CONTENTS

1. SAFETY PRECAUTIONS

2. PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES)DEVICES

3. CONTROL BUTTON LOCATIONS AND EXPLANATIONS

4. PREVERTION OF STATIC ELECTRICITY DISCHARGE

5. ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT

5.1 OPTICAL PICKUP UNIT EXPLOSED VIEW AND PART LIST

5.2 MISCELLANEOUS

6. ELECTRICAL CONFIRMATION

6.1 VIDEO OUTPUT (LUMINANCE SIGNAL) CONFIRMATION

6.2 VIDEO OUTPUT(CHROMINANCE SIGNAL) CONFIRMATION

7. MPEG BOARD CHECK WAVEFORM

1

1

2

3

4

4

6

7

7

8

9

8. IC BLOCK DIAGRAM & DESCRIPTION

8.1 MT1336 10

8.2 MT1379

8.3 AM29LV160D 34

8.4 HY57V641620HG

9. SCHEMATIC & PCB WIRING DIAGRAM

10. SPARE PARTS LIST 57

10

18

39

42

1.1 GENERAL GUIDELINES

1. SAFETY PREAUTIONS

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO

ELECTROSTATICALLY SENSITIVE(ES)DEVICES

1

1. When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barrier, insulation papers

shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD).

notice (1885x323x2 tiff)

Fr ont Panel I l l u s t r at i o n

2

2

Power indicator

2

IR SENSOR

3

4

OPEN/CLOSE button

5

PLAY/PAUSE button

546 7 9

7

PREV button

8

8

NEXT button

3

Display window

6

STOP button

9

POWER switch

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1. Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the

3. The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

3

4.PREVENTION OF STATIC ELECTRICITY DISCHARGE

4.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

4.1.1. Worktable grounding

sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

4.1.3.Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before

installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure. (See this Technical Guide).

2. Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2. When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the

optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

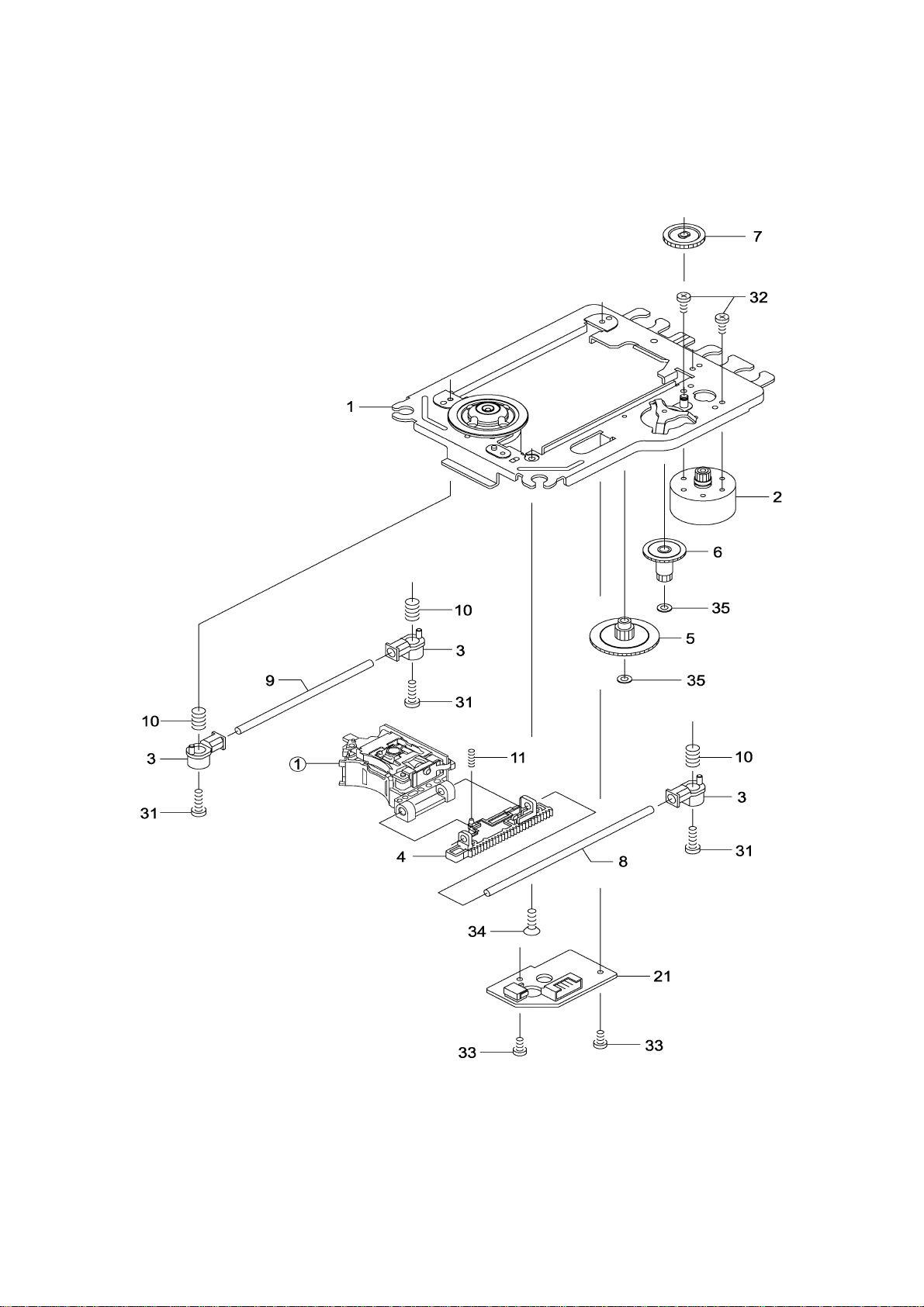

5.1 Optical pickup Unit Explosed View and Part List

5. Assembling and disassembling the mechanism unit

4

Pic (1)

Materials to Pic (1)

5

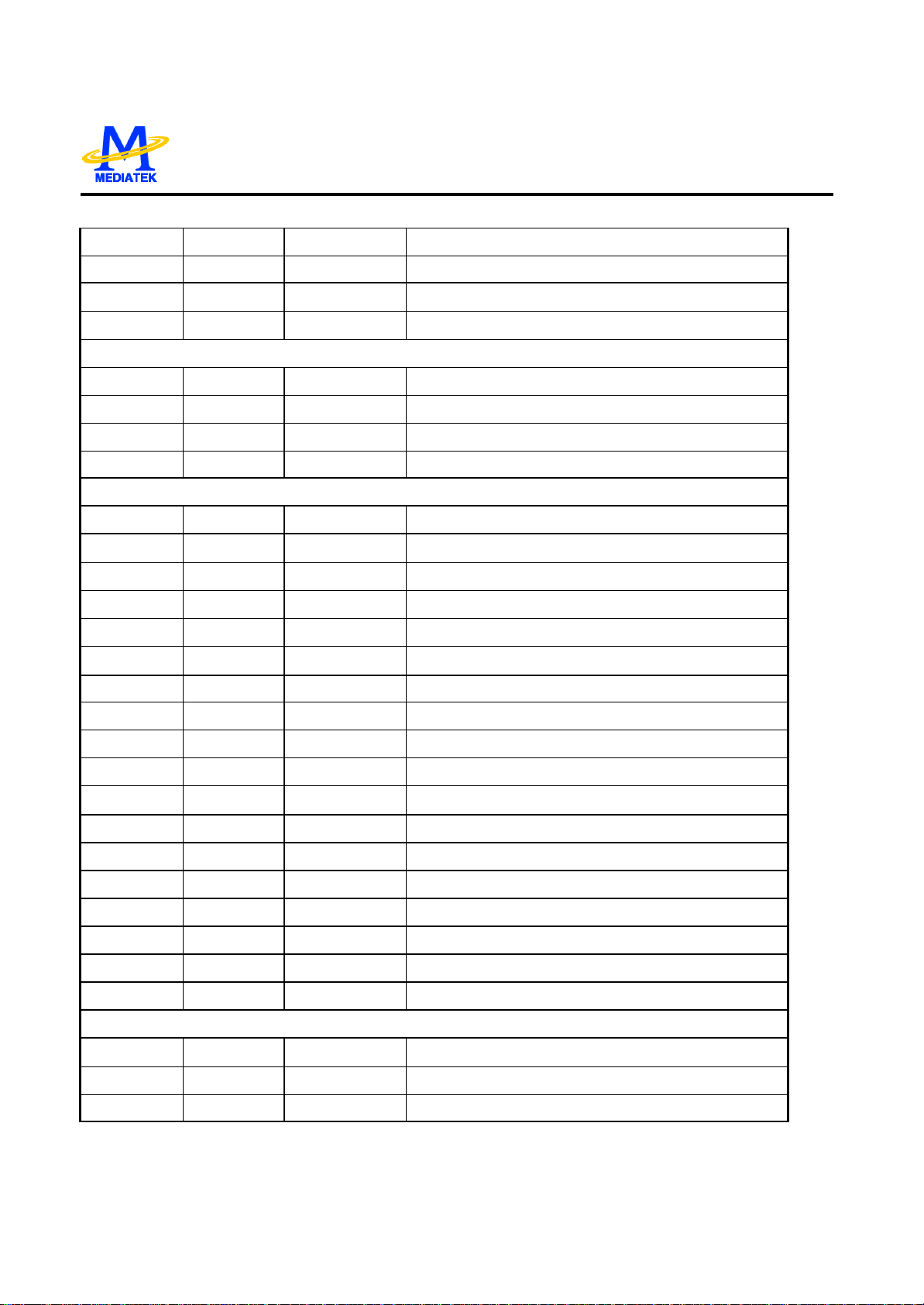

No. PARTS CODE PARTS NAME Q ty

14692200 SF-HD60 1

1

1EA0311A06300 ASSY, CHASSIS, COMPLETE 1

2

Or

3

4

5

6

7

8

9

10

11

21

Or

31

32

1EA0M10A15500 ASSY, MOTOR, SLED 1

1EA0M10A15501 ASSY, MOTOR, SLED 1

1EA2451A24700 HOLDER, SHAFT 3

1EA2511A29100 GEAR, RACK 1

1EA2511A29200 GEAR, DRIVE 1

1EA2511A29300 GEAR, MIDDLE, A 1

1EA2511A29400 GEAR, MIDDLE, B 1

1EA2744A03000 SHAFT, SLIDE 1

1EA2744A03100 SHAFT, SLIDE, SUB 1

1EA2812A15300 SPRING, COMP, TYOUSEI 3

1EA2812A15400 SPRING, COMP, RACK 1

1EA0B10B20100 ASSY, PWB 1

1EA0B10B20200 ASSY, PWB 1

SEXEA25700--- SPECIAL SCREW BIN+-M2X11 3

SEXEA25900--- SPECIAL SCREW M1.7X2.2 2

33

34

35

Note : This parts list is not for service parts supply.

SFBPN204R0SE- SCR S-TPG PAN 2X4 2

SFSFN266R0SE- SCR S-TPG FLT 2.6X6 1

SWXEA15400--- SPECIAL WASHER 1.8X4 X0.25 2

2 MISCELLANEOUS

6

5.

5.2.1 Protection of the LD(Laser diode)

Short the parts of LD circuit pattern by soldering.

5.2.2 Cautions on assembly and adjustment

Make sure that the workbenches,jigs,tips,tips of soldering irons and measuring instruments are

grounded,and that personnel wear wrist straps for ground.

Open the LD short lands quickly with a soldering iron after a circuit is connected.

Keep the power source of the pick-up protected from internal and external sources of electrical

noise.

Refrain from operation and storage in atmospheres containing corrosive gases (such as H2S,SO2,

NO2 and Cl2)or toxic gases or in locations containing substances(especially from the organic silicon,cyan,

formalin and phenol groups)which emit toxic gases.It is particularly important to ensure that none of the

above substances are present inside the unit.Otherwise,the motor may no longer run.

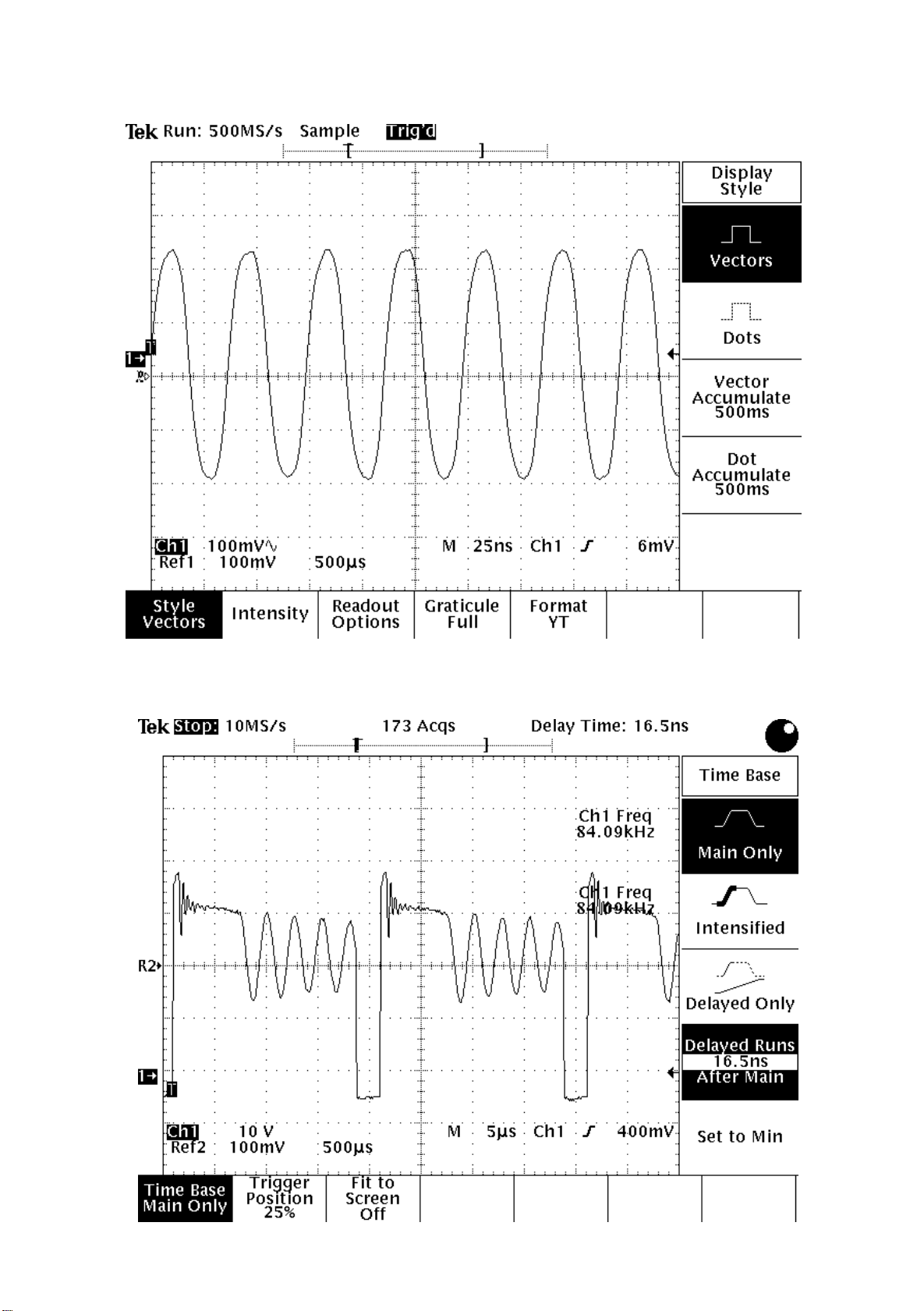

6.1. Video Output (Luminance Signal) Confirmation

6.Electrical Confirmation

7

DO this confirmation after replacing a P.C.B.

Measurement point

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Do the confirmation after replacing P.C.B.

Screwdriver,Oscilloscope

6.2 Video Output(Chrominance Signal) Confirmation

8

Measurement point

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

7.MPEG BOARD CHECK WAVEFORM

7.1 27MHz WAVEFORM

7.2 IC TEA1523 PIN.8 WAVEFORM DIAGRAM

9

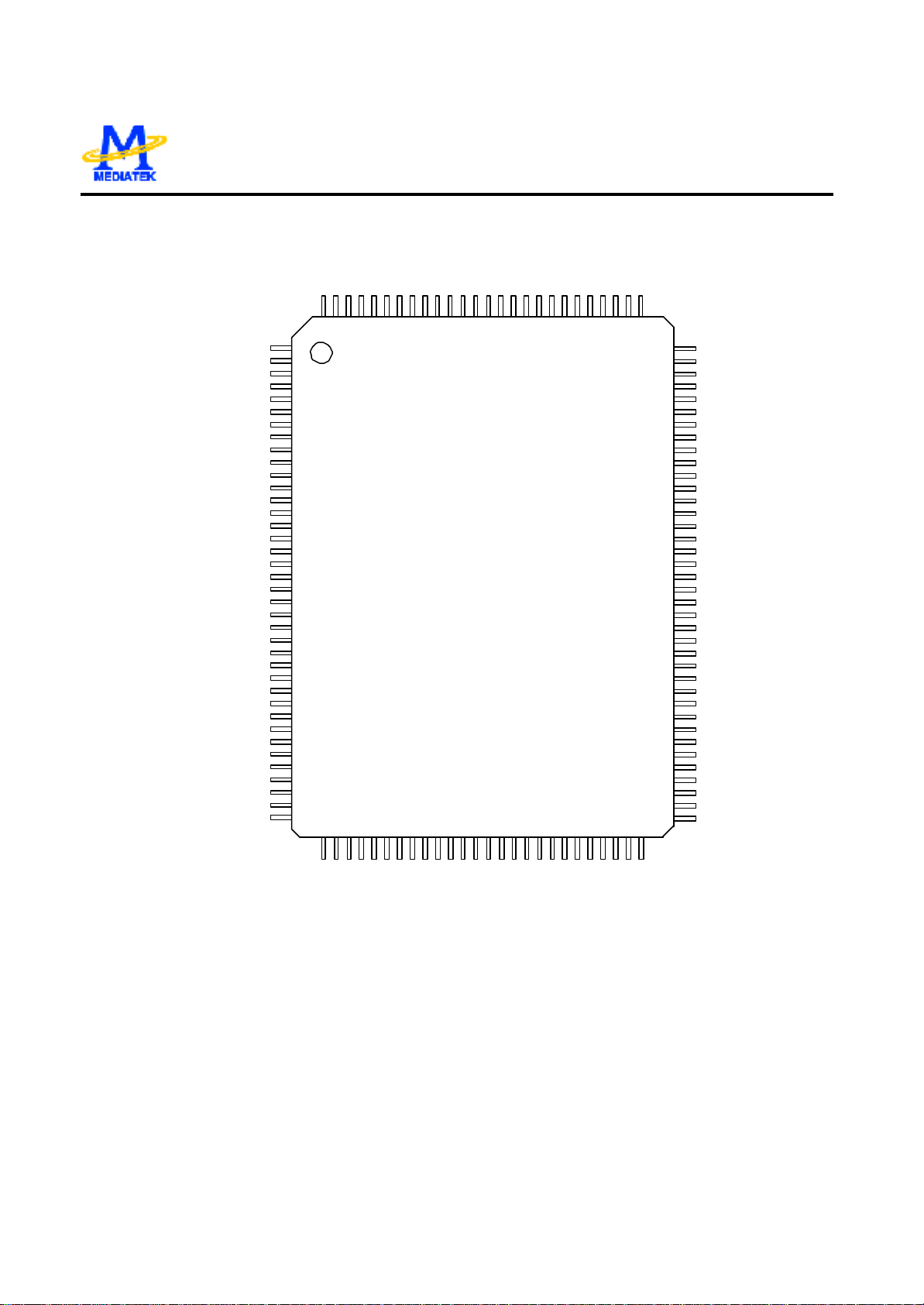

8.1 MT1336

8. IC BLOCK DIAGRAM & DESCRIPTION

10

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1336

GENERAL DESCRIPTION

MT1336 is a high performance CMOS analog front-end IC for both CD_ROM driver up to 48XS and

DVD-ROM driver up to 16XS. It also supports DVD-RAM read up to 4XS Version 2. It contains servo amplifiers

to generate focusing error, 3-beam tracking error, 1 beam radial push-pull signal, RF level and SBAD for servo

functions. It also includes DPD tracking error signal for DVD_ROM application. For DVD- RAM disks, there are

also Differential Push-Pull (DPP) method for generating tracking signal and Differential Astigmatic Detection

(DAD) for processing focusing signal. Programmable equalizer and AGC circuits are also incorporated in this

chip to optimize read channel performance. In addition, this chip has dual automatic laser power control circuits

for DVD- ROM (DVD-RAM) and CD -ROM seperately and reference voltage generators to reduce external

components. Programmable functions are implemented by the access of internal register through bi-directional

serial port to configure modes selection.

FEATURES

n RF equalizer with programmable

13dB.

n MT1336 supports at least eight different kinds of pick-up heads with versatile input configuration for

both RF input stages and servo signal blocks.

n Versatile on -line AGC.

n 3 beams tracking error signal generator for CD_ROM application.

n One beam differential phase tracking error (DPD) generator for DVD_ROM application.

n Differential push pull tracki ng error (DPP) generator for DVD_RAM application.

n Focusing error signal generator for CD-ROM, DVD-ROM and DVD-RAM (DAD method).

n RF level signal generator.

n Sub-beam added signal for 3 beams CD_ROM.

n One beam push-pull signal generator for central servo application.

n High speed RF envelop detection circuit with bandwidth up to 400KHz for CD-ROM.

n Defect and Blank detection circuits.

from 3MHz to 70 MHz and programmable boost from 3dB to

f

c

n Dual automatic laser power control circuits with programmable level of LD monitor voltage.

n Vref=1.4V voltage and V2ref=2.8V voltage generators.

n V20=2.0V voltage for pick-up head reference.

n Bi-directional serial port to access internal registers.

MT1336

11

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

DVDA

CDA

DVDB

CDB

DVDC

CDC

DVDD

CDD

DVDRFIN

DVDRFIP

MA

MB

MC

MD

SA

SB

SC

SD

DPFN

DPFO

IR

DPDMUTE

TPI

TNI

CDFOP

CDFON

RFGC

RFGCU

RFGCI

AGC1

AGC2

AGC3

RFSUBO

WOBSO

V20

V2REFO

VREFO

ATTENUATOR

INPUT MUX

WOBBLE

DET

VGA

VGA EQ

AGC

AGC

DPD

SBAD

TE

RF

LEVEL

FE

CENTRAL

SERVO

REF and 2VREF

REF and 2VREF

Voltage Generator

Voltage Generator

ENVELOP

ENVELOP

DETECTOR

DETECTOR

PCS

DVD

APC

CD

APC

SERIAL

PORT

OSP

OSN

RFOP

RFON

LRFRP

DEFECT

HRFRP

CRTP

CRTPLP

CSO

LVL

TEO

FEO

REFCOS

HALLCOS

COSPHI

REFSIN

HALLSIN

SINPHI

MDI2

LDO2

MDI1

LDO1

UDGATE

IDGATE

VFO13

SDATA

SLCK

SDEN

MT1336 FUNCTION BLOCKS DIAGRAM

12

MT1336

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

WGND

WOBSO

WVDD

AGNDX

AGNDX

AVDDO

RFOP

RFON

AGNDO

TM1

TM2

TM3

AGNDT

TM4

AVDDT

V2REFO

VREFO

V20

FEO

LVL

CSO

TEO

VDDP

DEFECT

LRFRP

HRFRP

CRTP

CRTPLP

TRLPA

TRLP

HTRC

GNDP

DPFN

DPFO

AGNDX

AGNDX

AGNDX

VDD

VFO13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

RFSUBO

LDO2

LDO1

127

126

125

128

3940414243

MDI1

124

WAVDD

MDI2

123

AGC1

AGC2

AGC3

121

120

119

122

MT1336

DVD-ROM

DVD_RAM

454647

44

48

WAGND

TNI

SGND

118

117

116

With

Read

495051

525453

SD

CDFOP

SVDD

TPI

CDFON

115

114

113

112

111

555657585960616263

SASBMC

IR

AVDD

SC

110

109

108

MD

AGND

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

MB

MA

DVDA

DVDB

DVDC

DVDD

DVDRFIP

DVDRFIN

CDA

CDB

CDC

CDD

OSN

OSP

RFGC

RFGCU

RFGCI

CEQP

CEQN

AGNDX

AGNDX

MON

MOP

SW1

SW2

SWO

SINPHI

REFSIN

HALLSIN

AGNDM

REFCOS

HALLCOS

COSPHI

AVDDM

AGNDX

AVDDF

VCON

AGNDF

IO0

GND

UDGATE

HDGATE

IO4

IO1

IO5

IO7

IO8

IO9

IO6

IO3

IO2

IOB

IOA

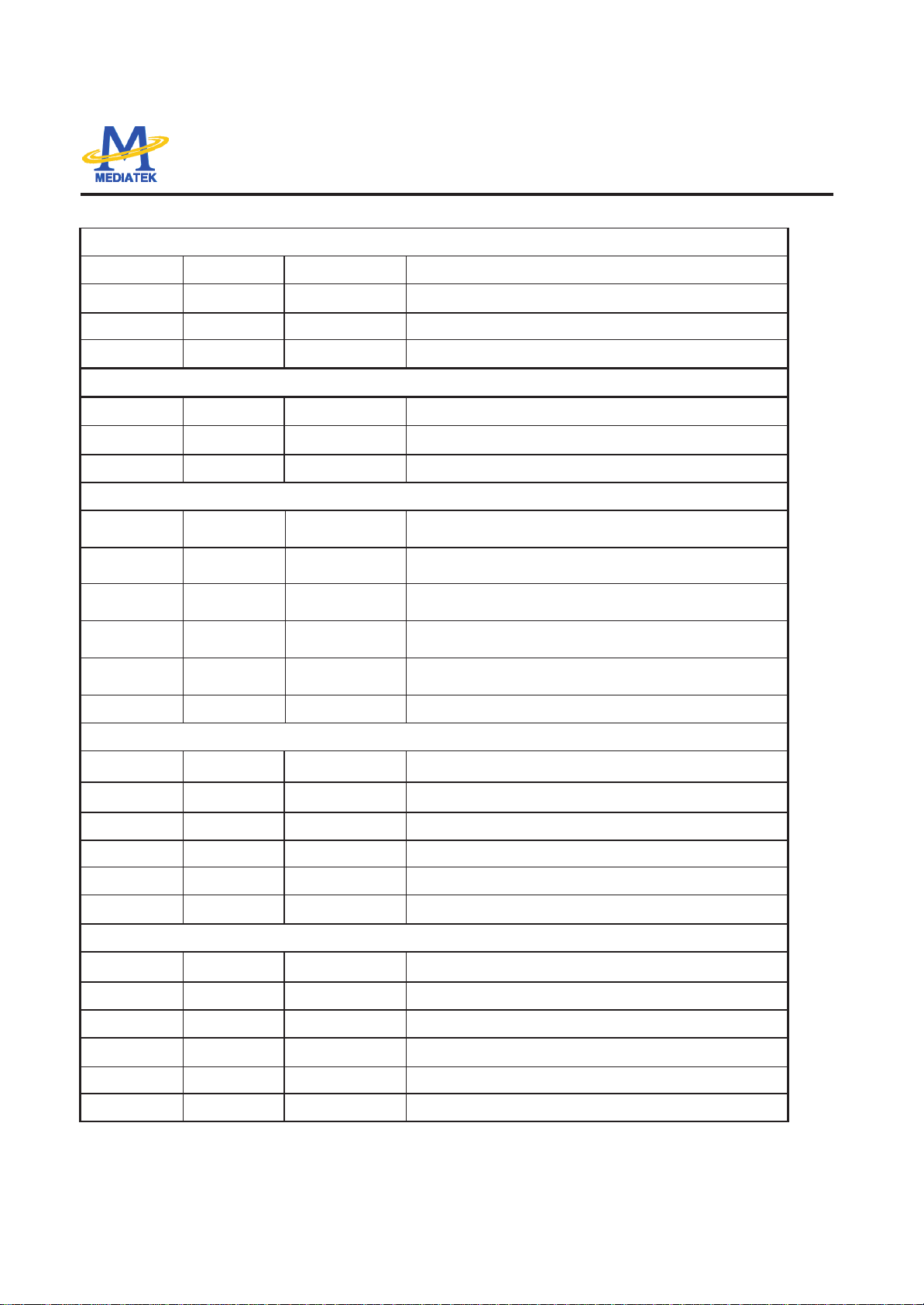

MT1336 PIN ASSIGNMENT

SCLK

VDDS

XCK16M

RST

SDEN

GNDS

SDATA

AGNDP

AGNDX

AVDDP

DPDMUTE

13

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1336

MT1336 PIN DESCRIPTIONS

Pin Numbers Symbol Type Description

LQFP128

RF Flag Interface

23 DEFECT Digital Output Flag of bad data output status

RF SIO interface

56 SCLK Digital Input RF serial clock input

58 SDEN Digital Input RF serial data enable

59 SDATA Digital IO RF serial data IO

60 RST Digital input Reset (active high)

55 XCK16M Digital Input 16.9MHz for verification

RF SERVO interface

40 UDGATE Digital Input Con trol signal for DVD-RAM

41 IDGATE Digital Input Control signal for DVD-RAM

38 VFO13 Digital Input DVD -RAM Header signal

RF

100 DVDA Analog input AC coupled DVD RF signal input A

99 DVDB Analog Input AC coupled DVD RF signal input B

98 DVDC Analog Input AC coupled DVD RF signal input C

97 DVDD Analog Input AC coupled DVD RF signal input D

95 DVDRFIN Analog Input AC coupled DVD RF signal input RFIN

96 DVDRFIP Analog Input AC coupled DVD RF signal input RFIP

94 CDA Analog Input AC coupled CD RF signal input A

93 CDB Analog Input AC coupled CD RF signal input B

92 CDC Analog Input AC coupled CD RF signal input C

91 CDD Analog Input AC coupled CD RF signal input D

90 OSN Analog RF Offset cancellation capacitor connecting

89 OSP Analog RF Offset cancellation capacitor connecting

85 CEQP Analog RF Offset cancellation capacitor connecting

84 CEQN Analog RF Offset cancellation capacitor connecting

88 RFGC Analog RF AGC loop capacitor connecting for DVD -ROM

14

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

87 RFGCU Analog RF AGC loop capacitor connecting for DVD -RAM

86 RFGCI Analog RF AGC loop capacitor connecting for DVD -RAM

101 MA Analog Input DC coupled DVD-RAM main-beam RF signal input A

102 MB Analog Input DC coupled DVD-RAM main-beam RF signal input B

103 MC Analog Input DC coupled DVD-RAM main-beam RF signal input C

104 MD Analog Input DC coupled DVD-RAM main-beam RF signal input D

105 SA Analog Input DC coupled DVD -RAM sub-beam RF signal input A

106 SB Analog Input DC coupled DVD-RAM sub-beam RF signal input B

110 SC Analog Input DC coupled DVD-RAM sub-beam RF signal input C

111 SD Analog Input DC coupled DVD-RAM sub-beam RF signal input D

108 IR Analog External current bias resistor (R=20K)

119 AGC1 Analog Wobble AGC loop1 capacitor

121 AGC2 Analog Wobble AGC loop2 capacitor

122 AGC3 Analog Wobble AGC loop3 capacitor

MT1336

127 RFSUBO Analog output Header push-pull RF output signal

1 WOBSO Digital output Wobble signal output

6 RFOP Analog output RF positive output

7 RFON Analog output RF negative output

TRACKING ERROR

32 DPFN Analog DPD amplifier negative input

33 DPFO Analog DPD amplifier output

61 DPDMUTE Digital input DPD mute control input

116 TNI Analog Input 3 beam satellite PD signal negative input

115 TPI Analog Input 3 beam satellite PD signal positive input

21 TEO Analog Output Tracking error output

FOCUSING ERROR & RF LEVEL & CENTRAL SERVO SIGNAL

112 CDFOP Analog Input CD focusing error positive input

113 CDFON Analog Input CD focusing error negative input

18 FEO Analog Output Focusing error output

19 LVL Analog Output RF level output

20 CSO Analog output Central servo signal output

ALPC

15

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1336

124 MDI1

125 LDO1 Analog Ou tput Laser driver output

123 MDI2

126 LDO2 Analog Output Laser driver output

RF RIPPLE

26 CRTP Analog RF top envelop filter capacitor connecting

27 CRTPLP Analog Defect level filter capacitor connecting

25 HRFRP Analog output High frequency RF ripple output or Blank detector’s output

24 LRFRP Analog output Low frequency RF ripple output

POWER

67, 69 AVDD Power Master PLL Filter power

65, 73 AGND GND GND for Master PLL Filter

64 AVDD Power DPD Power

62 AGND GND DPD GND

109 AVDD Power RF path Power

107 AGND GND RF path GND

Analog Input

Analog Input

Laser power monitor input

Laser power monitor input

114 SVDD Power Servo Power

117 SGND GND Servo GND

2,120 WAVDD Power Wobble Power

128,118 WAGND GND Wobble GND

5 AVDDO Power Power for RF output

8 AGNDO GND GND for RF output

14 AVDDT Power Power for Trimming PAD

12 AGNDT GND GND for Trimming PAD

22 VDDP Power Peak Detection Power

31 GNDP GND Peak Detection GND

37,54 VDD Power Serial I/O Power

39,57 GND GND Serial I/O GND

REFERENCE VOLTAGE

16 VREFO Analog output Reference voltage 1.4V

15 V2REFO Analog output Reference voltage 2.8V

17 V20 Analog Output Reference voltage 2.0V

16

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

ALPC TRIMMING

9 TM1 Analog input Trimming pin for ALPC1

10 TM2 Analog input Trimming pin for ALPC1

11 TM3 Analog input Trimming pin for ALPC2

13 TM4 Analog input Trimming pin for ALPC2

HIGH SPEED TRACK COUNTING

29 TRLP Analog Low-pass filter capacitor connecting

28 TRLPA Analog Low-pass filter capacitor connecting

30 HTRC Digital output High speed track counting digital output

PCS

74 HALLSIN Analog input Negative input of amplifier for hall sensor signal

75 REFSIN Analog input Positive input of amplifier for hall sensor signal

76 SINPHI Analog output Amplifier output for hall sensor signal

MT1336

71 HALLCOS Analog input Negative input of amplifier for hall sensor signal

72 REFCOS Analog input Positive input of amplifier for hall sensor signal

70 COSPHI Analog output Amplifier output for hall sensor signal

FOR MONITOR ONLY

81

80

66 VCON Analog output

77 SWO Analog output Output from mux of SW1 & SW2

78 SW2 Analog input External input for servo input select

79 SW1 Analog input External input for servo input select

FOR SERIAL I/O

42

43 IO1

44 IO2

45 IO3

46 IO4

MON Analog output

MOP Analog output

IO0

47 IO5

17

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

48 IO6

49 IO7

50 IO8

51 IO9

52 IOA

53 IOB

MT1336

18

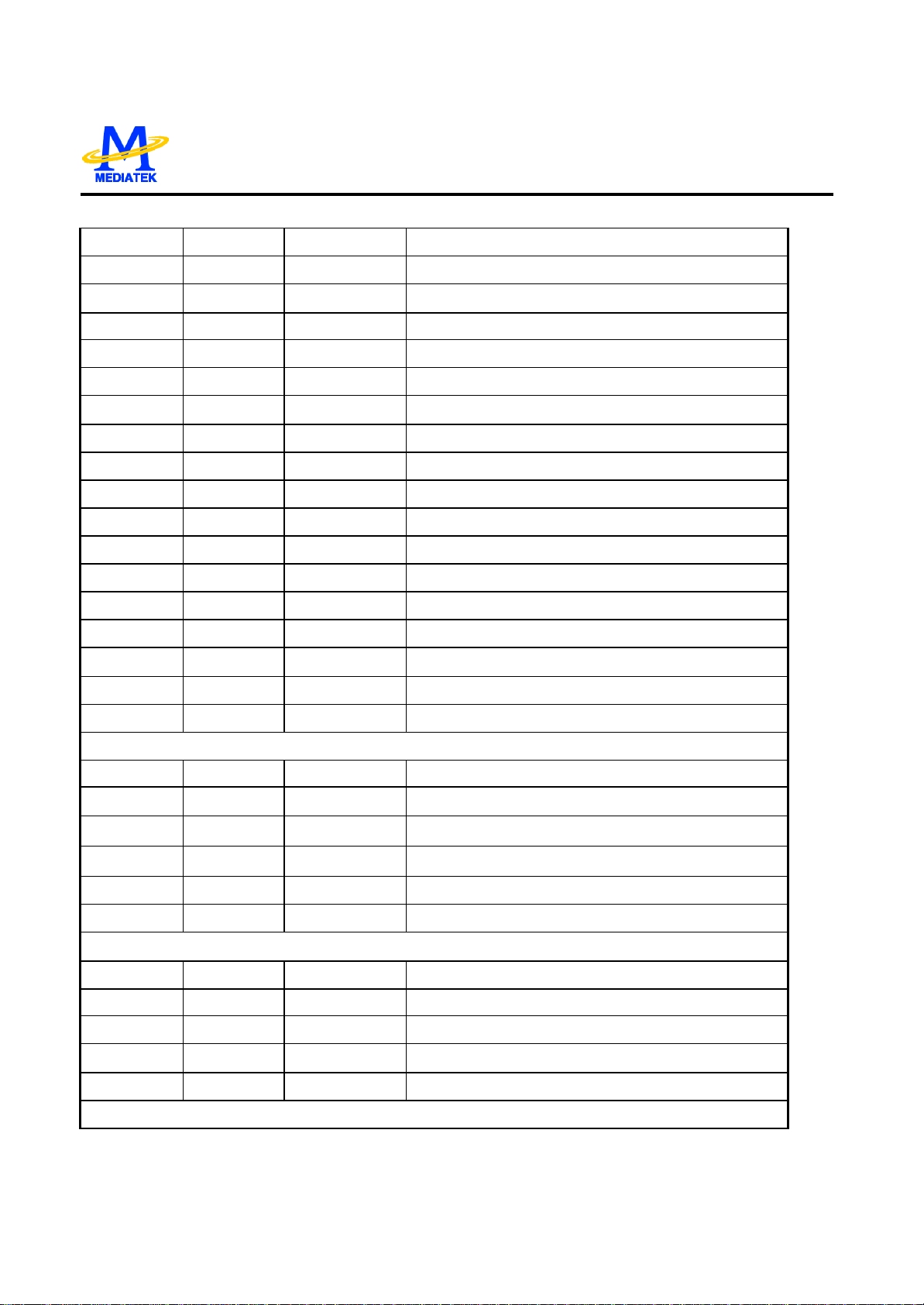

8.2 MT1379

Specifications are subject to change without notice

n Super Integration DVD player single chip

§

Servo controller and data channel processing

§

MPEG-1/MPEG-2/JPEG video decoding

§

Dolby AC-3/DTS/DVD-Audio audio decoding

§

Unified track buffer and A/V decoding buffer

§

Video processing for scaling and video quality

enhancement

§

OSD & Sub-picture decoding

§

Built-in clock generator

§

Built-in TV encoder

§

Built-in progressive video output

§

Video input port and audio/SPDIF input port

n Speed Performance on Servo and Decoding

§

DVD-ROM up to 8XS

§

CD-ROM up to 24XS

§

Built-in a frequency programmable clock to µP

and RSPC Decoder to optimize the performance

over power

n Channel Data Processor

§

Provides interface with analog front -end

processor

§

Analog data slicer for small jitter capability

§

Built-in high performance data PLL for channel

data demodulation

§

EFM/EFM+ data demodulation

§

Enhanced channel data frame sync protection &

DVD-ROM sector sync protection

n Servo Control and Spindle Motor Control

§

Programmable frequency error gain and phase

error gain of spindle PLL to control spindle motor

on CLV and CAV mode

§

Provide a varipitch speed control for CLV and CAV

mode

§

Built-in ADCs and DACs for digital servo control

§

Provide 2 general PWM

Progressive Scan DVD Player Combo Chip

§

Tray control can be PWM output or digital output

§

Built-in DSP for digital servo control

n Host Micro controller

§

Built-in 8032 micro controller

§

Built-in internal 373 and 8-bit programmable

MT1379

lower address port

§

1024-bytes on-chip RAM

§

Up to 2M bytes FLASH -programming interface

§

Supports 5/3.3-Volt. FLASH interface

§

Supports power-down mode

§

Supports additional serial port

n DVD-ROM/CD-ROM Decoding Logic

§

Supports CD-ROM Mode 1, CD-ROM XA Mode 2

Form 1, CD-ROM XA Mode 2 Form 2, and CD -DA

formats

§

High-speed ECC logic capable of correcting one

error per each P -codeword or Q-codeword

§

Automatic sector Mode and Form detection

§

Automatic sector Header verification

§

8-bit counter for decode completion check

§

Programmable descrambling and error

correction schemes

§

Automatically repeated error corrections

§

8-bit C2 Pointer counter

§

Decoder Error Notification Interrupt that signals

various decoder errors

§

Provide error correction acceleration

n Buffer Memory Controller

§

Supports 16Mb/32Mb/64Mb/128Mb SDRAM

§

Supports 16-bit/32-bit SDRAM data bus interface

§

Build in a DRAM interface programmable clock to

optimize the DRAM performance

§

Provide the se lf-refresh mode SDRAM

§

Programmable DRAM access cycle and refresh

19

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

cycle timings

§

Block-based sector addressing

§

Programmable buffering counter for buffer status

tracking

§

Maximum DRAM speed is 133MHz

§

Support 5/3.3-Volt. DRAM Interface

n Video Decode

§

Decodes MPEG 1 video and MPEG2 main level,

main profile video (720/480 and 720x576)

§

Maximum input bit -rate of 15Mbits/sec

§

Smooth digest view function with I, P and B

picture decoding

§

Baseline, extended-sequential and progressive

JPEG image decoding

§

RLE and non-RLE BMP image decoding

§

Support CD-G titles

n Video/OSD/SPU/HLI Processor

§

Arbitrary ratio vertical/horizontal scaling of video,

from 0.25X to 256X

§

65535/256/16/4/2-color bitmap format OSD,

§

256/16 color RLC format OSD

§

Automatic scrolling of OSD image

§

Provides 4-color/32x32-pixel hardware cursor

§

Fade-in, Fade out, and Wipe functions as

specified in the DVD-Audio Specification and

other slide show transition effects

§

Progressive scan output

n Audio Processing

§

Decoder format supports:

- Dolby Digital (AC-3) decoding

- DTS decoding

- MLP decoding for DVD-Audio

- MPEG-1 layer 1/layer 2 audio decoding

- MPEG-2 layer1/layer2 2-channel audio decoding

- Dolby Pro Logic decoding

- High Definition Compatible Digital (HDCD)

decoding

§

Up to 6 channel linear PCM output for DVD Audio

/ DVD Video

§

Downmix function

§

Support IEC 60958/61937 output

- PCM / bit stream / mute mode

- Custom IEC latency up to 2 frames

§

Pink noise and white noise generator

§

Karaoke functions

- Microphone echo with adjustable echo level,

echo -depth and delay length

- Microphone tone control with three custom

second-order IIR filter

- Vocal mute/vocal assistant

- Key shift up to +/- 8 keys controlled by 1/2 key

§

Channel equalizer

§

3D surround processing include virtual surround

and speaker separation

§

Power-down control

§

HDCD certified

n TV Encoder

§

Six 54MHz/12bit DA converters

§

Support NTSC, PAL-BDGHI, PAL-N, PAL-M

interlace TV format and 480p, 576p progressive

TV format

§

Automatically turn off unconnected channel(s).

§

Support PC monitor (VGA)

§

Support Macrovision 7.1

n Progressive Output

§

Automatic detect film or video source

§

3:2 pull down source detection

§

Advanced Motion adaptive de-interlace

§

Minimum external memory requirement

n Audio/Video Output

§

Line-in/SPDIF-in for versatile audio processing

§

CCIR601/656 video input port

§

Support picture -in-picture for video decoding and

input source

n Outline

§

216-pin LQFP package

§

3.3/2.5-Volt. Dual operating voltages

The 2nd general PWM output

20

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

P

IN DEFINITIONS

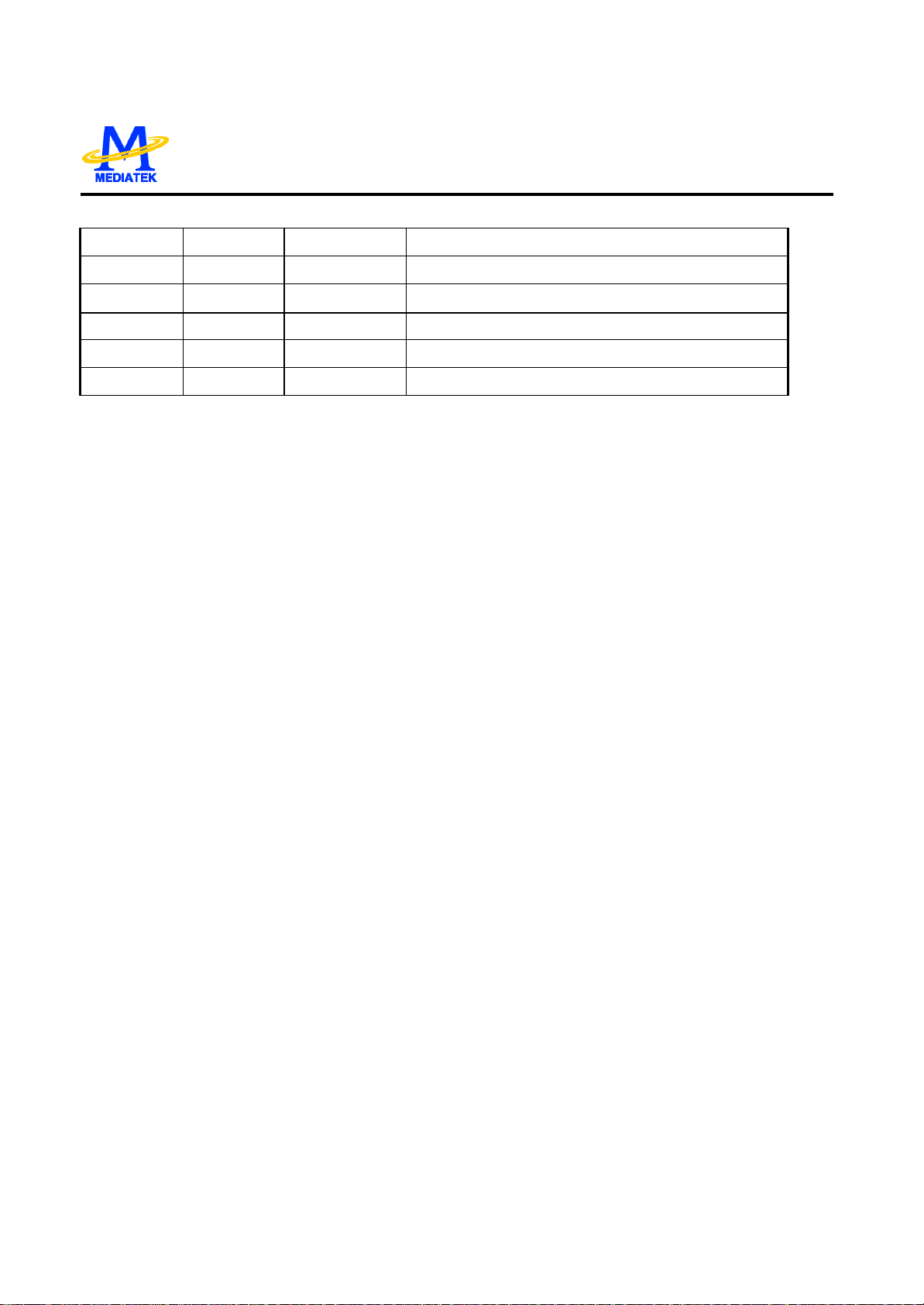

Pin Number Symbol Type Description

1 IREF Analog Input Current reference input. It generates reference current for data

2 PLLVSS Ground Ground pin for data PLL and related analog circuitry

3 LPIOP Analog Output Positive output of the low pass filter

4 LPION Analog Output Negative output of the low pass filter

5 LPFON Analog output Negative output of loop filter amplifier

6 LPFIP Analog Input Positive input of loop filter amplifier

7 LPFIN Analog Input Negative input of loop filter amplifier

8 LPFOP Analog Output Positive output of loop filter amplifier

9 JITFO Analog Output RF jitter meter output

10 JITFN Analog Input Negative input of the operation amplifier for RF jigger meter

11 PLLVDD3 Power 3.3V power pin for data PLL and related analog circuitry

12 FOO Analog Output Focus servo output. PDM output of focus servo compensator

13 TRO Analog Output Tracking servo output. PDM output of tracking servo compensator

14 TROPENPWM Analog Output Tray open output, controlled by microcontroller.

15 PWMOUT1 Analog Output The 1st general PWM output

16 PWMOUT2 Analog Output

17 DVDD2 Power 2.5V power pin for internal fully digital circuitry

18 DMO Analog Output Disk motor control output. PWM output

19 FMO Analog Output Feed motor control. PWM output

20 DVSS Ground Ground pin for internal fully digital circuitry

21 FG Input Motor Hall sensor input

22 HIGHA0 Inout

23 HIGHA1 Inout

24 HIGHA2 Inout

25 HIGHA3 Inout

26 HIGHA4 Inout

27 HIGHA5 Inout

28 DVSS Grou nd Ground pin for internal digital circuitry

PLL.

Connect an external 100K resistor to this pin and PLLVSS.

This is PWM output for TRWMEN27hRW2=1 or is digital output for

TRWMEN27hRW2=0

Microcontroller address 8

2~16MA, SR

PU

Microcontroller address 9

2~16MA, SR

PU

Microcontroller address 10

2~16MA, SR

PU

Microcontroller address 11

2~16MA, SR

PU

Microcontroller address 12

2~16MA, SR

PU

Microcontroller address 13

2~16MA, SR

PU

21

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

29 HIGHA6 Inout

30 HIGHA7 Inout

31 AD7 Inout

32 AD6 Inout

33 AD5 Inout

34 AD4 Inout

35 DVDD3 Power 3.3V power pin for internal digital circuitry

36 AD3 Inout

37 AD2 Inout

38 AD1 Inout

39 AD0 Inout

40 IOA0 Inout

41 IOA1 Inout

42 DVDD2 Power 2.5V power pin for internal digital circuitry

43 IOA2 Inout

44 IOA3 Inout

45 IOA4 Inout

46 IOA5 Inout

47 IOA6 Inout

Microcontroller address 14

2~16MA, SR

PU

Microcontroller address 15

2~16MA, SR

PU

Microcontroller address/data 7

2~16MA, SR

Microcontroller address/data 6

2~16MA, SR

Microcontroller address/data 5

2~16MA, SR

Microcontroller address/data 4

2~16MA, SR

Microcontroller address/data 3

2~16MA, SR

Microcontroller address/data 2

2~16MA, SR

Microcontroller address/data 1

2~16MA, SR

Microcontroller address/data 0

2~16MA, SR

Microcontroller address 0 / IO

2~16MA, SR

PU

Microcontroller address 1 / IO

2~16MA, SR

PU

Microcontroller address 2 / IO

2~16MA, SR

PU

Microcontroller address 3 / IO

2~16MA, SR

PU

Microcontroller address 4 / IO

2~16MA, SR

PU

Microcontroller address 5 / IO

2~16MA, SR

PU

Microcontroller address 6 / IO

2~16MA, SR

PU

MT1379

22

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

48 IOA7 Inout

49 A16 Output

50 A17 Output

51 IOA18 Inout

52 IOA19 Inout

53 IOA20 Inout

54 APLLVSS Ground Ground pin for audio clock circuitry

55 APLLVDD3 Power 3.3V Power pin for audio clock circuitry

56 ALE Inout

57 IOOE# Inout

58 IOWR# Inout

59 IOCS# Inout

60 DVSS Ground Ground pin for internal digital circuitry

61 UP1_2 Inout

62 UP1_3 Inout

63 UP1_4 Inout

64 UP1_5 Inout

65 UP1_6 Inout

66 DVDD3 Power 3.3V power pin for internal digital circuitry

Microcontroller address 7 / IO

2~16MA, SR

PU

Flash address 16

2~16MA, SR

Flash address 17

2~16MA, SR

Flash address 18 / IO

2~16MA, SR

SMT

Flash address 19 / IO

2~16MA, SR

SMT

Flash address 20 / IO

2~16MA, SR

SMT

2~16MA, SR

PU, SMT

2~16MA, SR

SMT

2~16MA, SR

SMT

2~16MA, SR

PU, SMT

4MA, SR

PU, SMT

4MA, SR

PU, SMT

4MA, SR

PU, SMT

4MA, SR

PU, SMT

4MA, SR

PU, SMT

OR Videoin Data PortB 0

Microcontroller address latch enable

Flash output enable, active low / IO

Flash write enable, active low / IO

Flash chip select, active low / IO

Microcontroller port 1-2

Microcontroller port 1-3

Microcontroller port 1-4

Microcontroller port 1-5

Microcontroller port 1-6

MT1379

23

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

67 UP1_7 Inout

68 UP3_0 Inout

69 UP3_1 Inout

70 INT0# Inout

71 IR Input

72 DVDD2 Power 2.5V power pin for internal digital circuitry

73 UP3_4 Inout Microcontroller port 3 -4

74 UP3_5 Inout Microcontroller port 3 -5

75 UWR# Inout

76 URD# Inout

77 DVSS Ground Ground pin for internal digital circuitry

78 RD7 Inout DRAM data 7

79 RD6 Inout DRAM data 6

80 RD5 Inout DRAM data 5

81 RD4 Inout DRAM data 4

82 DVDD2 Power 2.5V power pin for internal digital circuitry

83 RD3 Inout DRAM data 3

84 RD2 Inout DRAM data 2

85 RD1 Inout DRAM data 1

86 RD0 Inout DRAM data 0

87 RWE# Output

88 CAS# Output

89 RAS# Output

90 RCS# Output

91 BA0 Output

92 DVSS Ground Ground pin for internal digital circuitry

93 RD15 Inout

Microcontroller port 1-7

4MA, SR

PU, SMT

Microcontroller port 3-0

4MA, SR

PU, SMT

Microcontroller port 3-1

4MA, SR

PU, SMT

Microcontroller interrupt 0, active low

2~16MA, SR

PU, SMT

IR control signal input

SMT

Microcontroller write s trobe, active low

2~16MA, SR

PU, SMT

Microcontroller read strobe, active low

2~16MA, SR

PU, SMT

DRAM Write enable, active low

2~16MA, SR

DRAM columnaddress strobe, active low

2~16MA, SR

DRAM row address strobe, active low

2~16MA, SR

DRAM chip select, active low

2~16MA, SR

DRAM bank address 0

2~16MA, SR

DRAM data 15

2~16MA, SR

PU/PD, SMT

MT1379

24

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

Pin Number Symbol Type Description

94 RD14 Inout

DRAM data 14

2~16MA, SR

PU/PD, SMT

95 RD13 Inout

DRAM data 13

2~16MA, SR

PU/PD, SMT

96 RD12 Inout

DRAM data 12

2~16MA, SR

PU/PD, SMT

97 DVDD3 Power 3.3V power pin for internal digital circuitry

98 RD11 Inout

DRAM data 11

2~16MA, SR

PU/PD, SMT

99 RD10 Inout

DRAM data 10

2~16MA, SR

PU/PD, SMT

100 RD9 Inout

DRAM data 9

2~16MA, SR

PU/PD, SMT

101 RD8 Inout

DRAM data 8

2~16MA, SR

PU/PD, SMT

102 DVSS Ground Ground pin for internal digital circuitry

103 CLK Output

DRAM clock

2~16MA, SR

104 CLE Output

DRAM clock enable

2~16MA, SR

105 RA11 Output

DRAM address bit 11 or audio serial data 3 (channel 7/8)

2~16MA, SR

106 RA9 Output

DRAM address 9

2~16MA, SR

107 RA8 Output

DRAM address 8

2~16MA, SR

108 DMVDD3 Power 3.3V Power pin for DRAM clock circuitry

109 DMVSS Ground Ground pin for DRAM clock circuitry

110 RA7 Output

DRAM address 7

2~16MA, SR

111 DVDD3 Power 3.3V power pin for internal digital circuitry

112 RA6 Output

DRAM address 6

2~16MA, SR

113 RA5 Output

DRAM address 5

2~16MA, SR

114 RA4 Output

DRAM address 4

2~16MA, SR

115 DVSS Ground Ground pin for internal digital circuitry

116 DQM1 Output

Mask for DRAM input/output byte 1

2~16MA, SR

25

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

117 DQM0 Output

118 BA1 Output

119 RA10 Output

120 DVDD2 Power 2.5V power pin for internal digital circuitry

121 RA0 Output

122 RA1 Output

123 RA2 Output

124 RA3 Output

125 DVSS Ground Ground pin for internal digital circuitry

126 RD31 Inout

127 RD30 Inout

128 RD29 Inout

129 RD28 Inout

130 DVDD3 Power 3.3V power pin for internal digital circuitry

131 RD27 Inout

132 RD26 Inout

133 RD25 Inout

134 RD24 Inout

135 DVSS Ground Ground pin for internal digital circuitry

136 DQM3 Output

137 DQM2 Output

Mask for DRAM input/output byte 0

2~16MA, SR

DRAM bank address 0

2~16MA, SR

DRAM address10

2~16MA, SR

DRAM address 0

2~16MA, SR

DRAM address 1

2~16MA, SR

DRAM address 2

2~16MA, SR

DRAM address 3

2~16MA, SR

DRAM data 31

2~16MA, SR

PU/PD, SMT

DRAM data 30

2~16MA, SR

PU/PD, SMT

DRAM data 29

2~16MA, SR

PU/PD, SMT

DRAM data 28

2~16MA, SR

PU/PD, SMT

DRAM data 27

2~16MA, SR

PU/PD, SMT

DRAM data 26

2~16MA, SR

PU/PD, SMT

DRAM data 25

2~16MA, SR

PU/PD, SMT

DRAM data 24

2~16MA, SR

PU/PD, SMT

Mask for DRAM input/output byte 3

2~16MA, SR

Mask for DRAM input/output byte 2

2~16MA, SR

MT1379

26

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

138 RD23 Inout

139 RD22 Inout

140 DVDD2 Power 2.5V power pin for internal digital circuitry

141 RD21 Inout

142 RD20 Inout

143 RD19 Inout

144 RD18 Inout

145 DVSS Ground Ground pin for internal digital circuitry

146 RD17 Inout

147 RD16 Inout

148 ABCK Output

149 ALRCK Inout

150 DVDD3 Power 3.3V power pin for internal digital circuitry

151 ACLK Inout

152 MC_DATA Input Microphone serial input

153 SPDIF Output

154 ASDATA0 Inout

155 ASDATA1 Inout

156 ASDATA2 Inout

DRAM data 23 /

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

2~16MA, SR

PU/PD, SMT

4MA

4MA,

PD, SMT

4MA

2~16MA,

SR : ON/OFF

4MA

PD SMT

4MA

PD SMT

4MA

PD SMT

Videoin Data PortA 7

DRAM data 22 /

Videoin Data PortA 6

DRAM data 21 /

Videoin Data PortA 5

DRAM data 20 /

Videoin Data PortA 4

DRAM data 19 /

Videoin Data PortA 3

DRAM data 18 /

Videoin Data PortA 2

DRAM data 17 /

Videoin Data PortA 1

DRAM data 16 /

Videoin Data PortA 0

Audio bit clock

(1) Audio left/right channel clock

(2) Trap value in power-on reset :

1 : use external 373 0: use internal 373

Audio DAC master clock (384/256 audio sample frequency)

SPDIF output

(1) Audio serial data 0 (left/right channel)

(2) Trap value in power-on reset :

1 : manufactory test mode 0 : normal operation

(1) Audio serial data 1 (surround left/surround right channel)

(2) Trap value in power-on reset :

1 : manufactory test mode 0 : normal operation

(1) Audio serial data 2 (center/left channel)

(2) Trap value in power-on reset :

1 : manufactory test mode 0 : normal operation

MT1379

Analog Y output

27

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

157 ASDATA3 Inout

158 ASDATA4 Inout

159 DACVDDC Power 3.3V power pin for VIDEO DAC circuitry

160 VREF Analog input Bandgap reference voltage

161 FS Analog output Full scale adjustment

162 YUV0/CIN Output

163 DACVSSC Ground Ground pin for VIDEO DAC circuitry

164 YUV1/C Output

165 DACVDDB Power 3.3V power pin for VIDEO DAC circuitry

166 YUV2/Y Output

167 DACVSSB Ground Ground pin for VIDEO DAC circuitry

168 YUV3/CVBS Output

169 DACVDDA Power 3.3V power pin for VIDEO DAC circuitry

170 YUV4/G Output

171 DACVSSA Ground Ground pin for VIDEO DAC circuitry

172 YUV5/B Output

173 YUV6/R Output

174 ICE

175 BLANK# Inout

176 VSYN Inout

177 YUV7 Inout

178 DVSS Ground Ground pin for internal digital circuitry

179 HSYN Inout

180 SPMCLK Input Audio DAC master clock of SPDIF input /

(1) Audio serial data 3 (surround left/surround right channel)

4MA

PD SMT

4MA

PD SMT

4MA, SR

4MA, SR

4MA, SR

4MA, SR

4MA, SR

4MA, SR

4MA, SR

Input

PD, SMT

4MA, SR

SMT

4MA, SR

SMT

4MA, SR

SMT

4MA, SR

SMT

(2) Trap value in power-on reset :

1 : manufactory test mode 0 : normal operation

OR Videoin Data PortB 1

(1) Audio serial data 4 (center/left channel)

(2) Trap value in power-on reset :

1 : manufactory test mode 0 : normal operation

OR Videoin Data PortB 2

Video data output bit 0 /

Compensation capacitor

Video data output bit 1 /

Analog chroma output

Video data output bit 2 /

Video data output bit 3 /

Analog composite output

Video data output bit 4 /

Green or Y

Video data output bit 5 /

Blue or CB

Video data output bit 6 /

Red or CR

Microcontroller ICE mode enable

Video blank area, active low /

Videoin Field_601

Vertical sync /

Videoin Vsync_601

Video data output bit 7 /

Videoin Data PortB 3

Horizontal sync /

Videoin Hsync_601

Videoin Data PortB 4

MT1379

RF serial data output

28

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

Pin Number Symbol Type Description

181 SPDATA Input Audio data of SPDIF input /

182 DVDD2 Power 2.5V power pin for internal digital circuitry

183 SPLRCK Input Audio left/right channel clock of SPDIF input /

184 SPBCK Input Audio bit clock of SPDIF input /

185 DVDD3 Power 3.3V power pin for internal digital circuitry

186 XTALO Output Crystal output

187 XTALI Input Crystal input

188 PRST Input

189 DVSS Ground Ground pin for internal digital circuitry

190 VFO13 Output The 1st, 3rd header VFO pulse output

191 IDGATE Output Header detect signal output

192 DVDD3 Power 3.3V power pin for internal digital circuitry

193 UDGATE Output DVD_RAM recording data gate signal output

194 WOBSI Input Wobble signal input

195 SDATA Output

196 SDEN Output RF serial data latch enable

197 SLCK Output RF serial clock output

198 BDO Input Flag of defect data input status

199 ADCVSS Ground Ground pin for ADC circuitry

200 ADIN Analog Input General A/D input

201 RFSUBI Analog Input RF subtraction signal input terminal

202 TEZISLV Analog Input Tracking error zero crossing low pass input

203 TEI Analog Input Tracking error input

204 CSO Analog Input Central servo input

205 FEI Analog Input Focus error input

206 RFLEVEL Analog Input Sub beam add input or RFRP low pass input

207 RFRP_DC A Input RF ripple detect input

208 RFRP_AC Analog Input RF ripple detect input (through AC coupling)

209 HRFZC Analog Input High frequency RF ripple zero crossing

210 PWMVREF A Input A reference voltage input for PWM circuitry. A typical value of 4.0 v

211 PWM2VREF A Input A reference voltage input for PWM circuitry. A typical value of 2.0 v

212 ADCVDD3 Power 3.3V power pin for ADC circuitry

213 RFDTSLVP Analog Output Positive RF data slicer level output

214 RFDTSLVN Analog Output Negative RF data slicer level output

215 RFIN Analog Input Negative input of RF differential signal

216 RFIP Analog Input Positive input of RF differential signal

Videoin Data PortB 5

Videoin Data PortB 6

Videoin Data PortB 7

Power on reset input, active high

PD, SMT

MT1379

29

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

26 Jul, 2002

Page 1 of 2

IREF

PLLVSS

LPIOP

LPION

LPFON

LPFIP

LPFIN

LPFOP

JITFO

JITFN

PLLVDD3

FOO

TRO

TROPENPWM

PWMOUT1

PWMOUT2

DVDD2

DMO

FMO

DVSS

HIGHA0

HIGHA1

HIGHA2

HIGHA3

HIGHA4

HIGHA5

DVSS

HIGHA6

HIGHA7

AD7

AD6

AD5

AD4

DVDD3

AD3

AD2

AD1

AD0

IOA0

IOA1

DVDD2

IOA2

IOA3

IOA4

IOA5

IOA6

IOA7

A16

A17

IOA18

IOA19

IOA20

APLLVSS

RFRP_AC

RFRP_DC

FEI

RFLEVEL

RFDTSLVN

RFDTSLVP

ADCVDD3

212

213

214

59

58

575655

PWMVREF

210

211

209

626160

RFIN

RFIP

215

216

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

FG

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

HRFZC

PWM2VREF

CSO

TEI

ADIN

RFSUBI

TEZISLV

200

201

202

203

204

205

206

207

208

717069

686766

656463

BDO

ADCVSS

198

199

SLCK

197

747372

SDEN

196

SDATA

WOBSI

194

195

777675

UDGATE

193

PRST

VFO13

DVDD3

IDGATE

DVSS

XTALI

XTALO

186

187

188

189

190

191

192

MT1379

(216 pins)

84

838281

807978

DVDD3

SPBCK

184

185

878685

DVDD2

SPLRCK

182

183

89

88

SPDATA

SPMCLK

180

181

HSYN

179

929190

DVSS

178

YUV7

177

VSYN

176

959493

BLANK

175

ICE

174

YUV6/R

YUV5/B

172

173

989796

99

YUV4/G

DACVDDA

DACVSSA

169

170

171

102

101

100

DACVSSB

YUV2/Y

YUV3/CVBS

166

167

168

104

103

105

DACVDDB

DACVSSC

YUV1/C

163

164

165

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

YUV0/CIN

FS

VREF

DACVDDC

ASDATA4

ASDATA3

ASDATA2

ASDATA1

ASDATA0

SPDIF

MC_DATA

ACLK

DVDD3

ALRCK

ABCK

RD16

RD17

DVSS

RD18

RD19

RD20

RD21

DVDD2

RD22

RD23

DQM2

DQM3

DVSS

RD24

RD25

RD26

RD27

DVDD3

RD28

RD29

RD30

RD31

DVSS

RA3

RA2

RA1

RA0

DVDD2

RA10

BA1

DQM0

DQM1

DVSS

RA4

RA5

RA6

DVDD3

RA7

DMVSS

ALE

IOOE#

APLLVDD3

IOCS#

IOWR#

DVSS

UP1_2

UP1_3

UP1_4

UP1_5

UP1_6

DVDD3

UP1_7

UP3_0

UP3_1

INT0#

IR

UP3_4

DVDD2

UP3_5

UWR#

URD#

DVSS

RD7

RD6

RD5

RD4

RD3

DVDD2

RD2

RD1

RD0

RWE#

CAS#

RAS#

RCS#

BA0

DVSS

RD15

RD14

RD13

RD12

RD11

DVDD3

RD10

RD9

RD8

DVSS

CLK

CKE

RA11

RA9

RA8

DMVDD3

30

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

F

UNCTIONAL BLOCK

IR/

VFD

Servo

IO

Servo

DSP

Playback

Controller

System

Controller

DVD module

Analog

Front end

DRAM

Interface

Spindle

Controller

DPU

Processor

Audio

Channel

Decode

Debug

Port

Audio

Output

CSS/

CPPM

System

Parser

Microphone

Input

Video

Decoder

TV encoder

Video

Output

Servo Controller

The servo control is accomplished through the servo DSP (Servo Digital Signal Processor) and its accessory I/O circuits. This servo

DSP is capable of performing complex operations an d also provides a friendly interface for the system controller. By issuing type

1 and type 2 commands from the system controller, the servo DSP can accomplish various complicated servo control functions,

such as tracking, seeking and MT1336/MT1376 chip register programming. As for the servo I/O circuits, it provides interface

between the input servo signals and the Servo DSP. It has built-in ADCs to digitize the servo control signal and DACs to provide

signals for the actuator and sledge motor. It also has a serial interface to communicate with the MT1336/MT1376 chip.

Analog Front End

The analog front end contains a data slicer circuit and a data PLL circuit. The RF analog signal from MT1336/MT1376 is

quantized by the data slicer to form the EFM/EFM+ bit stream, from which the channel bit clock is extracted by the data PLL.The

EFM/EFM+bit stream and bit clock are then output to DPU for channel bit processing.

DPU

Data path unit (DPU) provides protection on data with lost synchronization patterns and demodulates EFM/EFM+ bit stream into

the channel raw data that will be corrected by the decoder. The synchronization protection makes data after the synchronization

pattern to be extracted even if the synchronization pattern is not found.

Spindle Controller

The sp indle controller is used to control disc spindle motor. It includes a varipitch CLV clock generator, a CLV/CAV controller,

and a PWM generator. The varipitch CLV clock enerator generates a reference colck for the speed of operation. The CLV/CAV

DRAMFlash

Audio DAC

SPDIF

MIC

31

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

controller changes the mode and speed of operation according to servo register setting. The PWM generator generates

pulse-width-modulated signal to drive disc spindle motor driver.

CSS/CPPM

The CSS/CPPM module provides functions necessary for decoding discs conforming to CSS/CPPM specification.

System Parser

The system parser is used to help the system controller to decode DVD/SVCD/VCD bitstream just after the channel decoder

performing error correction. Acting as a DMA master, it moves bitstream data from RSPC buffer to video, audio, or sub-picture

buffer according to system controller request. It also decrypts the scramble data of the CSS/CPPM sectors. Another function of

system parser is providing system controller/DSP a DRAM memory copy controller to enhance system controller/DSP performance.

Video Decoder

The primary function of MT1379 is to support MPEG1 and MPEG2 video decoding. The video decode engine comprises of

variable length decoder (VLD), inverse transformer (IT), motion compensator (MC), and block reconstructor (BR). The video

decode engine decodes the variable length encoded symbols in MPEG bitstream and performs inverse scan, inverse

quantization, mismatch control and inverse discrete cosine transform onto the variable length decoded data. The motion

compensator fetches prediction data from reference picture buffer according to motion vectors and motion prediciton mode for P

and B pictures. Finally, the block reconstructor combines both the results of inverse transformer and motion compensator to derive

the reconstructed image macroblock and write back to picture buffer.

The video decode engine can also support JPEG and BMP file decoding by common image compression hardware kernels.

Video Output

The Video Output unit contains Video Processor, SPU, OSD, Cursor, TV encoder units, it performs

§

§

§

§

§

§

Video Processor

SPU

Reading decoded video from DRAM buffer

Scaling the image

Gamma/Brightness/Hue/Saturation adjustment and edge enhancement

Reading and decoding SPU and OSD data from DRAM buffer

Generating hardware cursor image

Merging the video data, SPU, OSD and cursor

The Video Processor unit controls the transfer of video data stored in the DRAM to an internal or external TV encoder. It uses

FIFOs to buffer outgoing luminance and chrominance data, and performs YUV420 to YUV422 conversion and arbitrary

vertical/horizontal decimation/interpolation, from 1/4x to 256x. With this arbitrary ratio scaling capability, the Video Processor

can perform arbitrary image conversion, such as PAL to NTSC, NTSC to PAL, MPEG1 to MPEG2, Letterbox, Pan-Scan

conversion or zoom in, zoom out. It is also capible of interlace to progressive conversion.

The Video Processor unit performs the following functions:

§

Requests and receives the decoded picture data from the picture buffer in external DRAM for display

§

Resample vertical data to create 4:2:2 sample format

§

Optionally performs vertical/horizontal resampling of both luminance and chrominance data

§

Performs optional Gamma correction, luminance/chrominance adjustment, and edge enhancement

The V ideo Processor unit contains two 2-tap vertical filters for luminance and chrominance . These filters are used to

interpolate and reposition luminance and chrominance line to improve picture quality. These filters are capble of generating

up to eight, unique subline value between two consecutive scan lines. The generation of lines depends on the ratio between

the height of the source image and the target image. In applications where DRAM bandwidth are critical the filters can be

configured as simple line-repeating to reduce the DRAM bandwidth required.

The Video Processor unit integrates two separate horizontal postprocessing filter, a simple 2-tap linear horizontal filter and

an 8-tap programmable filter. These filters are provided for scaling images horizontally along the scan line. These two filters

is capable of generating up to eight, unique subpixel values between two consecutive pixels on a scan line. The generation

of pixels depends on the ratio between the width of the source image and the target image.

32

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

This is a hardware sub-picture decoder. It decodes the compressed SPU image bitstream and CHG_COLCON commands

according to SPU header information previously decoded by system controller. The SPU module also allows two SPU

objects to be displayed at the same time. SPU image is blended with main video stream.

OSD

The OSD module can operate with 2/4/16/256-color bitmap format (1/2/4/8 bits), and 16/256 color RLC format, all have 16

levels of transparency. In addition, it accepts an special WARP mode, which inserts one programmable RLC code in the

bitmap to reduce the image size stored in DRAM. It also features automatic shadow/outline generation in 2-color mode, 2

Hilight areas, 1 ChangeColor area and 1 OSDVoid area. One OSD area can occupy the full or a partial screen, or multiple

OSDs can occur in a screen at the same time, only if they don't occupy the same horizontal line. The output image is

blended with the video-SPU mixed stream.

Cursor

A hardware cursor generator is integrated in Video Output Unit. The cursor image is a 32x32 4-color bitmap image, each

colors are programmable. Cursor can be enlarged by 2 in both vertical and horizontal directions. Cursor image is multiplexed

with video-SPU-OSD mixed stream.

Audio Interface

Audio interface consists of Audio Output Interface and Microphone Input Interface.

Audio Output Interface

The MT1379 can support up to 8 channel audio outputs. The output formats can be 16, 24, or 32-bit frames. Left alignment,

right alignment, or I2S formats are all supported.

With built-in PLL, MT1379 can provide the audio clock (ACLK) for external audio DAC at 384Fs, where Fs is usually 32KHz,

44.1KHz, 48KHz, 96KHz, or 192KHz. ACLK can also be programmed to be from outside MT1379. When ACLK is input to

MT1379, the frequency could be 128*n Fs, where n is from 1 to 7.

Audio raw (encoded) data or cooked (decoded) data can be output on a single line using S/PDIF interface. The output slew

rate and driving force of this pad are programmable.

Microphone Input Interface

The MT1379 provides a microphone input interface. Two independent microphones’ data could be input to the MT1379.

There are two independent digital volume control for these two input channels. The input data formats can also be left

alignment, right alignment, or I2S formats.

MT1379

System Controller

MT1379 uses an embedded Turbo-8032 as System Controller and provide ICE interface to increase the feasibility of F/W

development. Also, MT1379 includes an build-in internal 373 to latch lower byte address from 8032 Port 0 and provide a

glue-logic free solution. MT1379 supports up to 1M X 16 bits Flash ROM to store 8032 code, H/W related data, User data, etc.

F/W upgrade can be achieved either by debug interface or by disk.

33

PRELIMINARY, SUBJECT TO CHANGE WITHOUT NOTICE MTK CONFIDENTIAL, NO DISCLOSURE

MT1379

E

LECTRICAL CHARACTERISTICS

Absolute Maximum Rating

Symbol Parameters Value Unit

VDD3 3.3V Supply voltage -0.3 to 3.6 V

VDD2 2.5V Supply voltage -0.3 to 3.0 V

VDDA Analog Supply voltage -0.3 to 3.6 V

VIN Input Voltage -0.3 to 5.5 V

V

Output Voltage -0.3 to VDD3+0.3 V

OUT

Ta Ambient Temperature 0 to 70 °C

DC Charateristics

Symbol Parameters Min Typ Max Unit

VIH Input voltage high 2.4 - 3.6 V

VIL Input voltage low - - 0.8 V

VOH Output voltage high 3.0 - VDD3 V

VOL Output voltage low - - 0.5 V

IIH High level input current 10 uA

IIL Low level input current -10 uA

PD Power dissapation 1.0 W

P

Power down mode 0.1 W

Down

16 Megabit (2 M x 8-Bit/1 M x 16-Bit)

34

8.3 Am29LV160D

CMOS 3.0 Volt-only Boot Sector Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single power supply operation

— Full voltage range: 2.7 to 3.6 volt read and write

operations for battery-powered applications

— Regulated voltage range: 3. 0 to 3.6 volt read and

write operations and for compatibility with high

performance 3.3 volt microprocessors

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies data at specified addresses

■ Manufactured on 0.23 µm process technology

— Fully compatible with 0.32 µm Am29LV160B device

■ High performance

— Access times as fast as 70 ns

■ Ultra low power consumption (typical values at

5MHz)

— 200 nA Automatic Sleep mode current

— 200 nA standby mode current

— 9 mA read current

— 20 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

thirty-one 64 Kbyte sectors (byte mode)

— One 8 Kword, two 4 Kword, one 16 Kword, and

thirty-one 32 Kword sectors (word mode)

— Supports full chip erase

— Sector Protection features:

A hardware method of locking a sector to prevent

any program or erase operations within that sector

Sectors can be locked in-system or via

programming equipment

Temporary Sector Unprotect featur e allows code

changes in previously locked sectors

■ Unlock Bypass Program Command

— Reduces overall pr ogramming time when issuing

multiple program command sequences

■ Top or bottom boot block configurations

available

■ Minimum 1,000,000 write cycle guarantee

per sector

■ 20-year data retention at 125°C

— Reliable operation for the life of the system

■ Package option

— 48-ball FBGA

— 48-pin TSOP

— 44-pin SO

■ CFI (Common Flash Interface) compliant

— Provides device-specific information to the

system, allowing host software to easily

reconfigure for different Flash devices

■ Compatibility with JEDEC standards

— Pinout and software compatible with single-

power supply Flash

— Superior inadvertent write protection

■ Data# Polling and toggle bits

— Provides a software method of detecting program

or erase operation completion

■ Ready/Busy# pin (RY/ BY#)

— Provides a hardware method of detecting

program or erase cycle completi on (not av ailable

on 44-pin SO)

■ Erase Suspend/Erase Resume

— Suspends an erase operation t o read data from,

or program data to, a sector that is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardware method to reset the devic e to reading

array data

This Data Sheet states AMD’s current technical specifications regarding the Product described herein. This Data

Sheet may be revised by subsequent versions or modificat ions due to changes in technical specif ic ations.

Publication# 22358 Rev: B Amendment/+3

Issue Date: November 10, 2000

PRODUCT SELECTOR GUIDE

35

Family Part Number Am29LV160D

Speed Option Voltage Range: V

Max access time, ns (t

Max CE# access time, ns (t

Max OE# access time, ns (t

)7090120

ACC

)7090120

CE

) 303550

OE

= 2.7–3.6 V -70 -90 -120

CC

Note: See “AC Characteristics” for full specifications.

BLOCK DIAGRAM

RY/BY#

V

CC

V

SS

RESET#

WE#

BYTE#

CE#

OE#

State

Control

Command

Register

PGM Voltage

Generator

Sector Switches

Erase Voltage

Generator

Chip Enable

Output Enable

Logic

STB

DQ0

–

DQ15 (A-1)

Input/Output

Buffers

Latch

Data

A0–A19

VCC Detector

Timer

STB

Address Latch

Y-Decoder

X-Decoder

Y-Gating

Cell Matrix

Am29LV160D

CONNECTION DIAGRAMS

36

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

A16

BYTE#

V

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

CE#

A0

SS

CC

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Standard TSOP

Reverse TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

CONNECTION DIAGRAMS

37

RESET#

A18

A17

A7

A6

A5

A4

A3

A2

A1

A0

CE#

V

SS

OE#

DQ0

DQ8

DQ1

DQ9

DQ2

DQ10

DQ3

DQ11

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

SO

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

WE#

A19

A8

A9

A10

A11

A12

A13

A14

A15

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

FBGA

Top View, Balls Facing Down

A6 B6 C6 D6 E6 F6 G6 H6

A5 B5 C5 D5 E5 F5 G5 H5

A4 B4 C4 D4 E4 F4 G4 H4

A3 B3 C3 D3 E3 F3 G3 H3

A2 B2 C2 D2 E2 F2 G2 H2

A1 B1 C1 D1 E1 F1 G1 H1

Special Handling Instructions

Special handling is required for Flash Memory products

in FBGA packages.

BYTE#A16A15A14A12A13

DQ15/A-1 V

SS

DQ13 DQ6DQ14DQ7A11A10A8A9

V

CC

DQ4DQ12DQ5A19NCRESET#WE#

DQ11 DQ3DQ10DQ2NCA18NCRY/BY#

DQ9 DQ1DQ8DQ0A5A6A17A7

CE#A0A1A2A4A3

OE# V

SS

Flash memory devices in FBGA packages may be

damaged if exposed to ultrasonic cleaning methods.

The package and/or data integrity may be compromised

if the package body is exposed to temperatures above

150°C for prolonged periods of time.

A

PIN CONFIGURATION

38

A0–A19 = 20 addresses

DQ0–DQ14 = 15 data inputs/outputs

DQ15/A-1 = DQ15 (data input/output, word mode),

A-1 (LSB address input, byte mode)

BYTE# = Selects 8-bit or 16-bit mode

CE# = Chip enable

OE# = Output enable

WE# = Write enable

RESET# = Hardware reset pin

RY/BY# = Ready/Busy output

(N/A SO 044)

= 3.0 volt-only single power supply

V

CC

(see Product Selector Guide for speed

options and voltage supply toleranc es)

LOGIC SYMBOL

20

A0–A19

CE#

OE#

WE#

RESET#

BYTE# RY/BY#

16 or 8

DQ0–DQ15

(A-1)

(N/A SO 044)

V

SS

= Device ground

NC = Pin not connected internally

HY57V641620HG

8.4 HY57V641620HG

39

4 Banks x 1M x 16Bit Synchronous DRAM

DESCRIPTION

The Hyundai HY57V641620HG is a 67,108,864-bit CMOS Synchronous DRAM, ideally suited for the main memory applications which

require large memory density and high bandwidth. HY57V641620HG is organized as 4banks of 1,048,576x16.

HY57V641620HG is offering fully synchronous operation referenced to a positive edge of the clock. All inputs and outputs are synchronized with the rising edge of the clock input. The data paths are internally pipelined to achieve very high bandwidth. All input and output

voltage levels are compatible with LVTTL.

Programmable options include the length of pipeline (Read latency of 2 or 3), the number of consecutive read or write cycles initiated

by a single control command (Burst length of 1,2,4,8 or Full page), and the burst count sequence(sequential or interleave). A burst of

read or write cycles in progress can be terminated by a burst terminate command or can be interrupted and replaced by a new burst

read or write command on any cycle. (This pipelined design is not restricted by a `2N` rule.)

FEATURES

• Single 3.3±0.3V power supply

• All device pins are compatible with LVTTL interface

• JEDEC standard 400mil 54pin TSOP-II with 0.8mm

of pin pitch

• All inputs and outputs referenced to positive edge of

system clock

• Data mask function by UDQM or LDQM

• Internal four banks operation

Note)

• Auto refresh and self refresh

• 4096 refresh cycles / 64ms

• Programmable Burst Length and Burst Type

- 1, 2, 4, 8 or Full page for Sequential Burst

- 1, 2, 4 or 8 for Interleave Burst

• Programmable CAS Latency ; 2, 3 Clocks

.

PIN CONFIGURATION

40

HY57V641620HG

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

DD

V

LDQM

/WE

/CAS

/RAS

/CS

BA0

BA1

A10/AP

A0

A1

A2

A3

DD

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54pin TSOP II

400mil x 875mil

0.8mm pin pitch

VSS

54

DQ15

53

VSSQ

52

DQ14

51

DQ13

50

VDDQ

49

DQ12

48

DQ11

47

VSSQ

46

DQ10

45

DQ9

44

VDDQ

43

DQ8

42

SS

V

41

NC

40

UDQM

39

CLK

38

CKE

37

NC

36

A11

35

A9

34

A8

33

A7

32

A6

31

A5

30

A4

29

SS

V

28

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK Clock

CKE Clock Enable

CS Chip Select Enables or disables all inputs except CLK, CKE and DQM

BA0,BA1 Bank Address

A0 ~ A11 Address

Row Address Strobe,

RAS, CAS, WE

LDQM, UDQM Data Input/Output Mask Controls output buffers in read mode and masks input data in write mode

DQ0 ~ DQ15 Data Input/Output Multiplexed data input / output pin

VDD/VSS Power Supply/Ground Power supply for internal circuits and input buffers

VDDQ/VSSQ Data Output Power/Ground Power supply for output buffers

NC No Connection No connection

Column Address Strobe,

Write Enable

The system clock input. All other inputs are registered to the SDRAM on the

rising edge of CLK

Controls internal clock signal and when deactivated, the SDRAM will be one

of the states among power down, suspend or self refresh

Selects bank to be activated during RAS activity

Selects bank to be read/written during CAS activity

Row Address : RA0 ~ RA11, Column Address : CA0 ~ CA7

Auto-precharge flag : A10

RAS, CAS and WE define the operation

Refer function truth table for details

FUNCTIONAL BLOCK DIAGRAM

I/O Buffer & Logic

41

1Mbit x 4banks x 16 I/O Synchronous DRAM

HY57V641620HG

Self refresh logic

& timer

CLK

CKE

CS

RAS

CAS

WE

UDQM

LDQM

Row active

State Machine

refresh

Column

Active

Internal Row

counter

Row

Pre

Decoders

Column

Pre

Decoders

1Mx16 Bank 3

X decoders

1Mx16 Bank 2

X decoders

X decoders

1Mx16 Bank 1

1Mx16 Bank 0

X decoders

Memory

Y decoders

Cell

Array

Sense AMP & I/O Gate

DQ0

DQ1

DQ14

DQ15

Bank Select

A0

A1

A11

BA0

BA1

Address buffers

Address

Registers

Mode Registers

Column Add

Counter

Burst

Counter

CAS Latency

Data Out Control

Pipe Line Control

A

FRONT SCHEMATIC DIAGRAM

42

9. SCHEMATIC & PCB WIRING DIAGRAM

B

C

D

E

6

R405

75R

+5V

5

23 4

+5V

+5V

+5V

+5V

Q402

8050DP2/S2

R415

R403

4.7K

R402

470R

R419

470R

R422

470R

1K

TC401

47uF/16V

C401

103

+5V

R404

62K

681

C404

C405

101

Q401

CE

B

R401

1K

Q403

CE

B

R421

1K

Q404

CE

B

R423

1K

R408 R409

8050D

8050D

8050D

R406

0R

C402

C403

(DNS) (DNS)

LED#

LED403

AK

AK

LED402

VD401

1N4148

K401

KS6

1 2

103

103

DOCECL

DI

R413

LED401

1 3

R420

1 2

K404

K403

K402

KS5

KS4

KS3

KS2

KS1

44

KS548KS447KS346KS245KS1

KS6

49

KI1