Page 1

ZZlliinnxx XXttrreem

mee -- IIPP6677

W

Wiirreelleessss II//OO

PRODUCT MANUAL

ZXT9-IO-222R2 ZXT24-IO-222R2

Manual Documentation Number: ZXTx-IO-x-4113m

Page 2

Zlinx Xtreme I/O

Documentation Number: Zlinx Xtreme IO

This product was designed and manufactured in Ottawa, Illinois USA

Using domestic and imported parts by

International Headquarters

B&B Electronics Mfg. Co. Inc.

707 Dayton Road

Ottawa, IL 61350 USA

Phone: (815) 433-5100 General Fax: (815) 433-5105

Website: www.bb-elec.com

European Headquarters

B&B Electronics Ltd.

Westlink Commercial Park

Oranmore, Co. Galway, Ireland

Phone: (+353) 91-792444 Fax: (+353) 91-792445

Website: www.bb-europe.com

____________________________________________________________________________________________________

2010B&B Electronics Mfg Co Inc. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photography, recording, or any information storage and retrieval system without written consent. Information in this manual is subject to change

without notice, and does not represent a commitment on the part of B&B Electronics Mfg Co Inc.

B&B Electronics Mfg Co Inc. shall not be liable for incidental or consequential damages resulting from the furnishing, performance, or use of this manual.

All brand names used in this manual are the registered trademarks of their respective owners. The use of trademarks or other designations in this publication

is for reference purposes only and does not constitute an endorsement by the trademark holder.

ii Manual Documentation Number: ZXTx-IO-x-4113m

Page 3

CONTENTS

1. OVERVIEW ..................................................................................................................................................................................... 1

1.1 PRODUCT OVERVIEW .................................................................................................................................................................. 1

1.2 PREREQUISITES ........................................................................................................................................................................... 1

1.3 SAFETY INFORMATION ................................................................................................................................................................ 1

1.4 INSTALLATION INFORMATION ..................................................................................................................................................... 1

1.5 ABOUT THIS MANUAL ................................ ................................ ................................................................ ................................ . 2

1.6 ZLINX XTREME I/O PRODUCT SPECIFICATION SUMMARY........................................................................................................... 4

2. PRODUCT INTRODUCTION ................................................................ ................................................................ ....................... 5

2.1 ZLINX XTREME I/O PRODUCT MODELS ...................................................................................................................................... 5

2.2 PACKAGE CONTENTS .................................................................................................................................................................. 5

2.3 ZLINX XTREME I/O MODES OF OPERATION ................................................................................................................................ 6

2.3.1 Peer-to-Peer I/O Mode ................................................................................................................................................... 6

2.3.2 Modbus I/O Mode ................................ ................................................................................................ ............................ 7

2.3.3 Repeater Mode ................................................................................................................................................................ 7

2.4 I/O TYPES AND CHARACTERISTICS ............................................................................................................................................. 8

2.4.1 Digital / Pulse Inputs ....................................................................................................................................................... 8

2.4.2 Digital Outputs ................................................................................................................................................................. 8

2.4.3 Analog Inputs ................................................................................................................................................................... 8

2.4.4 Analog Outputs ................................................................................................................................................................ 8

2.5 USER INTERFACE COMPONENTS ................................................................ ................................ ................................................. 9

2.5.1 Radio Signal Strength Indicator (RSSI) LEDs ........................................................................................................... 10

2.5.2 Mode LEDs ..................................................................................................................................................................... 10

2.5.3 Wireless LED ................................................................................................................................................................. 10

2.5.4 Power LED ..................................................................................................................................................................... 10

2.5.5 I/O Status LEDs ............................................................................................................................................................. 10

2.5.6 Configuration Pushbutton ............................................................................................................................................. 10

2.5.7 Power & I/O Terminals.................................................................................................................................................. 11

2.5.8 USB Port ......................................................................................................................................................................... 11

3. HARDWARE INSTALLATION .................................................................................................................................................. 12

3.1 RECOMMENDED PRACTICE BEFORE INSTALLATION .................................................................................................................. 12

3.2 RF SITE CONSIDERATIONS ........................................................................................................................................................ 12

3.3 DIMENSIONAL INFORMATION ................................................................................................................................................... 13

3.4 MOUNTING OPTIONS ................................................................................................................................................................. 13

3.4.1 Without the mounting ears ........................................................................................................................................... 13

3.4.2 With Mounting ears ....................................................................................................................................................... 13

3.5 CABLING OPTIONS .................................................................................................................................................................... 14

3.5.1 Cable Glands ................................................................................................................................................................. 14

3.5.2 Conduit Installation ........................................................................................................................................................ 15

3.5.3 IP67 Membrane Cable Gland ...................................................................................................................................... 15

3.5.4 Supplied Antenna .......................................................................................................................................................... 16

2.4 GHZ SUPPLIED ANTENNA: .............................................................................................................................................................. 16

3.5.5 Optional hardware ......................................................................................................................................................... 17

3.5.5.1 High Gain Omni Antenna ................................................................................................................................................................ 17

3.5.5.2 High Gain Yagi Antenna ................................................................................................................................................................. 18

3.5.5.3 Antenna Cables& Connectors .......................................................................................................................................................... 19

3.5.5.4 Lightning Arrestors .......................................................................................................................................................................... 21

3.5.5.5 IP67 Power Supply .......................................................................................................................................................................... 21

4. ELECTRICAL INSTALLATION ................................................................................................................................................ 22

4.1 POWER WIRING ........................................................................................................................................................................ 22

4.2 I/O WIRING ............................................................................................................................................................................... 23

4.2.1 DI Wiring ......................................................................................................................................................................... 23

4.2.2 DO (Relay) Wiring ......................................................................................................................................................... 24

4.2.3 AI Wiring ......................................................................................................................................................................... 24

Manual Documentation Number: ZXTx-IO-x-4113m iii

Page 4

4.2.4 AO Wiring ....................................................................................................................................................................... 24

5. SOFTWARE INSTALLATION ................................................................................................................................................... 25

5.1 ZLINX MANAGER SOFTWARE OVERVIEW ................................................................................................................................. 25

5.2 COMPUTER SYSTEM REQUIREMENTS ........................................................................................................................................ 25

5.3 INSTALLING ZLINX® MANAGER SOFTWARE............................................................................................................................. 25

5.4 INSTALLING USB DRIVERS ....................................................................................................................................................... 26

5.5 ESTABLISHING CONNECTION TO PC.......................................................................................................................................... 26

5.6 STARTING ZLINX I/O CONFIGURATION SOFTWARE ................................................................................................................... 27

5.7 UNIT DISCOVERY ...................................................................................................................................................................... 27

5.8 I/O CONFIGURATION OPTIONS ................................................................................................................................ .................. 29

5.8.1 Information Tab .............................................................................................................................................................. 29

5.8.2 Configuration Tab ................................ ................................................................................................ .......................... 30

5.8.3 Input/Output Tab ............................................................................................................................................................ 30

6. CONFIGURATION & OPERATION ......................................................................................................................................... 31

6.1 CONFIGURING THE I/O .............................................................................................................................................................. 31

6.1.1 Wireless Settings ................................................................ ................................................................ ........................... 31

6.1.1.1 Transmit Power ................................................................................................................................................................................ 32

6.1.1.2 Channel Number .............................................................................................................................................................................. 32

6.1.1.3 Network Identifier ............................................................................................................................................................................ 33

6.1.1.4 Repeater Mode ................................................................................................................................................................................. 33

6.1.1.5 RF Data Rate .................................................................................................................................................................................... 33

6.1.1.6 AES Encription ................................................................................................................................................................................ 34

6.1.2 Modbus Mode Settings ................................................................................................................................................. 36

6.1.3 Modbus I/O Addressing ................................................................................................................................................ 37

6.1.3.1 Modbus Function Codes .................................................................................................................................................................. 37

6.1.3.2 Modbus I/O Registers ...................................................................................................................................................................... 37

6.1.3.2.1 Digital (Relay) Outputs .............................................................................................................................................................. 37

6.1.3.2.2 Digital Inputs .............................................................................................................................................................................. 38

6.1.3.2.3 Analog Inputs ............................................................................................................................................................................. 38

6.1.3.2.4 Analog Outputs .......................................................................................................................................................................... 38

6.1.3.2.5 Modbus Frequency / Counters Inputs ......................................................................................................................................... 38

6.1.3.3 Modbus I/O Addressing ................................................................................................................................................................... 40

6.1.4 Peer-to-Peer Mode Settings ........................................................................................................................................ 40

6.1.4.1 Peer-to-Peer Master ......................................................................................................................................................................... 40

6.1.4.2 Peer-to-Peer Slave ............................................................................................................................................................................ 41

6.1.5 Input/Output Settings .................................................................................................................................................... 42

6.1.5.1 Digital Input Configuration .............................................................................................................................................................. 42

6.1.5.2 Digital (Relay) Output Configuration .............................................................................................................................................. 43

6.1.5.3 Analog Input Configuration ............................................................................................................................................................. 43

6.1.5.4 Analog Output Configuration .......................................................................................................................................................... 44

6.1.6 Exception Reporting ...................................................................................................................................................... 45

6.1.6.1 Sample Modbus Exception Packet ................................................................................................................................................... 45

6.1.6.2 Digital Exception Format ................................................................................................................................................................. 45

6.1.6.3 Analog Exception Format ................................................................................................................................................................ 45

6.1.7 Calibration ...................................................................................................................................................................... 46

6.1.8 Zlinx I/O Monitor ............................................................................................................................................................ 47

6.1.9 Saving the Configuration .............................................................................................................................................. 48

6.2 UPDATING ZLINX I/O FIRMWARE ............................................................................................................................................. 48

6.3 DIAGNOSTICS AND TESTING ..................................................................................................................................................... 50

6.3.1 Testing Modbus Mode Operation ................................................................................................................................ 50

6.3.2 Testing Peer-to-Peer Mode Operation ....................................................................................................................... 50

7. TROUBLESHOOTING ................................................................................................................................................................ 51

7.1 TESTING DIGITAL AND ANALOG I/O ......................................................................................................................................... 51

7.1.1 Testing DI ....................................................................................................................................................................... 52

7.1.2 Testing DO (Relay O/P)................................................................................................................................................ 52

7.1.3 Testing AI in “Voltage” Mode ....................................................................................................................................... 52

7.1.4 Testing AO in “Voltage” Mode ..................................................................................................................................... 53

APPENDIX A: DEFAULT CONFIGURATION SETTINGS .......................................................................................................... 54

iv Manual Documentation Number: ZXTx-IO-x-4113m

Page 5

APPENDIX B: PRODUCT SPECIFICATIONS ............................................................................................................................... 55

APPENDIX C: EXPECTED LATENCY............................................................................................................................................ 57

APPENDIX D: MODBUS I/O ASSIGNMENTS ................................................................................................................................ 58

APPENDIX E: ZLINX XTREME I/O MODELS AND FEATURES .............................................................................................. 59

APPENDIX F: CONVERT VOLTAGE/CURRENT TO DAC ........................................................................................................ 60

APPENDIX G: RADIO FREQUENCY BASICS ............................................................................................................................... 62

What is dBm? ................................................................................................................................................................................. 62

Lower Frequencies - Better Propagation ................................................................................................................................... 62

Range Performance ...................................................................................................................................................................... 62

RF Noise ......................................................................................................................................................................................... 62

Fade Margin ................................................................................................................................................................................... 63

Remember Your Math .................................................................................................................................................................. 63

RF Attenuation and Line of Sight ................................................................................................................................................ 63

Path Loss Rules of Thumb ................................................................................................................................................................................ 64

Antennas ............................................................................................................................................................................................................ 64

Cable Loss ......................................................................................................................................................................................................... 64

APPENDIX H: TRANSMIT POWER - DBM TO MW CONVERSION ........................................................................................ 66

GLOSSARY ........................................................................................................................................................................................... 67

INDEX .................................................................................................................................................................................................... 69

Manual Documentation Number: ZXTx-IO-x-4113m v

Page 6

Page 7

11..

OOvveerrvviieew

w

Overview

Thank you for purchasing a Zlinx Xtreme I/O product! This product has been manufactured to the highest standards of

quality and performance to ensure your complete satisfaction.

1.1 Product Overview

Zlinx Xtreme I/O is an, outdoor rated industrial grade wireless product. Its IP67 rating along with wide temperature ratings

make it suitable for monitoring and controlling remote analog and discrete devices without the need for a separate enclosure

resulting in costs and space savings.

1.2 Prerequisites

This manual assumes that the user has basic electronics knowledge and basic understanding of wireless communications.

Users are strongly encouraged to read and understand the manual to its entirety. Setting up the wireless device without proper

knowledge and understanding could result in equipment damage and bodily injury.

1.3 Safety Information

WARNING

Exposure to RF energy is an important safety consideration. The FCC has adopted a safety standard for human exposure to

radio frequency electromagnetic energy emitted by FCC regulated equipment as a result of its actions in Docket 93-62 and

OET Bulleting 65 Edition 97-01.

DO NOT:

Operate unless all RF connectors are secure and any open connectors are properly terminated.

Operate the equipment near electrical blasting caps or in an explosive atmosphere.

All equipment must be properly grounded for safe operations. All equipment should be serviced only by a qualified technician.

1.4 Installation Information

Electrical Ratings

INPUT:

ZXTx-IO-222R2, 10.0 - 30.0 VDC Class 2 input only

AMBIENT TEMPERATURE: 74°C maximum surrounding air ambient

WIRING TERMINALS:

Copper wire only

One conductor per terminal

Wire range: 10-28 AWG

Tightening Torque: 0.5 to 0.6 Nm.

Temperature rating of field wiring – 105 °C minimum (sized for 60°C ampacity).

Please see the Quick Start Guide for UL Class 1 Division 2 installation instructions.

Manual Documentation Number: ZXTx-IO-x-4113m 1

Page 8

Overview

1.5 About this manual

This manual has been created to assist you in installing, configuring, and using your Zlinx Xtreme I/O modules. Please read it

carefully and follow the instructions to achieve best results.

The manual is divided into the following major sections:

Table of Contents

The table of contents is hypertext linked in the electronic documentation. This allows rapid navigation to each chapter.

Overview

Overview section gives a general information on product standards compliance, prerequisites and safety information.

Product Introduction

This section covers the Zlinx Xtreme I/O models, package contents, modes of operation, IO types and characteristics and User

Interface components main features of the Zlinx Xtreme I/O products.

Hardware Installation

This section provides necessary information for mechanical installation of the Zlinx Xtreme I/O modules. Panel/machine mount

and conduit mount options are covered. Range estimates are shown for various terrains under different antenna options.

Installation instructions are included for both standard antenna and high gain antenna and cable options.

Electrical Installation

This section guides you through the wiring and termination for power supply as well as analog and digital I/Os.

Software Installation

This section guides you through the software and USB driver installation process. The Software Configuration screens are

explained in detail.

Startup & Configuration

In this section, both easy setup (through push button) and advanced setup using software are explained. Information about

setting the Zlinx Xtreme I/O module in Peer-to-Peer (Wire replacement) and Modbus mode are explained. Setting up I/Os,

calibration, exception reporting and configuring alarms is detailed.

Use Cases

This section provides setup & configuration instructions for setting up the product in Peer-to-Peer mode, and in Modbus mode

when configured with a Radio Modem.

Testing & Troubleshooting

Bench testing of the Zlinx Xtreme modules is explained in Peer-to-Peer and Modbus modes. The Built-in-Self-Diagnostics

section explains self diagnosis report by the module using supplied software.

Appendices

Appendixes include all essential reference information for Zlinx Xtreme I/O modules. Information found here includes a

comprehensive references and useful tables of product properties.

Product Technical Specification

This section contains detailed technical specifications about the Zlinx Xtreme I/O modules.

2 Manual Documentation Number: ZXTx-IO-x-4113m

Page 9

Overview

Default Configuration Settings

All parameter default settings are listed.

Dimensional Drawings

The hardware dimensional drawings are shown.

Modbus I/O Register Mapping

This section explains the Modbus register mappings when I/O modules are communicating to a Modbus master

(PLC/SCADA/etc.) through a radio modem.

Convert Voltage / Current to DAC

Analog to Digital conversation for voltage and current I/Os are explained.

RF Basics

This section offers a good description of Proprietary Radio Frequency communication.

Zlinx Xtreme to Zlinx Gen II Compatibility

This section shows the compatibility of both indoor and outdoor versions of I/O modules and radio modems

Glossary

Glossary covers main terms which are relevant to the understanding of the Zlinx Xtreme I/O concept.

Index

Index includes major terms and page numbers where referenced in the manual.

Manual Documentation Number: ZXTx-IO-x-4113m 3

Page 10

Overview

1.6 Zlinx Xtreme I/O

Product Specification Summary

Need to get an analog or a digital signal across a highway or river? Or just to the other end of your big warehouse? Zlinx

Xtreme I/O can do the job faster, easier, and less expensively than stringing cable. Easy plug-and-play set-up saves

installation and maintenance time.

Zlinx Xtreme I/Os are built to handle Xtreme hot and cold outdoor weather conditions.

IP67, Outdoor rated

Ranges to 40 miles.

Frequency ranges: ISM band, 902 to 928 MHz; 2.4 to 2.5 GHz.

Modulation: FSK – Frequency Shift Keying.

DSSS (2.4 GHz) and FHSS (900 MHz) Technology.

Signal strength indicator aids troubleshooting.

3 dBi for 900 MHz; 2.1 dBi for 2.4 GHz RPSMA male dipole.

Wide temperature range -40Cº to 74 Cº.

Versatile power: 10 to 30 VDC.

Software for Windows XP (Home or Professional SP3); Windows 2000 SP4; Vista 32 bit; Windows 7.

I/O Status Monitoring.

CE, CSA approvals.

Compatibility with Zlinx Gen II indoor models

AES Encryption – 128 Bit on SR models, 256 Bit on LR models

Software Selectable Transmitter Power

Software Selectable Over-the-air Data Rate on LR models

Exception Reporting option.

Analog I/O Calibration option.

Failsafe option for analog and digital outputs.

Communication Failure Alarm option.

Analog Inputs - True 16-Bit with 0-20mA, 4-20mA, 0-5V, 0-10V independent selections

Digital Inputs – PNP or NPN independent selections

Relay Driven Digital Outputs.

4 Manual Documentation Number: ZXTx-IO-x-4113m

Page 11

Product Introduction

22..

PPrroodduucctt IInnttrroodduuccttiioon

n

2.1 Zlinx Xtreme I/O

Product Models

Zlinx Xtreme I/O modules provide easy-to-use, cost-effective Peer-to-Peer (wire replacement) or Modbus connectivity

solutions through license free wireless spectrum.

Figure 2-1 Zlinx Xtreme I/O Modules

.

Following I/O models are available:

1) ZXT24-IO-222R2 2.4 GHz, Short range, IP67 I/O module (2 Analog In, 2 Analog Out, 2 Digital In, 2 Relay Out)

2) ZXT9-IO-222R2 900 MHz, Long range, IP67 I/O module (2 Analog In, 2 Analog Out, 2 Digital In, 2 Relay Out)

2.2 Package Contents

Zlinx Xtreme IO Modules are shipped with the following items included:

Zlinx Xtreme I/O module.

Standard antenna.

Optional mounting ears

Mounting screws

o M4-0.7 25mm SS Phillips Pan Hd Machine Screws – qty. 4

o M4-0.7 x 25mm SS Hex Head Cap screws – qty. 4

o M4-0.7 DIN 985 A4 S/S Nylon Insert Lock Nuts – qty. 4

A printed version of the Modbus Mode Zlinx I/O Quick Start Guide.

A printed version of the Peer-to-Peer Mode Zlinx I/O Quick Start Guide.

Manual Documentation Number: ZXTx-IO-x-4113m 5

Page 12

Product Introduction

Product CD (consisting of Zlinx Xtreme I/O documentation and Zlinx Manager configuration software)

o Zlinx I/O Manager Configuration Software.

o Zlinx I/O Firmware Updater.

o USB Driver for Xtreme Module

o Zlinx Xtreme I/O manual in PDF format.

o Zlinx Xtreme Radio Modem manual in PDF format.

o The Modbus Mode Zlinx I/O Quick Start Guide in PDF format.

o The Peer-to-Peer Mode Zlinx I/O Quick Start Guide in PDF format.

Note: A separate USB cable (not part of the contents) is necessary for programming the I/O module.

NOTE: the Cable Glands cannot be used for Class 1 Division 2 applications. Please see the

Quick Start Guide for additional information about UL Class 1 Division 2 installation

instructions.

2.3 Zlinx Xtreme I/O Modes

of Operation

Zlinx Xtreme I/O systems can operate in Peer-to-Peer or Modbus Slave RTU modes. 900 MHz I/O Modules can be configured

as repeaters to extend the radio coverage distance.

2.3.1 Peer-to-Peer I/O Mode

Peer-to-Peer configuration of IO modules is used in wire replacement applications for analog/digital IOs where cabling is not

possible or it is very expensive. Typical examples include remote monitoring and control applications in clean rooms, buildings

across parking lots or highways, remote water or fuel tank level monitoring, remote pump station control, etc.

In Peer-to-Peer mode, two Zlinx I/O modules of same type can be configured to provide wire replacement functionality. Input

count of one module must match the output count of the other module for both digital and analog types. For example, a pair of

2 analog input, 2 analog output, 2 digital input and 2 digital output I/O modules or a pair of 4 digital input and 4 digital output

modules can be configured in peer-to-peer mode. A pair of the following I/O modules is suitable for Peer-to-Peer configuration:

- ZXT9-IO-222R2

- ZXT24-IO-222R2

In this mode one Module is configured as a Master and the other as a Slave. It does not matter which end of the link is the

Master and which is the Slave. Analog and Digital Input signals connected to one module are mapped to the corresponding

analog and digital outputs on the other module and vice versa. Peer-to-Peer mode configuration can be established between

outdoor rated Zlinx Xtreme IOs and indoor rated Zlinx Gem II IOs.

Note: However, -MR versions of indoor rated Zlinx Gen II I/O modules are not compatible with Zlinx Xtreme modules.

Figure 1-2 Peer-to-Peer Mode

6 Manual Documentation Number: ZXTx-IO-x-4113m

Page 13

Product Introduction

NOTE: Placing a repeater in a system will introduce an additional delay of 4ms. Each

repeater introduced in a system will cut the data bandwidth to half.

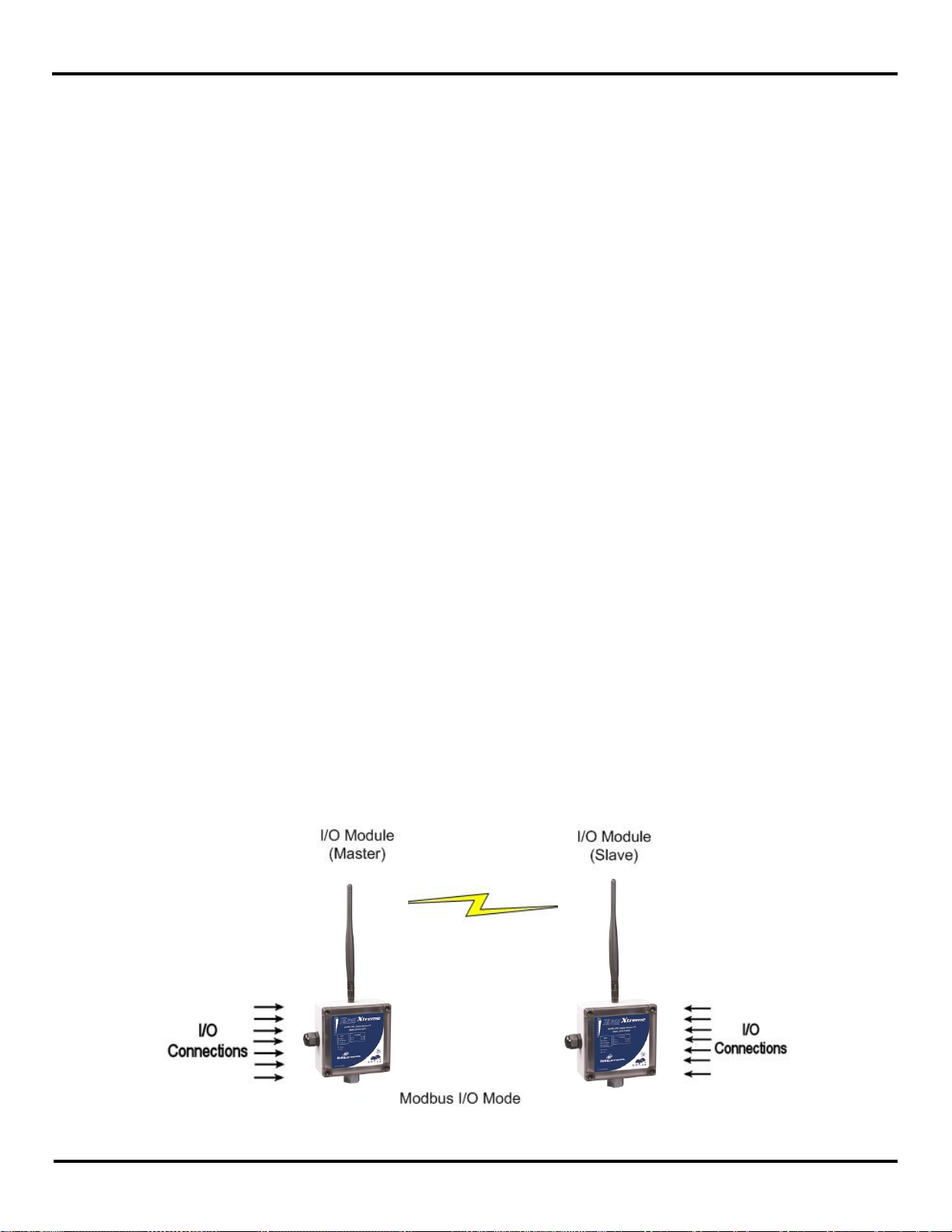

2.3.2 Modbus I/O Mode

In Modbus mode, the Zlinx Xtreme I/O modules shall be configured as Modbus Slaves and can be controlled and monitored by

a Modbus RTU Master (such as a PLC, SCADA, HMI, etc). A serial radio modem acts as a data pipe & has to be connected to

the Modbus master through its serial port. Up to 247 wireless I/O modules can be remotely monitored and controlled by the

Modbus master. The I/O signals appear in the Modbus register map resident in the I/O module memory that can be accessed

by the master through the radio modem. Refer to Appendix – D for information about the Modbus register mapping.

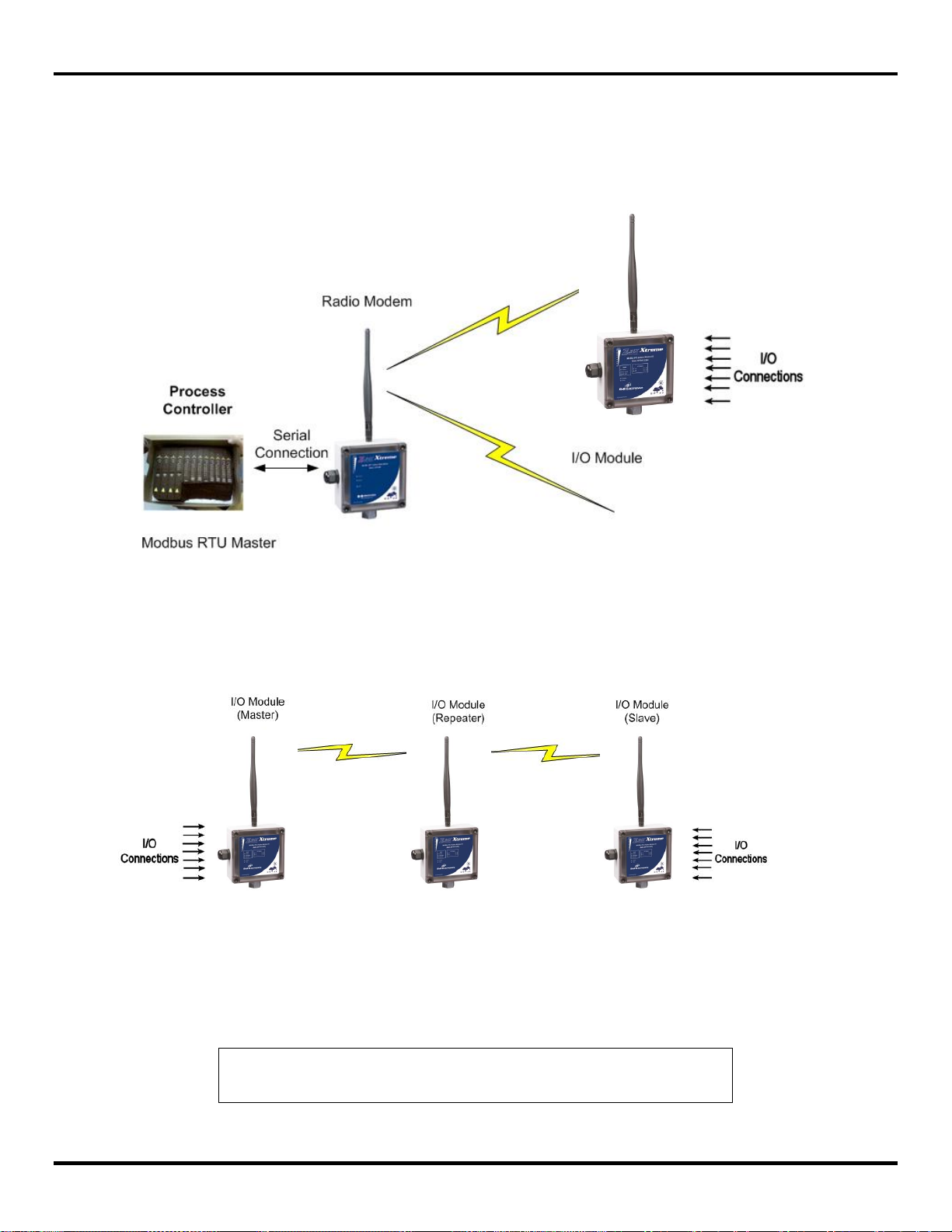

Figure 2-2 Modbus I/O Mode

In Modbus I/O mode, up to 247 Zlinx I/O modules can be connected to a Modbus RTU master through a Radio Modem.

Modules of both Zlinx Xtreme (outdoor) and Zlinx Gen II (indoor) types can be mixed and matched as long as their frequency

rating is the same.

2.3.3 Repeater Mode

Figure 2-3 I/O Module as a Repeater

When a Zlinx Xtreme I/O Module is configured as a repeater, it relays data from a Modbus modem or an I/O Module and

extends the range of communication. In a Peer-to-Peer System, a repeater unit can be placed between the Master and the

Slave IO modules.

Only 900 MHz radios support the repeater functionality.

Manual Documentation Number: ZXTx-IO-x-4113m 7

Page 14

Product Introduction

2.4 I/O Types and Characteristics

The analog inputs, analog outputs and digital inputs are not isolated. They share the same common within the module. Digital

outputs are isolated through relay contacts.

2.4.1 Digital / Pulse Inputs

Digital Inputs can detect the status of discrete control devices, contact closures, transistor switches or on/off DC voltage

signals (low or high logic levels). Voltages below 1 VDC are interpreted as a low state. Voltages above 1 VDC up to 48 VDC

are interpreted as a high state.

Each digital Input is selectable between NPN (sinking) and PNP (sourcing) types. The digital Input terminals can accept

voltages in the range 0-48VDC.

The digital inputs can also be used as a pulse/frequency input in Modbus mode only. The maximum pulse frequency is 20

KHz.

2.4.2 Digital Outputs

Digital Outputs send on/off signals (low or high logic levels) to drive external devices such as indicators, relay coils or the

inputs of other equipment such as PLC’s, SCADA, etc. Digital Outputs in Zlinx Xtreme I/O modules have a Form C Relay

(common, normally open and normally closed) rated at 4A and 250VAC.

2.4.3 Analog Inputs

Each analog input can be individually configured as voltage or current types. Following selections are available:

a) 0-10 Vdc

b) 0-5 Vdc

c) 0-20 mA

d) 4-20 mA

The data is automatically scaled as a 16 bit register (0-65,535) for full scale in the Modbus register. To see how to calculate

corresponding values in Modbus, refer to section Appendix F.

2.4.4 Analog Outputs

Each analog output can be individually configured as voltage or current types. Following selections are available:

a) 0-10 Vdc

b) 0-5 Vdc

c) 0-20 mA

d) 4-20 mA

The data is automatically scaled as a 12 bit register (0-4,096) for full scale in the Modbus register. To see how to calculate

corresponding values in Modbus, refer to section Appendix F.

8 Manual Documentation Number: ZXTx-IO-x-4113m

Page 15

Product Introduction

RSSI LEDs

Mode LEDs

I/O Status

LEDs

Wireless &

Power LEDs

USB Port

Configuration

Pushbutton

Power & I/O

Terminals

2.5 User Interface Components

Figure 2-4 External View of Zlinx Xtreme I/O module

Figure 2-6 Internal View of Zlinx Xtreme I/O module

Manual Documentation Number: ZXTx-IO-x-4113m 9

The external and internal view of the I/O modules is shown as above.

Page 16

Product Introduction

LEDs Number

turned ON

Signal Strength

0

No signal

1-3

Weak

4-6

OK

7-8

Strong

2.5.1 Radio Signal Strength Indicator (RSSI) LEDs

The Signal Strength LEDs provide an indication of the signal strength of the received radio signal. 8 Green LEDs in a bar

graph format show the signal strength from Weak to Strong. The table below explains the RSSI LEDs:

2.5.2 Mode LEDs

The I/O module operates in one of the following 3 modes and its status is shown by the corresponding green LEDs:

- Modbus

- Peer-to-Peer Master

- Peer-to-Peer Slave

2.5.3 Wireless LED

This LED will flash whenever wireless data is transmitted or received.

Figure 2-7 RSSI LED Status Table

2.5.4 Power LED

1) A green status LED indicates that an adequate dc power is available to the module.

2) This LED will flash on Comm. Fail.

2.5.5 I/O Status LEDs

Green status LEDs show the status of the digital inputs and relay outputs in the I/O module

2.5.6 Configuration Pushbutton

The Configuration Button allows the user to select one of the following I/O operation modes without the need for a PC:

- Modbus

- Peer-to-Peer Master

- Peer-to-Peer Slave.

Follow the steps below to change the I/O module configuration mode using the Configuration Push Button.

1) Press and HOLD the PB until all MODE LED's flash.

2) A single LED will begin to flash, which depends on the mode the device is currently in. An example would be the P2P

Master LED will flash, if the device was in P2P Master mode.

3) Pressing the Config PB will increment through the other modes; P2P Slave, Modbus, etc.

4) If the Push Button is not pressed for 4 sec, the device will exit and select the mode that was indicated by the flashing LED.

10 Manual Documentation Number: ZXTx-IO-x-4113m

Page 17

Product Introduction

ZXT24-IO-222R2

ZXT9-IO-222R2

Peer-to-Peer master mode

Radio Network:

0x0c

0x00

Radio ID Number:

0x11

0x11

Radio Output Power:

(4) 63mw

(4) 1w

Number of Retries:

10

10

AES Security:

Disabled

Disabled

P2P Address:

1

1

OTA Baud:

Fixed*

115200

P2P Polling Rate:

0 sec

0 sec

Peer-to-Peer slave mode

Radio Network:

0x0c

0x00

Radio ID Number:

0x11

0x11

Radio Output Power:

(4) 63mw

(4) 1w

Number of Retries:

10

10

AES Security:

Disabled

Disabled

P2P Address:

1

1

OTA Baud:

Fixed*

115200

P2P Slave Timeout:

30 sec

30 sec

Modbus mode

Radio Network:

0x0c

0x00

Radio ID Number:

0x11

0x11

Radio Output Power:

(4) 63mw

(4) 1w

Number of Retries:

10

10

AES Security:

Disabled

Disabled

Modbus Address:

1 1 OTA Baud:

Fixed*

115200

Modbus Slave Timeout:

30 sec

30 sec

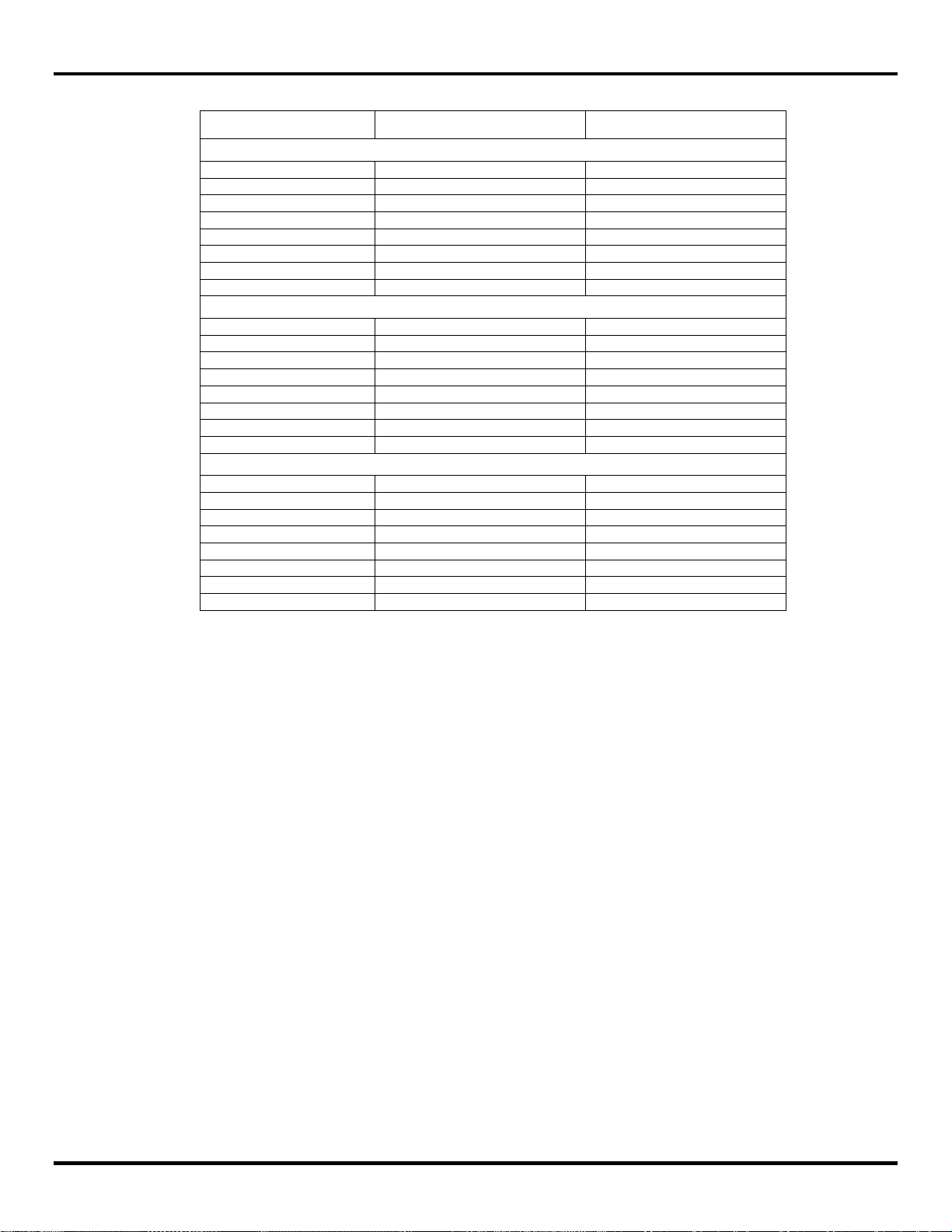

The following default settings established when the mode is changed:

* - “Fixed” for OTA Baud means that this parameter can’t be changed and is equal to 250 Kbps.

Refer to section 6 for parameter descriptions.

2.5.7 Power & I/O Terminals

Screw terminals are provided for Power & I/O interface connections as shown. Refer to Chapter 4 for wiring information.

2.5.8 USB Port

The USB port is used to configure the I/O module and for firmware updates. The I/O module must be connected and powered for the

Zlinx Manager Software to detect the IO module. Refer to section 4 for software installation and section 5 for programming the unit.

Manual Documentation Number: ZXTx-IO-x-4113m 11

Page 18

Electrical Installation

33..

HHaarrddwwaarree IInnssttaallllaattiioon

n

3.1 Recommended Practice

Before Installation

Before installing a new system, it is recommended to bench test the complete system and make sure the modules function

satisfactorily. Refer to appropriate sections for your setup in Chapter 8 for reference.

In actual installations, poor communications can be caused by:

Incorrectly installed antennas.

Radio interference.

Obstructions in the radio path.

Bad weather

Signal out of range.

If the radio path is a problem, higher gain antennas would help improve the range.

3.2 RF Site Considerations

When installing any radio equipment it is important to give careful consideration to the installation location and the surrounding

area. Radio transmission and reception is affected by absorption, reflection and refraction of the radio signals. These factors

are determined by the distance between the transmitting and receiving antennas, the type, position and amount of

obstructions, antenna heights, frequency band and RF power used, and other factors.

There are several ways to optimize the RF environment to ensure satisfactory performance. A partial list of these follows:

Select the Zlinx Xtreme I/O radio option that provides sufficient power for your application. Lower frequencies travel

farther and are less affected by absorption in materials. Higher power levels generally provide greater penetration

through objects.

Select installation locations that come as close as possible to providing Line Of Sight access between the antennas.

Avoid installation locations where metal objects may block, reflect, refract or cause multipathing of radio frequencies.

In some cases reflections may enhance reception but in others it can cause problems.

Select installation locations to increase antenna heights.

Consider signal loss across antenna cables and connectors. User larger cables for low signal loss.

Select equipment enclosures made of materials that minimize RF attenuation.

Avoid locations with other radio equipment that may cause interference.

In some cases alternate types of antennas (more directional) or remote antenna mounting (outside of enclosures or

at a higher elevation) may be required.

As necessary, site survey should be carried out. Sometimes small changes in location can make a significant improvement to

coverage. For RF information see Appendix G.

12 Manual Documentation Number: ZXTx-IO-x-4113m

Page 19

Hardware

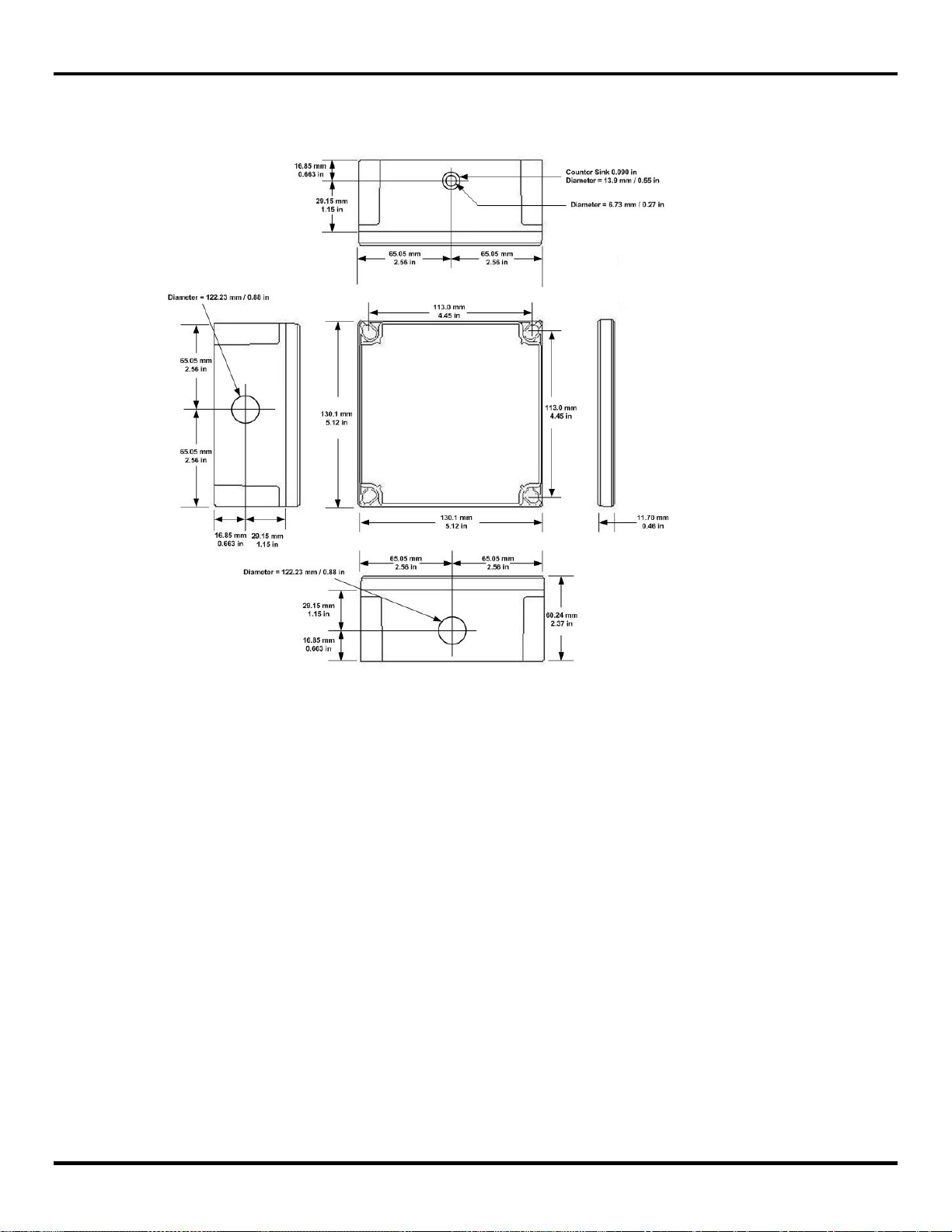

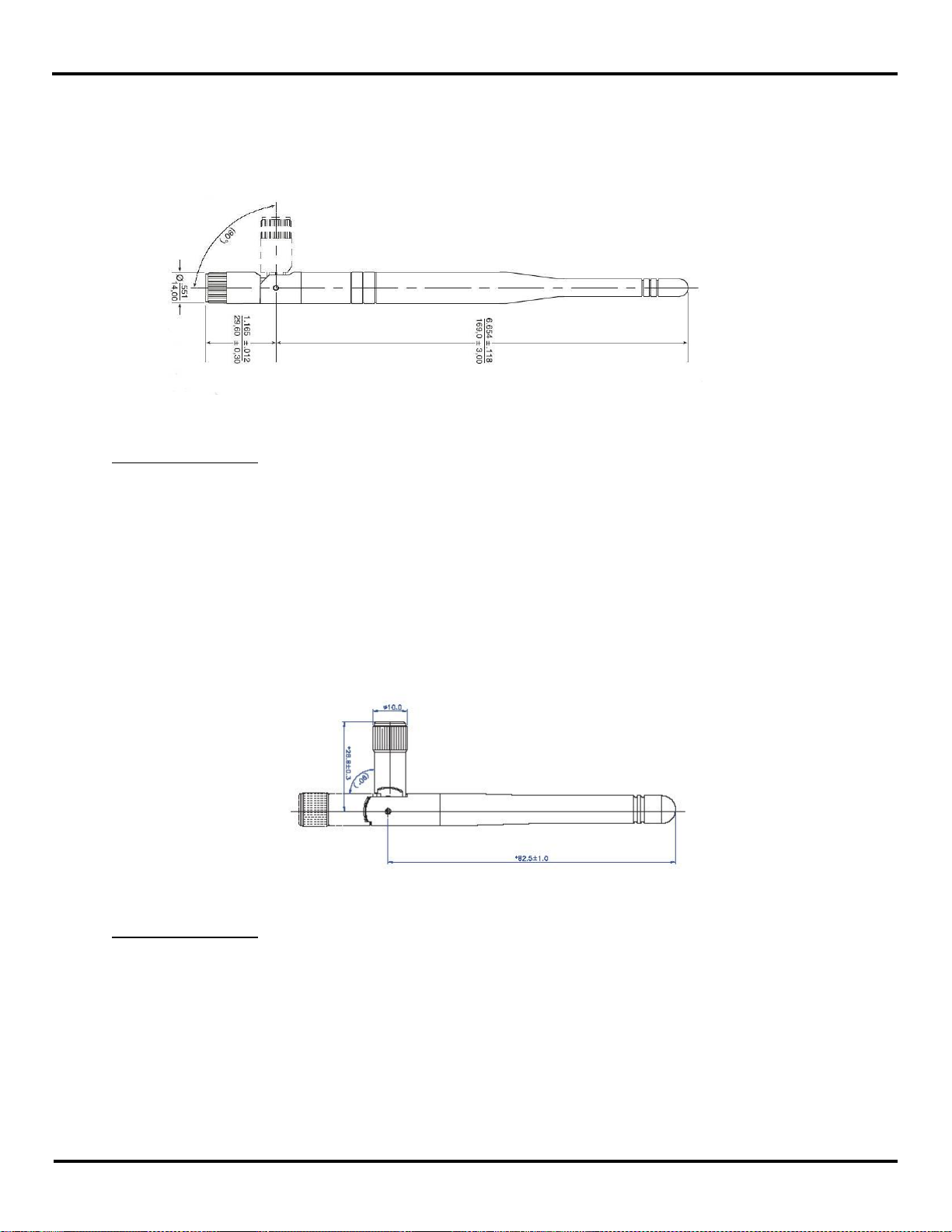

3.3 Dimensional Information

The dimensional information with mounting holes is shown below.

Figure 3-1 Dimensional Information

3.4 Mounting Options

The Zlinx Xtreme I/O module can be panel or machine mounted. The module can be mounted with or without the optional

mounting ears.

3.4.1 Without the mounting ears

The Zlinx Xtreme can be mounted on a back panel or a machine by removing the top lid. The top lid is removed by unscrewing

the 4 corner screws. The module can be mounted using the supplied screws and nuts through the corner holes. Once

secured, fasten the top cover.

3.4.2 With Mounting ears

4 optional mounting ears and screws are supplied as accessories. The ears can be attached to the Zlinx Xtreme by removing

the top cover and securing through the corner holes. The module then can be mounted on the panel by marking the position of

the holes on the back panel. Fig 3-2 shows the mounting scheme with ears.

Manual Documentation Number: ZXTx-IO-x-4113m 13

Page 20

Electrical Installation

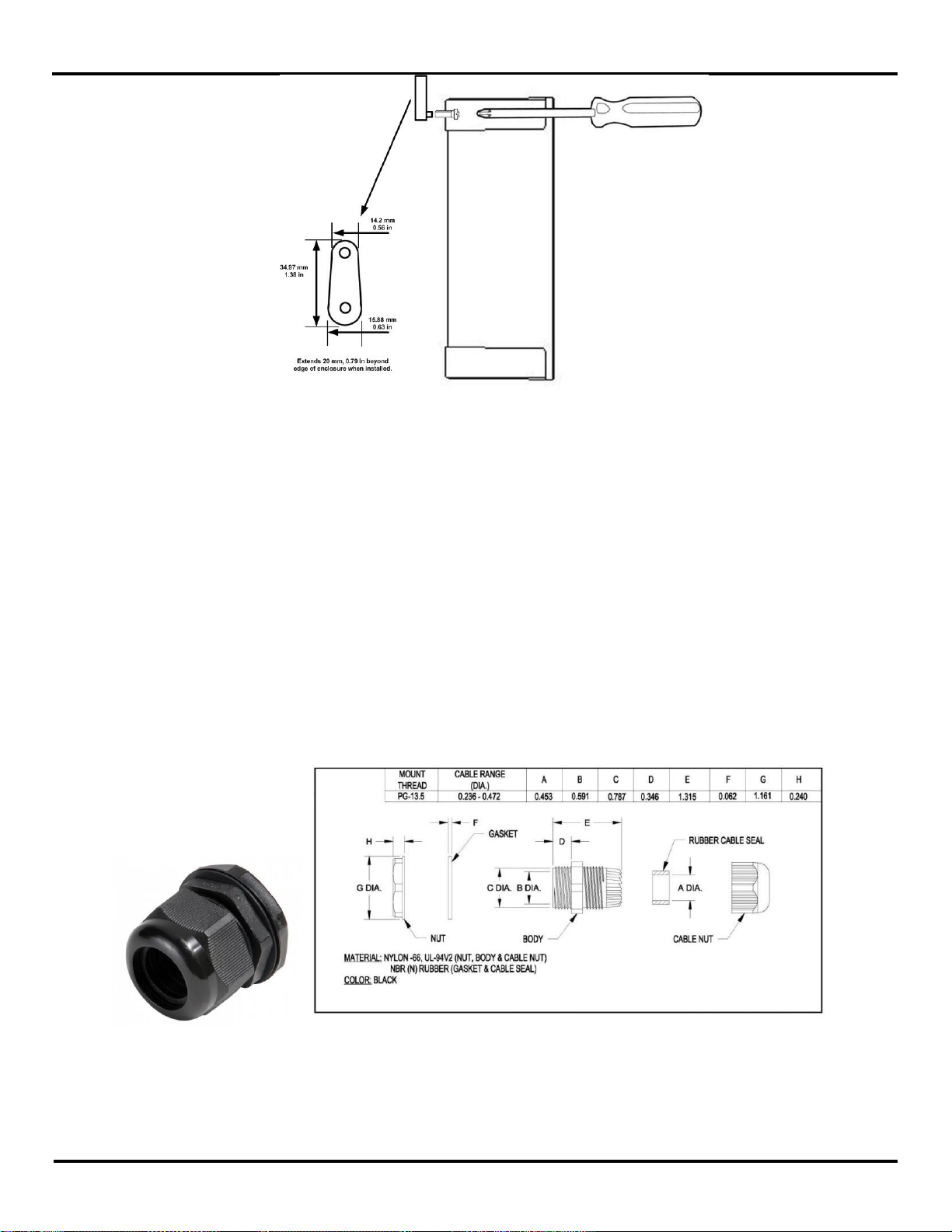

Figure 3-2 Mounting Ear dimensions

3.5 Cabling Options

The Zlinx Xtreme module has two holes of 0.875” diameter for cable installation. Cable gland or conduit mounting is possible.

A cable gland and conduit hub are included as accessories. Unused hole must be plugged by the supplied membrane gland in

order to maintain IP67 rating.

3.5.1 Cable Glands

NOTE: the Cable Glands cannot be used for Class 1 Division 2 applications. Please see the Quick Start

Guide for UL Class 1 Division 2 installation instructions.

A Cable Gland is used to maintain the water tight rating while allowing a cable to enter the enclosure. The assembly consists

of black molded nylon body, hex nut, cable nut and a rubber gasket and cable seal.

Figure 3-3 IP67 Cable Gland

14 Manual Documentation Number: ZXTx-IO-x-4113m

Page 21

Hardware

Follow the steps below to install the cable gland:

1. Insert the Non-tapered end of the Body (D) through the conduit knock-out on the I/O module enclosure.

2. Place the Gasket around the body on the outside of the enclosure.

3. Thread the Hex Nut onto the Body from the inside of the enclosure.

4. Insert the cable through the Cable gland into the enclosure. Ensure you leave enough slack in the cable to reach the

terminal blocks.

5. Place the Cable Nut onto the cable being careful to position the threaded side so that it can be attached to the Cable Body.

6. Tighten the Cable Nut. This will cause the tapered end of the Cable Body to compress, ensuring a water-tight seal.

3.5.2 Conduit Installation

Unused conduit openings: Class 1 Division 2 installation requires a UL Recognized plug (UL

Category Code QCRV2) be used when a conduit opening is not being used.

A conduit hub is supplied with the Zlinx Xtreme I/O module where conduit installation is preferred to route the cables. It is

suited to connect ½” or 3/8” conduit fittings and consists of a Body, Nut, and Gasket suitable for IP67 rating. It is used to

secure threaded half inch rigid service entrance conduit.

Figure 3-4 ½ inch Threaded Conduit Hub with dimensions

1. Insert the treaded end of the body into the conduit knock-out from the outside of the enclosure. The

rubber gasket should be on the outside of the enclosure.

2. Thread the Nut onto the conduit body from inside the enclosure.

3. ½ Inch, rigid, threaded conduit can be attached to the threaded hub.

3.5.3 IP67 Membrane Cable Gland

NOTE: the Cable Glands cannot be used for Class 1 Division 2 applications. Please see the Quick

Start Guide for UL Class 1 Division 2 installation instructions.

The membrane cable gland can be used to plug an unused hole in the enclosure or to route a cable.

Figure 3-5 IP67 Membrane Gland

Stuff the cable gland into the knock-out hole with the narrow end toward the inside of the I/ Module enclosure. The enclosure

wall will fit into the indentation between the inside and outside portions of the gland.

Manual Documentation Number: ZXTx-IO-x-4113m 15

Page 22

Electrical Installation

3.5.4 Supplied Antenna

900 MHz Supplied Antenna:

Your 900 MHz product comes supplied with a “rubber duck” style antenna which can be articulated up to 90 degrees. Then

antenna is a ¼ wave dipole with an Omni directional pattern and vertical polarization. It is recommended that your I/O product

be mounted with the antenna on the top, perpendicular with the horizon

Antenna Specifications:

Impedance: 50Ω

Connector: RPSMA Female

VSWR: 2.0 Max (in band)

Gain : 3.0 dBi

Polarization: Vertical

Part Number: ZXT9-ANT1

Figure 3-6 ZXT9-IO-222R2 Supplied Antenna

2.4 GHz Supplied Antenna:

Your Zlinx Xtreme 2.4 GHz product comes supplied with a “rubber duck” antenna which can be articulated up to 90 degrees.

Then antenna is a ¼ wave dipole with an Omni directional pattern and vertical polarization. It is recommended that your Zlinx

Xtreme product be mounted with the antenna on the top, perpendicular with the horizon.

Figure 3-7 ZXT24-IO-222R2 Supplied Antenna

Antenna Specifications:

Impedance: 50Ω

Connector: RPSMA Female

VSWR – 2.0 Max (in band)

Gain – 2.1 dBi

Polarization – Vertical

Replacement Part Number – ZZ24D-ANT1

16 Manual Documentation Number: ZXTx-IO-x-4113m

Page 23

Hardware

Clear Line of Sight

Required

Yagi Antenna

Yagi Antenna

Yagi

Antenna

Yagi

Antenna

Omni

Antenna

Radio Modem

I/O Module

I/O Module

3.5.5 Optional hardware

Optional high gain antennas may be necessary to extend the range of the wireless radios. Omni antennas help propagate the

radio frequency signals 360°. Yagi antennas are used for directional pointing. For point-to-point (aka peer-to-peer)

applications, 2 Yagi antennas would offer the best performance. For point-to-multi point applications, an Omni antenna at the

central location with Yagi antennas at the remote radios would offer the best performance. These high gain antennas must be

mounted at elevated locations. Line of sight is necessary for better communication. The figures below show Point-to-Point and

Point-to-Multi Point installations Using Omni and Yagi antennas.

Figure 3-8 Point-to-Point System Figure 3-9 Point-to-Multi Point ModbusSystem

Extension cables are available to connect the radios to the antennas. Lightning arrestors are highly recommended in outdoor

installations where thunderstorms and lightning are commonplace.

3.5.5.1 High Gain Omni Antenna

An Omni-directional antenna is an antenna system which radiates power uniformly in one plane with a directive pattern shape

in a perpendicular plane. This pattern is often described as "donut shaped". Omni-directional antenna can be used to link

multiple directional antennas in outdoor point-to-multipoint communication.

These Omni Directional antennas are a good choice if you need to mount your antenna on a mast to increase its elevation.

Please note that mounting brackets must also be purchased. Also note that these antennas have an N style connector. Refer

to section 3.9 to select the correct cable.

Figure 3-10 Representative Omni Antenna

Manual Documentation Number: ZXTx-IO-x-4113m 17

Page 24

Electrical Installation

FG9023 – High Gain Omni Directional (900 MHz)

Use With: ZXT9 radios (900 MHz)

Impedance: 50Ω

Connector: N Female

VSWR – 2:1 Max (in band)

Gain – 3 dBi

Polarization – Vertical

Length – 25 inches

Mounting Brackets (Sold Separately) – FM2

FG9026 – High Gain Omni Directional (900 MHz)

For Use With: ZXT9 radios (900 MHz)

Impedance: 50Ω

Connector: N Female

VSWR – 2:1 Max (in band)

Gain – 3 dBi

Polarization – Vertical

Length – 65 inches

Mounting Brackets (Sold Separately) – FM2

FG24008 – High Gain Omni Directional (2.4 GHz)

For Use With: ZXT24 radios (2.4 GHz)

Impedance: 50Ω

Connector: N Female

VSWR – 1.5:1 Max (in band)

Gain – 8 dBi

Polarization – Vertical

Length – 24.5 inches

Mounting Brackets (Sold Separately) – FM2

3.5.5.2 High Gain Yagi Antenna

A Yagi-Uda Antenna, commonly known simply as a Yagi antenna or Yagi, is a directional antenna system consisting of an

array of a dipole and additional closely coupled parasitic elements (usually a reflector and one or more directors). The dipole in

the array is driven, and another element, typically 5% longer, effectively operates as a reflector. Other parasitic elements

shorter than the dipole may be added in front of the dipole and are referred to as directors. This arrangement increases

antenna directionality and gain in the preferred direction over a single dipole.

Since Yagi Antennas are directional, they must point directly at the other antenna through a clear line of sight.

These Directional antennas are a good choice if you need to mount your antenna on a mast to increase its elevation. Note that

these antennas have an N style connector. Refer to section 3.9 to select the correct cable.

Figure 3-11 Enclosed Yagi – Model YE240015 for 2.4 GHz Models

18 Manual Documentation Number: ZXTx-IO-x-4113m

Page 25

Hardware

Figure 3-12 Representative Yagi Antenna

YS8963 – High Gain Yagi (900 MHz) - For Use With: ZXT9-RM (900 MHz)

Impedance: 50 Ω

Connector: N Female

VSWR – 1.5:1(in band)

Gain – 6 dBi

Polarization – Vertical

Length – 16.8 in

Mounting Brackets – Included

YS8966 – High Gain Yagi (900 MHz) - For Use With: ZXT9-RM (900 MHz)

Impedance: 50 Ω

Connector: N Female

VSWR – 1.5:1(in band)

Gain – 9 dBi

Polarization – Vertical

Length – 27.8 in

Mounting Brackets – Included

YS89612 – High Gain Yagi (900 MHz) - For Use With: ZXT9-RM (900 MHz)

Impedance: 50 Ω

Connector: N Female

VSWR – 1.5:1(in band)

Gain – 11 dBi

Polarization – Vertical

Length – 49 in

Mounting Brackets – Included

YE240015 – High Gain Yagi (2.4 GHz) - For Use With: ZXT24-RM (2.4 GHz)

Impedance: 50 Ω

Connector: N Female

VSWR – 1.5:1(in band)

Gain – 12.5 dBi

Polarization – Vertical

Length – 18 in

Mounting Brackets – Included

3.5.5.3 Antenna Cables& Connectors

Antenna cables and connectors must be used when extending the standard or high gain antenna for outdoor antenna

applications. Appropriate cable and connector must be chosen. It is important to know that RF signal is lost across the cables

and connectors and hence for better performance, the cable length and connectors must be kept to a minimum. Also it is

important to select a cable that matches the radio’s impedance. An impedance mismatch will cause the radio link to become

inefficient and could damage the radio. Selecting the incorrect cable could also cause significant signal loss. A rule of thumb is

for every 3 dB of loss, your system will lose one half the output power emitted from the radio.

Manual Documentation Number: ZXTx-IO-x-4113m 19

Page 26

Electrical Installation

Cable Type

900 MHz Loss Per 100 ft

2.4 GHz Loss Per 100 ft

Diameter

LMR-100

22.8 dB

38.9 dB

0.110 in

LMR-195

11.5 dB

19.0 dB

0.195 in

LMR-400

3.9 dB

6.8 dB

0.405 in

Three cable types are available, viz. LMR100, LMR195, and LMR400. LMR400 cable offers lower loss but is thicker and more

difficult to work with. LMR100 is thin and easy to work with, but has a larger loss. It is recommended that you use the shortest

possible cable run in your application.

Figure 3-13 Antenna Cable Options and Signal Loss Information

Figure 3-14 LMR400 Cable Cross Section

Figure 3-15 LMR195 Cable Cross Section

Figure 3-16 LMR100 Cable Cross Section

Along with the cable, a proper connector must be chosen. The I/O module uses an RPSMA Male (plug) connector. The

optional high gain antenna has an N type Female connector. Therefore, an antenna cable that has a RPSMA Female jack at

the module end and a N type Male connector at the antenna end the must be chosen.

If the supplied antenna needs to be extended, a cable with an RPSMA Female jack at the module end and an RPSMA Male

(plug) at the antenna end must be selected since the supplied antenna has an RPSMA female (jack).

20 Manual Documentation Number: ZXTx-IO-x-4113m

Page 27

Hardware

Antenna Cable Part Numbers

Following standard cables available for purchase. The cable part numbering format is as follows:.

TTTT-AABB-LLLL

Where,

TTTT = Cable Type (400M = LMR400, 195M = LMR195, 100M = LMR195)

AA = Connector A (NM = N-Male, SL = RPSMA (Plug)

BB = Connector B (NM = N-Male, SL = RPSMA (Plug)

LLLL = Length in inches (ex: 6 = six inches, leading zeros are not necessary)

For example, an 400M-NMSL-24 is an LMR400 cable with a N Male on one end and a RPSMA plug on the other, 24 inches in

length.

3.5.5.4 Lightning Arrestors

A lightning arrestor can prevent damage to the radio due to high energy transients during lightning strikes. The arrestors limit

surges to less than 45 volts in approximately 100 nanoseconds. A gas discharge tube changes from an open circuit to a short

circuit in the presence of energy and voltage surges giving those surges a direct path to ground, thus protecting equipment.

They are designed with a rugged housing and high quality plated brass "N" connectors. It also features a user replaceable gas

discharge tube (LA350GT) and are available in three models: the LABH350NN and the LABH2400N both allow bulkhead

mounting and connector pass-through and the LAIL350NN allows inline placement only.

3.5.5.5 IP67 Power Supply

Figure 3-17 IP67 Power Supply

An optional IP67 power supply (p/n: CLG-60-24) is available suitable for outdoor applications. The

Power Supply Specifications:

Input Voltage: 90 ~ 295 Vac

Output Voltage: 24 Vdc

Rated Power: 60 W

Env. Rating: IP67, Indoor / Outdoor

Temp rating: -30°C ~ +70°C

Manual Documentation Number: ZXTx-IO-x-4113m 21

Page 28

Electrical Installation

44..

EElleeccttrriiccaall IInnssttaallllaattiioon

n

PWR IN +

10-30 Vdc

(External Supply)

PWR IN -

V+

Com

Please see the Quick Start Guide for UL Class 1 Division 2 installation instructions.

Both power and I/O signals are connected to the terminal block provided in the I/O module. The terminal block can be

accessed by removing the top cover and are provided at the bottom. Figure 4-1 shows the layout.

Consider the following requirements for cable connections and terminations.

Wiring Terminals – Use Copper Wire Only, One Conductor per Terminal

Wire range: 10-28 AWG

Tightening Torque – 0.5 to 0.6 Nm

Temperature Rating of field installed conductors - 105°C minimum, sized for 60°C ampacity

Figure 4-1 I/O Terminal Layout

4.1 Power Wiring

The radio modem requires a dc power supply from an external source. The permissible voltage range is 10 to 30 VDC. The

typical power consumption is as follows:

ZXT24-IO-222R2:

Type: 1.7W

Max: 4.5W

ZXT9-IO-222R2:

Type: 2.1W

Max: 6.8W

An optional IP67 power supply shown in Section 3.5.5.5 may be used.

Connect the positive and negative power leads to the Power In(+) and Power In (-) terminals on the terminal block.

22 Manual Documentation Number: ZXTx-IO-x-4113m

Page 29

Electrical Installation

PWR IN +

DIx

(a) PNP (Sourcing) Input Wiring

with Internal Power Supply

DIx

(b) NPN (Sinking) Input Wiring

with Internal Power Supply

Com

+V

DIx

(c) PNP (Sourcing) Input Wiring with

External Power Supply

Com

Com

DIx

(d) NPN (Sinking) Input Wiring

with External Power Supply

Com

Com

DIx

(e) Pulse Input

Com

Figure 4-2 Power Wiring Connection

4.2 I/O Wiring

The I/O module has the following options, PNP/NPN for digital I/Os and voltage/current for analog I/Os. The follow the wiring

recommendations help the user to connect the devices to the I/O module.

4.2.1 DI Wiring

The digital inputs are software configurable for PNP (sourcing) and NPN (sinking) connections. Each Input selection can be

independent of the other I/Os. PNP is chosen as the default setting. The configuration can be changed using the Manager

Software as explained in Chapter 6. The following diagrams show typical connection wiring for both PNP and NPN

connections with internal module power supply:

Figure 4-3 Typical Digital Input Wiring for PNP and NPN connection types (with internal PS)

If an external power source is used for the digital input connections, the external power supply common should be connected

to the module power supply common. The diagrams below show the connection scheme:

Figure 4-4 Typical Digital Input Wiring for PNP and NPN connection types (with external PS)

A pulse/frequency input can be connected to the digital input as follows:

Figure 4-5 Pulse Input Connection

Manual Documentation Number: ZXTx-IO-x-4113m 23

Page 30

Electrical Installation

NO

(a) NO Connection

Com

NC

V+ /

Line

V- /

Neutral

Solenoid

(b) NC Connection

NO

Com

NC

V+ /

Line

V- /

Neutral

Light

AINx

COM

Voltage or

current Input

+

-

AOutx

COM

(a) Voltage Output

AOutx

COM

(b) Current Output

4.2.2 DO (Relay) Wiring

Common, NO (normally open) and NC (normally closed) contacts of the relays are brought to terminals for wiring. The

following diagram shows typical connection wiring for relay outputs:

Figure 4-6 Typical Digital Output Wiring for Relay Outputs

4.2.3 AI Wiring

The following diagram shows typical connection wiring for Analog Inputs:

Figure 4-7 Typical Analog Input Wiring

4.2.4 AO Wiring

The following diagram shows typical Analog Output Wiring:

24 Manual Documentation Number: ZXTx-IO-x-4113m

Figure 4-8 Typical Analog Output Wiring

Page 31

Software Installation

55..

SSooffttwwaarree IInnssttaallllaattiioon

n

NOTE: 1) Install the Zlinx Manager Software before connecting the I/O module to the PC.

2): The software is also available for download from http://www.bb-elec.com.

5.1 Zlinx Manager Software Overview

Zlinx Manager Software is supplied along with the module in a CD. The software must be installed in a PC and launched to

change the configuration of the wireless I/O module.

5.2 Computer System Requirements

The Zlinx Manager software requires the following computer hardware and operating systems:

A PC with one USB port available..

Operating System

o Windows XP 32 & 64 bit (Home or Professional with SP1, SP2 or SP3)

o Windows 2000 32 & 64 bit

o Vista 32 & 64 bit

o Windows 7 32 & 64 bit.

5.3 Installing Zlinx® Manager Software

The Zlinx manager software is available in the CD ROM which is included with the I/O module. Insert the CD into the CD drive.

The installation process will start automatically. If it does not, then navigate to the CD ROM drive using Windows Explorer

software and then double click the executable file on the CD.

1. The Welcome Screen will be displayed.

Figure 5-1 Installation Welcome Screen

2. Follow the prompts to install the software.

3. The Installation Complete Screen as shown below will be displayed. Click the “Finish” button.

Manual Documentation Number: ZXTx-IO-x-4113m 25

Page 32

Software Installation

Zlinx Xtreme

I/O (inside

view)

Configuration

PC

USB Cable

Figure 5-2 Installation Completion Screen

5.4 Installing USB Drivers

The USB drivers will automatically be installed when the software is installed. If the "Add New Hardware" wizard appears when

the hardware is attached, the USB drivers are available in the "USB Drivers" folder on the CD-ROM.

5.5 Establishing

Connection to PC

To connect Zlinx Xtreme I/O to a PC:

1. Open the front cover of the Zlinx Xtreme I/O module

2. Apply power to the I/O unit

3. Connect the PC USB port to the USB port of the Zlinx Xtreme I/O Module using a USB cable.

4. Now the Zlinx Xtreme I/O module is ready to be configured from the PC.

Figure 5-3 PC to I/O Module Connection

26 Manual Documentation Number: ZXTx-IO-x-4113m

Page 33

Software Installation

Note: In order for the PC to see the Xtreme module’s COM port, the Xtreme module must be powered. If power is removed

from the Xtreme module, the COM port will disappear from the PC even if you are configuring or monitoring the Xtreme

module.

5.6 Starting Zlinx I/O Configuration Software

1. From the Windows Start menu, start the Zlinx Manager software. Zlinx Manager is common for both the I/O Module

Configuration and the Radio Modem configuration. The default path is:

Programs/B&B Electronics/Zlinx/Zlinx Manager/Zlinx Manager

Zlinx Manager Screen opens offering navigation to Zlinx Manager or Radio Modem Manager.

Fig 5.4 Zlinx Manager Start Menu

2. Click on the Zlinx I/O. The following I/O menu screen opens. This screen allows access to I/O Configuration, Firmware Update

and Monitor I/O Status

Fig 5.5 Zlinx Manager I/O Menu Screen

5.7 Unit Discovery

1. To go to the configuration window click on the Zlinx I/O Configuration.

2. The Zlinx Xtreme I/O splash window appears briefly, followed by the discovery window.

3. The Connection drop down list defaults to Automatic discovery. The software scans through COM-ports looking for Zlinx

Xtreme I/O devices. The scan starts with the most recently used COM-port in which a device was found.

Manual Documentation Number: ZXTx-IO-x-4113m 27

Page 34

Software Installation

NOTE: Clicking the Stop button stops the module discovery process.

Fig 5.6 I/O Module Discovery Window

During the scan the Progress box displays information about the scanning process. The bar graph near the bottom of the

window indicates progress.

4. If the device is not found, the Progress box displays:

“The device was not found on any serial port.”

a. Check the power supply and serial cable connections.

b. Click the Connect button. The connection process will be repeated and the device should be found.

5. If Automatic connection is not desired, a particular COM port (1 to 16) can be specified:

a. Select the COM port number from the Connection drop down list.

b. Click the Connect button to initiate the connection process.

6. If the device is found, the I/O Configuration Menu Screen opens.

28 Manual Documentation Number: ZXTx-IO-x-4113m

Page 35

Software Installation

Fig 5.7 I/O Configuration Menu

The I/O Configuration Menu contains:

Three tabbed panes: Information, Configuration, and Input/Output.

A Help sidebar containing information and hints related to the current tab. If the sidebar is not visible enable it by

going to Help > Sidebar.

A graphic display of the I/O Modules discovered.

A Status bar (at the bottom) showing the COM port and communications parameters: baud rate, parity, data bits, stop

bits and flow control.

An Update button used to save configuration parameters to the modules.

An Exit button.

5.8 I/O Configuration Options

The following tabs are available in the I/O Configuration Manager. The configuration details are explained in Chapter 6.

5.8.1 Information Tab

The Information tab displays a tree structure listing:

I/O Modules detected and their model numbers.

Generation number.

Firmware version number for each module.

Hardware version number for each module.

Radio firmware version number for the Xtreme Module.

Radio hardware version number for the Xtreme Module.

Manual Documentation Number: ZXTx-IO-x-4113m 29

Page 36

Software Installation

5.8.2 Configuration Tab

The Configuration tab contains fields that allow configuration of:

Wireless (Radio) parameters: Transmit Power, Channel Number, Network Identifier, Repeater Mode and AES

Encryption settings.

Communications Modes: Peer-to-Peer Master, Peer-to-Peer Slave, Modbus and related parameters.

Parameters corresponding to the chosen communication mode.

5.8.3 Input/Output Tab

The Input/Output tab contains:

A tree structure listing input and output types for each module.

Input and output configuration options.

30 Manual Documentation Number: ZXTx-IO-x-4113m

Page 37

Configuration & Operation

66..

CCoonnffiigguurraattiioonn &&

OOppeerraattiioon

n

Xtreme Module

Transmit Power Selectable

RF OTA Data Rate

AES Encryption

ZXT24-IO-222R2 (SR)

YES

NO

128 BIT

ZXT9-IO-222R2 (LR)

YES

YES

256 BIT

The I/O Configuration software is used to configure the wireless I/O module. The I/O module can be configured to operate in

Peer-to-Peer (wire-replacement) or Modbus modes receiving commands from a Modbus RTU Master. Digital Inputs can be

configured to operate in Discrete (on/off) or Counter modes in PNP or NPN configuration, and Analog Inputs and Outputs are

configurable for voltage or current loop operation with selectable ranges. Digital outputs are relay outputs. Section 2.4 provides

more information on I/O Types and Characteristics.

6.1 Configuring the I/O

To enable the features described below (except Monitor):

1. Connect the I/O module to the Configuration PC

2. Start the Configuration Manager.

3. Choose Zlinx I/O Configuration

4. The Configuration Menu opens as shown in Fig 6-2. (See Section 5.6 for more details).

6.1.1 Wireless Settings

These settings are common for the I/O module irrespective of its operating mode, viz. Peer-to-Peer or Modbus I/O.

The I/O Modules can be configured for operation with different transmitter output power. They can also be configured to

operate on several different radio channels. This allows multiple Zlinx Xtreme I/O systems to operate in the same area without

interference. The number of different systems can be further increased by configuring a unique Network Identifier (which

selects the frequency hopping sequence). 900 MHz Modules also can be used as repeaters, to extend the range of a system.

Over-the-air (OTA) data rate can also be adjusted to increase range. A lower OTA data rate will increase the effective range of

the radio, but will also increase the total throughput time.

Fig 6-1 Transmit Power vs. OTA and AES Encryption for radios

Manual Documentation Number: ZXTx-IO-x-4113m 31

Page 38

Configuration & Operation

Xtreme Module

Power Selections

Factory Default

ZXT24-IO-222R2

10mW, 16mW, 25mW, 40mW, 63mW

63mW

ZXT9-IO-222R2

1mW, 10mW, 100mW, 500mW,

1000mW

1000mW

Fig 6-2 I/O Configuration Tab

6.1.1.1 Transmit Power

In the Transmit Power drop down list, select your desired output power in mW. The conversion between dBm and mW is

shown in Appendix H . Increasing the power will increase maximum range and electrical power consumption. Setting this value

too high may violate regulatory transmission limits for your region and could cause harmful interference to other devices. As a

responsible user, make sure the transmitted power is within allowed limits for your region.

Fig 6-3 Transmit Power Ranges

6.1.1.2 Channel Number

Set the Channel Number field to match the channel used by the device with which it will communicate.

a. If that device is another Zlinx Xtreme I/O Module, set the Channel Numbers the same when configuring each of them.

b. If the device is a Modbus radio modem, the modem must be configured by using Zlinx Radio Modem Configuration

Manager to match the Xtreme Module’s Channel Number.

32 Manual Documentation Number: ZXTx-IO-x-4113m

Page 39

Configuration & Operation

Type/Range

Xtreme Module

Channel Number

Range

Factory Default

ZXT24-IO-222R2

0x0C to 0x17

0x0C

ZXT9-IO-222R2

0x00 to 0x09

0x00

Type/Range

Xtreme Module Network

Identifier Range

Factory Default

ZXT24-IO-222R2

0x00 to 0xFF

0x00

ZXT9-IO-222R2

0x11 to 0xFF

0x11

NOTE: Repeater Mode can only be implemented on the ZXT9-IO-222R2 Xtreme I/O Modules.

c. Channel Number range is different for 900 MHz and 2.4 GHz Zlinx Xtreme I/Os. The table below shows the ranges and

commands in hexadecimal values:

Fig 6-4 Channel Number Range

6.1.1.3 Network Identifier

a. The Network Identifier field must match the Network Identifier used by the device with which it will communicate.

b. If that device is another Zlinx Xtreme I/O Module, set its Network Identifier the same as the local I/O Module