Page 1

Phone: (815) 433-5100

Fax: (815) 4334-5104

www.bb-elec.com

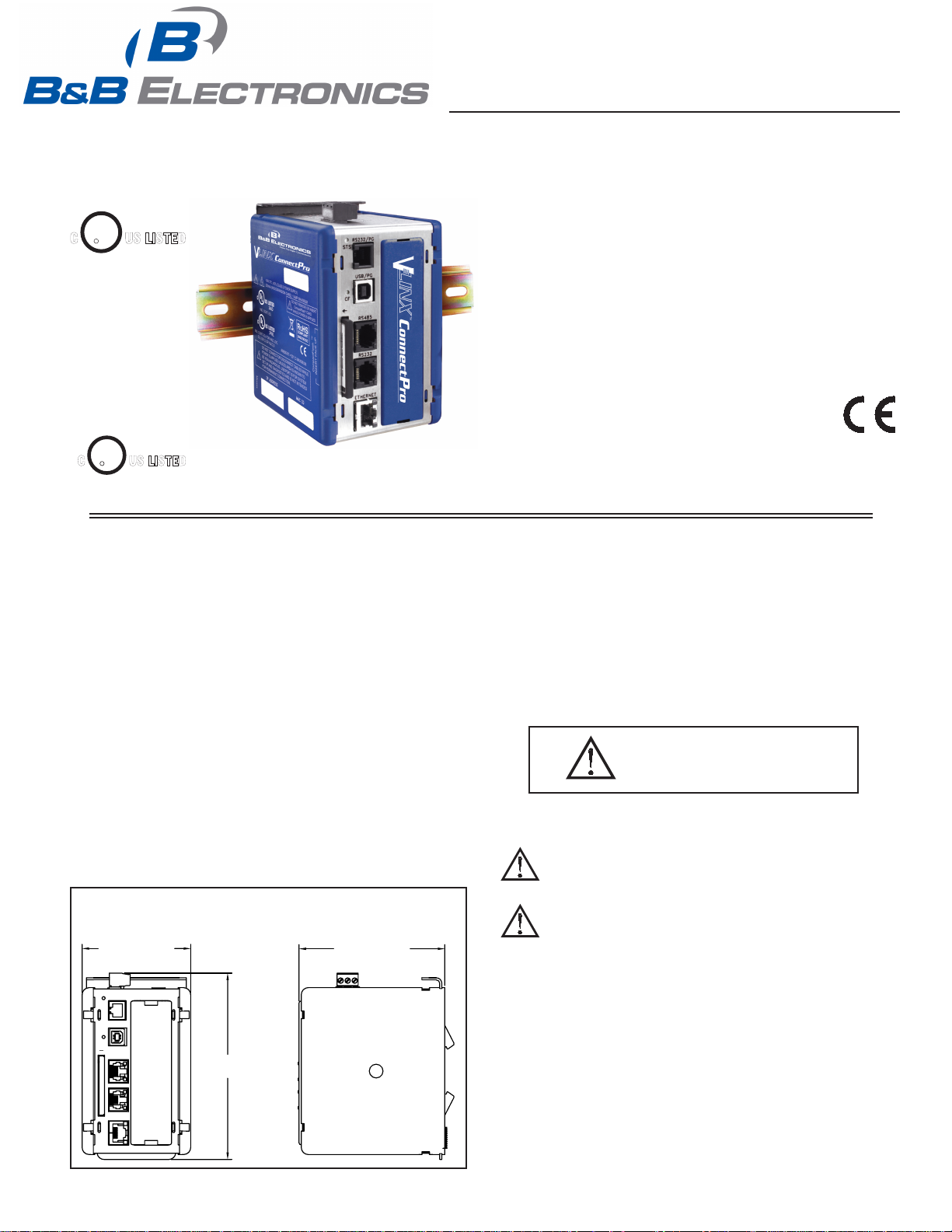

VLINX FIELDBUS GATEWAY

VFG1000--qsg

U

R

C

C

US LISTED

L

IND. CONT. EQ.

34AD

U

R

US LISTED

L

PROGRAMMABLE

CONTROLLERS

3PWL

FOR USE IN HAZARDOUS LOCATIONS:

Class I, Division 2, Groups A, B, C, and D

GENERAL DESCRIPTION

The Vlinx Fieldbus Gateway was designed to act as a nexus for industrial data

collection and management. With three built in serial ports and a 10 Base-T/100

Base-TX Ethernet port, the unit performs protocol conversion, allowing

disparate devices to communicate seamlessly with one another. The Ethernet

port supports up to four protocols simultaneously so even Ethernet to Ethernet

conversion may be performed.

The CompactFlash card allows new configuration files to be loaded into the

Vlinx Fieldbus Gateway. The USB port may be used for blazing fast file

downloads, or to mount the Vlinx Fieldbus Gateway’s CompactFlash card as an

external drive to your PC. The Vlinx Fieldbus Gateway’s DIN rail mounting

saves time and panel space and snaps easily onto standard top hat (T) profile

DIN rail.

SOFTWARE

The Vlinx Fieldbus Gateway is programmed with Fieldbus Gateway Manager

for Windows

interface which can be purchased as part of a kit that includes a manual and

cables, or downloaded free of charge.

®

2000 or later platforms. The software is an easy to use graphical

CONVERTS NUMEROUS PROTOCOLS SIMULTANEOUSLY

EXTENSIVE BUILT-IN DRIVER LIST ALLOWS EASY DATA

MAPPING TO PLCs, PCs, AND SCADA SYSTEMS

10 BASE-T/100BASE-TX ETHERNET PORT SUPPORTS FOUR

SIMULTANEOUS PROTOCOLS

INDEPENDENT SERIAL PORTS PROVIDE VIRTUALLY

UNLIMITED INTEGRATION METHODS

SUPPORTS UP TO NINE PROTOCOLS SIMULTANEOUSLY(with

expansion card)

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use the controller to directly command motors, valves, or other

actuators not equipped with safeguards. To do so can be potentially harmful to

persons or equipment in the event of a fault to the controller. An independent

and redundant temperature limit indicator with alarm outputs is strongly

recommended.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CompactFlash is a registered trademark of CompactFlash Association.

DIMENSIONS In inches (mm)

3.09 (78.5)

RS232/PG

STS

USB/PG

CF

RS485

RS232

ETHERNET

5.30 (134.7)

4.15 (105.4)

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I,

DIVISION 2, GROUPS A, B, C, D, OR NON-HAZARDOUS

LOCATIONS ONLY

LP0832X

Effective 01/10

1

Page 2

SPECIFICATIONS

BOTTOM

1. POWER: 24 VDC ± 10%

200 mA min., without expansion card

1 Amp maximum with expansion card fitted

Must use NEC Class 2 or Limited Power Source (LPS) rated power supply.

2. COMMUNICATIONS:

USB/PG Port: Adheres to USB specification 1.1. Device only using Type B

connection.

WARNING - DO NOT CONNECT OR DISCONNECT CABLES

WHILE POWER IS APPLIED UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS. USB PORT IS FOR SYSTEM SET-UP AND

DIAGNOSTICS AND IS NOT INTENDED FOR PERMANENT

CONNECTION.

Serial Ports: Format and Baud Rates for each port are individually software

programmable up to 115,200 baud.

RS232/PG Port: RS232 port via RJ12

COMMS Ports: RS422/485 port via RJ45, and RS232 port via RJ12

DH485 TXEN: Transmit enable; open collector, VOH = 15 VDC,

VOL = 0.5 V @ 25 mA max.

Ethernet Port: 10 BASE-T / 100 BASE-TX

RJ45 jack is wired as a NIC (Network Interface Card).

3. LEDs:

STS – Status LED indicates condition of Fieldbus Gateway.

TX/RX – Transmit/Receive LEDs show serial activity.

Ethernet – Link and activity LEDs.

CF – CompactFlash LED indicates card status and read/write activity

4. MEMORY:

On-board User Memory: 4 Mbytes of non-volatile Flash memory.

On-board SDRAM: 2 Mbytes

Memory Card: CompactFlash Type II slot for Type I and Type II cards.

Used for optional database storage only

5. REAL-TIME CLOCK: Typical accuracy is less than one minute per month drift.

Battery: Lithium Coin Cell. Typical lifetime of 10 years at 25 ºC.

A “Battery Low” system variable is available so that the programmer can

choose specific action(s) to occur when the battery voltage drops below

its nominal voltage.

This unit is NOT field serviceable. All work must be done by a qualified

technician.

6. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: 0 to 50 °C

Storage Temperature Range: -30 to +70 °C

Operating and Storage Humidity: 80% max relative humidity,

non-condensing, from 0 to 50 °C

Vibration According to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 2 g’s.

Shock According to IEC 68-2-27: Operational 30 g's, 11 msec in 3 directions.

Altitude: Up to 2000 meters

7. CONSTRUCTION: Case body is high impact plastic and stainless steel.

For indoor use only. Installation Category II, Pollution Degree 2.

8. POWER CONNECTION: Removable wire clamp screw terminal block.

Wire Gage Capacity: 24 AWG to 12 AWG

Torque: 4.45 to 5.34 in/lb (0.5 to 0.6 N-m)

9. MOUNTING: Snaps onto standard DIN style top hat (T) profile mounting

rails according to EN50022 -35 x 7.5 and -35 x 15.

10. CERTIFICATIONS AND COMPLIANCES:

SAFETY

UL Listed, File #E222870, UL508, CSA 22.2 No. 14-M05 and File #E245458,

ANSI/ISA 12.12.01-2007, CSA 22.2 No. 213-M1987

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment for

measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Emissions and Immunity to EN 61326: 2006: Electrical Equipment for

Measurement, Control and Laboratory use.

Immunity to Industrial Locations:

Electrostatic discharge EN 61000-4-2 Criterion B

4 kV contact discharge

8 kV air discharge

Electromagnetic RF fields EN 61000-4-3 Criterion A

10 V/m

Fast transients (burst) EN 61000-4-4 Criterion A

power 2 kV

I/O signal 1 kV

Surge EN 61000-4-5 Criterion B

power

1kV L-L,2 kV L-G

signal

1kV

RF conducted interference EN 61000-4-6 Criterion A

3 V/rms

Emissions:

Emissions EN 55011 Class A

Notes:

1. Criterion A: Normal operation within specified limits.

2. Criterion B: Temporary loss of performance from which the unit self-

recovers.

11. WEIGHT: 15.1 oz (428 g)

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR

AREA IS KNOWN TO BE NON-HAZARDOUS.

HARDWARE

INSTALLATION

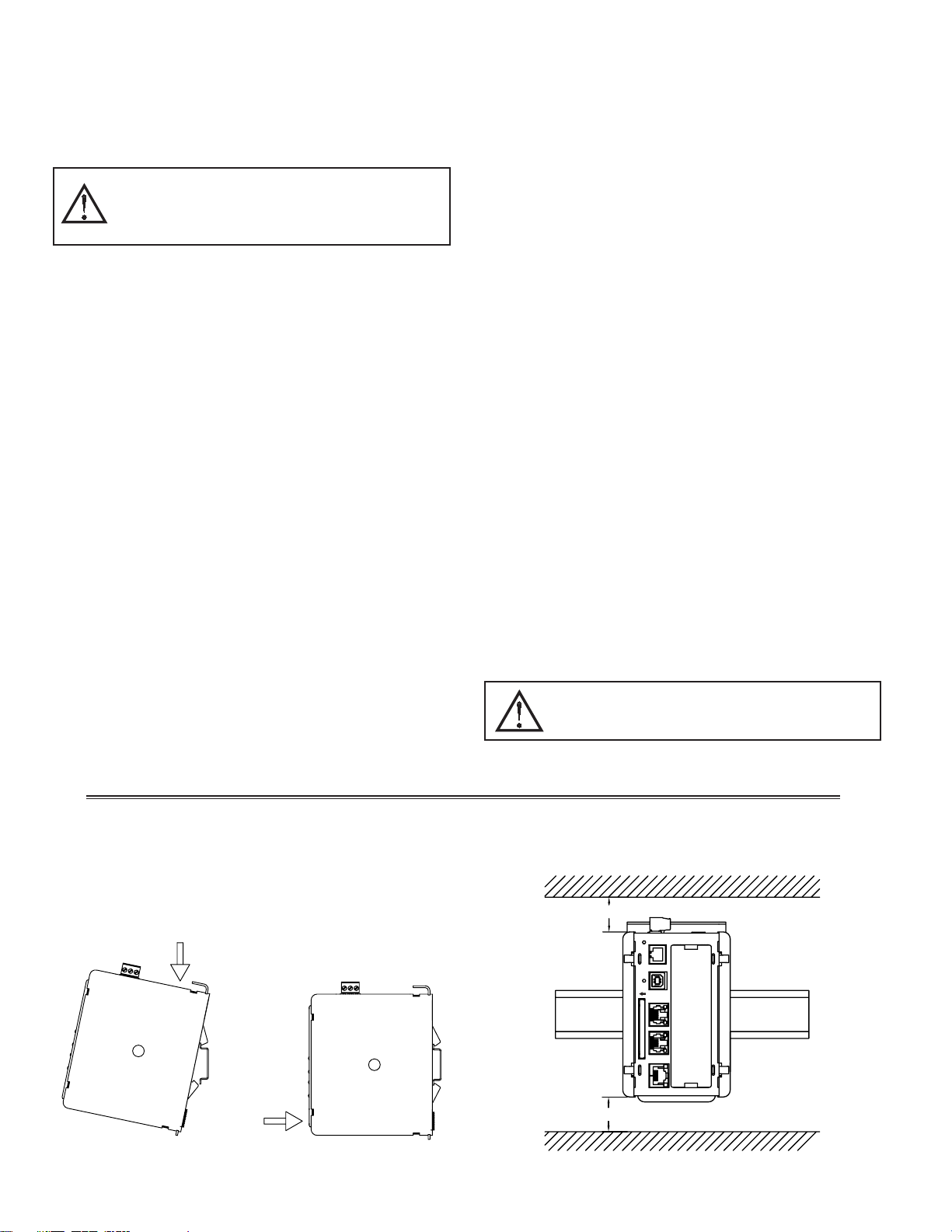

DIN rail should be mounted horizontally so that the unit’s ventilation holes

are vertical in relation to cabinet orientation. A minimum clearance of 1 inch

(25.4 mm) should be maintained above and below the unit in order to ensure

proper thermal regulation.

1

2

Figure 1 - Attach Fieldbus Gateway To DIN Rail

TOP

1.00"

min. clearance

RS232/PG

STS

USB/PG

CF

RS485

RS232

ETHERNET

1.00"

min. clearance

2

Page 3

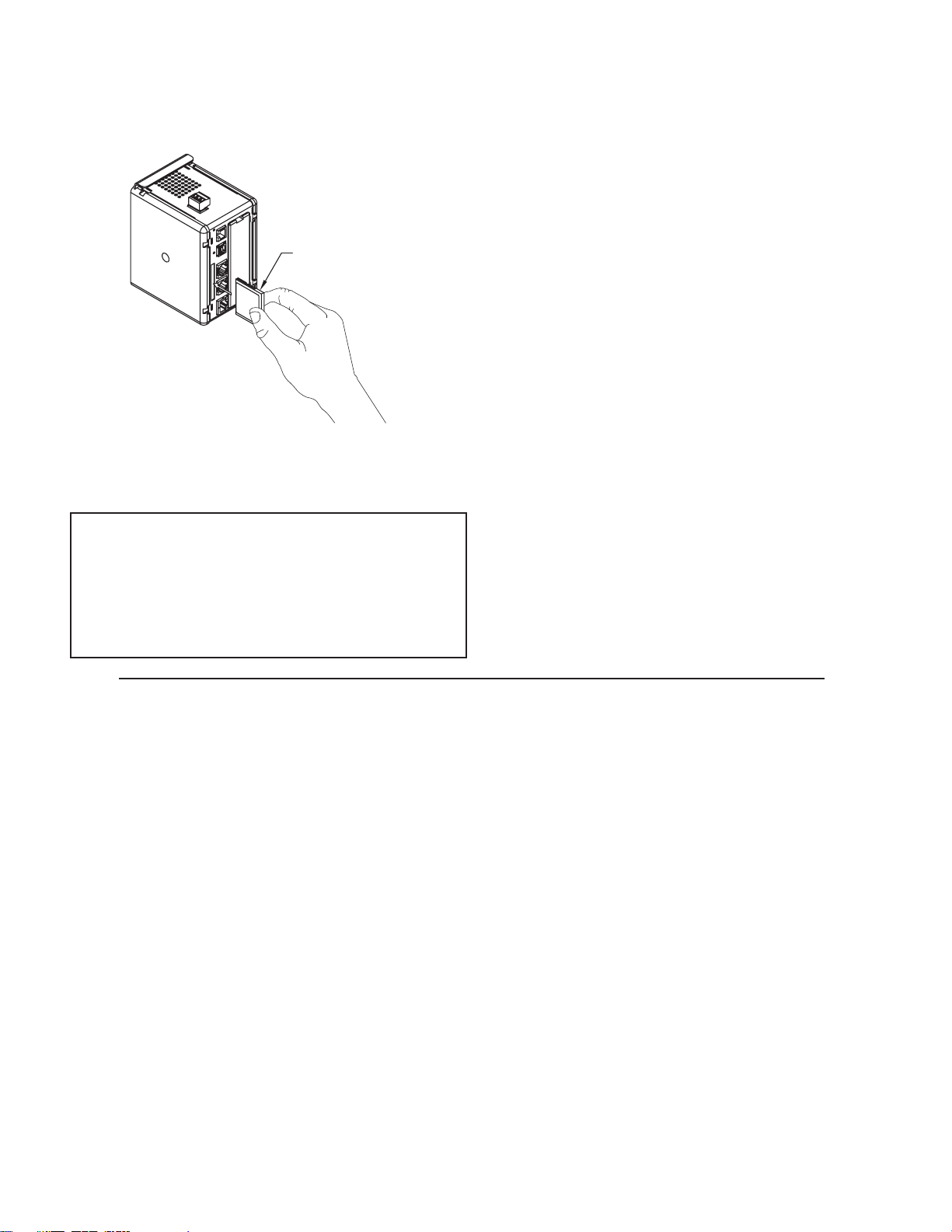

COMPACTFLASH® CARD

CompactFlash socket is a Type II socket that can accept either Type I or II

cards. Use cards with a minimum of 4 Mbytes and a maximum of 2 Gbytes with

the Fieldbus Gateway’s CompactFlash socket. Cards are available at most

computer and office supply retailers. The CompactFlash can be used for

optional database storage only.

CompactFlashInsert Top Side

Towards Left

CompactFlash

(Top Side)

Note: Do not remove or insert

the CompactFlash card while

power is applied.

Information stored on a CompactFlash card can be read by a card reader

attached to a PC. This information is stored in IBM (Windows®) PC compatible

FAT16 file format.

POWER SUPPLY REQUIREMENTS

It is very important that the power supply is mounted correctly if the unit is

to operate reliably. Please take care to observe the following points:

– The power supply must be mounted close to the unit, with usually not more

than 6 feet (1.8 m) of cable between the supply and the Fieldbus Gateway.

Ideally, the shortest length possible should be used.

– The wire used to connect the Fieldbus Gateway’s power supply should be

at least 22-gage wire. If a longer cable run is used, a heavier gage wire

should be used. The routing of the cable should be kept away from large

contactors, inverters, and other devices which may generate significant

electrical noise.

– A power supply with an NEC Class 2 or Limited Power Source (LPS) and

SELV rating is to be used. This type of power supply provides isolation to

accessible circuits from hazardous voltage levels generated by a mains

power supply due to single faults. SELV is an acronym for “safety extralow voltage.” Safety extra-low voltage circuits shall exhibit voltages safe

to touch both under normal operating conditions and after a single fault,

such as a breakdown of a layer of basic insulation or after the failure of a

single component has occurred.

NOTE

For reliable operation of this and other B&B Electronics products, one of

the following brands of CompactFlash card must be used...

SimpleTech SMART® Modular

®

SanDisk

Not all of the above manufacturers offer CompactFlash cards recognized

to UL standards, which may be required for your application.

Silicon Systems

EMC INSTALLATION GUIDELINES

Although B&B Electronics Products are designed with a high degree of

immunity to Electromagnetic Interference (EMI), proper installation and wiring

methods must be followed to ensure compatibility in each application. The type

of the electrical noise, source or coupling method into a unit may be different

for various installations. Cable length, routing, and shield termination are very

important and can mean the difference between a successful or troublesome

installation. Listed are some EMI guidelines for a successful installation in an

industrial environment.

1. To reduce the chance of noise spikes entering the unit via the power lines,

connections should be made to a clean source. Connecting to circuits that also

power loads such as contactors, relays, motors, solenoids etc. should be avoided.

2. The unit should be mounted in a metal enclosure, which is properly connected

to protective earth.

3. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end where the

unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is over 1 MHz.

c. Connect the shield to common of the Fieldbus Gateway and leave the other

end of the shield unconnected and insulated from earth ground.

4. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run through metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter. Also, Signal or Control cables within

an enclosure should be routed as far away as possible from contactors, control

relays, transformers, and other noisy components.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

6. In extremely high EMI environments, the use of external EMI suppression

devices is effective. The following EMI suppression devices (or equivalent)

are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite part number 0443167251

TDK part number ZCAT3035-1330A

Steward part number 28B2029-0A0

Line Filters for input power cables:

Schaffner part number FN610-1/07

Schaffner part number FN670-1.8/07

Corcom part number 1 VR3

3

Page 4

WIRING

POWER CONNECTION

COMMON

+24 VDC

PROGRAMMING PORTS

RS232/PG

CTS

Rx

RS232

USB/PG

COMM

COMM

Tx

RTS

RS232/PG

STS

USB/PG

CF

RS485

RS232

ETHERNET

COMM

N/C

+24

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

WHILE CIRCUIT IS ALIVE UNLESS AREA IS KNOW TO BE

NON-HAZARDOUS.

INPUT AND OUTPUT (I/O) WIRING MUST BE IN

ACCORDANCE WITH CLASS I, DIV. 2 WIRING METHODS

AND IN ACCORDANCE WITH THE AUTHORITY HAVING

JURISDICTION.

OR

OR

ETHERNET

GREEN/AMBER LED

YELLOW LED

COMMUNICATION PORTS

RS232/PG

CTS

Rx

COMM

COMM

RS232

Tx

RTS

RS232/PG

STS

USB/PG

CF

RS485

RS232

ETHERNET

Ethernet (Crossover)

OR

SLC 5/03 CPU

RUN

FORCE

FLT

DH485

BATT

RS232

REM

RUN

PROG

POWER

PWR OUT +24

VDC

USER

POWER

PWR OUT COM

120/240 VAC

VAC NEUT

CHASSIS GND

4

Page 5

RS232

RTS

Tx

COMM

COMM

Rx

CTS

RS232/PG

STS

USB/PG

CF

RS232

RS485

RS232

ETHERNET

SLC 5/03 CPU

RUN

FORCE

FLT

DH485

BATT

RS232

PROG

REM

RUN

POWER

PWR OUT +24

VDC

USER

POWER

PWR OUT COM

120/240 VAC

VAC NEUT

CHASSIS GND

* Use appropriate communications cable. See Ordering

Information for descriptions of the available cables.

RS485

RS232/PG

TxA

TxB

COMM

TxEN

RxB

RxA

TxA

TxB

RS485

STS

USB/PG

CF

RS485

RS232

ETHERNET

PORT 3 - ETHERNET CONNECTION

RS232/PG

STS

GREEN/AMBER LED

YELLOW LED

USB/PG

CF

RS485

RS232

Standard Ethernet cable

ETHERNET

FIELDBUS GATEWAY PORT PIN OUTS

1

COMMON

2

24VDC ±10%

3

N/C

POWER

CTS (PIN 1)

COMMTxCOMM

Rx

RS232

RS232/PG PORT

USB/PG

COMM

RxA

RxB

TxA

TxB (PIN 1)

TxEN

RS485

COMMS

PORT

RTS (PIN 6)

TxA (PIN 8)

CONNECTOR

RS232/PG

STS

USB/PG

CF

RS485

RS232

EXPANSION

PORT

SLC 5/03 CPU

RUN

FORCE

FLT

DH485

BATT

RS232

REM

RUN

PROG

POWER

WARNING: Do NOT use a standard DH-485

PWR OUT +24

PWR OUT COM

120/240 VAC

VAC NEUT

CHASSIS GND

cable to connect this port to Allen Bradley

VDC

USER

POWER

equipment.

TROUBLESHOOTING

If for any reason you have trouble operating,

connecting, or simply have questions concerning your

new Fieldbus Gateway, contact B&B Electronic’s

technical support. For contact information, refer to the

back page of this bulletin for phone and fax numbers.

Web Site: http://www.bb-elec.com

COMM

CTS (PIN 1)

COMMRxTx

RS232

COMMS

PORT

GREEN/

LED

AMBER

ETHERNET

(NIC)

RTS (PIN 6) TxB

YELLOW

LED

ETHERNET

5

Page 6

TX

5V

8

1

7

2

TxB

TxA

130K

130K

5

TxEN (OC)

RX

130K

5V

130K

RxB

4

RxA

3

GND

6

TxEN (OC)

TX/RX

130K

5

TxA

2

8

130K

5V

7

1

TxB

6 GND

COMMUNICATING WITH THE Fieldbus Gateway

CONFIGURING A FIELDBUS GATEWAY

The Fieldbus Gateway is configured using Fieldbus Gateway Manager

software. Updates to the software for new features and drivers are posted on the

website as they become available. By configuring the Fieldbus Gateway using

the latest version of the software, you are assured that your unit has the most up

to date feature set. The software can configure the Fieldbus Gateway through

the RS232/PG port, USB/PG port, Ethernet, or CompactFlash. The USB/PG

port is connected using a standard USB cable with a Type B connector.

The driver needed to use the USB port will be installed with the software.

The RS232/PG port uses a programming cable made by B&B to connect to the

DB9 COM port of your computer. If making your own cable, refer to the

“Fieldbus Gateway Port Pin Outs” for wiring information.

The CompactFlash can be used to program a Fieldbus Gateway by placing a

configuration file and firmware on the CompactFlash card. The card is then

inserted into the target Fieldbus Gateway and powered.

CABLES AND DRIVERS

B&B has a wide range of cables and drivers for use with many different

communication types. A list of these drivers and cables along with pin outs is

available from B&B’s website. If making your own cable, refer to the “Fieldbus

Gateway Port Pin Outs” for wiring information.

USB, DATA TRANSFERS FROM THE

COMPACTFLASH CARD

WARNING - DO NOT CONNECT OR DISCONNECT CABLES

WHILE POWER IS APPLIED UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS. USB PORT IS FOR SYSTEM SET-UP AND

DIAGNOSTICS AND IS NOT INTENDED FOR PERMANENT

CONNECTION.

RS232 PORTS

The Fieldbus Gateway has two RS232 ports. There is the RS232/PG port and

the COMMS port. Although only one of these ports can be used for

programming, both ports can be used for communications with a PLC. The

RS232/PG port can be used for either master or slave protocols.

RS422/485 PORT

The Fieldbus Gateway has one RS422/485 port. This port can be configured

to act as either RS422 or RS485.

RS422/485 4-WIRE

CONNECTIONS

RS485 2-WIRE

CONNECTIONS

In order to transfer data from the CompactFlash card via the USB port, a

driver must be installed on your computer. This driver is installed with the

software and is located in the folder C:\Program Files\B&B Electronics\Vlinx

Fieldbus Gateway Manager\Device after the software is installed. This may

have already been accomplished if your Fieldbus Gateway was configured

using the USB port.

Once the driver is installed, connect the Fieldbus Gateway to your PC with a

USB cable, and follow “Mounting the CompactFlash” instructions in the

Fieldbus Gateway Manager user manual.

Note: The USB port is for system set-up and diagnostics and is not intended for

permanent connection.

ETHERNET COMMUNICATIONS

Ethernet communications can be established at either 10 BASE-T or 100

BASE-TX. The Fieldbus Gateway’s RJ45 jack is wired as a NIC (Network

Interface Card). For example, when wiring to a hub or switch use a straightthrough cable, but when connecting to another NIC use a crossover cable.

The Fieldbus Gateway Manager manual contains additional information on

Ethernet communications.

Note: All B&B devices connect A to A and B to B.

DH485 COMMUNICATIONS

The Fieldbus Gateway’s RS422/485 COMMS port can also be used for Allen

Bradley DH485 communications.

WARNING: DO NOT use a standard DH485 cable to connect this port to Allen

Bradley equipment. A cable and wiring diagram are available from B&B.

6

Page 7

LEDS

STS – STATUS LED

The green Status LED provides information regarding the state of the

Fieldbus Gateway. This includes indication of the various stages of the start-up

routine (power-up), and any errors that may occur.

Startup Routine

INDICATION

Rapidly Flashing

Steady Fieldbus Gateway is operating properly.

Fieldbus Gateway is currently running the boot loader

and/or being flash upgraded by the software.

USER COMMUNICATION PORTS - TX/RX LEDS

INDICATIONLED

TransmittingGREEN

ReceivingRED

Note: LEDs are not available on the Programming Port: RS232/PG.

ETHERNET LEDS

INDICATIONLED

Link EstablishedYELLOW (Solid)

Network ActivityYELLOW (Flashing)

CF – COMPACTFLASH LED

INDICATIONLED

No CompactFlash Card is present.Off

Valid CompactFlash card is present.Steady

CompactFlash card is being checked.Flashing Rapidly

Unit is writing to the CompactFlash, either

Flickering

Flashing Slowly

1. Do not turn off power to the unit while this light is flickering. The unit writes

data in two minute intervals. Later Microsoft operating systems will not lock

the drive unless they need to write data; Windows 98 may lock the drive any

time it is mounted, thereby interfering with logging. Refer to “Mounting the

CompactFlash” in the Fieldbus Gateway Manager User Manual.

because it is storing data, or because the PC

connected via the USB port has locked the drive.

Incorrectly formatted CompactFlash card present.

1

ORDERING INFORMATION

TYPE MODEL NO DESCRIPTION PART NUMBER

Fieldbus Gateway VFG

Communications

Cables (10 feet)

Accessories VFG9

1

Visit www.bb-elec.com for a list of communication drivers and cables.

CBL

Fieldbus Gateway with multiple protocol converter, Comms, Ethernet

and expansion slot.

RS-232 Programming Cable CBL01500

USB Cable USBAMBM-6F

Communications Cables

CANopen option card for Fieldbus Gateway VFG9000-CAN

GSM/GPRS Cell Modem Option Card for Fieldbus Gateway VFG9000-CEL

DeviceNet option card for Fieldbus Gateway VFG9000-DN

PROFIBUS option card for Fieldbus Gateway VFG9000-PBDP

RS232/485 option card for Fieldbus Gateway VFG9000-SERIAL

1

10 BASE-T CommunicationsGREEN

100 BASE-TX CommunicationsAMBER

VFG1000

CBLxxxxx

7

Page 8

Loading...

Loading...