Page 1

Users Guide

Airborne Enterprise Evaluation Kit

WLNN-SE/SP/AN/ER-DP500

Revision 1.4

June 2013

File name: Enterprise WLNN EVB User Guide.doc

Series

Page 2

B&B Electronics

2

Airborne Enterprise WLNN EVB Users Guide

<Page Intentionally Left

Blank>

Page 3

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

3

Contents

1.0 Overview.................................................................................................................................... 8

2.0 Conventions ............................................................................................................................... 9

2.1 Terminology ........................................................................................................................... 9

2.2 Notes ..................................................................................................................................... 9

2.3 Caution .................................................................................................................................. 9

2.4 File Format ............................................................................................................................. 9

2.5 Courier Typeface ................................................................................................................. 10

3.0 Supported Devices and Kits ..................................................................................................... 11

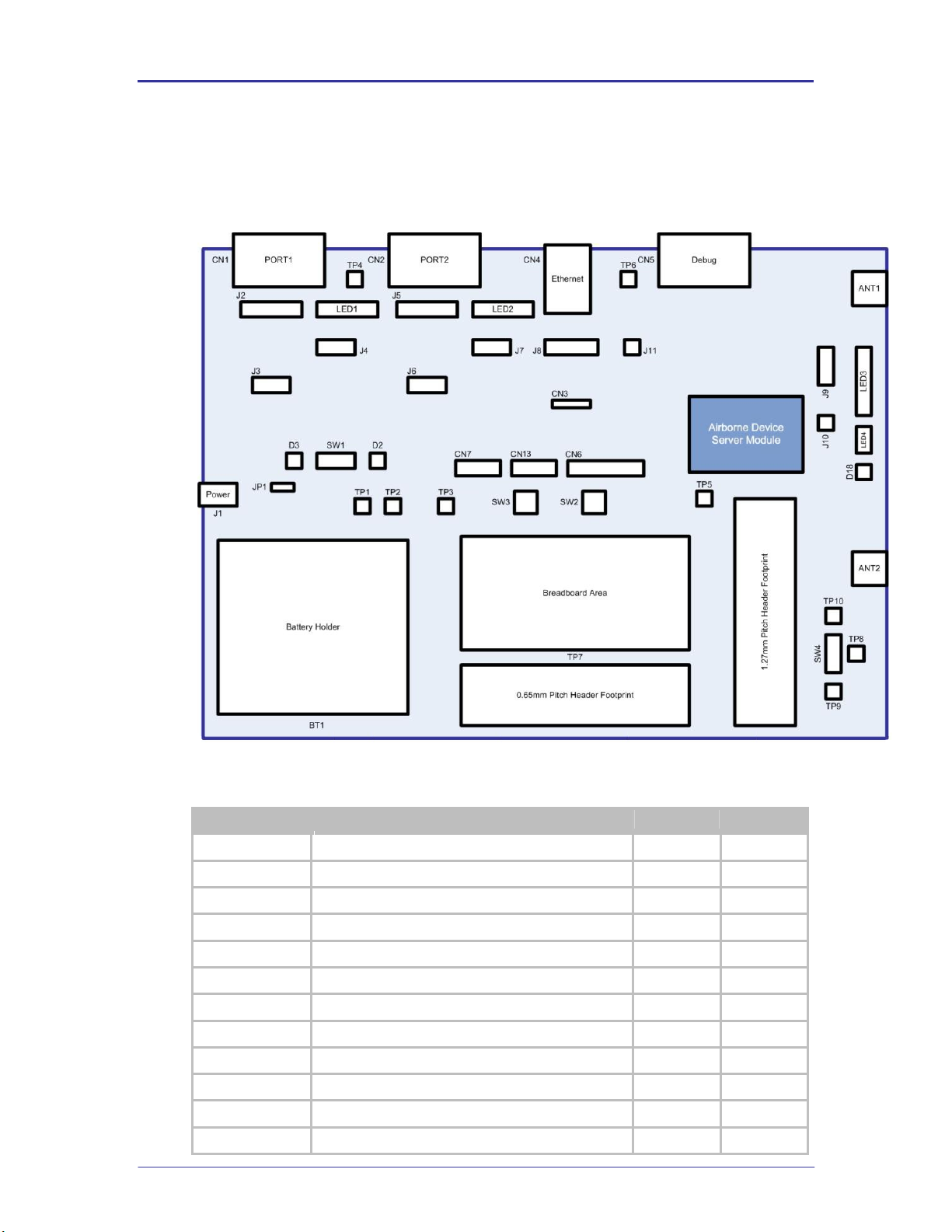

4.0 Evaluation Board Layout .......................................................................................................... 12

5.1 ANT1 .................................................................................................................................... 14

5.2 ANT2 .................................................................................................................................... 14

5.3 BT1 ....................................................................................................................................... 14

5.4 CN1 ...................................................................................................................................... 15

5.5 CN2 ...................................................................................................................................... 15

5.6 CN3 ...................................................................................................................................... 15

5.7 CN4 ...................................................................................................................................... 16

5.8 CN5 ...................................................................................................................................... 17

5.9 CN6 ...................................................................................................................................... 17

5.10 CN7 / CN13 .......................................................................................................................... 18

5.11 D2 ........................................................................................................................................ 19

5.12 D3 ........................................................................................................................................ 19

5.13 D18 ...................................................................................................................................... 19

5.14 J1 .......................................................................................................................................... 19

5.15 J2 .......................................................................................................................................... 20

5.16 J3 .......................................................................................................................................... 22

5.17 J4 .......................................................................................................................................... 23

5.18 J5 .......................................................................................................................................... 24

5.19 J6 .......................................................................................................................................... 26

5.20 J7 .......................................................................................................................................... 27

5.21 J8 .......................................................................................................................................... 27

5.22 J9 .......................................................................................................................................... 28

5.23 J10 ........................................................................................................................................ 29

5.24 J11 ........................................................................................................................................ 29

5.25 JP1........................................................................................................................................ 30

5.26 LED1 ..................................................................................................................................... 31

5.27 LED2 ..................................................................................................................................... 31

5.28 LED3 ..................................................................................................................................... 31

5.29 LED4 ..................................................................................................................................... 32

5.30 SW1 ..................................................................................................................................... 32

5.31 SW2 ..................................................................................................................................... 32

Page 4

B&B Electronics

4

Airborne Enterprise WLNN EVB Users Guide

5.32 SW3 ..................................................................................................................................... 33

5.33 SW4 ..................................................................................................................................... 33

5.34 TP1 – 6 ................................................................................................................................. 34

5.35 TP7 ....................................................................................................................................... 34

5.36 TP8 - 10 ................................................................................................................................ 36

6.0 A Typical Development System ................................................................................................ 36

7.0 Getting Started ........................................................................................................................ 37

7.1 Unpack the Airborne™ Module EVB Kit ............................................................................... 37

7.2 Attach Antenna and Power-up the EVB .............................................................................. 37

7.3 Install Serial to USB Adapter (Optional) .............................................................................. 37

7.4 Connection to SPI Host ........................................................................................................ 37

8.0 Serial Device Server Connection .............................................................................................. 38

8.1 Connect a Host Computer ................................................................................................... 38

8.2 Interacting with the Airborne™ Module ............................................................................. 38

8.3 Determine and Store the Access Point SSID ........................................................................ 39

8.4 Determine the Module’s IP address .................................................................................... 39

8.5 Accessing the Module Using Telnet .................................................................................... 39

9.0 Ethernet Bridge Connection .................................................................................................... 41

9.1 Connect a Host Computer ................................................................................................... 41

9.2 Interacting with the Airborne™ Module ............................................................................. 41

9.3 Determine and Store the Access Point SSID ........................................................................ 42

9.4 Determine the Module’s IP address .................................................................................... 42

9.5 Accessing the Module Using Telnet .................................................................................... 42

10.0 Using the Web Interface ............................................................................................................ 44

10.1 Navigation Bar ..................................................................................................................... 44

10.2 Navigating the Website ....................................................................................................... 45

10.3 Updating a Field ................................................................................................................... 46

10.4 Uploading Certificates ......................................................................................................... 46

10.5 Upload Configuration Files .................................................................................................. 47

10.6 Updating Firmware .............................................................................................................. 48

11.0 Using the AMC Application ......................................................................................................... 51

12.0 Ethernet Section ......................................................................................................................... 53

13.0 Indicator LED’s ............................................................................................................................ 54

Page 5

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

5

Tables

Table 1 - Model and kit part numbers ................................................................................................. 11

Table 2 – Summary Description of Evaluation Board .......................................................................... 12

Table 3 - ANT1 Connectors .................................................................................................................. 14

Table 4 - ANT2 Connectors .................................................................................................................. 14

Table 5 - Primary UART CONNECTOR .................................................................................................. 15

Table 6 - Primary UART Connector ...................................................................................................... 15

Table 7 - Ethernet PHY Header Pin Out ............................................................................................... 16

Table 8 - Ethernet Connector Pin Out ................................................................................................. 16

Table 9 - Debug Port Connector .......................................................................................................... 17

Table 10 - Debug Port Pin Out ............................................................................................................. 17

Table 11 - JTAG Header Pin Out .......................................................................................................... 17

Table 12 - SPI Header Pin Out ............................................................................................................. 18

Table 13 - Low Voltage Led indicator .................................................................................................. 19

Table 14 - POWER Status Led indicator ............................................................................................... 19

Table 15 - RF Activity Led Indicator ..................................................................................................... 19

Table 16 - Power Supply Jack .............................................................................................................. 20

Table 17 - Primary Uart Pin Out Header Configuration....................................................................... 20

Table 18 - Primary UART Header Pin-out ............................................................................................ 21

Table 19 - Primary UART Transceiver Configuration ........................................................................... 22

Table 20 - Primary UART Transceiver Header Pin-out ........................................................................ 22

Table 21 - Primary UART LED Indicator Header Pin-out ...................................................................... 23

Table 22 - Secondary UART Pin-out Header Configuration ................................................................. 24

Table 23 - Primary UART Header Pin-out ............................................................................................ 25

Table 24 - Secondary UART Transceiver Configuration ....................................................................... 26

Table 25 - Secondary UART Transceiver Header Pin-out .................................................................... 26

Table 26 - Secondary UART LED Indicator Header Pin-out ................................................................. 27

Table 27 - Ethernet Header Configuration .......................................................................................... 28

Table 28 - Ethernet Header Pin-out .................................................................................................... 28

Table 29 - Airborne Device Server Module Status Indicator Header Pin-out ..................................... 29

Table 30 - GPIO LED Header Configuration ......................................................................................... 29

Table 31 - GPIO LED Header Pin-out ................................................................................................... 29

Table 32 – Ethernet Indicator LED Header Configuration ................................................................... 30

Table 33 – Ethernet Indicator LED Header Pin-out ............................................................................. 30

Table 34 - Power Source Selector........................................................................................................ 30

Table 35 - JP1 Power Selector Pin-out................................................................................................. 30

Table 36 - Primary UART Indicator LED's ............................................................................................. 31

Table 37 - Secondary UART Indicator LED's ........................................................................................ 31

Table 38 – Airborne Device Server Module Indicator LED’s................................................................ 31

Table 39 - LED4 Description ................................................................................................................ 32

Table 40 - TP1-6 Configuration ............................................................................................................ 34

Table 41 - TP7 Label to WLNN Pin-out Table ...................................................................................... 35

Table 42 - UART Authentication .......................................................................................................... 38

Page 6

B&B Electronics

6

Airborne Enterprise WLNN EVB Users Guide

Table 43 - UART SSID & Authentication .............................................................................................. 39

Table 44 - UART Determine Module's IP Address ............................................................................... 39

Table 45 - Ethernet Authentication ..................................................................................................... 41

Table 46 - Ethernet SSID & Authentication ......................................................................................... 42

Table 47 - Ethernet Determine Modules IP Address ........................................................................... 42

Table 48 - Navigation Bar Items .......................................................................................................... 45

Table 49 - Uploading Certificates ........................................................................................................ 47

Table 50 - Uploading Configurations ................................................................................................... 48

Table 51 - Updating Firmware ............................................................................................................. 50

Table 52 - Indicator LED Status Description ....................................................................................... 54

Table 53 - Indicator LED Debug Answers ............................................................................................ 55

Page 7

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

7

Figures

Figure 1 - Evaluation board layout ...................................................................................................... 12

Figure 2 - Ethernet Jack Pin Out .......................................................................................................... 16

Figure 3 - JTAG Header ........................................................................................................................ 17

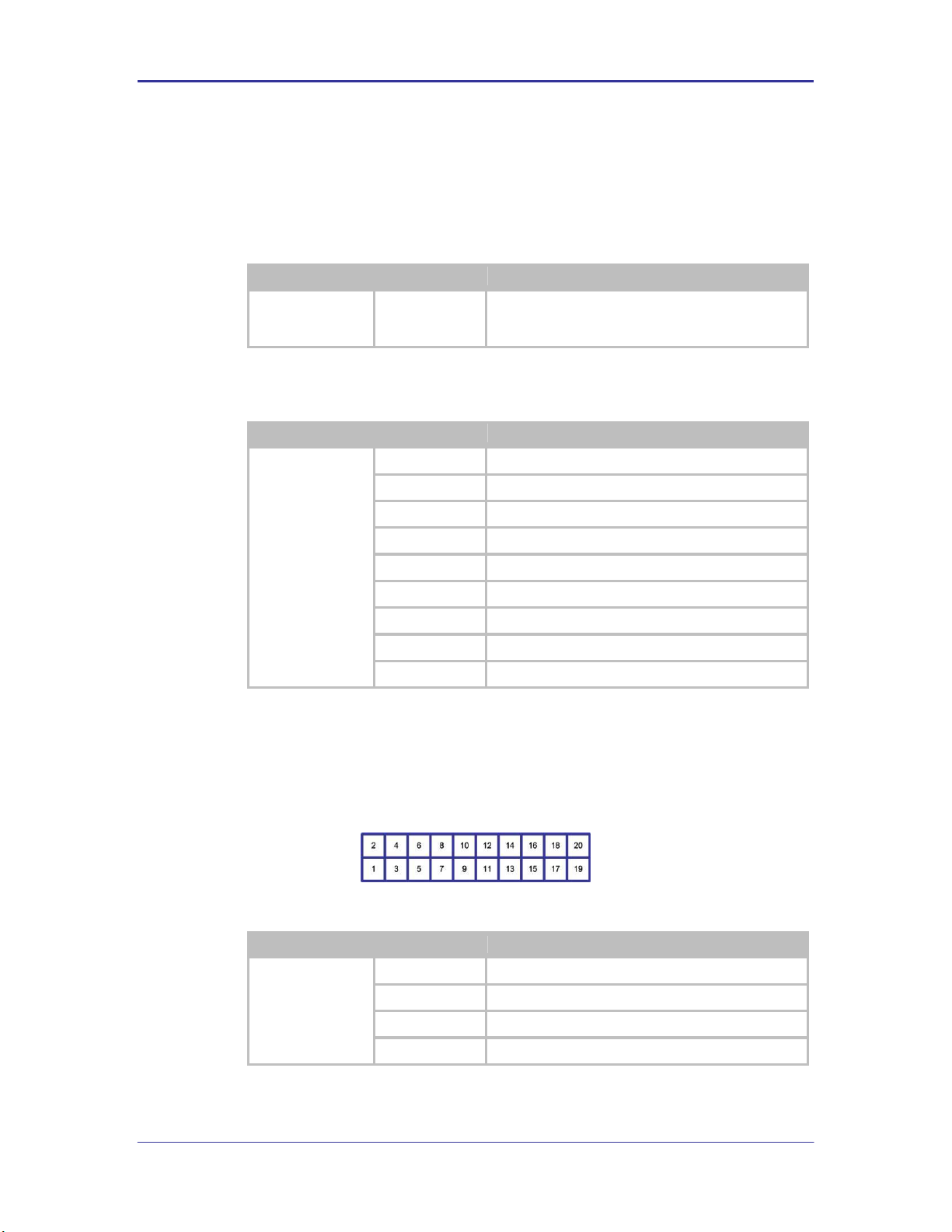

Figure 4 - SPI Header ........................................................................................................................... 18

Figure 5 - DE-9 Connector Pin-out ....................................................................................................... 20

Figure 6 - Primary UART Header.......................................................................................................... 21

Figure 7 - Primary UART Transceiver Header ...................................................................................... 22

Figure 8 - Primary UART LED Indicator Header ................................................................................... 23

Figure 9 - DE-9 Connector Pin-out ....................................................................................................... 24

Figure 10 - Secondary UART Header ................................................................................................... 25

Figure 11 - Secondary UART Transceiver Header ................................................................................ 26

Figure 12 - Secondary UART LED Indicator Header ............................................................................. 27

Figure 13 - Airborne Device Server Module Status Indicator Header ................................................. 28

Figure 14 - GPIO LED Header ............................................................................................................... 29

Figure 15 - Ethernet Indicator LED Header ......................................................................................... 30

Figure 16 - JP1 Pin-out ......................................................................................................................... 30

Figure 17 - SW1 Set-up ........................................................................................................................ 32

Figure 18 - SW2 Reset Circuit .............................................................................................................. 33

Figure 19 - OEM RESET Circuit ............................................................................................................. 33

Figure 20 - SW4 Configuration ............................................................................................................ 33

Figure 21 - TP7 Layout ......................................................................................................................... 34

Figure 22 - Website Login .................................................................................................................... 44

Figure 23 - Website Navigation Bar ..................................................................................................... 44

Figure 24 - Airborne Web Page ........................................................................................................... 45

Figure 25 - upload Certificate Web page ............................................................................................. 46

Figure 26 - Upload Configuration Web Page ....................................................................................... 47

Figure 27 - Firmware Update Page ...................................................................................................... 49

Figure 28 - Firmware Update in Progress ............................................................................................ 49

Figure 29 - Firmware Update Complete .............................................................................................. 50

Figure 30 - Ethernet schematic ........................................................................................................... 53

Page 8

B&B Electronics

8

Airborne Enterprise WLNN EVB Users Guide

1.0 Overview

This guide describes the Airborne™ Enterprise class Device Server Module Evaluation

Kit from B&B Electronics, Inc. The Module Evaluation Kit is intended as a testing and

development platform for B&B Electronics’ Airborne™ Enterprise Device Server Module.

The Airborne Module offers significant advantages over other wireless solutions in terms

of size, cost, power consumption, and performance. It is ideal for applications that require

a reliable embedded IEEE 802.11a/b/g/n-compliant wireless engine.

This Kit is a complete package powered by the Airborne Module. It includes an

Evaluation Board (EVB) that contains the Airborne Module along with connectors and

headers that provide access to all of the modules interfaces. It also includes the Airborne

Management Center (AMC) application you can use to observe, configure and evaluate

the operation and performance of the Airborne Module. For a complete list of the contents

provided with your Kit, refer to the Airborne Wireless Enterprise Device Server Module

Quick Start Guide.

The Airborne EVB is a versatile, full-featured tool specifically designed for evaluating the

Airborne Module. It incorporates all the circuitry, interfaces, push-buttons, and Light

Emitting Diodes (LEDs) needed to observe and evaluate the Airborne Module. The

portability of the Airborne EVB allows it to be observed and evaluated in variety of

locations and conditions.

Airborne™

Page 9

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

9

2.0 Conventions

The following section outlines the conventions used within the document, where

convention is deviated from the deviation takes precedence and should be followed. If

you have any question related to the conventions used or clarification of indicated

deviation please contact B&B Electronics Sales or Wireless Support.

2.1 Terminology

Airborne Enterprise Device Server and AirborneDirect Enterprise Device

Server is used in the opening section to describe the devices detailed in this

document, after this section the term module will be used to describe the

devices.

2.2 Notes

A note contains information that requires special attention. The following

convention will be used. The area next to the indicator will identify the specific

information and make any references necessary.

2.3 Caution

A caution contains information that, if not followed, may cause damage to the

product or injury to the user. The shaded area next to the indicator will identify

the specific information and make any references necessary.

2.4 File Format

These documents are provided as Portable Document Format (PDF) files.

read

them, you need Adobe Acrobat Reader 4.0.5 or higher. For your

convenience, Adobe Acrobat Reader is provided on the Radio Evaluation Kit CD.

Should you not have the CD, for the latest version of Adobe Acrobat Reader, go

to the Adobe Web site (www.adobe.com).

The area next to the indicator will identify the specific information and make any

references necessary.

The area next to the indicator will identify the specific information and make any

references necessary.

To

Page 10

B&B Electronics

10

Airborne Enterprise WLNN EVB Users Guide

2.5 Courier Typeface

Commands and other input that a user is to provide are indicated with Courier

typeface. For example, typing the following command and pressing the Enter key

displays the result of a command:

wl-info <cr>

Module Firmware Version: 3.20

Radio Firmware Version: 3.1.64.33

Link Status: Connected

SSID: Airborne_Connected

MAC Address: 000B6B7783A3

BSSID: 0016B637880D

Transmit Rate (Mb/s): 54

Signal Level (dBm): -40

Noise Level (dBm): -92

IP Address: 192.168.1.100

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.1.1

Primary DNS: 192.168.1.3

Secondary DNS: 192.168.1.4

Up Time (Sec): 48313

Page 11

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

11

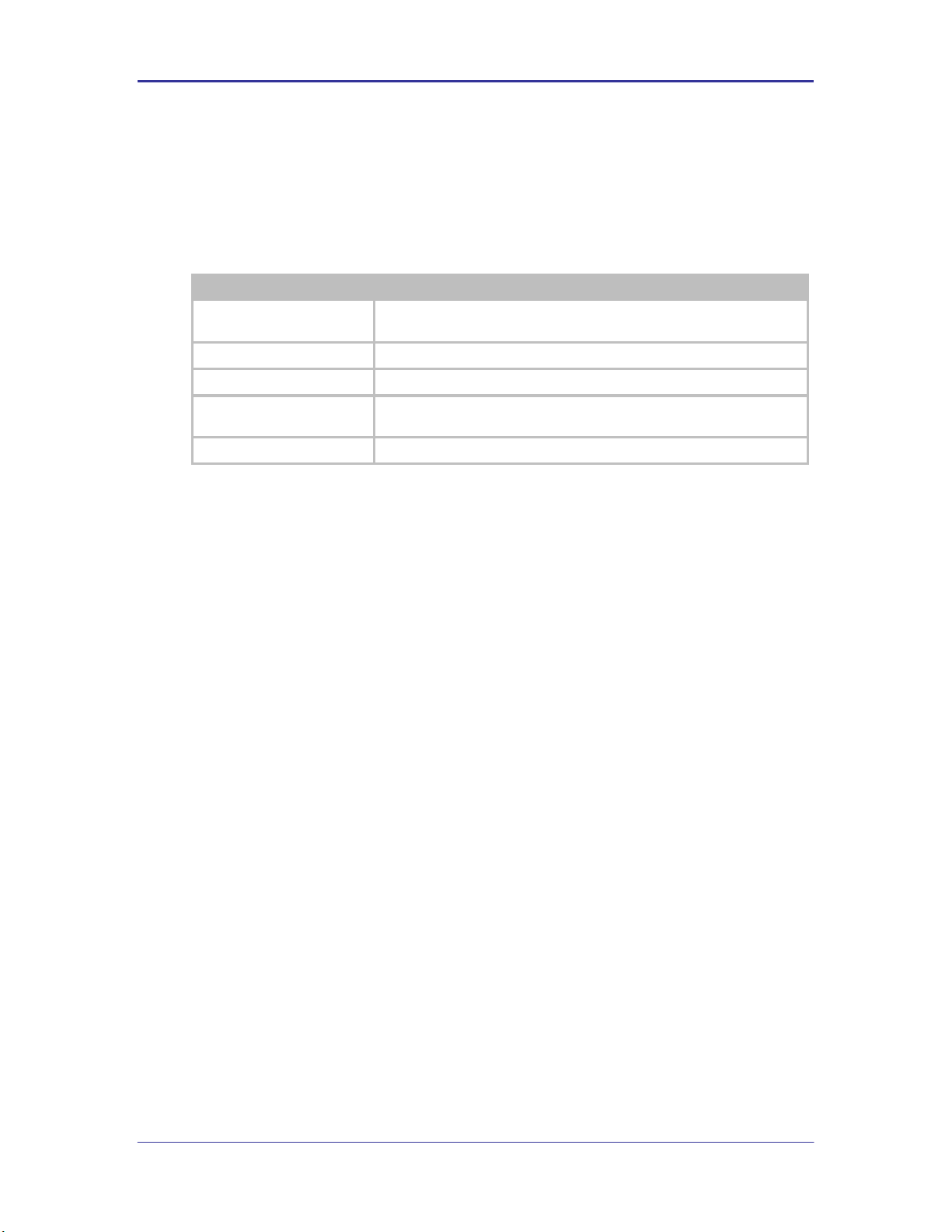

Part No.

Description

WLNN-SE-DP5XX

802.11a/b/g/n to RS232/422/485 and UART Serial Device Server

Module, Enterprise Class.

WLNN-AN-DP5XX

802.11a/b/g/n to UART Serial Device Server Module, Enterprise Class.

WLNN-SP-DP5XX

802.11a/b/g/n to SPI Serial Device Server Module, Enterprise Class.

WLNN-ER-DP5XX

802.11a/b/g/n to 10/100 Ethernet Router (NAT Level3) Module, Enterprise

Class.

WLNN-EK-DP5XX

802.11a/b/g/n Enterprise Class Airborne Development and Evaluation Kit.

3.0 Supported Devices and Kits

This manual supports the Evaluation Kit for all devices and platforms listed in Table 1.

TABLE 1 - MO DEL AND KI T P ART NUMBERS

Page 12

B&B Electronics

12

Airborne Enterprise WLNN EVB Users Guide

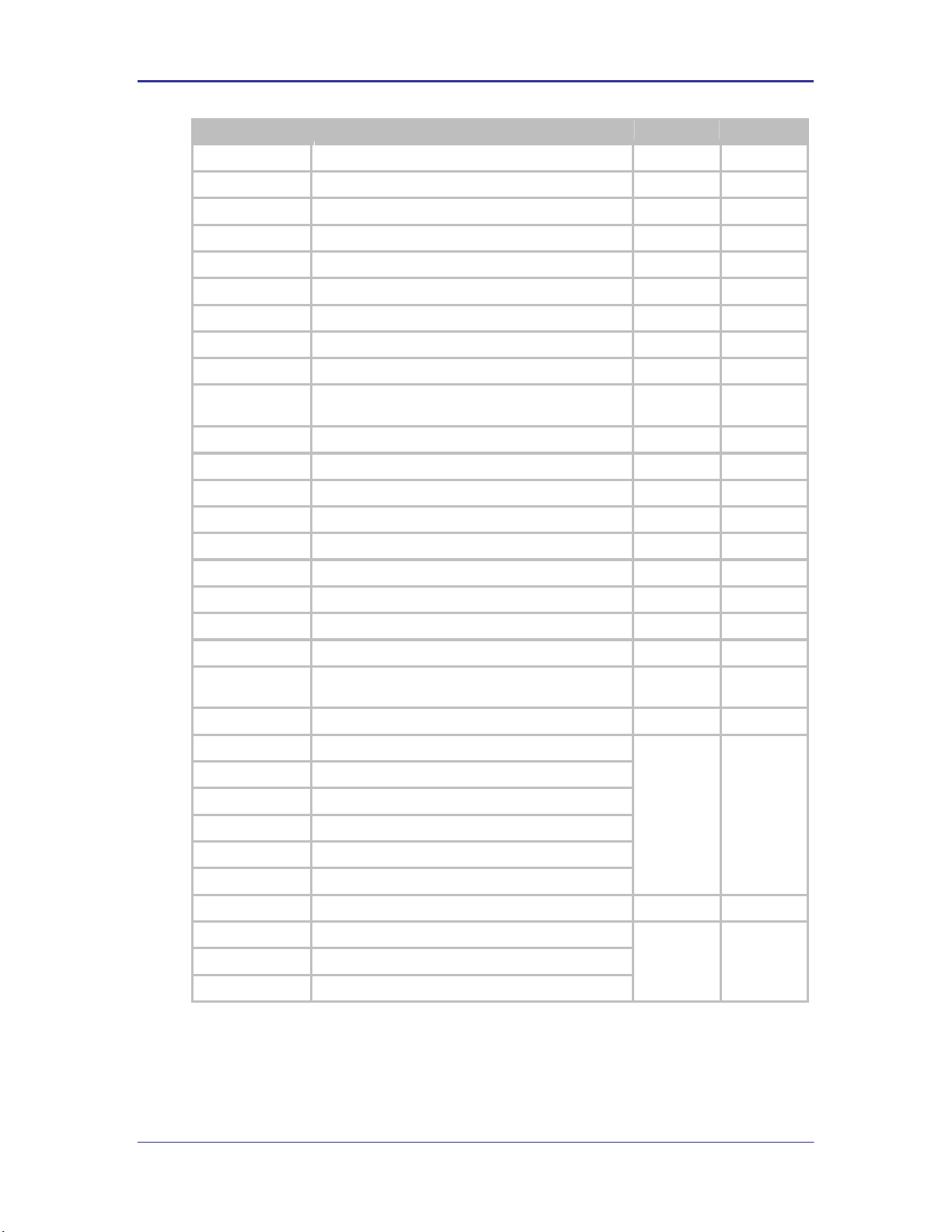

Designator

Description

Ref

Page

ANT1

Antenna connector

5.1

14

ANT2

Antenna connector

5.2

14

BT1

Battery holder

5.3

14

CN1

Primary UART Port connector (DE-9 Male)

5.4

15

CN2

Secondary UART Port connector (DE-9 Male)

5.5

15

CN3

Ethernet PHY connector (Header)

5.6

15

CN4

Ethernet RJ45 Socket (with Magnetics)

5.7

16

CN5

Debug Port connector (DE-9 Female)

5.8

17

CN6

JTAG connector (Header)

5.9

17

CN7

Primary SPI connector (Header)

5.10

18

D2

Power status indicator

5.11

19

D3

Battery Low indicator

5.12

19

4.0 Evaluation Board Layout

FIGURE 1 - E VAL UAT ION BOARD L AYOUT

TABLE 2 - SU MMARY DESC RIP TION OF EVALUATION BO ARD

Page 13

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

13

Designator

Description

Ref

Page

D18

Radio association status indicator

5.13

19

J1

Power Connector (Barrel Jack)

5.14

19

J2

Primary UART port pin out configuration

5.15

20

J3

Primary UART port Transceiver enable

5.16

22

J4

Primary UART indicator LED header

5.17

23

J5

Secondary UART pin out configuration

5.18

24

J6

Secondary UART port Transceiver enable

5.19

26

J7

Secondary UART indicator LED header

5.20

27

J8

Ethernet termination

5.21

27

J9

Airborne Device Server Module status indicator LED

header

5.22 28

J10

GPIO indicator LED header

5.23

29

J11

Ethernet indicator LED’s

5.24

29

JP1

Power Source Selector

5.25

31

LED1

Primary UART port indicator LED’s

5.26

31

LED2

Secondary UART port indicator LED’s

5.27

31

LED3

Airborne Device Server Module status indicator LED’s

5.28

31

LED4

GPIO indicator LED’s

5.29

32

SW1

Evaluation board power switch

5.30

32

SW2

Evaluation board restart/reboot push button switch

5.31

32

SW3

Evaluation board factory default reset push button

switch

5.32 33

SW4

SPDT Switch

5.33

33

TP1

Input voltage

5.34

34

TP2

3.3VDC

TP3

GND

TP4

GND

TP5

GND

TP6

GND

TP7

Breadboard area

5.35

34

TP8

Common for SW4

5.36

36

TP9

L1 for SW4

TP10

L2 for SW4

Page 14

B&B Electronics

14

Airborne Enterprise WLNN EVB Users Guide

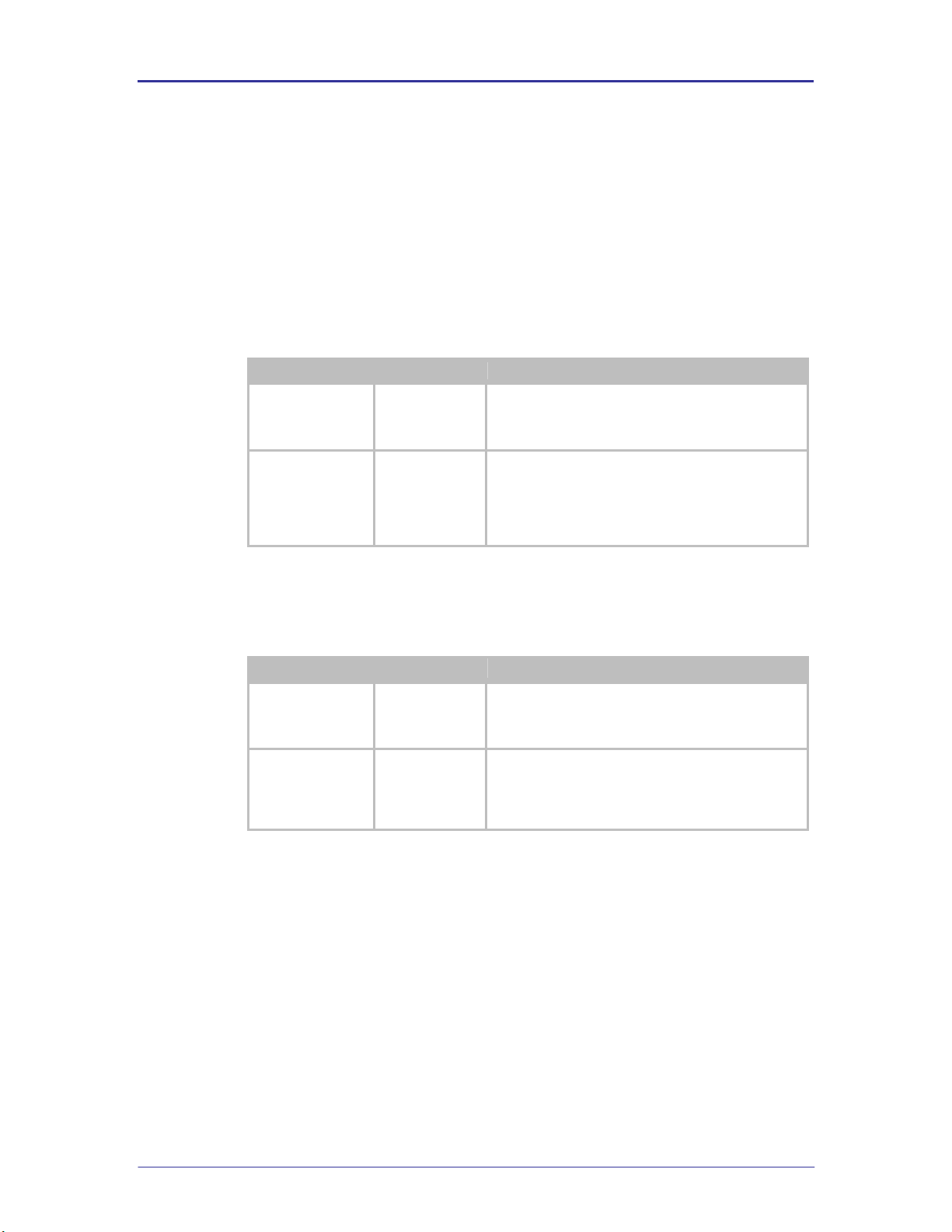

Designator

Connector

Description

CN9

RP-SMA

Antenna connection requires antenna with RP-SMA

connector.

Impedance: 50Ω

CN10

U.FL

Coaxial connector to Airborne Device Server antenna

connector. Requires U.FL to U.FL coaxial cable

(included in kit). Must be connected to either J1 or J2

of Device Server Module.

Impedance: 50Ω

Designator

Connector

Description

CN11

RP-SMA

Antenna connection requires antenna with RP-SMA

connector.

Impedance: 50Ω

CN12

U.FL

Coaxial connector to Airborne Device Server antenna

connector. Requires U.FL to U.FL coaxial cable

(included in kit). Must be connected to either J1 or J2.

Impedance: 50Ω

5.0 Feature Description

The following section provides detailed descriptions of the various connections, switches

and indicators provided by the Airborne Evaluation Board.

5.1 ANT1

This is one of two antenna connections available on the Evaluation board.

TABLE 3 - ANT1 CONNECT ORS

5.2 ANT2

This is one of two antenna connections available on the Evaluation board.

TABLE 4 - ANT2 CONNECT ORS

5.3 BT1

This section allows four (4) 1.5VDC Type AA cells to be installed and used to

power the evaluation kit for roaming and mobile tests.

To select the batteries as the Power Source use the correct setting for JP1.

A Low Battery status indicator is provided by D2.

Page 15

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

15

Designator

Connector

Description

CN1

DE-9 Male

Requires a DE-9 female connector. Depending upon

the configuration of J1 the following cable type should

be used:

DTE (Default): Straight through

DCE: Null Modem

Designator

Connector

Description

CN2

DE-9 Male

Requires a DE-9 Female connector. Depending upon

the configuration of J5 the following cable type should

be used:

DTE (Default): Straight through

DCE: Null Modem

5.4 CN1

This is the primary UART port and should be used for serial communication with

the card during initial evaluation. The pin out for the connector is managed by the

configuration of J2; it can support the following modes:

RS232 DTE

RS232 DCE

RS422/485 4-wire

RS422/485 2-wire

TABLE 5 - PR IMARY UART CO NNECTOR

5.5 CN2

This is the secondary UART port. This port can only be used if enabled via

firmware.

The pin out for the connector is managed by the configuration of J5; it can

support the following modes:

RS232 DTE

RS232 DCE

RS422/485 4-wire

RS422/485 2-wire

TABLE 6 - PR IMARY UART CO NNECTOR

5.6 CN3

This header provides direct connections to the Airborne Device Server module

Ethernet connections. The output of this header is provided by the embedded

Ethernet PHY built in to the Airborne Device Server module. Please refer to the

WLNN DP500 data book for details of this output.

This header allow for the implementation of external magnetic or a capacitive

coupled circuit between the Evaluation board and a test system. The pin out for

the header can be seen in Table 7.

Page 16

B&B Electronics

16

Airborne Enterprise WLNN EVB Users Guide

Designator

Pin

Description

CN3

1

TxD+

2

TxD- 3 RxD+

4

RxD-

Designator

Pin

Description

CN4

1

TxD+

2

TxD-

3

RxD+

4

NC 5 NC 6 RxD- 7 NC

8

NC

Green LED

Valid TCP/IP connection made with Airborne Device

Server:

Off No TCP/IP connection

On Valid TCP/IP Connection

Yellow LED

Power-on Self Test (POST):

Off Not powered or has failed POST

On Passed POST

TABLE 7 - ETHER NET PHY HE ADER PIN OUT

A detailed description of the Ethernet circuit on the Evaluation board can be

found in section 11.0.

5.7 CN4

This connector is a 10/100 Ethernet RJ45 Jack with integrated magnetic. The pin

out is shown in Figure 2. It supports two integrated indicator LED’s, the conditions

for these indicators can be seen in Table 8.

FIGURE 2 - ETHE RNE T JA CK PIN OUT

TABLE 8 - ETHER NET CONNEC TOR PIN OUT

Page 17

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

17

Designator

Connector

Description

CN5

DE-9 Female

Requires a DE-9 Male connector. To connect to a

laptop or desktop serial port a straight thru cable is

required (included in kit).

Designator

Pin

Description

CN5

1

No Connect

2

D

OUT

3

D

IN

4

No Connect

5

GND

6

No Connect

7

No Connect

8

No Connect

9

No Connect

Designator

Pin

Description

CN6

1

3.3VDC

2

3.3VDC

3

NTRST: Test RESET

4

GND

5.8 CN5

This connector provides access to the serial debug port available on the Airborne

Serial Device Server module. The debug/console port is supported by a 2-wire

serial interface defined in Table 10. This port is a bidirectional serial port intended

for debug of the unit only; it does not support data transfer.

TABLE 9 - DE BUG PO RT CONN ECTOR

TABLE 10 - DE BUG PO RT PIN OUT

5.9 CN6

This header provides connectivity to the JTAG interface available on the Airborne

Device Server Module. The pin out for the header can be seen in Figure 3 and

Table 11.

FIGURE 3 - J TAG HEADER

The default settings for the debug port are 115200, 8, N 1, No Flow Control.

TABLE 11 - JT AG HEADER PIN OUT

Page 18

B&B Electronics

18

Airborne Enterprise WLNN EVB Users Guide

Designator

Pin

Description

5

TDI: Test Data In

6

GND 7 TMS: Test Mode Select

8

GND

9

TCK: Test Clock

10

GND

11

RTCK: Return Test Clock

12

GND

13

TDO: Test Data Out

14

GND

15

/RESET (Active Low)

16

GND

17

No Connect

18

GND

19

No Connect

20

GND

Designator

Pin

Description

CN7

1

No Connect

2

GND

Use of this header requires that JTAG has been enabled on the Airborne Device Server

Module. Production devices do not support this feature.

To enable JTAG a hardware change to the module must be made, please contact

B&B Electronics Technical Support if this feature is required.

5.10 CN7 / CN13

Header CN7 is the primary SPI interface header; firmware selection of the SPI

interface is required before the interface can be used. CN13 allows a secondary

connection to the SPI interface. CN7 and CN13 have common connections.

The header pin out can be seen in Figure 4 and Table 12.

FIGURE 4 - S PI HEADER

TABLE 12 - SP I H EADER P IN OUT

Page 19

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

19

Designator

Pin

Description

3

No Connect

4

No Connect

5

MISO: D

OUT

6

No Connect

7

SPI_CLK: SPI Clock

8

MOSI: D

IN

9

SPI_SEL: SPI Select

10

GND

Designator

Status

Description

D2

ON

Power supply is 3.3VDC or less

OFF

Power supply is above minimum voltage

Designator

Status

Description

D3

ON

Power supplied to the card, SW1 on ON position

OFF

No power supplied to the card, SW1 on OFF position

Designator

Status

Description

D18

OFF

No valid Power to the module

BLINKING

Searching for valid SSID

ON

Associated with valid SSID

5.11 D2

This is a red indicator LED that provides feedback on the voltage level of the

power supply. This indicator will light when a low voltage state is detected.

TABLE 13 - LO W V OLTAGE LED INDI CAT OR

5.12 D3

This is a green indicator LED that provides feedback on the power status of the

Evaluation board.

TABLE 14 - POWER STATUS LED I NDICA TOR

5.13 D18

This indicator LED provides feedback on the association status of the radio. The

indicator is provided by the RF_ACT output of the Airborne Device Server

module.

TABLE 15 - RF ACTIVITY LED INDICATOR

5.14 J1

This is the main power jack for the Evaluation board. It requires a 5VDC/1.0A

minimum supply (supplied with kit).

Page 20

B&B Electronics

20

Airborne Enterprise WLNN EVB Users Guide

Designator

Connector

Description

J1

2.1mm Barrel

Jack

5.0VDC +/-10%, 1.00A minimum.

Designator

Configuration

Header

Pin Out

J2

RS232 DTE

(Default)

1

No Connect

2

RxD

3

TxD 4 No Connect

5

GND 6 No Connect

7

RTS 8 CTS

9

No Connect

TABLE 16 - POWER SUP PLY JACK

5.15 J2

This header configures the Primary UART port connector (CN1), selection of the

headers allows the connector pin-out to be changed to support one of the

following configurations:

RS232 DTE

RS232 DCE

RS422/485 4-wire

RS422/485 2-wire

For each of the configurations please note there is a pin out change and it may

be necessary to alter the cable being used for connection to the serial host. The

different configurations of jumpers and pin outs can be seen in Table 17.

It is not possible to independently select the transceiver type for each UART port

(CN1 and CN2) consequently both ports must be the same type (RS232 or

RS422/485).

FIGURE 5 - DE-9 CONNE CTOR PI N -OUT

TABLE 17 - PR IMARY U ART PIN -OUT HE ADER CO NFI GURA TION

Page 21

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

21

Designator

Configuration

Header

Pin Out

RS232 DCE

1

No Connect

2

TxD

3

RxD 4 No Connect

5

GND 6 No Connect

7

CTS 8 RTS

9

No Connect

RS422/485 2-Wire

1

No Connect

2

No Connect

3

TxD+

4

No Connect

5

GND 6 No Connect

7

No Connect

8

No Connect

9

TxD-

RS422/485 4-Wire

1

No Connect

2

RxD+

3

TxD+

4

No Connect

5

GND 6 RxD- 7 No Connect

8

No Connect

9

TxD-

Designator

Pin

Description

J2

1

RxD+

2

TxD+

3

CN1 Pin 2

FIGURE 6 - P RIMARY UART H EADE R

TABLE 18 - PR IMARY UART HEADE R PIN -OUT

Page 22

B&B Electronics

22

Airborne Enterprise WLNN EVB Users Guide

Designator

Pin

Description

4

RxD

5

TxD 6 CN1 Pin 3

7

TxD-

8

TxD+

9

CN1 Pin 9

10

CN1 Pin 6

11

TxD-

12

RxD-

13

CN1 Pin 8

14

CTS

15

RTS

16

CN1 Pin 7

Designator

Description

Configuration

J3

RS232

RS422/485

Software Select

Designator

Pin

Description

J3

1

RS422/485 Rx Enable (Active Low)

2

RXEN

3

GND

4

RS232 Rx Enable (Active Low) with 10KΩ Pull-up

5

3.3VDC

5.16 J3

This header correctly enables the primary UART transceivers for the interface

type selected by the configuration of J2. The available options are shown in

Table 19.

TABLE 19 - PR IMARY UART TRANSCEIVE R CONF IGUR ATIO N

FIGURE 7 - P RIMARY UART T RANSCEIV ER HEADER

TABLE 20 - PR IMARY UART TRANSCEIVE R HEADE R PIN-O UT

Page 23

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

23

Designator

Pin

Description

6

SER_MODE

7

RS422/485 Tx Enable (Active High)

8

/TXEN (Active Low)

Designator

Pin

Description

J4

1

RxD (EVB Signal Driver), D4 (Red LED)

2

RxD (Airborne Device Server Module)

3

TxD (EVB Signal Driver), D5 (Red LED)

4

TxD (Airborne Device Server Module)

5

CTS (EVB Signal Driver), D6 (Yellow LED)

6

CTS (Airborne Device Server Module)

7

RTS (EVB Signal Driver), D7 (Green LED)

8

RTS (Airborne Device Server Module)

Signal RXEN (Pin 2), SER_MODE (Pin 6) and /TXEN (Pin 8) are sourced from the

Airborne Device Server module, please refer to the WLNN DP500 data book for a

description of these signal.

5.17 J4

This header provides access to the Primary UART LED status indicators.

The default has all LED’s connected.

FIGURE 8 - P RIM ARY UART L ED I NDIC ATOR HE ADE R

TABLE 21 - PR IMARY U ART LED IND ICATOR HEA DER PIN -OUT

Removing the jumpers from this header will disconnect the signals to the Primary UART

connector CN1.

Signals on Pins 1, 3, 5 and 7 are sourced directly from the Airborne Device Server

module and are not buffered or driven by the Evaluation board.

Page 24

B&B Electronics

24

Airborne Enterprise WLNN EVB Users Guide

Designator

Configuration

Header

Pin Out

J5

RS232 DTE

(Default)

1

No Connect

2

RxD 3 TxD 4 No Connect

5

GND 6 No Connect

7

RTS

8

CTS 9 No Connect

RS232 DCE

1

No Connect

2

TxD 3 RxD 4 No Connect

5

GND

6

No Connect

7

CTS

5.18 J5

This header configures the Secondary UART port connector (CN2), selection of

the headers allows the connector pin-out to be changed to support one of the

following configurations:

RS232 DTE

RS232 DCE

RS422/485 4-wire

RS422/485 2-wire

For each of the configurations please note there is a pin out change and it may

be necessary to alter the cable being used for connection to the serial host. The

different configurations of jumpers and pin outs can be seen in Table 22.

It is not possible to independently select the transceiver type for each UART port

(CN1 and CN2) consequently both ports must be the same type (RS232 or

RS422/485).

FIGURE 9 - DE-9 CONNE CTOR PI N -OUT

TABLE 22 - SE CON DARY UART PIN-OUT HEADER CONFIG U RATION

Page 25

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

25

Designator

Configuration

Header

Pin Out

8

RTS

9

No Connect

RS422/485 2-Wire

1

No Connect

2

No Connect

3

TxD+

4

No Connect

5

GND 6 No Connect

7

No Connect

8

No Connect

9

TxD-

RS422/485 4-Wire

1

No Connect

2

RxD+

3

TxD+

4

No Connect

5

GND

6

RxD- 7 No Connect

8

No Connect

9

TxD-

Designator

Pi

n

Description

J2

1

RxD+

2

TxD+

3

CN1 Pin 2

4

RxD 5 TxD

6

CN1 Pin 3

7

TxD-

8

TxD+

9

CN1 Pin 9

FIGURE 10 - SE CONDARY UA RT HEAD E R

TABLE 23 - PR IMARY UART HEADE R PIN -OUT

Page 26

B&B Electronics

26

Airborne Enterprise WLNN EVB Users Guide

Designator

Pi

n

Description

10

CN1 Pin 6

11

TxD-

12

RxD-

13

CN1 Pin 8

14

CTS

15

RTS

16

CN1 Pin 7

Designator

Description

Configuration

J6

RS232

RS422/485

Software Select

Designator

Pin

Description

J6

1

RS422/485 Rx Enable (Active Low)

2

RXEN

3

GND 4 RS232 Rx Enable (Active Low) with 10KΩ Pull-up

5

3.3VDC

6

SER_MODE

7

RS422/485 Tx Enable (Active High)

8

/TXEN (Active Low)

5.19 J6

This header correctly enables the Secondary UART transceivers for the interface

type selected by the configuration of J5. The available options are shown in Table

25.

TABLE 24 - SE CON DARY UART T RANSCEI VER CONFIG URATION

FIGURE 11 - SE CONDARY UA RT T RAN S CEIVER HEA DER

TABLE 25 - SE CON DARY UART T RANSCEI VER HEA DER PIN -OUT

Page 27

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

27

Designator

Pin

Description

J4

1

RxD (EVB Signal Driver), D4 (Red LED)

2

RxD (Airborne Device Server Module)

3

TxD (EVB Signal Driver), D5 (Red LED)

4

TxD (Airborne Device Server Module)

5

CTS (EVB Signal Driver), D6 (Yellow LED)

6

CTS (Airborne Device Server Module)

7

RTS (EVB Signal Driver), D7 (Green LED)

8

RTS (Airborne Device Server Module)

Signal RXEN (Pin 2), SER_MODE (Pin 6) and /TXEN (Pin 8) are sourced from the

Airborne Device Server module, please refer to the WLNN DP500 data book for a

description of these signal.

5.20 J7

This header provides access to the Secondary UART LED status indicators.

The default has all LED’s connected.

FIGURE 12 - SE CONDARY UA RT L ED I NDI C ATO R HEADER

TABLE 26 - SE CON DARY UART L ED I NDI CATOR HEAD ER PIN-O UT

Removing the jumpers from this header will disconnect the signals to the Secondary

UART connector CN2.

Signals on Pins 1, 3, 5 and 7 are sourced directly from the Airborne Device Server

module and are not buffered or driven by the Evaluation board.

5.21 J8

This header controls the access to the Ethernet interface. The options available

for this header can be seen in Table 27.

Page 28

B&B Electronics

28

Airborne Enterprise WLNN EVB Users Guide

Designator Descripti

on

Configuration

J8 Ethernet Jack (Default)

CN3 Header

Designator

Pin

Description

J8

1

CN3 Pin 3

2

CN3 Pin 1

3

RxD+ (Airborne Device Server)

4

TxD+ (Airborne Device Server)

5

RxD+ (CN4)

6

TxD+ (CN4)

7

CN3 Pin 4

8

CN3 Pin 2

9

RxD- (Airborne Device Server)

10

TxD- (Airborne Device Server)

11

RxD- (CN4)

12

TxD- (CN4)

TABLE 27 - ETHER NET HEA DER CO NFIGURATION

This header provides direct connections to the Airborne Device Server module

Ethernet connections. The output of this header is provided by the embedded

Ethernet PHY built in to the Airborne Device Server module. Please refer to the

WLNN DP500 data book for details of this output.

TABLE 28 - ETHER NET HEA DER PIN - OUT

5.22 J9

This header provides access to the status indicators generated by the Airborne

Device Server module. The header provides a connection to the on board LED’s

in the LED3 section 5.28.

The default has all LEDs connected.

FIGURE 13 – AI RBO RNE DEVICE SER VER MODULE STATUS IND I CATOR HEAD ER

Page 29

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

29

Designator

Pin

Description

J9

1

D12 (POST LED)

2

LED_POST (Airborne Device Server Module)

3

D13 (RF_LINK LED)

4

LED_RF_LINK (Airborne Device Server Module)

5

D14 (WLN_CFG LED)

6

LED_CFG_WLN (Airborne Device Server Module)

7

D15 (CONN LED)

8

LED_CON (Airborne Device Server Module)

Designator Descripti

on

Configuration

J10

LED’s Connected

LED’s Disconnected

Designator

Pin

Description

J10

1

D16 (Yellow)

2

Port G0 (Airborne Device Server Pin 22)

3

D17 (Yellow)

4

Port G1 (Airborne Device Server Pin 19)

TABLE 29 - AI RBO RNE DEV ICE SERVER MODULE STATUS IND I CAT OR HEAD ER PIN-OUT

Signals on Pins 2, 4, 6 and 8 are sourced directly from the Airborne Device Server

module and are not buffered or driven by the Evaluation board.

5.23 J10

This header allows GPIO pins sourced from the Airborne Device Server module

to be connected to LED’s on the Evaluation board. These indicators can be used

to demonstrate control of the G0 and G1 ports via the CLI or web interface.

FIGURE 14 - GP IO LED HEA DER

5.24 J11

TABLE 30 - GPIO LED HEA DER CON F IGURATION

TABLE 31 - GPIO LED HEA DER PIN - OUT

This header connects the Airborne Device Server module sources indicator

signals to the Ethernet jack. A description of the signals can be seen in section

5.7.

Page 30

B&B Electronics

30

Airborne Enterprise WLNN EVB Users Guide

Designator Descripti

on

Configuration

J11

LED’s Connected (Default)

LED’s Disconnected

Designator

Pin

Description

J11

1

CN4 (Green LED)

2

LED_CON (Airborne Device Server Pin 23)

3

CN4 (Yellow LED)

4

Port F0 (Airborne Device Server Pin 25)

Designator Descripti

on

Configuration

JP1

External power Supply.

This selects J1 (5.14) as the source for

power.

Battery power.

This selects BT1 (5.3) as the source for

power.

Group

Pin

Description

JP1

1

J1 external 2.1mm Barrel jack.

2

EVB Power Supply Input

3

BT1 4 x AA cell holder

FIGURE 15 – ET HERNET INDICATOR LED HEADER

TABLE 32 – ET HERNET IND ICATOR L ED HEADER CONFIGU RAT IO N

TABLE 33 – ET HERNET INDICATOR LED HEADER PIN-OUT

5.25 JP1

This jumper provides the ability to select the power source for the Evaluation

Board. The options can be seen in Table 34.

FIGURE 16 - JP 1 PI N-O UT

TABLE 34 - POWER SOU RCE SEL ECT O R

TABLE 35 - JP 1 P OWER SE LECTOR P IN-OUT

Page 31

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

31

Group

Designator

Description

LED1

D7

Ready to Send (RTS), Green LED

D6

Clear-to-Send (CTS), Yellow LED

D5

Transmit Data (TxD), Red LED

D4

Receive Data (RxD), Red LED

Group

Designator

Description

LED2

D11

Ready to Send (RTS), Green LED

D10

Clear-to-Send (CTS), Yellow LED

D9

Transmit Data (TxD), Red LED

D8

Receive Data (RxD), Red LED

Group

Designator

Name

Description (w/ Power Applied)

LED3

D15

CONN

(Green)

OFF

No TCP/IP connection established

ON

TCP/IP connection established with Device

Server

D14

WLN_CFG

(Yellow)

OFF

The Device Server is not correctly

configured for network communication

(i.e. it does not have a valid IP

address/subnet mask)

ON

The Device Server is correctly configured

for network communication (i.e. it has a

valid IP address/subnet mask)

D13

RF_LINK

(Green)

OFF

Device Server has not authenticated with

a wireless network

ON

Device Server has successfully

authenticated with a wireless network

5.26 LED1

This is a group of LED’s that indicate Primary UART’s state of operation. A

description of the LED’s can be seen in Table 36. These LED’s are connected via

J4 (section 5.17), please refer to this section for more details.

TABLE 36 - PR IMARY UART IN DICATOR LED 'S

5.27 LED2

This is a group of LED’s that indicate Secondary UART’s state of operation. A

description of the LED’s can be seen in Table 37. These LED’s are connected via

J7 (section 5.20), please refer to this section for more details.

TABLE 37 - SE CON DARY UA RT INDIC ATO R L ED'S

5.28 LED3

This is a group of LED’s that indicate the state of the Airborne Device Server

module. A description of the LED’s can be seen in Table 38. These LED’s are

connected via J9 (section 5.22), please refer to this section for more details.

TABLE 38 – AI RBORNE DEV ICE SER V ER MODULE INDICATOR L ED’S

Page 32

B&B Electronics

32

Airborne Enterprise WLNN EVB Users Guide

Group

Designator

Name

Description (w/ Power Applied)

D12

POST

(Yellow)

OFF

Passed Power-on-Self-Test

ON

Failed Power-on-Self-Test

Group

Designator

Description

LED4

D17

G1 (Yellow LED)

D16

G0 (Yellow LED)

A more detailed description of these status indicators can be seen in section

13.0.

5.29 LED4

This group of LED’s is available for use. They can be connected to and driven by

GPIO G0 and G1, via the CLI of the Airborne Device Server module. It is possible

to demonstrate I/O control using this combination.

They can be connected to the GO and G1 ports via J10 (section 5.23). Please

refer to this section for more details.

TABLE 39 - LED4 DESCRIP TION

5.30 SW1

This is the main power switch for the evaluation board. A valid power supply

(included with kit) must be connected to J1 and JP1 must be configured for an

external power supply (default set-up) or BT1 must have a valid set of cells and

JP1 must be configured for Batteries before the switch is enabled.

If a valid power source is attached, D3 (section 5.12) will light. This will indicate

the start of the Airborne Device Server boot cycle. The cycle may take several

seconds; please allow enough time to complete the boot cycle before resetting

the switch.

When the Airborne Device Server boot successfully you will see the POST

(section 5.28) and RF_ACT LED (section 5.28) indicators light.

FIGURE 17 - SW 1 SET-UP

5.31 SW2

This push button switch restarts or reboots the Airborne Device Server module. If

pressed for more than 100ms the module will initiate an internal power-on restart

cycle. This switch is connected to pin 7 (/RESET) pin of the module; please refer

to the WLNN DP500 Data-book for more details.

The /RESET behavior is not the same as a Power-on-restart; please refer to the

WLNN DP500 Data-book for details.

Page 33

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

33

FIGURE 18 - SW 2 RESET CIRCUIT

5.32 SW3

This push button switch allows the user to reset the Airborne Device Server

module settings back to OEM default. The button cannot reset settings by itself; it

requires either a power cycle or restart.

To reset the module configuration back to OEM defaults SW3 must be pushed

and held while the restart or power cycle is initiated. It is required that SW3 be

held for approximately 3 seconds after the restart or power cycle has been

initiated, it can then be released. The module will then continue the boot cycle

and the OEM parameter values will be reinstalled.

FIGURE 19 - OE M RESET CI RCUIT

Doing an OEM reset will reset all parameters back to OEM default values; this may

place the module in a state that will not allow the user to communicate with it.

IMPORTANT: Confirm that the OEM settings installed on the module will allow the

user to communicate with the module after the reset has been completed.

5.33 SW4

This is an additional SPDT switch that may be used in conjunction with the test

points (TP7, 8, 9, 10) to demonstrate functionality provided by the Airborne

Device Server module.

FIGURE 20 - SW 4 CO NFI GURATION

Page 34

B&B Electronics

34

Airborne Enterprise WLNN EVB Users Guide

Group

Designator

Description

Test Point

TP1

Input Voltage: This test point provides access to the

input voltage on J1.

TP2

3.3VDC: This test point provides access to the

regulated power supply output.

TP3

GND

TP4

GND

TP5

GND

TP6

GND

5.34 TP1 – 6

Included on the Evaluation board is a number of test points; these are available

for use by the user when evaluating or developing with the evaluation board. The

set of test points provide measurement or sourcing points for the various power

and ground options available on the board; Table 40 indicates the test point

function.

TABLE 40 - TP1-6 CON FIG URAT ION

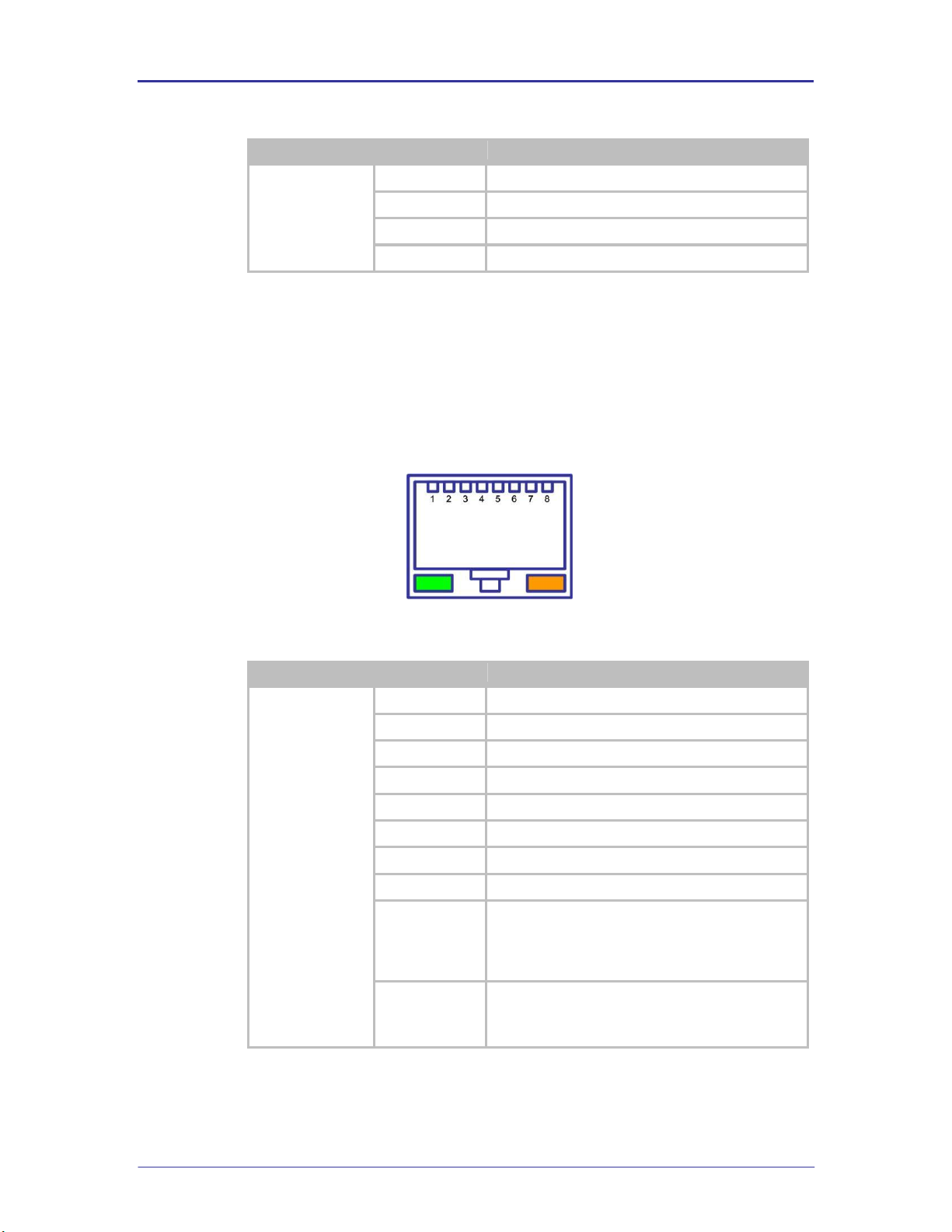

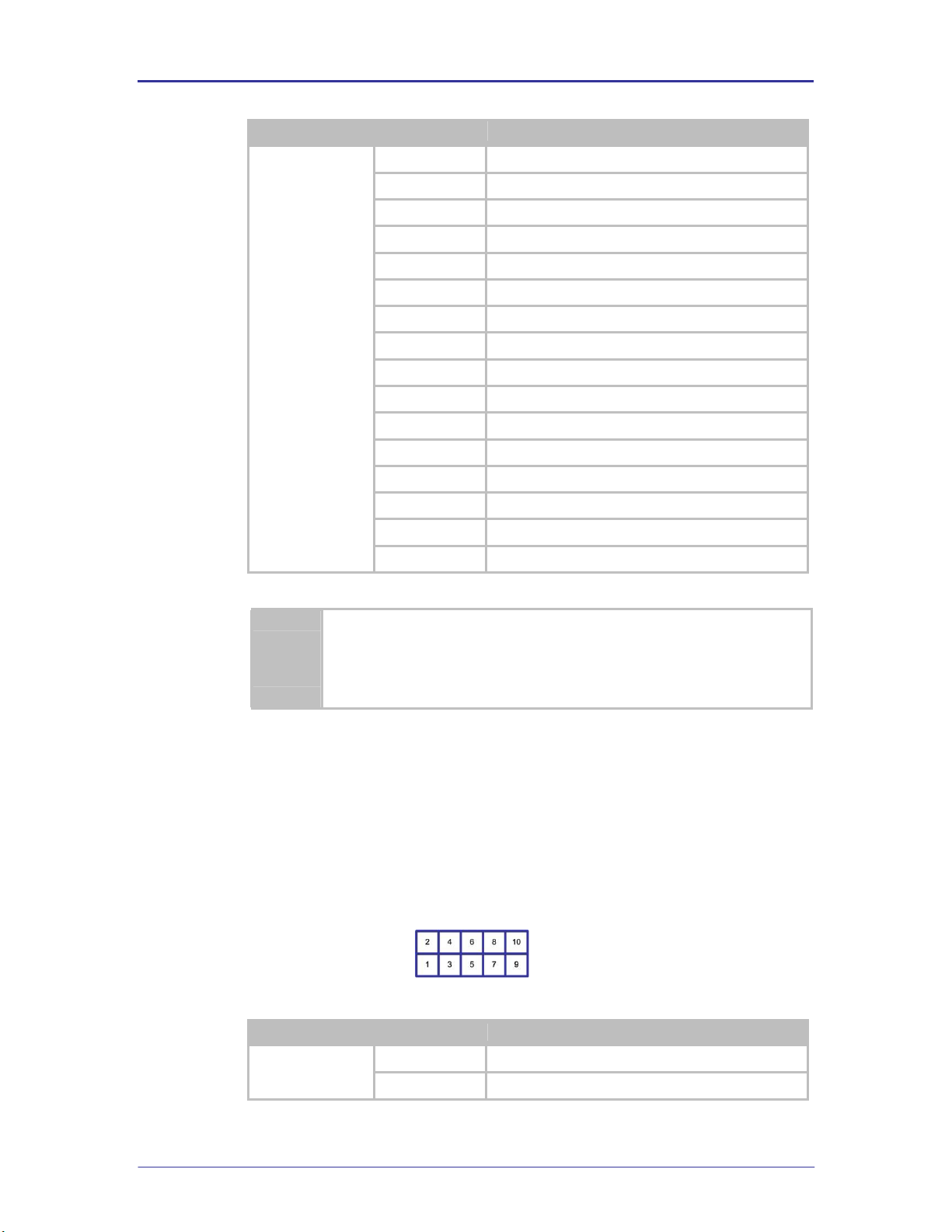

5.35 TP7

This section of the Evaluation board provides space for development of prototype

application hardware directly on the board. The matrix provides access to the full

interface of the Airborne Device Server module as well as an ample supply of

power and ground signals.

Since the signal definition could change depending upon the type of module

being used (UART, Serial, SPI, Ethernet) details of the signals and their

characteristics can be found in the WLNN DP500 Data book. A translation of

prototype area (TP7) designator to WLNN pin out can be seen in Table 41.

FIGURE 21 - TP7 LAYOUT

Page 35

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

35

TP7 Designator

WLNN Pin

+3.3V

3, 4, 33, 34

VIN

CGND

GND

1, 15, 16, 36

G7

21

G6 9 G2

17

G1

19

F1

28

F7

24

F4

18

F5

12

G0

22

DTXD

6

DRXD

8

/FRESET

11

/RESET

7

NTRESET

31

TDO

10

TDI 2 TCK

20

RTCK

5

TMS

32

TX+

30

TX-

29

RX+

13

RX-

14

F0

25

F2

27

F3

26

F6

23

/RF_ACT

35

TABLE 41 - TP7 LABEL TO WL NN P I N-O UT T ABL E

Page 36

B&B Electronics

36

Airborne Enterprise WLNN EVB Users Guide

5.36 TP8 - 10

These test points have bee n made available for prototyping using the Evaluation

board; they are connected to SW4 (section 5.33). Please refer to this section for

detail.

6.0 A Typical Development System

It is necessary to have additional equipment to get the most out of the Airborne™

Evaluation board and fully experience the power of the Airborne™ Device Server module.

A typical evaluation system includes:

A host computer that communicates with the Airborne Device Server module, the

interface options are:

WLNN-EK-DP501 via the EVB RS-232 interface (PORT 1, CN1)

WLNN-EK-DP502 via the EVB SPI interface (CN7)

WLNN-EK-DP503 via the EVB RJ-45 interface (ETHERNET, CN4)

A host computer that communicates with the Airborne Device Server module via

the network interface.

An IEEE-compliant 802.11b/g/n or 802.11a/n AP (or a Wireless Router) for

A DHCP server (this may be resident in the Wireless Router).

which you know the association and authentication settings.

A terminal emulation program like HyperTerminal, PuTTy or TerraTerm

Page 37

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

37

7.0 Getting Started

7.1 Unpack the Airborne™ Module EVB Kit

Unpack the Airborne Device Server Module EVB and compare the package

contents with the items listed on the front of this User Guide. If any item is

missing or damaged, contact B&B Electronics immediately.

7.2 Attach Antenna and Power-up the EVB

7.3 Install Serial to USB Adapter (Optional)

7.4 Connection to SPI Host

The Evaluation kit contains the following items:

One Airborne™ Device Server Module Evaluation Circuit Board

Assembly (EVB)

One WLNN-XX-DP501 module (mounted on the EVB)

Two monopole Antennas (2dBi RP-SMA)

One AC adapter (5VDC/500mA)

One DB9-to-DB9 serial cable (Null Modem)

USB to serial Adapter (SSU2-100)

One CD containing drivers, evaluation software, PDF documents, and

Adobe® Acrobat® Reader® for viewing the documents

Contact details can be found at http://www.bb-elec.com/Tech-Support.aspx

Attach the supplied antenna to connector CN11 on the EVB. Connect the

supplied AC adapter to the power (J1) connector on the Airborne EVB. Confirm

that the EVB is receiving power by verifying that the Power LED (D3) is lit when

POWER (SW1) is in the ON position.

If your host computer does not have a RS232 port the Evaluation Kit includes a

USB to Serial adapter (SSU2-100). This adapter provides the ability to connect

using a virtual serial port on the host to the EVB. Please refer to the enclosed CD

and documentation for the installation of the adapter.

To connect and communicate with the EVB it will be necessary for an SPI based

host to comply with the SPI host interface specification outlined in the WLNN

DP500 Databook, please refer to this document before connecting an SPI host.

Page 38

B&B Electronics

38

Airborne Enterprise WLNN EVB Users Guide

CLI Command

Description

auth dpac dpac <CR>

The module responds with OK, indicating that it

executed the command successfully. (If you did not

receive OK, check the settings in your terminal

emulation program.

8.0 Serial Device Server Connection

If you have purchased the WLNN-EK-DP501 or WLNN-EK-DP502 kit please use the

following instructions for connecting to and evaluating the Airborne Serial Device Server.

The following describes initial connection to an Airborne Device Server module loaded

with UART (WLNN-AN-DP501) firmware; if you have a module loaded with Ethernet

(WLNN-ER-DP501) firmware, please skip to section 9.0.

8.1 Connect a Host Computer

Use the supplied serial cable or USB adapter (see USB-to-Serial Adapter User’s

Manual for USB adapter installation) to connect the DB9 serial port (CN1)

connector on the Airborne EVB to the Host computer. On the Host

start

a terminal emulation program such as HyperTerminal. Configure

program

for 9600 baud, 8 data bits, no parity, and no flow control. For COM Port,

select the COM port that corresponds to the host’s physical serial port connected

to the EVB (or in the case of the USB adapter, the virtual COM port created

the

adapter software).

If supplying your own cable when connecting to the Evaluation Kit please confirm it

supports the default configuration (female DE-9, DCE) for connection to the

Evaluation kit.

If you are unable to connect to the kit please refer to sections 5.4, 5.15 and 5.16 for

details on the Evaluation kit CN1 requirements.

8.2 Interacting with the Airborne™ Module

On the Host computer, use the terminal emulation program to interact with the

module by issuing Command Line Interface (CLI) commands. CLI commands let

you request status or change parameter settings. Press the Enter key (<CR>)

after each command line you type. After the module starts, type the following CLI

command to log in (you must log in before CLI commands can be recognized):

TABLE 42 - UA RT AUTHENT ICATION

computer,

the

by

You will have to log into the module after any reset or restart.

Page 39

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

39

CLI Command

Description

wl-scan<CR>

The module scans for APs and returns information on

each one it discovers. Note the SSID value that is

returned, as you will need to enter it in the next

command

wl-ssid [SSID]<CR>

Associates the module with the AP whose [SSID] you

specify. [SSID] is the value returned by the wl-scan

command.

commit<CR>

Stores the information to flash memory.

CLI Command

Description

auth dpac dpac <CR>

Authenticate with the device server.

wl-ip<CR>

The module returns the IP address assigned to it by

the DHCP server.

8.3 Determine and Store the Access Point SSID

On the Host computer, use the terminal emulation program to type the following

CLI commands in the order shown:

TABLE 43 - UA RT SSID & AUT HENTI CAT ION

If your acc ess point has security enabled, you will also need to use the CLI to

enter those parameters (See the Enterprise CLI Reference Guide for details).

That setup is outside the scope of this user guide, which assumes that the AP

being tested with has no security.

After issuing the commands, press the reset switch (SW2) on the EVB. The EVB

restarts and the RF_ACT LED blinks to show that the module is searching for an

AP. Once the module has found and associated to the AP entered using the wl-

ssid command the RF_ACT LED will turn on continuously.

8.4 Determine the Module’s IP address

On the Host computer, use the terminal emulation program to type the following

CLI commands:

TABLE 44 - UA RT DET E RMI NE MODUL E'S IP ADD RES S

8.5 Accessing the Module Using Telnet

On the Remote computer, use HyperTerminal to start a Telnet session. In the

first screen, name the session ‘TCP <Module IP>’ (for reference purposes only),

click on any icon you want to associate with this Telnet session, and click OK. In

the next screen, click TCP/IP (Winsock) for Connect Using. In the Host Address

field, type the module’s IP address. Leave the default Port Number value of 23

and click OK.

The HyperTerminal application will then attempt to open a TCP session with the

module, Connecting is shown in the status bar at the bottom-left side of the

screen as HyperTerminal tries to make the Telnet connection. When the

connection is made, Connecting is replaced by Connected. You can know

interact with the Airborne Device Server, to authenticate with the module type

auth dpac dpac<CR>.

Page 40

B&B Electronics

40

Airborne Enterprise WLNN EVB Users Guide

After the connection is authenticated you can enter CLI commands e.g. type wlinfo to view basic information on the module.

For more information on the full CLI command set please refer to the Command

Line Reference Manuals.

The above process can be achieved by any of the available Terminal Emulation

programs. Please follow the specific applications requirements to make the TCP/IP

connection and authenticate with the module.

Page 41

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

41

CLI Command

Description

auth dpac dpac <CR>

The module responds with OK, indicating that it

executed the command successfully. (If you did not

receive OK, check the settings in your terminal

emulation program.

9.0 Ethernet Bridge Connection

If you have purchased the WLNN-EK-DP503 kit, please use the following instructions for

connecting to and evaluating the Airborne Ethernet Bridge Module.

9.1 Connect a Host Computer

Using a Cat5 cable, connect the RJ45 port (CN4) connector on the Airborne EVB

to the Ethernet port on the Host computer. First make sure the Host PC has

IP

address of its Ethernet port set to be assigned by DHCP or assigned a static

address of 192.168.2.100.

9.2 Interacting with the Airborne™ Module

On the Host computer, use HyperTerminal to start a Telnet session. In the first

screen, name the session Wired Telnet (for reference purposes only), click on

any icon you want to associate with this Telnet session, and click OK. In the next

screen, click TCP/IP (Winsock) for Connect Using. In the Host Address field,

enter the IP address 192.168.2.1. Leave the default Port Number value of 23 and

click OK. Use the terminal emulation program to interact with the module by

issuing command Line Interface (CLI) commands. CLI commands let you request

status or change parameter settings. Press the Enter key

command line you type. After the module starts, type the following CLI command

to log in (You must log in before CLI commands can be recognized):

TABLE 45 - ETHER NET AUT HENT ICA T ION

(

<CR>)

the

after each

You will have to log into the module after any reset or restart

Page 42

B&B Electronics

42

Airborne Enterprise WLNN EVB Users Guide

CLI Command

Description

wl-scan<CR>

The module scans for APs and returns information on

each one it discovers. Note the SSID value that is

returned, as you will need to enter it in the next

command

wl-ssid [SSID]<CR>

Associates the module with the AP who’s [SSID] you

specify. [SSID] is the value returned by the wl-scan

command.

commit<CR>

Stores the information to flash memory.

CLI Command

Description

auth dpac dpac <CR>

Authenticate with the firmware

wl-ip<CR>

The module returns the IP address assigned to it by the

DHCP server.

9.3 Determine and Store the Access Point SSID

On the Host computer, use the terminal emulation program to type the following

CLI commands in the order shown:

TABLE 46 - ETHER NET SSI D & AUT HENT ICATION

If your access point has security enabled, you will also need to use the CLI to

enter those parameters (See the CLI Reference Guide for details). That setup is

outside the scope of this user guide, which assumes that the AP being used has

no security.

After issuing the commands, press the reset switch (SW2) on the EVB. The EVB

restarts and the RF_ACT LED turn on solid to show that the module has

connected to the AP. You will need to reconnect the Telnet session after each

reset or restart.

9.4 Determine the Module’s IP address

On the Host computer, use the terminal emulation program to type the following

CLI commands:

TABLE 47 - ETHERNET D ETE RMINE M O DULES I P A DDRESS

9.5 Accessing the Module Using Telnet

On the Remote computer, use HyperTerminal to start a Telnet session. In the

first screen, name the session ‘TCP <Module IP>’ (for reference purposes only),

click on any icon you want to associate with this Telnet session, and click OK. In

the next screen, click TCP/IP (Winsock) for Connect Using. In the Host Address

field, type the module’s IP address. Leave the default Port Number value of 23

and click OK.

Page 43

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

43

The HyperTerminal application will then attempt to open a TCP session with the

module, Connecting is shown in the status bar at the bottom-left side of the

screen as HyperTerminal tries to make the Telnet connection. When the

connection is made, Connecting is replaced by Connected. You can know

interact with the Airborne Device Server, to authenticate with the module type

auth dpac dpac<CR>.

After the connection is authenticated you can enter CLI commands e.g. type wl-

info to view basic information on the module.

For more information on the full CLI command set please refer to the Command

Line Reference Manuals.

The above process can be achieved by any of the available Terminal Emulation

programs. Please follow the specific applications requirements to make the TCP/IP

connection and authenticate with the module.

Page 44

B&B Electronics

44

Airborne Enterprise WLNN EVB Users Guide

10.0 Using the Web Interface

The Airborne Device Server includes a web interface that provides access to module

status, parameter modification and certificate and configuration file management. To use

the web interface follow the steps outlined in section 8.0 to establish the IP address of the

module. Once the IP address is known open a web browser and enter the IP address of

the module in the URL window.

The web interface currently supports Internet Explorer v6.0 thru 8.0, Firefox v3.x, Opera

v9.6+ and Chrome v1.0+.

When the authentication request is returned enter:

FIGURE 22 - WE BSITE L OGI N

Username:

Password:

dpac

dpac

After successfully authenticating with the module, you will be logged into the web server

and allowed to browse and update module settings if required. A quick overview of the

web interface follows.

10.1 Navigation Bar

FIGURE 23 - WE BSITE N AVI GATI ON B AR

Page 45

B&B Electronics

Airborne Enterprise WLNN EVB Users Guide

45

Title

Description

Status

Provides status and performance characteristics for the network

interfaces available. Includes connection status, radio and Ethernet

statistics.

Configuration

Allows viewing and configuration of all the interface settings

including wireless LAN, network connectivity, security, FTP client,

serial port and web server.

Includes the interface for delivery of OEM and user configuration

files, as well as management and viewing of current configurations.

Certificates

This menu items provides the interface for certificate delivery and

management. Included in this section are the abilities view resident

certificates, upload and delete certificates.

Network

With this section it is possible to locate other Airborne Device

Server modules on the current network.

It is also possible to scan for available Access Points.

Maintenance

This section allows the updating of the modules firmware. You can

also OEM reset and also restart the module remotely.

The module locate function is also enabled in this section.