Page 1

Quick Start Guide

Zlinx™ Xtreme I/O

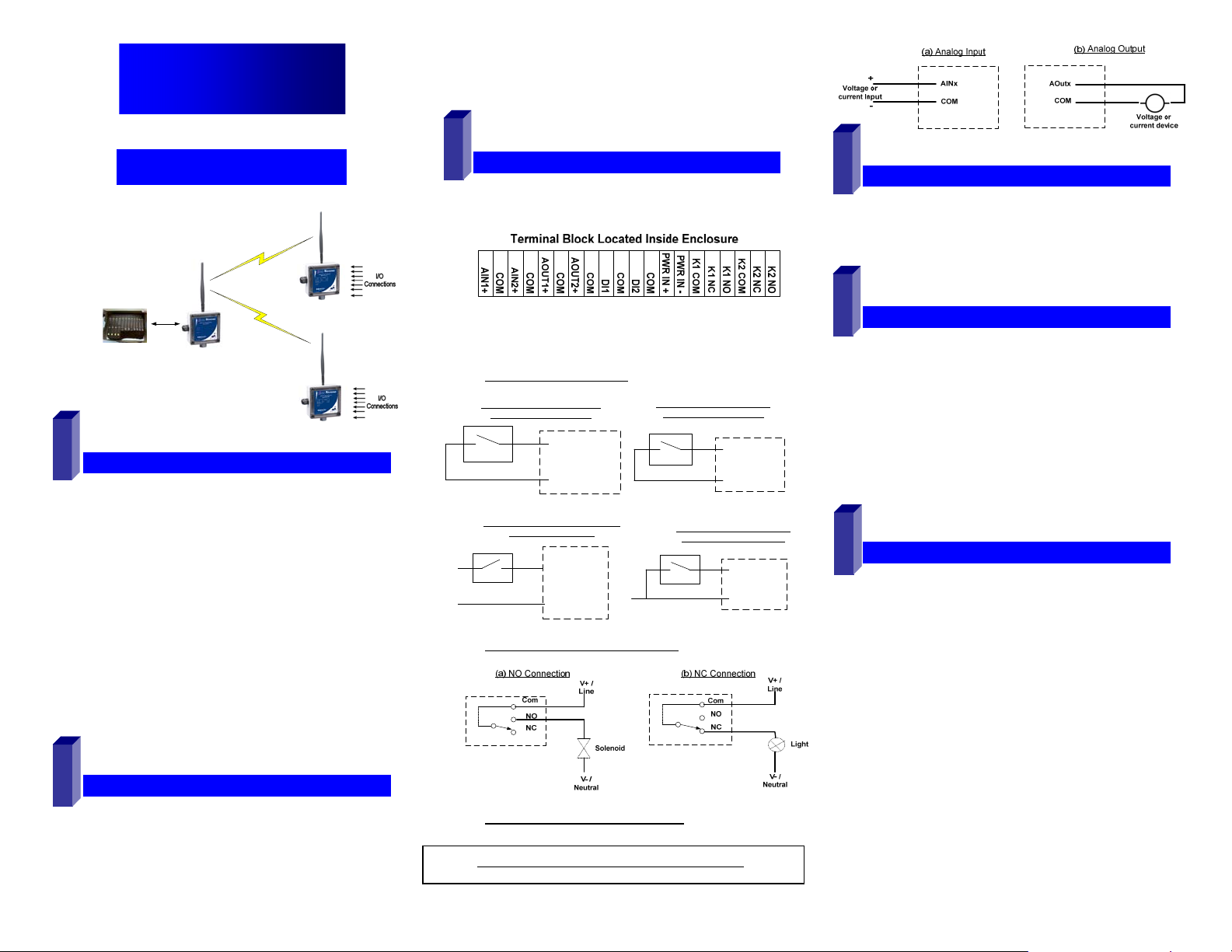

MMooddbbuuss MMooddee

I/O Module

Radio Modem

Process

Controller

Modbus RTU Master

1

CChheecckk RReeqquuiirreedd HHaarrddwwaarree

Zlinx Xtreme I/O Modules & Radio Modem of same type

o ZXT24-IO-222R2 and ZXT24-RM (OR)

o ZXT9-IO-222R2 and ZXT9-RM

This Quick Start Guide

CD with Zlinx™ Manager Software and manual

Antenna

Mounting ears and hardware

Additional items required but not included:

o 10 – 30 VDC Power Supply

o USB Cable

Conduit mounting accessories sold separately model:

ZXTMT

o Cable Gland

o Conduit Accessories

2

IInnssttaallll HHaarrddwwaarree

Mount the Zlinx Xtreme I/O module & the Radio Modem

Serial

Connection

I/O Module

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

Attach antennas to the RPSMA connectors

Attach Conduit hubs, cable glands, etc. as necessary.

Plug the unused hole, if any, using the Membrane Gland.

Accessories kit ZXTMT sold separately.

3

CCoonnnneecctt FFiieelldd WWiirriinngg

See Section 11 – “UL Class 1 Div 2 Requirements” for

wiring instructions.

Power Supply Connections:

Connect the10-30 VDC power supply to the PWR IN

+/- terminals on the terminal blocks.

Digital Input Connections:

(a) PNP (Sourcing) Input Wiring

with Internal Power Supply

PWR IN +

DIx

(c) PNP (Sourcing) Input Wiring with

External Power Supply

+V

Com

Digital Output (Relay) Connections:

Analog Input & Output Connections:

DIx

Com

(b) NPN (Sinking) Input Wiring

with Internal Power Supply

(d) NPN (Sinking) Input Wiring

with External Power Supply

Com

DIx

Com

DIx

Com

4

IInnssttaallll ZZlliinnx

Insert the CD into your CD ROM Drive. The Zlinx™

Manager Install Wizard should start. Follow the on-screen

instructions to install the software.

If auto run is disabled, locate the ZlinxMgr.exe file on the

CD-ROM drive and double click to launch it. The Install

Wizard should start. Follow the on-screen instructions.

5

IInnssttaallll UUSSBB DDrriivveerrss

Connect the I/O module to the USB port on your PC.

The “Found New Hardware Wizard” will guide you through

the installation process.

When prompted to connect to Windows Updates to search for

drivers, select “No, not at this time” and follow the instructions

for installing from the CD or the location on the hard drive.

Choose the drivers manually from the CD or the location

where Zlinx™ Manager Software is installed.

When the driver is installed a new COM port labeled

“Xtreme” will show up in Windows Device Manager.

6

EEaassyy MMooddee CCoonnffiigguurraattiioonn

With power applied to the Zlinx Xtreme I/O module, press

and HOLD the Configuration Push Button on the inside

top lid until all the Mode LED’s on the front cover flash.

A single LED will flash depending on the current mode

Press the Push Button until the configuration mode

increments to Modbus mode. Modbus LED will be ON.

If the Push Button is not pressed for 4 sec, the device will

exit with Modbus mode selected.

The Zlinx Xtreme I/O module is now ready to communicate to

the Radio Modem in default mode.

Detailed setup changes can be done using the Zlinx

Manager Software using the following steps.

M

TTM

x

MMaannaaggeerr SSooffttwwaarree

Refer to Zlinx Xtreme I/O manual for more details

Page 2

7

SSttaarrtt ZZlliinnxx II//OO MMaannaaggeer

Connect the USB port of your PC to the Zlinx Xtreme I/O

module using a USB cable.

Click Start\Programs\B&B Electronics\Zlinx\Zlinx

Manager\Zlinx Manager, then click Zlinx I/O and then

Zlinx I/O Configuration. It will auto-search for attached

Zlinx Xtreme I/O Module on startup. Zlinx I/O will open

and display the Information tab showing the I/O model

number, version numbers and firmware rev levels.

r

Set encryption key to match that of the Modbus radio

modem.

Select the communication mode to ‘Modbus’ Mode.

Set the Modbus address to the address number desired

for the Module being configured.

Click Update to save configuration.

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

Configure each Analog Inputs and Outputs in one of the

following modes

o 0-5V, 0-10V, 0-20mA, 4-20mA

Refer to Zlinx Xtreme I/O manual for more details

Set Exception Reporting for Analog Inputs and Fail Safe

settings for Analog Outputs if necessary.

Set Calibration option if you desire to better match a

sensor, or a portion of a signal, to the I/O.

Refer to appropriate sections in the Zlinx Xtreme I/O

manual.

Click Update button to apply the settings.

8

CCoonnffiigguurree CCoommmmuunniiccaattiioonn MMooddee

On the Configuration tab:

Configure Wireless settings:

o Select the desired RF Transmit Power

o Set the Channel Number to match the Modbus Radio

Modem you will be communicating with.

o Set the Network Identifier to match the Modbus

Radio Modem you will be communicating with.

o Set Repeater checkbox if desired. Note that ONLY

the (ZXT9-IO- xx) modules supports this mode.

10

9

CCoonnffiigguurree IInnppuuttss//OOuuttppuuttss

OOppeerraattiioonn

LED

Power

RSSI

(8 LED

bar

graph)

Wireless Off

Mode

I/O

Status

STATUS FUNCTION

Solid

Flash

0

1-3

4-6

7-8

Blinking

Modbus

P2P Master

P2P Slave

DI1

DI2

DO1

DO2

Power applied

Communication Fail

No signal

Weak signal

OK signal

Strong signal

No radio link data

Wireless data Transmit / Receive

Modbus Mode

Peer-to-Peer Master

Peer-to-Peer Slave

Digital Input 1 ON

Digital Input 2 ON

Digital Output (Relay) 1 ON

Digital Output (Relay) 2 ON

Set Digital Inputs for Discrete or Counter, as required.

o Choose PNP or NPN selection as appropriate.

Each input is individually configurable.

Configure Digital Relay Outputs. Enable the Fail Safe

and Communications Fail Alarm if necessary.

11

UULL CCllaassss 11 DDiivv 22 RReeqquuiirreemmeennttss

Operating Voltage – 10 to 30 VDC

WARNING: SUITABLE FOR USE IN CLASS I, DIVISION 2,

GROUPS A, B, C AND D HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY.

Page 3

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF ANY

COMPONENT MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

WARNING – EXPLOSION HAZARD – WHEN IN HAZARDOUS

LOCATIONS, TURN OFF POWER BEFORE REPLACING

ANTENNA.

Intended use of equipment – please see the B&B Electronics

Data Sheets and Quick Start Guides for each Zlinx Xtreme

product for explanations of the intended use of this equipment.

Wiring Terminals – Use Copper Wire Only, one conductor per

terminal

Wire Range 30 – 12 AWG

Maximum Surrounding Ambient Air Temperature - 74°C

UL Class I, Division 2 wiring methods. The Zlinx Xtreme

enclosure is provided with two conduit knockouts that serve as

wiring provisions for Class I, Division 2 wiring methods per the

National Electrical Code (NEC).

The following instructions include procedures to be followed in

order to ensure UL "separation between circuits" as defined in

the NEC.

The low-voltage (LV) wiring – DC power, analog & digital signals

– must be separated from the high voltage (HV) wiring for the

relay contacts. In all cases HV wiring must be rated minimum

250V.

Separation between circuits can be accomplished by using one

of the three following methods:

a. Use one conduit knockout to route LV wiring and the

second conduit knockout to route the HV wiring, OR

see methods 2 and 3 below.

The remaining two methods use one conduit

knockout for all wiring. In this case a UL Recognized

(UL type QCRV2) conduit plug must be used per the

NEC to plug the second conduit knockout.

b. Enclose LV wiring in a 250V rated insulated sheath

to separate it from the HV wiring, OR

c. Use 250vac rated wires for both LV and HV wiring.

Temperature rating of field installed conductors - Field

conductors shall be rated 60C/75C minimum (either are

acceptable) and sized accordingly.

When conduit openings are not being used, a UL Recognized

plug (type QCRV2) shall be used.

The following is UL-required information regarding the Sealed

Relay Devices:

WARNING – Exposure to some chemicals may degrade the

sealing properties of materials used in the Sealed Relay Device.

RECOMMENDATION – It is recommended to inspect the

sealed relay device periodically and to check for any

degradation of the materials and to replace the component

product, not the sealed device, if any degradation is found.

Sealed Relay Device Information:

Sealed Device: Relay Models G6RL-14-ASI-DC5, G6RL14-ASI-DC6, G6RL-14-SR-ASI-DC5 or G6RL-14-SR-ASIDC6 manufactured by Omron Corp.

Manufacturer Type

Relay Case and

Base

Mitsubishi

Engineering

5010GN6-30M8AM

Plastics

Corp.

Sealant

Three Bond

TB2225G

Ltd.

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

Page 4

Quick Start Guide

Zlinx™ Xtreme I/O

PPeeeerr--ttoo--PPeeeerr MMooddee

1

CChheecckk ffoorr AAllll RReeqquuiirreedd HHaarrddwwaarree

Two Zlinx Xtreme I/O Modules of same type

o ZXT24-IO-222R2 (OR)

o ZXT9-IO-222R2

This Quick Start Guide

CD with Zlinx™ Manager Software and manual

Antenna

Mounting ears and hardware

Additional items required but not included:

o 10 – 30 VDC Power Supply

o USB Cable

Conduit mounting accessories sold separately, model

ZXTMT

o Cable Gland

o Conduit Accessories

2

IInnssttaallll HHaarrddwwaarree

Mount the Zlinx Xtreme I/O modules

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

Attach antennas to the RPSMA connectors

Attach Conduit hubs, cable glands, etc. as necessary.

Plug the unused hole, if any, using the Membrane Gland.

Accessories kit ZXTMT sold separately.

Analog Input & Output Connections:

3

CCoonnnneecctt FFiieelldd WWiirriinngg

See Section 11 – “UL Class 1 Div 2 Requirements” for

wiring instructions.

Power Supply Connections:

Connect the10-30 VDC power supply to the PWR IN

+/- terminals on the terminal blocks.

Digital Input Connections:

(a) PNP (Sourcing) Input Wiring

with Internal Power Supply

PWR IN +

DIx

(c) PNP (Sourcing) Input Wiring with

External Power Supply

+V

Com

Digital Output (Relay) Connections:

Refer to Zlinx Xtreme I/O manual for more details

DIx

Com

(b) NPN (Sinking) Input Wiring

with Internal Power Supply

(d) NPN (Sinking) Input Wiring

with External Power Supply

Com

DIx

Com

DIx

Com

M

TTM

IInnssttaallll ZZlliinnx

4

Insert the CD into your CD ROM Drive. The Zlinx™

Manager Install Wizard should start. Follow the on-screen

instructions to install the software.

If auto run is disabled, locate the ZlinxMgr.exe file on the

CD-ROM drive and double click to launch it. The Install

Wizard should start. Follow the on-screen instructions.

5

IInnssttaallll UUSSBB DDrriivveerrss

Connect the I/O module to the USB port on your PC.

The “Found New Hardware Wizard” will guide you through

the installation process.

When prompted to connect to Windows Updates to search for

drivers, select “No, not at this time” and follow the instructions

for installing from the CD or the location on the hard drive.

Choose the drivers manually from the CD or the location

where Zlinx™ Manager Software is installed.

When the driver is installed a new COM port labeled

“Xtreme” will show up in Windows Device Manager.

6

EEaassyy MMooddee CCoonnffiigguurraattiioonn

With power applied to the Zlinx Xtreme I/O module, press

and HOLD the Configuration Push Button on the inside

top lid until all the Mode LED's on the front cover flash.

A single LED will flash depending on the current mode

In one I/O module, press the Push Button until the

configuration mode increments to P2P Master mode.

Corresponding LED will be flashing.

If the Push Button is not pressed for 4 sec, the device will

exit with ‘P2P Master’ mode selected.

Using similar steps to above, set the other I/O module to

‘P2P Slave’ mode

x

MMaannaaggeerr SSooffttwwaarree

Page 5

Now the Zlinx Xtreme I/O modules are ready to

communicate Peer-to-Peer mode with default setup.

Detailed setup can be done using the Zlinx Manager

using the following steps.

7

r

SSttaarrtt ZZlliinnxx II//OO MMaannaaggeer

Connect the USB port of your PC to the Zlinx Xtreme I/O

module using a USB cable.

Click Start\Programs\B&B Electronics\Zlinx\Zlinx

Manager\Zlinx Manager, then click Zlinx I/O and then

Zlinx I/O Configuration. It will auto-search for attached

Zlinx Xtreme I/O Module on startup. Zlinx I/O will open

and display the Information tab showing the I/O model

number, version numbers and firmware rev levels.

Select the communication mode to ‘P2P Master’ Mode.

Set the P2P Master address as desired.

Set Polling Rate and Retry Count.

Click Update to save configuration.

P2P Slave Configuration – From Configuration tab

Configure Wireless settings:

o Select the desired RF Transmit Power

o Set the Channel Number to match that of master.

o Set the Network Identifier to match that of master.

o Set encryption key the same as that of master.

Select the communication mode to ‘P2P Slave’ Mode.

Set the P2P Salve address to match that of Master.

Click Update to save configuration

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

Configure each Analog Inputs and Outputs in one of the

following modes

o 0-5V, 0-10V, 0-20mA, 4-20mA

Set Exception Reporting for Analog Inputs and Fail Safe

settings for Analog Outputs if necessary.

Set Calibration option if you desire to better match a

sensor, or a portion of a signal, to the I/O.

Refer to appropriate sections in the Zlinx XtremeI/O

manual.

Click Update button to apply the settings.

8

CCoonnffiigguurree CCoommmmuunniiccaattiioonn MMooddeess

P2P Master Configuration – From Configuration tab

Configure Wireless settings:

o Select the desired RF Transmit Power

o Set the Channel Number.

o Set the Network Identifier.

o Set Repeater checkbox if desired. Note that ONLY

the (ZXT9-IO- xx) modules supports this mode.

o Set encryption key.

10

OOppeerraattiioonn

9

CCoonnffiigguurree IInnppuutt//OOuuttppuutt

Set Digital Inputs for Discrete. Counter configuration is

not applicable to Peer-to-Peer mode

o Choose PNP or NPN selection as appropriate.

Each input is individually configurable.

Configure Digital Relay Outputs.

Enable the Fail Safe and Communications Fail Alarm if

necessary.

Refer to Zlinx Xtreme I/O manual for more details

LED

Power

RSSI

(8 LED

bar

graph)

Wireless Off

Mode

I/O

Status

STATUS

Solid

Flash

0

1-3

4-6

7-8

Blinking

Modbus

P2P Master

P2P Slave

DI1

DI2

DO1

DO2

FUNCTION

Power applied

Communication Fail

No signal

Weak signal

OK signal

Strong signal

No radio link data

Wireless data Transmit / Receive

Modbus Mode

Peer-to-Peer Master

Peer-to-Peer Slave

Digital Input 1 ON

Digital Input 2 ON

Digital Output (Relay) 1 ON

Digital Output (Relay) 2 ON

Page 6

11

UULL CCllaassss 11 DDiivv 22 RReeqquuiirreemmeennttss

Operating Voltage – 10 to 30 VDC

WARNING: SUITABLE FOR USE IN CLASS I, DIVISION

2, GROUPS A, B, C AND D HAZARDOUS LOCATIONS,

OR NONHAZARDOUS LOCATIONS ONLY.

WARNING - EXPLOSION HAZARD - SUBSTITUTION

OF ANY COMPONENT MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2.

WARNING – EXPLOSION HAZARD – WHEN IN

HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING ANTENNA.

Intended use of equipment – please see the B&B

Electronics Data Sheets and Quick Start Guides for each

Zlinx Xtreme product for explanations of the intended use of

this equipment.

Wiring Terminals – Use Copper Wire Only, one conductor

per terminal

Wire Range 30 – 12 AWG

Maximum Surrounding Ambient Air Temperature - 74°C

UL Class I, Division 2 wiring methods. The Zlinx Xtreme

enclosure is provided with two conduit knockouts that serve

as wiring provisions for Class I, Division 2 wiring methods

per the National Electrical Code (NEC).

The following instructions include procedures to be followed

in order to ensure UL "separation between circuits" as

defined in the NEC.

The low-voltage (LV) wiring – DC power, analog & digital

signals – must be separated from the high voltage (HV)

wiring for the relay contacts. In all cases HV wiring must be

rated minimum 250V.

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

Separation between circuits can be accomplished by using one

of the three following methods:

a. Use one conduit knockout to route LV wiring and the

second conduit knockout to route the HV wiring, OR

see methods 2 and 3 below.

The remaining two methods use one conduit

knockout for all wiring. In this case a UL Recognized

(UL type QCRV2) conduit plug must be used per the

NEC to plug the second conduit knockout.

b. Enclose LV wiring in a 250V rated insulated sheath

to separate it from the HV wiring, OR

c. Use 250vac rated wires for both LV and HV wiring.

Temperature rating of field installed conductors - Field

conductors shall be rated 60C/75C minimum (either are

acceptable) and sized accordingly.

When conduit openings are not being used, a UL

Recognized plug (type QCRV2) shall be used.

The following is UL-required information regarding the

Sealed Relay Devices:

WARNING – Exposure to some chemicals may degrade

the sealing properties of materials used in the Sealed

Relay Device.

RECOMMENDATION – It is recommended to inspect the

sealed relay device periodically and to check for any

degradation of the materials and to replace the

component product, not the sealed device, if any

degradation is found.

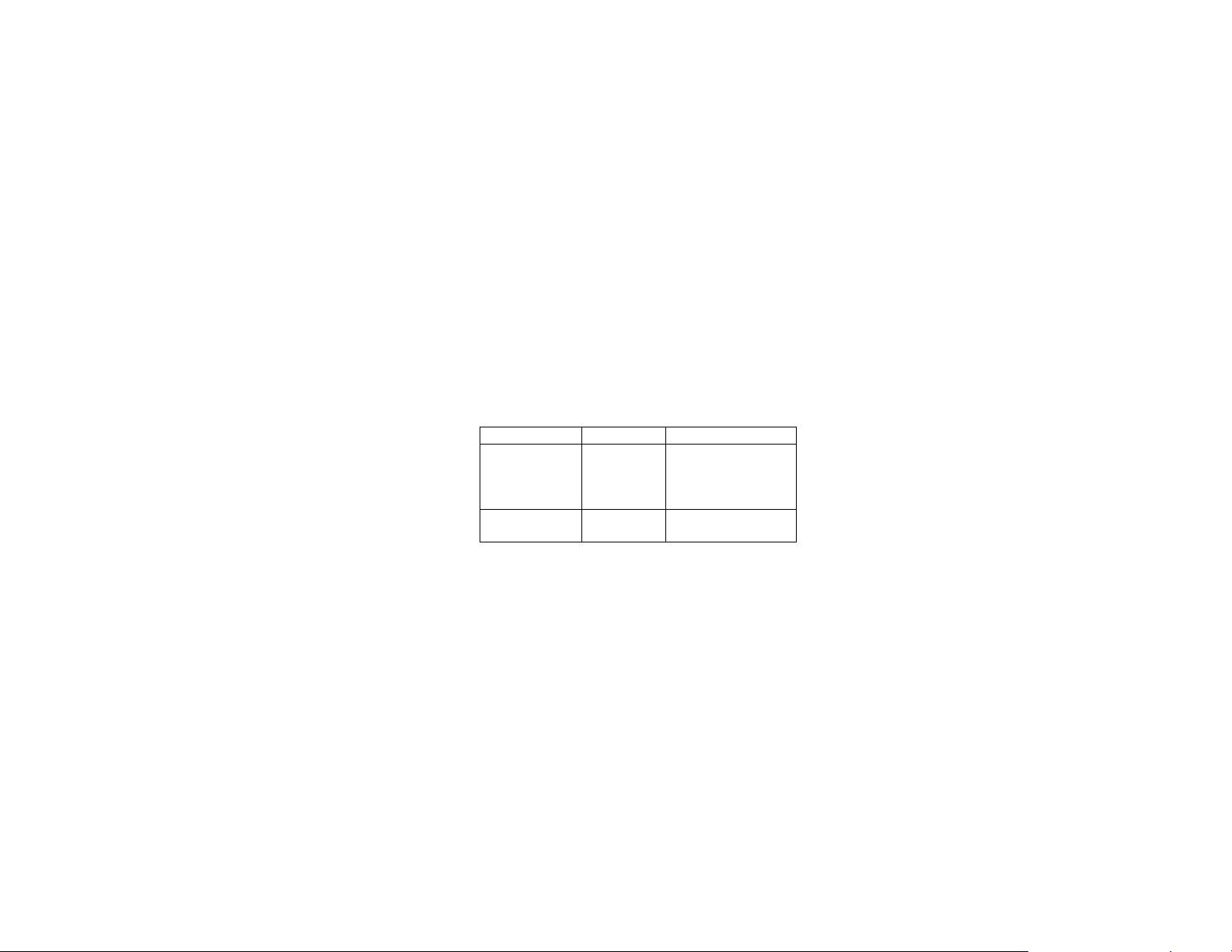

Sealed Relay Device Information:

Sealed Device: Relay Models G6RL-14-ASI-DC5, G6RL14-ASI-DC6, G6RL-14-SR-ASI-DC5 or G6RL-14-SR-ASIDC6 manufactured by Omron Corp.

Relay Case and

Base

Sealant

Manufacturer Type

Mitsubishi

Engineering

Plastics

Corp.

Three Bond

Ltd.

5010GN6-30M8AM

TB2225G

Loading...

Loading...