BBK DL372SI Service Manual

SERVICE MANUAL

DL372D

CONTENTS

1. SAFETY PRECAUTIONS

2. PREVE NTION OF ELE CTR O STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENS ITIVE(ES)DEVICES

3. CONTROL BUTTON LOCATIONS AND E XPLANATIONS

4. PREVE RTION OF STATIC ELE CTRICITY DISCHARGE

5. E LE C TR IC AL C ONFIR MATION

5.1 VIDE O OUTP UT (LUMINANC E S IG NAL) C ONFIR MATION

5.2 VIDE O OUTP UT(C HR OMINANC E S IG NAL) C ONFIR MATION

6. MP E G BOAR D C HE C K WAVE FOR M

7.2 MT1389

7.3 HY29LV160 9

7.4 HY57V641620HG

1

1

2

4

5

5

6

7

8

14

8. S C HE MATIC & P C B WIR ING DIAG R AM

15

9. S P AR E P AR TS LIS T 30

1.1 GENERAL GUIDELINES

1. SAFETY PREAUTIONS

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO

ELECTROSTATICALLY SENSITIVE(ES)DEVICES

1

1. When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barrier, insulation papers

shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

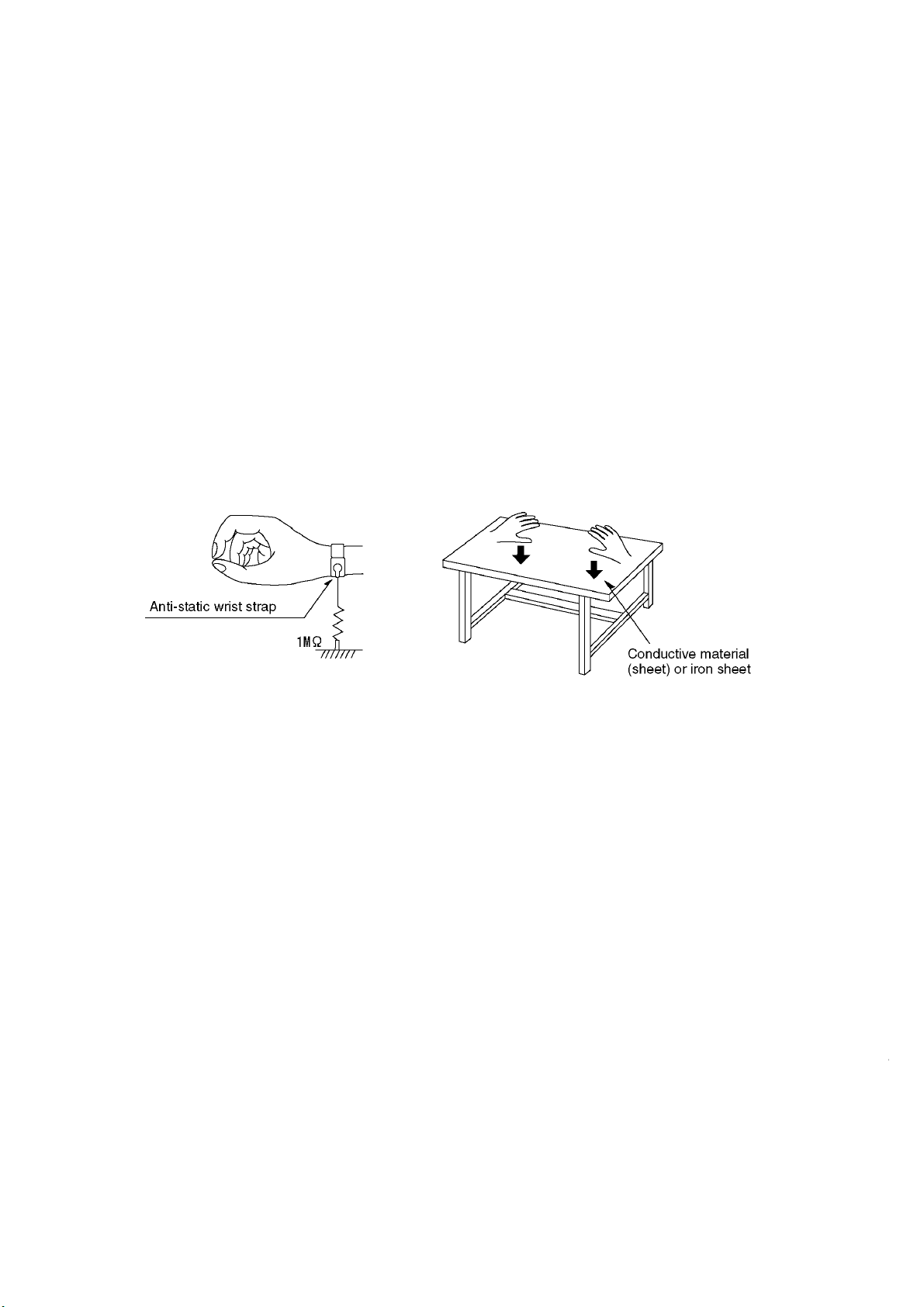

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD).

notice (1885x323x2 tiff)

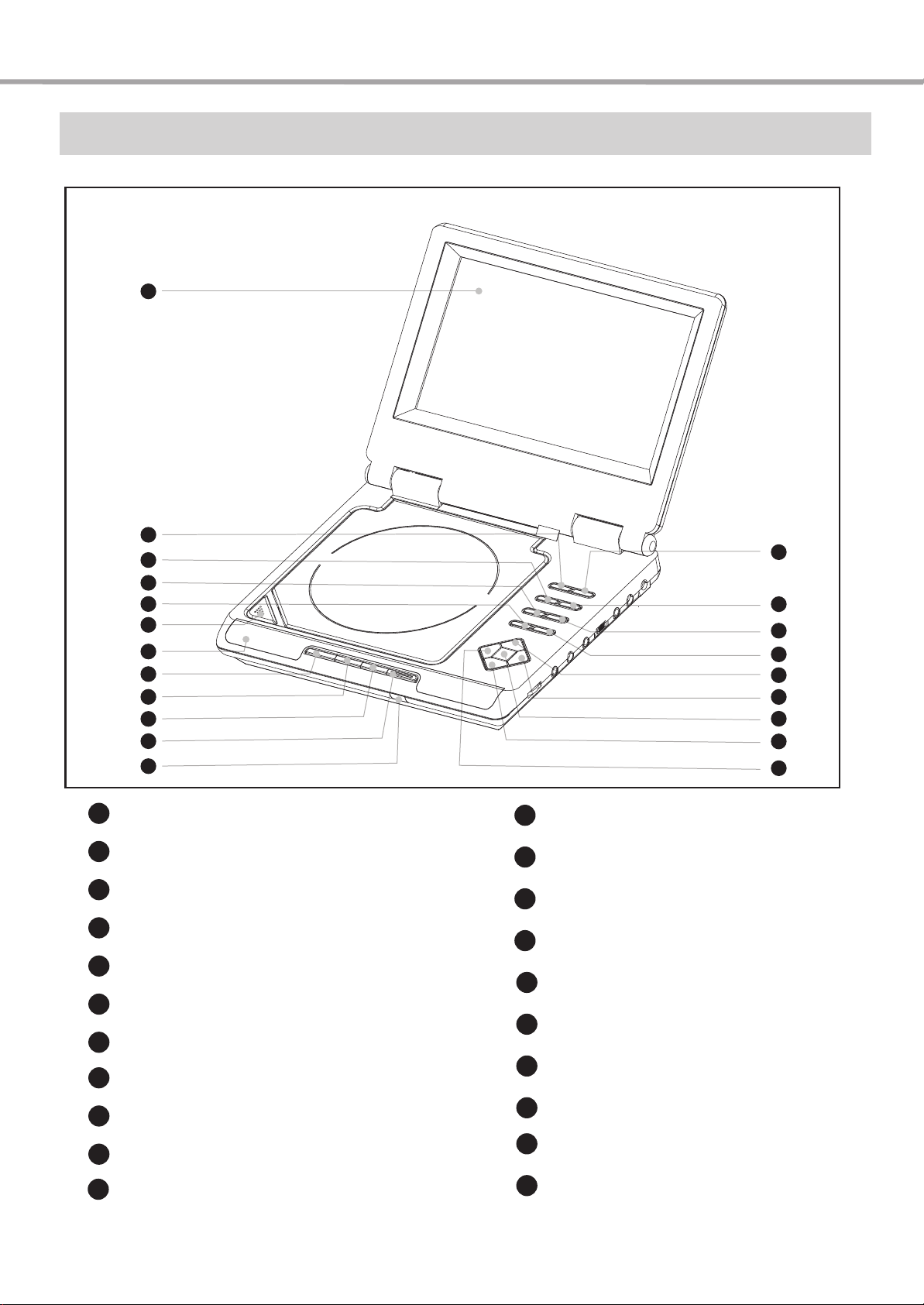

Control Button Locations and Explanations

2

1

2

3

4

5

6

7

8

9

10

11

12

21

20

19

18

17

16

15

14

13

1

Color TFT LCD

2

REW Button

3

P/N button

4

Keyboard Button

5

SETUP Button

6

OPEN/CLOSE button

7

Speakers

8

PLAY button / PAUSE button

9

PREV Button

10

NEXT Button

11

Power indicator

12

IR sensor

13

LEFT direction arrow

DOWN direction arrow

14

15

SELECT button

RIGHT direction arrow

16

17

UP direction arrow

MENU Button

18

19

PICTURE button

20

STOP button

21

Forward Button

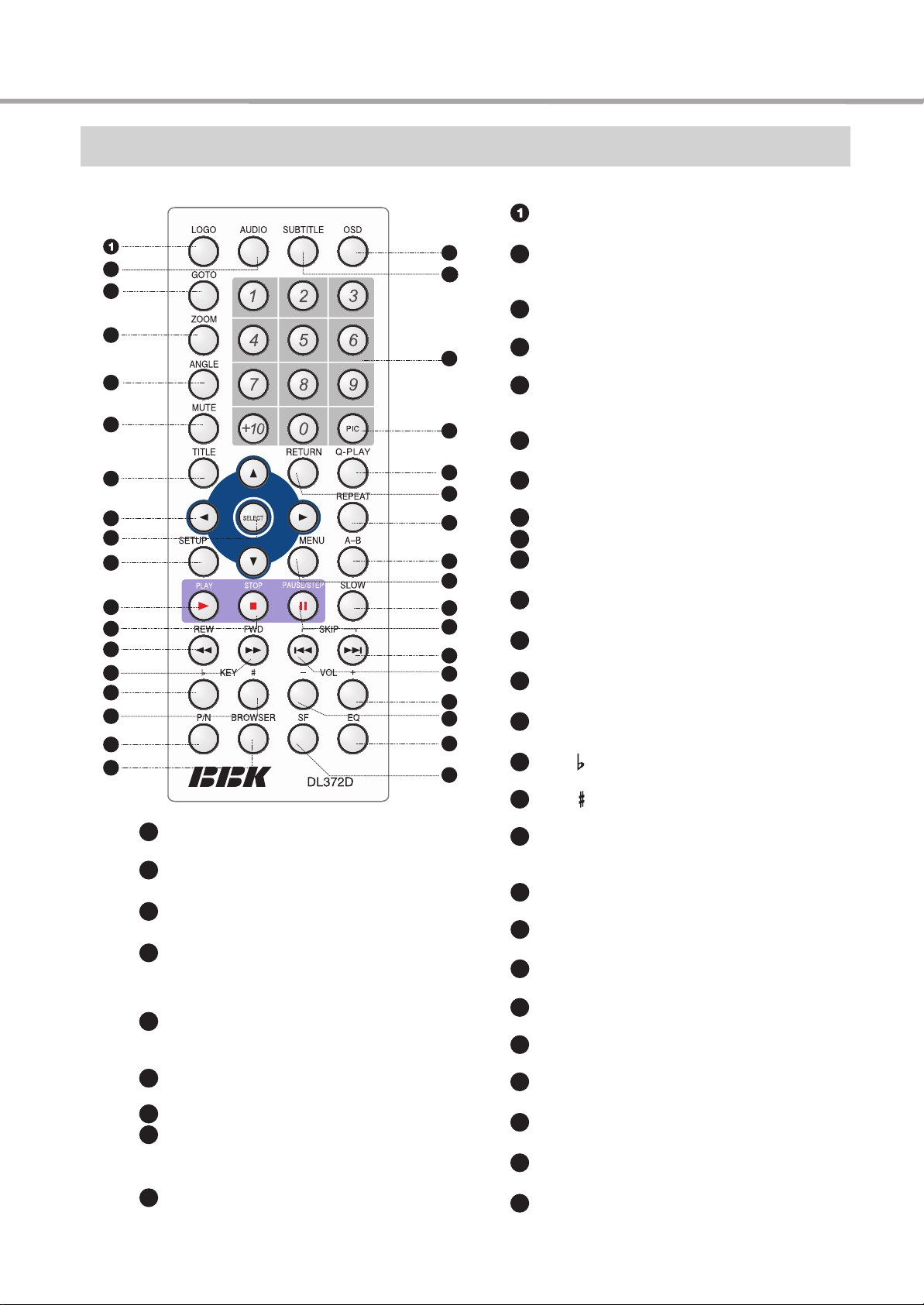

Remote Control Illustration

3

35

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

9

27

MENU Button

Display DVD menu or open/close PBC.

28

A-B Button

Repeat the select.

29

REPEAT Button

Repeat play.

30

RETURN Button

Back to the previous menu/Clearing input

numbers.

31

27

Q-PLAY Button

Skip the advertisement/warning and play

DVD directly.

32

27

PIC Button

Set video.

33

27

NUMBER Buttons

34

SUBTITLE Button

Change subtitle languages/

Switch JPEG display modes.

35

OSD Button

Display or hide disc information.

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

LOGO Button

Set the played image as the power-on logo.

2

AUDIO Button

Change the audio language or

audio channel.

3

GOTO button

Play from the desired location.

4

ZOOM Button

Zoom in /out the displayed frame.

5

ANGLE Button

Change camera angles, MP3/JPEG

playback modes switch.

6

MUTE button

Press once to mute, twice to unmute.

7

TITLE button

DVD titles.

8

CURSOR Buttons

9

SELECT Button

10

SETUP Button

Function setup.

11

PLAY Button

Normal playback.

12

STOP Button

Stop playback.

13

REW Button

Fast backward play.

14

FWD Button

Fast forward play.

15

KEY Button

Fall tone.

16

KEY Button

Rise tone.

17

P/N Button

Switch the TV system between

PAL, NTSC and AUTO.

18

BROWSER

Switch new user interface.

19

SF Button

Adjusting sound field effects.

EQ Button

20

Adjusting equalization effects.

21

VOLUME-

Decrease volume.

22

VOLUME+

Increase volume.

23

PREV Button

Skip backward.

24

NEXT Button

Skip forward.

25

PAUSE/STEP Button

Pause or play frame by frame.

26

SLOW Button

Slow play.

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1. Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the

3. The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

4

4.PREVENTION OF STATIC ELECTRICITY DISCHARGE

4.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

4.1.1. Worktable grounding

sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

4.1.3.Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before

installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure. (See this Technical Guide).

2. Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2. When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the

optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

5.1. Video Output (Luminance Signal) Confirmation

5

5.Electrical Confirmation

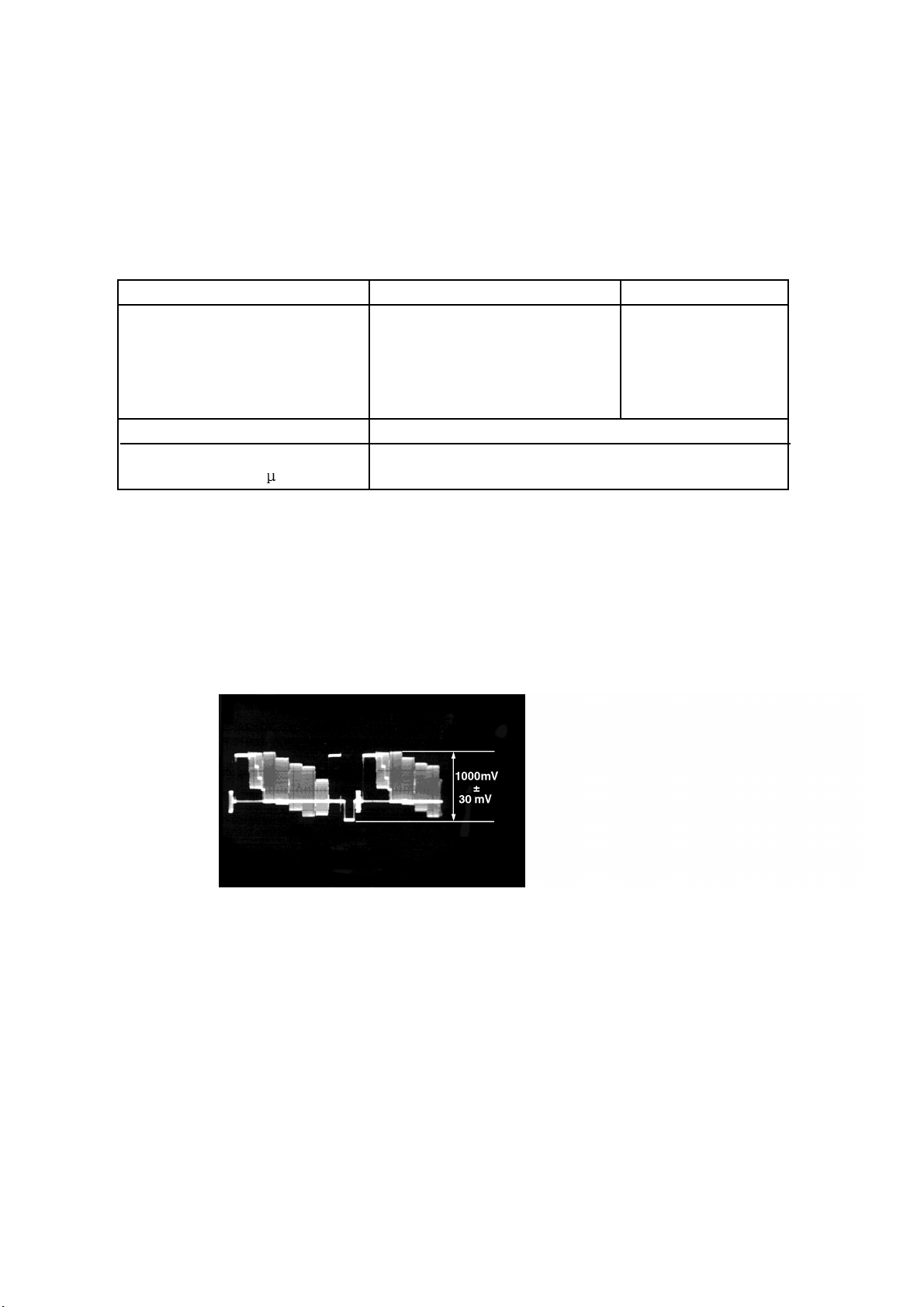

DO this confirmation after replacing a P.C.B.

Measurement point

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Do the confirmation after replacing P.C.B.

Screwdriver,Oscilloscope

5.2 Video Output(Chrominance Signal) Confirmation

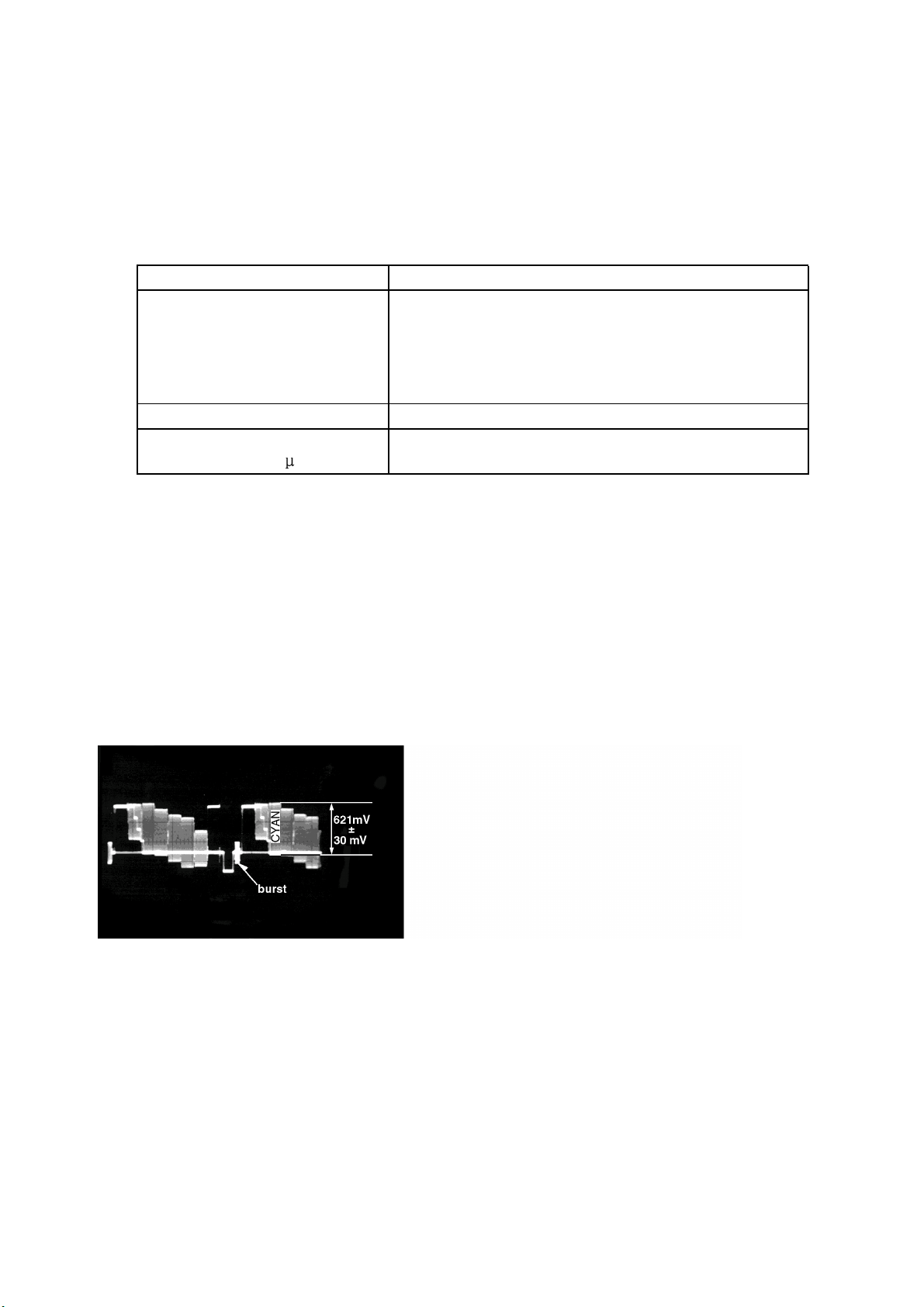

6

Measurement point

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

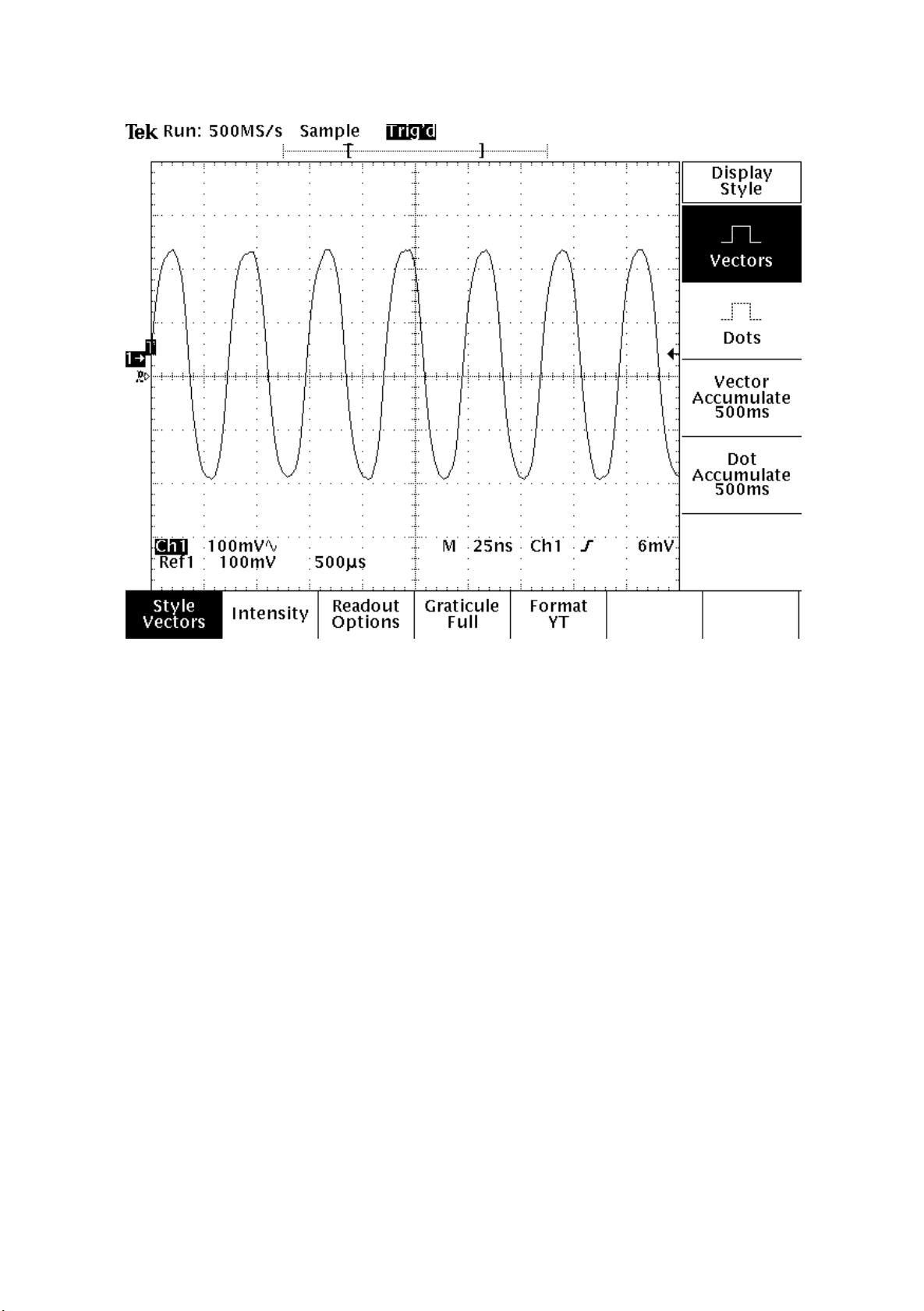

6.MPEG BOARD CHECK WAVEFORM

6.1 27MHz WAVEFORM

7

7.2 MT1389

8

MT1389

Specifications are subject to change without notice

Progressive-Scan DVD Player SOC

MediaTek MT1389 is a DVD player system-on-chip (SOC) which incorporates advanced features like high

quality TV encoder and state-of-art de-interlace processing. The MT1389 enables consumer electronics

manufacturers to build high quality, cost-effective DVD players, portable DVD players or any other home

entertainment audio/video devices.

rd

Based on MediaTek’s world-leading DVD player SOC architecture, the MT1389 is the 3

player SOC. It integrates the MediaTek 2

decoder.

The progressive scan of the MT1389 utilized a proprietary advanced motion-adaptive de-interlace algorithm to

achieve the best movie/video playback. It can easily detect 3:2/2:2 pull down source and restore the correct

original pictures. It also supports a patent-pending edge-preserving algorithm to remove the saw-tooth effect.

nd

generation front-end analog RF amplifier and the Servo/MPEG AV

generation of the DVD

Key Features

RF/Servo/MPEG Integration

High Performance Audio Processor

Motion-Adaptive, Edge-Preserving De-interlace

108MHz/12-bit, 6 CH TV Encoder

Applications

Standard DVD Players

Portable DVD Players

DVD

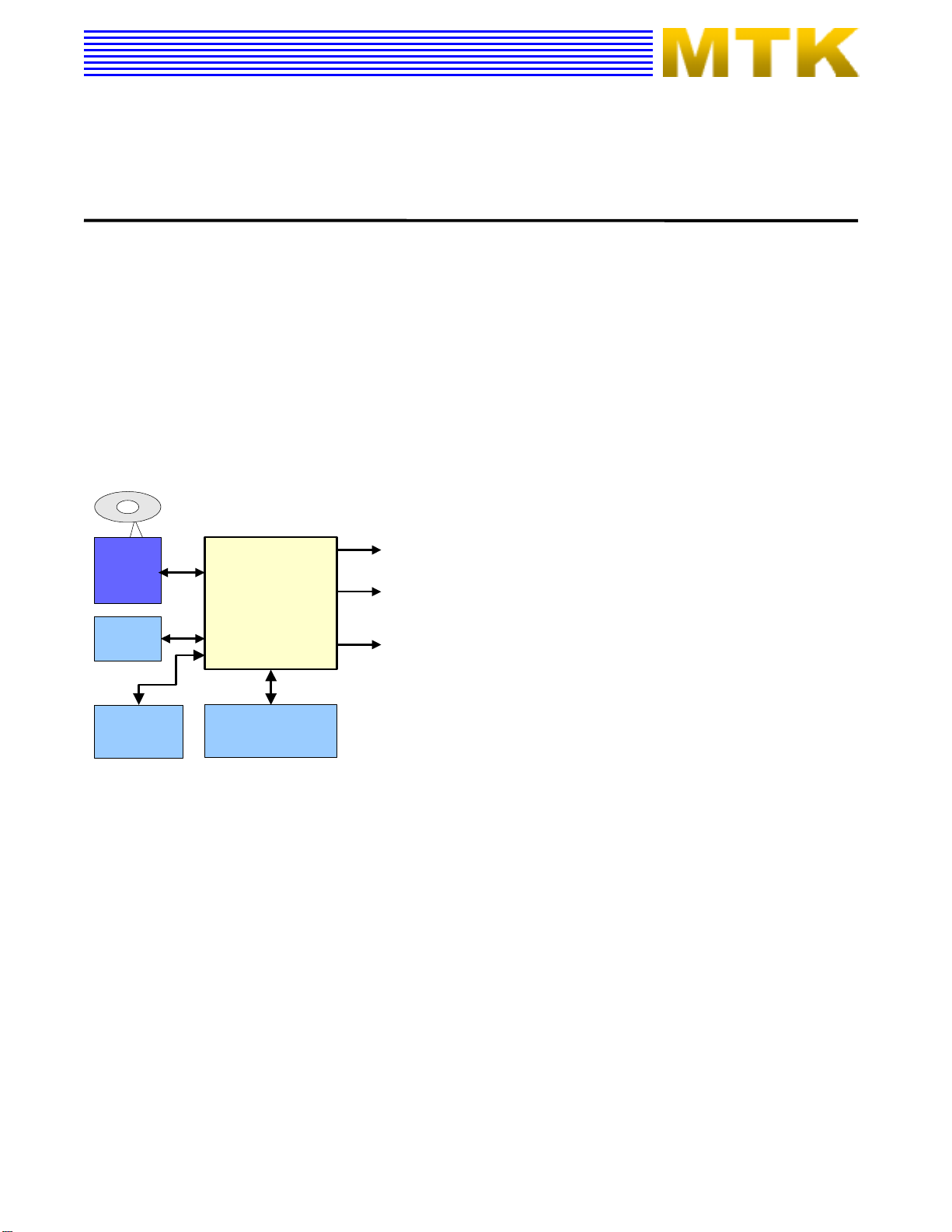

PUH

Module

FLASH

Front-panel

Remote

CVBS, Y/C,

Component

SDPIF

MT1389E

Audio L

Audio R

SDRAM

DVD Player System Diagram Using MT1389

KEY FEATURES

IC BLOCK DIAGRAM & DESCRIPTION

9

HY29LV160

16 Mbit (2M x 8/1M x 16) Low Voltage Flash Memory

nn

n Single Power Supply Operation

nn

– Read, program and erase operations from

2.7 to 3.6 volts

– Ideal for battery-powered applications

nn

n High Performance

nn

– 70, 80, 90 and 120 ns access time

versions

nn

n Ultra-low Power Consumption (Typical

nn

Values At 5 Mhz)

– Automatic sleep mode current: 1 µA

– Standby mode current: 1 µA

– Read current: 9 mA

– Program/erase current: 20 mA

nn

n Flexible Sector Architecture:

nn

– One 16 KB, two 8 KB, one 32 KB and

thirty-one 64 KB sectors in byte mode

– One 8 KW, two 4 KW, one 16 KW and

thirty-one 32 KW sectors in word mode

– Top or bottom boot block configurations

available

nn

n Sector Protection

nn

– Allows locking of a sector or sectors to

prevent program or erase operations

within that sector

– Sectors lockable in-system or via

programming equipment

– Temporary Sector Unprotect allows

changes in locked sectors (requires high

voltage on RESET# pin)

nn

n Fast Program and Erase Times

nn

– Sector erase time: 0.25 sec typical for

each sector

– Chip erase time: 8 sec typical

– Byte program time: 9 µs typical

nn

n Unlock Bypass Program Command

nn

– Reduces programming time when issuing

multiple program command sequences

nn

n Automatic Erase Algorithm Preprograms

nn

and Erases Any Combination of Sectors

or the Entire Chip

nn

n Erase Suspend/Erase Resume

nn

– Suspends an erase operation to allow

reading data from, or programming data

to, a sector that is not being erased

– Erase Resume can then be invoked to

complete suspended erasure

nn

n Automatic Program Algorithm Writes and

nn

Verifies Data at Specified Addresses

nn

n 100,000 Write Cycles per Sector Minimum

nn

nn

n Data# Polling and Toggle Bits

nn

– Provide software confirmation of

completion of program and erase

operations

nn

n Ready/Busy# Pin

nn

– Provides hardware confirmation of

completion of program and erase

operations

nn

n Hardware Reset Pin (RESET#) Resets the

nn

Device to Reading Array Data

nn

n Compliant With Common Flash Memory

nn

Interface (CFI) Specification

– Flash device parameters stored directly

on the device

– Allows software driver to identify and use

a variety of different current and future

Flash products

nn

n Compatible With JEDEC standards

nn

– Pinout and software compatible with

single-power supply Flash devices

– Superior inadvertent write protection

nn

n Space Efficient Packaging

nn

– 48-pin TSOP and 48-ball FBGA packages

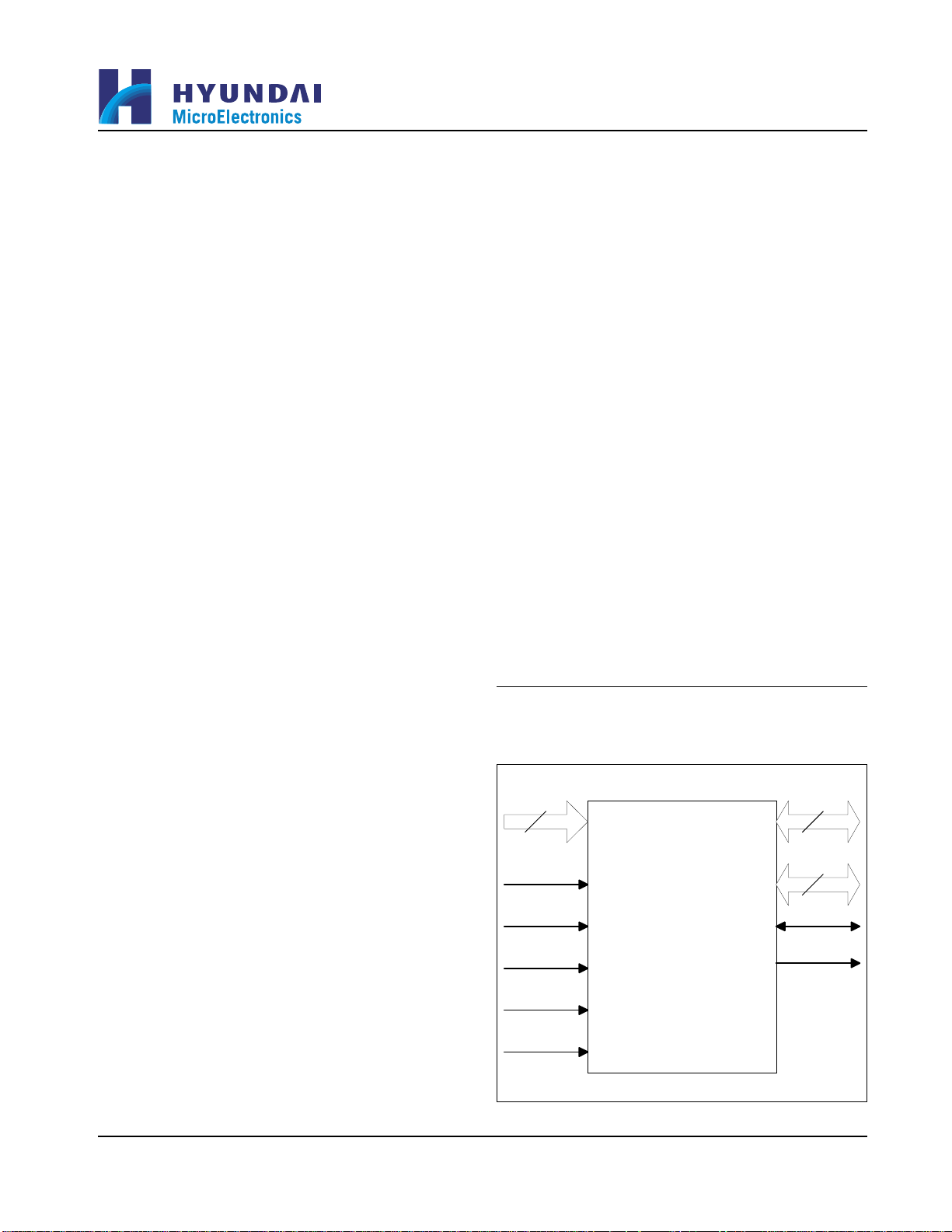

LOGIC DIAGRAM

20

A[19:0]

CE#

OE#

WE#

RESET#

BYTE#

DQ[7:0]

DQ[14:8]

DQ15/A-1

RY/BY#

8

7

Preliminary

Revision 1.0, June 2000

Loading...

Loading...