Page 1

OP10

User Manual

A D C

Page 2

Contents

1 Summary ........................................................................................................................................1

1.1 Function ..............................................................................................................................1

1.2 General Specification..........................................................................................................1

1.3 Dimension...........................................................................................................................2

1.4 Installation...........................................................................................................................2

1.5 Components ........................................................................................................................2

1.5.1 LCD..........................................................................................................................2

1.5.2 Keys .........................................................................................................................2

1.5.3 Communication Ports...............................................................................................4

2 The Editing Software OP10-PCLINK............................................................................................6

2.1 General Introduction of OP10-PCLINK .............................................................................6

2.2 About the Project and Screen..............................................................................................6

2.3 Contents of the Screen ........................................................................................................6

2.4 Flowchart of Using..............................................................................................................6

2.5 Editing the User’s Screen....................................................................................................7

2.5.1 Create a New Project................................................................................................7

2.5.2 Making Basic Screen................................................................................................9

2.5.3 Configuration of OP10...........................................................................................10

2.5.4 Properties of OP10................................................................................................. 11

2.5.5 Text.........................................................................................................................12

2.5.6 Dynamic Text.........................................................................................................13

2.5.7 Function Keys ........................................................................................................15

2.5.8 Data Display...........................................................................................................18

2.5.9 Data Setting............................................................................................................21

2.5.10 LED......................................................................................................................24

2.5.11 Function Keys (for controlling the status switches).............................................25

2.5.12 Bar Graph.............................................................................................................26

2.5.13 Trend Line ............................................................................................................28

2.5.14 Alarm List ............................................................................................................29

2.5.15 Chief button..........................................................................................................31

2.5.16 Copy the value of registers form one device to other...........................................32

2.5.17 Preset dynamic text ..............................................................................................34

2.5.18 Preset register.......................................................................................................36

2.6 Save Project.......................................................................................................................38

2.7 Download Window ...........................................................................................................38

2.8 Importing .OPf Project......................................................................................................40

3 Manipulation................................................................................................................................44

3.1 Communication.................................................................................................................44

3.2 Changing the screens ........................................................................................................44

3.3 System Password...............................................................................................................44

4 Create new device ........................................................................................................................48

5 Communication............................................................................................................................57

1

Page 3

5.1. Communication port ........................................................................................................57

5.2 Communication connect....................................................................................................58

5.2.1 OP10 downloading cable ( write configuration screens ) ......................................58

5.2.2 Connect with TP03 (include SR type) PG port through RS-422............................58

5.2.3 Connect with TP03 through 485 port.....................................................................59

5.2.4 Connect with SG2 through 232 port (suitable for all types of SG2)......................60

5.2.5 Connect with SG2-V type with 485 port................................................................60

5.2.6 Connect with EV300 through 485 port ..................................................................61

5.2.7 Connect with SV300 ..............................................................................................61

2

Page 4

1 Summary

1.1 Function

OP10 is a Human-Machine Interface that is used with many kinds of PLC (or the other

intelligent controllers with communication ports). With OP10, both the values of the PLC inner

registers and the relays status of PLC can be monitored or changed through texts or LEDs. So the

operation of the machines or the devices is more easy and convenient.

OP10 programmable text monitor has many features:

The screens are made with the editor OP10-PCLINK on PC. Text including Chinese

characters can be input and the PLC address can be set. The screens are downloaded with serial

port.

The PLC communication protocols are downloaded to the OP10 with the data of the

screens, so the engineer don’t need to program of communication.

Support modbus RTU protocol.

Users can set 6 passwords, which have 3 levels.

Alarm list function. The current alarm information is displayed one by one.

It has 24 keys, which can be defined as function keys. There is a keyboard for numeric

input. The manipulation is simple. Some of the mechanic buttons on the controlling cabinet can be

substituted with them.

Various communication modes can be selected. Any of RS232, RS422 and RS485 is OK.

OP10 supports different screens in one project communicating with other devices through

different ports.

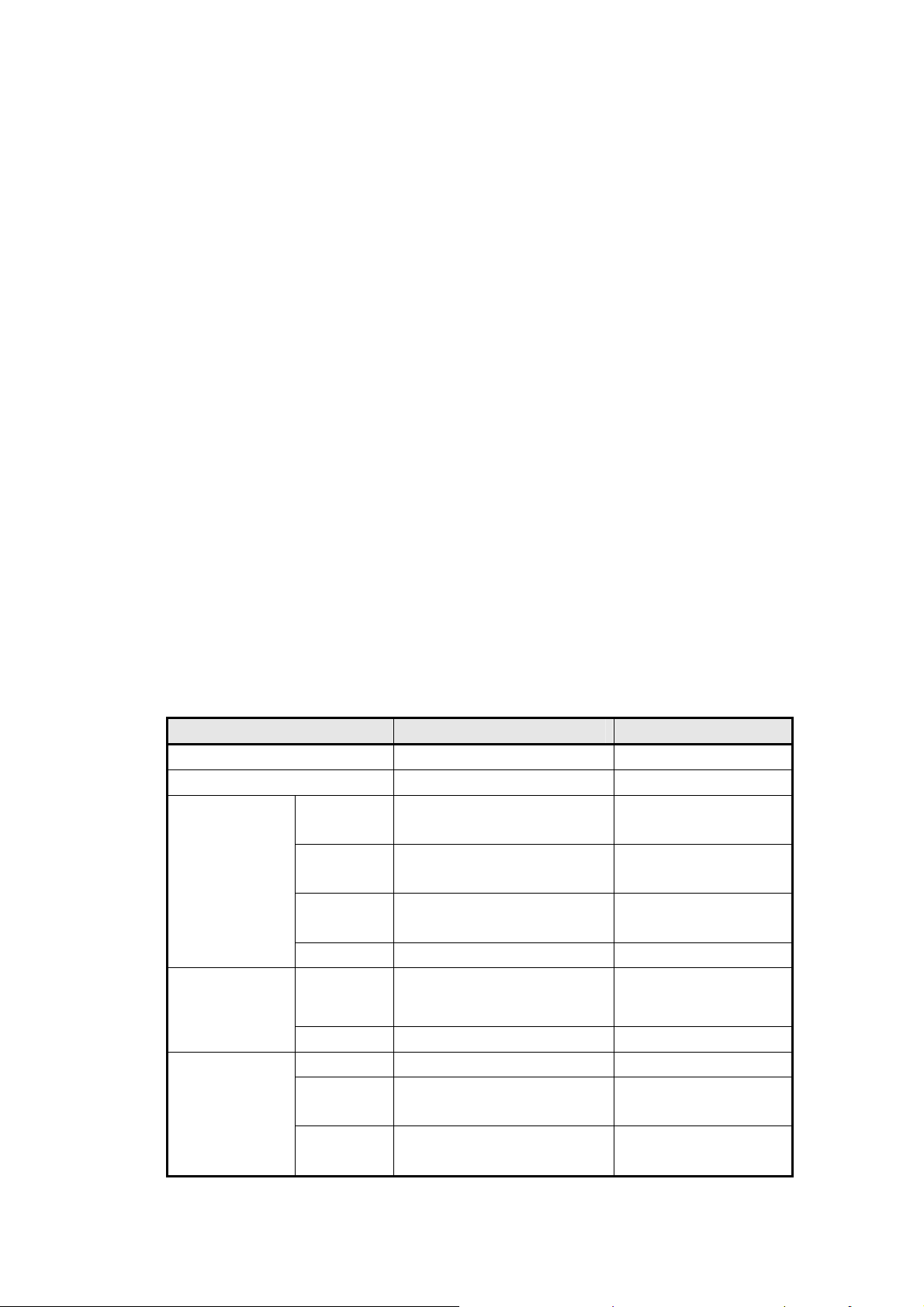

1.2 General Specification

Item Specification Remark

Power

Dimension 179.5*101.5*33 mm

Operation

Temperature

Height Not higher than an altitudes of

Environment

Relative

Humidity

Pollute level Pollute level 2 IEC61131-3-3.45.2

Mechanical

Running Status

Transport &

Storage

Condition

Shake

Strike 3 vertical directions 15g,11ms

Temperature -40℃~70℃

Height Not higher than an altitudes of

Fall down

freely

DC24V -15%~+10%

0℃~55℃

2000m

10%~95%,no dew

5≤f < 9 Hz 1.75mm range

shaking

9≤f≤150Hz 0.5g shaking

3000m

With production packing 0.3m

With transport packing 1m

1

Page 5

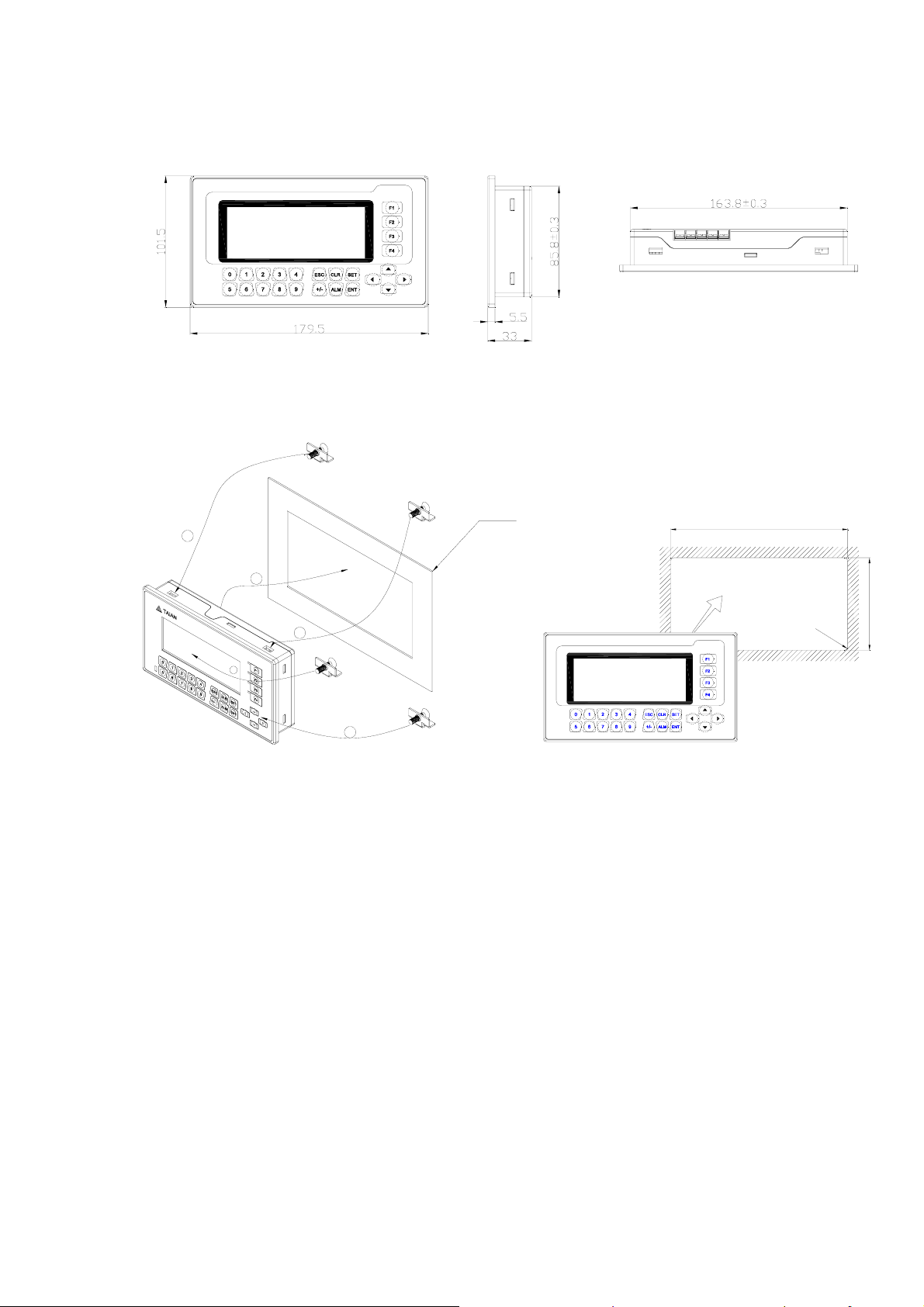

1.3 Dimension

1.4 Installation

TOP VIEW

Fix plate

2

1

2

2

2

1.5 Components

1.5.1 LCD

4.3” monochromic display, 192*64 pixels, olivine background.

165±0.25

R

87±0.25

2

±

0

.

5

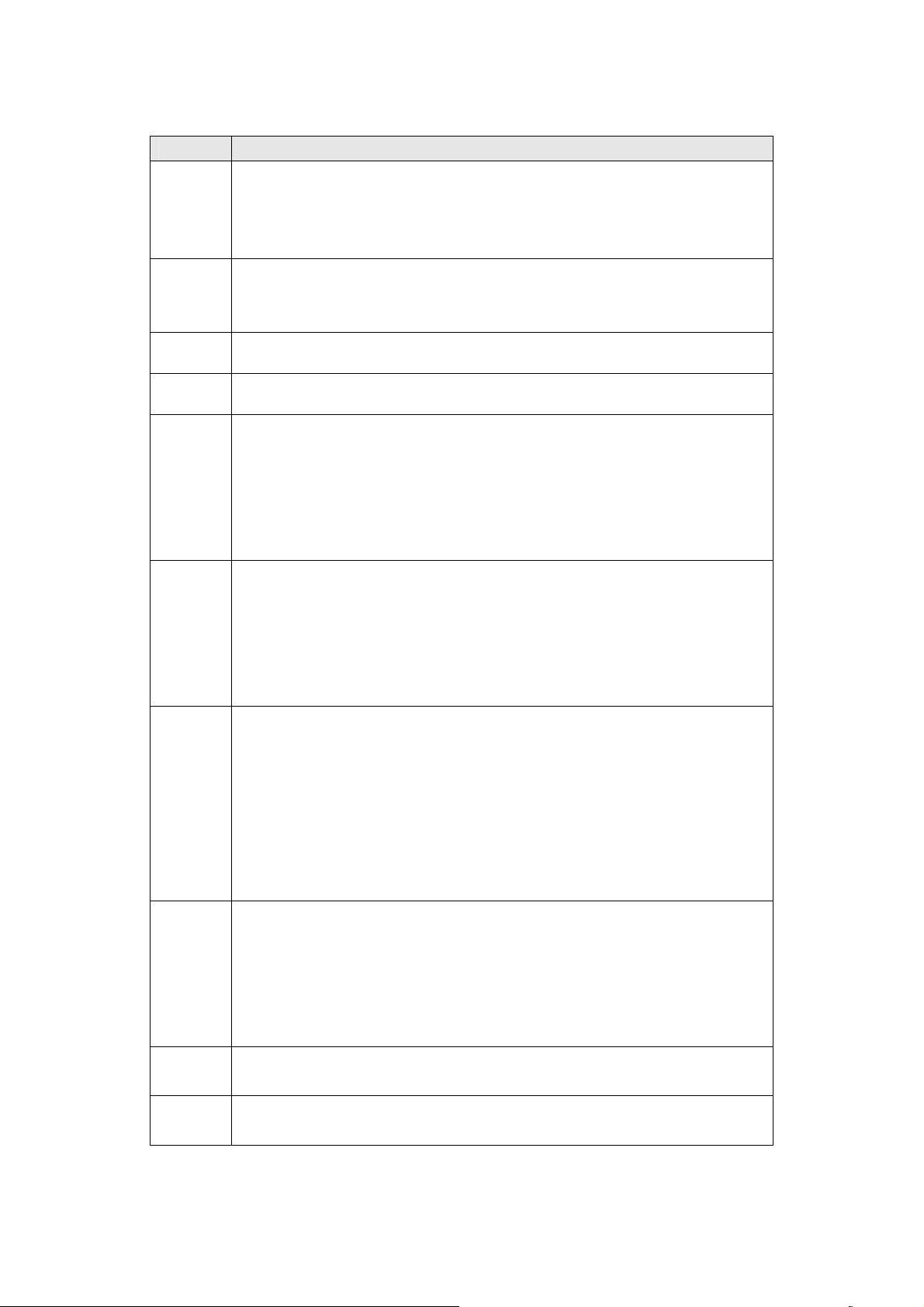

1.5.2 Keys

On the front panel of OP10, there is a LCD display and 24 thin film switches. The keys have

a good touch feeling, and they are endurable and reliable. Besides being used for the basic

functions, all the 24 keys can be set for local functions or Chief functions.

2

Page 6

The basic functions of the function keys:

KEY Basic Function

[ESC]

[ALM]

[◄]

[►]

[▲]

[▼]

[SET]

[ENT]

When pressed, the OP10 will return to system initial screen. The user can

designate the system initial screen during the screen making procedure (default

value is screen no. 1, screen no.0 is prohibited). Usually the Main Menu screen

or the most-frequently-used screen is set to be the initial screen.

When pressed, the OP10 will shift to the predefined alarm list information

screen. It can also be defined as a specific function key.(If there is no alarm list

in the project, system function is ineffective.)

Left shift the digit being edited when changing the register data. When pressed,

the digit twinkling will be shifted to the left one.

Right shifting the digit being edited when changing the register data. When

pressed, the digit twinkling will be shifted to the right one.

Jump to the previous screen. The number of the previous screen is designated in

the Screen Attribute option (default value is the result of subtracting 1 from the

current screen number).

In the data setting mode, pressing it can add 1 to the digit being edited. The

value will increase from 0 to 9, then return to 0…… (DEC); increase from 0 to

F, then return to 0……(HEX)

Jump to the next screen. The number of the next screen is designated in the

Screen Attribute option (default value is the result of adding 1 to the current

screen number)

In the data setting mode, pressing it will subtract 1 from the digit being edited.

The value will decrease from 9 to 0, then return to 9……(DEC); increase from

0 to F, then return to 0……(HEX)

Press it to enter the mode for editing the value of registers. The register being

operated is displayed in reverse color. The digit being edited is flickeringly

displayed. If the current screen contains no register setting components, no

operation will be executed. When [SET] is re-pressed before [ENT] is pressed,

the edition done to the current register will be canceled. The user can continue

to operate the next data register.

NOTE: The function of register setting for [SET] can NOT be disabled by

the user-defined function.

When password protection is enabled, pressing it will pop up a screen for

password setting.

In register setting mode, pressing it means the edition on the current register is

finished. The edited data will be saved. Then the edition will move to the next

register. After the edition on the last register on the current screen has been

finished, it will quit from the register setting mode.

When pressed in the process of data input, you can clear the current data.

[CLR]

[+/-]

When you input the numbers with symbol, pressing it can change the symbol.

3

Page 7

0-9

F1-F4

Keys , which are user-defined for local-button function

All of the 24 keys can be defined for specific functions by users, for example, setting the

status of the coils, screen jumping, setting the registers, increasing by degrees, descending, etc.

Local button can be set in the current screen. It is effective only when the current screen is

displayed.

Keys, which are user-defined for Chief-button function

All of the 24 keys can be defined for specific functions by users, for example, setting the

status of the coils, screen jumping, setting the registers, increasing by degrees, descending, etc.

Chief button can be set under the tool menu. It is effective whatever which screen is

displayed.

The priority of the functions

When a key is user-defined for a specific function, it has many functions. But only when the

function which has the highest priority can be executed. Other functions are ignored.

Except for the [SET], [ALM] keys, the priority from high to low is: local buttonÆChief

buttonÆbasic function.

[SET], [ALM] keys, the priority from high to low is: basic functionÆlocal buttonÆChief

button.

The basic function of register setting for [SET] has the highest priority. So if there is a

function of setting register in the current screen, please don’t define [SET] for other functions.

Pressing [SET], after entering the setting function, all of the user-defined keys’ functions are not

effective until setting function is ended.

[ALM] key has the highest priority when there is a alarm list. So if there is a function of

adding alarm list, please don’t define [ALM] for other functions. Pressing [ALM] key, after

entering the alarm list, the user-defined local buttons are ineffective. [▲], [▼], [ESC] keys return

to their basic functions. Others hold the Chief button functions which have been defined before.

OP10 display has LED background light itself. As long as there is a key manipulation, the

background light will be on. Consumers also can set the background light always on.

1. They can be used as button controller, setting status of the coils, screen

jumping or editing the values of the registers

2. When users in the mode of editing the value of registers, the keys can input

values directly.

Chief control keys. Their basic function is switching screens, changing the

status of the coils and IO, editing the values of the registers, etc. The high-level

function is controlling the destination machine to be powered on or off, etc.

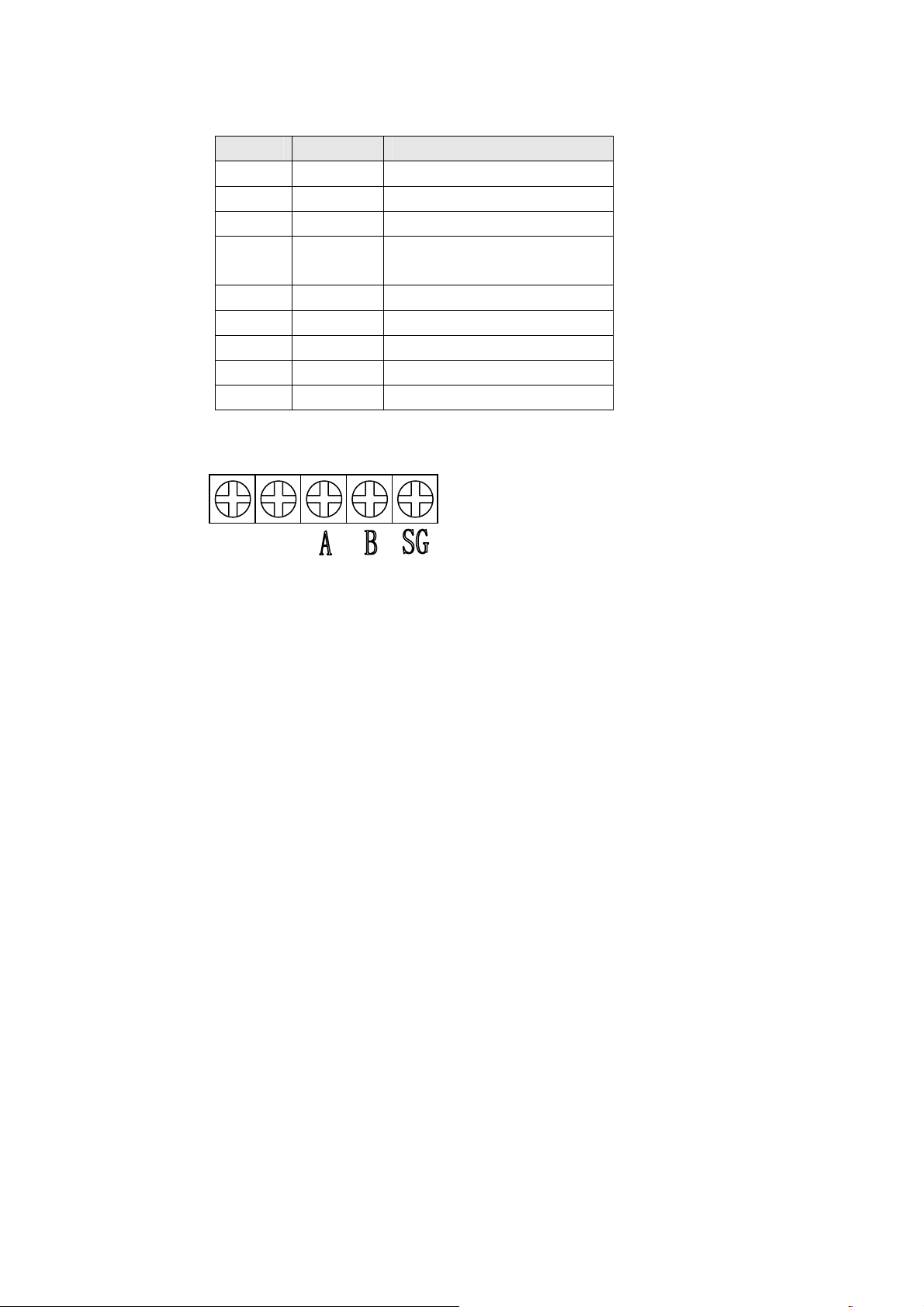

1.5.3 Communication Ports

OP10 has two communication ports: COM1 and RS485. COM1 is used for downloading user

programs, and offers RS422/RS232 port. RS485 offers RS485 port.

4

Page 8

COM1:

RS485:

Pin Definition Explanation

1 TX+ 422 send positive signal

2 RX 232 receive signal

3 TX 232 send signal

4 NC Interior used, can not be

connected with GND

5 GND 0 level

6 TX- 422 send negative signal

7 VCC 5V high level

8 RX- 422 receive negative signal

9 RX+ 422 receive positive signal

5

Page 9

2 The Editing Software OP10-PCLINK

2.1 General Introduction of OP10-PCLINK

OP10-PCLINK is the specific configuration software for the programmable text monitor

OP10. It can run on the SCREENS 98/2000/XP/vista platforms. It is easy to study and convenient

to use. The user can input English/Chinese characters directly.

2.2 About the Project and Screen

The basic element of a project is the screen. All the screens for one certain project are saved

in a single project file. Every screen is made to execute some certain functions. By arranging the

screens, the user can jump from one screen to another. The application project file is composed of

all the screens.

2.3 Contents of the Screen

After opening a project, users can create (“new”) or open (“open”) a screen. The user can put

some elements such as characters (English or Chinese), LEDs, switches, data inputting boxes and

jump keys on every screen. Jumping between different screens is allowed. The operator can carry

on the operations such as data monitoring, parameter setting, switch controlling, alarm list

monitoring and data transferring between registers of PLCs.

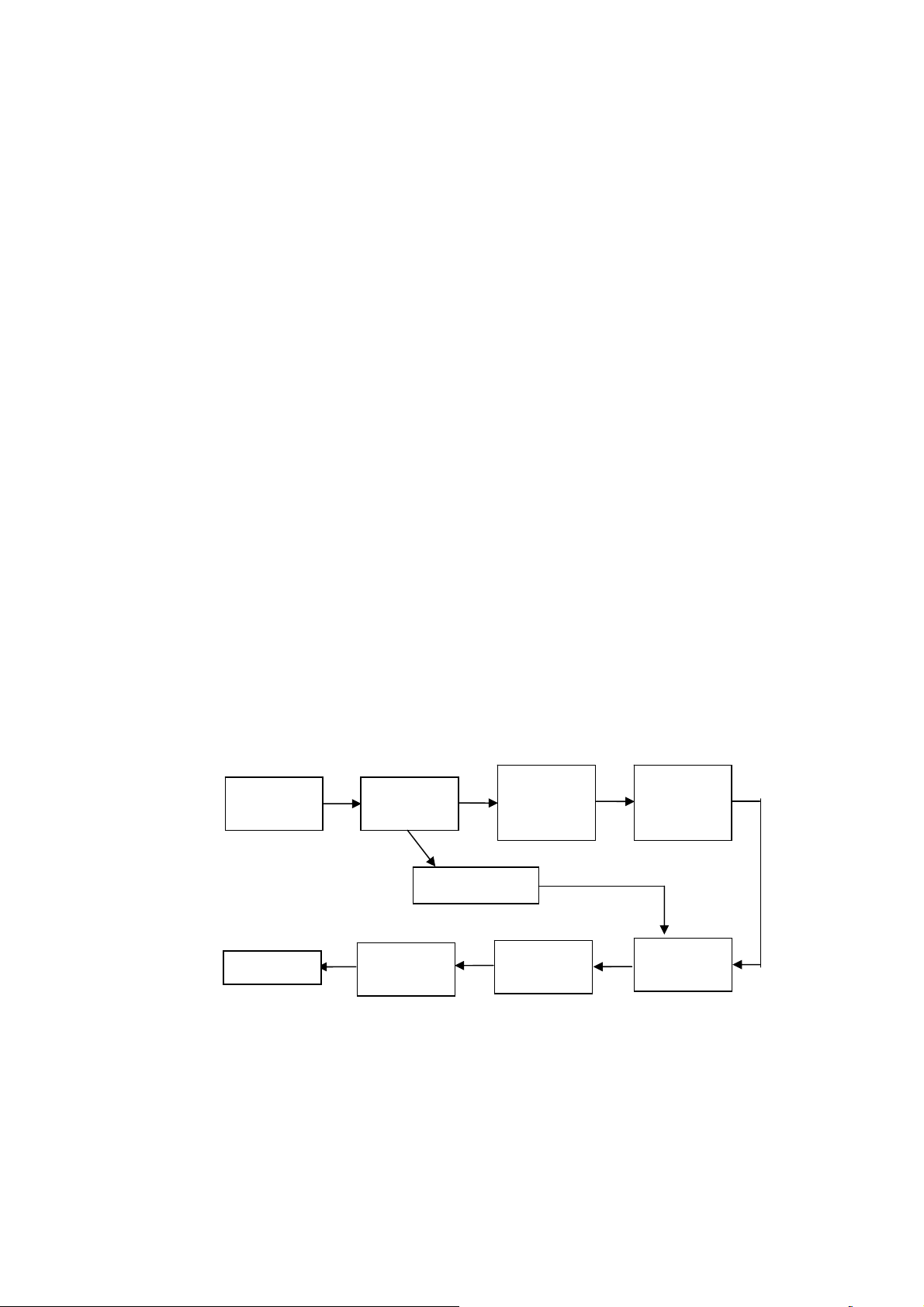

2.4 Flowchart of Using

The basic flowchart of using is shown in the following figure:

Software

installation

Run

Run the

software

Read OP10

Download

the screens

Create or

Open a

project

Save the

project

Create or

Open a

screen

Edit the

screen

6

Page 10

2.5 Editing the User’s Screen

2.5.1 Create a New Project

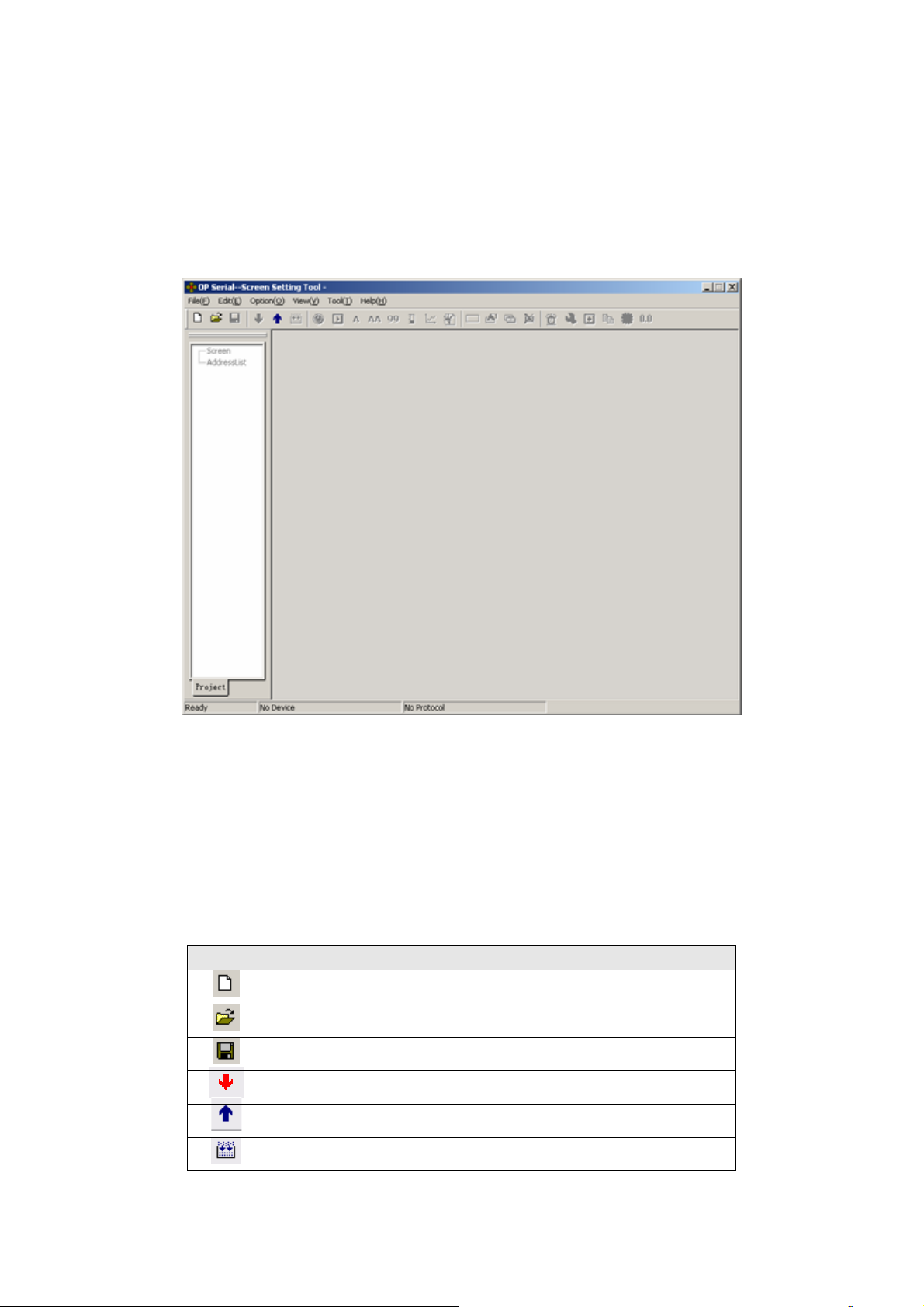

Run the software OP10-PCLINK and create a project, after which a screen editor will be

showed on the screen.

The screen-editing region is on the center of the editor. There is a grid of white dots in the

display region. The distance between every two rows and two columns is 16 points. The whole

region is a matrix of 192*64 points. The user can refer to the dots nearby to align the components

when laying or moving them. When necessary, change X and Y positions of the components to

locate them in arbitrary positions.

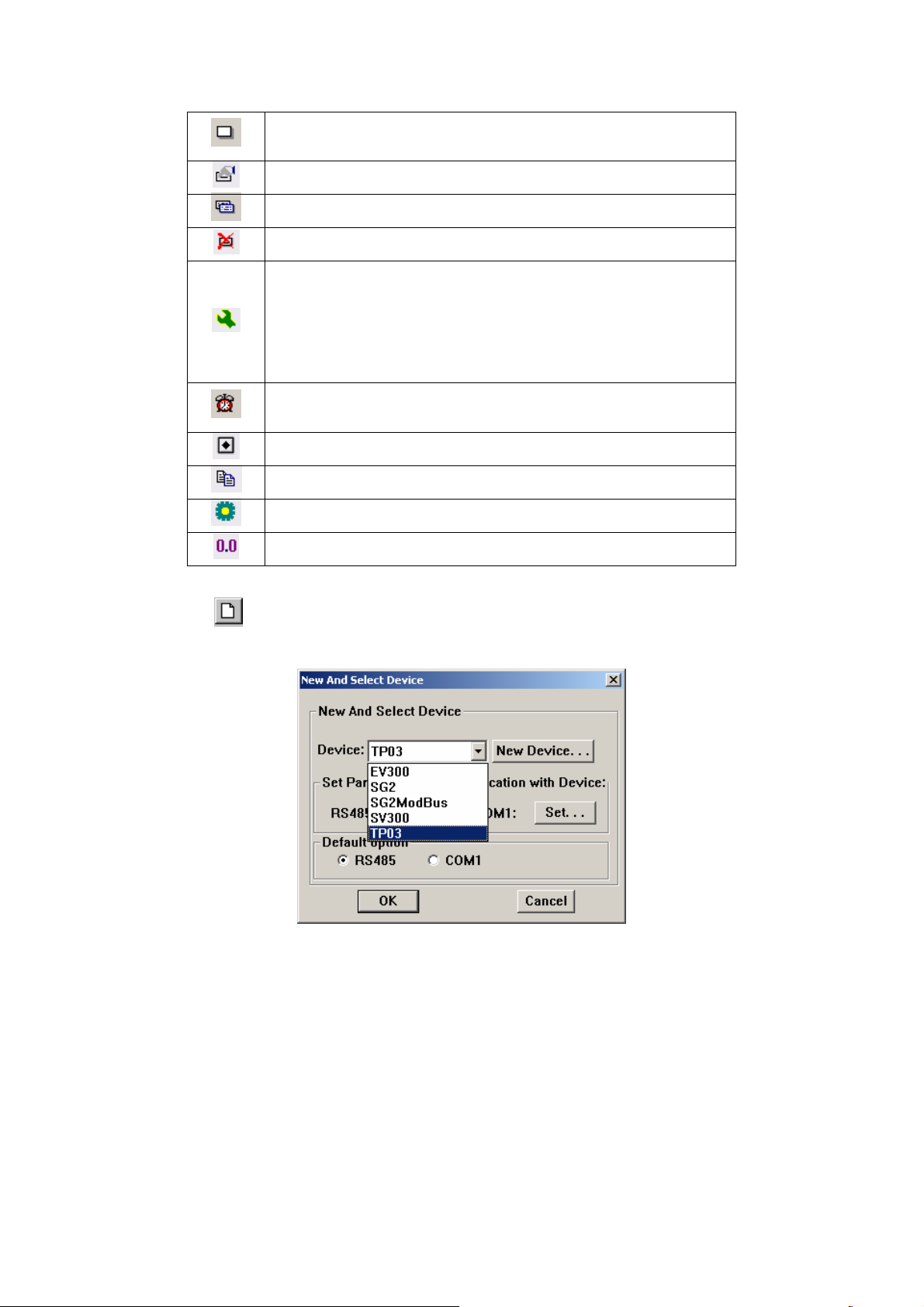

The table below is the description of all the buttons in the toolbar:

Button Function

Create a new project

Open project

Save project

Download the configuration project to OP10.

Upload the project inside OP10

Translate and edit the project, show the information of the project.

7

Page 11

New screen, pressing the key “New” in the screen indicator will also

new a screen.

Edit the attribute of the screen

Change a screen with the copy of another one

Delete the current screen

Designate the initial screen. When the display is running, the system

will return to the initial screen directly if [ESC] is pressed. Usually

the main menu or the screen most-frequently used is set to be the

initial screen; set the system password; set the definition number of

the interactive controlling register.

Login the Alarm List information. Every piece of information

represents a status of the select variable.

Set Chief button

Change the data of the registers with the copy of another device.

Preset dynamic text

Preset register

Press

selection:

Select the proper PLC type. Then click “Set” button down beside the port name to set

communication parameter.

or activate [File]→[New] command in the menu to pop up a dialog box for PLC

8

Page 12

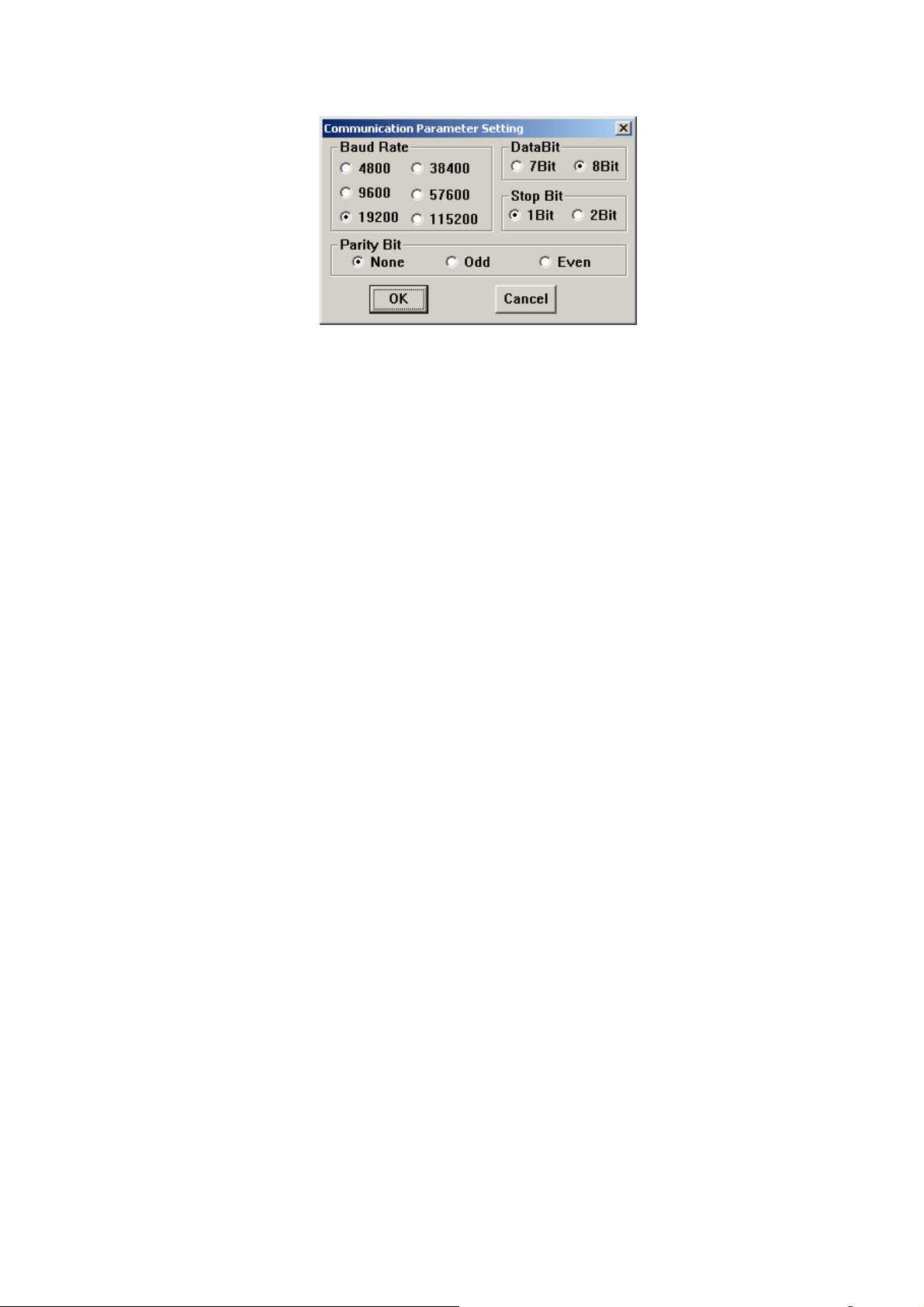

Select the proper baud rate, data bits, stop bits, parity and communication port in the dialog

box. OP10 supports the function that two communication ports can connect with different PLCs

and transducers using different communication formats.

Selecting the proper PLC type which bases on the destination controller. When

OP10-PCLINK downloads (writes) the screens, it sends the appointed PLC communication

protocol and the data of the screens to OP10 all together. When the display is running, it

communicates with PLC through the protocol.

2.5.2 Making Basic Screen

In the example given below, the PLC type is TP03. The example will give you a general

description of screen making.

Firstly, enter the system initial screen (default value is screen no.1) editing mode. The

properties of the current screen (screen no.1) are shown at the right and bottom edge of the

interface. Every screen has its own properties, which include 4 items:

Screen Description:

Descript the use of the screen. It helps the designer to note the use of all the screens.

(can be omitted),for example:“ main menu”

When Up Arrow key ([▲]) pressed, jump to screen:

The number of the screen that it will jump to when Up Arrow key pressed.

When Down Arrow key ([▼]) pressed, jump to screen:

The number of the screen that it will jump to when Down Arrow key pressed.

Choose communication port:

OP10 supports every individual screen choosing its own communication ports.

The most convenient way for screen jumping is to press [ESC], [▲] and [▼] when the OP10

is running. The user can also jump from one screen to another by pressing the user-defined

function keys.

Note:

If the [▲] and [▼] key in the current screen are defined for other functions, the screen

jumping parameters of the screen properties are invalid.

If the screen designated by the [▲] key doesn’t exist, the system will search up until the

existing screen is found and jump to it. It will stop at screen 1 if no screen is found. The

situation of the [▼] key is similar, that means the system will search down for the

screen if the designated one doesn’t exist..

9

Page 13

If there are some data setting components in the screen, [▲] and [▼] key will execute

the function of value increase and decrease in the data setting mode. After quitting the

data setting mode, the [▲] and [▼] key will execute the basic function for screen

jumping.

Choose the communication port of the screen. Users can choose COM1/485 port as the

communication port of the current screen. Users also can set the COM1/485

communication port of OP10 to demand the data of different destination host at the

same time.

For example: Screen 1 can be set as communicating through 232; Screen 2 can be set as

communicating through 485.They are separate.

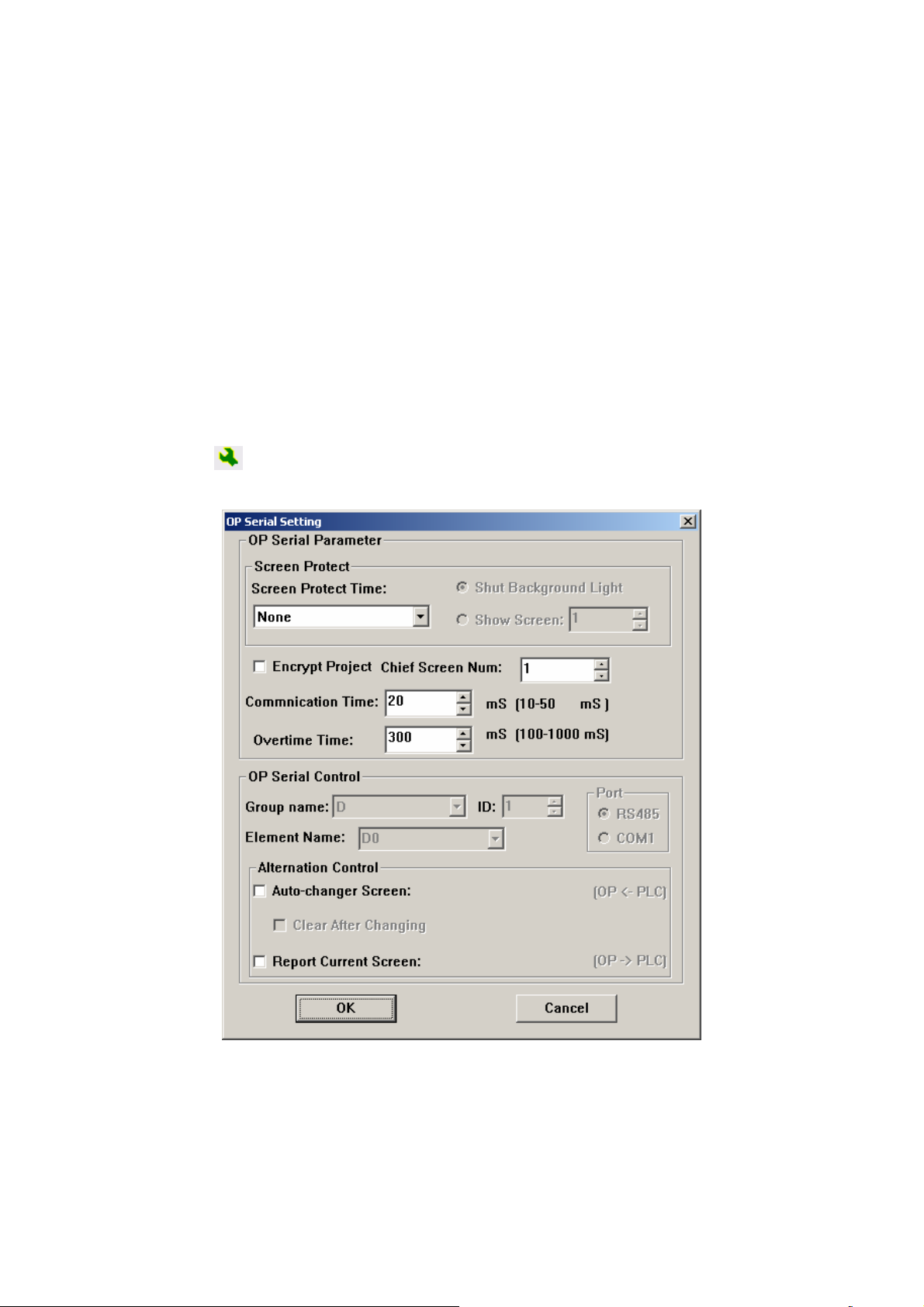

2.5.3 Configuration of OP10

Press

or activate [Tools]→[OP10 serial Set] command to pop up a dialog box for

configuring the system parameters of OP10:

Initial Screen

The first screen will be displayed after power on. Usually this screen is set to be the

main menu screen or the most-frequently-used screen. Press [ESC] when the OP10 is running,

the system will jump to this screen directly.

Screen Saver

Under default conditions, the backlight is set to be “never”. The time can be set by the

10

Page 14

user. If it is set to be “never”, the backlight will keep on. Also, the screen can be set to jump

to a screensaver screen when no key is pressed in configurable time.

Note: If the screen has jumped to a screen saver screen, the pressing of any key will not carry

out any function. Any operation will awake the screen saver to return to the original screen.

OP10 serial Status Control

Usually the screen changing is executed by pressing the keys. Besides, the PLC can

change screen by changing the data in register. If this property is selected, the number ‘n’ will

be written into the D300 (for example) controlling register at the beginning of running, then

OP10 will jump to screen No.n. OP10 write the current screen no. into D301, so PLC can

know the status of the status of OP10. (Users can choose the function to clear the register in

the screen. After jumping to that screen, the data in controlling register will be cleared.)

Note: The user can define the address of the interactive controlling register.

Encrypt the project

Users can upload the project from OP10 to Pc and edit it. If the users hope the

configuration screens in the production can’t be uploaded illegally, they can choose this

option. After choosing the option, although someone has the highest level password in the

project, he can’t upload the data.

Communication time

Communication time is the interval between OP10 sends two communication commands.

Its value can be set between 10ms-100ms. If the corresponding controller answers fast, the

communication time can be reduced. On the contrary, increase the time. Under the default

condition, OP10 sends communication data every 20ms.

Overtime

The time decides when OP10 demanding data overflows. Some controllers read data fast,

but take a long time to write data. At this condition, users can set the longest write time as

overtime to avoid data setting errors when increase data of register by degrees.

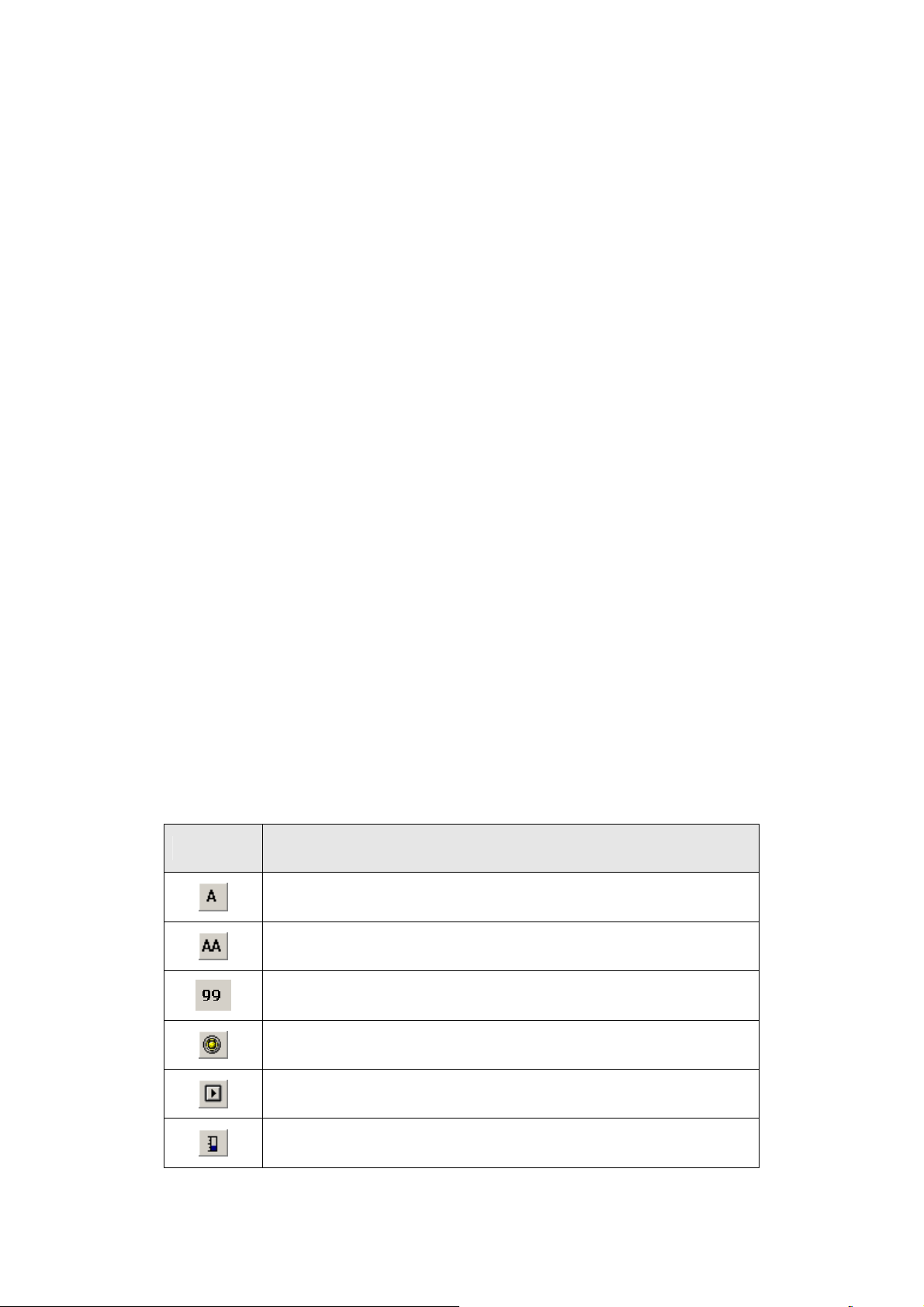

2.5.4 Properties of OP10

Component Function

Input text, including Chinese characters and English letters.

Dynamic text list. The content of the text can be changed under the

control of PLC register.

Register components. The user can dispose some data setting/monitoring

components with it. (the relate address are the PLC registers)

LED indicator. Indicate the on/off status of the inner delays in PLC.

Function key. All of 24 keys can be defined to be function keys. They

can execute the functions such as screen jumping and switch control.

Bar graph. Monitor the data change in PLC in the form of bar graphs.

11

Page 15

Trend line. Monitor the data change in PLC in the form of trend lines.

Paste pictures. Paste a monochrome BMP picture (Max. 192×64 pixels)

onto the screen.

Alarm list. Users can set 8 groups of alarm lists corresponding to 8

different hosts at most. There are at most 32 pieces of alarm information

in each group.

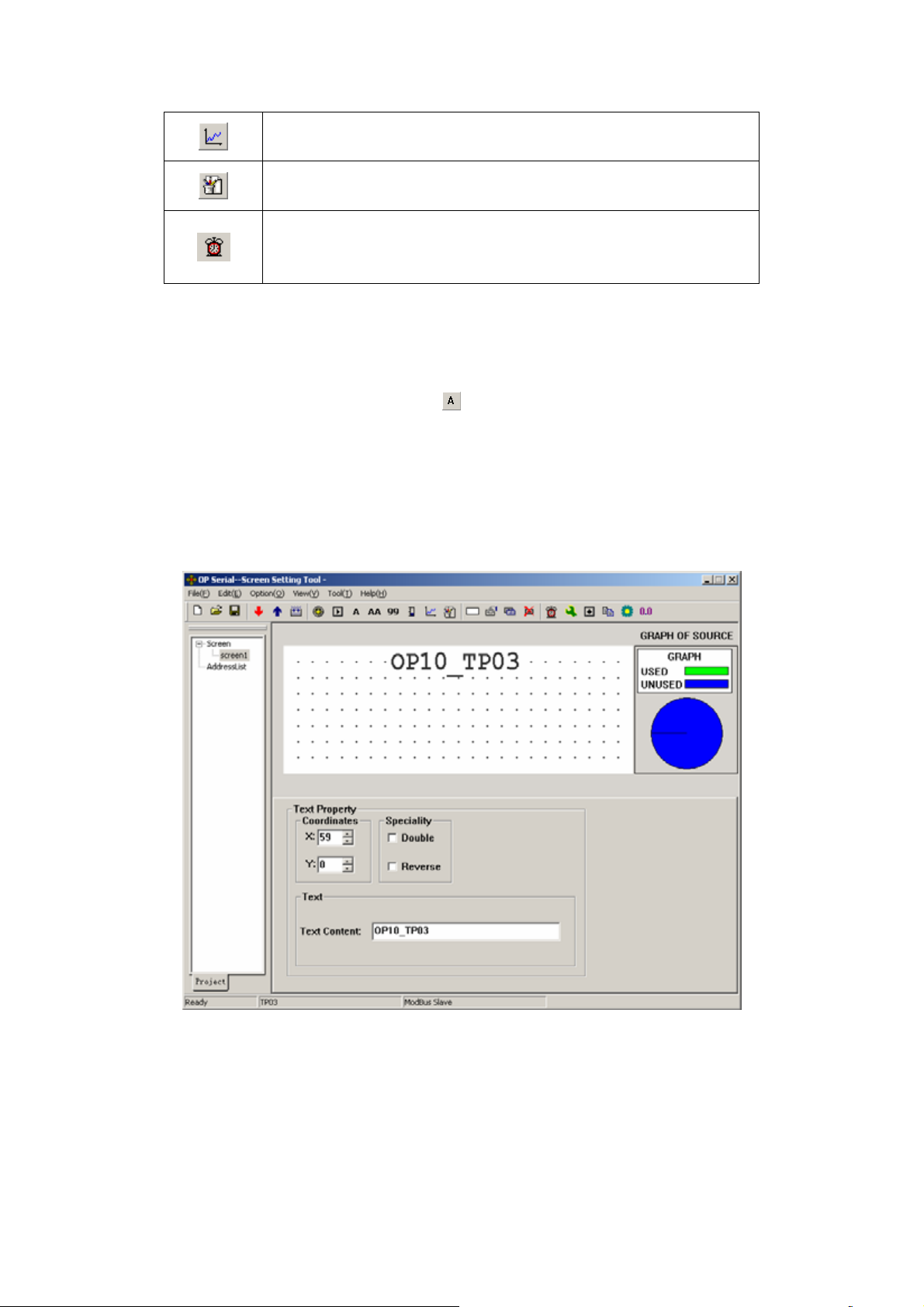

2.5.5 Text

The example below shows how to design a main menu screen as the screen no.1.

Firstly, lay the text “Main Menu”. Press

and click the left button on the editing region to

affirm the operation (right click will cancel it). After left click, the default text “TEXT” will be

displayed in the editing region. The properties of the text are displayed below the editing region.

The text string will move as the user moves the cursor. To locate the text in an arbitrary position,

edit the X and Y coordinates. Changing the content of the text to “OP10_TP03”, the

corresponding text string will be displayed in the editing region.

Coordinates

X value represents the horizontal position of the text string.

Y value represents the vertical position of the text string.

The origin of the position is the up-left corner of the screen.

Speciality

Double: The text will be displayed in double size, both horizontally and vertically.

Reverse: The text and the background will be displayed in reversed color.

12

Page 16

Tex t

The content that will be actually displayed is input here. The user can input English

letters or Chinese characters with various kinds of Chinese input methods in this textbox. The

content in it can be copied or pasted.

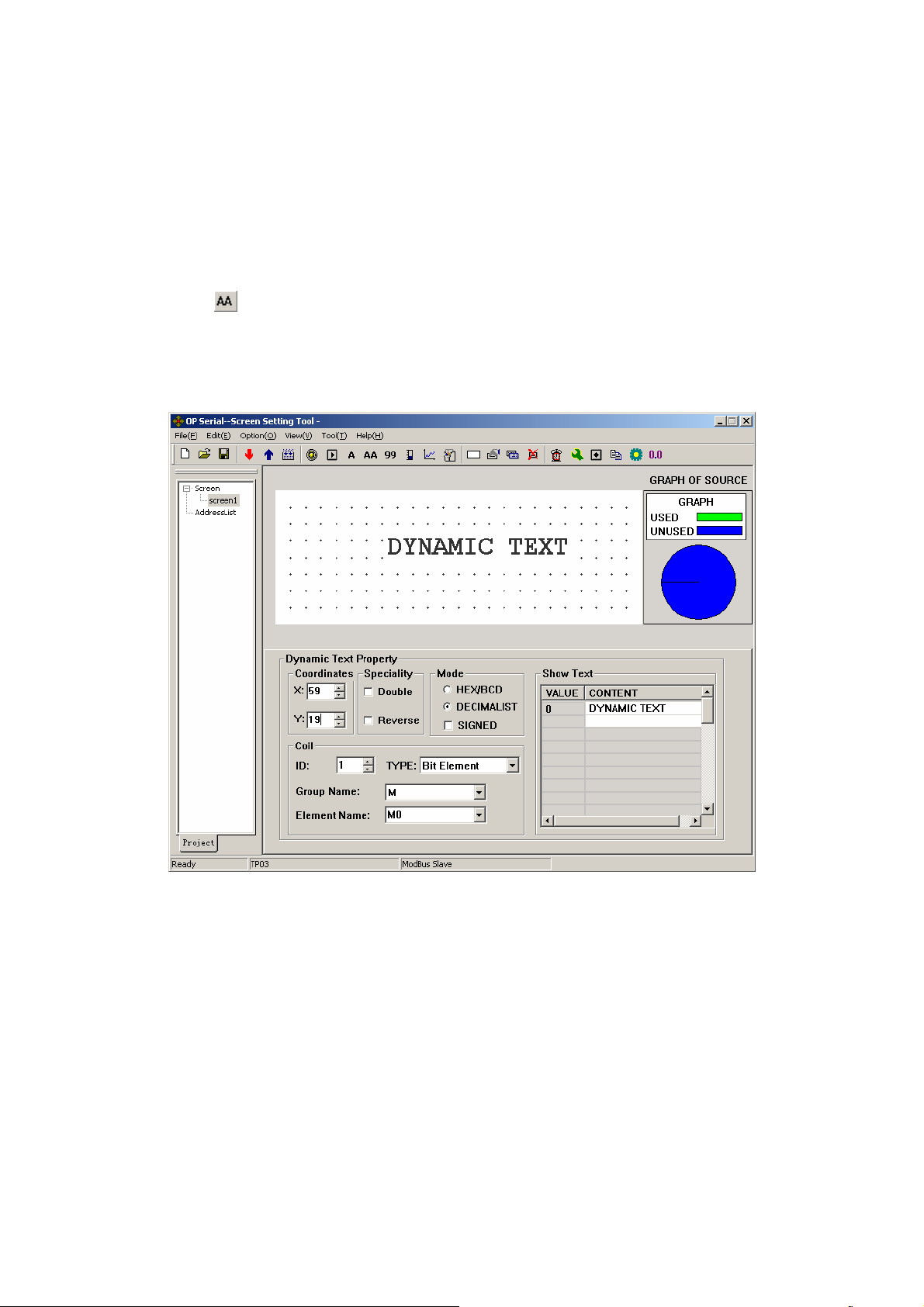

2.5.6 Dynamic Text

Press

and click the left button on the editing region to affirm the operation (right click

will cancel it). After left click, the default text “DYNAMIC TEXT” will be displayed on the

editing region. The properties of the dynamic text are displayed below the editing region. The text

string will move as the user moves the cursor. To locate the dynamic text in an arbitrary position,

edit the X and Y coordinates.

Coordinates

X value represents the horizontal position of the text.

Y value represents the vertical position of the text.

The origin of the position is at the up-left corner of the screen.

Speciality

Double: The text will be displayed in double size, both horizontally and vertically.

Reverse: The text and the background will be displayed in reversed color.

Coil

The PLC data register for controlling the status change of the dynamic text.

Mode

Determine the data form of the data register. The form will affect the display form of the

numeric items in the dynamic text.

Type

13

Page 17

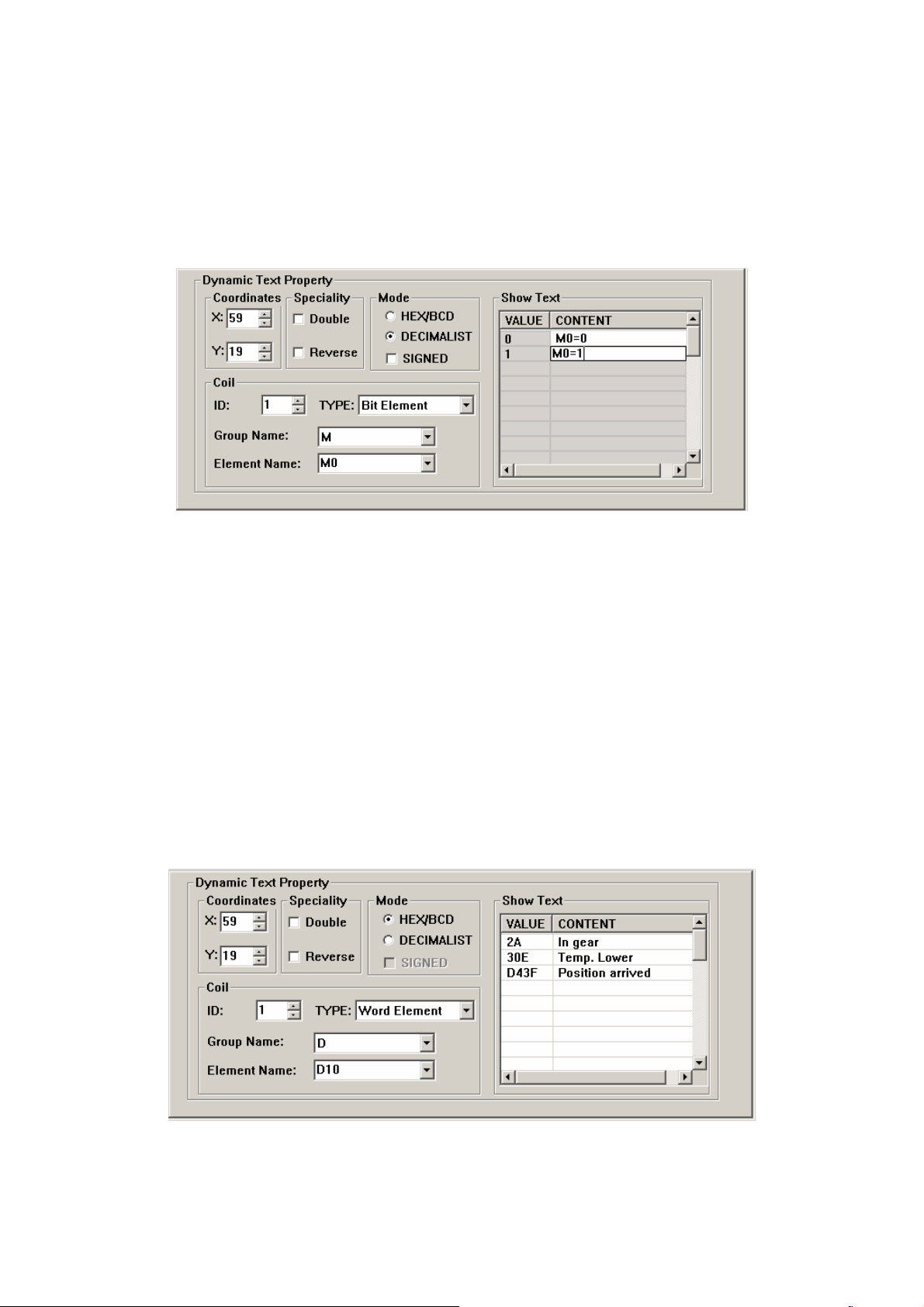

Users can choose “Bit element” or “word element”.

When users choose bit element, dynamic text relates with the status of the select

variable inside the PLC. The corresponding text can be set to 0 or 1, two kinds of status .

The picture below shows bit text:

When M0 is 0, the dynamic text shows “M0=0”. By contraries, it shows “M0=1”.

If the dynamic text corresponding to word element, it can keep the texts corresponding

to as many as 32 different statuses.

Display Text

Log the different text content corresponding to different values of the data register. It

can keep the texts corresponding to as many as 32 different statuses. The value of the text can

be inconsecutive. Consumers can input the value themselves.

Example: Display the dynamic text controlled by register D10. The dynamic text to be

displayed has three statuses: “In gear”, “Temp. Lower” and “Position arrived”. The three

texts correspond to the D10 register value 2a, 30e and d43f (HEX form) respectively. Input

“2a” in the “Value” space of the first row and “In gear” in the “Context” space on the right.

Input the other two statuses in the same way. If the value of register D10 is 2a, the dynamic

text be displayed is “In gear”. If it is 30e, “Temp Lower” will be displayed. Other conditions

can be inferred from the two examples above. The example is shown in the figure below:

14

Page 18

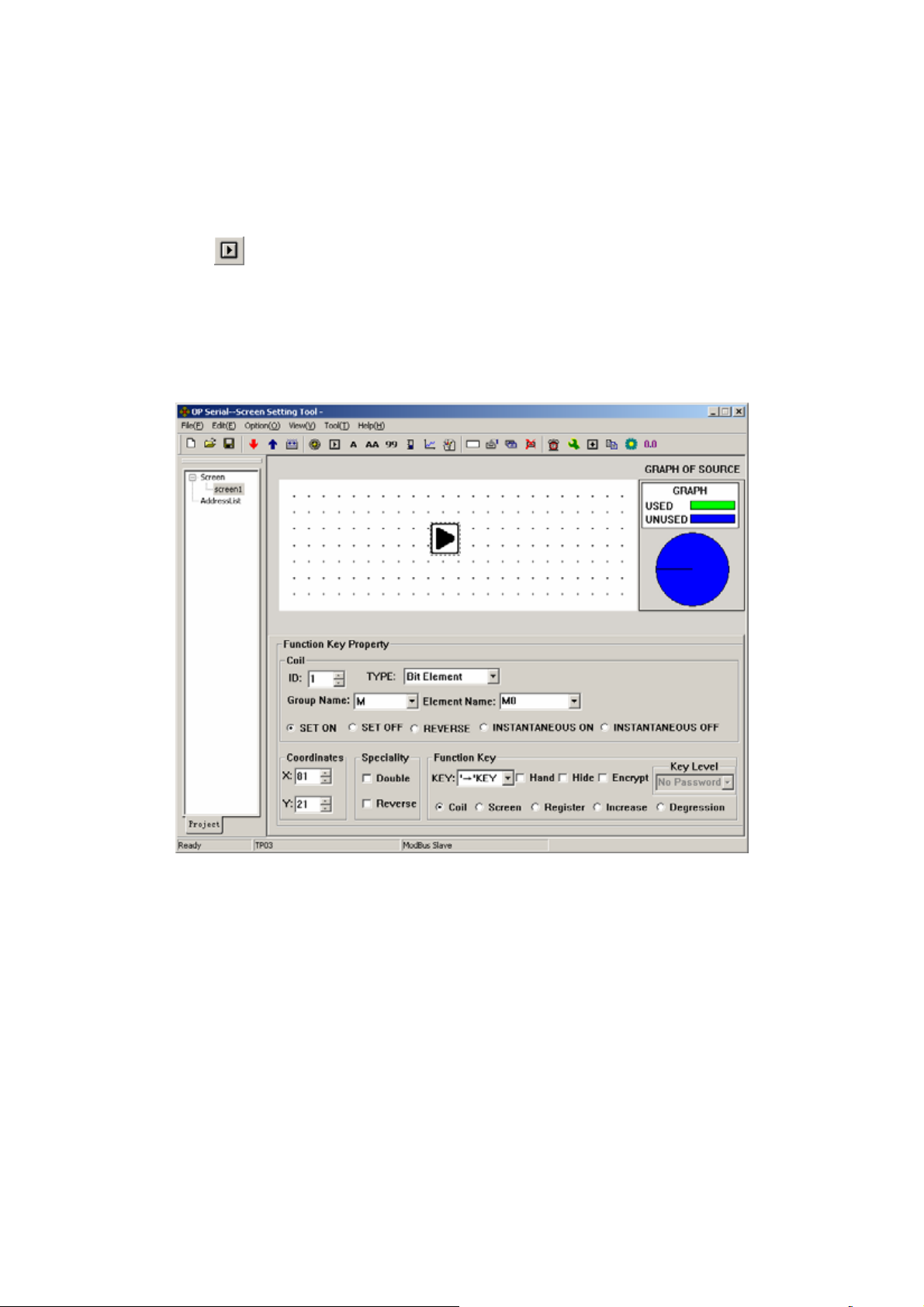

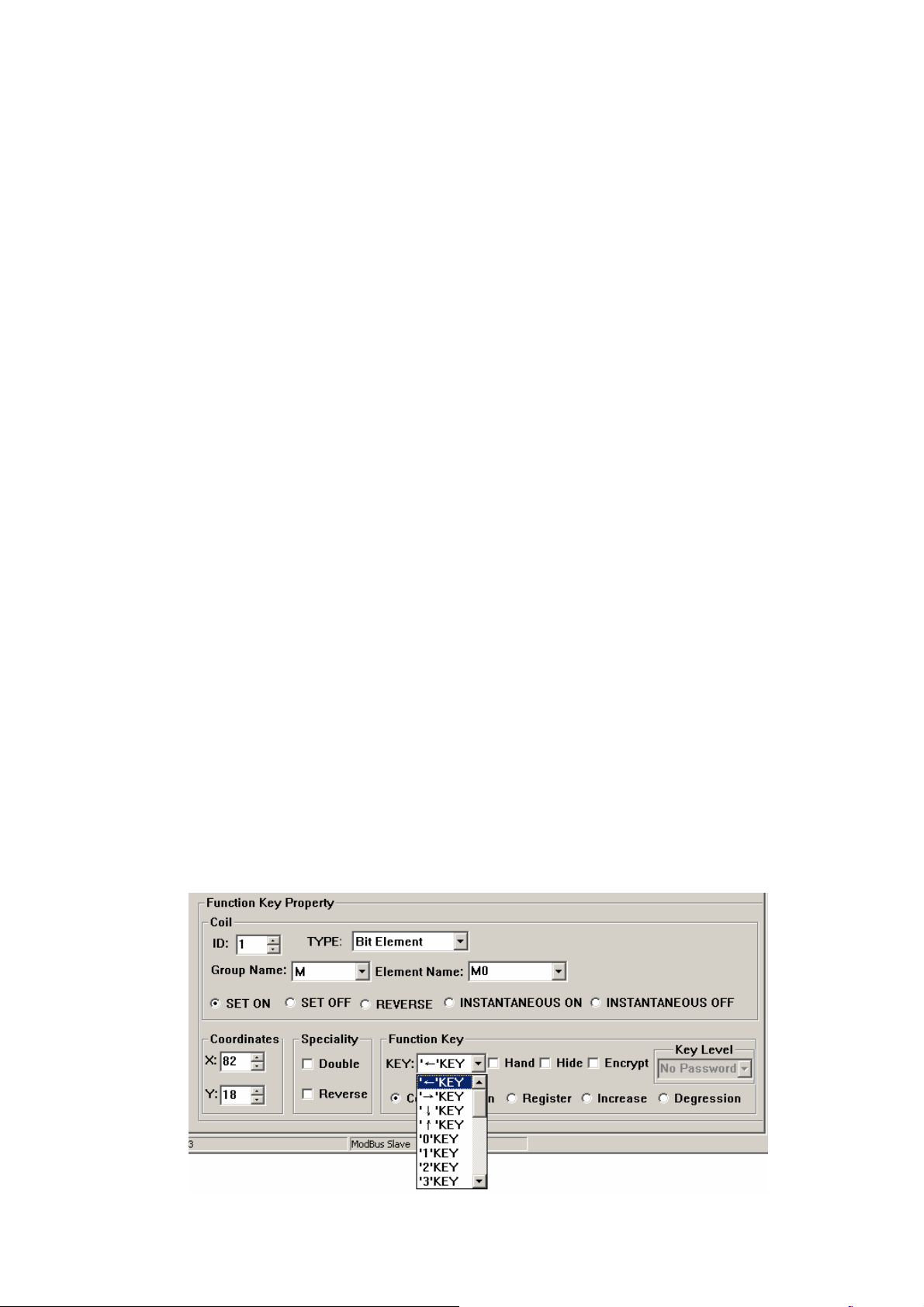

2.5.7 Function Keys

Next, configure the function keys in the main menu screen to execute the function of screen

jumping (for example, press [◄] to jump to the parameter setting screen; press [►] to jump to the

mode setting screen). The procedure of defining the function keys is:

Press

to activate a dotted rectangular box. The box moves as the cursor moves. Click

the left button to determine the position of the function key. A hand shape and the function key to

be defined (default key is [►]) are displayed in the editing region. The properties of the function

key are displayed below the editing region. The meanings of position and style are the same as

those in the text property. They indicate the position,the size and the color of the graph.

The function key setting screen is shown in the figure below:

Key

Select a proper key from the 24 keys. Do not conflict with system keys.

Hand

For the convenience of use, add a hand shape symbol before the key symbol. The hand

indicates that pressing the key will carry out an operation. The user can remove the hand

shape to save the space.

Hide

The user can make the symbols of some keys invisible in the screen. But the functions

of those keys are still valid.

Encrypt

Only when the system password is entered correctly, the function key can execute its

function.

Coil

The function key is defined to set a switch.

15

Page 19

Screen

The key is defined to execute the screen jumping function.

Register

The key is defined to set the register parameters.

Increase

The value of the destination register will increase an appointed constant in the range of

user-defined.

Degression

The value of the destination register will decrease an appointed constant in the range of

user-defined.

ID

The station number of PLC

Type

When the key is defined to set a switch, the definition number of the PLC relay

corresponding to the switch is determined by the type here.

Group name & Element name

Set the address of the relay.

Set ON

Set the designated relay on.

Set OFF

Set the designated relay off.

Reverse

Set the designated relay to be of negative logic.

Instantaneous on

The designated relay will be set on when the key is pressed down. When the key is

released, the relay will be set off.

Instantaneous off

The designated relay will be set off when the key is pressed down. When the key is

released, the relay will be set on.

Click the down arrow on the right of the list to show the names of the 24 keys. Select the

proper key to be defined.

16

Page 20

To make the screen simple, the hand shape can be removed by not selecting the checkbox

“Hand”. So only the keys are shown on the screen. Select the option button “Jump to” to define

the key as a screen jumping function key. Designate the target screen number below the key. If the

number is 10, it means screen no.10 is the parameter setting screen.

To hide the parameter setting screen, select the checkbox “Password” to enable the password

property. Thus the system will jump to screen no.10 only when the password entered has the same

or higher priority and it is correct.

After setting the function key, put the text “set parameter” beside the key symbol to inform

the operator that it will jump to the screen for parameter setting when [►] is pressed.

Note: To leave some margin for inserting new screens, the number of different kinds of screens

should be non-continuous.

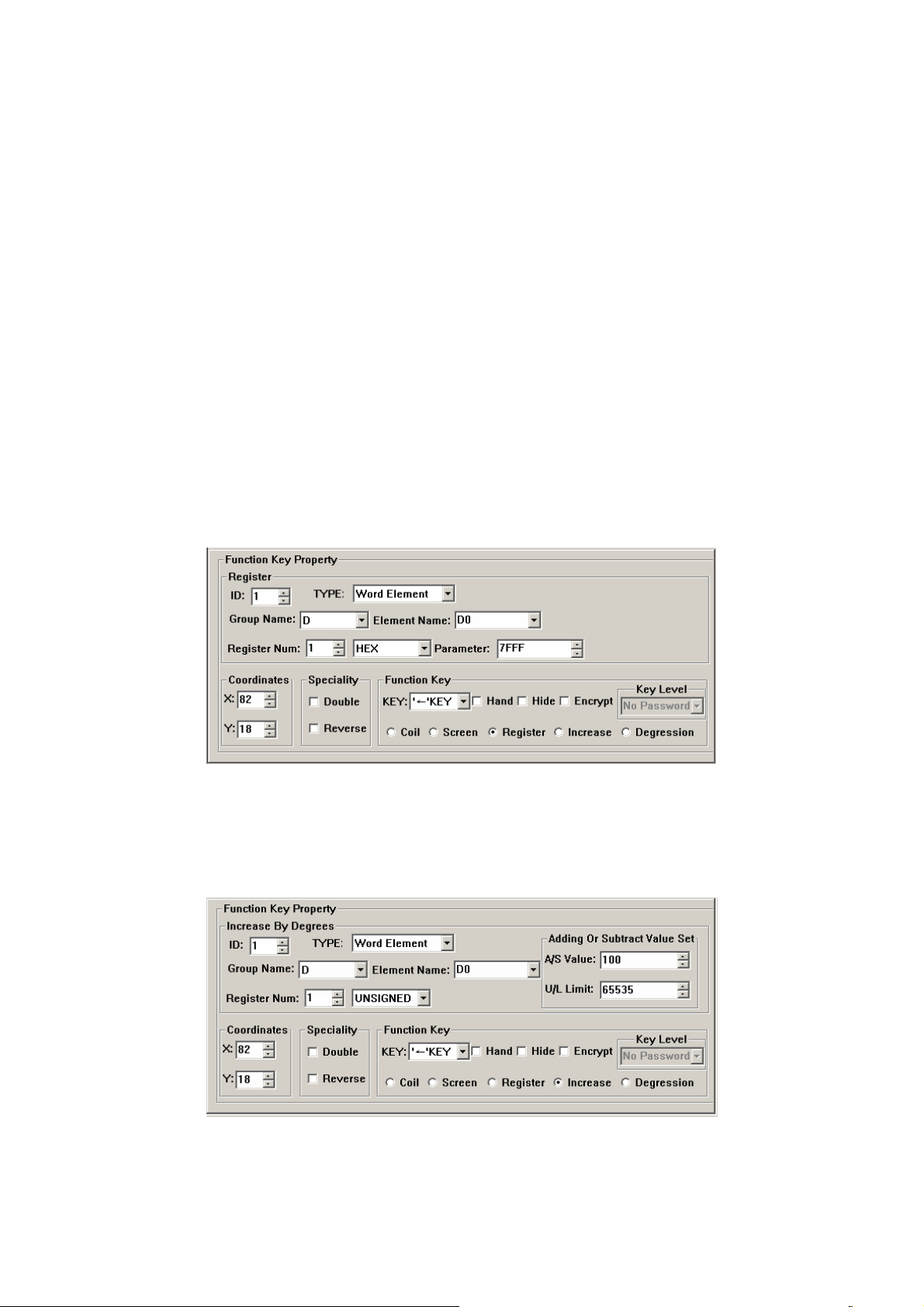

Setting register parameter with a single function key:

To write a parameter (or constant) to a designated register, select a function key from the key

list and select the option button “Register”. The constant parameter will be written to the

designated register when that key is pressed during running. Setting as the following figure will

write the hexadecimal number 7FFF to the D register at address 0.

Increasing the constant of the register with a single function key:

To increase a parameter (or constant) to a designated register, select a function key from the

key list and select the option button “Increase”. The constant parameter will increase by degrees

until reach the upper limit value. The example below can let the register D0 add 100 every time

when the key pressed, the upper limit value is FFFF (Hex).

Degression is similar. Users should set the lower limit value. Under the default condition, the Min

limit value is 0.

17

Page 21

2.5.8 Data Display

This section will introduce how to make a Set parameter screen. The methods of setting the

components such as parameter display, parameter setting and password setting are discussed in

detail.

The procedure of making the screen:

Click [Tool]→[New Screen] or click the screen description to pop up a dialog box for setting

the screen number and the screen description.

Screen Num:

The serial number of the new screen.

Screen Description

Descript the character of the new screen.

Click the blank of the screen editing region or click the screen description in the left of the

dialogue box to pop “Screen Property” dialogue box of the current screen.

“Up”/“Down” Key To Screen:

Choose the screen which to jump to when the [▼]/[▲] key pressed.

Option

Choose the communication port of the current screen. OP10 supports different screens

in one project communicating with other devices through different ports.

Put the data display boxes. Press

to show a rectangular dotted box moving with the

cursor. Click the left button in the proper position. The number “12345” in the dotted box

indicates that this component is a five-digits register displaying/setting box.

18

Page 22

The properties in the dialog box are:

ID

The definition number of the PLC register corresponding to the display component.

Register num

It is the amount of the registers being displayed or set. The minimum number is 1, and

the maximum is 2.

Encrypt

If selected, the data can be changed only when the correct system password is entered.

The command for setting the password is in the menu “Tools(T

)”.

Show

Input Digit

The maximum number of digits of the data being displayed or set

Point Digit

The length of the significant digits behind the decimal point

Indent Manner

Right Indent. When users only want to show the high bit, right Indent can be chosen.

Left Indent. When users only want to show the high bit, left Indent can be chosen.

Example: The presettable value of T register of SG2 is from 0 to 99999. Users can

choose 4 bits to show, left indent, ignore high bits. Now, the value is from 0 to 9999.

Decimalist.

The data in the register will be displayed in decimal form.

Signed

Only valid when the “Dec.” mode is selected. If the highest digit of the register is 1, the

data will be displayed as a negative number. For example, the hexadecimal number FFFEH

represents –2.

HEX/BCD

The data is displayed in hexadecimal form.

Set

The component can be used for setting data if it is selected. So the component can be

used for both monitoring and setting the data. The register set box has some special

properties: maximum, minimum and password.

Project data

Project data shows proportional data.

Example 1:

Set A output as below:

Group name= D; Element name= D0; Register Num= 1; Input Digit= 5; Point Digit= 0;

Decimalist; not show the negative.

19

Page 23

Use the same method to set the current screen, which shows the output of B. The register

address is D1. Other properties are the same as A.

After downloading the configuration screens from PC to OP10, OP10 will demand the value

of D0 and D1. Then the value will be displayed on the screen in time. Users only need to put the

output of A in D0, B in D1. They do not need to care the communication between TP03 and OP10.

Example 2: Project Data

If the input voltage of TP03 AD module voltage is 0-10V, the value of the corresponding

register is 0-1023 and that users only want to show the current voltage, users can set project data.

Suppose the corresponding register with AD is D0.

20

Page 24

The Converted Data= (original register data – Min Input) * (Eng. Max – Eng.Min) / (Max

Input – Min Input)

2.5.9 Data Setting

Continue the configuration of the parameter-setting window. Press

to show a dotted

box moving with the cursor. Move the cursor until the proper position is reached, then click the

left button to confirm the position. Select the “Set” checkbox. So the component has the function

of monitoring and setting the data.

If the “Set” checkbox is selected, two additional options, “Encrypt” and “Upper/Lower

Limited”, are enabled.

Encrypt

To enhance the security of the device, the operation of parameter setting can be

protected by password.

To set or change the password, activate the command “Tool(T)”→ “Encryption lever

set” to pop up a dialog for password setting:

21

Page 25

Enter a new password, change the original password or set the priorities of the passwords.

For example, enter “5678” , choose the priority “Mid-Level” and click “Ok”. Then the password is

affirmed.

There are at most 6 passwords which can be set in OP10. Those passwords are classified into

3 ranks. “High-level” has the highest priority with “Low-Level” having the lowest. For example,

if one specific key need a “Mid-Level” password to react, now inputting “Low-Level” password is

useless. You can input “Mid-Level” or “High-Level” password to run this function.

When the operator press the key [ENT], the OP10 will pop up a password enter window.

Appointed data can be changed only when the priority of the entered password the same as or

higher than the one of the registers, users can modify appointed data.

The password is effective only once. Users need to input the password again, when they want

to modify the data for a second time.

Limit Set

The designer can set limits to the data to make the data out of limits invalid. Thus the

possible damage done by inputting data too great or tiny is avoided. For example, let the

maximum input be 9000 and the minimum be 0. The setting value will be written into the

register only when it is between 0 and 9000, or the system will halt until a correct value is

entered.

Original and Project data

After selecting the “Limit Set” checkbox, the designer can select the original data or the

project data from the list.

Original data

The original data option means that the data in the register will be displayed without any

operation. The position of the decimal point is determined by the value of the “Decimal”

22

Page 26

property. For example, if “Decimal”=2 and the register value is 14561, it will be displayed as

14561

Project data

This option means that the data read from the register will be converted to project data

before being displayed. The conversion is done following the formula below:

The Converted Data= (original register data – Min Input) * (Eng. Max – Eng. Min) /

(Max Input – Min Input)

Users can use project data in such conditions, for example:

AD real input is 0-1023. But users want to show the data as 0-10V.

Calculate the new data which according to the input of project data.Then modify the

value of corresponding register inside the PLC to the new data. Etc.

Example: Users should set 0-10V to correspond with the AD inputting register D0(0-1023).

Set as below:

When user set 10, the value of D0 is 1023.

When user set 0, the value of D0 is 0.

The value of D0 (original register data – Min Input) * (Eng. Max – Eng. Min) / (Max Input –

Min Input)

23

Page 27

2.5.10 LED

Create a new screen like this:

Press

to put a LED. There is a dotted box moving with the cursor in the editing region.

Click the left button in the proper position to locate the LED.

Coil

The definition of the PLC intermediate relay that is corresponding to the LED

Shape

The shape of the LED, round and square.

Positive Logic

The LED is filled when the corresponding intermediate relay is ON. Unfilled when the

corresponding intermediate relay is OFF.

Negative Logic

The LED is unfilled when the corresponding relay is ON. Filled when is OFF.

24

Page 28

2.5.11 Function Keys (for controlling the status switches)

Press

to activate a dotted rectangular box. The box moves as the cursor moves. Click

the left button to determine the position of the function key.

Select button

. Set the attribute as below:

It means the status of coil M0 is reverse when

is pressed

25

Page 29

2.5.12 Bar Graph

The bar graph can give a direct view of some analog parameters such as flow rate, pressure

and level. The user can set the height, width and the direction of it arbitrarily.

Press

to show a dotted box that moves with the cursor. Move the cursor to the proper

position and click the left button to locate the bar graph there.

Register

The address of the register corresponding to the bar graph

Full Value

The register value corresponding to the full bar graph

Zero Value

The register value corresponding to the empty bar graph

Direction

The direction of the bar graph, including four options: up, down, left and right.

Size

The height and width of the bar graph

The next example shows how to use bar graph to show the pressure.

26

Page 30

The bar graph demands the data in D0.When the bar is full, it means the data is 1000 in

D0.When the bar shows the scale of 500, it means the data is 500 in D0.

Bar graph shows data directly. And it is real-time updating. It’s fit for showing pressure,

voltage or other signals like these.

27

Page 31

2.5.13 Trend Line

Some parameters in industrial control applications vary at a slow rate. Often, the operators

want to know the variations of these parameters in a certain of time. Trend line should be the best

choice.

Press

to show a dotted box that moves with the cursor. Move the cursor to the proper

position and click the left button to locate the trend line there.

Register

The address of the register corresponding to the trend line

Full Value

The register value when the trend line reaches the 100% of the scale

Zero Value

The register value when the trend line reaches the 0% of the scale

Data Collection (number of dots)

The total of the sample points in the whole trend line. The more sample dots does the

trend line has, the more detail it can provide. Certainly more sample dots make the time

period longer. The largest number of the dots is the width of the trend Line minus 2.

Timing Interval

The interval between two sample points . Max: 65535 seconds, Min: 1 second

Size

The length and width of the trend line. Max: 192*64 point, Min: 16*16point

Note:

1. A trend line component can display only one line.

2. There is no limit to the amount of the trend lines on the screen. But the amount of data

collection can’t be more than 384 on one screen.

3. The newest data is appeared on the right side of the trend line. When a new data comes,

other former data move to the next left grid.

28

Page 32

2.5.14 Alarm List

In industrial auto-control applications, alarming is a very important function. It can be used in

many cases. Alarm list is the most direct and simple method.

Every project of OP10 can have a cluster of alarm list information. Every piece of

information corresponds to a relay. The addresses of all the relays are continuous. The user can

designate the initial address of the relays. When any of the relays jumps from OFF to ON, the

corresponding alarm information is activated. OP10 will pop up the alarm window, where the

alarm information is displayed in the first row. If another relay jumps to ON, the new information

will be displayed in the second row. When some alarm relay jumps to OFF, the corresponding

alarm information will disappear automatically.

To log the alarm information, press

to pop up the alarm list dialog box:

The list is blank for no information has been logged. Move the cursor to the “Alarm

description” column and enter the information “Temp. too high”. Press “Enter” to show the screen

as the following figure:

29

Page 33

Input other information in the same way.

After entering all the information, set the coil type and address to M0 (for example) to

indicate that the relays M0-M2 correspond to three pieces of alarm information.

When OP10 is in gear, if M0 and M1 are set ON, it will pop up an alarm window and display

as the figure below shows:

Seeing this alarm window, the operator can take some measures to solute the breakdowns. To

return to the monitoring window, press [ESC]. When OP10 is displayed a common screen, users

can press [ALM], if they need to inquire about the status of the alarm information of current

destination controller. Then system will jump to the alarm screen.

30

Page 34

2.5.15 Chief button

Click

in the toolbar to pop a Chief Button dialogue box.

Click [New] to add “Å” button. Set the function as “set M0 on”.

The button of OP10 can be set for chief function. The priority order from high to low is:

basic function > local button > Chief button. So if there is a [Å] on the screen, OP10 will execute

the function which on the current screen when the button is pressed.

31

Page 35

2.5.16 Copy the value of registers form one device to other.

Click

in the toolbar to pop a Copy Register dialogue box.

Users can set 3 groups of relationships about registers transferring. Every communication

scanning cycle, OP10 will check the synchronization between source PLC and those of destination

PLC once. If source PLC has communication errors, OP10 won’t update the registers of

destination PLC. Every corresponding relationship contains one group of source addresses, 5

groups of destination addresses and can transfer 16 seriate word registers (not support double

words register transfer) at most.

Click “New” Button. An “Add Register” dialogue box will be popped.

Set the attribute of the register:

Example: Copy the content from D0-D10 of ID1 to D20-D30 of ID2.

32

Page 36

It doesn’t matter that source PLC and destination PLC are not on the same bus. OP10 can use

download port to communicate with source PLC, then send the data of registers to the destination

PLC through 485 bus. Users only need to choose the communication port in the dialogue box

simply.

33

Page 37

2.5.17 Preset dynamic text

In the example given below, the PLC type is TP03. Establish a new project, choose SV300 as

the device.

Click

in the toolbar to pop a dialogue box like this:

Set the relationship between the status of CMD component (Operation) and the dynamic text:

Choose the type “bit element”. Element name is “Operation”. When users use dynamic text

in the project, the relationship which is preset will be loaded automatically.

34

Page 38

Presetting dynamic text can correspond Chinese characters with the function of the registers.

It can help the users to be familiar with the registers inside the PLC quickly.

35

Page 39

2.5.18 Preset register

Example: SV300

Click

in the toolbar to pop Preset Register dialogue box.

Some register value has its own prescriptive format, such as the “Set Frequency” register of

SV300. If we set the value of the register as 50Hz, the real value of the register is 5000. Using the

presetting, we can set the actually frequency to be the same with the value which we set. Both of

them

are 50.

Set “Set frequency” register as the following picture.

Now if users put “Register components” in the editing region. Choose “Set Frequency”

register. The picture below will be shown on the screen:

36

Page 40

It is convenient for users to use Register components to control registers with prescriptive

format.

37

Page 41

2.6 Save Project

Press or ckick [File]→[Save] to show the save dialog box:

Select the proper path and filename to save the file. The system defines “opf” as the default

external filename.

Enter the filename and select the proper path, then click “Save”.

2.7 Download Window

Connect the 9-pin RS232 serial port of PC and that of OP10 with the communication cable.

Make sure that OP10 is connected with a 24V DC power supply.

Click “File(F)”→“Port” to set communication attribute:

38

Page 42

Pop such a dialogue box:

This dialogue box is used to setting the communication port of downloading configuration

screen. Users should set the attribute of serial port carefully.

Choose “Option(O)”→“write” or press

to begin the download process.

Each screen has a certain character room to describe its own function. Users can choose

whether these characters download to the memory of OP10. Next time, these characters can be

displayed when the project is uploading.

If choose “No (

N)”, OP10 won’t these characters.

A dialog box will be displayed to indicate the progress of downloading:

If OP10 successfully downloads all the screens:

If OP10 fails to download the screens:

When you see the communication error, please check the power supply, whether the

download cable connected in the right way and whether users have chosen the proper COM port.

39

Page 43

2.8 Importing .OPf Project

Users can read the data of project in OP10. The precondition is that the project isn’t

encrypted (the “Encrypt Project” option has not been chosen , ss pre

dialogue box).

you can see the

Encrypt: When this option has been chosen, the data is protected. Users can’t use

OP10-PCLINK to read the project.

The flow of reading project is as follows:

Press “File”→ “Port”:

Choose the proper PC serial port.

40

Page 44

Click in the toolbar or choose “Option”→“Read”.

Reading:

41

Page 45

Reading successful:

Just as the picture show, after successful reading the project, users can go on to edit it.

The condition we just talk about is that users didn’t set password (level) yet.

If users already set password (level) like this:

42

Page 46

Click in the toolbar or choose “Option”→“read”. The dialogue box will be displayed on

the Pc screen.

Input the highest-level password of the project ---“6666” to go to the next step. If there are

more than one high-level password, inputting anyone of them is suitable.

43

Page 47

3 Manipulation

3.1 Communication

Connect OP10 and PLC with a communication cable. (Pay attention to 3 ways of connection:

232/422/485.)

Turn on the power supply for both OP10 and PLC. If communication is in gear, OP10 can

carry on the operations such as data monitoring. If there are communication-parameter errors or

connection-cable errors, the communication will be failed. The type of error will be winked in the

center of the display. It shows the condition of communication.

3.2 Changing the screens

Consult other examples.

3.3 System Password

( Read the data of the project by using password: If there are passwords in the project, and there

are no options to encrypt the system, users can upload the project to pc and use the software to edit

it again.User must input the high-level password to read the data, when there is a dialogue box,

which inquired inputting password, popped during reading.)

44

Page 48

Example 1:Encrypt the key when the key controls registers.

Put

button in the editing region. Set the function as: Change the value of D0 into 1234.

Users must set password (level) first to use the “Encrypt” function. So now if you choose

“Encrypt” box, a warning dialogue will be popped. Because the system has not been set password

yet.

45

Page 49

Choose “Tool” Æ“Encryption level set” to pop dialogue. Set 6 passwords.

Return to the screen to set the key level. Choose “Mid-Level”.

After configuring the function well, users need to input password when press

46

button.

Page 50

Because we set the Key Level as “Mid-Level”, when users input low-level password can not

carry out the function to set the register. Only to input Mid-Levei or High-Level password can set

the value of D0 1234.

Example 2: Encrypt when set the value of registers.

Users correspond the widget with D0, choose “Set” and “Encrypt” option. Set “Key-Level”

as “High-Level”.

Users need to input the password, when they press [SET] button. Users won’t have the right

to modify the data, unless the password they have just input having the high level. Any of the

high-level password is ok. Then the passoword is effective for one time. The next time when you

need to input password, you should input the password again.

Remind of setting password: OP10 has different levels of passwords. And the password is

effective for just once. So if in one screen there are more than one widgets used for inputting and

all of these widgets are needed passwords to work, users can let the screen hidden. Set a certain

button (Pressing the button the display will jump to the hidden screen. )with high-level password.

Make sure that only system controller can interview this screen.

47

Page 51

4 Create new device

OP10 supports that users can add new devices based on the existent communicaiton protocol,

such as adding a new PLC device which sustains MODBUS RTU protrocol.

Click

will be popped.

in the toolbar to create a new project. A “New and Select Device” dialogue box

48

Page 52

Click “New Device”:

Protocol Select: There is a ModBus Slave protocol inside OP10. Based on the

proto ,

col users can define address lists of communication buffer (of destination controller).

The size of Communication buffer: the maximal limit of communication buffer.

Display Format of 32Bit-Register: In the communi

cont r

rolle whether displays the low word in the front or nor.

Device Name: Set the name of new devic

es. The names will appear in the device

cation command, the destination

list. Users can choose the new device expediently.

Set communication protocol, the size of the buffer, display form

at of 32bit-register and the

device name. Users can edit the address list after Clicking “OK”.

49

Page 53

Choose “Edit”→“New Element Group”:

calle

elem

com

themselves.

Element Group Name

: the name of new group. For example, there are registers

d X,Y,M,TD,etc. in TP03.

Element Property: T

here are 3 types of elements can be chosen. Bit element, word

ent and dword element.

Whether have communication command of read

munication command of read and write coil.

Th

e Interval of 32 Bit-Register: Users can define the interval of 32bit-register

and write coil:: Whether have

50

Page 54

Set the Element group name as “M”. default other attribute default Click “OK”.

Choose “Edit” now, some options are changed.

New Element Group: Repeat former works

Delete Element Group: Delete the group which has been selected

New Element: Create a new element in the selected group.

Delete El

51

ement: Delete a new element in the selected group.

Page 55

Create a new element

Click “New Element”:

Element Group Set: Select the group of new elements

New Manner: Add a single element or create elements as a batch

Element Set:

1. Element: add the name of the element

2. (start) Address: the primal ad

3. Position: the primal address

Add a single element:

dress of creating elements as a batch

52

Page 56

Clicking “Ok”, then there will be a new coil called M0 in the group M. Its address is 0.

Creating elements as a batch:

Choose “Batch new”, you will see:

53

Page 57

Element Number Type: Set the type of element number as oct, dec or hex. For

example: The X,Y elements of TP03 are octal, but the D,T,C elements are decimal.

Address Interval ( Increase ):可 Set interval of two closer elements discretionarily.

New Element Amount: The amount of new elements.

Start Element Name Number: Set Start Element Name Number.

Set M1 as the primal element. The amount of new elements is 9. Its address is 1. Other

attributes are default. Clicking “OK”, The elements in the M group are shown in the picture as

below.

According to the picture, the result of creating elements as a batch is the same as creating a

single element. If there is a certain rule of those elements, we suggest that users can create

elements as a batch.

54

Page 58

Delete elements:

Select M9 in the address list:

Choose “Edit”→“Delete Element”:

Select “Delete element” to pop a confirmation dialogue box:

55

Page 59

Click “Yes (

Y)”. Address list has changed:

M9 has already been cancelled.

56

Page 60

5 Communication

5.1. Communication port

OP10 has two communication ports:COM1 and RS485.COM1 is using for downloading

(writing) users’ program, and affords RS422 port. RS485 affords RS485 port.

1. 9-pin D-shape male plug (COM1)

Pin1

Pin9

2. RS485:

Num Name Description

1 TX+ 422 send positive signal

2 RX 232 receive signal

3 TX 232 send signal

4 NC (This pin connect to the CPU pin inside OP10. Low

level: The 232 communication port of OP10 is ready

to receive configuration data. High level: no use )

5 GND GND

6 TX- 422 send negative signal

7 RTS (VCC, give power supply to SG2 program cable)

8 RX- 422 receive negative signal

9 RX+ 422 receive positive signal

Num Name Description

1 A 485 positive signal

2 B 485 negative signal

3 SG 485 GND

57

Page 61

5.2 Communication connect

d

(OP10-PCLINK)

5.2.1 OP10 downloading cable ( write configuration screens )

PC side 2 RX 3TX OP10 side

3 TX 2 RX (9-pin D-shape

female plug)

Black 4 Gray

5 GND 5GND

ownload cable

9PIN(

4KA97X033W01

female)

shielded

PC side(black)

shielded

OP10 side(gray)

(9-pin D-shape

female plug)

9PIN(male)

1

6

2

7

3

8

4

9

5

Black

(PC with serial port)

Gray

(If there are no serial ports on PC, we need a USB serial port: 4KA97X017W01)

5

9

4

8

3

7

2

6

1

5.2.2 Connect with TP03 (include SR type) PG port through RS-422

1 TX+ 2RX+

OP10 side 6 TX- 1RX- PLC side

8 RX- 4TX- (9-pin D-shape

female plug)

5GND 3GND

58

9 RX+ 7TX+

(8-pin round male

plug)

Page 62

Idiographic connection: (TP03-102MC cable)

COM

COM

0

1234

5

6

RUN

+24V

STOP

output

0V

IN

1

324657

013

SG

OUT

01 324657

B

A

COM0

COM1

0

123

710 1211

PWR

20SR-A

5

9

4

8

3

7

2

6

1

RUN

1110

12

13

6547

shielded

9PIN(female)

SR-A系列

TP03系列

(TP03-102MC)

TP03-102MC

8PIN(male)

7 8

6

45

3

21

5.2.3 Connect with TP03 through 485 port

0P10

RS-485

A A 1

B

TP03:

TP03 485 port

B 2

59

Page 63

TP03SR:

COM

COM

0

123

+24V

output

0V

IN

SG

OUT

B

A

COM0

5.2.4 Connect with SG2 through 232 port (suitable for all types of SG2)

A2

A1I4 I6I5+-I1 I2 I3

DC 24V Input 8 x DC(A1,A2 0~10V)

5

710 1211

4

6

RUN

PWR

STOP

1

324657

01

01 324657

20SR-A

COM1

123

0

13

RUN

12

1110

3

547

6

Run

SG2-12KR-D

Q1 Q2

SG2-Client

5.2.5 Connect with SG2-V type with 485 port

60

Page 64

5.2.6 Connect with EV300 through 485 port

JNSIF-485

SIF-485

5.2.7 Connect with SV300

black

red

red

black

SIF-485

61

Page 65

62

Loading...

Loading...