encoder

Built-in progressive video processor

Audio effect post-processor

Audio input port

Up to 4M bytes FLASH-programming

interface

Supports 5/3.3-Volt. FLASH interface

Supports power-down mode

Supports additional serial port

DVD-ROM/CD-ROM Decoding Logic

High-speed ECC logic capable of correcting

one error per each P-codeword or

Q-codeword

Automatic sector Mode and Form detection

Automatic sector Header verification

Decoder Error Notification Interrupt that

signals various decoder errors

Provide error correction acceleration

High Performance Analog RF Amplifier

Programmable fc

Dual automatic laser power control

Defect and blank detection

RF level signal generator

Speed Performance on Servo/Channel Decoding

DVD-ROM up to 4XS

CD-ROM up to 24XS

Channel Data Processor

Digital data slicer for small jitter capability

Built-in high performance data PLL for

channel data demodulation

EFM/EFM+ data demodulation

Enhanced channel data frame sync protection

& DVD-ROM sector sync protection

Servo Control and Spindle Motor Control

Programmable frequency error gain and

phase error gain of spindle PLL to control

spindle motor on CLV and CAV mode

Built-in ADCs and DACs for digital servo

control

Provide 2 general PWM

Tray control can be PWM output or digital

output

Embedded Micro controller

Built-in 8032 micro controller

Built-in internal 373 and 8-bit programmable

lower address port

Buffer Memory Controller

Supports 16Mb/32Mb/64Mb/128Mb SDRAM

Supports 16-bit SDRAM data bus

Provide the self-refresh mode SDRAM

Block-based sector addressing

Support 3.3 Volt. DRAM Interface

Video Decode

Decodes MPEG1 video and MPEG2 main level,

main profile video (720/480 and 720x576)

Smooth digest view function with I, P and B

picture decoding

Baseline, extended-sequential and

progressive JPEG image decoding

Support CD-G titles

Video/OSD/SPU/HLI Processor

Arbitrary ratio vertical/horizontal scaling of

video, from 0.25X to 256X

65535/256/16/4/2-color bitmap format OSD,

256/16 color RLC format OSD

Automatic scrolling of OSD image

Slide show transition as DVD-Audio

Specification

2-D Graphic Engine

Support decode Text and Bitmap

Support line, rectangle and gradient fill

Support bitblt

Chroma key copy operation

Clip mask

Page 12

10

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1389

Audio Effect Processing

Dolby Digital (AC-3)/EX decoding

DTS/DTS-ES decoding

MLP decoding for DVD-Audio

MPEG-1 layer 1/layer 2 audio decoding

MPEG-2 layer1/layer2 2-channel audio

High Definition Compatible Digital (HDCD)

Windows Media Audio (WMA)

Advanced Audio Coding (AAC)

Dolby ProLogic II

Concurrent multi-channel and downmix out

IEC 60958/61937 output

- PCM / bit stream / mute mode

- Custom IEC latency up to 2 frames

Pink noise and white noise generator

Karaoke functions

- Microphone echo

- Microphone tone control

- Vocal mute/vocal assistant

- Key shift up to +/- 8 keys

- Chorus/Flanger/Harmony/Reverb

Channel equalizer

3D surround processing include virtual

surround and speaker separation

TV Encoder

Six 108MHz/12bit DACs

Support NTSC, PAL-BDGHINM, PAL-60

Support 525p, 625p progressive TV format

Automatically turn off unconnected channels

Support PC monitor (VGA)

Support Macrovision 7.1 L1, Macrovision

525P and 625P

CGMS-A/WSS

Closed Caption

Progressive Output

Automatic detect film or video source

3:2 pull down source detection

Advanced Motion adaptive de-interlace

Edge Preserving

Minimum external memory requirement

Audio Input

Line-in/SPDIF-in for versatile audio

processing

Outline

256-pin LQFP package

3.3/1.8-Volt. Dual operating voltages

Page 13

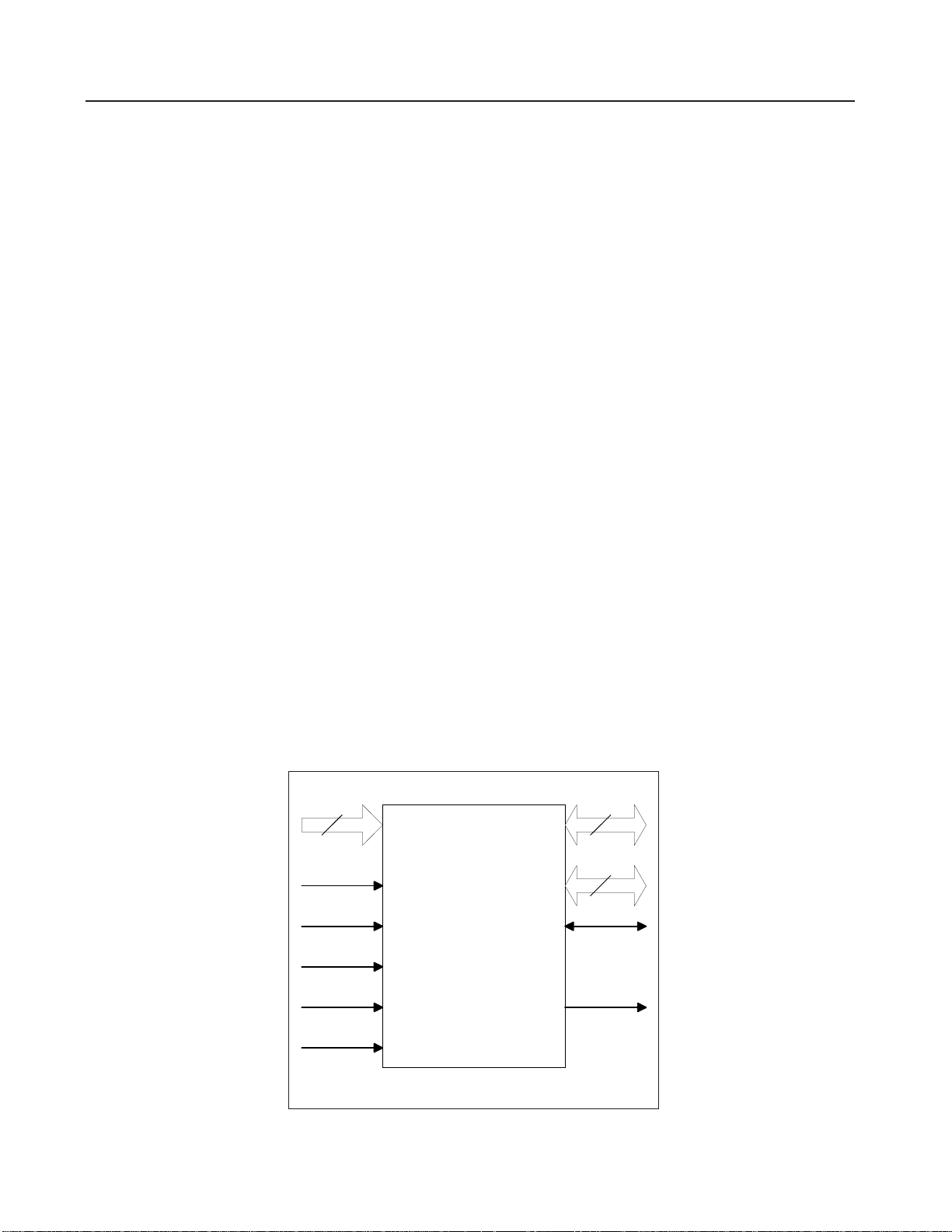

KEY FEATURES

IC BLOCK DIAGRAM & DESCRIPTION

11

7.3 U214 HY29F800

n 5 Volt Read, Program, and Erase

– Minimizes system-level power requirements

n High Performance

– Access times as fast as 55 ns

n Low Power Consumption

– 20 mA typical active read current in byte

mode, 28 mA typical in word mode

– 35 mA typical program/erase current

– 5 µA maximum CMOS standby current

n Compatible with JEDEC Standards

– Package, pinout and command-set

compatible with the single-supply Flash

device standard

– Provides superior inadvertent write

protection

n Sector Erase Architecture

– Boot sector architecture with top and

bottom boot block options available

– One 16 Kbyte, two 8 Kbyte, one 32 Kbyte

and fifteen 64 Kbyte sectors in byte mode

– One 8 Kword, two 4 Kword, one 16 Kword

and fifteen 32 Kword sectors in word mode

– A command can erase any combination of

sectors

– Supports full chip erase

n Erase Suspend/Resume

– Temporarily suspends a sector erase

operation to allow data to be read from, or

programmed into, any sector not being

erased

n Sector Protection

– Any combination of sectors may be

locked to prevent program or erase

operations within those sectors

n Temporary Sector Unprotect

– Allows changes in locked sectors

(requires high voltage on RESET# pin)

n Internal Erase Algorithm

– Automatically erases a sector, any

combination of sectors, or the entire chip

n Internal Programming Algorithm

– Automatically programs and verifies data

at a specified address

n Fast Program and Erase Times

– Byte programming time: 7 µs typical

– Sector erase time: 1.0 sec typical

– Chip erase time: 19 sec typical

n Data# Polling and Toggle Status Bits

– Provide software confirmation of

completion of program or erase

operations

n Ready/Busy# Output (RY/BY#)

– Provides hardware confirmation of

completion of program and erase

operations

n Minimum 100,000 Program/Erase Cycles

n Space Efficient Packaging

– Available in industry-standard 44-pin

PSOP and 48-pin TSOP and reverse

TSOP packages

19

A[18:0]

CE#

OE#

WE#

RESET#

BYTE#

8

DQ[7:0]

7

DQ[14:8]

DQ[15]/A-1

RY/BY#

Page 14

BLOCK DIAGRAM

IC BLOCK DIAGRAM & DESCRIPTION

12

DQ[15:0]

A[18:0], A-1

DQ[15:0]

WE#

CE#

OE#

BYTE#

RESET#

RY/BY#

STATE

CONTROL

COMMAND

REGISTER

PROGRAM

VOLTAGE

GENERATOR

VCC DETECTOR TIMER

ERASE VOLTAGE

GENERATOR AND

SECTOR SWITCHES

A[18:0], A-1

ADDRESS LATCH

I/O CONTROL

Y-DECODER

X-DECODER

I/O BUFFERS

DATA LATCH

Y-GATING

8 Mb FLASH

MEMORY

ARRAY

Page 15

PIN CONFIGURATIONS

IC BLOCK DIAGRAM & DESCRIPTION

13

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1910

A0

CE#1112

V

SS

OE#1314

DQ0

DQ81516

DQ1

DQ91718

DQ2

DQ101920

DQ3

DQ112122

1

2

3

4

5

6

7

8

PSOP44

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

RESET#

WE#

A8

A9

A10

A11

A12

A13

A14

A15

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC910

WE#

RESET#1112

NC

NC1314

RY/BY#

A181516

A17

A71718

A6

A51920

A4

A32122

A2

A12324

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A16

1

2

3

4

5

6

7

8

Standard

TSOP48

1

2

3

4

5

6

7

8

9

Reverse

TSOP48

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

Page 16

HY57V641620HG

14

7.4 HY57V641620HG

4 Banks x 1M x 16Bit Synchronous DRAM

DESCRIPTION

The Hyundai HY57V641620HG is a 67,108,864-bit CMOS Synchronous DRAM, ideally suited for the main memory applications which

require large memory density and high bandwidth. HY57V641620HG is organized as 4banks of 1,048,576x16.

HY57V641620HG is offering fully synchronous operation referenced to a positive edge of the clock. All inputs and outputs are synchronized with the rising edge of the clock input. The data paths are internally pipelined to achieve very high bandwidth. All input and output

voltage levels are compatible with LVTTL.

Programmable options include the length of pipeline (Read latency of 2 or 3), the number of consecutive read or write cycles initiated

by a single control command (Burst length of 1,2,4,8 or Full page), and the burst count sequence(sequential or interleave). A burst of

read or write cycles in progress can be terminated by a burst terminate command or can be interrupted and replaced by a new burst

read or write command on any cycle. (This pipelined design is not restricted by a `2N` rule.)

FEATURES

• Single 3.3±0.3V power supply

• All device pins are compatible with LVTTL interface

• JEDEC standard 400mil 54pin TSOP-II with 0.8mm

of pin pitch

• All inputs and outputs referenced to positive edge of

system clock

• Data mask function by UDQM or LDQM

• Internal four banks operation

Note)

• Auto refresh and self refresh

• 4096 refresh cycles / 64ms

• Programmable Burst Length and Burst Type

- 1, 2, 4, 8 or Full page for Sequential Burst

- 1, 2, 4 or 8 for Interleave Burst

• Programmable CAS Latency ; 2, 3 Clocks

.

Page 17

PIN CONFIGURATION

15

HY57V641620HG

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

DD

V

LDQM

/WE

/CAS

/RAS

/CS

BA0

BA1

A10/AP

A0

A1

A2

A3

DD

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54pin TSOP II

400mil x 875mil

0.8mm pin pitch

VSS

54

DQ15

53

VSSQ

52

DQ14

51

DQ13

50

VDDQ

49

DQ12

48

DQ11

47

VSSQ

46

DQ10

45

DQ9

44

VDDQ

43

DQ8

42

SS

V

41

NC

40

UDQM

39

CLK

38

CKE

37

NC

36

A11

35

A9

34

A8

33

A7

32

A6

31

A5

30

A4

29

SS

V

28

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK Clock

CKE Clock Enable

CS Chip Select Enables or disables all inputs except CLK, CKE and DQM

BA0,BA1 Bank Address

A0 ~ A11 Address

Row Address Strobe,

RAS, CAS, WE

LDQM, UDQM Data Input/Output Mask Controls output buffers in read mode and masks input data in write mode

DQ0 ~ DQ15 Data Input/Output Multiplexed data input / output pin

VDD/VSS Power Supply/Ground Power supply for internal circuits and input buffers

VDDQ/VSSQ Data Output Power/Ground Power supply for output buffers

NC No Connection No connection

Column Address Strobe,

Write Enable

The system clock input. All other inputs are registered to the SDRAM on the

rising edge of CLK

Controls internal clock signal and when deactivated, the SDRAM will be one

of the states among power down, suspend or self refresh

Selects bank to be activated during RAS activity

Selects bank to be read/written during CAS activity

Row Address : RA0 ~ RA11, Column Address : CA0 ~ CA7

Auto-precharge flag : A10

RAS, CAS and WE define the operation

Refer function truth table for details

Page 18

FUNCTIONAL BLOCK DIAGRAM

I/O Buffer & Logic

16

1Mbit x 4banks x 16 I/O Synchronous DRAM

HY57V641620HG

Self refresh logic

& timer

CLK

CKE

CS

RAS

CAS

WE

UDQM

LDQM

Row active

State Machine

refresh

Column

Active

Internal Row

counter

Row

Pre

Decoders

Column

Pre

Decoders

1Mx16 Bank 3

X decoders

1Mx16 Bank 2

X decoders

X decoders

1Mx16 Bank 1

1Mx16 Bank 0

X decoders

Memory

Y decoders

Cell

Array

Sense AMP & I/O Gate

DQ0

DQ1

DQ14

DQ15

Bank Select

A0

A1

A11

BA0

BA1

Address buffers

Address

Registers

Mode Registers

Column Add

Counter

Burst

Counter

CAS Latency

Data Out Control

Pipe Line Control

Page 19

F

8.SCHEMATIC & P.C.B WIRING DIAGRAM

DECODE BOARD

17

E

123

C123 151

C112

104

FMSO

R123 20K

R106

10K

TRSO

V1P4

STBY

28

U104

BA5954

VINSL+

VINSL-

VINFC

VOSL

CF12CF2

4

5

6

3

1

V1P4

FOSO

R124 20K

C124

151

XS15

SL-

SL+

MO_VCC

R126

47R

104

104

H-

R127

104

47R

HV+

HV-

HW+

HW-

15

30

BA6849/6869

G2

GND

CNF

BR

G1

HSOP28/SMD

16

17

18

29

8

R131

C116

104

R

C117

104

47uF/16V

TC109

PREGND22VINLD23CTK224CTK125VINTK26BIAS27STBY

VINFFC

HU+H+UVW

FR20SB

A

1

XS101

30

AVCC

23 4

R101

100K

CE

V101

3904-S

B

R103

10K

R104

10K

AVCC

IOA

R140

0R

DQS0

AT24C16X4050

U101

8

DV33

C103

104

R109

680R

R110

680R

5

VR-DVD

V104

104

B

VR-CD

V20

DVDRFIP

SPLRCK

L104

L102

L105

L106

L103

C104

L114

L115

104

FBSMT

FBSMT

FBSMT

FBSMT

FBSMT

CCCBSUBB

SUBC

R111

4.7R

LDO-AV33

TC103

47uF/16V

LDO1

FBSMT

L119

AV33

AVCC VCC

C106

104

10uH 2012

L107

C107

104

C108

104

+9V

A5V

C102

DV33

FBSMT

FBSMT

C E

EEPROM

102(DNS)

C118

C119

102(DNS)

L101

L116

L113

L112

L111

FCM2012-120T2A

FBSMT

FBSMT

FBSMT

FBSMT

D

AVCC

SUBD

SUBAAIOA

C105

104

100uF/16V

TC102

2SK3018-S

V102

2SK3018-S

V103

B

R102

100K

4

DC/NC1RST_/NC2WP/RST_3VSS

RST/WP

VCC

SDA

SCL

7

5

6

SDA

SCL

4.7R

XS103

翻盖检测关闭开关

1

TRIN

R105

10K

R137

15K

R139

47K

5

电池电压检测电路

4 8

LM393

DET 6.0V AND LOWBAT WARNING

C

XS30

2341568910711121415161317182021221923242627282529

R112

DV33

6

7

33R

LOWBAT_DE T

T-

T+

F+

47uF/16V

TC104

LDO-AV33

R136

470R

4 8

U105B

R134

4.7K

R143

MDI1

LD-CD

LD-DVD

AVCC

F-

L118

L117

10uH 2012

10uH 2012

2SB1132-S

V105

2SB1132-S

LDO2

R135

20K

R138

47K

3

2

U105A

LM393

1

R133

4.7K

DET 5.7V AND SYSTEM OFF

R142

33R

POWEROFF_DET

D

TC105

47uF/16V

MO_VCC

C126

104

104

C110

C111

104

SL-

21

PVCC1

VOSL-

PGND

VCC

7

10

9

11

8

R107

10K

SP+

HW+

HV-

HV+

HU-

WVU

C113

C114

R1290RR1280RR130

C115

HU-

HU+

0R

A32A24A17RNF

H1+9H1-10H2+11H2-12H3+13H3-14VH

ECR

FG

EC

PS

21

23

24

22

FG

STBY

V1P4

DMSO

SL+

VOFC-

VO2+

12

13

SP-

234156891071112141513

LIMITH-HW-

VCC25VM1

VM2

26

VOTK+15VOTK-16VOLD+17VOLD-18PGND19VNFTK20PVCC2

GND

GND

VOFC+

22uF/16V

TC101

V1P4

R116

1R

R117

1R

T-

T+

29

30

F+

14

XS104

28

27

F-

MO_VCC

L120

10uH 2012

R118

1R

R119

1R

U103

VCC

XS02

2

R120

1R

R121

1R

R122

1R

C109

104

TC108

47uF/16V

MO_VCC

R144

10K

TC107

100uF/16V

R141

100K(DNS)

R145

33R

URST#

DV33

VD101

1N4148

U106

IMP8009(DNS)

3

VCC

2

RST

1

GND

C125

104(DNS)

XS102

CPU5V

IR

R114 100R

R132

150R

D

C121

47pF(DNS)

R115

4.7K(DNS)

TC106

47uF/10V

C122 103

CPU5V

R113

10R

1

U102

HS0038B

GND2VCC3OUT

IR遥控 输入电路

C

B

XS04

C120

47pF

234

1

1 2

L110

L108

L109

C101

27pF

10uH 2012

FBSMT

FBSMT

POWER

VSDA

DV33

6

A

Page 20

A

DECODE BOARD

18

DQ0

DQ1

DQ2

DQ4

DQ5

DQ6

DQ7

XI

XO

C264

33pF

R227 0R

R204 100K

R226 0R

X201

6

27MHz

33pF

C263

DMA5

DMA4

R255

0R(DNS)

R256

0R(DNS)

R257

DMA5#

DMA4#

DMA10# DMA10

5

L202

FBSMT

DACVDD3 DV33

Y1

Y2

Y3

R210 (DNS)

R211 (DNS)

R212 (DNS)

Y4

Y5

Y6

1K

SPLRCK

R214

(DNS)

(DNS)

(DNS)

(DNS)

89V33

ALRCK

ABCK

ACLK

R209

R208

R207

R206

ASDAT0

MUTE_DAC

V18

RST#

AMDAT

ASPDIF

R205

(DNS)

XO

RFV18

XI

JITFO

JITFN

C261 0.47uF

PLLVDD3

0.047uF

TC204

10uF/16V

C260

0.047uF

C259

ADCVDD3

C251 1uF

20pF

C258

C257

V1P4

23 4

C277

PLLVDD3

4.7R

L206

1

VREFP

VREFN

1000pF

RFVDD3

100K

R203

104

C211

0.033uF

C256

104

C210

104

C209

104

C208

R201

15K

C207

104

104

C250 1uF

C205

104

VREFN VREFP

TC201

47uF/16V

RFVDD3

ADCVDD3

C201

104

C202

104

FBSMT

FBSMT

L207

L208

L201

FBSMT

RFV33

DQ3

DQ02DQ14DQ25DQ37DQ48DQ510DQ611DQ713DQ842DQ9

A023A124A225A326A429A530A631A732A833A934A10/AP22A1135BA0/A1320BA1/A1221CLK38CKE37/CS19/RAS18/CAS17/WE16DQML15DQMH39NC36NC40VSS54VSS41VSS

U202

DMA0#

DMA1#

DMA2#

DMA3#

DMA4#

DMA5#

DMA6#

DMA7#

JITFNJITFO

1000pF

C262

0R(DNS)

C214

C213

C212

AVDD3

C203

104

DMA11

R254

BA0

BA1

R216 750K

560R

TC205

Y0

10uF/16V

104

104

104

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

C206

104

RFSVDD3

FBSMT

L209

89V33 V18

ABCK

ACLK

DVSS

DVSS

SPDIF

XTALI

JITFO

JITFN

LPFIP

LPFIN

LPFOP

CEQP

CEQN

OSP

OSN

RFGC

IREF

C249 1uF

BAD

C204

104

YUV1/Y

YUV2/C

YUV4/G

YUV5/B

YUV6/R

DVDD3

SPMCLK

SPDATA

SPLRCK

DVDD3

ALRCK

DVDD18

XTALO

PLLVSS

LPFON

S_VCM

ADCVSS

S_VREFP

S_VREFN

RFVDD3

RFRPDC

RFRPAC

HRFZC

CRTPLP

RFGND

AVDD3

C252 1uF

C269 104

R236

FS

191

192

190

FS

DACVSSC

YUV0/CIN

DACVDDB

DACVSSB

YUV3/CVBS

DACVDDA

DACVSSA

VSYNC/V_ADIN1

YUV7/ASDATA5

HSYNC/V_ADIN2

SPBCK/ASDATA5

ASDATA0

ASDATA1

ASDATA2

ASDATA3

ASDATA4

MC_DATA

RFGND18

RFVDD18

IDACEXLP

PLLVDD3

ADCVDD3

DVDA

DVDB3DVDC4DVDD

AGND

2

1

C253 1uF

C254 1uF

CCC

L210

FBSMT

V18 RFV18

A

B

SD33

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

44

DQ1045DQ1147DQ1248DQ1350DQ1451DQ15

DMA8#

DMA9#

DMA10#

MA11

#BA0

#BA1

R224

33R

33R

1 2

R223

33R

ASTB#

NFC#

0R

R261

NFC

ASTB

0R(DNS)

R252 0R

R258

188

187

186

185

184

183

189

RD16

RD17

RD18

RD19

RD20

VREF

DACVDDC

DVDRFIP6DVDRFIN7MA8MB9MC10MD11SA12SB13SC14SD15CDFON16CDFOP17TNI18TPI19MDI120MDI221LDO222LDO1

5

CCC

C255 1uF

DAB

DVDRFIP

104

C215

SD33

DQ15

27

53

VCC1VCC14VCC

DCS#

DRAS#

SDCLK

SDCKE

DCAS#

DWE#

876

5

33R

123

4

R219

R218 33RDCLK

RN201

CS#

RAS#

CAS#

WE#

DCKE

0R

MS_BS

0R

MS_SDIO

R259

R262

SD_CDN

SD_WP

MS_INS

POWEROFF_DET

LOWBAT_DE T

NFC#

ASTB#

179

178

181

180

177

176

182

RD21

RD22

RD23

RD24

RD25

DQM2

DQM3

DVDD3

SUBA

SUBB

SUBC

SUBD

TN1

C268

15P

C267

15P

C266

15P

C265

15P

RFV33

104

C216

TC206

L203

FBSMT

220uF/16V

DV33

B

VCCQ3VCCQ9VCCQ43VCCQ

DQM0

DQM1

33R

33R

RN204

0R

R260

MS_CLK

174

173

175

RD26

DVSS

TP1

MDI1

MDI2

0R

R230

C218

DMA0#

876

123

DMA0

DVDD18

C

TC202

49

52

VSSQ6VSSQ12VSSQ46VSSQ

28

DMA1#

DMA2#

DMA3#

DMA6#

DMA7#

DMA8#

5

876

4

123

DMA1

DMA2

DMA3

DMA6

DMA7

DMA8

DMA4

SD_CLK

SD_CMD

SD_D0

VOL-DATA

VOL-CLOCK

172

171

170

169

168

166

167

RA4

RD27

RD28

RD29

RD30

DVDD3

RD31/ASDATA5

V2REFO28SGND27VREFO30V2029TEO32FEO

RFLVL/RFO N26CSO/RFOP

SVDD3

23

25

24

RFOP

RFON

104

R229 0R(DNS)

LDO2

LDO1

V2P8

RFSVDD3

C225

C224

C223

SDRAM 64M

C222

C221

C220

SD33

C219

DMA9#

5

FBSMT

33R

L204

4

DV33

RN205

DMA9

DMA9

DMA8

DMA7

DMA6

DMA5

165

164

162

160

159

163

161

RA5

RA6

RA7

RA8

RA9

DVSS

DVSS

MT1389

U201

TEZISLV33OP_OUT34OP_INN35OP_INP36FOO42TRO41USBM

31

FEO

TEO

TEZISLV

OPO

OP-

V20

V1P4

C217 104

R228

0R(DNS)

V2P8

47uF/16V

104

104

104

104

104

104

104

DMA11

DCKE

DCLK

158

157

156

CKE

RA11

37

DMO

FMO

OP+

15K

10K

R240

DMSO

FMSO

TC207

T47uF/16V

C226

104

C

U203 8/16/32M_FLASH(TSOP)

UPA[20..0]

UPD[15..0]

A20

DMA2

DMA3

DCLKB

152

151

150

155

154

153

RA3

RCLK

DVDD3

RCLKB

DVDD18

RVREF/V_ADIN3

USB_VSS

TROPENPWM39PWMOUT1/V_ADIN940USB_VDD3

FMO38DMO

43

TRO

FOO

TROPEN

USBP

18K

20K

C275

R243

R244

R202

C274

C273

C272

TRSO

FOSO

D

A17

GNDA0AD7

AD14

AD6

AD13

48

41

42

44

47

46

45

Vss

A16

DQ6

DQ7

DQ1443DQ13

BYTE

DQ15/A-1

A12

A9

A151A142A133A115A106A88A199WE11RESET

4

7

A15

A14

A13

A12

A11

A10

A9

A16

0R(DNS)

VD

CS#

BA0

BA1

DMA0

DMA1

DMA10

146

142

149

147

145

143

148

144

RA2

RA1

RA0

BA1

BA0

RCS

RA10

DVSS

DVSS

45

46

USBVDDFGTROUT

USBM

330pF

103

V1P4

52

51

TRIN

TRCLOSEA2A3A4A5A6A7A8A18

STBY

V18

FBSMT

104

C227

L211

89V33

DVDD18

V1P4

USBP44FG/V_ADIN847TDI/V_ADIN448TMS/V_ADIN549TCK/V_ADI N650TDO/V_ADIN7

330pF

153pF

D

AD5

DQ540DQ4

AA20

141

DVDD3

IOA253IOA354IOA455IOA5

V20

AD12

AD4VDAD11

38

DQ1239DQ11

NC10NC

DWR#

AA21

R249

R248 0R(DNS) A21

R241 10K

R247 4.7K

R246 4.7K

R245 4.7K

R253 4.7K

RAS#

CAS#

140

139

RAS

CAS

37

36

Vcc

13

12

WE#

DQM1

137

138

RWE

56

DQM1

IOA657IOA7

AD3

AD10

34

35

DQ10

14

DQ8

LIMIT

135

136

RD8

DQS1

HIGHA0

59

58

TC209

T47uF/16V

C230

104

TC208

T47uF/16V

C228

104

E

AD2

AD9

AD1

AD8

AD0

DRD#

32

29

31

28

DQ830DQ9

DQ233DQ3

DQ0

DQ1

A619A1717RY/BY15A1816NC

A520A421A322A7

18

A19

A18A7A6A5A4A3A2

A8

R250

4.7K(DNS)

DQ9

DQ10

DQ11

DQ12

DQ13

129

132

131

130

133

134

RD9

RD10

RD11

DR12

DVSS

DVSS62APLLCAP

APLLVSS

IOA1860IOA19

63

64

61

A19

C276

R231 0R

F

GND

DCE#

A1

VCC

25

27

CE26A0

OE

Vss

L214

FBSMT

L215

FBSMT(DNS)

TC203

VD DV33

DV33

RD14

DVDD3

RD15

RD0

RD1

RD2

DVDD18

RD3

RD4

DVSS

RD5

RD6

DVSS

RD7

DQS0

DQM0

INT0

IR

PRST

ICE

DVDD3

UP3_5

UP3_4

UP3_1

UP3_0

UP1_7

UP1_6

UP1_5

UP1_4

UP1_3

UP1_2

DVDD18

URD

UWR

DVSS

IOA0

A17

AD7

ALE

IOA21/V_ADIN0

AD6

AD5

AD4

DVSS

AD3

AD2

AD1

AD0

DVDD3

IOOE

IOA1

IOCS

IOA20

HIGHA1

HIGHA2

DVDD3

HIGHA3

HIGHA4

HIGHA5

HIGHA6

HIGHA7

A16

IOWR

APLLVDD3

L205

33R

C236

104

C235

104

C234

104

C233

104

C232

104

C231

104

C229

104

47uF/16V

C248

104

CLOCKCLOCK#

876

5

RN203

33R(DNS)

123

4

CS## CS

DATA# DATA

STROBE# STROBE

R215

1K(DNS)

DQ14

128

127

DQ15

126

125

DQ0

DQ1

124

DQ2

123

122

DQ3

121

120

DQ4

119

118

DQ5

DQ6

117

116

DQ7

115

DQS0

114

113

DQM0

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

C246

TC210

22uF/16V

C244

104

C242

104

C240

104

DV33A

DV33A

AVDD3

L216

FBSMT

L212

FBSMT

R251 4.7K

URST#

TXD

RXD

STROBE#

DATA#

SDA

SCL

CS## AIN-DET

CLOCK#

V18

A0

A17

AD7

A21

AD6

AD5

AD4

AD3

AD2

AD1

AD0

PRD#

A1

PCE#

A20

A9

A10

A11

A12

A13

A14

A15

A16

PWR#

104

1

3

2

VSDA

IR

VD201

MMBD4148CA

DV33

C247

104

DV33

RXD

TXD

GND

R213

0R(DNS)

234

1

XS201

XS04(DNS)

DWR#

DCE#

DRD#

876

5

RN202

0R

123

4

PWR#

PCE#

PRD#

C245

104

C243

104

C241

104

C239

104

C238

104

V18

C237

104

123

F

A223A1

24

R242

10K

RD13

1500pF

89V33

L213

FBSMT

DV33

E

Page 21

A

DECODE BOARD

19

JK301

A-out

23415

6

6

C321

102

Lt

L301

FBSMT

LOUT

R318

5

R317 36K

4

R308

330R

CH-L

TC304

T10uF/16V

L

1

U305A

+8V

3

2

C319 68P

C317

R314

4.7K

R312

10K

C315

R310

11K

15K

ALIN

TC303

T10uF/16V

L331

A5V VCC1

3

LL

MUTECRST#

16

15

MUTEC

RST1SDA2SCLK3LRCK4MCLK5DIF16DIF07DEM0

U304 CS4340/1

TC302

T10uF/16V

A5V

2

GND

1

OUT

2

IN

3

U302 78L05

SDATA0

MUTE9V

GND

1

OUT

2

IN

3

U301

AN77L08M

MUTE9V +8V

C322

102

AGND

R320

100K

V301

2SC1815-Y

R319

1K

MUTE-1

4580

4 8

152

102

FCM2012-120T2A (DNS)

TC311

10uF/25V

C301

104

RR

13

12

14

VA

AGND

AOUTA

AOUTB

SBCLK

SLRCK

SACLK

TC301

100uF/16V

L326

R321

100K

V302

2SC1815-Y

R328

R327

1K

TC308

+8V

R316 36K

6

C320 68P

R315

4.7K

AGND

R313

10K

12

R311

11K

R309

15K

ARIN

TC307

TC306

T10uF/16V

C305

104

TC305

T10uF/16V

C304

104

9

10

11

VQ

FILT+

REF-GND

8

0R

R302

0R

R303

R304

0R

C303

104

AGND

C302

104

+8V

1

A

Rt

ROUT

CH-R

R

7

VCC1

A5V

FBSMT

5

C318

C316

T10uF/16V

AGND

U303

AGND

JK302

Ain

R330

421

3

1 2

T10uF/16V

ALIN

AIN-DET

TC316

C306

104

47K

5

4

ASDAT0 SDATA0

BL9V

BLGND

FBSMT

L305

9

1K

1K

R329

TC329

TC310 T10uF/16V

AGND

ARIN

47uF/10V

V304

AGND

R342

1K

MUTE9V

VCC1

MUTE9V

L308

10uH 2012

L325

FCM2012-120T2A

VIN

33R

DV33

GND

TC312

47uF/16V

CLOCK

DATA

GND

-10V

+15V

STROBE

FBSMT(DNS)

FBSMT

FBSMT

FBSMT(DNS)

FBSMT(DNS)

L320

L307

L306

L321

L322

23416785101112

R340

82K

82K

R368

TC309

+8V

330R

R326

39K

T10uF/16V

R322

U305B

4580

4 8

152

AGND

102

876

RN301

123

ACLK SACLK

ABCK SBCLK

ALRCK SLRCK

GND

1

OUT

2

IN

3

78L05

BL9V

+7.5V

STBTA

FBSMT

L304

L302 0R

XS301

XS12

B

C

JK301

OPTICAL

23415

6

AGND

C332

27pF

R346

33R

47uF/10V

DV33

ASPDIF

C307

104

MUTE9V

VD302

1N4148

TC315

47uF/16V

AGND

R345 150R

MUTE-1

V305

8550

R344

DNS

VD303

4.7V

8550

1K

R332

R331

MUTEC V303

TC317

47uF/10V

GND

VGND

1K

R367

L324 0R(DNS)

XS302

CS

C326

C325

C324

C323

TC314

FBSMT(DNS)

L323

TC313

AGND

V306

8050

1K

R341

R333

1K

8550

VD301

1N4148

1K

MUTE_DAC

C345

27PF

RSOUT-

LSOUT+

LSOUT-

C#

Y#

RSOUT+

VGND

NFC

FBSMT

FBSMT

FBSMT

FBSMT

FBSMT

FBSMT

L313

L312

L309

L310

L314

L311

L303 0R

2341568

7

DNS

DNS

DNS

DNS

47uF/16V

47uF/16V

C

JK304

Vin

1

3

2

11

10

104

TC320

10uF/10V

VD304

MMBD4148SE

2

V5V

1

VGND

AGND

R361

V5V

R343

1K

AGND

V5V

TC319

47uF/10V

L327

FBSMT

47uF/10V

VCC1

TC318

C331

27pF

C330

27pF

XS08

TO TFT-LCD

VDD

R347

C308

C#

Y#

2

V5V

3

1

75R 1%(DNS)

VGND

VGND

10K

R362

0R

VDD

TC321

Q301

3906(DNS)

C336

C333

L328

1.8uH 1608

Y1

R350

R348

R336

R370

330R

R372

T100uF/10V

LSOUT+

VDD

U306

V5V

101

47PF

150R1%

100K

1K

V311

2SC1815-Y

1K

MUTE-1

12

11

GND

BYPASS

GND13PC-BEEP14SE/BTL15ROUT-16CLK17PVDD18VDD19RHPIN20ROUT+21/SHUTDOWN22RLINEIN23GND

R305

D

D

JK305

S-Video

C344

20pF(DNS)

421

3

Y

C

VGND

C343

L316

FBSMT

L315

FBSMT

20pF(DNS)

VD306

2

VD305

MMBD4148SE

VGND

R363

75R 1%(DNS)

VGND

421

PGND

R373

R325

R324

LSOUT-

8

10

7

9

LIN

RIN

PVDD

LOUT-

0R

C327

RSOUT-

V5V

1

3

VGND

R366

V5V

Q302

3906(DNS)

R364

0R

C337

101

VGND

C334

47PF

L329

1.8uH 1608

Y2

R352

150R1%

JK306

HP

3

R349

100K

R339

1K

PGND

V312

2SC1815-Y

VOL-DATA

1K

R338

1K

V309

4.7K

4.7K

6

4

5

3

LHPIN

LOUT+

LLINEIN

272

PGND

2SC1815

V308

2SC1815

0.47

C341

C3400.47

C3390.47

2

1

/UP

GND

/DOWN

PGND

TPA0152

24

56K

33K

33K

56K

R358

R360

R359

R357

105

105

105

C348 105

C346

C347

C349

ROUT

LOUT

E

JK307

VIDEO-OUT

421

3

CVS

VGND

C342

20pF(DNS)

L317

FBSMT

CVBS

MMBD4148SE

3

75R 1%(DNS)

Q303

3906(DNS)

VGND

R365

0R

C338

101

VGND

C335

47PF

L330

1.8uH 1608

Y3

R351

150R1%

R371

330R

T100uF/10V

TC322

PGND

TC328

47uF

TC326

VDD

VCC1

PGND

47uF

C311

104

C310

104

C309

104

PGND

L318

TC327

47uF

10uH CDRH5D18

AGND

1K

PGND

R337

AGND

VOL-CLOCK

RSOUT+

R356 open

C329

open

R355 open

C328

open

123

E

F

Page 22

D

20

V18

L514

FBSMT

C537

104

VD510

4

321

1N4004(DNS)

VD509

1N4004(DNS)

U507

LM1117

DV33

C505

104

VCC

CPU5V

TC503

T100uF/16V

L508

FCM2012-120T2A

5

C504

104

vout1vout

GND

2

ce4vin

U502

RT9701

3

L504 FCM2012-120T2A

STB

C503

104

TC517

220uF/10V

GND

1

R545

1.8K

R546

OUT

2

IN

3

1K

C539

104

VCC1

TC518

T100uF/16V

L517

FCM2012-120T2A

5

C538

vout1vout

GND

2

ce4vin

U508

RT9701

3

STB

C

SW2

SW501

R511

10K

CPU5V

STBTA

VD503

1N4148

R516

DNS

CPU5V

GND

IR

TC513

47uF/10V

STBT

8

7

STB

GP25GP16GP0

GND

GP52GP43GP34vdd

C540 104

U505

12C508A

1

R510

10K

104

R508

10K

V501

C511

104

R509

R515

DNS

POWER

ASTB

V502

8550

R527

330R

RED

R517

1K

R526

8050

330R

VCC1

10K

R512

10k

B

A21

R520

0R(DNS)

R533

10K

SDPWR

MSPWR

FBSMT

L513

DV33

LED501

R-G LED

2

1 3

MSPWR

SDPWR

MS_SDIO

MS_INS

MS_CLK

23

22

MS-10

SD-11SD-22SD-33SD-44SD-55SD-66SD-77SD-88SD-99SD-CD110SD-CD211SD-WP112SD-WP2

JK502

SD_D3

SD_CMD

SD_CLK

SD_D0

SD_D1

R532 10K

R531 10K

R530 10K

R529 10K

R528 10K

SD_D2

C518

104

SD_CDN

A

104

C536

R534

10K

C520

104

MS_BS

维修手册 杂件 Drawn By:

MS-114MS-215MS-316MS-417MS-518MS-619MS-720MS-821MS-9

MS/SD/MMC

13

Number RevisionSize

B

Title

Date: 22-Dec-2004 Sheet of

File: D:\ \ \967\2373D-31.DDB

TC502

5V

VIN

123

JK501

T100uF/16V

5V

C509

104

R506

10K

R505

30K

C512

104

TC505

V33

L503

22UH±20% CDRH8D43

8

d25d26d17d1

U501

C502 104

4

4

7

C521

105/16V

pdrv

cvh

8

in

6

+9V

R502

100K

C501

FCM2012-120T2A

L515

FCM2012-120T2A

L501

VD501

4

BA-CON

1N5822

2

1

XS501

XS02

D

L502

S11G12S23G2

FDS8958A

5.4UH±20% CDRH5D18

10

12

16

11

cs-

inc15lxc

cs+

fbm

ndrv

/shdnm1/shdnc

104

TC501

pgnd

cvl

ref

2

3

5

9

STB

51K

R501

220uF/25V(AL)

T100uF/10V

TC511

104

C507

R514

3K

R513

20K

R507

10K

13

fbc

gnd

U504

MAX1775

14

C523

224

C522

105/16V

AV33

L507

BLGND

BL9V

TC506 47uF/16V

L516

L511

10uH CDRH5D18

10uH CDRH5D18

+9V

C

100uF/10V

FBSMT

L505

FCM2012-120T2A

C510

104

V33 DV33

C508

104

+7.5V

TC509

10UF

TC508

10UF

VO1

TC507

10UF

VD502

1N5819

C541 102

L509

5V

B

C517

104

+15V

2UF

TC515

ZD501

BZT52C-15.6-V

8050

Q502

TC519

1K

R524

2

VD506

3

C526

0.47UF

LX

L512

2.2UH±20% CDRH5D18

R548

0R(DNS)

104

C515

TC512

100uF/10V

FCM2012-120T2A

10uF/10V

C531

1UF

1UF

C530

VO1

104

2

1

1

C516

VD507

BAT54S

BAT54S

3

C527

0.47UF

U506

AAT1102

GND

LX

5

6

7

8

R518

SHDN

IN

FB

FREQ

COMP

SS

C524

0.22uf

0R

R547

STBTA

C514

104

1K

C519

104

-10V

TC516

2UF

8550

ZD502

Q501

1

VD505

4

3

2

1

BZT52C-11.1V

TC520

10uF/10V

R523

1K

C529

1UF

C532

1UF

2

1

2

VD508

BAT54S

BAT54S

3

3

C525

0.47UF

C528

0.47UF

LX

VO1

C535

100PF

STBTA

R542

51K

R539

10K

C534

4700PF

R522

100R

C533

27PF

A

1 2 3 4

Page 23

DECODE BOARD

21

Page 24

BATTERY CHARGER

22

Page 25

BATTERY CHARGER

23

Page 26

XS401

MAIN FRONT PANEL

24

XS04

234

1

DV33

10R

R403

POWER

V33

VSDA

GND

KIO0

R401 10K V401

POWER

SW411

8550

SW1

KI4

C401

104

V33

TC401

47uF/16V

C402

201

X401

455E

C403

201

VSDA

7

13

8

10

11

U401

22

SEL9VSS12CSS

REM

/DREN

VDD

OSC0

OSC1

KI/O7

KI/O6

KI/O5

KI/O4

KI/O3

KI/O2

KI/O1

KI/O0

HT6222

14

15

16

17

18

19

20

21

SW405

SW404

SW403

SW402

SW401

SW1

SW1

SW1

SW1

SW1

KI7

SW410

SW409

SW408

SW407

SW406

SW1

SW1

SW1

SW1

SW1

KI6

KIO4

SW414

KIO3

SW413

KIO2

SW412

KIO1

KIO0

SW1

SW1

SW1

KI4

VD403

1N4148

VD402

1N4148

VD405

1N4148

VD404

1N4148

VD401

1N4148

KI023KI124KI21KI32KI43KI54KI65KI7

6

Page 27

MAIN FRONT PANEL

25

Page 28

VCOM

LCD DRIVE BOARD

26

VCC1

イkアオツI

LOUT,ROUT ?T

TP32

TP1

VCC1

C48

VCC1

S2B-ZR1

ROUT

1

1

1234567

J5

6

7

8

104Z25

R16

R7

R4

R6

R14

R12

R18

R20

R22

R2

2

A

473J

223J

333J

103J

333J

333J

333J

393J

223J

473J

LOUT

V+

R10

1

U3

-I/P B

O/P B

VR103F

BRT

CNT

VR103F

COL

TIN

VR103F

SBB

VR103F

SBR

VR103F

RGB

GM0

VR103F

GM2

PIC

153J

2

C

R41 103J

NJM3414AM

GND +I/P B

+I/P A

-I/P A

O/P A

TP9

2SC2412K

Q1

TP5

TP3

TP4

TP8

TP7

TP10

TP11

TP12

TP2

TP6

S2B-ZR

ZXX

CVS/Y

A

8

53261-0890

VCC1

1

B

1

1

1

1

1

1

1

1

COMA

VGL

4 5

3

2

1

BRT1

1

CNT1

SBB1

SBR1

RGB1

1

TP26

TP25

TP28

TP29

J2

R62

103J

R15

R23

E C

R8

R3

R5

153J

R13

R11

R17

203J

R19

R21

203J

GM2

R1

563J

R9

C4

VGL

-10V

+15V

1

1

1

1

1234567

R65

333J

273J

203J

393J

223J

223J

103J

123J

103K50

VGH

+5V

203J

+

C7

C12

C2

C3

C6

C5

C8

C9

C10

C1

R66

103J

R61

COMO

103K50

103K50

103K50

103K50

103K50

103K50

103K50

103K50

103K50

103K50

+7.5V

A

R60

203J

103J

C40

10uF/16V Tan

A

A

TP34

1

GND

CTL

8

53261-0890

U2

VCC1

Modify

Modify

VCC1

C D A

TP27

VIN

123

3802-03

VCON

153

by

C37

CSYN

/HSY

1

VCOP

2

bx

bcVDD

15416

VCO

104Z25

R141 102J

ャー

J8? 3PIN

J8

TIN

cy

a

14

TRAP

A

L3

%22uHA

FRP

R25

R24

CVS/Y

TINT

ay

13

330J50

C45

GM2

GM0

RGB

BRT

SBB

SBR

102J

474J

R142 103J

+7.5V

12

L2

C14

105Z25

R26

C11

105Z25

A

+7.5V

611

cx

ax

%22uHA

560J50

C43

561J

TP14

BOROGO

B

APC

A

17

GND1

F ADJ

R37 1802F

R38

000J

R

VCC1

R54

562J

C29

474Z16

16

VCO OUT

CLAMP

C25 682K50

C27

R40

OPEN

VCOM

G

VCOM

+

C26

OPEN

R35

302J

R36

152J

VCO

APC

14

15

VCO IN

APC FILTER

AGC FILTER

AGC OUT

A

+

OPEN

TP38

L8

%150uHD

R53

VCC_D

/HSY

/HSY

7

INHA

VEE

B

10

NPC

A

A

25

26

27

28

29

30

31

32

33

34

35

36

C13

TP16

1

BIN

FRP

/VSY

FRP

/VSY

A

8

VSS

74HC4053M

C

9

CC15

10uF/1206

+

C17

104Z25

+7.5V

TP18

B

R27 101J

TP17

U1

24

B OUT

B DC DET

GM2

GM0

RGB AMP. ADJ

BRIGHT

SBB

SBR

COM FRP

FRP

SYNC IN

SYNC OUT

SYNC SEP

COM ADJ.

3738394041424344454647

A

COMA

TP44

821J50

R28

R30

750J

R31

TP19

1

1

GIN

RIN

1

1

23

VCC2

COM OUTSWB IN

COMO

1

103J

750J

R33

C18 105Z25

TP20

22

G DC DET

104Z25

R29 103J

A

750J

C15

+

G

C20 105Z25

R34 101J

R32 101J

TP22

1

19

20

21

G OUT

R DC DET

IR3Y29BM

G IN

104Z25

104Z25

C19

C16

C21

A

A

VCC1

R

R OUT

R IN

BRT

33uF/10V Tan

1

18

GND2

VCC1

+15VA

VGH

822J

C28

TINT

13

TINT

PICTURE

48

PIC

1

-10VA

VGL

103K50

C22

150J50

C24

120J50

C23

R39

334J

C59

+

C50

104Z25

VCC_L

VCC_D

VCC_C

VCC_L

VCC_C

VCC_D

A

Modify

VCON

Y1

3.58MHzD

VCOP

Y2

4.43MHzD

CHROMA OUT

12

ACC FILTER

11

B-Y

10

R-Y

9

KILLER FILTER

8

BURST OUT

7

COLOR

6

C IN

5

IDENT FILTER

4

VIDEO IN

3

CONTRAST

2

TRAP

1

000J

R143

A

104Z25

COL

VCC_L

DD

TP40

10uF/16V Tan

L10

%150uHD

+5V

+5V

COL

CNT

TRAP

1

C52

VCC1

VCC1

VCC1

562J

R44

C33

+

C30

C60

10uF/16V Tan

+

104Z25

R49

331J

EC

Q2

B

2SB709A

C35

103K50

C34

103K50

R51

105J

C36

C41

473K16

C32

104Z25

103K50

R47

10uF/16V Tan

R43

OPEN

R45

000J

CVS

R57

331J

CVS/Y

VCC_C

TP39

1

L9

%150uHD

D D

R52

R50

104Z25

C31

681J50

106J

R64

331J

C62

+

C51

104Z25

152J

A

562J

C42

820J50

A

L1

%23uHA

C38

560J50

VCC1

331J

R144

A

R42

OPEN~331J

A

VCC1

10uF/16V Tan

CC

TP37

L7

%150uHD

A

R48

OPEN

CVS

C

AA

C58

330uF/6.3V

+

1

C49

104Z25

Page 29

12345678910111213141516171819202122232425

LCD DRIVE BOARD

27

JP5

26

ELCO26PA

SCAN

VCOM

DATA

D17

シW・[・│ケqョe

101J

R118

CK3A

R145

D[1:26]

D18

D16

D15

D19

D7

101J

101J

561J

R117

R116

R115 561J

R114 561J

R113

CK1A

CK2A

CKV

101J

R146

R122

GND

C

C65

561J50

101J

ZXX

242J

R97

C80

C79

C78

C77

R105

L11

105J

102Z25

C68

101J

1R5uHA

C70

222K50

C66

R108

These signals

are outputs

102Z25

102Z25

D

102Z25

225Z16

R101

105J

VR2

VR103F

103J

R107

U5

3 4

104Z25

823J

R102

243J

D3

D4

D5

D1

D2

to panel!

UPS017

U4

STHL

13

STHR

14

15

V_CK

16

CK1A

17

CK2A

18

CK3A

19

ZX1

20

ZX2

21

ZX3

22

GND

23

VCC

24

D2

MA335

C71

OPEN

5

V

+

G

_ O

1

2

R111

683J

D6

D5

D6

101J

R103

R104

101J

D

R98 OPEN

C67

104Z25

91011

12

VCC

VO2

VO1

PD_OUT

F_OUT

F_IN

VSY_OUT

2526272829303132333435

R100

000J

101J

R106

/VSY

C

220J50

C64

R121

242J

6.8V/150mW

-10VA

AC

C

D3

A C

C72

104Z25

C69

104Z25

NJM2107F

C C

R110

472J

D8

D7

D13

R90 000J

8

RES_C

HSYW

R99

D11

D9

D10

D12

D

7

GND

MOD_OUT

UPS017

GR_IN

V_IN

C63

OPEN

VCC1

D15

D14

D13

R128 OPEN

D_MOD

FDV_OUT

UD_OUT

ZTC

OPEN

OPEN

R96

R67

R78

D16

D17

D9

D14

561J

R95

R92 561J

D

456

VOE_OUT

AUXS

102J

R94

R93

EC

Q4

393J

R77

103J

153J

D19

D18

D20

HZOUT2

2

3

HOE_OUT

HSY_OUT

102J

B

2SB709A

D21

D22

NPFRP1

1

HZ_OUT

CSYNC

36

D

123

Q3

654

D24

D25

D23

NPFRP

VCC

CP_IN

CP_OUT

NP_SW

PFRP_OUT

NPC

TC

CSYN_OUT

LR_A

L_R

PD_SW

UDC

GND

C1B2E2

E1B1C2

204J

R75

R74

153J

R73

153J

D26

D

C56

C57

C39

104Z25

48

47

46

45

44

43

42

41

40

39

38

37

102J

R86

R91

000J

103J

R76

R68

302J

XN4501

221K50

221K50

D1:GND

D2:VCC(+5V)

D4:VGH

D3:VGL

(Oposite order assignment in layout!)

D20

D2

D8

D12

D

C61

391J50

VR1

VR103F

561J

R88

R83 561J

R79 102J

R80 102J

101J

R81

NPC

R87

R85

102J

102J

D

D D

1

TP43

A

D6:STVL

D7:CLK

D8:U/D

D5:STVR

D25

VCC1

TP41

VCC1

D9:OEV

D4

R72

561J

D10:VCOM

D12:L/R

D11:VCOM

1

TP35

D13:Q1H

D15:STHL

D14:OEH

D3

101J

R69

1

D18:CPH2

D19:CPH1

D17:CPH3

D16:STHR

D1

D21

D

103J

R71

R70

104J

C55

+

10uF/16V Tan

CC55

+

10uF/16V Tan

C54

104Z25

CC54

+

10uF/16V

10uF/16V Tan

C47

+

D20:DVDD

D22:VA

D21:DVSS

D23:VB

D26

D24

BRG

BOUT

A

D25:AVDD

D24:VC

D26:AVSS

D23

D22

ROUT

GOUT

TP33

VCC1

GO

153

by

VDD

U8

+5V

+7.5V

D10

VCOM

R59 563J

2

bx

b

14

15416

GOUT

C76

104Z25

1

D11

BO

cy

a

ROUT

A

BOUT

13

R133

c

ay

RO

NPFRP1

cx

ax

12

303J

R58

A

HZOUT2

101F

R134

101F

A

611

8

7

INHA

VSS

VEE

74HC4053M

B

C

9

10

/PD

R109

473J

R112

472J

VCC_C

CSYN

/HSY

VCC_D

FRP

VCC_L

VCC1

+15VA

-10VA

VCOM

+7.5V

Page 30

LCD DRIVE BOARD

28

Page 31

29

BOOST BOARD

Page 32

30

BOOST BOARD

Page 33

31

BOOST BOARD

Page 34

32

BOOST BOARD

Page 35

DL373D MATERIAL LIST

D

9.DL373D MATERIAL LIST

33

1. LCD DRIVE BOARD

TERIAL CO

0090001 SMD RESISTOR 1/16W 0Ω ±5% 0603 PCS 7

0090222 SMD RESISTOR 1/16W 160Ω ±5% 0603 PCS 2 R64,R57

0090006 SMD RESISTOR 1/16W 75Ω ±5% 0603 PCS 3 R30,R31,R33

0090181 SMD RESISTOR 1/16W 100Ω ±5% 0603 PCS 10

0090009 SMD RESISTOR 1/16W 330Ω ±5% 0603 PCS 1 R49

0090012 SMD RESISTOR

0090014 SMD RESISTOR 1/16W 1K ±5% 0603 PCS 10

0090016 SMD RESISTOR 1/16W 1.5K ±5% 0603 PCS 1 R52

0090253 SMD RESISTOR 1/16W2.4K ±5% 0603 PCS 1 R121

0090021 SMD RESISTOR 1/16W 6.8K ±5% 0603 PCS 1 R122

0090183 SMD RESISTOR 1/16W 3K ±5% 0603 PCS 2 R68,R35

0090019 SMD RESISTOR 1/16W 4.7K ±5% 0603 PCS 5

0090225 SMD RESISTOR 1/16W 5.6K ±5% 0603 PCS 2 R44,R50

0090023 SMD RESISTOR 1/16W 10K ±5% 0603 PCS 9

0090187 SMD RESISTOR 1/16W 12K ±5% 0603 PCS 1 R9

0090024 SMD RESISTOR 1/16W 15K ±5% 0603 PCS 8

0090188 SMD RESISTOR 1/16W 18K ±5% 0603 PCS 3 R7,R18,R37

0090025 SMD RESISTOR 1/16W 20K ±5% 0603 PCS 6 R8,R17,R21,R60,R65,R54

0090026 SMD RESISTOR 1/16W 22K ±5% 0603 PCS 2 R11,R13

0090255 SMD RESISTOR 1/16W24K±5% 0603 PCS 1 R102

0090027 SMD RESISTOR 1/16W 27K ±5% 0603 PCS 3 R15,R23,R14

0090189 SMD RESISTOR 1/16W 30K ±5% 0603 PCS 1 R58

0090028 SMD RESISTOR 1/16W 33K ±5% 0603 PCS 2 R4,R12

0090190 SMD RESISTOR 1/16W 36K ±5% 0603 PCS 1 R16

0090191 SMD RESISTOR 1/16W 39K ±5% 0603 PCS 3 R20,R67,R61

0090029 SMD RESISTOR 1/16W 47K ±5% 0603 PCS 2 R2,R109

0090030 SMD RESISTOR 1/16W 56K ±5% 0603 PCS 2 R1,R59

0090032 SMD RESISTOR 1/16W 68K ±5% 0603 PCS 2 R3,R111

0090193 SMD RESISTOR 1/16W 82K ±5% 0603 PCS 1 R108

0090034 SMD RESISTOR 1/16W 100K ±5% 0603 PCS 1 R70

0090200 SMD RESISTOR 1/16W 200K ±5% 0603 PCS 1 R75

0090205 SMD RESISTOR 1/16W 330K ±5% 0603 PCS 2 R39,R38

0090212 SMD RESISTOR 1/16W 750K ±5% 0603 PCS 1 R40

0310234 SMD CAPACITOR 16V 105 +80%-20% 0603 PCS 1 C27

0090208 SMD RESISTOR 1/16W 470K ±5% 0603 PCS 1 R24

0090109 SMD RESISTOR

0090219 SMD RESISTOR 1/16W 10MΩ ±5% 0603 PCS 1 R47

0160158 ROTATED POTENTIOMETER W203-10K±20% PCS 8

0310219 SMD CAPACITOR 16V 106 +80%-20% 1206 PCS 11

0310376 SMD TANTALUM CAPACITOR NRS10V47U±20%3528(B2) PCS 2 C58,C81

0310042 SMD CAPACITOR 50V 15P ±5% NPO 0603 PCS 2 C22,C24

0310043 SMD CAPACITOR 50V 22P ±5% NPO 0603 PCS 1 C64

0310045 SMD CAPACITOR 50V 47P ±5% NPO 0603 PCS 4 C77,C78,C79,C80

310192 SMD CAPACITOR 50V 56P ±5% NPO 0603 PCS 2 C38,C43

0310046 SMD CAPACITOR 50V 82P ±5% NPO 0603 PCS 1 C42

0310047 SMD CAPACITOR 50V 101 ±5% NPO 0603 PCS 1 C45

0310049 SMD CAPACITOR 50V 221 ±5% NPO 0603 PCS 2 C56,C57

0310052 SMD CAPACITOR 50V 391 ±5% NPO 0603 PCS 1 C61

0310197 SMD CAPACITOR 50V 561 ±10% 0603 PCS 1 C65

0310054 SMD CAPACITOR 50V 681 ±5% NPO 0603 PCS 1 C31

0310215 SMD CAPACITOR 50V 821 ±10% 0603 PCS 1 C13

0310068 SMD CAPACITOR 50V 222 ±10% 0603 PCS 1 C70

0310071 SMD CAPACITOR 50V 682 ±10% 0603 PCS 1 C25

0310072 SMD CAPACITOR 50V 103 ±10% 0603 PCS 15

0310056 SMD CAPACITOR 16V 473 ±10% 0603 PCS 1 C41

MATERIAL NAME SPECIFICATIONS UNIT QUANTITY LOCATION

R45,R90,R91,R100,R143,C

32,R141

R27,R32,R34,R81,R103,R1

04,R105,R106,R133,R134

1/16W 560Ω ±5% 0603

1/16W 1MΩ ±5% 0603

PCS 8

PCS 3 R51,R97,R101

R26,R72,R83,R88,R92,R95,

R113,R114

R36,R25,R41,R79,R80,R85,

R86,R87,R93,R94

R110,R112,R145,R146,R14

4

R6,R28,R29,R62,R66,R71,

R76,R77,R107

R5,R10,R19,R22,R73,R74,

R78,R53

VR1,SBR1,SBB1,RGB1,CN

T1,BRT1,VR2,GM2

C30,C40,C47,C55,C59,C60,

C62,CC15,CC54,CC55,C15

C1,C2,C3,C4,C5,C6,C7,C8,

C9,C10,C12,C28,C33,C34,

C35

Page 36

C16,C17,C19,C21,C23,C36,

R

R

D

D

D

34

0310207 SMD CAPACITOR 50V104 ±20% 0603 PCS 18

0310084 SMD CAPACITOR 50V 104 +80%-20% 0603 PCS 18

0310170 SMD CAPACITOR 25V 474 ±20% 0805 PCS 1 C29

0310163 SMD CAPACITOR 50V 474 +80-20% 0805 PCS 1 C29

0310368 SMD CAPACITOR 25V 105+80%-20% 0805 PCS 4 C11,C14,C18,C20

0310217 SMD CAPACITOR 16V 225 +80%-20% 1206 PCS 1 C68

0390302 SMD MAGNETIC BEADS MGHB1608S102 PCS 13

0390042 SMD INDUCTOR 1.2UH ±10% 2012 PCS 1 L11

0390199 SMD INDUCTOR 22uH ±10% 3216 PCS 2 L2,L3

0390215 SMD INDUCTOR 33uH±10% 3225 PCS 3 L8,L9,L10

0390198

0390202

0700052 SMD DIODE MA335 PCS 1 D2

0780209 SMD TRIODE 2SB709A PCS 2 Q2,Q4

0780210 SMD TRIODE XN4501 PCS 1 Q3

0780204 SMD TRIODE 2SC2412K PCS 1 Q1

0881533 IC IR3Y29B QFP PCS 1 U1

0880743 IC BU4053BCF SOP PCS 2 U2,U8

0881539 IC NJM3414AM SOP PCS 1 U3

0881540 IC UPS017 QFP PCS 1 U4

0881538 IC NJM2107 SOP PCS 1 U5

0960212 SMD CRYSTAL OSCILLATOR 3.58MHz 49-S PCS 1 Y1

960213 SMD CRYSTAL OSCILLATOR 4.43MHz 49-S

1940152 SOCKET 8P 1.0mm SMD PCS 2 J2,J5

1940194 CABLE SOCKET 26P 0.5mm SMD WITH CLASP PCS 1 JP5

0700072

0700007 SMD DIODE 1N4148 PCS 1 D1

1631638 PCB C373A-4 PCS 1

SMD MAGNETIC-CORE

INDUCTO

SMD MAGNETIC-CORE

INDUCTO

SMD VOLTAGE REGULATOR

DIODE

150uH ±10% CR32 PCS 1 L7