g

N

I-7565-H1 / I-7565-H2

Hi

h Speed USB/CA

Converter

User’s Manual

Warranty

All products manufactured by ICP DAS are under warranty regarding

defective materials for a period of one year from the date of delivery to the

original purchaser.

Warning

ICP DAS assumes no liability for damages resulting from the use of

this product. ICP DAS reserves the right to change this manual at any time

without notice. The information furnished by ICP DAS is believed to be

accurate and reliable. However, no responsibility is assumed by ICP DAS

for its use, or for any infringements of patents or other rights of third

parties resulting from its use.

Copyright

Copyright 2009 by ICP DAS. All rights are reserved.

Trademark

The names used for identification only may be registered trademarks

of their respective companies.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 1

Table of Contents

1. Introduction ........................................................................................4

1.1 Features............................................................................................. 5

1.2 Specifications..................................................................................... 5

2. Hardware.............................................................................................7

2.1 Block Diagram.................................................................................... 7

2.2 Pin Assignment of CAN Port .............................................................. 8

2.3 Hardware Connection ........................................................................ 8

2.4 Terminator Resistor Settings ............................................................ 10

2.5 Init / Normal Dip-switch .....................................................................11

2.5.1 Firmware Update Mode...................................................................11

2.5.2 Firmware Operation Mode.............................................................. 12

2.6 LED Indication.................................................................................. 14

2.7 Cable Selection................................................................................ 15

3. Driver Installation.............................................................................17

3.1 Install I-7565-H1/H2 Driver:.............................................................. 17

3.2 Verify Driver Installation: .................................................................. 20

3.3 Uninstall I-7565-H1/H2 Driver .......................................................... 21

4. Software Utility.................................................................................22

4.1 INI File Function............................................................................... 22

4.2 Connection Function ........................................................................ 22

4.3 Communication Function ................................................................. 24

4.4 Config Function................................................................................ 26

4.4.1 Module Config Function ................................................................. 27

4.4.2 Advanced Config Function ............................................................. 30

4.5 Data Log Function............................................................................ 31

4.6 Status Bar Function.......................................................................... 33

5. API Library -- VCI_CAN.dll...............................................................35

5.1 API Library Overview ....................................................................... 35

5.2 API Library Function Table............................................................... 36

5.3 Flow Chart for Users’ Program Development by Using API ............. 38

5.4 Init Function ..................................................................................... 39

5.4.1 VCI_OpenCAN............................................................................... 39

5.4.2 VCI_CloseCAN .............................................................................. 41

5.5 Module Config Function ................................................................... 42

5.5.1 VCI_Set_CANFID .......................................................................... 42

5.5.2 VCI_Get_CANFID .......................................................................... 44

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 2

5.5.3 VCI_Get_CANStatus ...................................................................... 46

5.5.4 VCI_Clr_BufOverflowLED .............................................................. 47

5.5.5 VCI_Get_MODInfo ......................................................................... 48

5.5.6 VCI_Rst_MOD ............................................................................... 49

5.6 Communication Function ................................................................. 50

5.6.1 VCI_SendCANMsg ........................................................................ 50

5.6.2 VCI_RecvCANMsg......................................................................... 52

5.6.3 VCI_EnableHWCyclicTxMsg.......................................................... 54

5.6.4 VCI_DisableHWCyclicTxMsg ......................................................... 56

5.7 Software Buffer Function.................................................................. 57

5.7.1 VCI_Get_RxMsgCnt....................................................................... 57

5.7.2 VCI_Get_RxMsgBufIsFull .............................................................. 58

5.7.3 VCI_Clr_RxMsgBuf ........................................................................ 59

5.8 Other Function ................................................................................. 60

5.8.1 VCI_Get_DllVer .............................................................................. 60

5.8.2 VCI_DoEvents................................................................................ 61

5.9 Return Code..................................................................................... 62

6. Troubleshooting...............................................................................63

6.1 The Connection Issue ...................................................................... 63

6.2 The CAN Baud Rate Issue............................................................... 64

6.3 The Same CAN-ID Conflict Issue..................................................... 66

6.4 The PC Rebooting Issue.................................................................. 66

6.5 The Max Data Transfer Rate (fps) Issue .......................................... 66

6.6 The Data Loss Issue ........................................................................ 66

6.7 The Module Number Applied to One PC Issue ................................ 67

6.8 The Long Driver Installation Time Issue ........................................... 67

6.9 The Supported CAN Filter-ID Number Issue.................................... 68

6.10 Other Issue ...................................................................................... 69

7. History of Version ............................................................................70

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 3

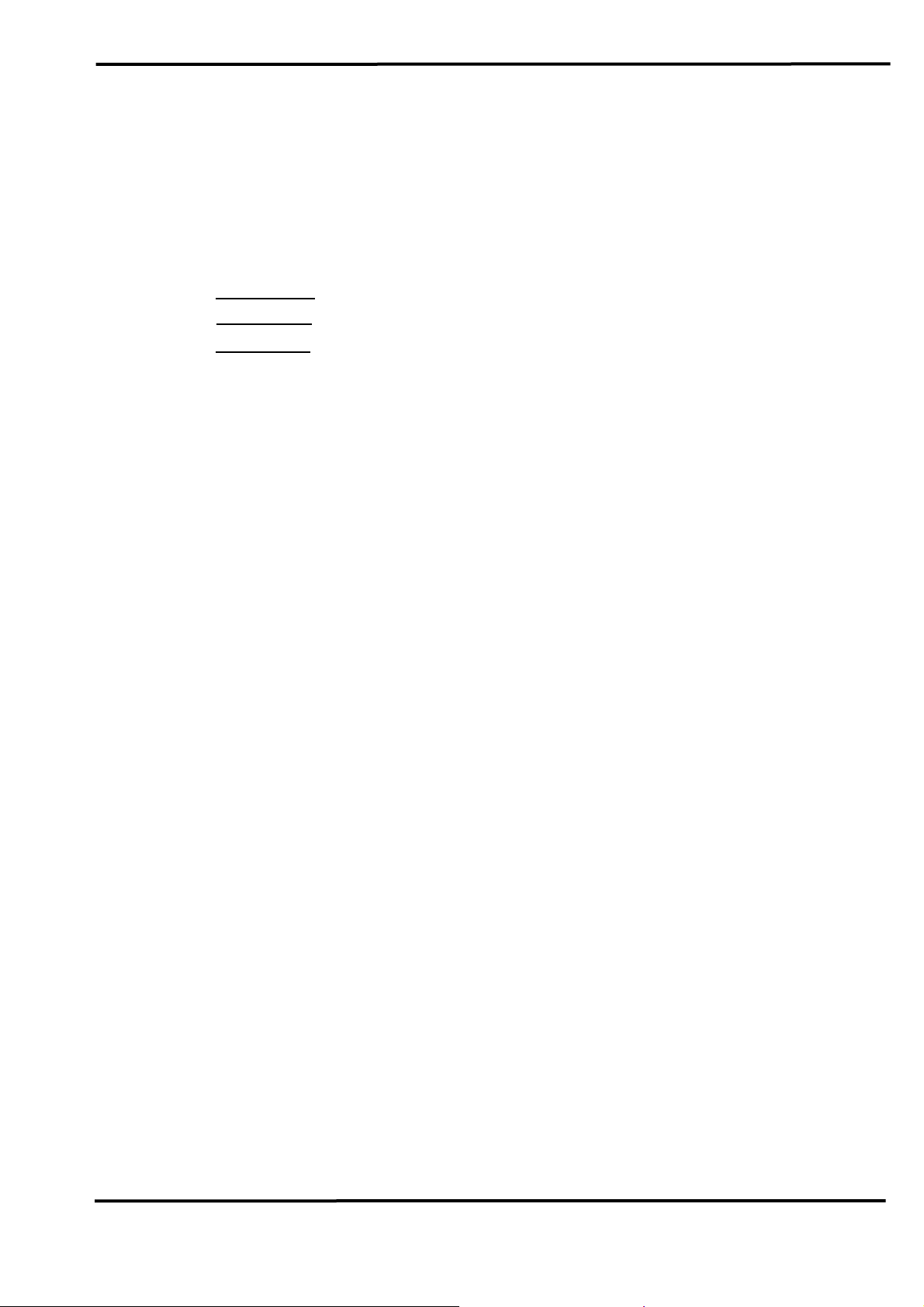

1. Introduction

I-7565-H1 and I-7565-H2 are the high speed intelligent USB to CAN

converters with one and two CAN channels separately. They provide

faster CAN bus communication performance than I-7565. Both I-7565-H1

and I-7565-H2 support CAN2.0A/2.0B protocol and different baud rates

from 5 Kbps to 1 Mbps. The important feature of I-7565-H1/H2 is to

support the user-defined baud rate function no matter what the baud rate

is. When connecting I-7565-H1/H2 to PC, PC will load the relevant device

driver automatically (hot plug & play). Therefore, users can make data

collection and processing of CAN bus network easier and quicker by

applying I-7565-H1/H2. The application fields can be CAN bus monitoring,

building automation, remote data acquisition, environment control and

monitoring, laboratory equipment & research, factory automation, etc.

The following is the application structure for these two USB/CAN

modules :

(1) I-7565-H1: High Speed intelligent USB to 1- port CAN bus Converter.

(2) I-7565-H2: High Speed intelligent USB to 2- port CAN bus Converter.

Figure 1-1: Application of I-7565-H1/H2

I-7565-H1 application I-7565-H2 application

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 4

1.1 Features

• RoHS Design

• Fully compliant with USB 1.1/2.0 (Full Speed)

• Fully compatible with the ISO 11898-2 standard

• Support both CAN2.0A and CAN2.0B

• No external power supply (powered by USB)

• Integrated with one or two CAN bus interface

• Programmable CAN bus baud rate from 5Kbps to 1Mbps or user-

defined baud rate

• Support CAN bus acceptance filter configuration

• Timestamp of CAN message with at least ±1ms precision

• Support firmware update via USB

• Provide utility tool for users module setting and CAN bus

communication testing conveniently

• Provide API library for user program development

• Provide PWR / RUN / ERR indication LED

• Built-in jumper to select 120 ohm terminal resister

• Max data flow for CAN channel: 3000 fps ( depends on users’ PC

hardware performance )

• The CAN buffer is 256 data frames for I-7565-H1 and 128 data frames

in each CAN port for I-7565-H2.

• Watchdog inside

• Driver supported for Windows 2000/XP and WinCE (available soon)

1.2 Specifications

[ USB specs: ]

• Input port : USB (USB Type B)

• Compatibility : USB 1.1 and 2.0 standard

• Driver Supported : Windows 2000/XP and WinCE (available soon)

[ CAN specs: ]

• CAN interface connector:

I-7565-H1 : 9-pin D-sub male

I-7565-H2 : 10-pin terminal-block

• CAN Baud Rate : 5K ~ 1Mbps or User-defined baud rate

• Isolation Voltage : 3000Vrms on the CAN side

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 5

[ Module specs: ]

• Dimensions : 108mm x 72mm x 35mm (H x W x D)

• Operating temperature : -25 to 75ºC (-13 to 167ºF);

• Storage temperature : -40 to 80ºC (-40 to 176ºF);

• Humidity : 5 to 95%, non-condensing;

• LEDs :

PWR LED for power

RUN LED for communication

ERR LED for error

[ Software Utility Tool / API Library: ]

• Provide CAN bus user-defined baud rate / acceptance filter

configuration

• Easily transmit / receive CAN messages for testing and display the

time-stamp of each received CAN message.

• Provide saving the CAN message as “TXT” file for data log.

• Provide sending CAN message by using the internal timer of module

for high precision transmission.

• Check / Reset module status remotely and get current CAN bus

message flow.

• Users can develop own program by API library quickly and easily.

[ Application: ]

• Factory Automation;

• Building Automation;

• Home Automation;

• Control system;

• Monitor system;

• Vehicle Automation;

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 6

2. Hardware

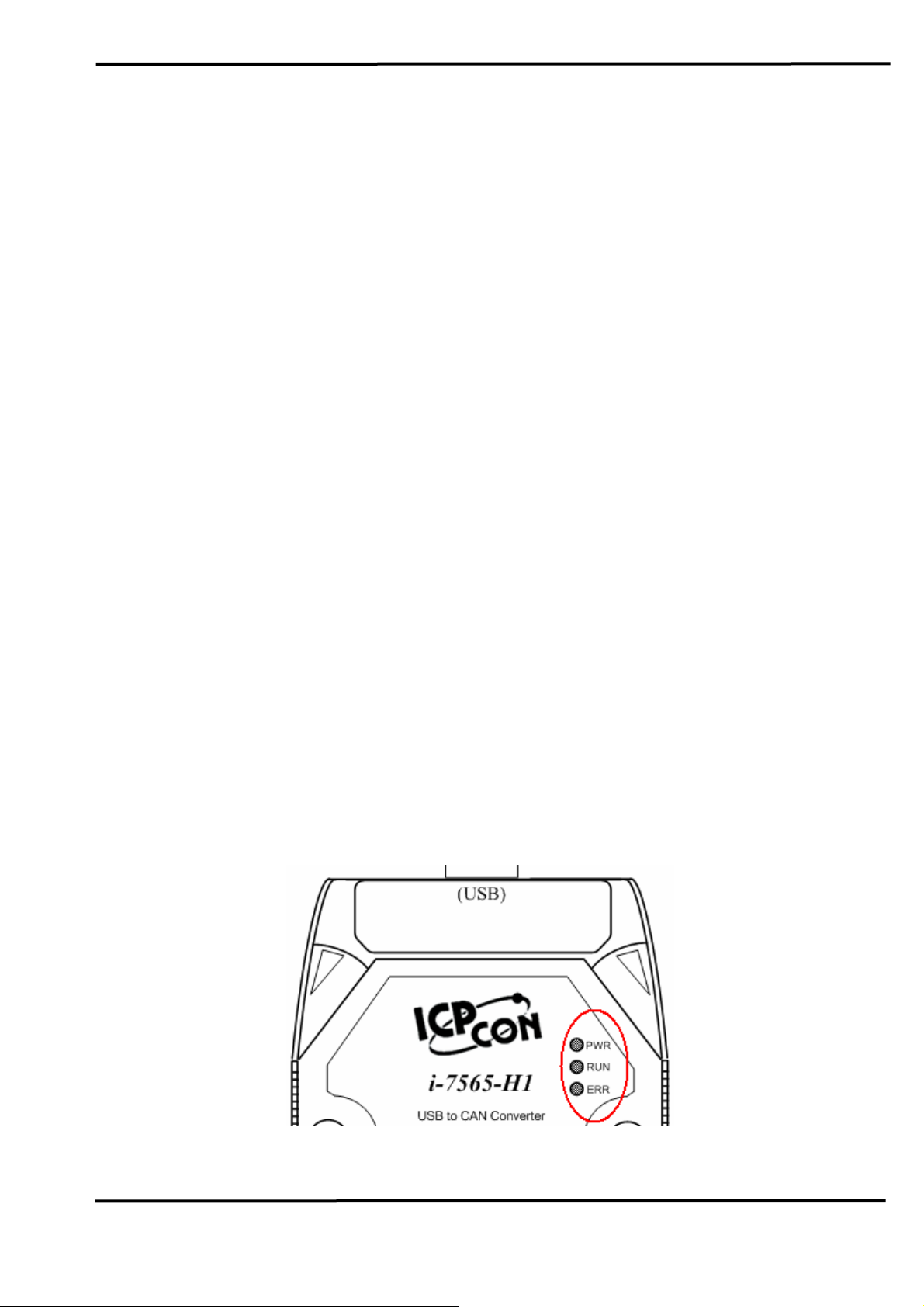

Figure 2-1: Hardware externals of I-7565-H1/H2

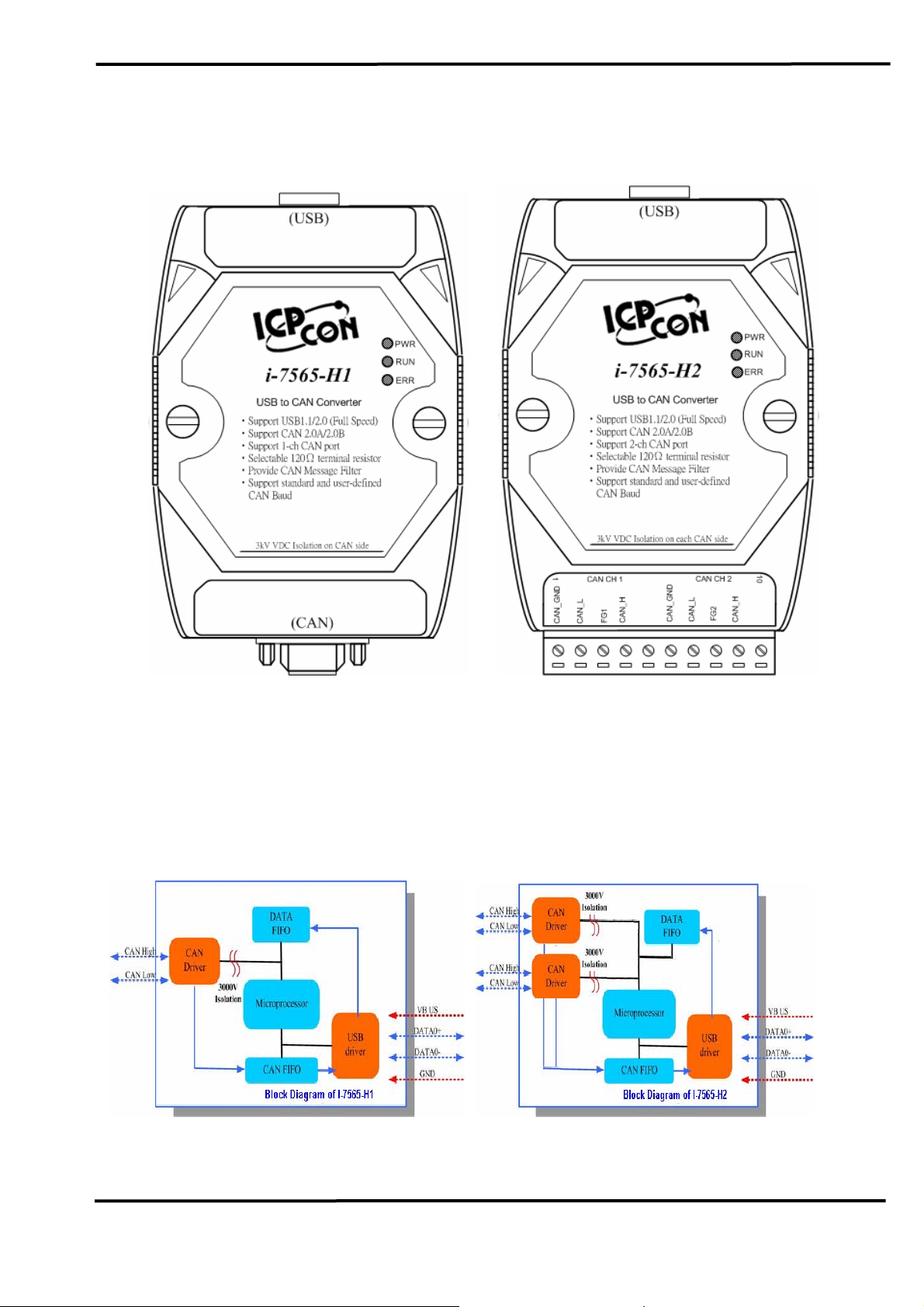

2.1 Block Diagram

Figure 2-2 is a block diagram illustrating the functions on the I-7565H1/H2 module. It provides the 3000Vrms Isolation in the CAN interface

site.

Figure 2-2: Block diagram of I-7565-H1 / I-7565-H2

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 7

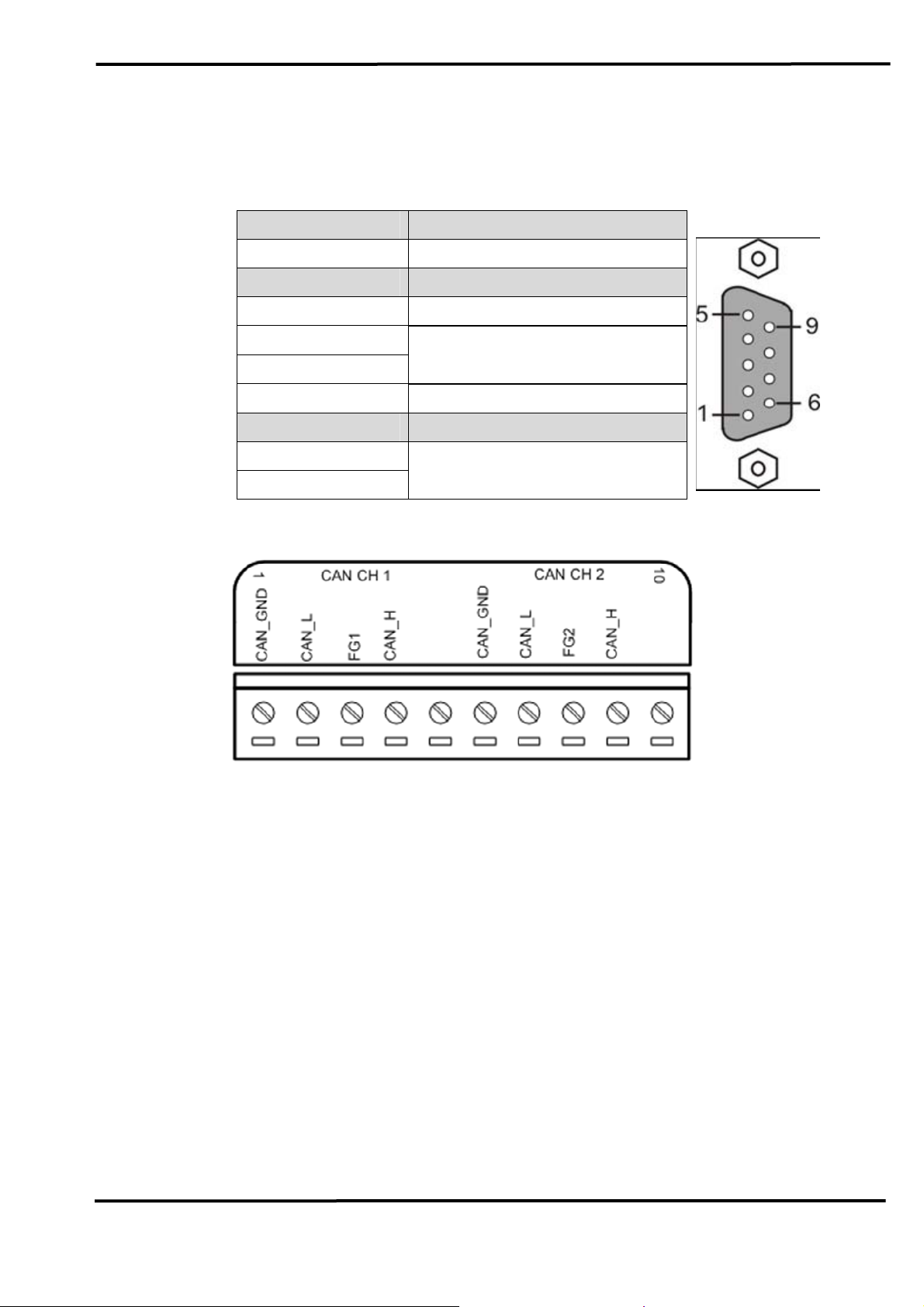

2.2 Pin Assignment of CAN Port

Table 1: CAN DB9 Male Connector on I-7565-H1

Terminal 2-wire CAN

1 Not Connect

2 CAN Low

3 CAN Ground

4

Not Connect

5

6 CAN Ground

7 CAN High

8

Not Connect

9

Figure 2-3: Pin Assignment on I-7565-H2

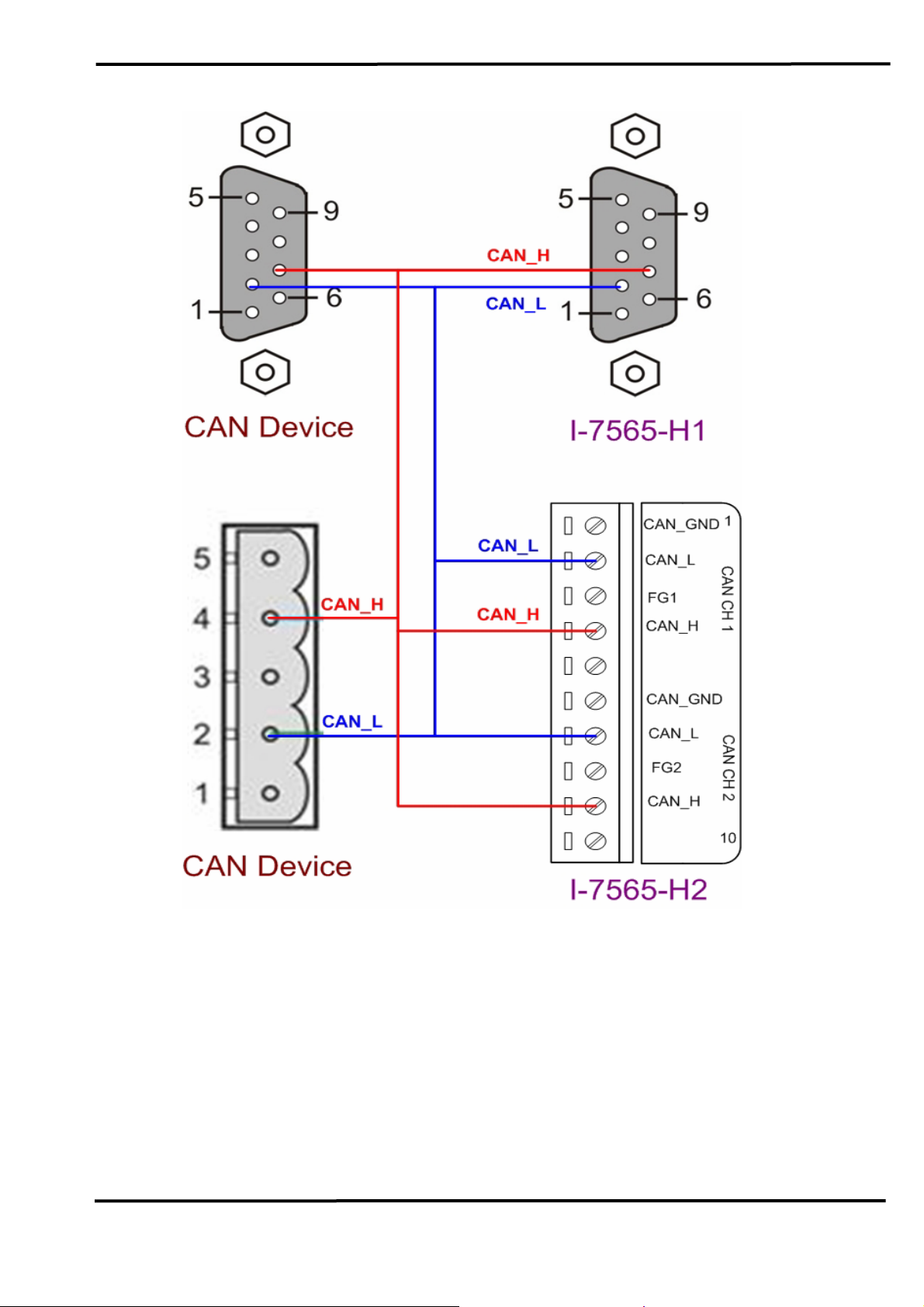

2.3 Hardware Connection

The pin assignment of the CAN port on the I-7565-H1 (DB9 male)

defined in both the CANopen DS102 profile and in appendix C of the

DeviceNet specifications. It is the standard pin assignment for CAN. The

hardware connection between device and I-7565-H1/H2 is like Figure 2-4.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 8

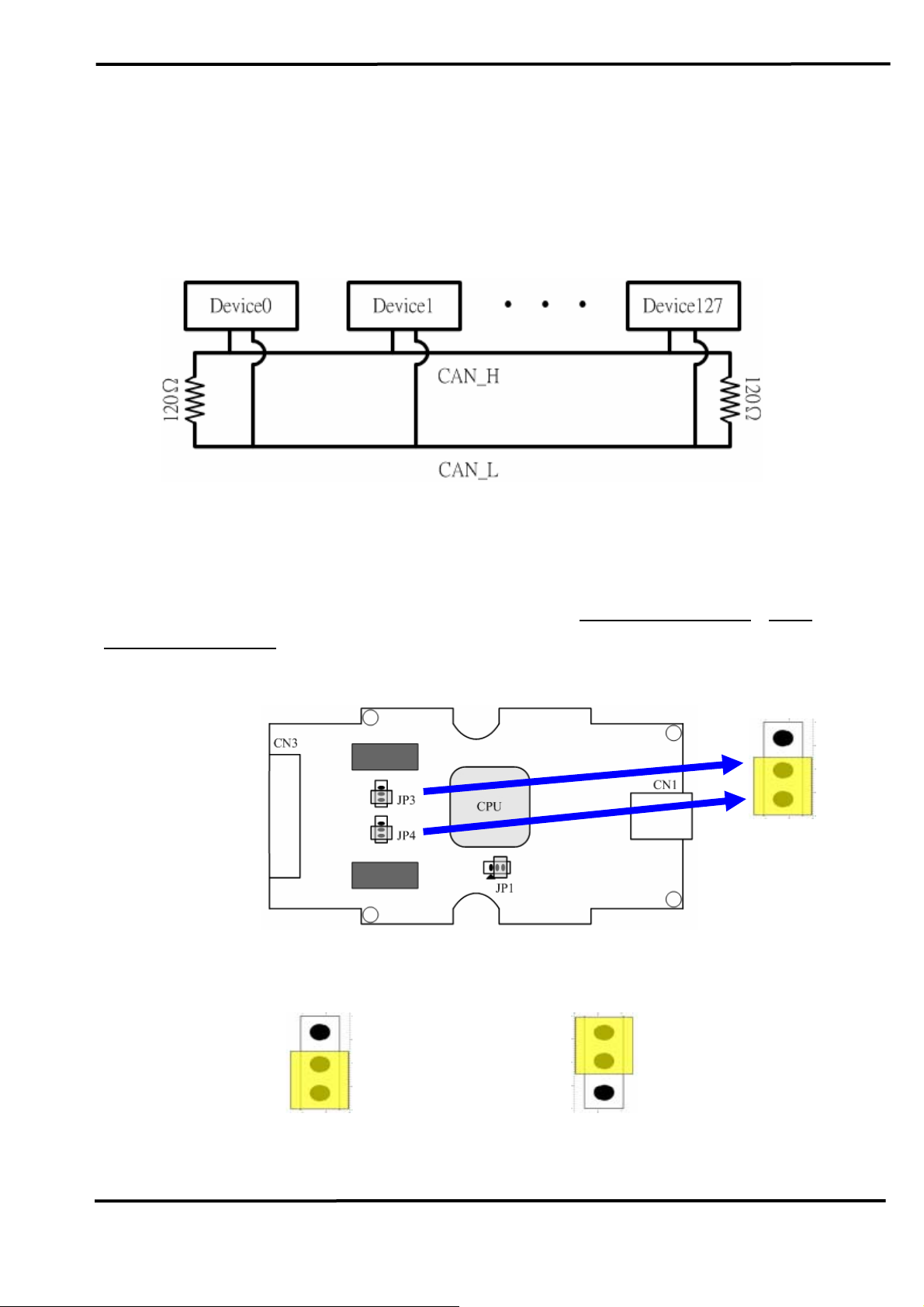

Figure 2-4: CAN Hardware Wire Connection

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 9

2.4 Terminator Resistor Settings

According to the ISO 11898 specifications, the CAN Bus network

must be terminated by two terminal resistors (120

Ω) for proper operation,

as shown in the below figure.

Figure 2-6: Terminal Resistor

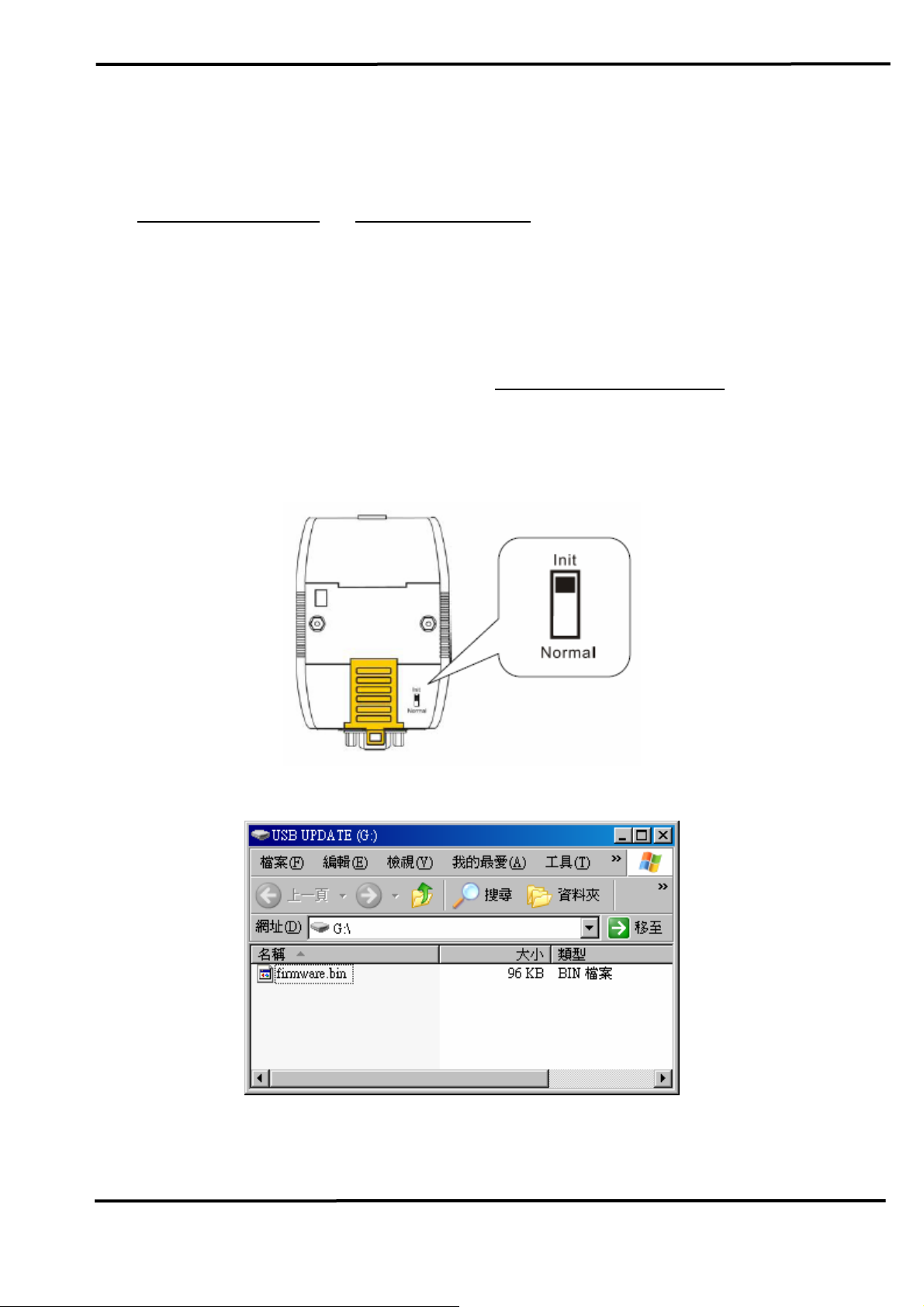

Therefore, the I-7565-H1/H2 module supplies a jumper for users to

active the terminal resistor or not. If users want to use this terminal resistor,

please open the I-7565-H1/H2 cover and use the

JP3 for I-7565-H1 / JP3,

JP4 for I-7565-H2 to activate the 120Ω terminal resistor built in the module,

as the Figure 2-7. Note that the default setting is active.

Figure 2-7: Terminal Resistor Jumper

Enable (default), (Position: 1-2) Disable, (Position: 2-3)

Figure 2-8: JP3/JP4 Jumper Position

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 10

2.5 Init / Normal Dip-switch

On the back of the I-7565-H1/H2 module, there is a dip-switch used

firmware operation or firmware updating of the module. The following

for

steps show how to use this dip-switch.

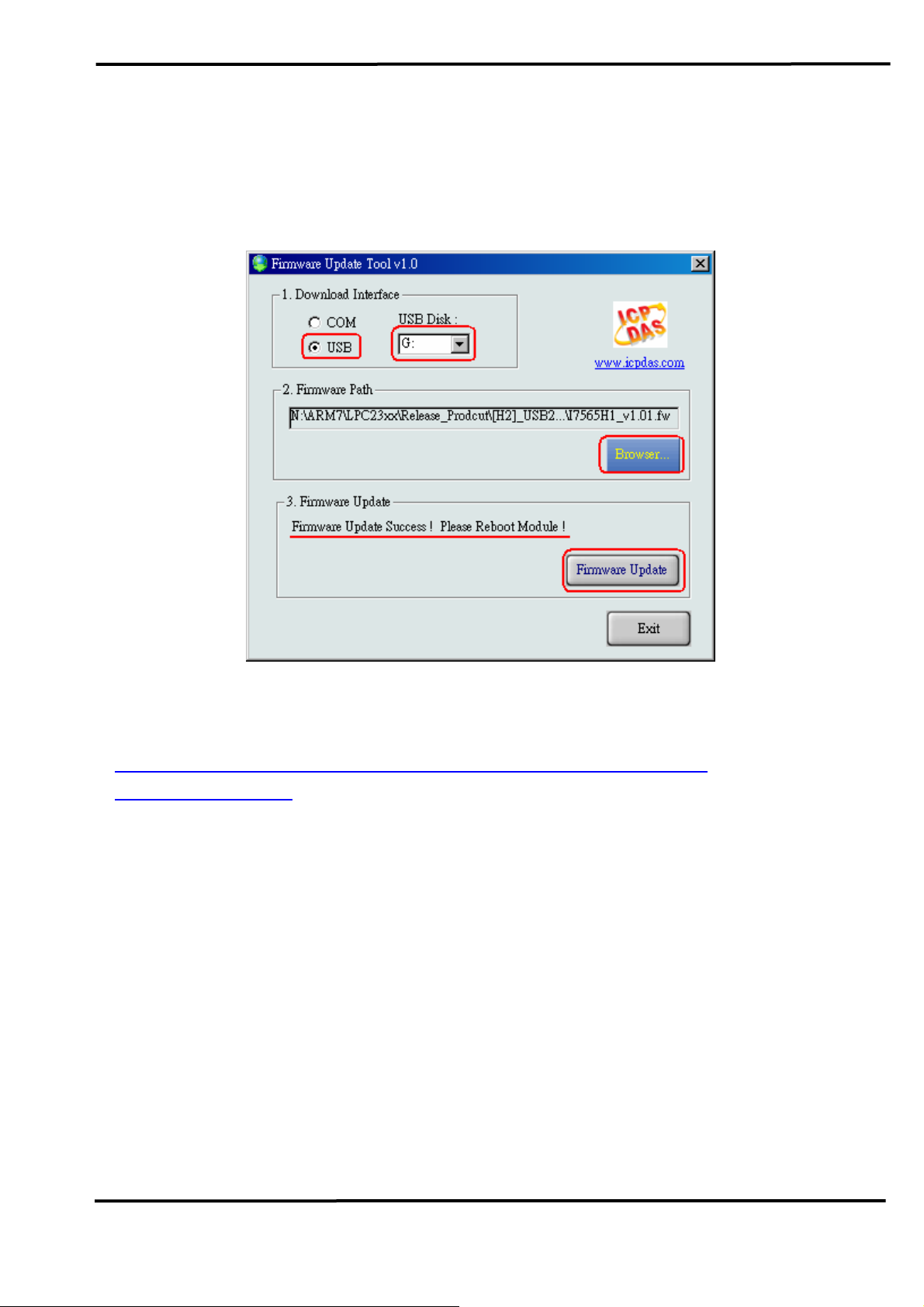

2.5.1 Firmware Update Mode

Please set the dip-switch to the “Init” (Initial) position like Figure 2-9.

Then the I-7565-H1/H2 will work in the “

Firmware Update Mode” after the

power of the module has been turned on again. In this mode, users can

update the firmware of the I-7565-H1/H2 module via USB and the module

will become a “USB Mass Storage Device” and also shows a folder like

Figure 2-10 automatically.

Figure 2-9: Init Position of Dip-Switch

Figure 2-10: USB Mass Storage Device

Users just need to execute “Firmware_Update_Tool.exe” and follow

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 11

the below steps to complete the firmware updating process.

[1] Choose “USB” interface and “USB Disk”.

[2] Click “Browser” button to choose firmware file. (like I7565H1_v1.01.fw)

[3] Click “Firmware Update” button to start firmware updating process.

The result will show in “Firmware Update” field.

Figure 2-11: Normal Position of Dip-Switch

The Firmware_Update_Tool program can be downloaded from

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7565h1h2/software/tool

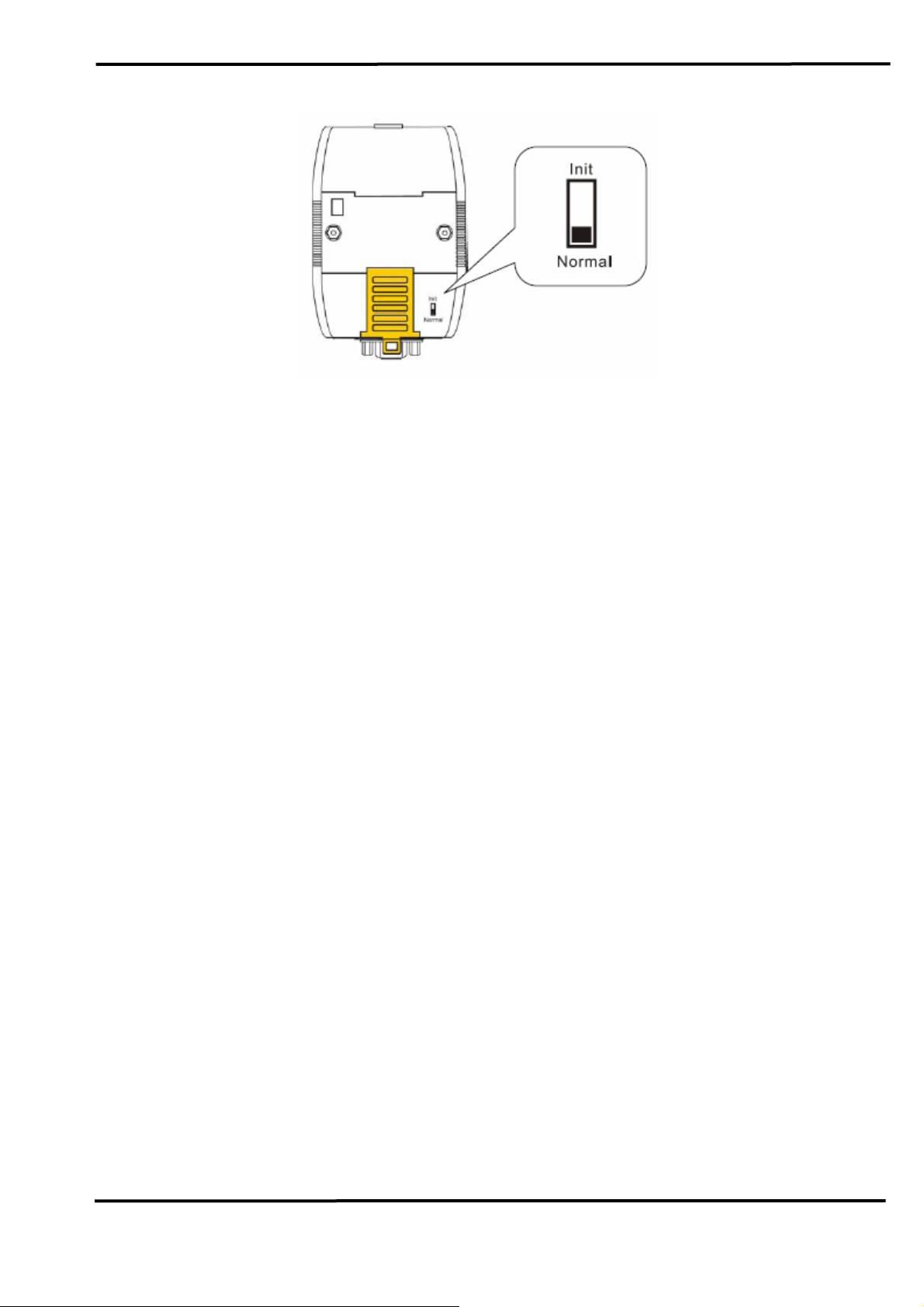

2.5.2 Firmware Operation Mode

In operation mode, users need to set the dip-switch to the “Normal”

position like Figure 2-12 and turn the power off then on again so that the I7565-H1/H2 can run in the operation mode. In this mode, users can send /

receive CAN messages via PC USB port.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 12

Figure 2-12: Normal Position of Dip-Switch

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 13

2.6 LED Indication

There are three LEDs provided to indicate to users what situation the

I-7565-H1/H2 is in. The following is the illustration of these three LEDs

and the position of these three LEDs shows as Figure 2-12.

(1) PWR LED :

It is used to help users to check whether the I-7565-H1/H2 is standby.

If the module is working in “firmware operation” mode, the PWR LED is

always turned on. However, when the module is working in the “firmware

updating” mode, the PWR LED will flash approximately once per second.

(2) RUN LED :

It is used to show whether the I-7565-H1/H2 is transmitting/receiving

CAN messages. The RUN LED will flash whenever a CAN message is

sending or receiving. In I-7565-H2, the RUN LED is shared by CAN1 port

and CAN2 port.

(3) ERR LED :

It is used for demonstrating an error that has occurred. The ERR LED

is normally turned off when the module works in a good condition. When

the Bus-Off error happened, the ERR LED will always turn on until the

Bus-Off condition disappeared. If the CAN/USB buffer built in I-7565H1/H2 overflows or CAN message can’t be sent out successfully, then the

ERR LED will flash continuously. In I-7565-H2, the ERR LED is shared by

CAN1 port and CAN2 port.

Figure 2-13: LED position of I-7565-H1/H2

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 14

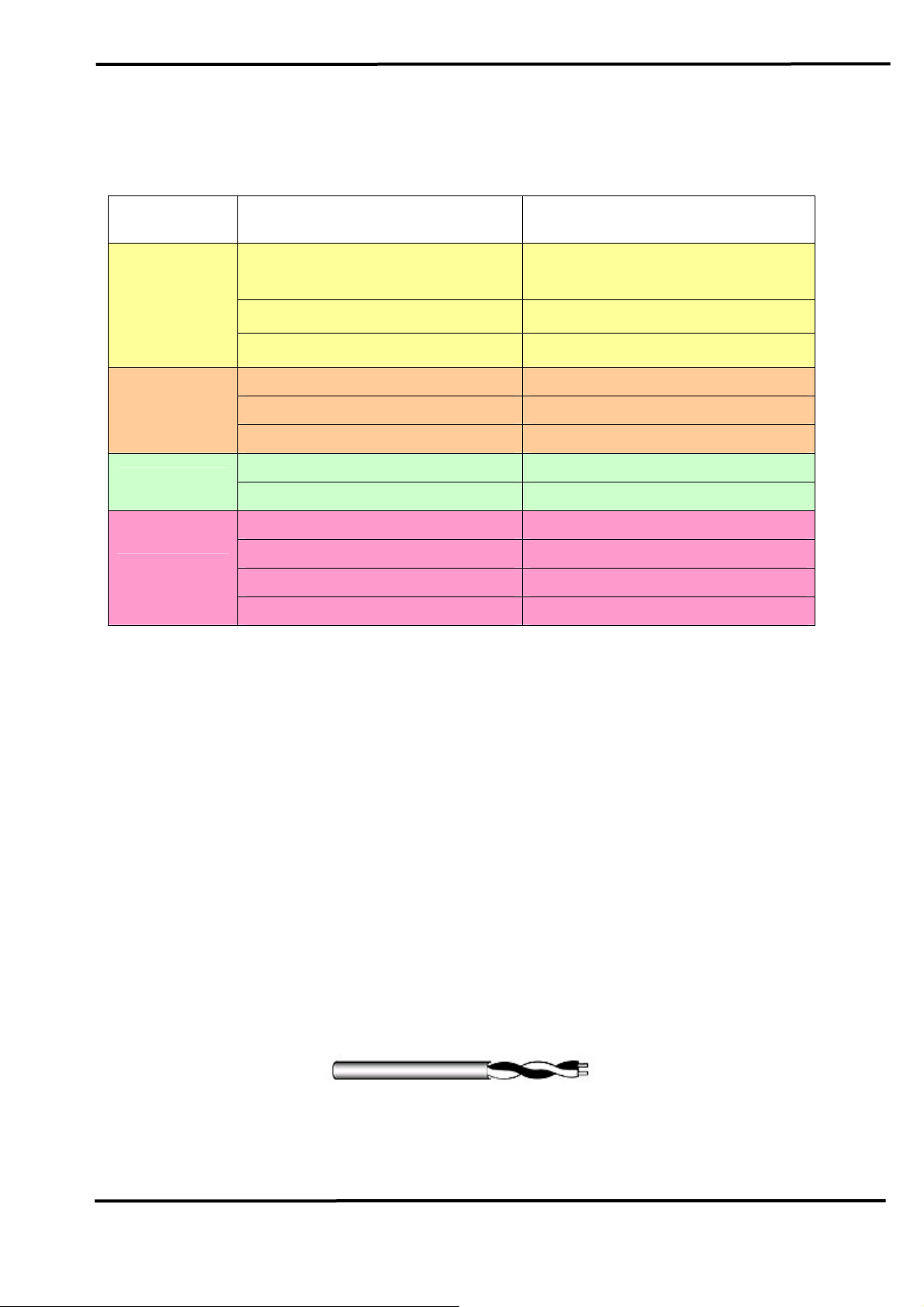

Table 2: LED indication of I-7565-H1/H2

LED Name I-7565-H1/H2 Status LED Status

ALL LED

PWR LED

RUN LED

ERR LED

Hardware Init Fail

All LED always turned on

permanently after reset

Hardware WDT Fail All LED flash per 2 second

Contact to ICP DAS All LED flash take turns

Firmware Updating Mode Flash per second

Firmware Operation Mode Always turned on

Power Off Off

Transmission Flash

Bus Idle Off

Transmission Fail Flash per 100 ms

Buffer Overflow Flash per second

Bus-Off Always turned on

No Error Off

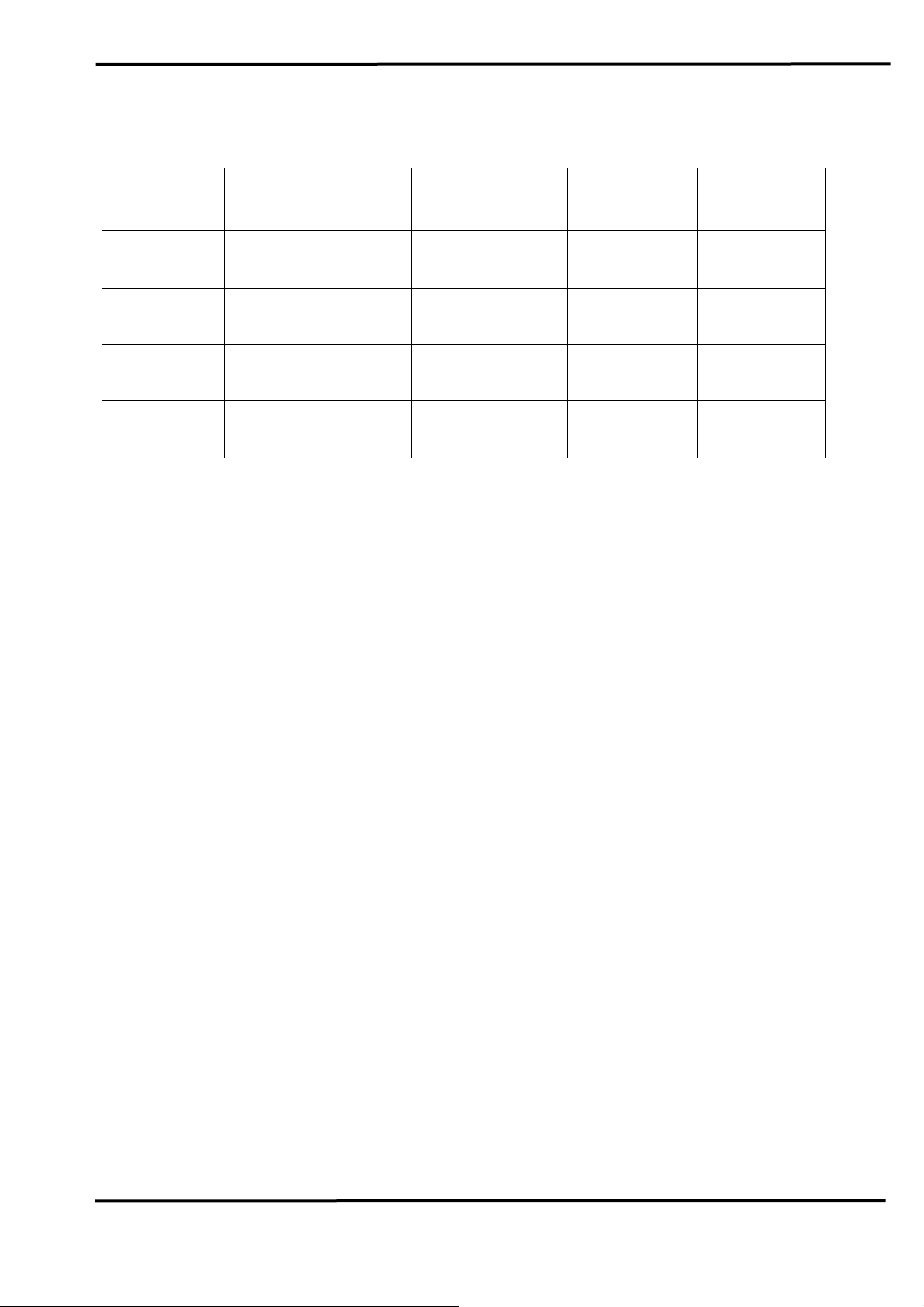

2.7 Cable Selection

The CAN bus is a balanced (differential) 2-wire interface running over

either a Shielded Twisted Pair (STP), Un-shielded Twisted Pair (UTP), or

Ribbon cable. The CAN-L and CAN-H Wire start on one end of the total

CAN network that a terminator of 120 Ohm is connected between CAN-L

and CAN-H. The cable is connected from CAN node to CAN node,

normally without or with short T connections. On the other end of the cable

again a 120

lines. How to decide a cable type, cable length, and terminator depends

on the baud rate in the CAN bus network, please refer to the following

table 3.

Ω(Ohm) terminator resistor is connected between the CAN

Figure 2-14: Un-shielded Twisted Pair (UTP)

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 15

Table 3: Cable selection

Bus speed Cable type

Terminator Bus Length

Resistance/m

Cable

50k bit/s

at 1000m

100k bit/s

at 500m

500k bit/s

0.75~0.8mm2

18AWG

0.5~0.6 mm2

20AWG

0.34~0.6mm2

70 mOhm

< 60 mOhm

150~300

600~1000m

Ohm

150~300

300~600m

Ohm

< 40 mOhm 127 Ohm 40~300m

at 100m

1000k bit/s

22AWG, 20AWG

0.25~0.34mm2

< 40 mOhm 124 Ohm 0~40m

at 40m

23AWG, 22AWG

Note: The AWG means a standard method used to measure wire. The

numbering system works backwards from what people would think, the

thicker (heavier) the wire, the lower the number. For example: a 24AWG

wire is thicker/heavier than a 26AWG wire.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 16

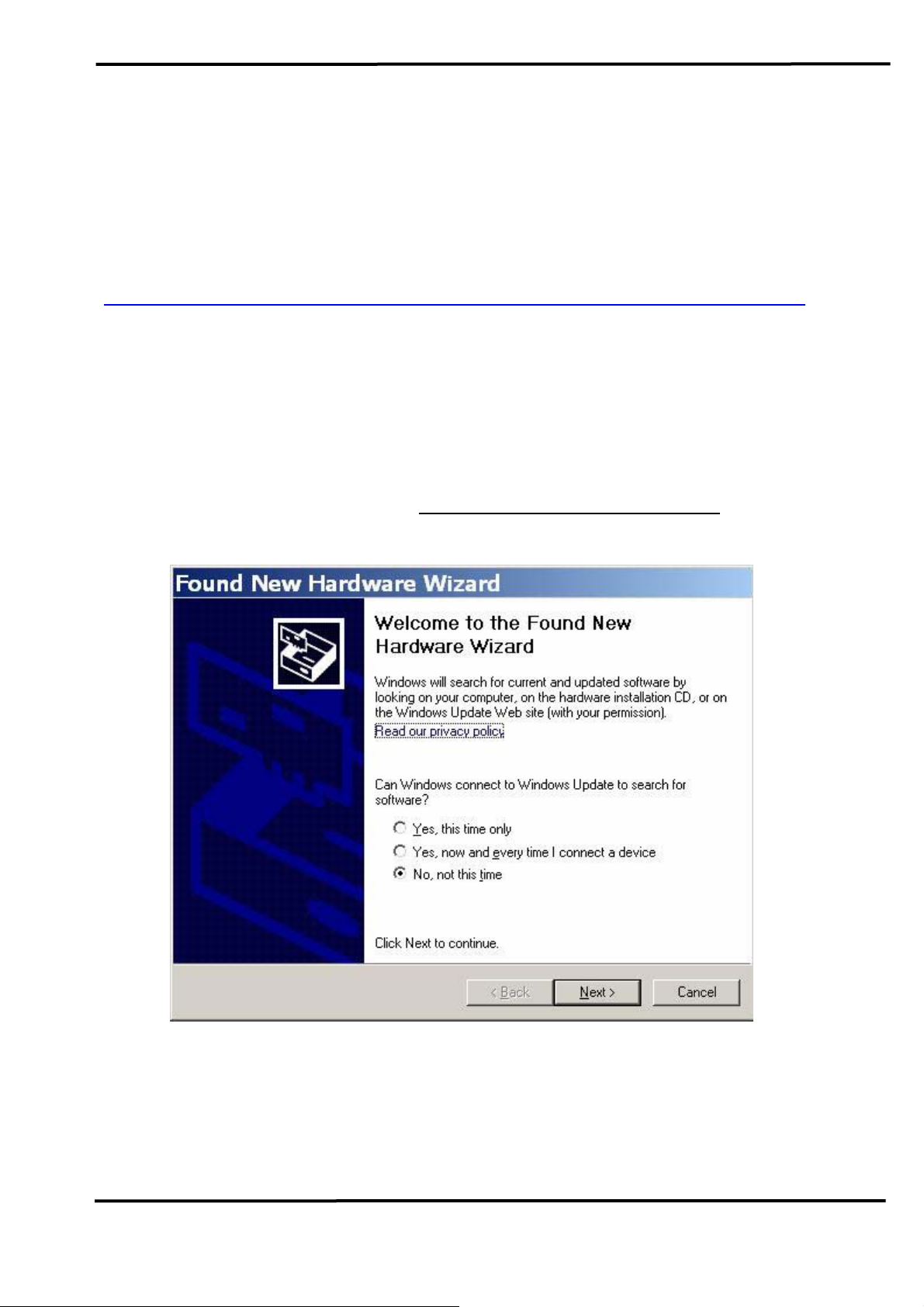

3. Driver Installation

This section will show how to install the I-7565-H1/H2 USB/CAN

converter device driver under Windows 2000/XP and users can

download the I-7565-H1/H2 device driver from ICP DAS web site:

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7565-h1h2/driver.

Please follow the below steps to finish I-7565-H1/H2 driver installation.

3.1 Install I-7565-H1/H2 Driver:

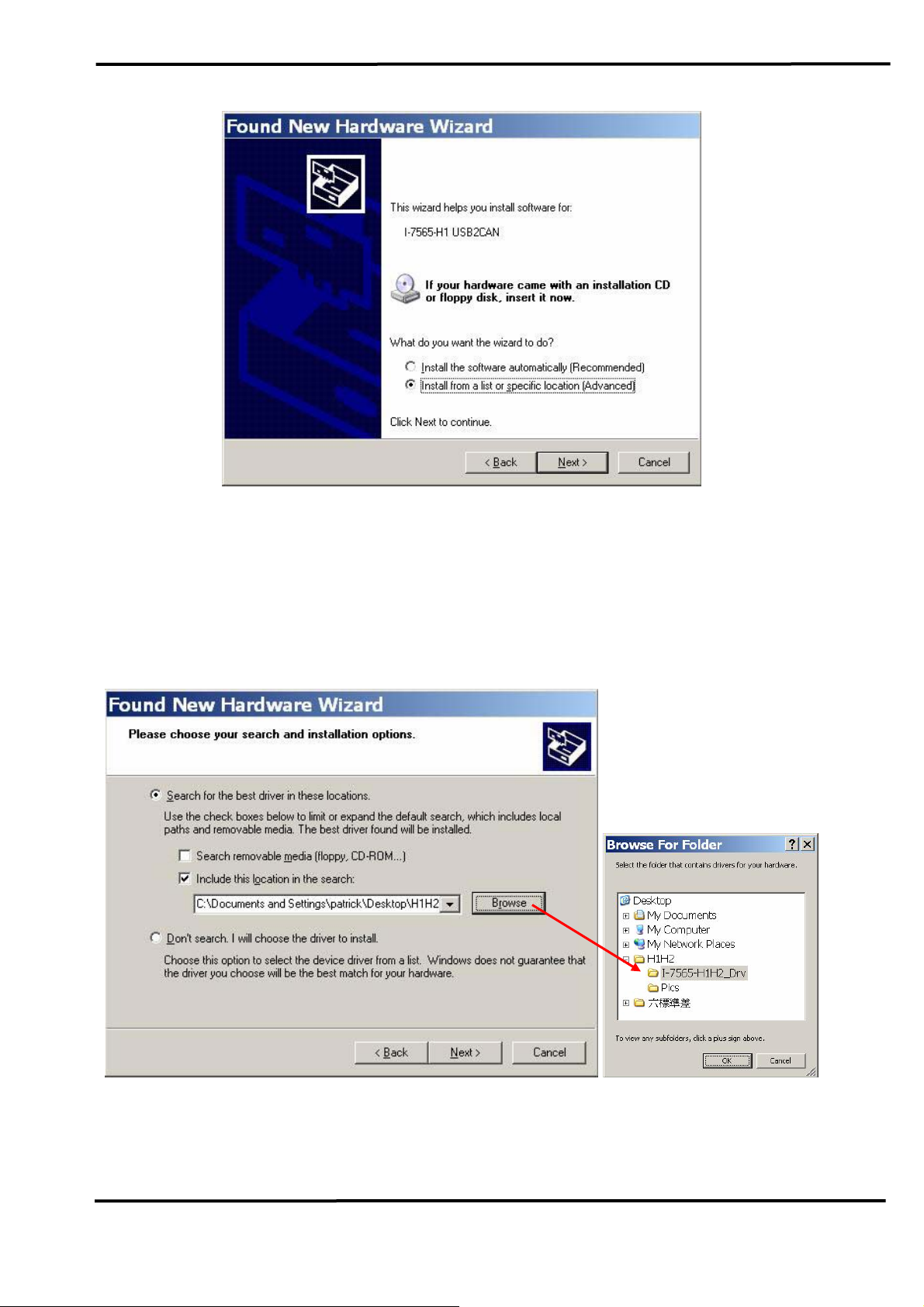

[ Step - 1 ]

Plug in the I-7565-H1 or I-7565-H2 to PC and Windows will detect the

new device and shows the “

prompting you to install the driver for the detected USB Device. Please

select “No, not this time” option and click “Next” button like Figure 3-1.

Found New Hardware Wizard” screen

Figure 3-1: New Hardware Wizard (1)

[ Step - 2 ]

Please select “install from a list or specific location (Advanced)” option

and click “Next” button like Figure 3-2.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 17

Figure 3-2: New Hardware Wizard (2)

[ Step - 3 ]

Please select “Search for the best driver in these locations” option and

check “include this location in the search:” checkbox and click “Browser”

button to assign the I-7565-H1/H2 driver location and then click “Next”

button like Figure 3-3.

Figure 3-3: New Hardware Wizard (3)

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 18

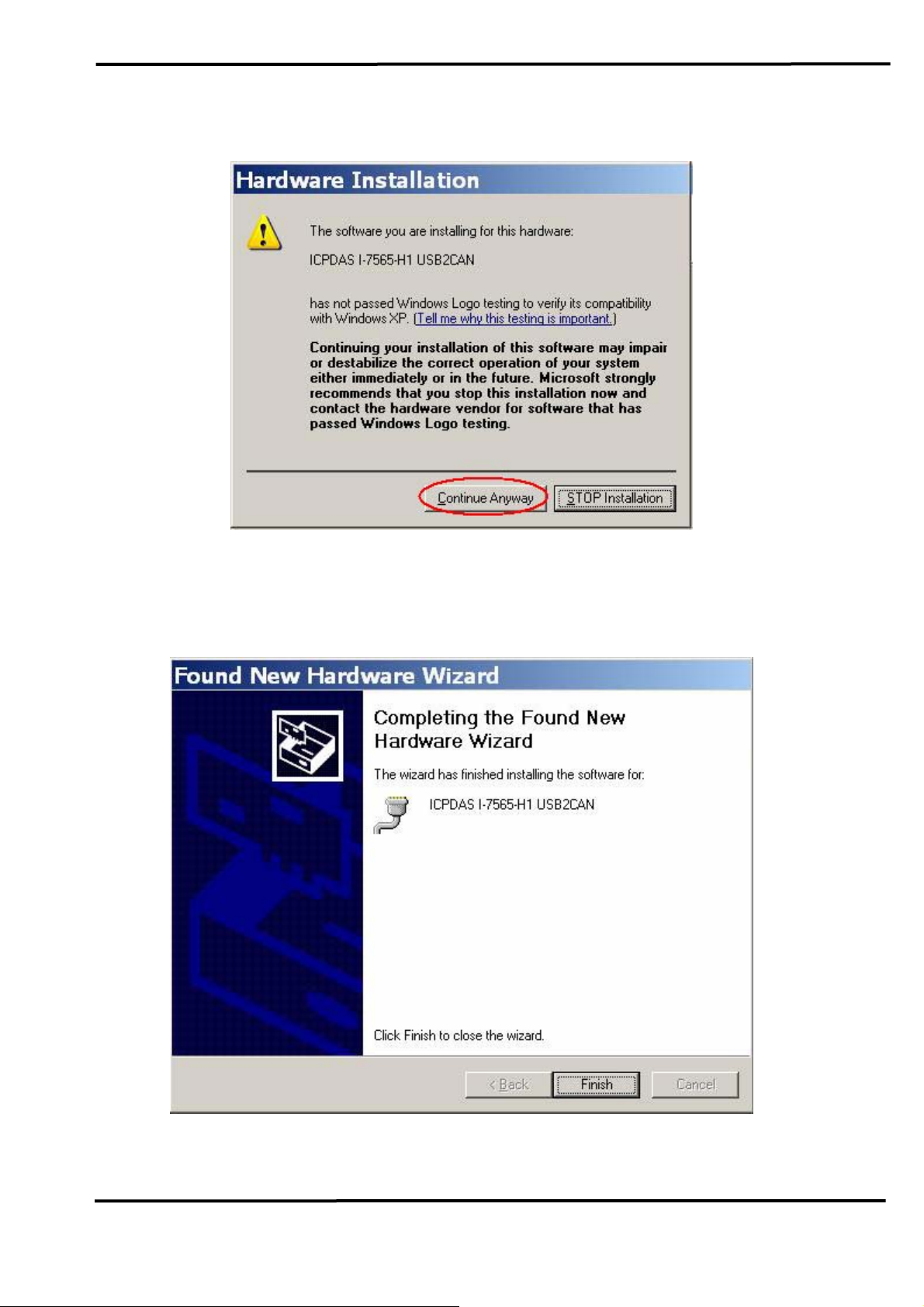

[ Step - 4 ]

Please click “Continue Anyway” button like Figure 3-4 .

Figure 3-4: New Hardware Wizard (4)

[ Step - 5 ]

Please click “Finish” button to complete I-7565-H1/H2 device driver

installation like Figure 3-5.

Figure 3-5: New Hardware Wizard (5)

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 19

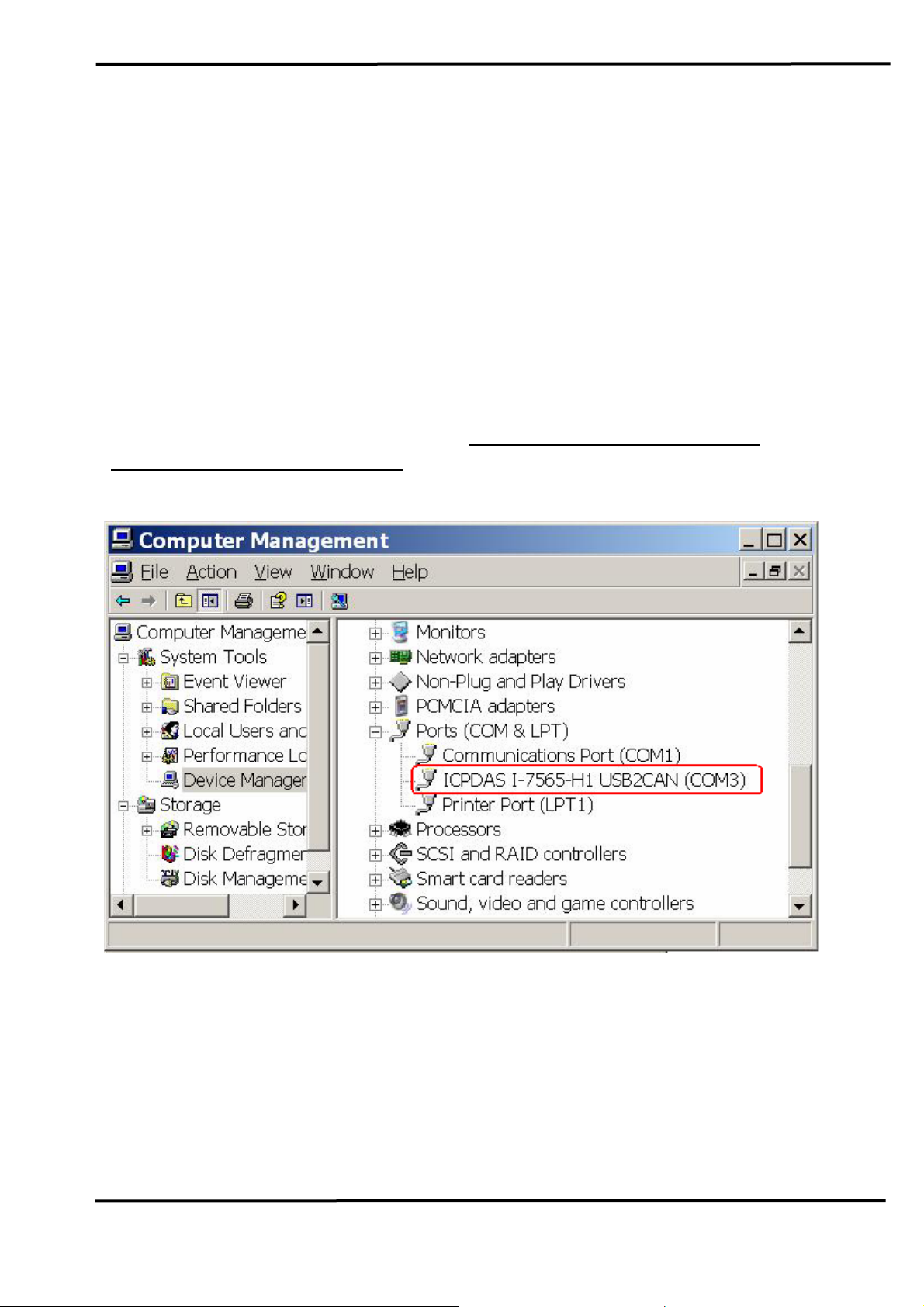

3.2 Verify Driver Installation:

This section will show how to verify whether the driver of I-7565-H1/H2

was properly installed. If the driver is installed successfully, then there will

be a “Virtual COM Port” assigned by Windows. Please follow the below

steps to check it.

Click “Start” Æ “Settings” Æ “Control Panel” and then double click on

the “System” icon. Once the “System Properties” screen displayed, click

on ” Hardware” tab and then click on the “Device Manager” button.

Double-click on Ports (COM & LPT) item. If the device driver was

correctly installed, users can find the “

ICPDAS I-7565-H2 USB2CAN” device listing and the “Virtual COM Port”

“

number that Windows has assigned to the device is COM3 like Figure 3-6.

ICPDAS I-7565-H1 USB2CAN” or

Figure 3-6: Virtual COM Port Number

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 20

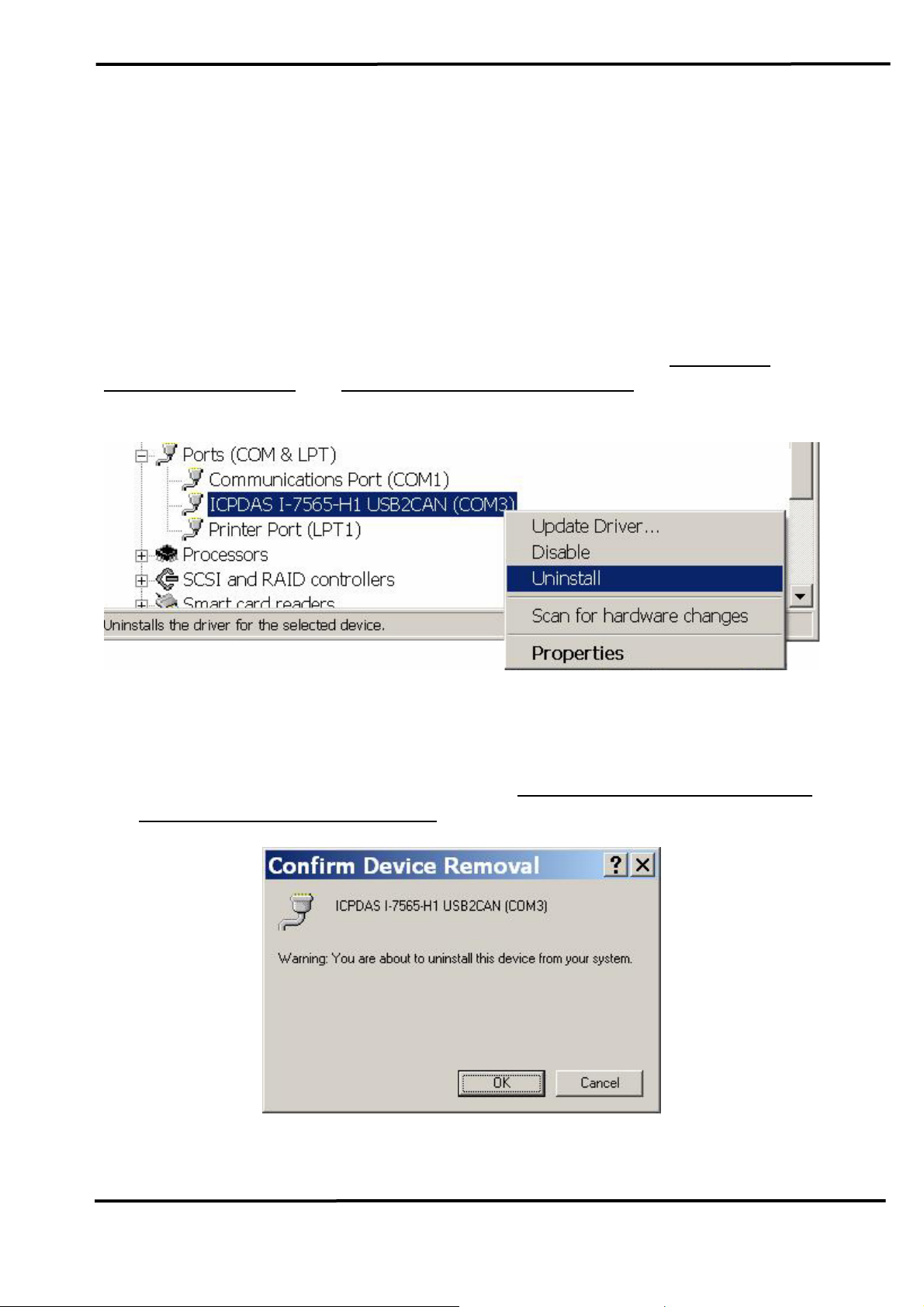

3.3 Uninstall I-7565-H1/H2 Driver

Please follow the below steps to uninstall I-7565-H1/H2 device driver.

[ Step - 1 ]

Click “Start” Æ “Settings” Æ “Control Panel” and then double click on

the “System” icon. Once the “System Properties” screen displayed, click

on ” Hardware” tab and then click on the “Device Manager” button.

Double-click on Ports (COM & LPT) item. Please find the “

7565-H1 USB2CAN” or “ICPDAS I-7565-H2 USB2CAN” device listing and

right click mouse button on it and choose “Uninstall” item like Figure 3-7.

ICPDAS I-

Figure 3-7: Uninstall I-7565-H1/H2 Driver (1)

[ Step - 2 ]

Click “OK” button to complete I-7565-H1/H2 device driver un-

installation like Figure 3-8. After that, the “

ICPDAS I-7565-H2 USB2CAN” device listing will disappear on Ports

or “

ICPDAS I-7565-H1 USB2CAN”

(COM & LPT) item.

Figure 3-8: Uninstall I-7565-H1/H2 Driver (2)

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 21

4. Software Utility

I-7565-H1/H2 Utility is provided by ICP DAS to transmit / receive CAN

messages for CAN bus communication testing easily and quickly. In the

meanwhile, it can also display the time-stamp of each received CAN

message for data analyzing conveniently. I-7565-H1/H2 Utility can be

downloaded from the ICP DAS web site :

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7565h1h2/software/utility. The following is the main functions provided by I-

7565-H1/H2 Utility :

4.1 INI File Function

Whenever users execute the I-7565-H1/H2 Utility, it will look for the

INT file :

If the INI file doesn’t exist, then it will load the default setting. The below is

the format illustration of the INI file like Figure 4-1.

[1] COM : The Virtual COM Port Number.

[2] TYPE : 1: I-7565-H1; 2: I-7565-H2.

[3] C1BR : CAN1 Baud Rate

[4] C2BR : CAN2 Baud Rate

[5] C1EN : CAN1 Port Function. (1: Enable; 0: Disable)

[6] C2EN : CAN2 Port Function. (1: Enable; 0: Disable)

I-7565-H1H2_Utility.ini first to load the initial connection setting.

Figure 4-1: Connection Screen of I-7565-H1/H2 Utility

4.2 Connection Function

When users execute the I-7565-H1/H2 Utility, it will show connection

function screen first for connecting to I-7565-H1/H2 like Figure 4-2. The

following is the illustration for connection parameters.

[1] Com Port : The Virtual COM Port Number.

[2] Mod Name : The Module Name.

[3] CAN Port Enable : Enable CAN Port Function. (Checked: Enable)

[4] CAN Baud Rate : CAN bus Baud Rate Setting.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 22

Figure 4-2: Connection Screen of I-7565-H1/H2 Utility

After finish the connection setting, please click “Connect” button to

connect to I-7565-H1/H2 module. Note that I-7565-H1/H2 doesn’t affect

the CAN bus communication when power on because the CAN port

function will keep disabled until users connect to I-7565-H1/H2

successfully. As soon as users disconnect to I-7565-H1/H2, the CAN port

function on I-7565-H1/H2 will be disabled again. Besides, users can also

click “Connect” item in the menu bar and choose “Connect To I-7565H1/H2” function to connect to I-7565-H1/H2 like Figure 4-3 or “Disconnect”

function to disconnect to I-7565-H1/H2 like Figure 4-4.

Figure 4-3: “Connect To I-7565-H1/H2” function

Figure 4-4: “Disconnect” function

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 23

4.3 Communication Function

If the connection to I-7565-H1/H2 is successful, then the screen for

CAN bus communication function will show up like the Figure 4-5.

Figure 4-5: Communication Screen of I-7565-H1/H2 Utility

The following is the illustration for the communication screen and it

can be divided to two blocks in each CAN port function. One is “SendMsg”

block and the other is “RecvMsg” block. Besides, “Port 1” / “Port 2” tab is

used to switch CAN1 / CAN2 communication screen.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 24

[1] For “

CAN1/2 SendMsg” block :

<1> “SendMsg Configuration” frame :

It is used to edit the CAN message parameters and users can

use “Add” button to add the CAN message to “CAN Message

Send Area”.

<2> “Add” button :

It will add the CAN message from “SendMsg Configuration”

area to the last row in “CAN Message Send Area”.

<3> “Modify” button :

It will modify the CAN message parameter from “SendMsg

Configuration” area to the assigned green row in “CAN

Message Send Area”.

<4> “Delete” button :

It will delete the CAN message of the assigned green row in

“CAN Message Send Area”.

<5> “Send” button :

It will send the CAN message of the assigned green row in

“CAN Message Send Area”. If the value in the “Timer” field is

zero, it will just send once. If not, it will send continuously by

PC timer.

<6> “HWSend” button :

It will send the CAN message of the assigned green row in

“CAN Message Send Area”. If the value in the “Timer” field is

zero, it will just send once. If not, it will send continuously by

module hardware timer and it will be more precise than PC

timer. If users want to send the CAN message with fixed

number, then before clicking “HWSend” button, please check

the “HWSendCnt” checkbox first like Figure 4-6.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 25

Figure 4-6: Send CAN Message by Hardware Timer

<7> “Clear” button :

It will clear the “SendCnt” value to be zero in “CAN Message

Send Area”.

<8> “SendCnt” field :

Whenever the CAN message is sent out once, the “SendCnt”

value will be added by 1 except “HWSend” function.

[2] For “

CAN1/2 RecvMsg” block :

<1> “Display Type” option :

It is used to show the received CAN message data with

“Decimal “or “Hex” format in “CAN Message Receive Area”.

<2> “Start Record / Stop Record” button :

When clicking “Start Record” button, the received CAN

messages will be recorded in a file as ASCII text replacing

showing in “CAN Message Send Area”. When clicking “Stop

Record” button, it will stop recording the received CAN

messages on a file.

The filename format will be “CAN1_YYMMDD_HHMMSS.txt”

or “CAN2_YYMMDD_HHMMSS.txt”.

<3> “Rx Pause / Rx Start” button :

When clicking “Rx Pause” button, it will stop receiving the

CAN messages. When clicking “Rx Start” button, it will start to

receive the CAN messages.

<4> “Clear” button :

It will clear all the CAN message data in “CAN Message

Receive Area“ and the “RecvCnt” value to be zero.

<5> “Scrolling” checkbox :

If the “Scrolling” checkbox is checked, the received CAN

message data in “CAN Message Receive Area“ will be

updated and the “RecvCnt” value to be the newest

automatically. If not, it will not update the received CAN

message data in “CAN Message Receive Area“.

4.4 Config Function

In I-7565-H1/H2 Utility, it provides two kinds of configuration functions.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 26

One is “Module Config” and the other is “Advanced Config”. Users can

click “Configuration” item in the menu bar and choose one of them to show

the corresponding function screen like Figure 4-7.

Figure 4-7: Configuration Function of I-7565-H1/H2 Utility

4.4.1 Module Config Function

The following is the illustration for “Module Config” screen. It can be

divided to two blocks. One is “

Config / Info Option” block like Figure 4-8.

“

CAN Filter Setting” block and the other is

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 27

Figure 4-8: Module Config Screen of I-7565-H1/H2 Utility

[1] For “

CAN Filter Setting” block :

If users don’t set the CAN Filter function, then all CAN messages

will be able to be received in default. In “CAN Filter Setting” block,

users can set which CAN ID able to be received by I-7565-H1/H2

module.

<1> “Single ID” frame :

By clicking “Add” button to add the assigned single CAN ID to

“CAN Filter-ID Table” to set these assigned single CAN ID

able to be received.

<2> “Group ID” frame :

By clicking “Add” button to add the assigned group CAN ID to

“CAN Filter-ID Table” to set these assigned group CAN ID able

to be received.

<3> “CAN Controller” combobox :

It is used to choose which CAN port that users want to

configure currently.

<4> “Get CAN Accepted IDs” button :

It is used to get CAN Filter-ID data of the assigned CAN port

and showed in the “CAN Filter-ID Table”. The command result

also returns in the “Response” frame of “Config / Info Option”

block.

<5> “Set CAN Accepted IDs” button :

It is used to set CAN Filter-ID data of the assigned CAN port

according to the “CAN Filter-ID Table” content. The command

result also returns in the “Response” frame of “Config / Info

Option” block.

<6> “Save File” button :

It is used to save the “CAN Filter-ID Table” content to file.

<7> “Load File” button :

It is used to load the CAN Filter-ID data from file to “CAN

Filter-ID Table”.

<8> “Delete Row” button :

It is used to delete the CAN Filter-ID data of the assigned

green row in “CAN Filter-ID Table”.

<9> “Clear Table” button :

It is used to clear all the contents in “CAN Filter-ID Table”.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 28

[2] For “

Config / Info Option” block :

There are several option functions provided for I-7565-H1/H2. The

following will illustrate all these functions.

<1> “Get_ModInfo” option :

It is used to get the related module info including “Module

Name” and “Firmware Version” like Figure 4-9.

Figure 4-9: Module Info

<2> “Get_CANStatus” option :

It is used to get the assigned CAN port status like Figure 4-10.

Figure 4-10: CAN Status

In “Register” item, clicking the “Detail” button it will show the

more detailed CAN port register status like Figure 4-11. If the

corresponding bit is 1, it means that the corresponding state

happened.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 29

Figure 4-11: CAN Register Detailed Information

In “Mod State” item, clicking the “Detail” button it will show the

more detailed module status like Figure 4-12. If the

corresponding bit is 1, it means that the corresponding state

happened.

Figure 4-12: module state Detailed Information

<3> “Clear Buffer Overflow LED” option :

When CAN/USB buffer overflows, then the ERR LED will

flash one second permanently. The button is used to clear

the ERR LED flash state.

<4> “Reset Module” option :

It is used to reset I-7565-H1/H2 remotely.

4.4.2 Advanced Config Function

The following is the illustration for “Advanced Config” screen like

Figure 4-13 and Figure 4-14.

Figure 4-13: Configuration Function of I-7565-H1/H2 Utility

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 30

Figure 4-14: Advanced Config of I-7565-H1/H2

<1> “Get CAN2USB Current Flow” option :

It is used to get the current CAN message flow (unit: fps) in

the CAN port of I-7565-H1/H2.

<2> “Get CAN2USB Hardware Speed” option :

It is used to get the current setting value for CAN to USB

hardware transmission speed of I-7565-H1/H2.

<3> “Set CAN2USB Hardware Speed” option :

It is used to set CAN to USB hardware transmission speed of

I-7565-H1/H2 module. Users can set the speed from 1000 fps

~ 3000 fps. The setting rule is that users can use “

CAN2USB Current Flow

” function first to know the current

Get

CAN message flow and then choose a setting value that is

larger a little than that. Apply the rule and it will reduce the

CAN message loss condition especially when the

performance on users’ PC is not good.

4.5 Data Log Function

By clicking “File” item in the menu bar to execute the related data log

function. The following is the illustration like Figure 4-15.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 31

Figure 4-15: Advanced Config of I-7565-H1/H2

<1> “Load Configuration” function :

It is used to load the previous “CAN Send Message Configuration”

to “CAN Message Send Area” from the assigned “TXT” file like Figure

4-16.

Figure 4-16: Load Configuration

<2> “Save Configuration” function :

It is used to save the current “CAN Send Message Configuration”

in the “CAN Message Send Area” to the assigned “TXT” file like Figure

4-17.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 32

Figure 4-17: Save Configuration

<3> “Save Reception List” function :

It is used to save the current all CAN received messages in “CAN

Message Receive Area” to the assigned “TXT” file as ASCII text like

Figure 4-18.

Figure 4-18: Save Reception List

4.6 Status Bar Function

It is used to indicate the current module connection and each CAN

port status. The following is detailed illustration for status bar of I-7565H1/H2 Utility.

If the connection to I-7565-H1/H2 is not built, the status bar

information is showed as Figure 4-19.

Figure 4-19: Status Bar of I-7565-H1/H2 Utility for disconnection

When the connection to I-7565-H1/H2 is successful, the status bar

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 33

information is showed as Figure 4-20 and it can be divided for four blocks.

(1) Module Name => Indicate the connected module name and the

virtual com port which is in use.

(2) Port Status => Indicate the CAN port enabled or not.

(3) Baud Rate => Indicate the CAN port baud rate.

(4) Company => ICP DAS Co., LTD

Figure 4-20: Status Bar of I-7565-H1/H2 Utility for disconnection

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 34

5. API Library -- VCI_CAN.dll

Users can develop own CAN bus program by I-7565-H1/H2 API

library, VCI_CAN.dll, quickly and easily. The VCI_CAN library and demos

can be downloaded from the ICP DAS web site :

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7565h1h2/software/library.

5.1 API Library Overview

All the functions provided by VCI_CAN library can be separated into

five groups shown in Figure 5-1.

Figure 5-1: Five Function Groups of VCI_CAN Library

[ Init Function ]

These functions are used to enable / disable CAN port function of

I-7565-H1/H2.

[ Module Config Function ]

These functions are used to set / get the parameters or information of

I-7565-H1/H2.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 35

[ Communication Function ]

These functions are used to send / receive CAN message through

I-7565-H1/H2.

[ Software Buffer Function ]

When “VCI_OpenCAN” function is successful, the received CAN

messages will be saved in software buffer provided by VCI_CAN library

first and users need to use “VCI_RecvCANMsg” function to get them.

The software buffer size is 65536 for each CAN port. These related

functions are used to operate the software buffer of VCI_CAN library.

[ Other Function ]

These functions are used to get the VCI_CAN library information or

helpful for users’ program.

5.2 API Library Function Table

All the functions provided in the VCI_CAN.dll are listed in the

following table.

Table 5-1: “Init” Function Table

No. Function Name Description

VCI_OpenCAN Enable CAN port function of I-7565-H1/H2

1

VCI_CloseCAN Disable CAN port function of I-7565-H1/H2

2

Table 5-2: “Module Config” Function Table

No. Function Name Description

VCI_Set_CANFID Set CAN Filter-ID in the assigned CAN port

1

VCI_Get_CANFID Get CAN Filter-ID in the assigned CAN port

2

VCI_Get_CANStatus Get the assigned CAN port status

3

VCI_Clr_BufOverflowLED

4

VCI_Get_MODInfo Get the module information

5

VCI_Rst_MOD Reset module

6

Clear buffer overflow ERR LED state in the

assigned CAN port

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 36

Table 5-3: “Communication” Function Table

No. Function Name Description

VCI_SendCANMsg

1

VCI_RecvCANMsg

2

VCI_EnableHWCyclicTxMsg

3

VCI_DisableHWCyclicTxMsg

4

Send CAN message in the assigned CAN

port

Receive CAN message in the assigned CAN

port

Send CAN message in the assigned CAN

port by using module hardware timer

Stop sending CAN message by module

hardware timer

Table 5-4: “Software Buffer” Function Table

No. Function Name Description

Get the count of the received CAN messages

VCI_Get_RxMsgCnt

1

VCI_Get_RxMsgBufIsFull

2

saved in software buffer that are not received

by users’ program in the assigned CAN port

Get the software buffer state whether it is full

or not in the assigned CAN port

VCI_Clr_RxMsgBuf

3

Clear the software buffer in the assigned CAN

port

Table 5-5: “Other” Function Table

No. Function Name Description

VCI_Get_DllVer Get the version of VCI_CAN library.

1

VCI_DoEvents Release CPU resource temporarily

2

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 37

5.3 Flow Chart for Users’ Program Development by Using API

The following is the basic control flow chart of users’ CAN bus

program development by using API Library – VCI_CAN.dll shown in

Figure 5-2.

Figure 5-2: Flow Chart of API Library – VCI_CAN.dll

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 38

5.4 Init Function

These functions are used to enable / disable CAN port function of I7565-H1/H2.

5.4.1 VCI_OpenCAN

This function is used to enable the assigned CAN port function of I7565-H1/H2. After the CAN port function is enabled, users can use

“Communication” functions to send / receive CAN messages.

Syntax :

int VCI_OpenCAN (

PVCI_CAN_PARAM pCANPARAM

);

Parameter :

pCANPARAM:

[in] A structure pointer of _VCI_CAN_PARAM is used to set the CAN

port communication parameters shown as below.

typedef struct _VCI_CAN_PARAM{

BYTE DevPort;

BYTE DevType;

DWORD CAN1_Baud;

DWORD CAN2_Baud;

} _VCI_CAN_PARAM, *PVCI_CAN_PARAM;

DevPort : The virtual com port number

DevType : The module type (

CAN1_Baud : CAN1 port baud rate

(0 : Disable CAN1 port

Others: Enable CAN1 port)

CAN2_Baud : CAN2 port baud rate

(0 : Disable CAN2 port

Others: Enable CAN2 port)

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

_VCI_CAN_PARAM pCANPARAM;

pCANPARAM.DevPort = 1; // Virtual com port = 1

1: I-7565-H1; 2: I-7565-H2)

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 39

pCANPARAM.DevType = 1; // I-7565-H1

pCANPARAM.CAN1_Baud = 250000; // 250 Kbps

pCANPARAM.CAN2_Baud = 1000000; // 1000K bps

Ret = VCI_OpenCAN(&pCANPARAM); // Enable CAN port

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 40

5.4.2 VCI_CloseCAN

This function is used to disable all CAN port function of

I-7565-H1/H2. After the CAN port function is disabled, it will not interfere

the communication of CAN bus network even if I-7565-H1/H2 is power on.

Syntax :

int VCI_CloseCAN (

BYTE DevPort

);

Parameter :

DevPort:

[in] The virtual com port number

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE ComPort;

ComPort = 1;

Ret = VCI_CloseCAN(ComPort); // Disable CAN port

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 41

5.5 Module Config Function

These functions are used to set / get the parameters or information of

I-7565-H1/H2.

5.5.1 VCI_Set_CANFID

This function is used to set CAN Filter-ID in the assigned CAN port.

Syntax :

int VCI_Set_CANFID (

BYTE CAN_No,

PVCI_CAN_FID pCANFID

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

pCANFID:

[in] A structure pointer of _VCI_CAN_FilterID is used to set the CAN

Filter-ID data shown as below.

typedef struct _VCI_CAN_FilterID{

WORD SSFF_Num;

WORD GSFF_Num;

WORD SEFF_Num;

WORD GEFF_Num;

WORD SSFF_FID[512];

DWORD GSFF_FID[512];

DWORD SEFF_FID[512];

DWORD GEFF_FID[512];

} _VCI_CAN_FilterID, *PVCI_CAN_FID;

SSFF_Num : Single 11-bit CAN Filter-ID number

GSFF_Num : Group 11-bit CAN Filter-ID number

SEFF_Num : Single 29-bit CAN Filter-ID number

GEFF_Num : Group 29-bit CAN Filter-ID number

SSFF_FID[512] : Single 11-bit CAN Filter-ID data array

GSFF_FID[512] : Group 11-bit CAN Filter-ID data array

SEFF_FID[512] : Single 29-bit CAN Filter-ID data array

GEFF_FID[512] : Group 29-bit CAN Filter-ID data array

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 42

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

_VCI_CAN_FilterID pCANFID1;

//Single 11-bit Fitler-ID

WORD SSFID[3]={0x0003, 0x0002, 0x0001};

//Group 11-bit Fitler-ID

DWORD GSFID[2]={0x00300040, 0x00100020};

//Single 29-bit Fitler-ID

DWORD SEFID[3]={0x00000013, 0x00000012, 0x00000011};

//Group 29-bit Fitler-ID

DWORD GEFID[4]={0x00000300, 0x00000400, 0x00000100, x00000200};

CAN_No=1;

pCANFID1.SSFF_Num = sizeof(SSFID)/sizeof(WORD);

pCANFID1.GSFF_Num = sizeof(GSFID)/sizeof(DWORD);

pCANFID1.SEFF_Num = sizeof(SEFID)/sizeof(DWORD);

pCANFID1.GEFF_Num = sizeof(GEFID)/sizeof(DWORD);

memcpy(pCANFID1.SSFF_FID, SSFID, pCANFID1.SSFF_Num*2);

memcpy(pCANFID1.GSFF_FID, GSFID, pCANFID1.GSFF_Num*4);

memcpy(pCANFID1.SEFF_FID, SEFID, pCANFID1.SEFF_Num*4);

memcpy(pCANFID1.GEFF_FID, GEFID, pCANFID1.GEFF_Num*4);

Ret = VCI_Set_CANFID(CAN_No, &pCANFID1); // Set CAN Filter-ID

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 43

5.5.2 VCI_Get_CANFID

This function is used to get CAN Filter-ID in the assigned CAN port.

Syntax :

int VCI_Get_CANFID (

BYTE CAN_No,

PVCI_CAN_FID pCANFID

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

pCANFID:

[out] A structure pointer of _VCI_CAN_FilterID is used to receive the

CAN Filter-ID data shown as below.

typedef struct _VCI_CAN_FilterID{

WORD SSFF_Num;

WORD GSFF_Num;

WORD SEFF_Num;

WORD GEFF_Num;

WORD SSFF_FID[512];

DWORD GSFF_FID[512];

DWORD SEFF_FID[512];

DWORD GEFF_FID[512];

} _VCI_CAN_FilterID, *PVCI_CAN_FID;

SSFF_Num : Single 11-bit CAN Filter-ID number

GSFF_Num : Group 11-bit CAN Filter-ID number

SEFF_Num : Single 29-bit CAN Filter-ID number

GEFF_Num : Group 29-bit CAN Filter-ID number

SSFF_FID[512] : Single 11-bit CAN Filter-ID data array

GSFF_FID[512] : Group 11-bit CAN Filter-ID data array

SEFF_FID[512] : Single 29-bit CAN Filter-ID data array

GEFF_FID[512] : Group 29-bit CAN Filter-ID data array

Return Values :

Return 0 means success, others means failure.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 44

Examples :

Int Ret;

BYTE CAN_No;

_VCI_CAN_FilterID pCANFID;

WORD SID11_EndNum=0, GID11_EndNum=0;

WORD SID29_EndNum=0, GID29_EndNum=0;

CAN_No=1;

Ret = VCI_Get_CANFID(CAN_No, &pCANFID); // Get CAN Filter-ID

SID11_EndNum = CANFID.SSFF_Num;

GID11_EndNum = CANFID.GSFF_Num;

SID29_EndNum = CANFID.SEFF_Num;

GID29_EndNum = CANFID.GEFF_Num;

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 45

5.5.3 VCI_Get_CANStatus

This function is used to get the assigned CAN port status.

Syntax :

int VCI_Get_CANStatus (

BYTE CAN_No,

PVCI_CAN_STATUS pCANStatus

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

pCANStatus:

[out] A structure pointer of _VCI_CAN_STATUS is used to receive the

CAN port status shown as below.

typedef struct _VCI_CAN_STATUS{

DWORD CurCANBaud;

BYTE CANReg;

BYTE CANTxErrCnt;

BYTE CANRxErrCnt;

BYTE MODState;

DWORD Reserved;

} _VCI_CAN_STATUS, *PVCI_CAN_STATUS;

CurCANBaud : Return the assigned CAN port baud rate

CANReg : Return the assigned CAN port register value

CANTxErrCnt : Return the assigned CAN port Tx error count

CANRxErrCnt : Return the assigned CAN port Rx error count

MODState : Return the module state

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No, Module_State;

_VCI_CAN_STATUS CANSTA;

CAN_No=1;

Ret = VCI_Get_CANStatus(CAN_No, &CANSTA); // Get CAN port status

Module_State = CANSTA.MODState;

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 46

5.5.4 VCI_Clr_BufOverflowLED

This function is used to clear buffer overflow ERR LED state (flash per

second) in the assigned CAN port.

Syntax :

int VCI_Clr_BufOverflowLED (

BYTE CAN_No,

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

CAN_No=1;

Ret = VCI_Clr_BufOverflowLED(CAN_No); // Clear Buffer Overflow LED

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 47

5.5.5 VCI_Get_MODInfo

This function is used to get module information.

Syntax :

int VCI_Get_MODInfo (

PVCI_MOD_INFO pMODInfo

);

Parameter :

pMODInfo:

[out] A structure pointer of _VCI_MODULE_INFO is used to receive

the module information shown as below.

typedef struct _VCI_MODULE_INFO{

char Mod_ID[12];

char FW_Ver[12];

} _VCI_MODULE_INFO, *PVCI_MOD_INFO;

Mod_ID[12] : Return the module name string

FW_Ver[12] : Return the module firmware version string

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

char Module_ID[12], Firmware_Ver[12];

_VCI_MODULE_INFO CAN_ModInfo;

Ret = VCI_Get_MODInfo(&CAN_ModInfo); // Get module information

sprintf(Module_ID, “%s”, CAN_ModInfo.Mod_ID);

sprintf(Firmware_Ver, “%s”, CAN_ModInfo.FW_Ver);

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 48

5.5.6 VCI_Rst_MOD

This function is used to reset module.

Syntax :

int VCI_Rst_MOD (

void

);

Parameter :

None

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

Ret = VCI_Rst_MOD(); // Reset Module

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 49

5.6 Communication Function

These functions are used to send / receive CAN messages.

5.6.1 VCI_SendCANMsg

This function is used to send CAN messages in the assigned CAN

port.

Syntax :

int VCI_SendCANMsg (

BYTE CAN_No,

PVCI_CAN_MSG pCANMsg

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

pCANMsg:

[in] A structure pointer of _VCI_CAN_MSG is used to set the CAN

message parameters shown as below.

typedef struct _VCI_CAN_MSG{

BYTE Mode;

BYTE RTR;

BYTE DLC;

BYTE Reserved;

DWORD ID;

DWORD TimeL;

DWORD TimeH;

BYTE Data[8];

} _VCI_CAN_MSG, *PVCI_CAN_MSG;

Mode : CAN message Mode (0: 11-bit; 1: 29-bit)

RTR : CAN message RTR (0: No RTR; 1: RTR)

DLC : CAN message Data Length (0~8)

ID : CAN message ID

TimeL : CAN message Time-Stamp (Lo-DWORD)

TimeH : CAN message Time-Stamp (Hi-DWORD)

Data[8] : CAN message Data Array

Return Values :

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 50

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

_VCI_CAN_MSG CAN_SendMsg;

CAN_No=1;

CAN_SendMsg.Mode = 1;

CAN_SendMsg.RTR = 0;

CAN_SendMsg.ID = 0x1;

CAN_SendMsg.DLC = 8;

CAN_SendMsg.Data[0]= 0x12;

CAN_SendMsg.Data[1]= 0x34;

CAN_SendMsg.Data[2]= 0x56;

CAN_SendMsg.Data[3]= 0x78;

CAN_SendMsg.Data[4]= 0x90;

CAN_SendMsg.Data[5]= 0xAB;

CAN_SendMsg.Data[6]= 0xCD;

CAN_SendMsg.Data[7]= 0xEF;

Ret = VCI_SendCANMsg(CAN_No, &CAN_SendMsg); // Send CAN Msg

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 51

5.6.2 VCI_RecvCANMsg

This function is used to receive CAN messages that are saved in

software buffer in the assigned CAN port.

Syntax :

int VCI_RecvCANMsg (

BYTE CAN_No,

PVCI_CAN_MSG pCANMsg

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

pCANMsg:

[out] A structure pointer of _VCI_CAN_MSG is used to receive the

CAN message shown as below.

typedef struct _VCI_CAN_MSG{

BYTE Mode;

BYTE RTR;

BYTE DLC;

BYTE Reserved;

DWORD ID;

DWORD TimeL;

DWORD TimeH;

BYTE Data[8];

} _VCI_CAN_MSG, *PVCI_CAN_MSG;

Mode : CAN message Mode (0: 11-bit; 1: 29-bit)

RTR : CAN message RTR (0: No RTR; 1: RTR)

DLC : CAN message Data Length (0~8)

ID : CAN message ID

TimeL : CAN message Time-Stamp (Lo-DWORD)

TimeH : CAN message Time-Stamp (Hi-DWORD)

Data[8] : CAN message Data Array

Return Values :

Return 0 means success, others means failure.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 52

Examples :

Int Ret, i;

BYTE CAN_No;

BYTE CANMsg_Mode, CANMsg_RTR, CANMsg_DLC, CANMsg_Data[8];

DWORD CANMsg_ID, CANMsg;

Double CANMsg_Time;

_VCI_CAN_MSG CAN_RecvMsg;

CAN_No=1;

Ret = VCI_RecvCANMsg(CAN_No, &CAN_RecvMsg); // Recv CAN Msg

CANMsg_Mode = CAN_RecvMsg.Mode;

CANMsg_RTR = CAN_RecvMsg.RTR;

CANMsg_ID = CAN_RecvMsg.ID;

CANMsg_DLC = CAN_RecvMsg.DLC;

CANMsg_Time =

(double)(CAN_RecvMsg.TimeH*pow(2.0,32.0))+(double)((double)CAN_R

ecvMsg.TimeL/10000));

For(i=0; i< CANMsg_DLC; i++){

CANMsg_Data[i] = CAN_RecvMsg.Data[i]

}

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 53

5.6.3 VCI_EnableHWCyclicTxMsg

This function is used to send CAN messages in the assigned CAN

port by using module hardware timer and it will be more precise than PC

software timer.

Syntax :

int VCI_EnableHWCyclicTxMsg (

BYTE CAN_No,

PVCI_CAN_MSG pCANMsg,

DWORD TimePeriod,

DWORD TransmitTimes

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

pCANMsg:

[in] A structure pointer of _VCI_CAN_MSG is used to set the CAN

message parameters shown as below.

typedef struct _VCI_CAN_MSG{

BYTE Mode;

BYTE RTR;

BYTE DLC;

BYTE Reserved;

DWORD ID;

DWORD TimeL;

DWORD TimeH;

BYTE Data[8];

} _VCI_CAN_MSG, *PVCI_CAN_MSG;

Mode : CAN message Mode (0: 11-bit; 1: 29-bit)

RTR : CAN message RTR (0: No RTR; 1: RTR)

DLC : CAN message Data Length (0~8)

ID : CAN message ID

TimeL : CAN message Time-Stamp (Lo-DWORD)

TimeH : CAN message Time-Stamp (Hi-DWORD)

Data[8] : CAN message Data Array

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 54

TimePeriod:

[in] The time period of module hardware timer for sending CAN

message. If the value is zero, this function doesn’t work.

TransmitTimes:

[in] The count for sending CAN message. If the value is zero, it means

that CAN message will be sent periodically and permanently.

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

_VCI_CAN_MSG CAN_SendMsg;

CAN_No=1;

CAN_SendMsg.Mode = 1;

CAN_SendMsg.RTR = 0;

CAN_SendMsg.ID = 0x1;

CAN_SendMsg.DLC = 8;

CAN_SendMsg.Data[0]= 0x12;

CAN_SendMsg.Data[1]= 0x34;

CAN_SendMsg.Data[2]= 0x56;

CAN_SendMsg.Data[3]= 0x78;

CAN_SendMsg.Data[4]= 0x90;

CAN_SendMsg.Data[5]= 0xAB;

CAN_SendMsg.Data[6]= 0xCD;

CAN_SendMsg.Data[7]= 0xEF;

//Send 200 CANMsg with 10ms period and then stop

Ret = VCI_EnableHWCyclicTxMsg(CAN_No, &CAN_SendMsg, 10, 200);

//Send CANMsg with 10ms period permanently

//Ret = VCI_EnableHWCyclicTxMsg(CAN_No, &CAN_SendMsg, 10, 0);

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 55

5.6.4 VCI_DisableHWCyclicTxMsg

This function is used to stop sending CAN messages by module

hardware timer.

Syntax :

int VCI_DisableHWCyclicTxMsg (

void

);

Parameter :

None

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

Ret = VCI_DisableHWCyclicTxMsg(); // Disable module hardware timer

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 56

5.7 Software Buffer Function

When users’ program receives CAN messages, these received CAN

messages will be saved in software buffer provided by VCI_CAN library

first and users need to use “VCI_RecvCANMsg” function to get these

received CAN messages saved in software buffer. The software buffer

size is 65536 for each CAN port.

5.7.1 VCI_Get_RxMsgCnt

This function is used to get the count of these received CAN

messages saved in software buffer that are not received by users’

program in the assigned CAN port.

Syntax :

int VCI_Get_RxMsgCnt (

BYTE CAN_No,

DWORD* RxMsgCnt

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

RxMsgCnt:

[out] The pointer is used to receive the CAN message count saved in

software buffer.

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

DWORD RxMsgCnt;

CAN_No=1;

Ret = VCI_Get_RxMsgCnt(CAN_No, &RxMsgCnt); // Recv RxMsg count

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 57

5.7.2 VCI_Get_RxMsgBufIsFull

This function is used to get the software buffer state whether it is full or

not in the assigned CAN port. If the software buffer is full, it means that

some CAN messages are lost.

Syntax :

int VCI_Get_RxMsgBufIsFull (

BYTE CAN_No,

BYTE* Flag

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

Flag:

[out] The pointer is used to receive the state of software buffer. If the

value is zero, the software buffer is not full. If not, it means that

the software buffer is full.

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

BYTE RxSoftBufFull_Flag;

CAN_No=1;

Ret = VCI_Get_RxMsgBufIsFull(CAN_No, &RxSoftBufFull_Flag);

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 58

5.7.3 VCI_Clr_RxMsgBuf

This function is used to clear the software buffer in the assigned CAN

port.

Syntax :

int VCI_Clr_RxMsgBuf (

BYTE CAN_No,

);

Parameter :

CAN_No:

[in] The assigned CAN port number.

Return Values :

Return 0 means success, others means failure.

Examples :

Int Ret;

BYTE CAN_No;

CAN_No=1;

Ret = VCI_Clr_RxMsgBuf(CAN_No);

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 59

5.8 Other Function

These functions are used to get the VCI_CAN library information or

helpful for users’ program.

5.8.1 VCI_Get_DllVer

This function is used to get the version of VCI_CAN library.

Syntax :

DWORD VCI_Get_DllVer (

void

);

Parameter :

None

Return Values :

Return the VCI_CAN library version. Hi-byte is the major version and

lo-byte is the minor version.

Examples :

DWORD DllVer;

char VCI_DllVer[10];

DllVer = VCI_Get_DllVer();

sprintf(VCI_DllVer, “v%lu.%02lu", (DllVer>>8)&0xFF, DllVer&0xFF);

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 60

5.8.2 VCI_DoEvents

This function is used to release CPU resource temporarily.

Syntax :

void VCI_DoEvents (

void

);

Parameter :

None

Return Values :

None

Examples :

VCI_DoEvents() ;

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 61

5.9 Return Code

The return value is used to show the result of executing VCI_CAN

library functions. The following is the all return codes.

#define No_Err 0 //No Error

#define DEV_ModName_Err 1 //The Module Name Error

#define DEV_ModNotExist_Err 2 //The Module doesn't exist in this

Port

#define DEV_PortNotExist_Err 3 //The Port doesn't Exist

#define DEV_PortInUse_Err 4 //The Port is in Used

#define DEV_PortNotOpen_Err 5 //The Port doesn't Open

#define CAN_ConfigFail_Err 6 //CAN Hardware Init Fail

#define CAN_HARDWARE_Err 7 //CAN Hardware Init Fail

#define CAN_PortNo_Err 8 //The Device doesn't support this

CAN Port

#define CAN_FIDLength_Err 9 //The CAN Filter-ID Number

exceed Max Number

#define CAN_DevDisconnect_Err10 //The Connection of device is

broken

#define CAN_TimeOut_Err 11 //The Config Command Timeout

#define CAN_ConfigCmd_Err 12 //The Config Command doesn't

support

#define CAN_ConfigBusy_Err 13 //The Config Command is busy

#define CAN_RxBufEmpty 14 //The CAN Receive Buffer is empty

#define CAN_TxBufFull 15 //The CAN Send Buffer is full

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 62

6. Troubleshooting

6.1 The Connection Issue

If the driver installation of I-7565-H1/H2 is successful, the virtual

com port will be assigned by Windows automatically. Then users can

use “I-7565-H1/H2 Utility” to connect to I-7565-H1/H2 module via the

virtual com port for CAN bus communication.

[Q1] When users open the virtual com port, if it shows the below error

message like Figure 6-1-1, there are two conditions for that.

(1) This com port is not existed in system and please check the

com port number again.

(2) If the virtual com port number is bigger than COM16, then

users need to copy the new version “MSCOMM32.OCX” file in

I-7565-H1H2 utility folder to “C:\WINDOWS\system32\” to

replace the old version file and then register MSCOMM32.ocx

again.

If it still failed, please check that the driver installation is completed

or the virtual com port is correct for I-7565-H1/H2.

Figure 6-1-1: Invalid port number

[Q2] When users open the virtual com port, if it shows the below error

message like Figure 6-1-2, it means that the com port is occupied by

other programs like VxComm Utility. Please “UnMap” the same com

port used in VxComm Utility and then click “Restart Driver” function

like Figure 6-1-3. After that, reset I-7565-H1/H2 and try to connect to

I-7565-H1/H2 again.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 63

Figure 6-1-2: The device is not open

Figure 6-1-3: Virtual COM of VxComm Utility

6.2The CAN Baud Rate Issue

(1) The CAN baud rate mismatch:

If the I-7565-H1/H2 CAN baud rate is not the same as the CAN

baud rate on the CAN bus network, the RUN LED on the I-7565H1/H2 will flash per 100ms because the I-7565-H1/H2 cannot send

any CAN message to the CAN bus network. Users can get the CAN

status of I-7565-H1/H2 by using “I-7565-H1/H2 Utility” to help users

understand what is going in the module.

The user-defined CAN baud rate setting:

(2)

If users want to use the user-defined CAN baud rate, in the

“Connect to I-7565-H1/H2” screen of “I-7565-H1/H2 Utility”, users can

choose the “Defined” item and input the user-defined CAN baud rate

value (for example: 83.333) in the right field of the “Baud Rate” frame

like Figure 6-2. Then click “Connect” button to connect to I-7565H1/H2.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 64

Figure 6-2: User-defined CAN Baud Rate for I-7565-H1/H2

The rule of user-defined CAN baud rate setting in the SJA1000

(3)

CAN devices for communication compatible with I-7565-H1/H2:

If users use I-7565-H1/H2 to communicate with SJA1000 CAN

devices and CAN baud rate is user-defined CAN baud rate. Then in

SJA1000 CAN devices, users need to choose a set of proper CAN

parameter (BTR0 & BTR1) for communication compatible with I7565-H1/H2 and the rule is as follows:

(1) The “Samples” value is 1.

(1) The “SJW” value is as small as possible. (1 is the best).

(2) The “Tseg2” value is as small as possible. (1 is the best)

(3) The “Tseg1” value is as large as possible.

According to the above four rules, users can choose the proper

BTR0 and BTR0. For example, if uses want to use the CAN baud rate

is 83.333 Kbps, according to the above rules, users should choose

BTR0=05 and BTR1=1C for the CAN parameter of SJA1000 CAN

devices like Figure 6-3.

Figure 6-3: User-defined CAN Baud Rate for SJA1000 Device

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 65

6.3 The Same CAN-ID Conflict Issue

If the same CAN-ID conflict condition in CAN bus network

happened frequently, it may cause CAN bus communication failed in

I-7565-H1/H2 module. Users should solve the CAN-ID conflict

condition and reset I-7565-H1/H2 module for the later CAN bus

communication.

6.4 The PC Rebooting Issue

If users use I-7565-H1/H2 module for a while, the PC reboots

automatically. Please update the newest “

to your PC platform. For example, if users use Windows XP, please

update the service pack to SP3 or newer version to solve this

problem.

Service Pack of Windows”

6.5 The Max Data Transfer Rate (fps) Issue

The max CAN bus data transfer rate in I-7565-H1/H2 is up to 3000

fps and it can be adjusted by I-7565-H1/H2 Utility. If users’ PC

performance is not good enough, the data loss condition may happen.

In this time, users can use “Advanced Config” function to adjust

hardware transfer rate of “CAN to USB” in I-7565-H1/H2 and it may

improve the data loss problem. Remember that hardware data

transfer rate can not be lower than the current CAN bus flow, or the

data loss will happen in I-7565-H1/H2 module.

6.6 The Data Loss Issue

There are two possible causes for the data loss problem. They are

described as follows:

(1) Software receiving buffer provided by API library overflow.

It means that the users’ program could not receive the CAN

messages from software buffer in time. Therefore, users should

optimize the communication strategy.

(2) Hardware receiving buffer overflow.

A large delay of the interrupt happened in the receiving-end PC

and it can be solved by enhancing the PC hardware performance

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 66

or properly slowing down the transmitting speed for the other CAN

bus nodes.

6.7 The Module Number Applied to One PC Issue

In theory, there is no the limitation. It supports synchronous

operation in a PC with more than one I-7565-H1/H2 modules but the

total communication efficiency depends on the PC hardware

performance.

6.8 The Long Driver Installation Time Issue

If users install the driver of I-7565-H1/H2 followed by the steps of

chapter 3 and it takes more than 2 minutes, please follow the below

steps to solve this problem.

(1) Copy these two files, “I-7565-H1.inf” and “I-7565-H2.inf”, to the

path:

C:\WINDOWS\inf\.

(2) Copy the file, “usbser.sys”, to the path:

C:\WINDOWS\system32\drivers\.

(3) Please follow the steps in chapter 3 to install the I-7565-H1/H2

driver again. In the below step like Figure 6-4, please choose

Don’t search. I will choose the driver to install” option and then

“

click “Next” button.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 67

Figure 6-4: Driver Installation of I-7565-H1/H2 (1)

(4) When the Figure 6-5 shows, click “Next” button and the other

steps are the same with those in chapter 3.

Figure 6-5: Driver Installation of I-7565-H1/H2 (2)

6.9 The Supported CAN Filter-ID Number Issue

The total capacity for CAN Filter-ID provided by I-7565-H1/H2 is

440 WORD. The following table describes the size of every different

type CAN Filter-ID.

11-bit Single ID 1

11-bit Group ID 2

29-bit Single ID 2

29-bit Group ID 4

Size

(Unit: WORD)

Table 6-1: Size of Every Different Type CAN Filter-ID

According to the Table 6-1, the following table describes the

supported CAN Filter-ID number of I-7565-H1/H2.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 68

I-7565-H1

( CAN Port )

I-7565-H2

( Each CAN Port )

11-bit Single ID 440/1 = 440 220

11-bit Group ID 440/2 = 220 110

29-bit Single ID 440/2 = 220 110

29-bit Group ID 440/4 = 110 55

Table 6-2: size of every different type CAN ID

6.10 Other Issue

In general, the following errors could also occur. For example,

CAN media connection problem, terminal resistor problem, different

baud rate configuration with CAN network and so on.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 69

7. History of Version

Version Author Date Description of changes

1.0 Edward 22-Sep-2009 The First Version

1. Modify the connection screen of

1.1 Edward 25-Nov-2009

Utility.

2. Add connection issue content.

3. Provide Firmware Update Tool.

I-7565-H1/H2 High Speed USB/CAN Converter User’s Manual (Ver 1.1, Nov/2009) ------------- 70

Loading...

Loading...