Page 1

P

MMooddeellss:: MMEESS11AA,, MMEESS11BB

MMooddbbuuss TTCCP

ttoo

MMooddbbuuss AASSCCIIII // RRTTUU

CCoonnvveerrtteerrss

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 2

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 3

International Headquarters

B&B Electronics Mfg. Co. Inc.

707 Dayton Road

Ottawa, IL 61350 USA

Phone (815) 433-5100 -- General Fax (815) 433-5105

Website: www.bb-elec.com

Sales e-mail: orders@bb-elec.com

Technical Support e-mail: support@bb.elec.com

European Headquarters

B&B Electronics Ltd.

Westlink Commercial Park

Oranmore, Co. Galway, Ireland

Phone +353 91-792444 -- Fax +353 91-792445

Website: www.bb-europe.com

Sales e-mail: sales@bb-europe.com

Technical Support e-mail: support@bb-europe.com

© B&B Electronics – May 2006

-- Fax (815) 433-5109

-- Fax (815) 433-5104

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 4

Page 5

©

2006 B&B Electronics. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photography, recording, or any information storage and retrieval system without written consent. Information

in this manual is subject to change without notice, and does not represent a commitment on the part of B&B Electronics.

B&B Electronics shall not be liable for incidental or consequential damages resulting from the furnishing, performance, or use of

this manual.

All brand names used in this manual are the registered trademarks of their respective owners. The use of trademarks or other

designations in this publication is for reference purposes only and does not constitute an endorsement by the trademark holder.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 6

Page 7

TTaabbllee ooff CCoonntteennttss

CHAPTER 1: INTRODUCTION............................................................................. 1

ABOUT THIS MANUAL ............................................................................................... 1

SUPPORT.................................................................................................................... 1

ABOUT YOUR MES1A/B CONVERTER ...................................................................... 1

FEATURES.................................................................................................................. 2

CHAPTER 2: HARDWARE OVERVIEW............................................................. 3

PACKAGE CHECKLIST ................................................................................................ 3

INDICATORS, SWITCHES AND CONNECTORS............................................................... 3

Power LED ........................................................................................................... 3

Link LED............................................................................................................... 4

Activity LED.......................................................................................................... 4

RS-422/485 Switch (MES1B only) ........................................................................4

Ethernet Port Connector.......................................................................................5

DB-9M Serial Port Connector (MES1A only).......................................................5

RS-422/485 Connector (MES1B only).................................................................. 5

Power Connector.................................................................................................. 7

CONNECTING THE HARDWARE .................................................................................. 7

CHAPTER 3: GETTING STARTED.................................................................... 11

QUICKSTART ........................................................................................................... 11

1. Check the contents of your MES1A/B package. It should contain…........... 11

2. Set up the Hardware ................................................................................... 11

3. Software Installation................................................................................... 11

4. Discover the MES1A/B on the Network...................................................... 12

5. Configure the MES1A/B.............................................................................. 12

6. Modbus Device Installation........................................................................ 12

USING THE DEVICE INSTALLER SOFTWARE ............................................................. 13

System Requirements .......................................................................................... 13

Installing the Device Installer............................................................................. 13

Starting the Device Installer............................................................................... 14

Discovering Devices ........................................................................................... 14

Getting Device Details........................................................................................ 15

Connecting to the MES1A/B ............................................................................... 16

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

i

Page 8

CHAPTER 4: CONFIGURING THE MES1A/B.................................................. 19

NAVIGATING THE CONFIGURATION MENU .............................................................. 20

1) NETWORK/IP SETTINGS....................................................................................... 22

IP Address........................................................................................................... 22

Default Gateway ................................................................................................. 23

Netmask............................................................................................................... 24

Telnet Configuration Password.......................................................................... 24

2) SERIAL AND MODE SETTINGS.............................................................................. 24

Protocol .............................................................................................................. 25

Serial Interface.................................................................................................... 26

3) MODEM/CONFIGURABLE PIN SETTINGS............................................................... 27

4) ADVANCED MODBUS PROTOCOL SETTINGS ........................................................ 28

Slave Address / Unit ID Source........................................................................... 29

Allow Modbus Broadcasts .................................................................................. 30

Use MB/TCP 00BH/00AH Exception Responses................................................ 30

Disable Modbus/TCP Pipeline............................................................................ 31

Character Timeout.............................................................................................. 31

Message Timeout ................................................................................................ 31

Serial TX Delay after RX .................................................................................... 32

Swap 4x/0H to Get 3x/1x..................................................................................... 32

5) UNIT ID TO IP ADDRESS LOOKUP TABLE SETTINGS............................................ 32

Close Idle TCP Sockets After.............................................................................. 32

Redundant Entry Retries After............................................................................ 33

Add, Delete, Exit - Select Function.................................................................... 33

Modbus Address From/To................................................................................... 33

Slave IP Address................................................................................................. 34

CHAPTER 5: USING OTHER DEVICE INSTALLER FEATURES................ 35

MANAGING DEVICE LISTS ....................................................................................... 35

Creating a New Device List................................................................................ 35

Saving Device Lists............................................................................................. 36

Opening Device Lists.......................................................................................... 36

Device List Display Options ............................................................................... 36

Adding a Device Manually.................................................................................. 37

ASSIGNING AN IP ADDRESS (USING DEVICE INSTALLER).........................................38

Using Device Installer to Assign an IP Address................................................. 38

USING THE DEVICES DETAILS TAB.......................................................................... 39

UPGRADING FIRMWARE........................................................................................... 40

INSTALLING PRE-SAVED CONFIGURATION FILES.....................................................41

Saving Setup Records.......................................................................................... 41

Installing Setup Records..................................................................................... 42

LOGGING SEARCH AND UPGRADE DATA ................................................................. 43

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

ii

Page 9

USING PING ............................................................................................................. 45

USING HELP............................................................................................................. 45

CHAPTER 6: MODBUS BASICS.......................................................................... 47

MODBUS ASCII/RTU.............................................................................................. 47

MODBUS/TCP.......................................................................................................... 48

HINTS AND TIPS....................................................................................................... 49

APPENDIX A: DEFAULT CONFIGURATION SETTINGS.............................. 51

APPENDIX B: PRODUCT SPECIFICATIONS .................................................. 53

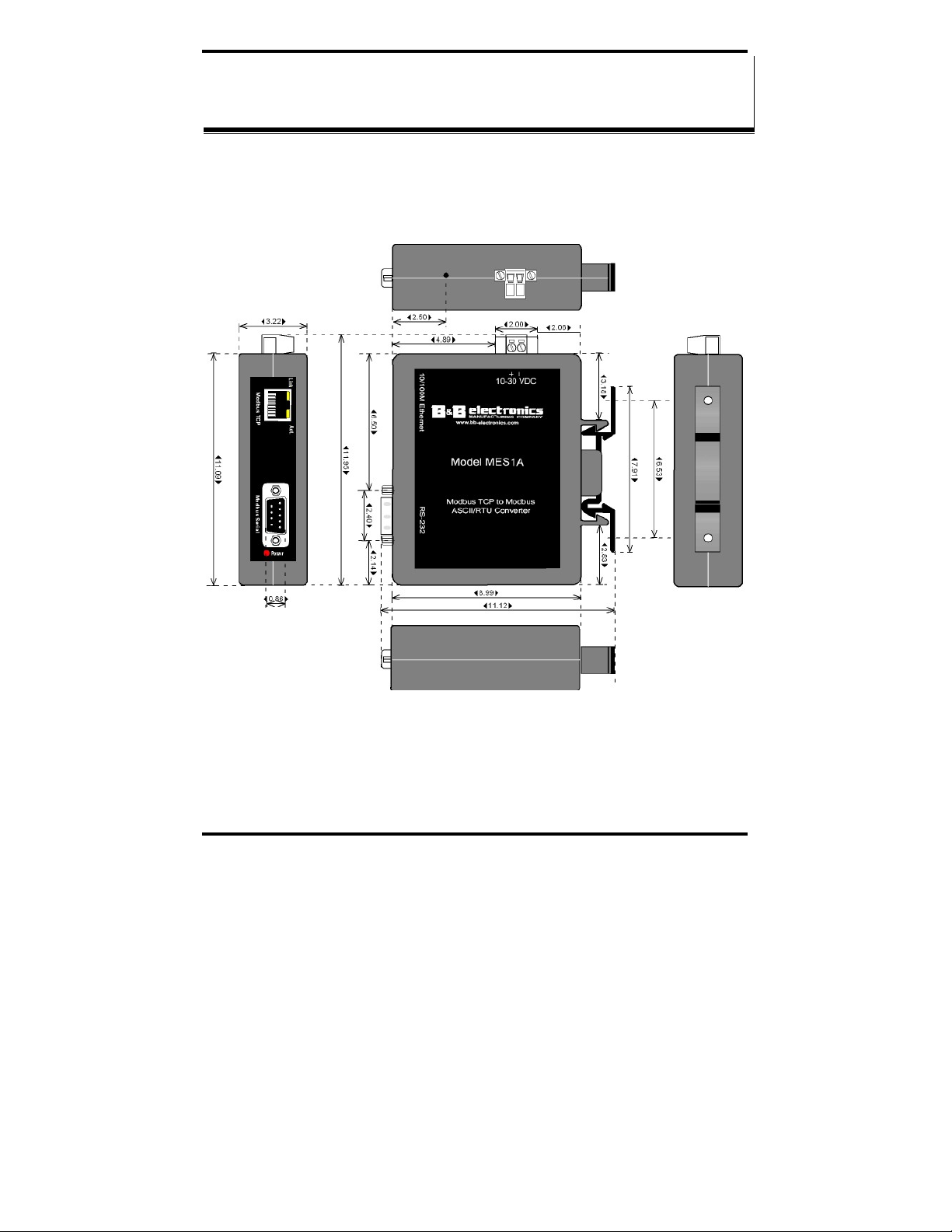

APPENDIX C: DIMENSIONAL DIAGRAMS.....................................................55

APPENDIX D: SERIAL CONNECTIONS........................................................... 57

APPENDIX E: NETWORK CONNECTIONS.....................................................59

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

iii

Page 10

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

iv

Page 11

Introduction

CChhaapptteerr 11:: IInnttrroodduuccttiioonn

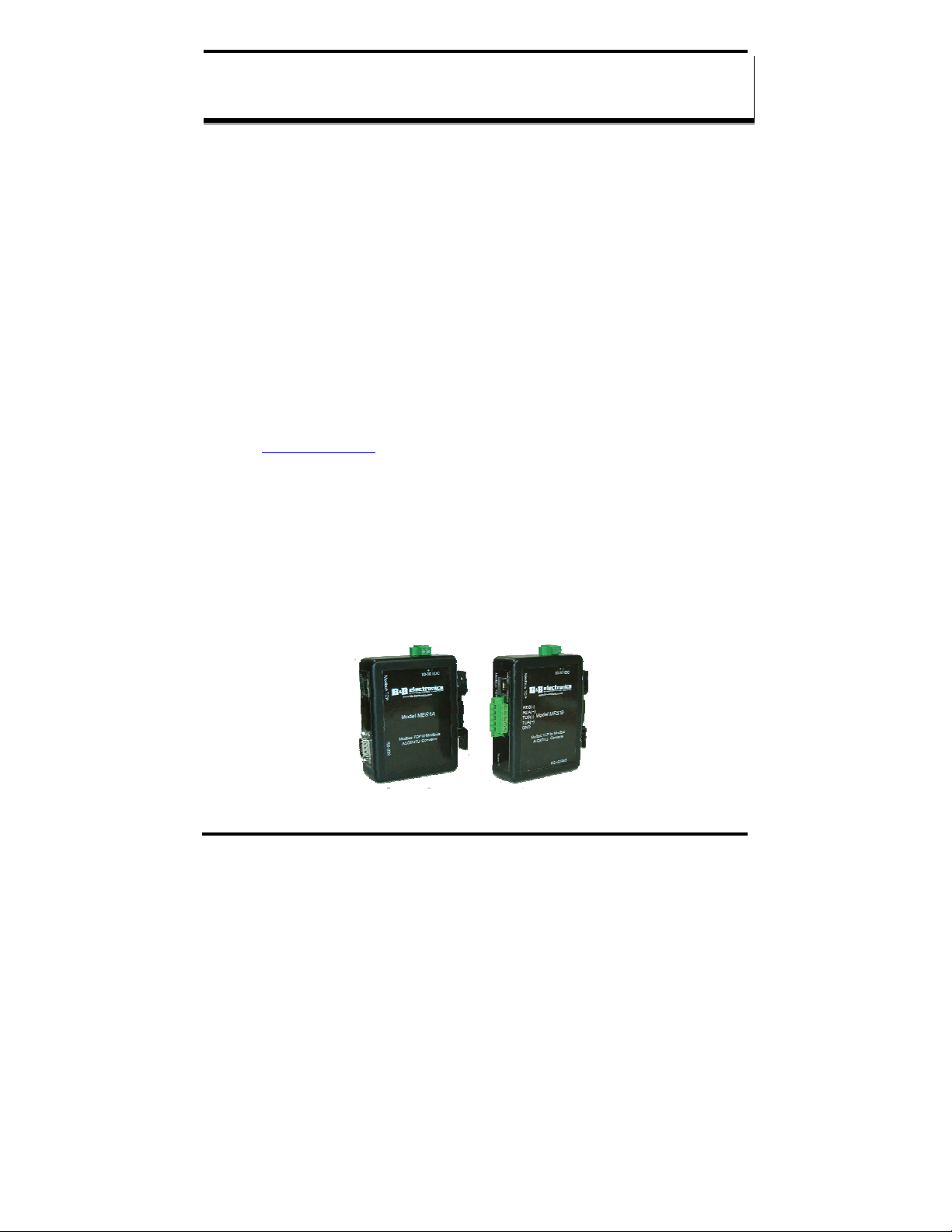

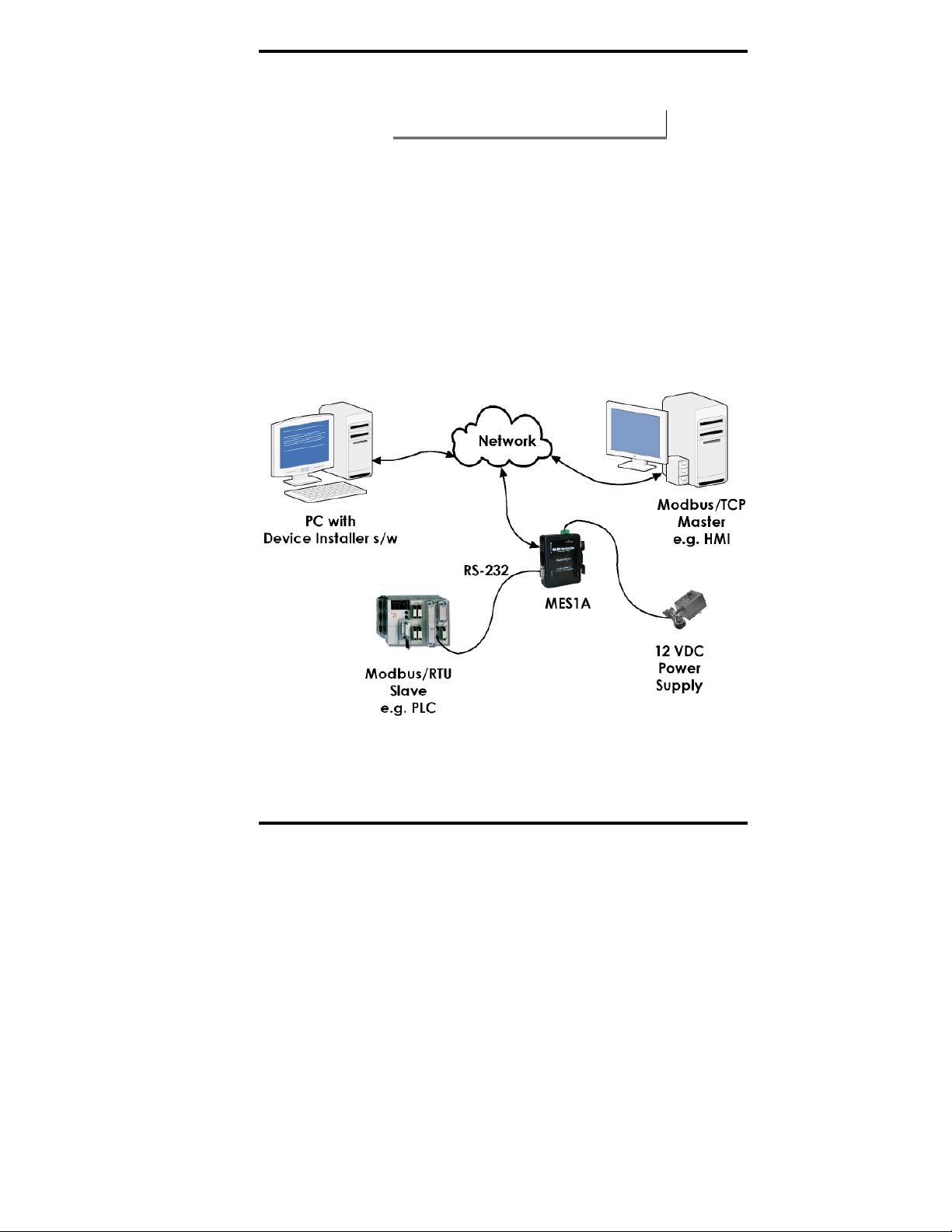

Thank you for purchasing an MES1A or MES1B Modbus TCP to

Modbus ASCII/RTU Converter! Like all B&B Electronics products, this

product has been manufactured to the highest standards of quality and

performance to ensure your complete satisfaction.

About this Manual

This manual has been created to assist you in installing, configuring and

using the MES1A/B. Please read it carefully and follow the instructions to

achieve best results.

Support

For additional information on this and other B&B products, and for technical

support, call 815.433.5100 option 3, or access B&B Electronics’ website at:

www.bb-elec.com

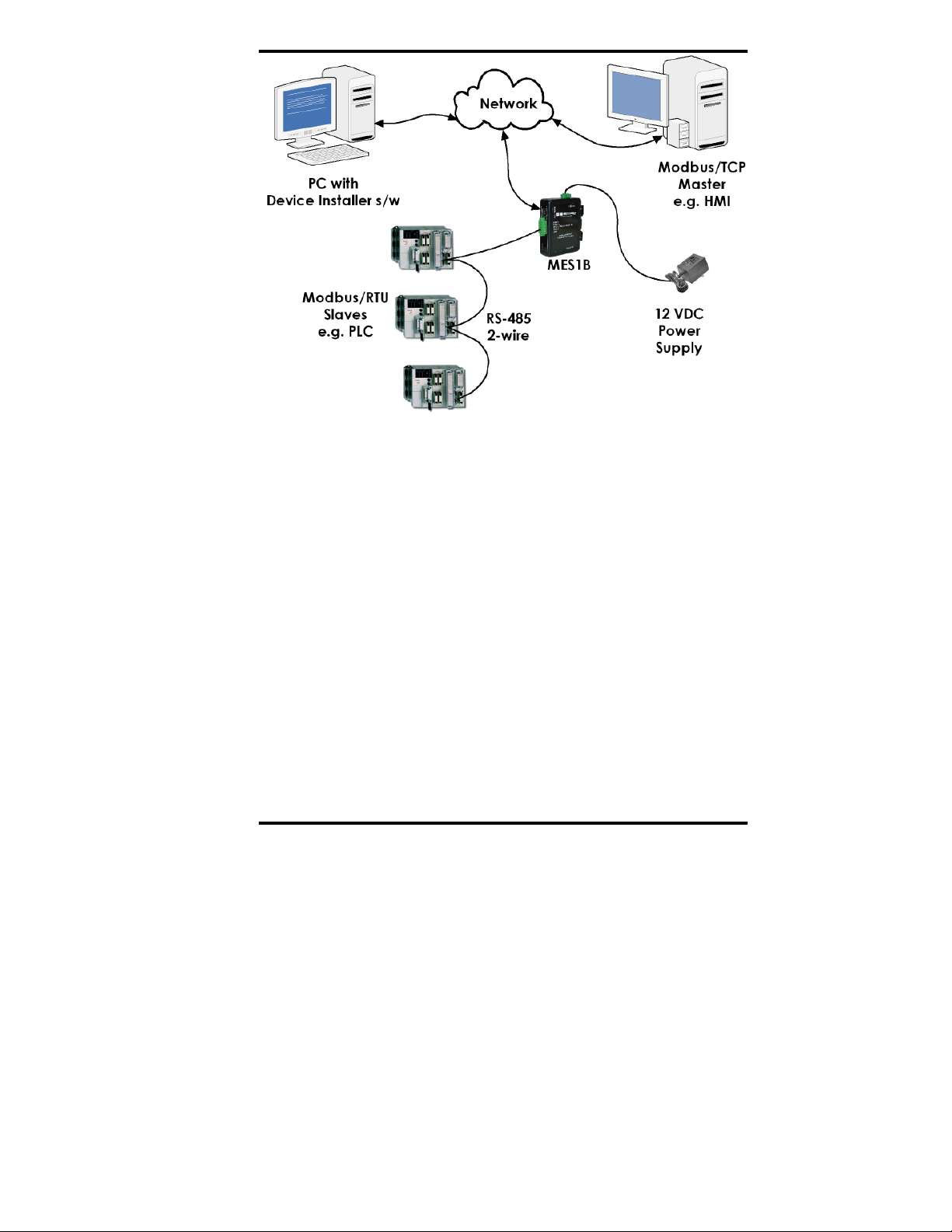

About Your MES1A/B Converter

MES1A and MES1B Modbus TCP to Modbus ASCII/RTU Converters

are easy-to-use, cost-effective solutions for connecting new and existing

Modbus ASCII/RTU serial devices to TCP/IP networks. The MES1A

provides this connection for Modbus devices with RS-232 interfaces; the

MES1B facilitates Modbus devices with RS-422 four-wire point-to-point

interfaces, or RS-485 four or two-wire multi-drop bus connections.

Figure 1. MES1A and MES1B Converters

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

1

Page 12

Introduction

MES1A Converters allow new and legacy Modbus ASCII/RTU slave

devices with RS-232 serial ports to operate on a TCP/IP network as full

Modbus TCP slaves. All Modbus TCP devices on the network can share

access to the Modbus ASCII/RTU device.

MES1B Converters allow Modbus/RTU slave devices with RS-422/485

interfaces to operate on a TCP/IP network as full Modbus TCP slaves. All

Modbus devices on an RS-485 bus can be connected to the TCP/IP network

via the MES1B, allowing them all to be accessed by Modbus TCP/IP devices

on the network.

Traditional Modbus ASCII/RTU master devices also can be connected to

TCP/IP networks using the MES1A/B, making the device appear to be a full

Modbus TCP master on the network. It can directly access Modbus TCP

slave devices. It also can access other Modbus ASCII/RTU slaves that are

connected to the network via other MES1A/B Converters, as if it is talking

directly to a Modbus ASCII/RTU slave.

Features

• Converts Modus ASCII/RTU to Modbus/TCP

• Small, economical and configurable

• MES1A supports TD, RD and GND RS-232 lines

• MES1B supports TDA(-), TDB(+), RDA(-), RDB(+) RS-422/485 lines

• LEDs on network connection indicate link integrity and data transfer

• 10/100 Mbps auto-detecting operation

• Removable screw terminal strips for power supply

• Removable screw terminal strips for RS-422/485 connection (MES1B)

• Device Installer user interface software included

• DIN rail mountable

activity

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

2

Page 13

Hardware Overview

CChhaapptteerr 22:: HHaarrddwwaarree OOvveerrvviieeww

Package Checklist

MES1A/B Modbus ASCII/RTU to Modbus TCP Converters are

shipped with the following items included:

9 the MES1A or MES1B module

9 a printed version of this user manual

9 a printed version of the MES1A/B Quick Start Guide

9 a CD-ROM disc with

o Device Installer software

o this manual in pdf format

o a Quick Start guide in pdf format

Indicators, Switches and Connectors

Power LED

The Power LED illuminates (red) immediately on power up

indicating that 10 VDC to 30 VDC power is present on the Power

Supply terminals. (Typically 12 VDC is used.)

Figure 2. LED Indicators on the MES1A

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

3

europe.com

Page 14

Hardware Overview

Link LED

When the Link LED located on the Ethernet jack is illuminated it

indicates that a connection (link integrity) has been established

between the converter and the network. Its color is green if

connected to a 100BaseT network; orange if connected to a

10BaseT network. It turns orange briefly during the power up

process.

Activity LED

When the Activity LED located on the Ethernet jack is flashing

(green) it indicates data is being sent across the network. This LED

turns orange briefly during the power up pr o cess.

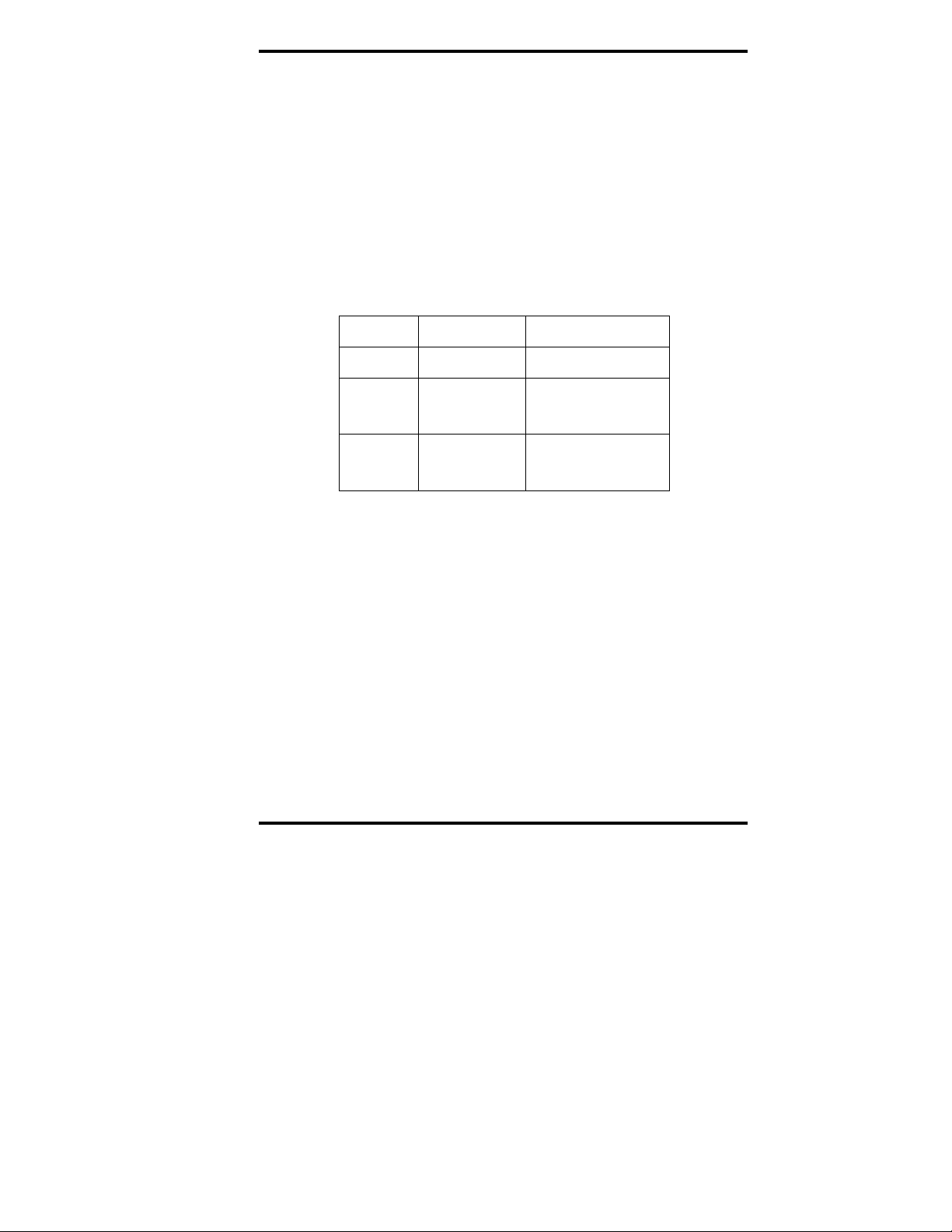

LED

Power

Link

Activity

Color/Status Function

Red Power applied

Orange

Green

Green (Blinking)

Orange

Figure 3. LED Status Table

Bootup, 10BaseT

100BaseT

Data on the network

Bootup

Reset Switch

The Reset switch is accessible on the top edge of the MES1A/B

(same edge as the power supply connector) through a small hole in

the MES1A/B enclosure. It allows you to reset the MES1A/B by

inserting a small tool through the hole and pressing the momentary

switch for about 1 second. The MES1A/B restarts with its last saved

configuration settings.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

4

Page 15

Hardware Overview

RS-422/485 Switch (MES1B only)

The RS-422/485 switch allows you to set the MES1B Converter for

RS-422/485 four-wire or RS-485 two-wire operation.

• When the switch is in the left position, the ME S1B oper ates in

RS-422/485 four-wire mode.

• When the switch is in the right position, the MES1B operates

in the RS-485 two-wire mode.

Ethernet Port Connector

The Ethernet Port connector is a standard RJ-45 receptacle that

allows the converter to be connected to an Ethernet network. Two

indicator LEDs (described above) are built into the RJ-45

connector.

DB-9M Serial Port Connector (MES1A only)

The Serial Port Connector on the MES1A is a DB-9 male

connector (configured as a DTE) supporting RS-232 serial

communications including TD (Pin 3), RD (Pin 2) and GND (Pin 5)

signal lines. If the Modbus device you are connecting to the

MES1A is configured as a DCE you will use a straight-through

serial cable. If the Modbus device is configured as a DTE, use a null

modem cable.

Refer to Appendix D for connection pin-outs.

RS-422/485 Connector (MES1B only)

The RS-422/485 connector on the MES1B is a five position

removable terminal block with screw downs. The connector

provides screw connections for:

• Terminal 1 - RDB(+)

• Terminal 2 - RDA(-)

• Terminal 3 - TDB(+)

• Terminal 4 - TDA(-)

• Terminal 5 – Ground

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

5

europe.com

Page 16

Hardware Overview

Figure 4. MES1B Serial Connector

RS-422/485 Four-Wire Mode

When the MES1B is configured to operate in RS-422/485 four-wire

mode (RS-422/485 switch in the left position) its receive terminals

are connected to the transmit terminals of the Modbus device it is

communicating with. Its transmit terminals are connected to the

receive terminals of the Modbus device it is communicating with.

Figure 5. RS-422/485 Four-Wire Connection

RS-485 Two-Wire Mode

When the MES1B is configured to operate in RS-485 two-wire

mode (RS-422/485 switch in the right position) the two-wire RS485 two-wire communications cable pair is connected to Terminals

TDB and TDA. The communications cable ground/shield is

connected to GND.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

6

Page 17

Hardware Overview

Figure 6. RS-485 Two-Wire Connection

No jumpers are required to bridge the transmit and receive lines in

two-wire mode.

Power Connector

The Power Connector is a removable two-position screw terminal

block with screw down. The MES1A/B requires between 10 VDC

and 30 VDC (3.6 Watts). Typically a 12 VDC power adapter is

connected to the terminal block via bare wires. The terminal block

can be unplugged to remove the converter from service.

Figure 7. MES1A/B Power Connector

Connecting the Hardware

The MES1A is connected to its Modbus device via a DB-9M

connector and an RS-232 cable. The MES1A is configured as a

DTE. If the connected Modbus device is configured as a DCE, use a

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

7

europe.com

Page 18

Hardware Overview

straight-through cable. If the connected Modbus device is

configured as a DTE, use a null modem cable.

The MES1B is connected to its Modbus device via the RS-422/485

terminal block. In RS-422/485 four-wire mode a cable containing

two pairs and a ground/shield is used. In RS-485 two-wire mode a

cable containing one pair and a ground/shield is used.

Power is supplied to the converter via the power supply terminal

block.

Typically, the MES1A/B is connected to the network via a hub

switch or router using standard straight-through CAT-5 cable. (If

you are connecting the MES1A/B directly to a PC’s network

interface a crossover Ethernet cable is required.)

Always check the interface specifications of the Modbus device to

determine whether it is a DTE or DCE before connecting.

Figure 8. MES1A Connections

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

8

Page 19

Hardware Overview

Figure 9. MES1B Connections

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

europe.com

9

Page 20

Hardware Overview

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

10

Page 21

Getting Started

CChhaapptteerr 33:: GGeettttiinngg SSttaarrtteedd

QuickStart

The following section is a quick, step-by-step procedure that will

assist you to get started configuring the MES1A/B. Additional

details on how to use the Device Installer software to discover and

connect to devices is included in the section following this one.

MES1A/B configuration details are included in Chapter 4.

1. Check the contents of your MES1A/B package. It should

contain…

The MES1A or MES1B unit

A printed version of this user manual

A printed version of the MES1A/B Quick Start Guide

Software CD with Device Installer software, this manual, Quick

Start guide

2. Set up the Hardware

Connect the MES1A/B to the network using an Ethernet cable.

Connect your PC to the network

Connect a 12 VDC power supply (not included) to the MES1A/B

and apply power. (10 to 30 VDC, 3.6 Watts.)

3. Software Installation

Insert the software CD and it should auto-start into the

installation wizard.

Follow the on-screen installation wizard to install the Device

Installer software.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

europe.com

11

Page 22

Getting Started

4. Discover the MES1A/B on the Network

Open the Device Installer software. It should detect the

MES1A/B and display XPort in the third level of the Devices

Tree.

Expand the Devices Tree and click the device IP Address.

Select the Telnet Configuration tab, then click Connect.

When the Modbus/TCP to RTU Bridge, MAC address and

Software version information appears, Press Enter to go into

Setup Mode.

5. Configure the MES1A/B

To change the IP Address, Default Gateway or Netmask, type 1.

To configure Master/Slave and serial Interface settings, type 2.

Do not change any configuration settings in section 3.

To configure Modbus/TCP settings, type 4.

To configure Modbus Master settings, type 5.

To save your settings to the MES1A/B, type S.

6. Modbus Device Installation

Connect the Modbus device to the serial interface on the

MES1A/B using the correct cabling:

MES1A is a DTE: Use a straight through serial cable if the

Modbus device is a DCE; null modem if device is DTE.

MES1B: Four-wire for RS-422, Two-wire for RS-485, Set

RS-422/485 switch.

Your Modbus device should now be operational o n the net wo rk .

Note: The MES1A/B can be reset (rebooted) by pressing the

Reset switch for one second. Reset switch is accessed through a

small hole in the top of the enclosure.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

12

Page 23

Getting Started

Using the Device Installer Software

This section provides more detailed information on how to install

and use the Device Installer software.

Device Installer is used to set up and configure the MES1A/B on a

network. It detects all MES1A/Bs on the network and allows you to

configure the network and serial port settings. It also allows you to

monitor the MES1A/B and verify its status.

System Requirements

• Windows XP, Windows 2000, Windows NT4.0 (with service

pack 6.0a or later), Windows ME, or Windows 98

• Internet Explorer 5.01 or later

• 30 MB hard drive space

• 64 MB RAM

Installing the Device Installer

Note: Device Installer requires Microsoft .NET software to

operate.

To install the Device Installer software:

1. Insert the CD included with your MES1A/B into the CD

ROM drive of your PC.

2. The installation should launch au tomatically. If not:

a. Click Start on the Task Bar and select Run

b. Type in [CD drive letter]:\Launch.exe

3. When the Device Installer Setup Wizard dialog box

appears, click Next to open the Select Installation Folder

dialog box.

4. Accept the suggested installation folder or click Browse…

to select a different installation folder.

5. Click Next to open the Confirm Installation dialog box.

6. Click Next to begin the installation. When finished, the

Installation Complete dialog box appears.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

europe.com

13

Page 24

Getting Started

Starting the Device Installer

Run the Device Installer from the Start, Programs, Lantronix,

DeviceInstaller menu.

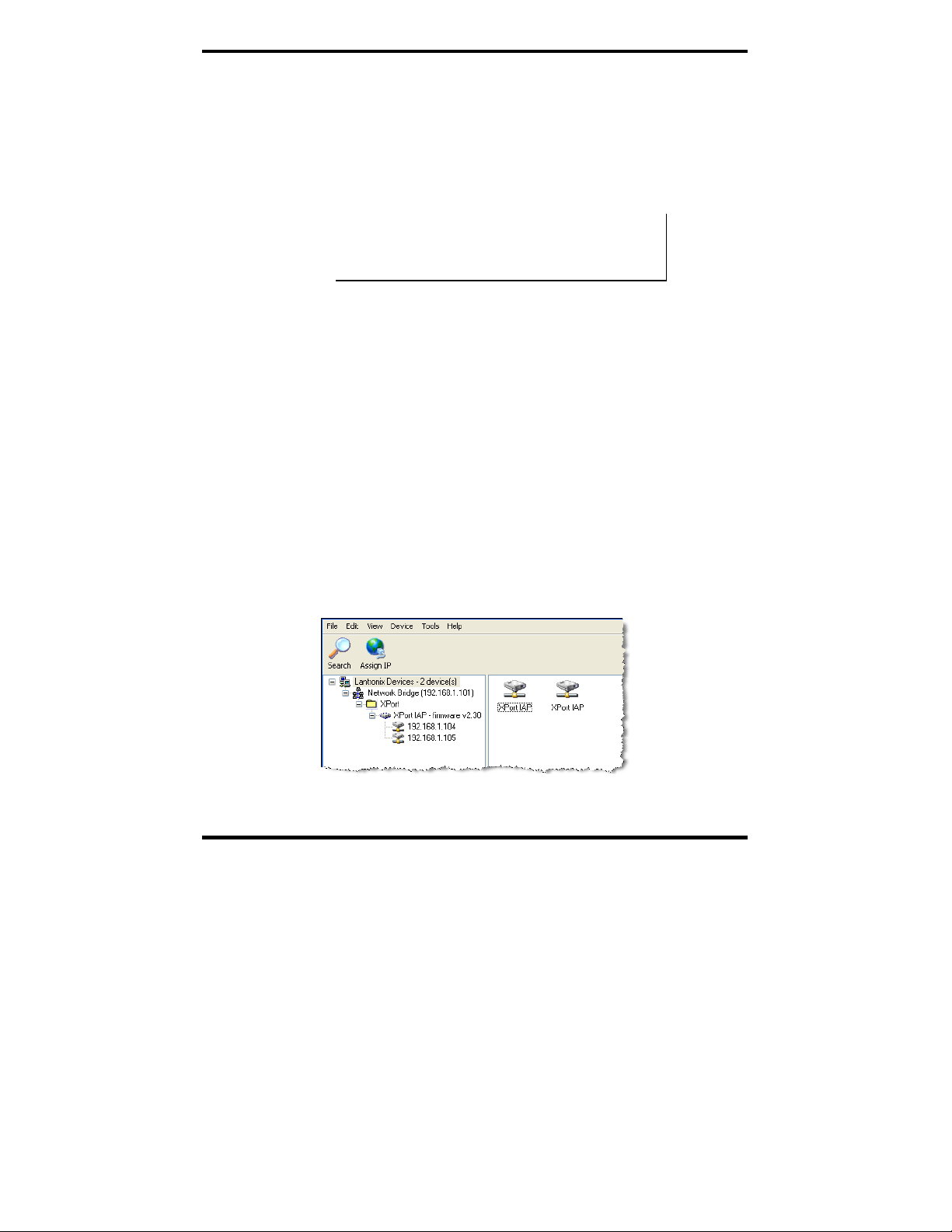

Discovering Devices

When Device Installer opens it automatically scans the network for

MES1A/B devices.

Any of the following steps will initiate a manual search for devices:

• Click the Search icon

• On the Device menu, click Search

• Press the F5 function key

When discovered for the first time, any MES1A/B devices present

are listed in the Devices Tree pane and Device List pane as XPort

and XPort IAP respectively. (XPort is the name of the internal

module of the MES1A/B.)

The Devices Tree shows a hierarchy including any n etwork bridges

under which the MES1A/B is found.

The Device List pane is a table showing:

• Device Type

• Device Name

• Group

• IP Address

• Hardware (MAC) Address

• Status

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

14

Page 25

Getting Started

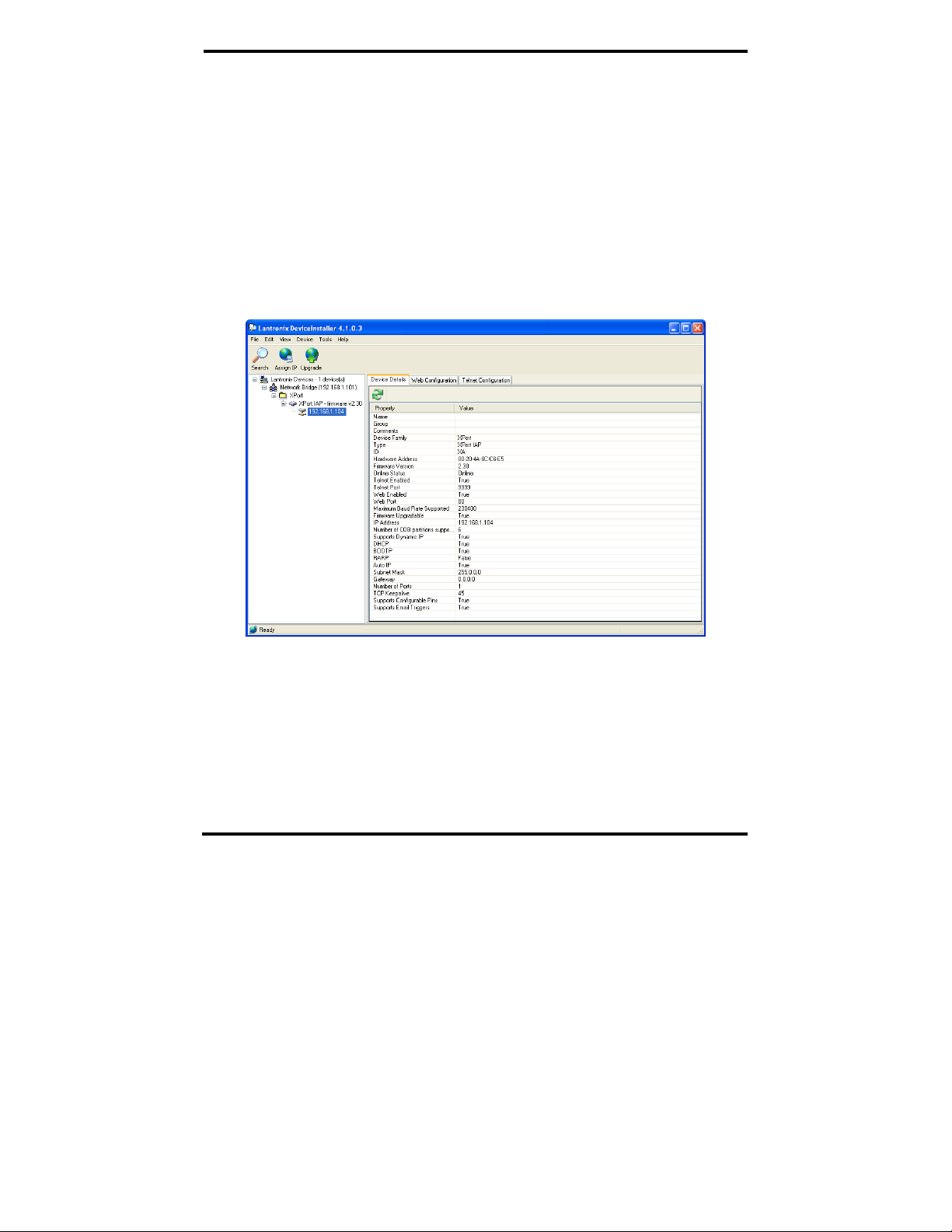

Figure 10. The Device Installer Main Window

Getting Device Details

The Device Installer provides a variety of information about the

MES1A/B under the Device Details tab.

To access the Device Details tab:

1. Expand the Device Tree by clicking the + symbol next to

XPort. Keep expanding until the IP Address of the

MES1A/B appears.

2. Click the IP Address on the Device Tree. The Device

Details tab appears where the Device List was.

Figure 11. Device Details Tab

Note: The Web Configuration tab is not used with the MES1A/B.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

europe.com

15

Page 26

Getting Started

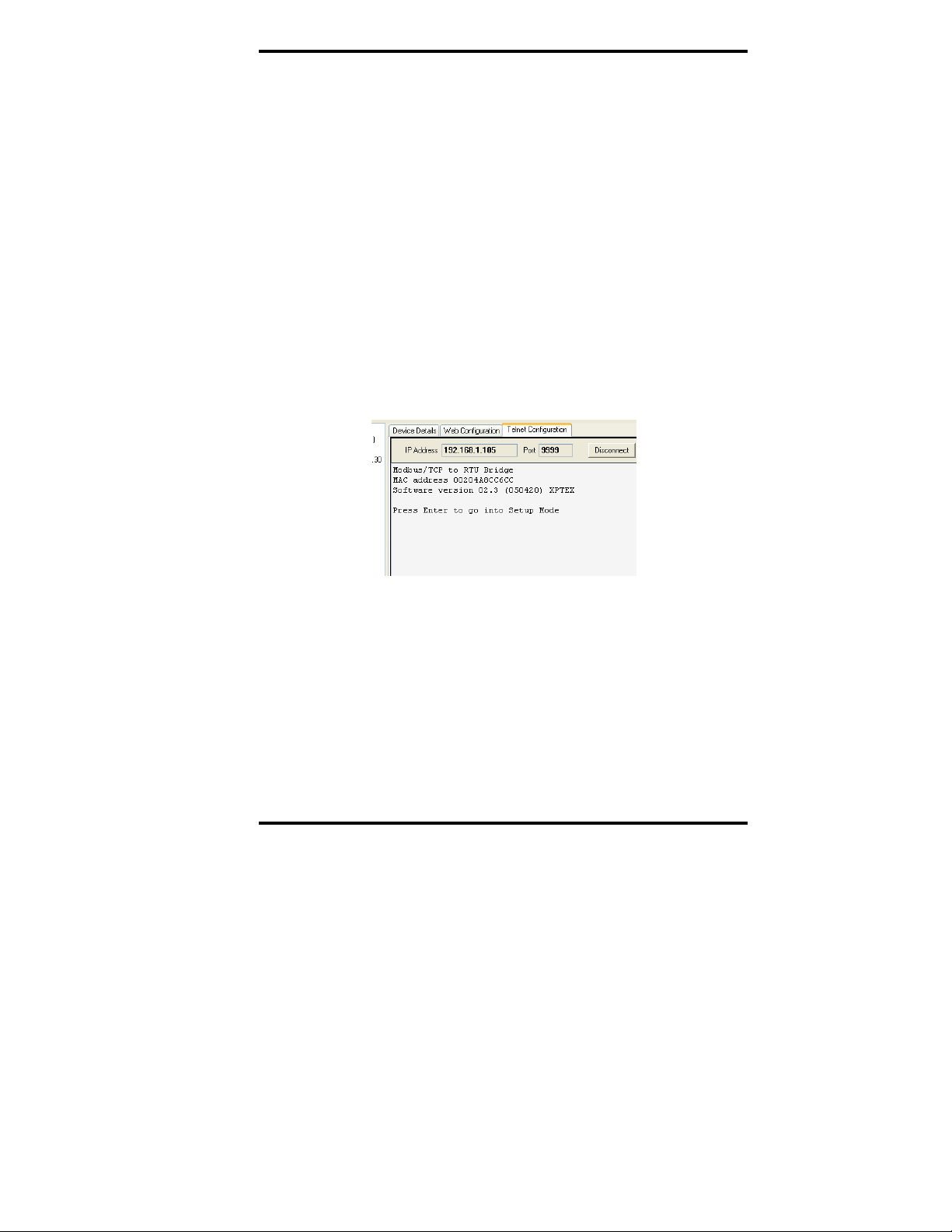

Connecting to the MES1A/B

Before configuration can occur you must set up a telnet connection

with the MES1A/B to access the Configuration Menu. You can

access the Configuration Menu using a standard telnet window, or

use the telnet implementation within the Device Installer software.

The Device Installer option provides an all-in-one user interface for

working with the MES1A/B

To connect:

3. Select the Telnet Configuration tab. The tab shows the IP

Address of the MES1A/B and the Port Number used to

communicate with it via telnet. The rest of the window is

blank.

4. Click Connect to connect to the MES1A/B. When a

connection is established the following window appears,

which contains information on the MAC address and

Software version of the MES1A/B.

Figure 12. Press Enter to go into Setup Mode

The background color of the window remains white for

five seconds, then changes to gray when it times out.

5. Press the Enter key within five seconds to go into Setup

Mode or it will time out (and you will have to click Clear

and repeat the process).

The MES1A/B Configuration Menu appears.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

16

Page 27

Getting Started

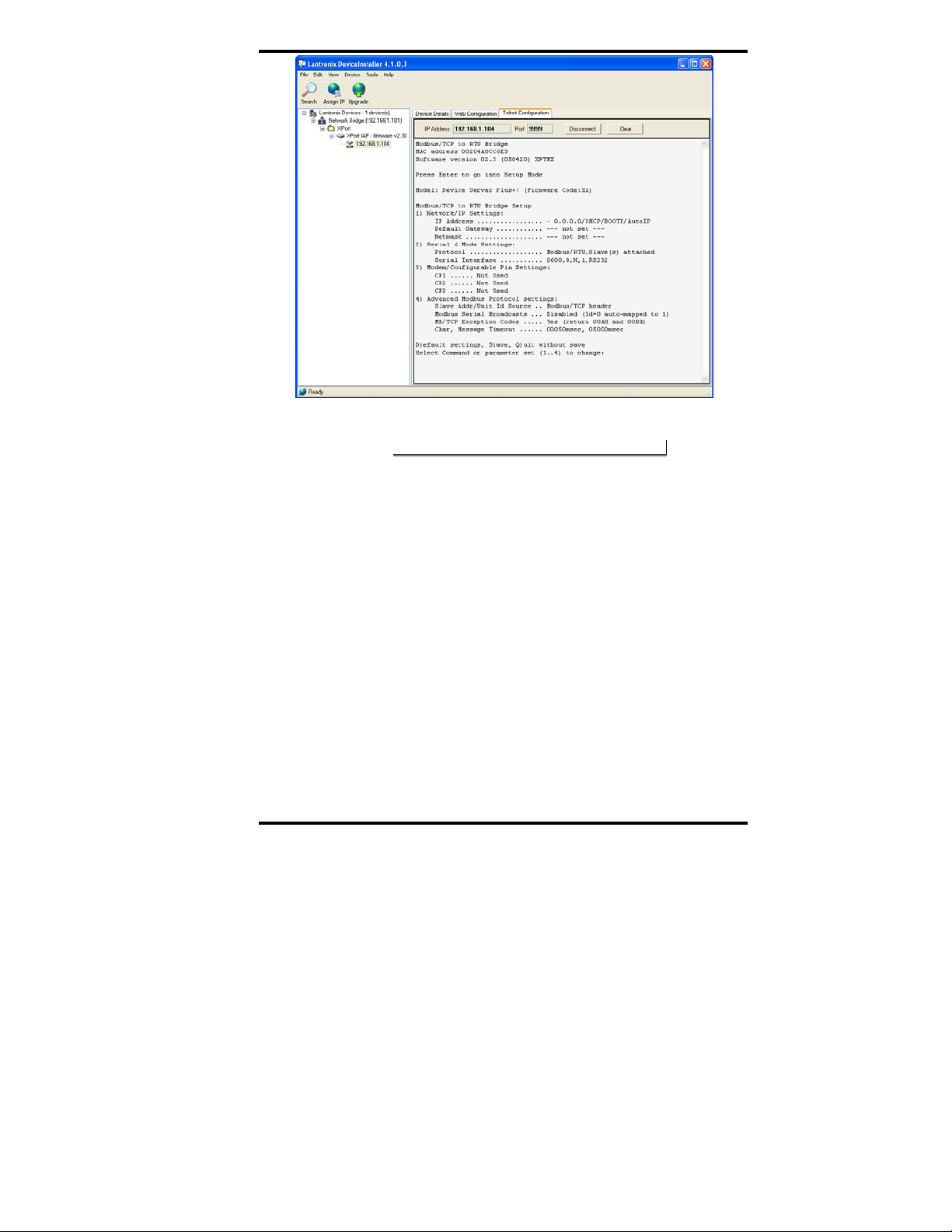

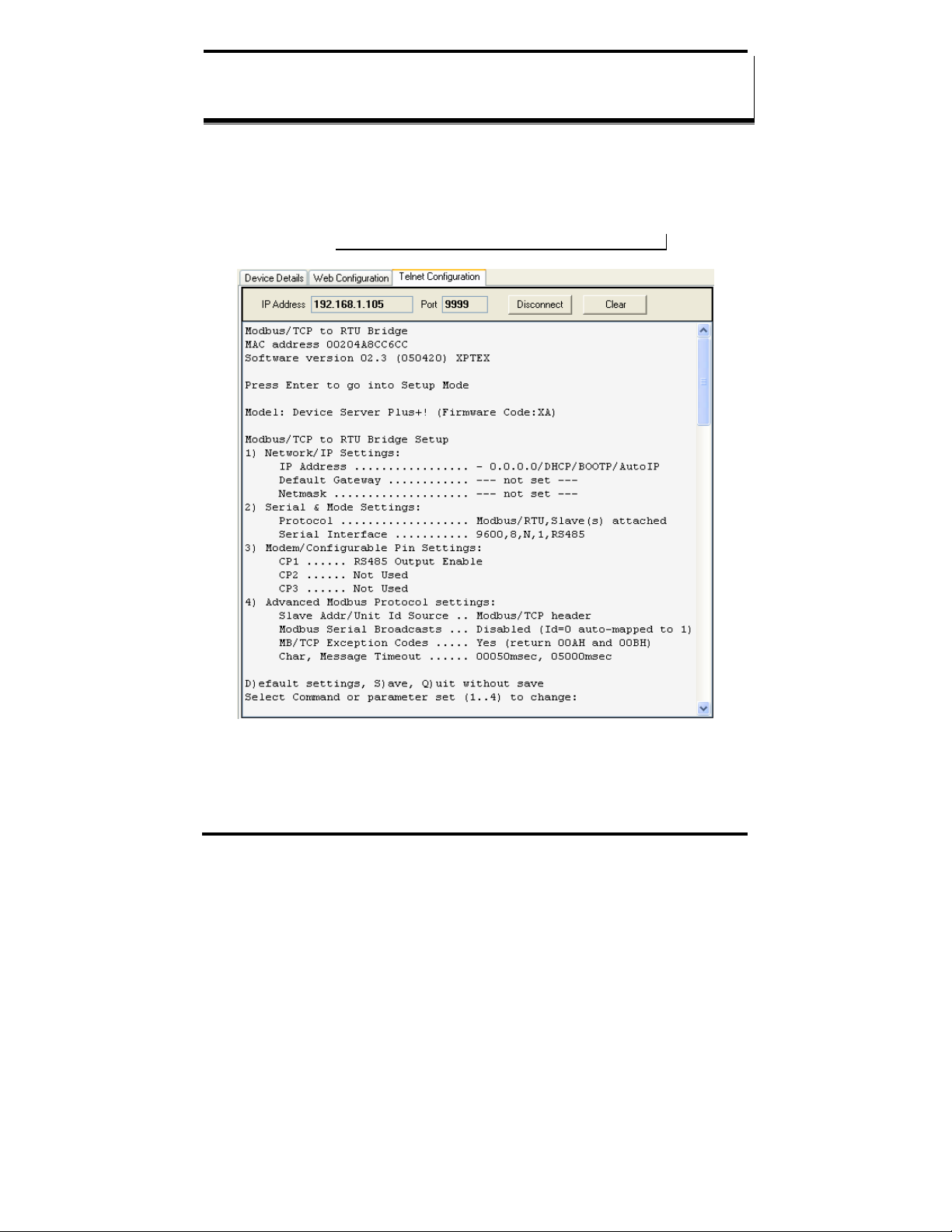

Figure 13. Telnet Configuration Tab with Settings

Refer to Chapter 4 for configuration details.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-

europe.com

17

Page 28

Getting Started

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

18

Page 29

Configuring the MES1A/B

CChhaapptteerr 44:: CCoonnffiigguurriinngg tthhee MMEESS11AA//BB

Configuration of the MES1A/B is accomplished from the Configuration

Menu, which is accessed via a standard telnet window, or through the telnet

implementation within the Device Installer software.

Note: The Web Configuration tab is not used with the MES1A/B.

Figure 14. Telnet Configuration Tab

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

19

Page 30

Configuring the MES1A/B

Navigating the Configuration Menu

On initial power-up there are four sections in the MES1A/B configuration

menu. A fifth menu item appears if you are configuring a Modbus Master

device. The menu items are:

6. Network/IP Settings

7. Serial & Mode Settings

8. Modem/Configurab le Pin Settings

9. Advanced Modbus Protocol Settings

The following menu item 5) appears if the MES1A/B is configured as a

Modbus Master in section 2) Serial Protocol

10. Unit ID to IP Address Table

Each section of the configuration menu includes several parameters.

11. Begin the configuration by typing the menu section number at the

Select Command or parameter set (1..4) to change:

prompt.

The first configuration parameter of the section will appear at the

bottom of the pane. The current setting is shown in brackets.

Example:

Figure 15. Setting the IP Address

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

20

Page 31

Configuring the MES1A/B

12. To change the parameter, type in a new value, then press Enter. If

you wish to leave the parameter as it was, simply press Enter. A

prompt for the next parameter will appear.

13. When all parameters in the currently selected section are complete

you will again be prompted to select a menu item. Select another

section and continue the configuration process.

Saving Configuration Settings

When all categories have been configured you must save your configuration

to the MES1A/B.

To Save the configuration settings to the MES1A/B, at the

Command or parameter set (1..4) to change:

Quitting Without Saving

To Quit the configuration session without saving, type Q. The background

color will change to gray and the MES1A/B will re-start without updating the

configuration settings.

Reconfiguring to Factory Settings

The MES1A and MES1B come from the factory preconfigured for correct

operation with their respective interfaces. The following procedure describes

how you can return the MES1A and MES1B to their original factory settings.

To Reconfigure the MES1A to Factory Settings:

Type D at the Select Command or parameter set (1..4) to

change: prompt. The Configuration Menu is upd ated with the new settings

displayed.

To Reconfigure the MES1B, to Factory Settings:

14. Type D at the Select Command or parameter set (1..4)

to change: prompt.

Select

prompt type S.

15. Type 2 to enter the Serial & Mode Settings section and set the

Serial Mode for RS-485 Two-Wire (see the next section for

details).

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

21

Page 32

Configuring the MES1A/B

16. Type 3 to enter the Modem/Configurable Pin Settings section and

set CP1 to RS-485 Enable Wire (see the next section for details)..

See the following sections for details on how to set Serial & Mode Settings and

Modem/Configurable Pin Settings.

1) Network/IP Settings

In the Network/IP Settings section of the Configuration Menu you can

configure:

• IP Address of the MES1A/B

• Default Gateway

• Netmask

• Telnet Configuration Password

IP Address

Every device connected to a TCP/IP network must have a unique IP

Address. This includes every MES1A/B. However, there is more than one

way to set up an IP address for the MES1A/B

DHCP

The MES1A/B is shipped with a default IP address of 0.0.0.0. This

configures the converter to obtain an IP address via DHCP (Dynamic Host

Configuration Protocol) from a DHCP server on the network when the

MES1A/B boots up.

If a DHCP server is available to respond to the DHCP request, the MES1A/B

will receive an IP address, gateway address and subnet mask from the server.

A DHCP-generated IP address will appear in the Device Tree, Device List

and at the top of the Telnet Configuration tab, but it will not be displayed

in the IP Address field of the Network/IP Settings section of the

Configuration Menu.

Figure 16. Network/IP Settings Menu

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

22

Page 33

Configuring the MES1A/B

Auto-IP

If a DHCP server is NOT available on the network, the MES1A/B will revert

to Auto-IP and generate its own IP address in the 169.254.xxx.xxx range.

Static IP Address

The IP address of the MES1A/B can be changed via the Telnet Configuration

Menu interface.

To determine an appropriate static IP address, consult your network

administrator. The Device Installer Help feature also provides some useful

information related to IP addressing.

17. At the Select Command or parameter set (1..4) to

change:

At the IP Address (000)prompt

18.

o To keep the current setting, press Enter

o To change the IP address, type the first octet

19. Press Enter to accept the new IP address

After the new settings have been accepted they will appear in the

Configuration Menu. After the Configuration has been saved to the

MES1A/B, the new settings will appear in the Device Details tab.

prompt, type 1.

Press Enter to accept the change

Repeat for all octets

The IP Address can also be changed from the Device Installer menu. See

Chapter 5 for details.

Default Gateway

A Default Gateway address is only required if your MES1A/B must

communicate with devices on remote TCP/IP networks through a router or

gateway. The default value for this parameter is

• If you DO NOT require remote communication, type N or just press

Enter at the

Set Gateway IP Address (N) prompt.

• If you DO require remote communication through a router or gateway,

type Y. The

Gateway IP Address: (000) prompt appears. Enter the

IP address of the default gateway within your local network by typing

each address octet followed by pressing Enter.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

23

---not set---.

Page 34

Configuring the MES1A/B

After the new settings have been accepted they will appear in the

Configuration Menu. After the Configuration has been saved to the

MES1A/B, the new settings will appear in the Device Details tab.

Netmask

Typically you will type N, or just press Enter to cause the MES1A/B to

automatically use the standard Netmask appropriate for the IP address being

used. The default value for this parameter is

To change the Netmask setting

20. Press Enter to keep the current setting

21. Press Y to change the setting

22. At the prompt type in four octets representing the new Netmask.

After the new settings have been accepted they will appear in the

Configuration Menu. After the Configuration has been saved to the

MES1A/B, the new settings will appear in the Device Details tab.

For more information or direction on the netmask you may require, consult your

network administrator.

Telnet Configuration Password

---not set---.

You can set up a Telnet Configuration Password to control unauthorized

access to the Telnet Configuration interface.

23. Type Y. The

24. Type in a password. The words

Enter New Password: prompt appears.

Telnet config password set

appears in the 1) section of the configuration menu.

The default value for this parameter is

N (for Not Set).

Warning: Do not forget your password if used. There is no easy way to get

into the unit for configuration once you forget your pa ssword .

2) Serial and Mode Settings

In the Serial and Mode Settings section of the Configuration Menu you can

configure:

• the serial Protocol to be used with your Modbus device

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

24

Page 35

Configuring the MES1A/B

• the Serial Interface type and communications parameters

Figure 17. Serial & Mode Settings Menu

To configure Serial and Mode Settings, type 2 at the Select Command or

parameter set (1..4) to change:

prompt. The Attached Device

prompt appears.

Protocol

Protocol parameters must be set to match the type of Modbus device (master

or slave) connected to the serial side of the MES1A/B device, and the type of

Modbus protocol (ASCII or RTU) that will be used.

Attached Device

Modbus devices operate as either Masters (polling Slaves) or Slaves

(responding to polls from Masters). An example of a Modbus master is a

computer running HMI (human machine interface) software. Examples of

Modbus slaves are controllers, remote terminal units (RTU) or programmable

logic controllers (PLC).

To configure the type of Attached Device:

25. At the

Attached Device (1=Slave 2=Master)(1) prompt

o To keep the current setting, press Enter

o To select Slave, type 1

o To select Master, type 2

26. To accept changes, press Enter

Note: When Master mode is selected a fifth item (Unit ID -> IP Address Table is

added to the Configuration Menu.

Serial Protocol

Modbus devices communicate in either of two Serial Protocols: ASCII or

RTU. Modbus/ASCII protocol is slower and uses two ASCII characters to

represent each 8 bit data byte. Modbus/RTU uses 8 bit binary data characters.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

25

Page 36

Configuring the MES1A/B

The MES1A/B must be configured to use the same protocol used by the

attached Modbus device.

To configure the type of Serial Protocol

27. At the Serial Protocol (1=Modbus/RTU 2=Modbus/ASCII)

(1) prompt

o To keep the current setting, press Enter

o To select Modbus/RTU, type 1

o To select Modbus/ASCII, type 2

28. To accept changes, press Enter

Serial Interface

Serial Interface parameters include the type of interface and the data

rate/format of the data. The MES1A/B must use the same type of interface

and serial parameters as that of the Modbus device it is connected to.

MES1A Serial Interface

Since the MES1A is designed with an RS-232 interface, its default Interface

Type is RS-232.

Although RS-422/485 four-wire and RS-485 two-wire options are given in the

configuration menu, reconfiguring the MES1A for anything other than RS-232

will prevent the device from operating correctly.

MES1B Serial Interface

The MES1B is designed with an RS-422/485 interface and can be configured

for four-wire operation or two-wire operation.

Although RS-232 option is provided in the configuration menu, reconfiguring the

MES1B for RS-232 will prevent the device from operating correctly.

To configure Interface Type parameters:

29. At the

3=RS485+2-wire) (3) prompt:

o To keep the current setting, press Enter

o To select RS-422/RS-485 four-wire, type 2

o To select RS-485 two-wire, type 3

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

Interface Type (1=RS232 2=RS422/RS485+4-wire

26

Page 37

Configuring the MES1A/B

30. To accept changes, press Enter

When RS-422/485 four-wire operation is selected:

When RS-422/485 four-wire operation is selected the RS-422/485 switch

on the MES1B must be in the left position.

When RS-485 two-wire operation is selected:

• CP1 (configured in the next section under Modem/Configurable Pin

Settings) must be enabled to ensure Send Data control is implemented.

• The RS-422/485 switch on the MES1B must be in the right position.

• The multidrop bus is connected to Terminals 3 [DataB(+) to TDB(+)

terminal] and 4 [DataA(-) to TDA(-) terminal].

• No jumpers are required to bridge transmit and receive lines on the

terminal block

Serial Parameters

MES1A/B Serial Parameters must be set up to match the parameters of the

Modbus device connected to its serial interface. MES1A/B Serial Parameter

options include:

• Data rates from 300 bps to 115200 bps

• 7 or 8 data bits

• No, Even or Odd parity

• 1 or 2 stop bits.

To configure Serial Parameters:

31. At the

Enter serial parameters (9600,8,N,1)prompt

o To keep the current setting, press Enter

o To change the serial parameters, type in new parameters in the

format

9600,8,N,1

32. To accept changes, press Enter

3) Modem/Configurable Pin Settings

There is only one configurable setting required in the Modem/Configurable

Pin Settings section of the Configuration Menu. When configuring an

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

27

Page 38

Configuring the MES1A/B

MES1B for RS-485 two-wire operation, the CP1 parameter must be set for

RS485 Enable to ensure Send Data Control is implemented.

No configuration is required in this section for MES1A converters.

To configure RS485 Enable in the Modem/Configurable Pin Settings

section:

33. Type 3 at the

to change: prompt. The CP1 Function prompt appears.

Select Command or parameter set (1..4)

34. Type 4 to select RS485 Enable

35. To accept the change, press Enter

36. Press Enter three more times to exit the Modem/Configurab le Pin

Settings section of the Configuration Menu.

4) Advanced Modbus Protocol Settings

In the Advanced Modbus Protocol Settings section of the Configuration

Menu you can configure:

• whether the Slave Address is fixed or used as received

• whether to Allow Modbus Broadcasts

• whether to Use MB/TCP 00BH/00AH Exception Responses

• whether to Disable Modbus/TCP Pipeline

• Character Timeout values

• Message Timeout values

• Serial TX delay after RX values

• whether to Swap 4x/0H to get 3x/1x register conversions

Figure 18. Advanced Modbus Protocol Settings Menu

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

28

Page 39

Configuring the MES1A/B

Slave Address / Unit ID Source

All devices connected to a TCP/IP network require a unique IP address. Each

MES1A/B Converter has a unique IP address on the network, allowing

messages to be directed to it. However, when multiple Modbus/RTU devices

are connected to the RS-485 bus of an MES1B there must be a way to

address them individually.

Standard Modbus/RTU fields are encapsulated inside Modbus/TCP

messages. Modbus/RTU’s Slave Address field is called the Unit ID in

Modbus/TCP. The Unit ID is used to specify a particular Modbus/RTU

device on the serial side of the MES1A/B. When the MES1A/B receives a

message (sent to its IP address), it looks at the Unit ID field of the message

and passes the message to the specified slave.

0 for Auto

Setting the Slave Address field to 0 allows the MES1A/B to use the Unit ID

received from a Modbus master to direct messages to a specific slave

address. The MES1A/B receives the Unit ID number on the Modbus/TCP

side and passes it along as the Slave Address on the serial side of the

converter.

1…255

Unfortunately, some early Modbus/TCP products assumed that each IP

address would have only one slave. These products always set their Unit ID

to 0 (relying on the IP address only to address the slave). The lack of an

appropriate Unit ID presents a problem for the MES1B. It must include a

Slave Address in its messages to Modbus/RTU slaves.

To overcome this problem, the MES1A/B Slave Address field can be set to

the address of one Modbus/RTU slave (any number in the range of 1 to 255).

This limits the number of slaves that can be connected to the MES1A/B to

one, but ensures that when any message for the MES1A/B’s IP address is

received (regardless of its Unit ID), it is passed along to the slave.

To configure the Slave Address field:

• If Modbus TCP masters on your system use appropriate Unit ID

addresses, select 0. You will be able to connect multiple Modbus/RTU

slaves with RS-485 interfaces to an MES1B.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

29

Page 40

Configuring the MES1A/B

• If any Modbus TCP masters on your system use 0 for all Unit ID fields,

select a slave address that matches the Modbus/RTU slave attached to

your MES1A/B. You will not be able to connect multiple slaves to the

RS-485 multidrop bus.

Allow Modbus Broadcasts

If you configured the Slave Address for any number between 1 and 255 the

Allow Modbus Broadcasts does not appear in the menu.

When a Modbus/RTU slave receives a slave address of 0 it interprets this as a

broadcast message. All slaves accept the message. Setting the

Modbus Broadcasts (1=Yes, 2=No)

to No reassigns a Unit ID of 0 from

a Modbus TCP master as a slave address 1. This ensures that a Unit ID is not

interpreted as a broadcast message.

Use MB/TCP 00BH/00AH Exception Responses

In Modbus/RTU, when a master initiates a query it expects to receive a

response. If it does not receive one within an acceptable length of time it

interprets the silence as an indication that a communications error has

occurred. Because delays in TCP/IP networks are not predictable, problems

can occur. To address this, Modbus/TCP defines two exception codes that

can be enabled to be sent in the event of a communications failure.

Allow

1 = No

If Use MB/TCP 00BH/00AH Exception Responses (1=No 2=Yes)is

disabled (1=No), the MES1A/B operates like a Modbus/RTU slave. It

answers timeouts, un-configured slave addresses and CRC errors with

silence.

2 = Yes

If the Use MB/TCP 00BH/00AH Exception Responses (1=No

2=Yes)is enabled (2 = Yes), the MES1A/B will return the following codes

under any of the conditions described:

0A (hex) - Path Unavailable

• If it receives a query from a Modbus master in which the Unit ID

specifies a Slave Address not listed in the Unit ID to IP Mapping Table

• If the TCP socket fails to open.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

30

Page 41

Configuring the MES1A/B

0B (hex) - Target Device Failed to Respond

• If the slave did not answer, or the answer contained a CRC error

• If a TCP socket is open, but no response is received within the defined

message timeout period

• If a TCP socket is open, but the remote Modbus TCP slave/server

returned exception 0B (hex)

Disable Modbus/TCP Pipeline

Typically a Modbus master issues a query and waits for a response before

issuing another. However, when using Modbus/TCP, multiple queries can be

issued and the MES1A/B will buffer them in a “pipeline”. The MES1A/B

can fetch each query one at a time, and respond. In some situations this is

useful, but in others the sequence of query/response can get out of sync

(especially if any queries or responses are lost). The Disable Modbus/TCP

Pipeline setting allows you to decide how you want the system to operate.

• Setting this field to 1 = No configures the MES1A/B to allow pipeline

operation. This is considered the safest default setting. It is

recommended that you choose this option unless you are experiencing

problems.

• Setting this field to 2 = Yes configures the MES1A/B to always fetch the

latest request from the TCP buffer (discarding all older requests).

Character Timeout

Although Modbus/RTU specifies a 3.5 character time out period between

characters, the Character Timeout field allows you to set a custom value for

this field.

• If you set this field to 0, the MES1A/B will automatically calculate a

minimum timeout based on the baud rate being used.

• Although you can set this field to any value between 1 milliseconds and

6959 milliseconds, a recommended safe value for general use is about 50

milliseconds (which is the default value).

Message Timeout

The Message Timeout field allows you to set the timeout period for

responses from a connected slave to any value between 200 milliseconds and

65000 milliseconds. The default value is 5000 millisecon ds.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

31

Page 42

Configuring the MES1A/B

Serial TX Delay after RX

When the MES1A/B receives a request from a master it relays the request to

the Modbus slave connected to the MES1A/B’s serial connection. When the

slave responds a timer is triggered and, after the delay time configured in the

Serial TX De lay after TX field, the next master request is allowed to pass

through the serial connection to the slave. When using 2-wire RS-485

connections, this delay value can be set to ensure that RS-485 devices have

time to disable their drivers and enable their receivers to receive the next

request. Typically this is not a concern and the default value is 0. The delay

can be set to a maximum of 1275 milliseconds.

Swap 4x/0H to Get 3x/1x

This field allows you to configure the MES1A/B to convert holding reg ister

(4x) data to input register (3x) data, and convert coil (0x) data to contact (1x)

data. This is useful when connecting to Modicon I/O scanners.

5) Unit ID to IP Address Lookup Table Settings

The Configuring Unit ID to IP Address Table Settings section of the

Configuration Menu becomes available if the MES1A/B has been configured

as a Modbus Master in Configuration Menu section 2).

From Configuration Menu section 5) you can configure:

• whether to Close Idle TCP Sockets after a specified number of seconds

• whether to enab le Redundant entry retries after a specified number of

seconds

• the Unit ID to IP Address Lookup Table

Figure 19. Unit ID -> IP Address Table Settings Menu

Close Idle TCP Sockets After

The Close Idle TCP Sockets After field allows you to configure

whether a socket is held open, or the number of seconds to hold the last

socket open.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

32

Page 43

Configuring the MES1A/B

• If you configure this field for 0 it hold a single socket open to the last

remote Modbus TCP slave accessed

• If you configure this field for any value between 3 and 60 seconds, it

will close the last socket after the configured length of idle time.

Redundant Entry Retries After

The Redundant Entry Retries After field allows you to disable

redundant retries or set a maximum length of time for retries.

• If you configure this field for 0 is disables the feature.

• If you configure this field for any value between 15 seconds and 60

seconds it will set the retry period to the configure time.

Add, Delete, Exit - Select Function

The Add, Delete, Exit - Select Function field is the starting point

for managing entries in the IP Address Table.

• Type A to add an entry. The

• Type D to delete an entry. The

Modbus addr from prompt appears.

Delete entry number prompt

appears.

• Type E to exit.

Modbus Address From/To

Configuring these fields sets up the range of Modbus slave addresses that

will be forwarded to the IP address (that you will configure in the next step).

The prompt:

have been added to the list so far. If other slave addresses have already been

configured, the number will reflect the first available slave address number.

37. Press Enter to accept

38. Type in an slave address number that reflects the range of slaves

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

33

Modbus addr from (1) indicates that no slave addresses

(1) as the first slave address number, or type

in the number you prefer. After you press Enter, the

Address To prompt appears.

that will be found at the IP address that will be entered in the next

step. When you press

Enter the Slave IP address prompt

appears.

Modbus

Page 44

Configuring the MES1A/B

Slave IP Address

Type in the four octets of the IP address of the slaves being addressed.

• If you configure the last octet as 000 the MES1A/B will use the Slave

Address/Unit ID of the slave as part of the IP address. This allows a

Modbus/RTU master (connected through the MES1A/B) to access up to

255 remote Modbus TCP slaves.

• If you configure the last octet for a number between 1 and 254, all slave

polls in this group will be sent to the same IP address.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

34

Page 45

Using Other Device Installer Features

CChhaapptteerr 55:: UUssiinngg OOtthheerr DDeevviiccee IInnssttaalllleerr

FFeeaattuurreess

In addition to the capabilities already mentioned, the Device Installer

software provides other important and useful features. This section provides

a brief overview of those features. For more information, access the Help

files from the main menu.

Device Installer features which are not used or supported by the MES1A/B

include:

• Console Mode (via Serial port) configuration

• Recover Firmware (Tools menu, Advanced selection)

• Web Configuration

Managing Device Lists

This section included information on how to:

• Create a New Device List

• Save a Device List

• Open a Device List

• Configure Device List Display Options

Creating a New Device List

To create a new Device List, on the File menu, select New. The Device

Installer software will create a new list but will not initiate a search to

discover devices on the network.

To initiate a search, select Search On the Device menu, click the Search Icon or

press F5.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

35

Page 46

Using Other Device Installer Features

Saving Device Lists

After a list of MES1A/B devices has been discovered on the network, you

can save the list, including details such as the Device Name, Group,

Comments and IP Address.

To save a Device List, On the File menu, select Save or Save As, type in a

file name of your choice and click Save.

Note: The configuration of the MES1A/B is NOT saved using this method. To

store the configuration in the MES1A/B, on the Telnet Configuration Menu, set

up the configuration, then type S at the Default settings, Save,

Quit without Save prompt. To store the configuration in a Setup

Record file see the procedure later in this chapter.

Opening Device Lists

To open an existing Device List, on the File menu, select Open. In the Open

dialog box that appears, select or type in a file name and click Open.

The MES1A/B will search for all devices listed in the Device List file and

display them in the Devices Tree. Devices not listed in the Device List file

will not be shown. To discover other devices not already on the list you must

initiate a search.

Device List Display Options

Device Installer provides several options for displaying devices in the Device

Tree and List.

Display Devices Using Icons

• On the View menu, select Device List, then select Icons.

Figure 20. Device List Icon View

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

36

Page 47

Using Other Device Installer Features

Display the Hardware (MAC) Address

• On the View menu, select Device Node Text, then select Hardware

Address.

Figure 21. Device Node Hardware Address View

Display the Device Name

• On the View menu, select Device Node Text, then select Name.

Figure 22. Device Node Name View

Adding a Device Manually

Although you will typically discover MES1A/B devices on the network

using the Search tool, you can also add a device to the network manually. To

do so you must know the IP address of the device.

Figure 23. Add Device Dialog Box

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

37

Page 48

Using Other Device Installer Features

To manually add a device to the Device List:

39. On the Device menu, select Add Device.

40. In the Add Device dialog box, type the IP address of the device.

41. Click OK

• If a device with that IP address is not found on the network a dialog box

will appear indicating Device at [IP address] was not found!

• If a device is found it will be listed in the Device Tree and the Device

Details tab for the device appears.

Assigning an IP Address (using Device Installer)

The MES1A/B can obtain its IP address in several ways:

• Via DHCP when it is first connected to the network (See Chapter 4)

• By changing the IP address from the Telnet Configuration Menu (See

Chapter 4)

• Using the Assign IP feature of the Device Installer software

Using Device Installer to Assign an IP Address

To use Device Installer to Assign an IP address:

42. Click the Assign IP icon, press F7, or on the Device menu, select

Assign IP Address. The Assign IP Address wizard appears.

If a specific MES1A/B device is not selected in the Devices Tree,

the first page of the wizard will ask for the Hardware (MAC)

Address of the device to be configured. You will find the Hardware

Address of your particular MES1A/B on a sticker attached to the

device. Type the Hardware Address into the wizard and click next.

43. Since the MES1A/B is pre-configured to use DHCP (its IP address

is pre-configured for 0.0.0.0 which causes it to use DHCP).

Therefore, do not use the Obtain an IP address automatically

option in the wizard.

44. If you wish to assign a different IP address to the MES1A/B, select

Assign a specific IP address and click Next. The IP Settings page

of the wizard appears.

45. Type the desired IP address into the appropriate text box.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

38

Page 49

Using Other Device Installer Features

46. If required, type the Subnet Mask and Default Gateway addresses

into the appropriate text boxes.

47. Click Next. The Assignment page of the wizard appears.

48. Click Assign. A Progress of task bar graph appears. When the

process is Completed successfully, click Finish.

49. The new IP address appears in the Devices Tree, Device Details tab

and Telnet Configuration tab.

Using the Devices Details Tab

The Device Details tab provides useful information about the MES1A/B

currently selected in the Device List.

Figure 24. Device Details Tab

Although most fields in are fixed, the Name, Group and Comments fields

are user configurable, allowing you to add information specific to your

application.

To change any of these fields, double-click the field, then type your text into

the text box that appears.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

39

Page 50

Using Other Device Installer Features

Figure 25. Adding Info to the Device Details Tab

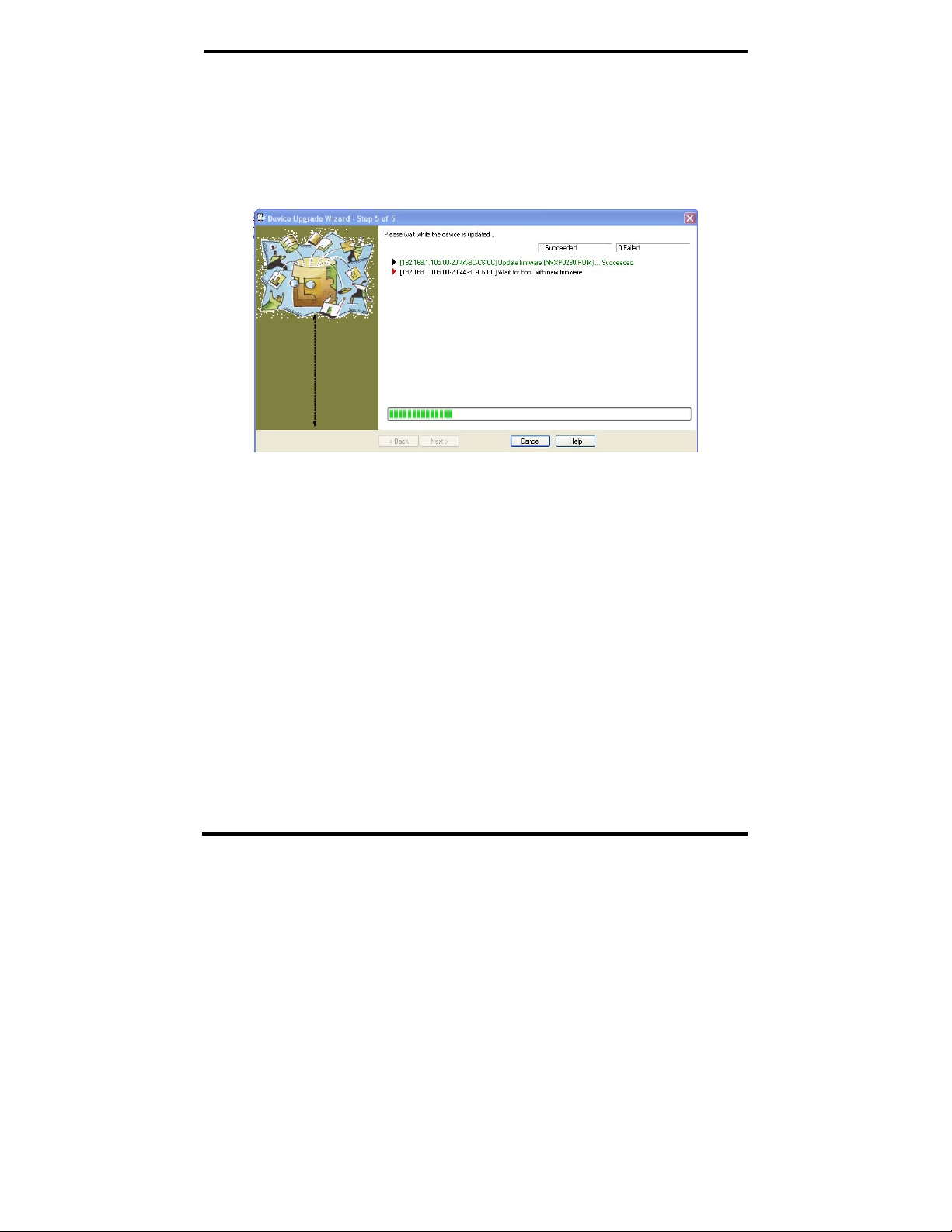

Upgrading Firmware

From time to time updated firmware versions for the MES1A/B may become

available (from the B&B Electronics website). Device Installer provides a

Device Upgrade Wizard which can be used to install updated firmware into

the MES1A/B.

To install firmware in the MES1A/B:

On the Device menu, select Upgrade…, or click the Upgrade icon. The Device

Upgrade Wizard – Step 1 of 5 dialog box appears.

Figure 26. Device Upgrade Wizard Step 1

50. If an Installation File (lxi) has already been created, select Use a

specific installation file (LXI) (previously saved by user)

51. If an Installation File has not been created, select Create a custom

installation by specifying individual files (Typical) and then click

Next.

52. In the Device Upgrade Wizard – Step 2 of 5 dialog box, browse to

find the Firmware (ROM, SYS & SPB) File, then click Next.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

40

Page 51

Using Other Device Installer Features

53. In the Device Upgrade Wizard – Step 3 of 5 dialog box, select No

other files to install (typical), then browse and select the

previously saved Setup file.

54. In the Device Upgrade Wizard – Step 4 of 5 dialog box, click

Next. The Device Upgrade Wizard – Step 5 of 5 dialog box

appears and displays a bar graph indicating progress. Succeeded

appears next to a listing of each step as it is accomplished.

Figure 27. Device Upgrade Wizard – Step 5 of 5

Installing Pre-Saved Configuration Files

The same wizard can be used to install previously saved configuration

settings (Setup Records) into the MES1A/B. This can be useful if you want

to configure multiple MES1A/Bs with the same settings, or if you must

replace an MES1A/B and want to load identical settings into the new unit.

To use the Upgrade Wizard to install configuration setting in an MES1A/B

you must first save the settings in the form of a Setup Record.

Saving Setup Records

To save the Setup Records for a particular device (MES1A/B)

55. Select the device in the Device List.

56. On the File menu, select Save Setup Records. The Save Setup

Records dialog box appears.

Manual Documentation Number: MES1A/MES1B-2106m PN7138-rev001

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

41

Page 52

Using Other Device Installer Features

Figure 28. Save Setup Records Dialog Box

57. Select a Setup Record from the list and click Save. The Save As

dialog box appears.

58. Create a filename and click Save.

Installing Setup Records

To install a Setup Record in the MES1A/B:

59. On the Device menu, select Upgrade…, or click the Upgrade icon.

The Device Upgrade Wizard – Step 1 of 5 dialog box appears.

Figure 29. Device Upgrade Wizard Step 1

60. Select Create a custom installation by specifying individual files

(Typical) and then click Next.

61. In the Device Upgrade Wizard – Step 2 of 5 dialog box, click

Next.