Page 1

LDVDSV2 Data Sheet v1.03 Page 1

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

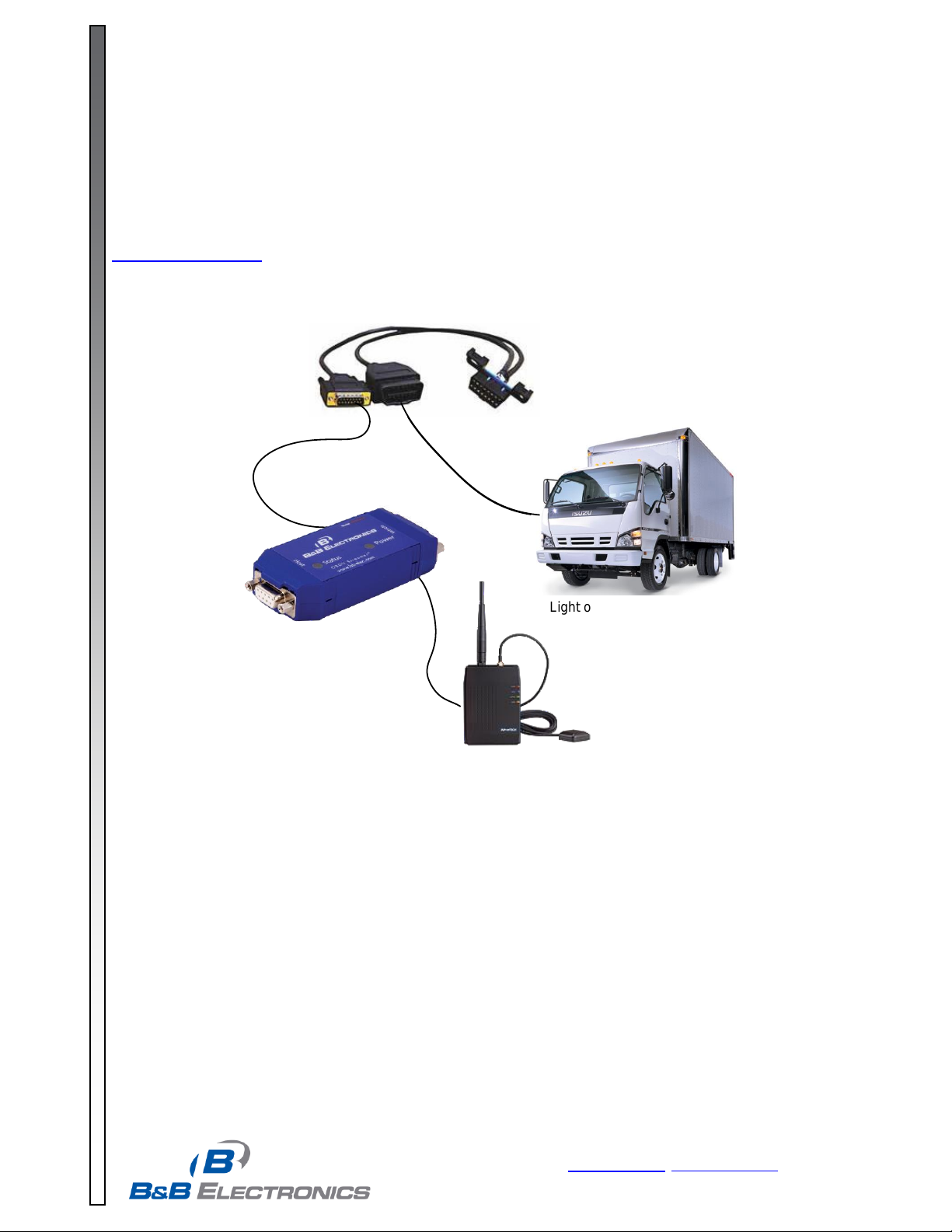

On-Board Computer

w/GPS & Wireless

Light or Medium Duty Car or

Truck

OBDII Y-Cable

RS-232

On-Board Computer

w/GPS & Wireless

Light or Medium Duty Car or

Truck

OBDII Y-Cable

RS-232

RS-232

Model LDVDSV2

The B&B Electronics AutoTap™ OBDII Data Streamer Model LDVDSV2 connects your PC, driver terminal, Java-enabled

phone, or other on-board computing device to the OBDII diagnostic bus of light and medium duty vehicles. It enables the

retrieval of the most commonly used parameters of value in telematics and fleet management applications.

The LDVDSV2 provides a simple operational protocol to communicate to the OBDII bus. It provides a common interface and

deterministic response time for all vehicles. The complete Command and Response protocol is published on B&B’s website

www.rvdstreamer.com.

Advanced OBDII Data Streamer

Supported Vehicles

The OBDII Streamer supports any 1996 or newer

vehicles that comply with the SAE’s J1979 OBDII

specification.

Supported Parameters

Vehicle Identification Number

Vehicle Speed - Monitor aggressive driving

Engine Speed - Monitor idle time and engine

abuse

Throttle Position

Odometer/Distance Traveled - Monitor trip

distance and HOS

Instantaneous Fuel Rate in Gallons per Hour

Total Fuel - Monitor MPG & Protect against theft

Ignition status – Track Idle time

Supported Protocols

SAE J1850 VPW

SAE J1850 PWM

SAE J2284/ ISO 15765 (CAN)

ISO 9141-2

ISO 14230-4 (KWP2000)

Battery Voltage – Watch for charging system failures

PTO Status - Automatically figure fuel tax savings

Diagnostic Trouble Codes

MIL Status

Emissions Readiness Monitors - Check remotely if

vehicles are ready for emissions certification

Brake Switch Status and Seatbelt Fastened available

on most Ford & GM trucks/vans

Other parameters available on a custom basis

Page 2

LDVDSV2 Data Sheet Page 2

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

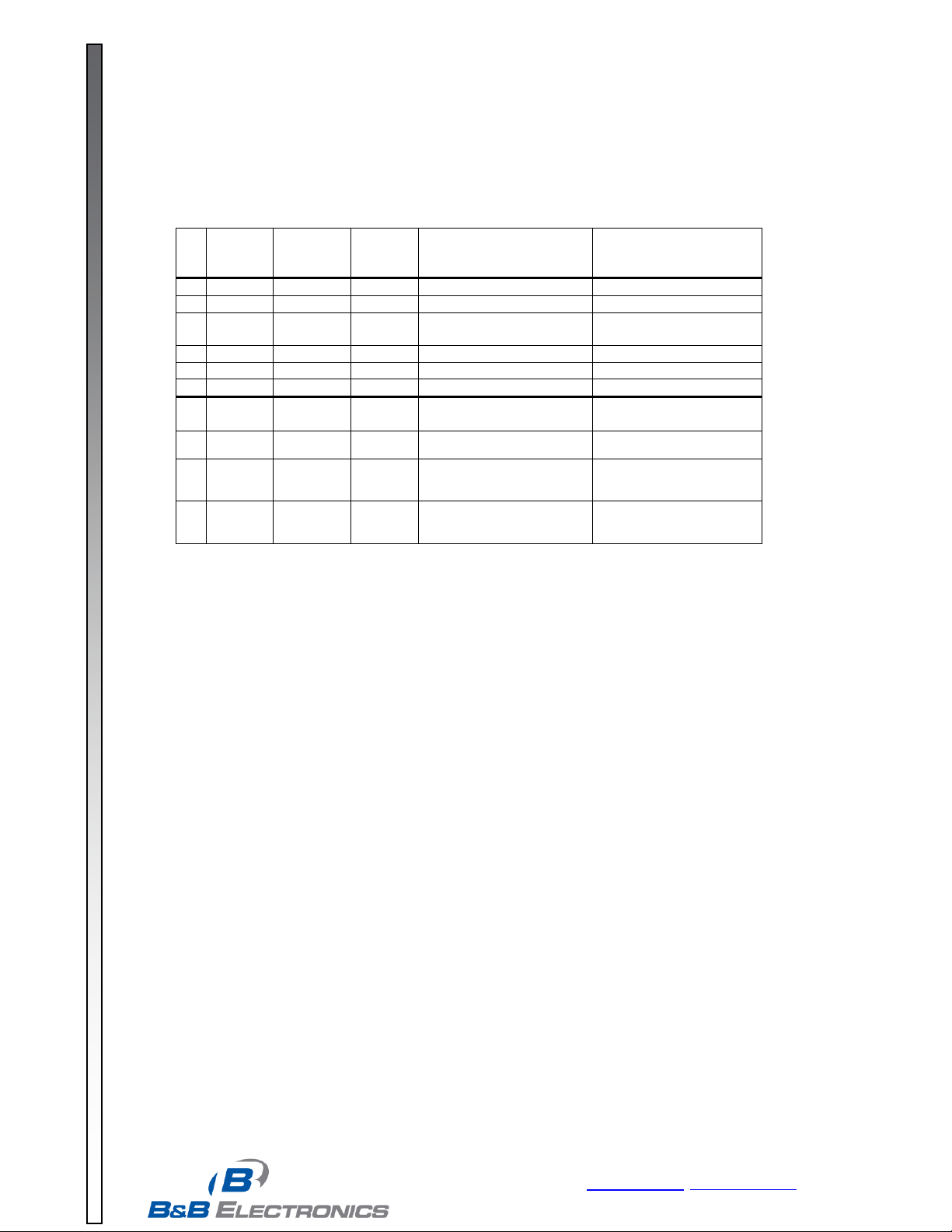

Red

LED

(Power)

Green

LED

(Activity)

Red

LED

(Debug)

Actual State

Customer Description

1

On

On

Off

Normal operation

Normal operation

2

On

SB

Off

Detecting vehicle

Detecting vehicle

3

Off

FB

Off

Database version mismatch

Database needs to be

updated

4

Off

SB

Off

Update in progress

Update in progress

5

Off

VSB

VSB

Device asleep

Device asleep

6

Off

Off

Off

Device unpowered

Device unpowered

7

Off

On

FB

Error FPGA Image Invalid

Firmware needs to be

updated

8

Off

Off

FB

Error with EMM code

Update System Manager

9

Off

Off

FB

EMM checking CRC of

Images

Wait 10 seconds if state

does not change see 8

10

Off

SB

FB

Error writing/reading

to/from flash during update

Restart update of current

component

Vehicle Speed Signal Output pulse for driving external distance meters

o 0V to 5V pulses, 1 kOhm output impedance.

o 50% Duty Cycle

o 3,500 pulses/km (5,632.7 pulses/mi.)

Ignition-On Signal Output

Status LED’s for vehicle connection and power

Additional Features

LED state descriptions:

On (LED_ON): lit, solid

Off (LED_OFF): unlit

FB (LED_FAST): Alternating on-off; 125ms on, 125ms off

SB (LED_SLOW): Alternating on-off; .5 sec on, .5 sec off

VSB (LED_VERY_SLOW): Alternating on-off; .25 sec on, 2 sec off

Automatic low power mode senses when vehicle speed & engine speed is zero.

Automatic disconnect when technician scan tool is connected (Requires separate OBDII Y-Cable)

Proprietary vehicle detection algorithm and embedded database lets the same hardware work on all compliant vehicles

Configurable parameter reporting by polling, at a fixed rate, or when a threshold is exceeded.

Wide Operating Temperature: -40 to 85 ºC (-40 to 185 ºF)

Low Power Consumption: 2W in Operating Mode; 0.15W in Automatic Sleep Mode (Key Off)

Page 3

LDVDSV2 Data Sheet Page 3

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

Available Form Factors

Vehicle Bus Connection: DB15 female

Pin 1 ISO9141 K/

Pins 4, 5: J1850-, J1850+

Pin 6, 7 Ground

Pin 9 Vehicle unswitched Vbat

Pin 10 ISO9141 L

Pin 11 Vehicle Vbat to external scan tool

Pin 12 CAN Low

Pin 13 CAN High

RS-232 Connection: DB9 female, DCE

Pins 1,4,6 Connected together

Pin 2 RD

Pin 3 TD

Pin 5 Ground

Pin 7 RTS

Pin 8 CTS (Vehicle Ignition Status)

Pin 9 Vehicle Speed Sensor Output Signal, VBAT Power in, VBAT Power out (3 separate build options)

Dimensions: 4.1 x 1.7 x 0.8 in (104.1 x 43.2 x 20.3 mm)

Operating Voltage Range: 8 to 30 VDC

Calculated MTBF: 111,440 Hours

Page 4

LDVDSV2 Data Sheet Page 4

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

1.750"

0.078" Max.

1.750"

0.110" Max.

2.0 mm

2

1

24

23

0.382"

ø 0.103" x4

0.075"

0.267"

Daughter Board Module

Connector:

24-Pin Header

0.5mm Square Pins

2.0mm Pin Spacing

Samtec P# TMM-112-06-T-D-SM

Suggested Stand-Off:

Page 5

LDVDSV2 Data Sheet Page 5

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

Signal

Pin

Direction

Description

Serial Rx

1

Board to Streamer

0 to 3.3V Asynchronous serial signal (0V = Space, +5V = Mark)

Max Voltage 3.3V

Serial Tx

2

Streamer to Board

0 to 3.3V Asynchronous serial signal (0V = Space, +5V = Mark)

Max Voltage 3.3V

+5V 3 Board to Streamer

Regulated (+/-5%) 5V Supply @ 200 mA Max

Max Voltage 5.5V

Enable

4

Board to Streamer

OBDII Streamer Enable/Reset Pin (0-5V, Enabled = High)

Max Voltage 5V

Engine On

5

Streamer to Board

Indicates RPM or Vehicle Speed > 0

Vehicle Speed Pulse

6

Streamer to Board

0 to 5V signal with frequency proportional to vehicle speed

J1850+ 7 Both

J1850+ line from J1962 Pin 2

J1850- 9 Both

J1850- line from J1962 Pin 10

CANh 8 Both

CAN High line from J1962 Pin 6

CANl

10

Both

CAN Low line from J1962 Pin 14

ISO K

11

Both

ISO 9141 K Line from J1962 Pin 7

ISO L

12

Both

ISO 9141 L Line from J1962 Pin 15

Scan Tool Present

13

Streamer to Board

Indicates a technician scan tool has been plugged in

Max continuous voltage 45V

Max transient voltage 65V

Vbat

14

Board to Streamer

Vehicle battery voltage from J1962 Pin 16

+12V to Service Tool

15

Streamer to Board

+12V out to 3rd party scan tool

GND

16

Both

Vehicle battery ground from J1962 Pin 4 and 5

PGC

17

Board to Streamer

Microchip ICSP Clock for programming & debug

PGD

18

Both

Microchip ICSP Data for programming & debug

MCLR

19

Board to Streamer

Microchip ICSP MCLR/Program Voltage for programming & debug

+3.3V

20

Streamer to Board

+3.3V supply for Microchip ICSP programming & debug

TDI

21

Board to Streamer

JTAG data pin for FPGA programming & debug

TDO

22

Streamer to Board

JTAG data pin for FPGA programming & debug

TMS

23

Board to Streamer

JTAG pin for FPGA programming & debug

TCK

24

Board to Streamer

JTAG clock pin for FPGA programming & debug

Page 6

LDVDSV2 Data Sheet Page 6

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

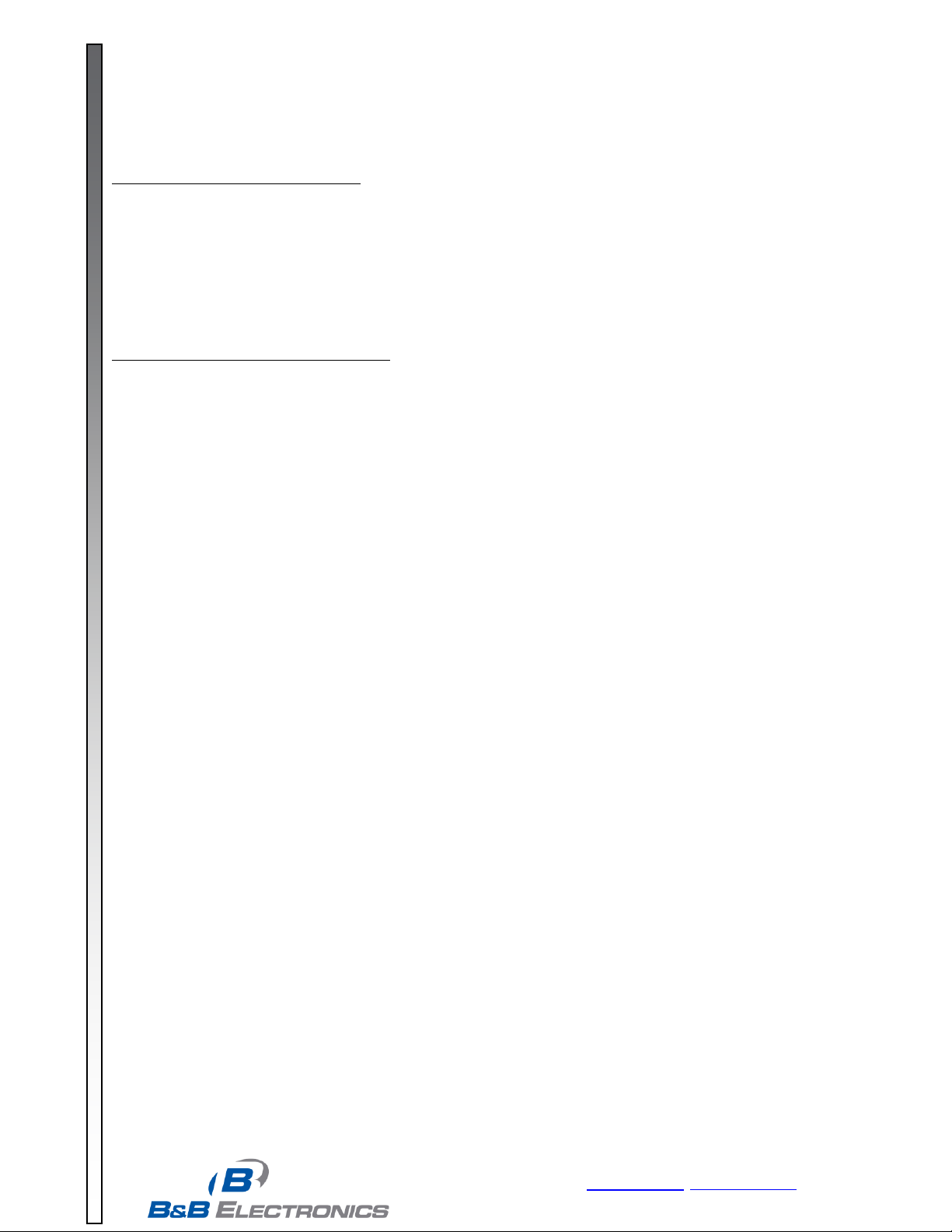

Vehicle Data

OBDII Streamer

Module

OBDII

Diagnostic

Busses

Data

Acquisition

& Storage

Cellular Network

Or

WiFi to Internet

On-Vehicle System

Wireless

Connectivity

Central

Server/

Database

Fleet Manager

Other

Sensors &

Displays

On-Board

Computing

Device

Mount Your Own Chip Set

Included:

Bill of Materials with manufacturer part numbers and suggested vendor information

Schematic in Adobe Acrobat and P-CAD Schematic Formats

Net List

PCBD Layout in Adobe Acrobat, P-CAD PCB, & Gerber Formats

Hex file with hardware description and firmware

Serial interface command and response specifications

External box w/OBDII Y-Cable to be used in application development.

QuickTester PC application w/source code

Unlimited Layout & Integration support for 1 year.

Maintenance releases and vehicle upgrades for 1 year.

Production test specifications.

Production test software w/source code

Page 7

LDVDSV2 Data Sheet Page 7

PRODUCT INFORMATION B&B Electronics

ELECTRONICS

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

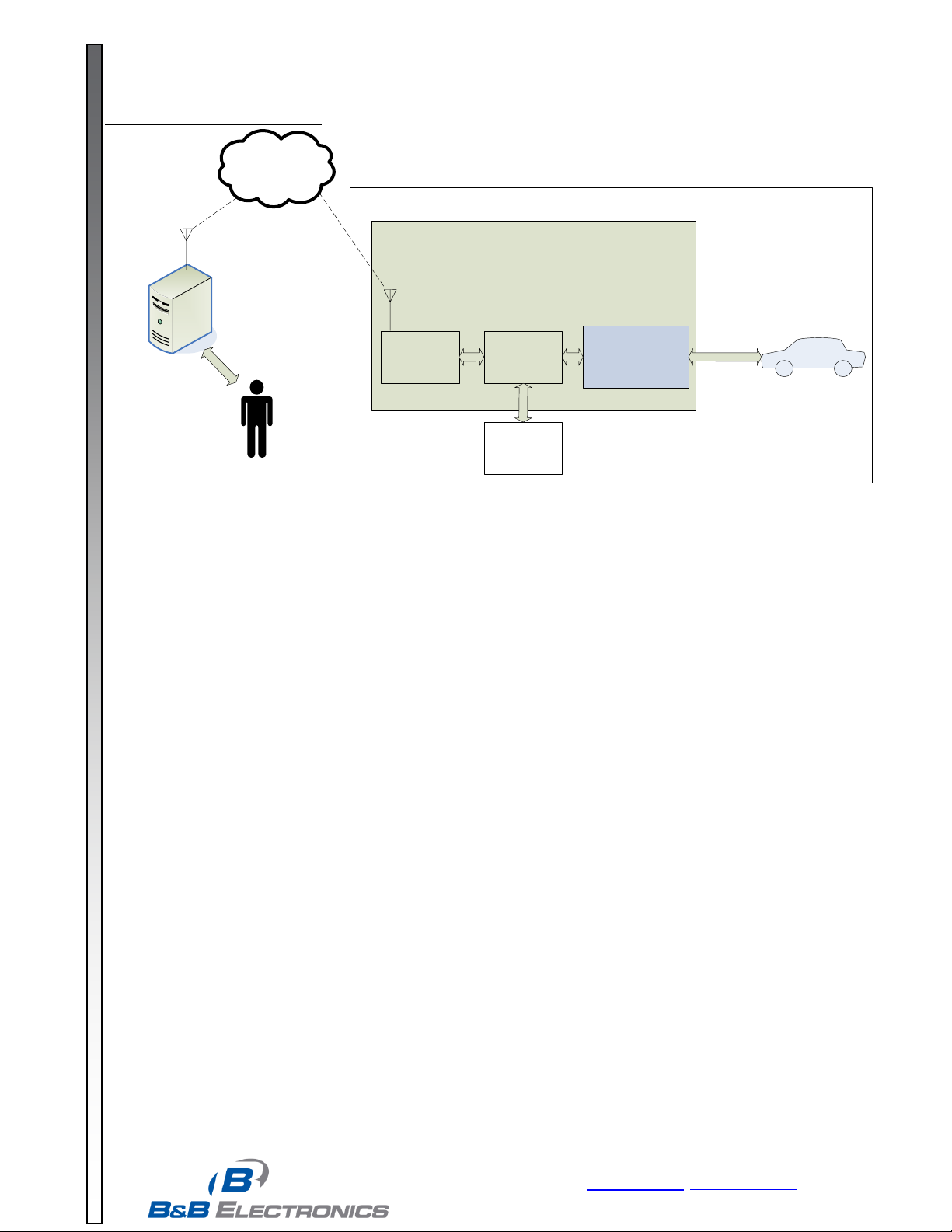

Product

B&B Supplied Items

Customer Requirements

Advantages

Disadvantages

Pricing Model

Box

Interface external box

Optional OBDII Y-Cable

On-board computer (OBC) with

RS-232 Serial Port

Software to read/write to serial

port

Quickest time to market

No hardware modification required to

the OBC

Automatic updates to new units

Most expensive solution

Two cables in the installation

Can’t test OBC/OBDII combination

until install

Per-piece hardware price

Daughter

Board

OBDII module with plug-

in interconnect &

mounting holes

Optional OBDII Y-Cable

OBC with TTL serial port,

matching plug-in interconnect, 5V

Supply, DB-15 connector to go to

OBDII Y-Cable.

Software to read/write to serial

port

Minimal software integration.

Reduce steps of installation

Less expensive than box

Automatic updates to new units

Test OBC/OBDII combination in the

factory at build time

PCBD Change required on OBC

OBC enclosure has to accommodate

daughter board

Possibly more expensive than chip

set.

Per-piece hardware price

Chip Set

Schematic

Bill of Materials

Example layout

FPGA HW Description

Firmware in executable

form

Integrate Streamer design into

the OBC.

Software to read/write to serial

port

Source OBDII chip set for

production

Minimal software integration.

Reduce steps of installation

Can lay out OBC PCBD to fit best in

enclosure

Possibly less expensive than daughter

board

Test OBC/OBDII combination in the

factory at build time

Extensive PCBD layout on OBC

Software updates for OBDII have to

be implemented in customer

production

Any hardware updates require a new

PCBD layout for the OBC.

Requires high quantities of chip set

purchase to get cost savings.

Replicates processors compared to IP

version.

First year NRE

Consecutive year

maintenance fee

Per-piece license fee

IP Libraries

Firmware in library form

(CAN Only)

Embedded Database

(CAN Only)

Design a CAN interface into the

OBC

Write an interface between the

Streamer libraries and the OBC

application.

Write board support libraries

between the Streamer libraries

and the OS/Hardware.

No redundant hardware costs.

Can achieve a small form factor.

No support for vehicles without CAN

(older than 2008)

Extensive software integration

required.

Hardware CAN interface design

required.

Longest time to market

Software updates for OBDII have to

be integrated into software before

production

First year NRE

Consecutive year

maintenance fee

Per-piece license fee

Choosing the right Product:

Page 8

LDVDSV2 Data Sheet Page 8

www.bb-elec.com orders@bb-elec.com support@bb-elec.com

International Office: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA 815-433-5100 Fax 433-5104

European Office: Westlink Commercial Park Oranmore Co. Galway Ireland +353 91 792444 Fax +353 91 792445

PRODUCT INFORMATION B&B ELECTRONICS

EMC Testing

Radiated RF Interference: SAE J1113/41

Load Dump and Transient Protection SAE J1113/11

ESD Immunity SAE J1113/13

Environmental Testing

Temperature Test:

Ten (10) temperature cycles as follows with unit operating normally

1. Room (25ºC) to Tmin in 15 minutes.

2. Soak at Tmin 1 Hour with power removed from unit

3. Start unit at Tmin, confirm successful start by executing a command/response. Power-down unit. Maintain unit unpowered for one minute between power-ups.

4. Repeat Step 3 three times

5. Start unit at Tmin and ramp Tmin to Tmax in 30 minutes

6. Operate at Tmax for 1 hour

7. Ramp Tmax to Tmin in 15 minutes

8. Repeat steps 1 through 7 nine times for a total of 10 cycles:

a. 5 cycles at Vmin input

b. 5 cycles at Vmax input

Vibration Test:

IEC 60068-2-6

10 sweeps of 10 to 500 to 10Hz at rate 0.5 oct/min. each axis.

Level to be 10 to 36Hz, 0.06 in DA 36 to 500Hz, 4g’s

Unit must remain operational during and after the test.

Shock Test:

IEC 60068-2-27

18 to 50g’s, 11ms, ½ sine pulses, 3 each direction each axis

Unit must remain operational during and after the test.

Drop Test:

IEC 60068-2-32

10 Freefall drops from 1 meter onto concrete surface.

Drop 1 time one each face (6), 1 on a corner and the 3 edges of this corner.

The drop unit shall return to normal operation without physical damage.

Loading...

Loading...