INSTRUCTION MANUAL

M3LDY

CURRENT LOOP SUPPLY

(linearizing; field- and PC-configurable)

BEFORE USE ....

Thank you for choosing M-System. Before use, check the

package you received as below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner .......................................................(1)

I/O range and tag name label sheet ........................... (1)

■ MODEL NO.

Check that the model No. described on the specification label

is exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes the necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

The M3LDY with Option /A is programmable using the PC

configurator software. For detailed information on the PC

configuration, refer to the M3CON instruction manual. The

M3CON PC Configurator Software is downloadable at MSystem’s web site: http://www.m-system.co.jp.

MODEL

■ WIRING

• Do not install cables (power supply, input and output) close

to noise sources (relay drive cable, high frequency line, etc.).

• Do not bind the unit's cables together with cables where

high noise levels are present. Do not install them in the same

duct.

■ AND ....

• The unit is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data sheet.

M3LDY

COMPONENT IDENTIFICATION

Body

Specification Label

(side)

SW Setting Label

POINTS OF CAUTION

■ CONFORMITY WITH UL

(UL is unavailable for certain model suffix options.)

• This equipment is suitable for use in a Pollution Degree 2

environment.

• This equipment is to be used with the maximum operating

voltage 30Vrms and 42.4Vpeak or 60V DC.

• The equipment must be mounted inside a suitable fire

enclosure.

• Operating temperature: -25 to +55°C (-13 to +131°F)

■ POWER INPUT RATING & OPERATIONAL RANGE

• Check the power rating for the unit on the specification

label.

Rating 24V DC: 24V ±10%, approx. 3W

• Power fuse: A power fuse of the rating as shown below is

incorporated for safety. However, DO NOT replace it by the

user.

T 0.25A 125V

■ SAFETY PRECAUTION

• Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -25 to +65°C

(-13 to +149°F) with relative humidity within 0 to 95% RH in

order to ensure adequate life span and operation.

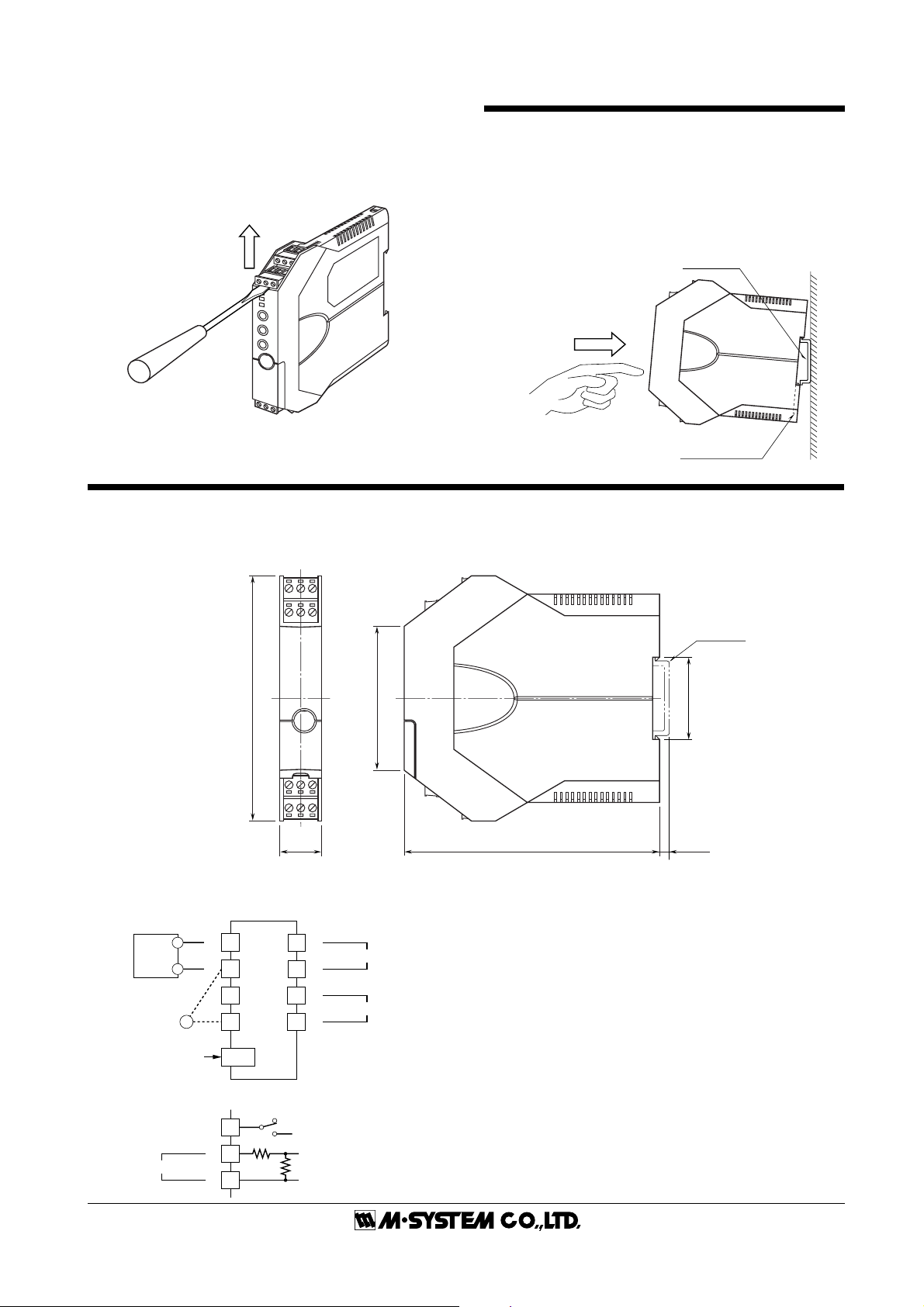

■ HOW TO OPEN THE COVER WHEN SETTING DIP SW

Hold at the top and bottom of the unit as shown below and

slide the housing cover gently to open until it hits the latching

inside the unit.

Caution:

Handle the cover carefully to protect internal components from damage.

DO NOT pull beyond where the housing cover is latched. The plastic

housing may be damaged.

• Housing Cover Fully Opened

EM-2664 Rev.2P. 1 / 6

■ HOW TO SEPARATE THE TERMINAL BLOCKS

When you need to separate the terminal blocks from the

transmitter body for wiring, insert a minus driver between

the terminal block and the housing body, pull up the driver

and pull out the terminal block.

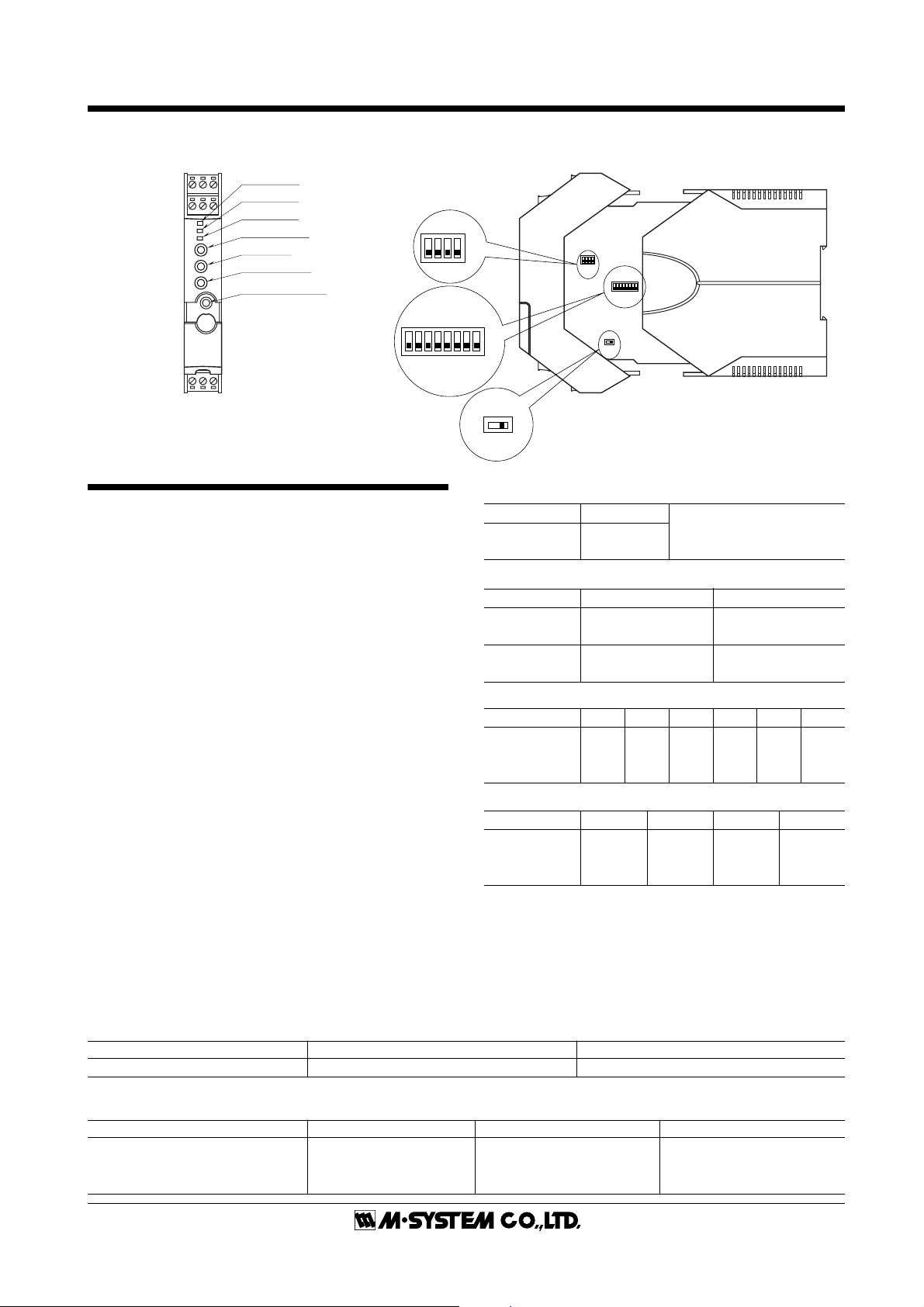

TERMINAL CONNECTIONS

Connect the unit by referring to the diagram below.

■ EXTERNAL DIMENSIONS mm (inch)

M3LDY

INSTALLATION

■ DIN RAIL MOUNTING

Set the unit so that its DIN rail adaptor is at the bottom.

Position the upper hook at the rear side of the unit on the DIN

rail and push in the lower. When removing the unit, push

down the DIN rail adaptor utilizing a minus screwdriver and

pull.

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

■ CONNECTION DIAGRAM

2-WIRE

TRANSMITTER

+

+

–

MONITOR

(1 – 5VDC)

CONFIGURATOR

1

–

2

3

+

4

V

–

JACK

10 11 12

789

106 (4.17)

123

456

18 (.71) 110.5 (4.35)

+

7

–

8

+

11

–

12

62 (2.44)

¥When mounting, no extra space is needed between units.

OUTPUT

POWER

DIN RAIL

35mm wide

35.4 (1.39)

[3.3 (.13)]

■When Used as Isolator

No Connection

INPUT

1

+

2

–

3

250Ω

24.9Ω

EM-2664 Rev.2P. 2 / 6

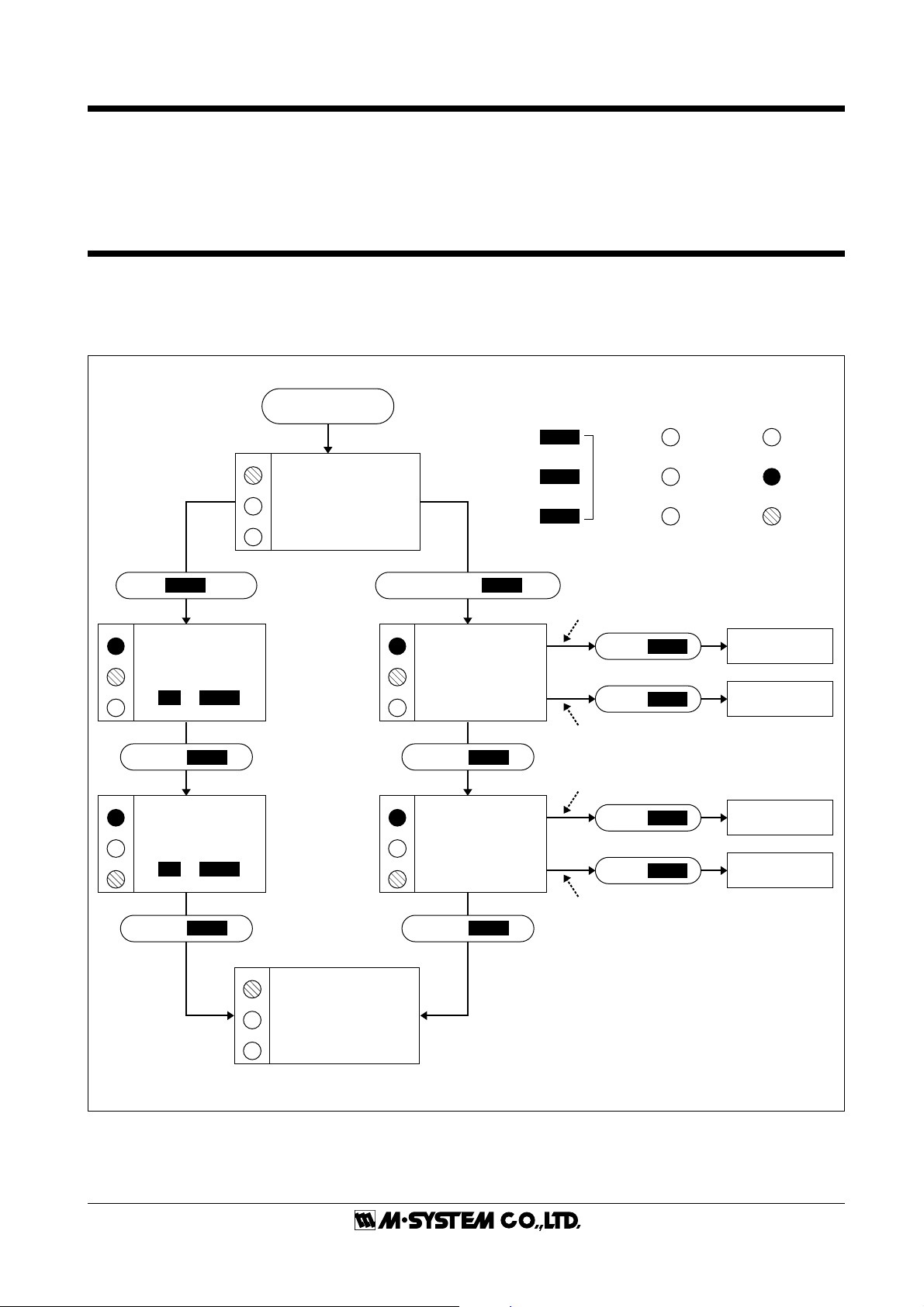

EXTERNAL & INTERNAL VIEWS

■FRONT VIEW ■SIDE VIEW

10 11 12

789

123

456

LED1 (LD1)

LED2 (LD2)

LED3 (LD3)

MODE Button

UP Button

DOWN Button

Configurator Jack

Configuration DIP SW

4321

87654321

CONFIGURATION MODE & DIP SW SETTINGS

When you program the transmitter module, two configuration modes are available: Field Configuration using DIP SW

/ control buttons, and PC Software. (The Option B type is for

the field configuration only.)

The internal DIP switches are used to configure input and

output type. Once the module is configured, precise ranges

are set up with the front control buttons using a simulator

connected to the input terminals and a multimeter connected

to the output terminals as a reference.

The calibrated input and output ranges are stored in the

internal memory. The module reads the DIP-switch-calibrated configuration only once after the power supply is

turned on. Set the switches with the power supply removed.

Selectable I/O type and ranges are listed in Table 5 and 6.

■ DIP SW CONFIGURATION MODE

Turn the SW2-8 OFF to enable the DIP SW (Field Configuration) mode as shown in Table 1.

See Table 2 to configure the input and Table 3 for the output.

■ PC CONFIGURATION MODE

Turn the SW2-8 ON to enable the PC Configuration mode as

shown in Table 1. All programmable features can be set up

on a PC regardless of other DIP SW setting except that the

output type must be selected with the DIP SW1-1 through

SW1-4 (See Table 4).

For detailed information on the PC configuration, refer to the

M3CON instruction manual.

M3LDY

OFF

ON

OFF

ON

ONOFF

■CONFIGURATION MODE (SW2) Table 1

MODE SW2-8

DIP SW OFF

PC ON

■INPUT TYPE (SW2 & 3) Table 2

INPUT TYPE SW2-7 SW3

DC current

(isolator use)

2-wire loop

(

DC supply use

■OUTPUT TYPE (SW2 & 1) Table 3

OUTPUT SW2-4 SW2-3 SW1-4 SW1-3 SW1-2 SW1-1

0 – 20mA OFF OFF OFF ON OFF OFF

-2.5 – +2.5V OFF ON ON OFF OFF ON

-10 – +10V ON OFF ON OFF ON OFF

■OUTPUT TYPE / PC CONFIG (SW1) Table 4

OUTPUT SW1-4 SW1-3 SW1-2 SW1-1

0 – 20mA OFF ON OFF OFF

-2.5 – +2.5V ON OFF OFF ON

-10 – +10V ON OFF ON OFF

SW1

SW2

SW3

Configuration mode can be

confirmed with the front LED.

ON OFF

)

OFF ON

■ INPUT TYPE & RANGE Table 5

INPUT TYPE MINIMUM SPAN MAXIMUM RANGE

DC Current 2mA 0 to 20mA

■ OUTPUT TYPE & RANGE Table 6

OUTPUT TYPE MINIMUM SPAN MAXIMUM RANGE CONFORMANCE RANGE

DC Current 1mA 0 to 20mA 0 to 24mA

DC Voltage, Narrow Spans 250mV -2.5 to +2.5V -3 to +3V

DC Voltage, Wide Spans 1V -10 to +10V -11.5 to +11.5V

EM-2664 Rev.2P. 3 / 6

M3LDY

CHECKING

1) Terminal wiring: Check that all cables are correctly connected according to the connection diagram.

2) DIP SW setting: Check that the switches are set to appropriate positions.

3) Power input voltage: Check voltage across the terminal 11 – 12 with a multimeter.

4) Input: Check that the input signal is within 0 – 100% of full-scale.

5) Output: Check that the load resistance meets the described specifications.

I/O RANGING & FINE ADJUSTMENTS

After the DIP SW setting is complete, set up the precise input and output range using the front control buttons.

The front LEDs’ colors and flashing patterns help you to easily identify the transmitter’s status and confirm the setup actions

in each step of Calibration Modes. Please read the following explanations referring to “Calibration Flow Chart” below.

■ CALIBRATION FLOW CHART

POWER ON

LD1

G

Fine Adjustments ? I/O Ranging ?

LD2

LD3

RUN MODE

G

MODE

PUSH

LD1

R

LD2

CALIBRATION MODE

G R

LD3

PUSH

LD1

R

LD2

CALIBRATION MODE

LD3

G

PUSH

1 – 2 s PRESS & HOLD

1

*

FINE ZERO

UP

or

DOWN

MODE

1

*

FINE SPAN

UP

or

DOWN

MODE

LD1

LD1

R

LD2

LD3

LD1

R

LD2

LD3

R

CALIBRATION

PUSH

CALIBRATION

PUSH

MODE

INPUT

MODE

MODE

OUTPUT

MODE

MODE

G

LD2

LD3

RUN MODE

MODE

Control

UP

Buttons

DOWN

> 5s

Apply simulated 0% input signal.

PUSH

PUSH

Apply simulated 100% input signal.

Adjust simulated input until the output meter

shows desired 0% output.

PUSH

PUSH

Adjust simulated input until the output meter

shows desired 100% output.

When you set 0% or 100% input/output ranges,

keep pressing UP or DOWN button until the

LD1 flashes for approx. 2 seconds and turns off,

which indicates the setup is complete.

When you release the button, the LD1 is returned

to ON.

If the LED does not change, the entered level may

be inappropriate, i.e. out of usable range.

A

G

R

DOWN

UP

DOWN

UP

Amber LED

Green LED

Red LED

OFF

ON

Blink

0% INPUT

CONFIGURED

100% INPUT

CONFIGURED

0% OUTPUT

CONFIGURED

100% OUTPUT

CONFIGURED

*1. Fine zero and calibrations are performed for 0% and 100% output regardless of the input value.

EM-2664 Rev.2P. 4 / 6

M3LDY

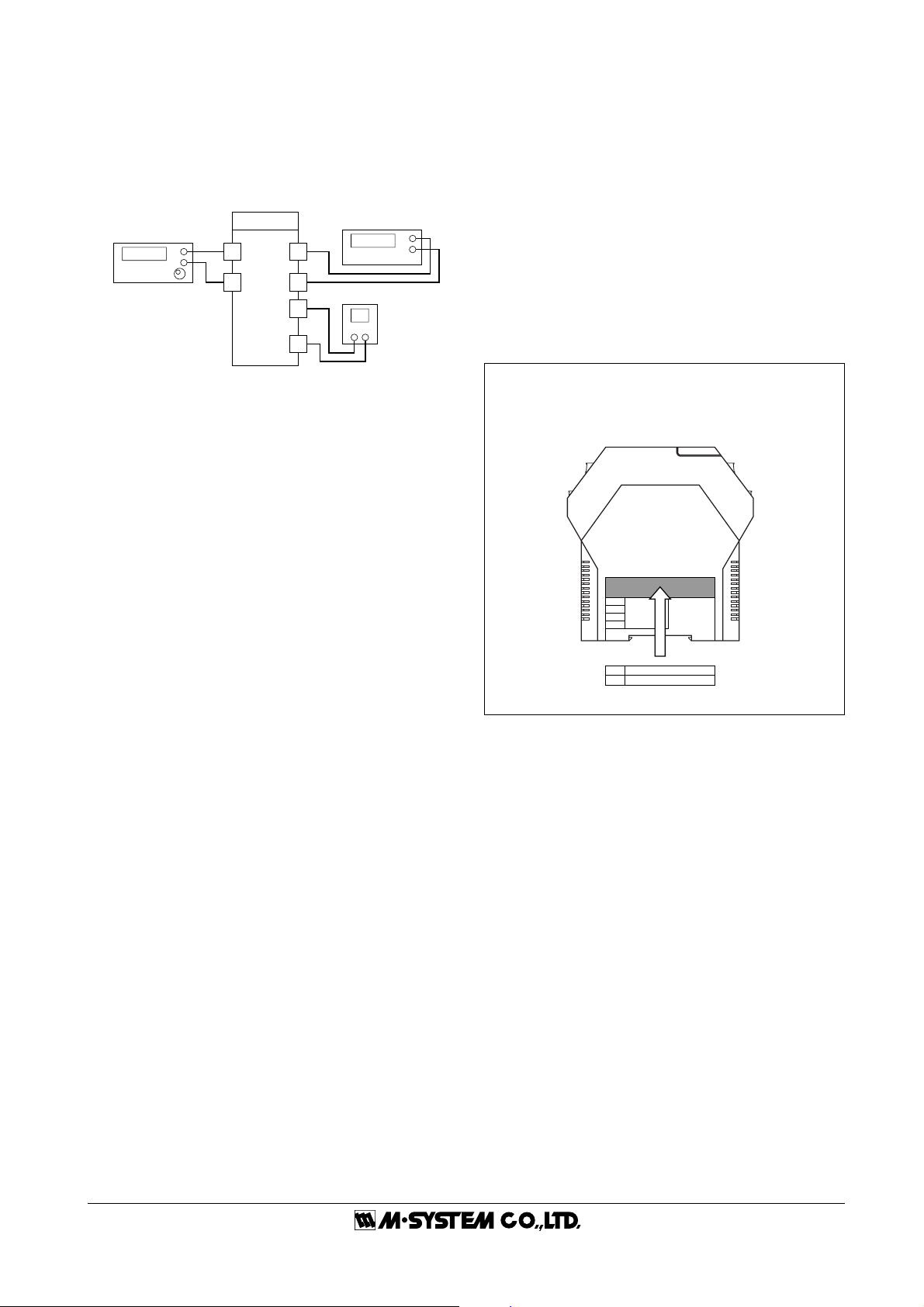

■ PREPARATION (e.g. M3LDY-R/A)

1) Mount the DIP-SW-configured M3LDY on to a DIN rail.

2) Connect the M3LDY to a simulator and a multimeter and

to a DC power source as shown to the right.

3) Turn the power supply on and wait for 10 minutes.

Simulator

M3LDY

+

–

2

3

7

8

11

12

Multimeter

+

–

DC Power Source

+–

■ INPUT & OUTPUT RANGING

[Example]

Setting input to 4 – 20mA DC and output to 1 – 5V DC

1) Run Mode: Confirm that the LD1 green light is blinking.

2) Input Configuration Mode: Press MODE button for longer

than 5 seconds until the LD1 red light is ON and the LD2

red light is blinking.

3) 0% Input Ranging: Apply the desired minimum input

level (e.g. 4mA) from the simulator and push DOWN

button until the LD1 flashes for approx. 2 sec. and then

turns OFF. When you release the button, the LD1 is

returned to ON.

The flashing LD1 means that the value is stored in the

memory. If the LED does not change, the entered level

may be inappropriate: too small a span, or out of usable

range (same for all steps).

4) 100% Input Ranging: Apply the desired maximum input

level (e.g. 20mA) from the simulator and push UP button

until the LD1 flashes for approx. 2 sec. and then turns

OFF. When you release the button, the LD1 is returned to

ON.

5) Output Configuration Mode: Push MODE button and

confirm that the LD3 red light instead of LD2 is blinking.

6) 0% Output Ranging: Increase or decrease the simulated

input until the meter shows the desired minimum output

level (e.g. 1V). Push DOWN button until the LD1 flashes

for approx. 2 sec. and then turns OFF. When you release

the button, the LD1 is returned to ON.

7) 100% Output Ranging: Increase or decrease the simulated

input until the meter shows the desired maximum output

level (e.g. 5V). Push UP button until the LD1 flashes for

approx. 2 sec. and then turns OFF. When you release the

button, the LD1 is returned to ON.

8) Run Mode: Programming complete, push MODE button

and confirm that only the LD1 green light is blinking.

4) Fine Span Calibration Mode: Push MODE button and

confirm that the LD3 green light instead of LD2 is blinking.

5) Use UP (increase) and DOWN (decrease) buttons to adjust

the output to 100%.

6) Run Mode: Push MODE button and confirm that only the

LD1 green light is blinking.

Note 1: Calibration steps can be skipped when not needed by

repeating pushing MODE buttons.

Note 2: There is no stated order of setting 0% and 100% levels

or no limitation of entering values for multiple times within

one step of Calibration Mode. Signal level is stored each time

the respective UP or DOWN button is pressed.

■ I/O RANGE LABEL

Blank I/O range labels are included in the product package. Write in the configured ranges and put the label on

the side above the specification label as shown below.

INPUT

OUTPUT

I/O Range Label (included in the product package)

■ ZERO & SPAN ADJUSTMENTS

After the transmitter is installed and operational, fine zero

and span tuning can be performed as explained below. Both

zero and span are adjustable within ±15%.

1) Run Mode: Confirm that the LD1 green light is blinking.

2) Fine Zero Calibration Mode: Press MODE button for 1 or

2 seconds until the LD1 red light is ON and the LD2 green

light is blinking.

3) Use UP (increase) and DOWN (decrease) buttons to adjust

the output to 0%.

EM-2664 Rev.2P. 5 / 6

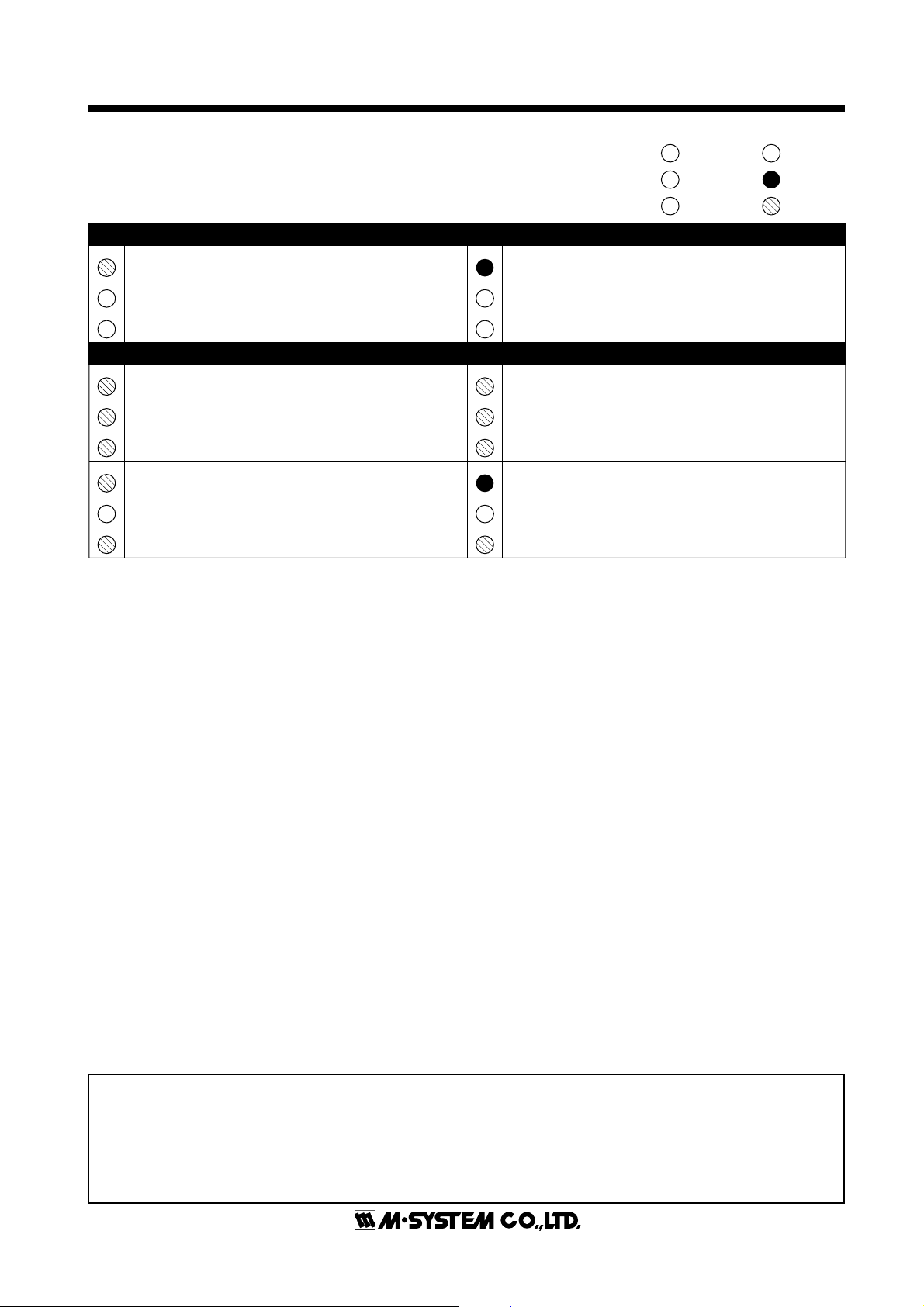

STATUS INDICATOR LED

Combinations of the three front LEDs (LD1, LD2, LD3)

indicate the transmitter’s operating status by different flashing patterns.

Examples are shown below.

NORMAL OPERATION (RUN) MODE

LD1

PC Configuration RUN Mode (Option A)

G

The transmitter is configured via PC and

LD2

is in normal operating conditions.

LD3

ERROR MODE

LD1

System Error

A

Indicates the CPU’s communication error.

LD2

A

LD3

A

LD1

Output Saturated in PC Configuration Mode

G

(Option A)

LD2

The output is saturated.

(approximately below -15% or above +115%)

LD3

A

Amber LED

A

Green LED

G

Red LED

R

LD1

DIP SW Configuration RUN Mode

G

The transmitter is configured via DIP SW and

LD2

is in normal operating conditions.

LD3

LD1

DIP SW Error

R

DIP SW configuration is inappropriate.

LD2

Check the DIP SW setting referring to Tables 2 – 11.

R

LD3

R

LD1

Output Saturated in DIP SW Configuration Mode

G

The output is saturated.

LD2

(approximately below -15% or above +115%)

LD3

A

M3LDY

OFF

ON

Blink

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

product was originally purchased if such product has been used under normal operating conditions and properly maintained, M-System's sole liability, and purchaser's exclusive remedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System Co., Ltd., 5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN, Phone: (06) 6659-8201, Fax: (06) 6659-8510, E-mail: info@m-system.co.jp

EM-2664 Rev.2P. 6 / 6

Loading...

Loading...