Page 1

Basic Operation

Page 2

Basic Operation

Table of Contents

Table of Contents...........................................................................................................3

Basic Ladder Elements ..................................................................................................4

3

i Memory Locations..................................................................................................5

Input / Output Types......................................................................................................6

Assigning Function Keys and Screens...........................................................................7

Basic Ladder Logic......................................................................................................10

Or Gate.....................................................................................................................12

And Gate..................................................................................................................12

Function Blocks.......................................................................................................13

Timers and Counters................................................................................................14

Timer Set up.........................................................................................................14

Counter Set up......................................................................................................18

Move Functions .......................................................................................................19

Set Points .................................................................................................................21

Download Options...................................................................................................22

Connecting to your i3...........................................................................................22

Configuring the correct model.............................................................................24

Downloading the Program...................................................................................25

Screen Editor................................................................................................................26

Screen Editor Tool Bar. ...........................................................................................27

Static Text................................................................................................................28

Numeric Data...........................................................................................................29

Time Data.................................................................................................................30

Password..................................................................................................................31

Text Table data ........................................................................................................32

Notepad....................................................................................................................33

Menu Item................................................................................................................34

Indicator Lamp.........................................................................................................35

Button.......................................................................................................................36

Selector Switch ........................................................................................................37

Slider........................................................................................................................38

Screen Jump.............................................................................................................39

Bar Graph.................................................................................................................40

Meter........................................................................................................................41

Gauge.......................................................................................................................42

Static Bitmap............................................................................................................43

Animation ................................................................................................................44

Trend........................................................................................................................45

X – Y Data Graph ....................................................................................................46

Alarms......................................................................................................................47

Configure the Alarm Log.....................................................................................48

Recipe Editor ...........................................................................................................49

© IMO Precision Controls ltd. 3

Page 3

N

p

Basic Ladder Elements

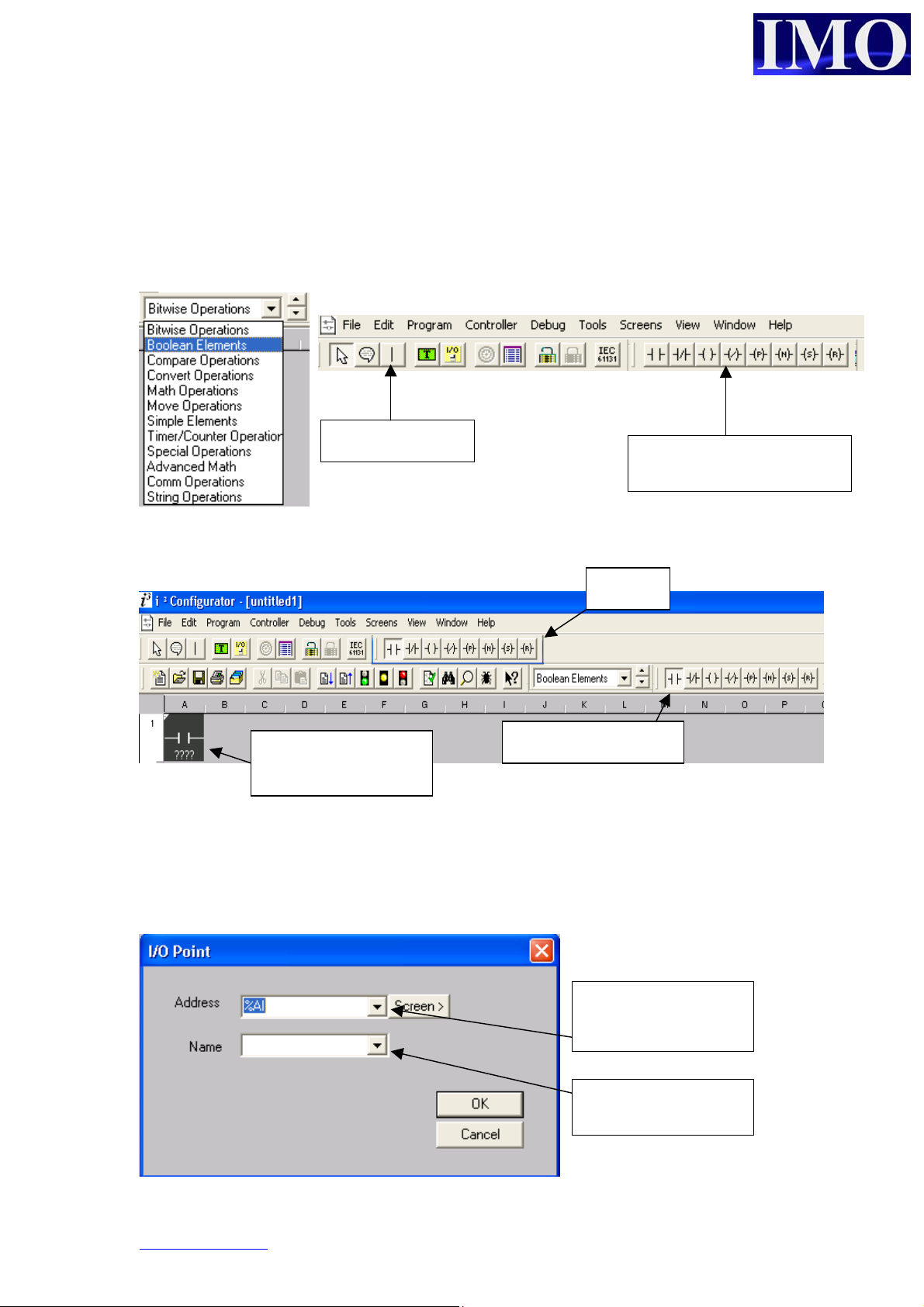

All the Functions, contacts and coils for the ladder programming are contained in a

drop down menu to select what range of functions you want to insert. It is also

possible to scroll through the sub-sections using the up and down arrow keys. These

sub sections can also be docked on to the main programming interface.

Vertical line tool

Once you have selected your sub section it is now possible to click on the icon to

insert it into the ladder diagram.

Icon attaches to mouse

Enter the contact / coil / function into the diagram by clicking it into the Ladder

diagram.

When inserting a Contact or a Coil you will need to assign the variable to a location

and giving it a name is a good idea for documentation.

for insertion into

ladder diagram

O Contact selected

Docked Boolean elements

Docked

Select from the drop

down location

Drop down menu of

redefined variables

www.imopc.com 4

Page 4

Basic Operation

n

3

i Memory Locations

Type Description and example of what might use the type Format

%I Discrete Inputs from the field; proximity sensors, panel

BOOL

buttons, etc

%Q Discrete Outputs to the field; relays, indicator lamps,

BOOL

etc.

%AI Analogue Inputs from the field; Thermocouples, WORD

4-20mA inputs

%AQ Analogue Outputs to the field; 0-10VDC or 4-20mA

WORD

outputs

%IG Global Discrete Inputs from the CAN smart I/O; BOOL

%QG Global Discrete Outputs to the CAN smart I/O; BOOL

%AIG Global Analogue Inputs from the CAN smart I/O; WORD

%AQG Global Analogue Outputs to the CAN smart I/O; WORD

%T Internal Temporary bits, use for contacts and coils BOOL

%M Internal Memory bits, use for contacts and coils BOOL

%R Internal Registers, use for timers, counters & other data WORD

%K Keypad bits, reflect Function Key status BOOL

%D Display bits, control screens or indicate screen on/off BOOL

%S Internal System Bits (See System Registers) BOOL

%SR Internal System Registers (See System Registers) WORD

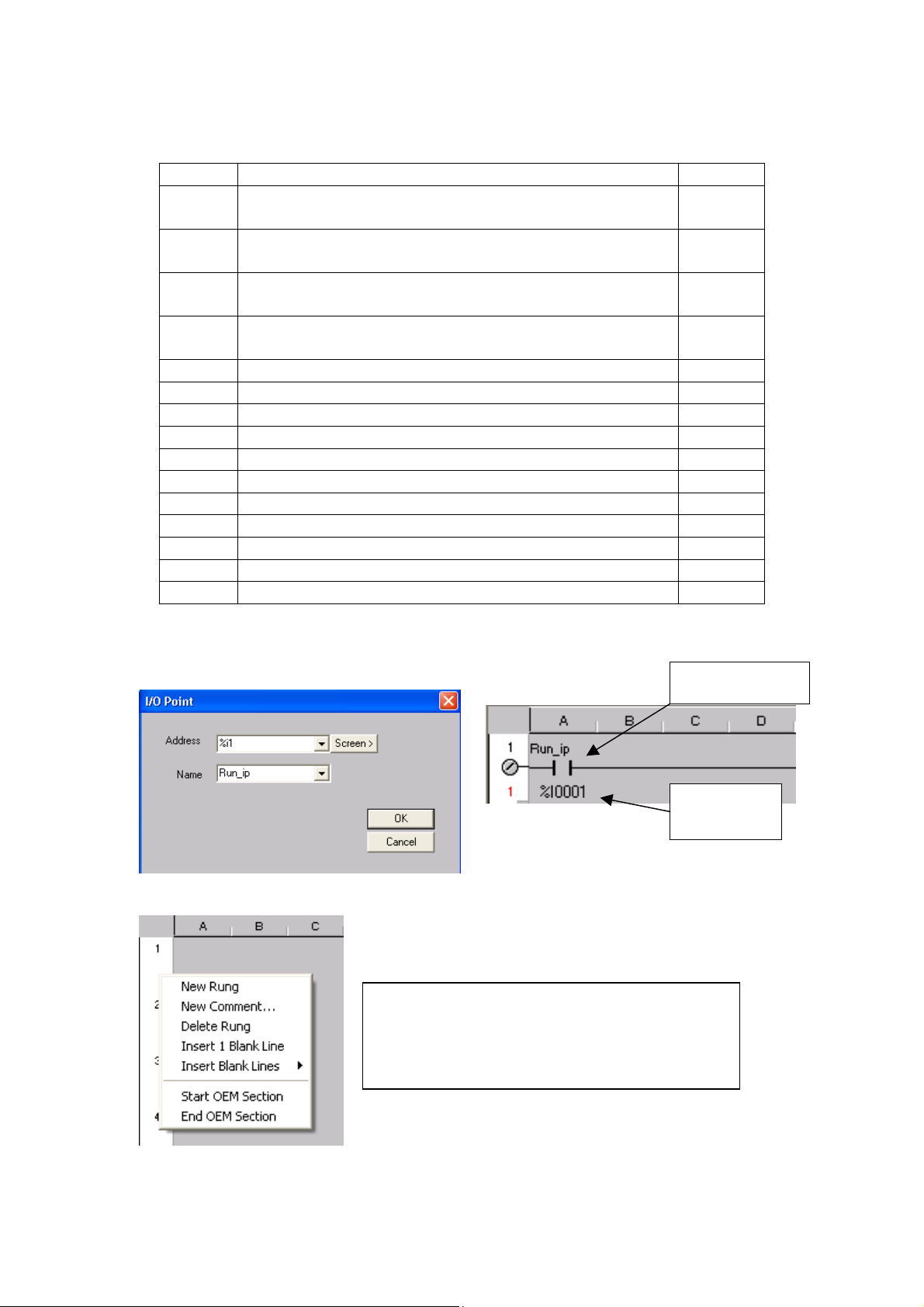

Note: The allocation of I/O starts from 1 the first input is %*01 and not %*00

.

Contact name

By right clicking the mouse in the left margi

we can have some more options.

We have the options to add or remove rungs,

insert documentation and start OEM sections.

© IMO Precision Controls ltd. 5

Contact

address

Page 5

p

Input / Output Types

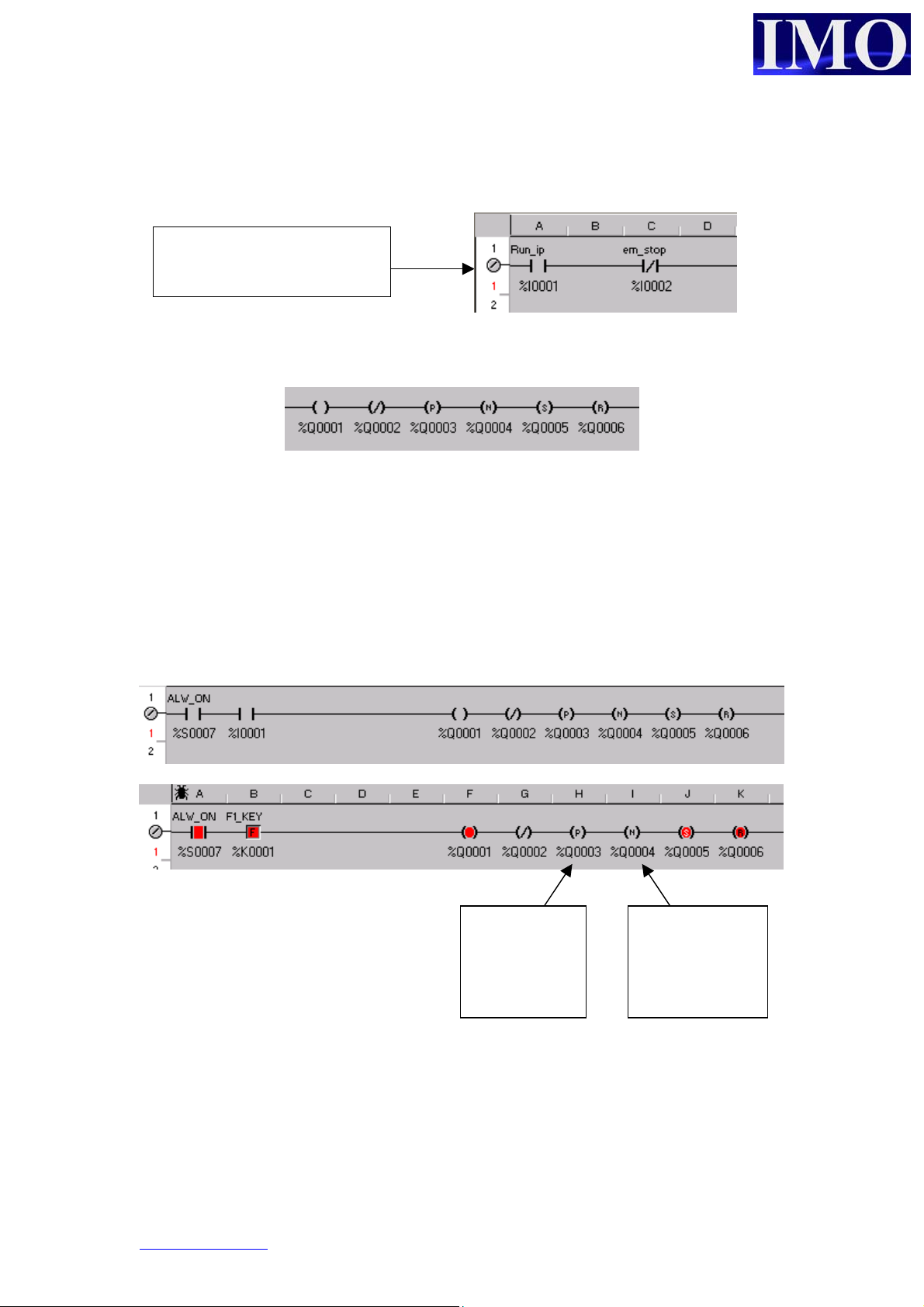

The i3 has 2 types of inputs: Normally Open (N/O) and Normally Closed (N/C).

The rung has been “Made”

when this symbol is present.

The i3 has 6 types of outputs: N/O, N/C, Positive Edge, Negative Edge, Set and Reset.

More than one output can be put on a single rung. This performs the same function as

OR’ing the outputs. When the input condition is met all of the outputs on the rung

will be activated.

Example 1:

When %I0001 is enabled, %Q0001 switches state, as does %Q0002. Whereas

%Q0003 switches on the positive edge of %I0001 and %Q0004 will switch on the

negative edge of %I0001. %Q0006 will reset from its current state.

Q3 was on

only on the

ositive edge

of the input

Q4 was on

only on the

negative edge

of the input

www.imopc.com 6

Page 6

Basic Operation

d

N

N

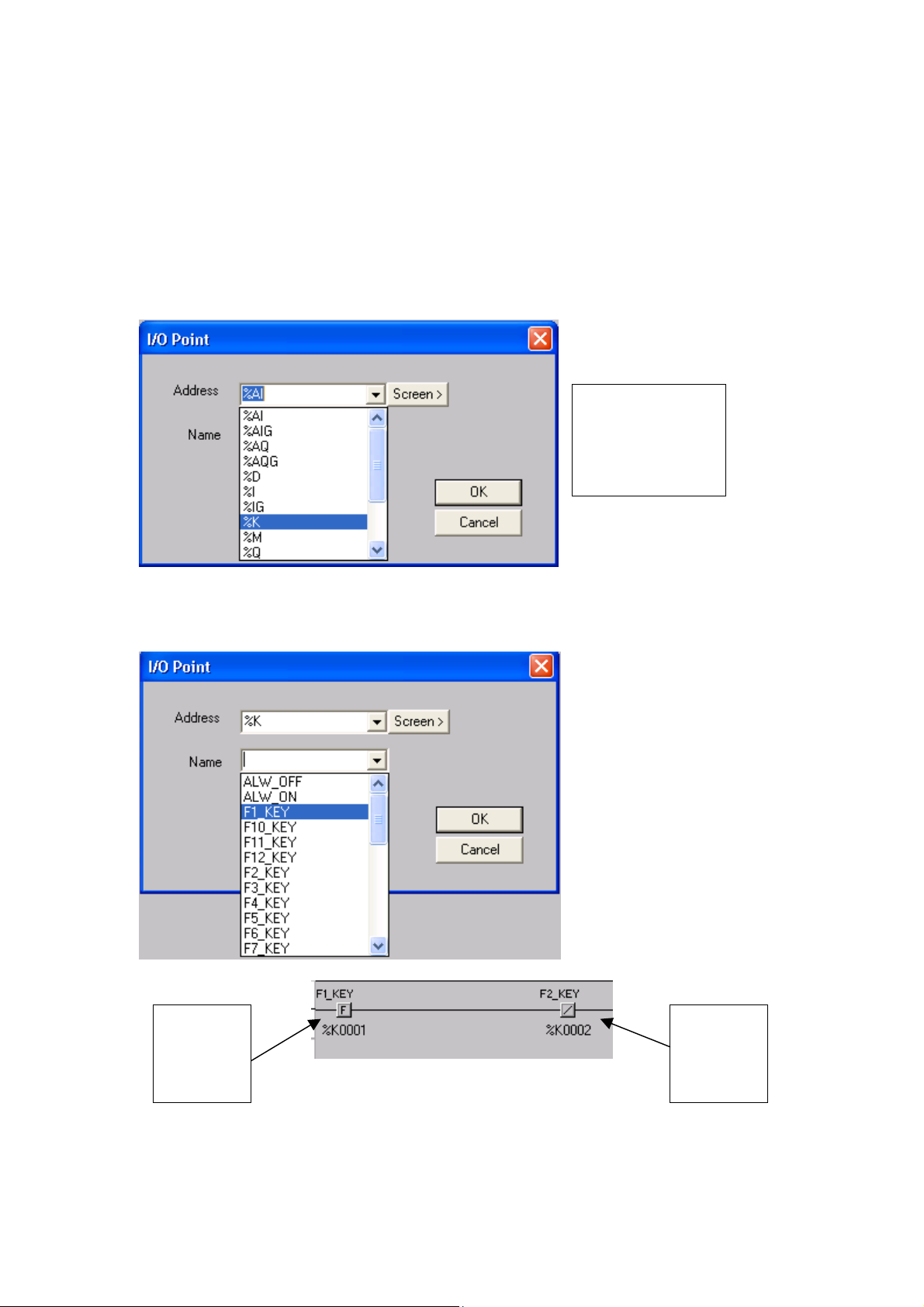

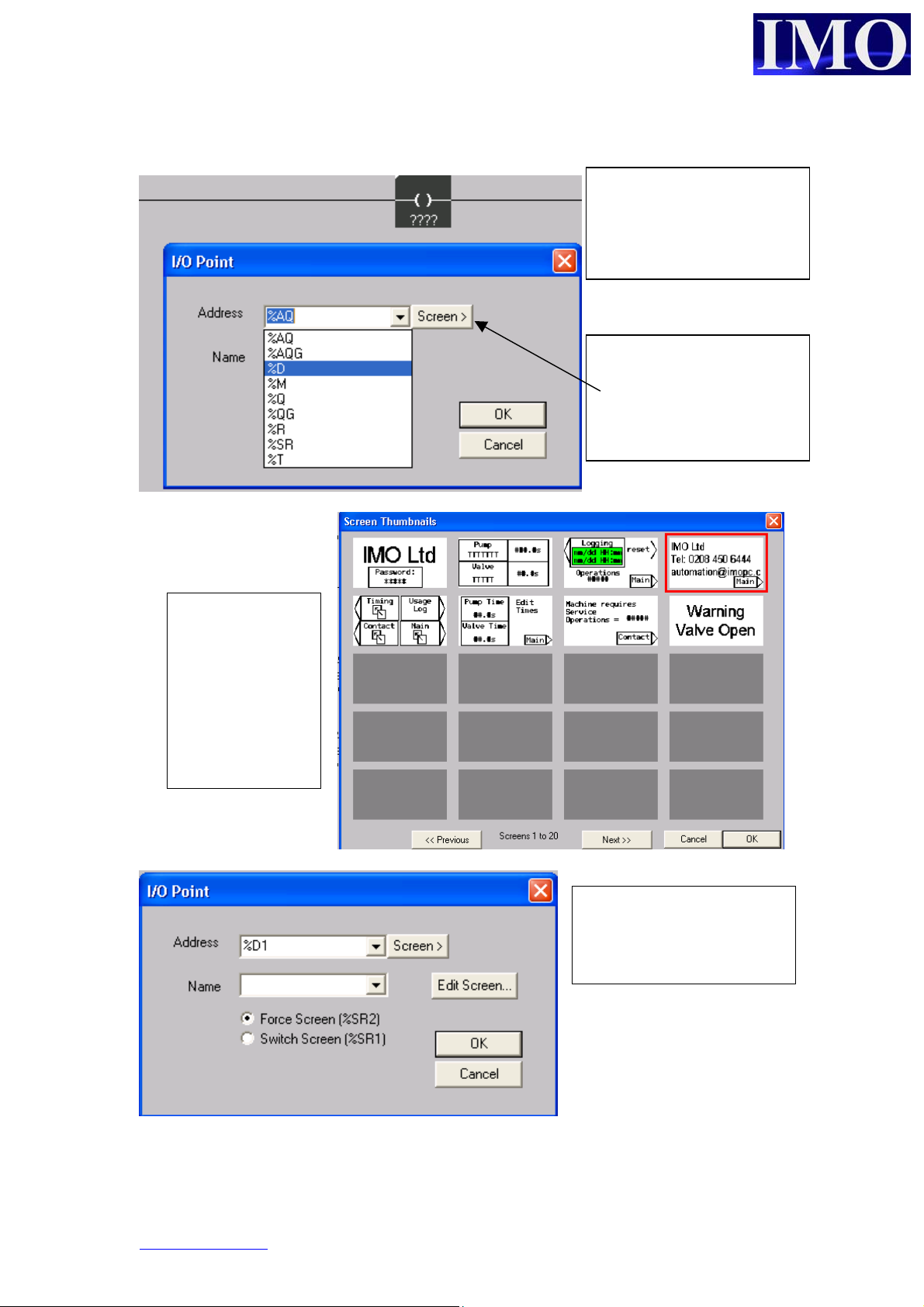

Assigning Function Keys and Screens

The i3 has 11 function keys that can be programmed into the ladder diagrams. It also

has four buttons that can be programmed through the screen editor which are

discussed later in this document.

Assigning Function Keys in the ladder diagram is very simple. Select an input contact

and address it to the Keys!

Select %K an

then assign the

address for the

key, 1-12

Or, select it by its predefined name.

O

Function

Key

contact

© IMO Precision Controls ltd. 7

C

Function

Key

contact

Page 7

n

b

a

s

n

u

n

To insert a screen into the ladder logic, select an output coil and click it into the ladder

diagram.

Select %D and then enter

the number for the screen

to display, i.e. %D0001 is

screen 1.

By clicking the scree

utton you can choose

screen from the thumbnail

menu.

The screens

hown were set

up previously. If

no screen has

been set up then

it will be shown

as a blank grey

box.

We can open the scree

editor from this men

which is covered later i

this document.

There are now two options to choose from which control the way an individual screen

is presented.

www.imopc.com 8

Page 8

Basic Operation

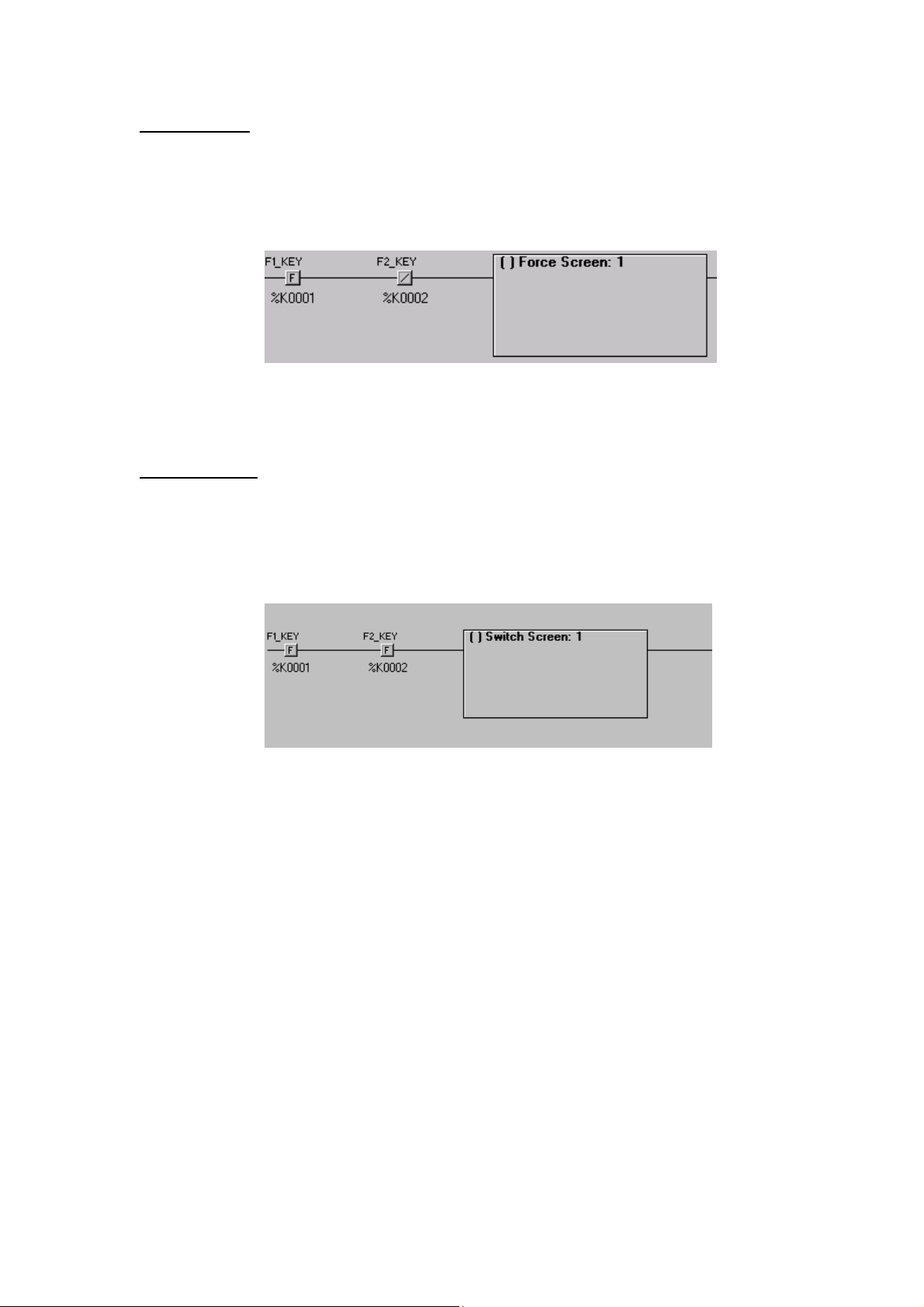

Force Screen:

Displays the screen whilst the conditions to make the contact are met. When the

condition is not met anymore the screen will go back to the previously set screen.

Example 2: Warning Message when a valve is open.

When F1_KEY AND NOT F2_KEY are pressed the i will display screen 1. When F1

3

has been released the i3 will display the previously set screen.

Switch Screen:

Changes the display to the desired screen when the condition is met.

When the logical condition is no longer true the selected screen remains on display.

Example 3: Changing screens on a menu selection.

When F1_KEY AND F2_KEY are pressed the i3 will display screen 1. When F1 has

been released the i3 Screen 1 will remain on the display until the next Screen is called.

© IMO Precision Controls ltd. 9

Page 9

n

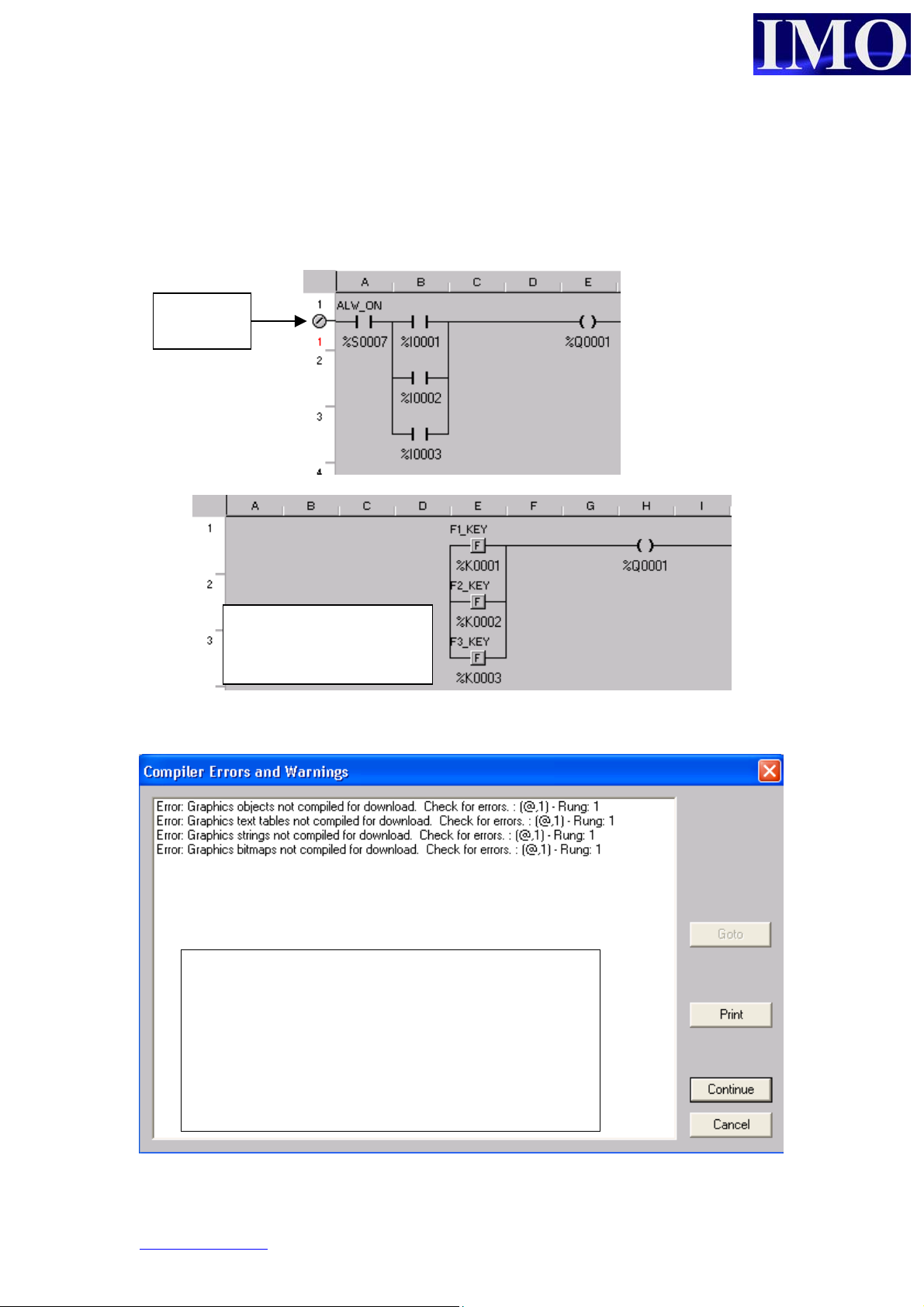

Basic Ladder Logic

Using Ladder logic it is necessary to insert a contact in the first column. A good

practice is to insert an ALWAYS ON (ALW_ON) contact at the beginning then add

your logic after.

Rung is

complete

Rung not complete. The

program logic will fail to

compile and Download.

A common error message will appear if no scree

has been configured.

An initial screen must be configured before the

3

program can be successfully downloaded to the

i

www.imopc.com 10

Page 10

Basic Operation

n

N

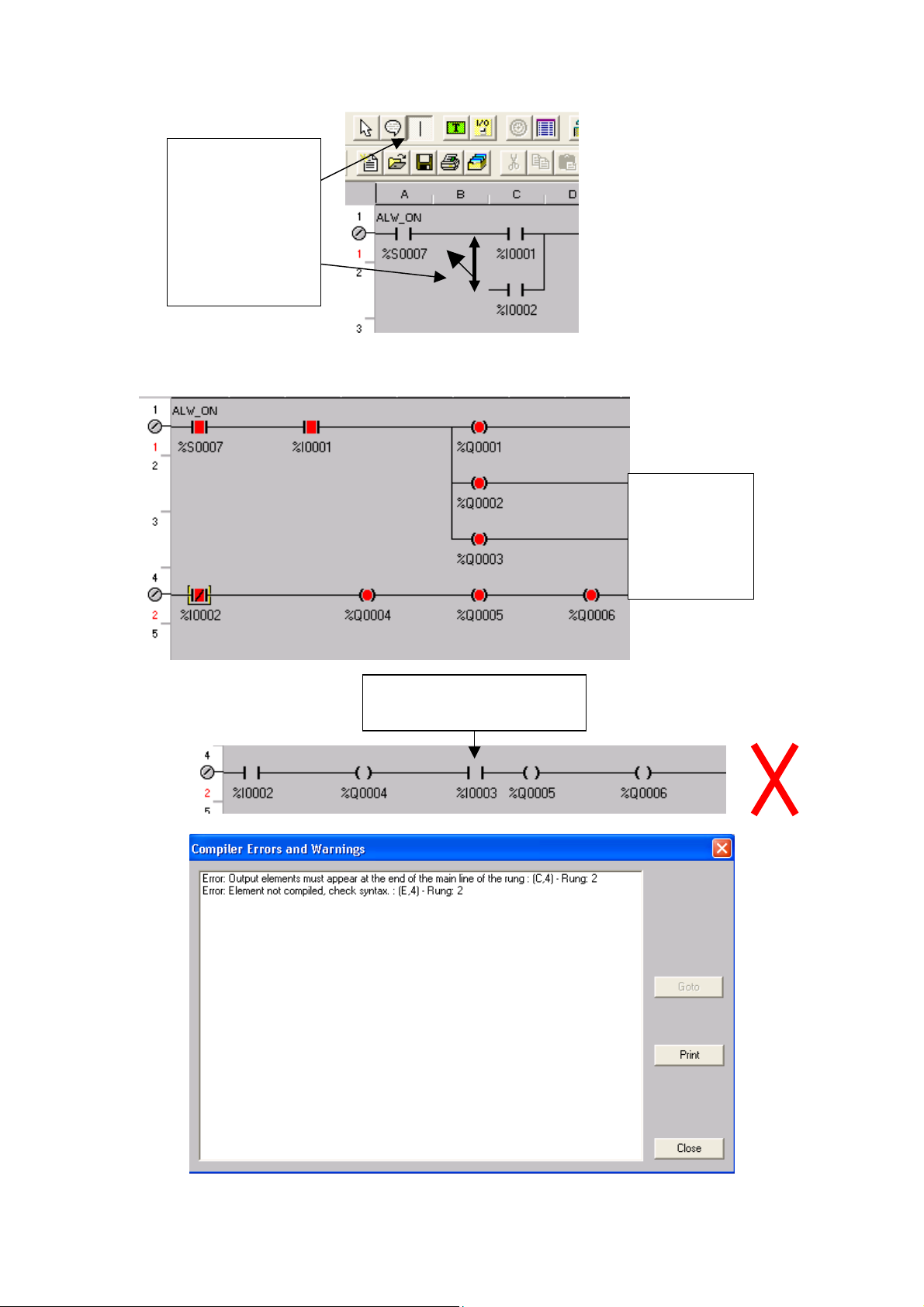

Vertical lines

can be draw

using the tool.

The tool attaches

to the mouse

icon.

Each rung can have multiple outputs but they must be at the end of the line.

ested

outputs can

also be put

horizontally.

An input in this position

will cause an error

© IMO Precision Controls ltd. 11

Page 11

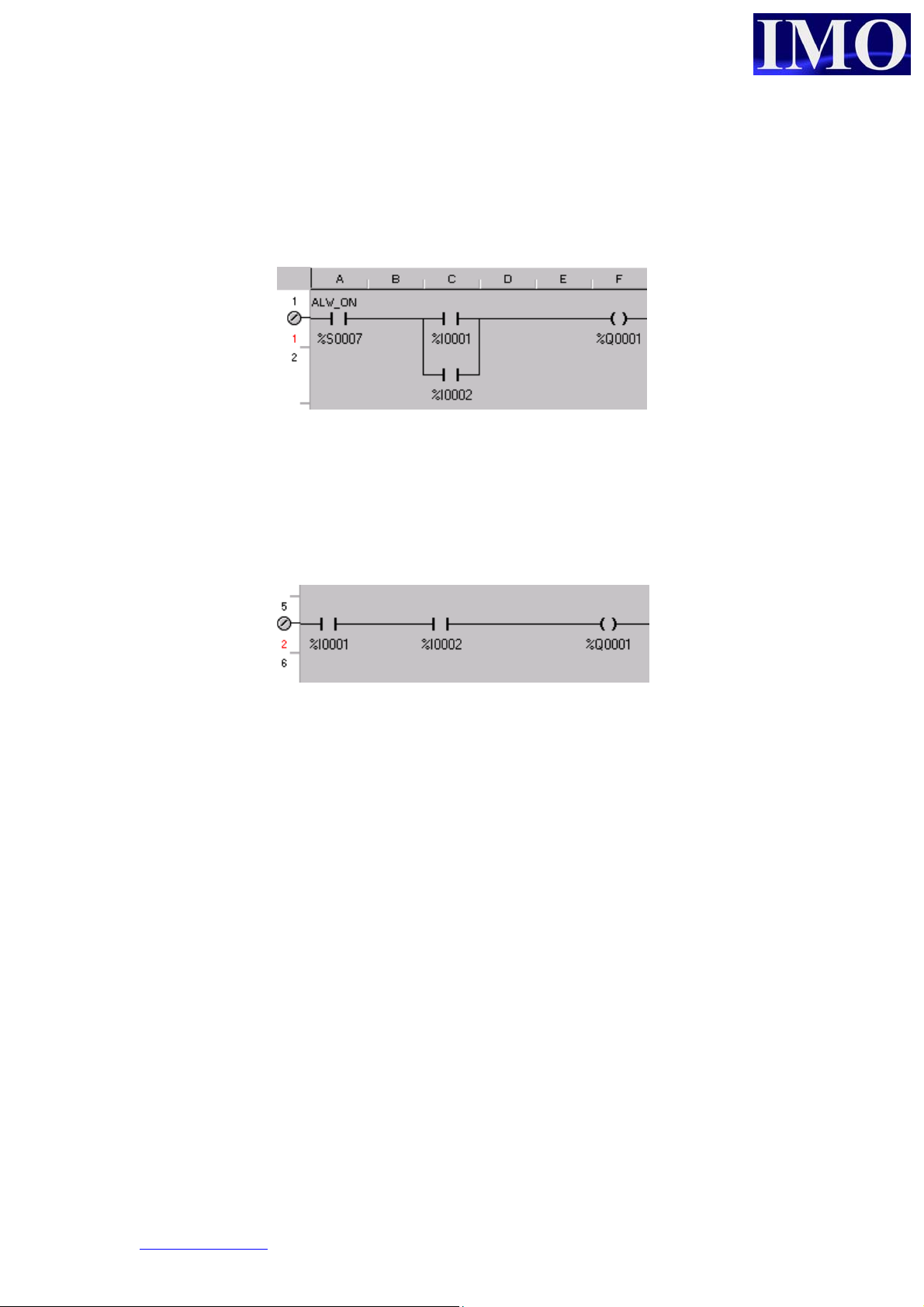

Or Gate

When any one of two or more inputs will switch on the output: In this example either

%I0001 or %I0002 will switch ON %Q01.

And Gate

When all input conditions on a single rung are met the output will switch ON. In this

example both %I0001 AND %I0002 must be on for the output %Q0001 to be

energised.

www.imopc.com 12

Page 12

Basic Operation

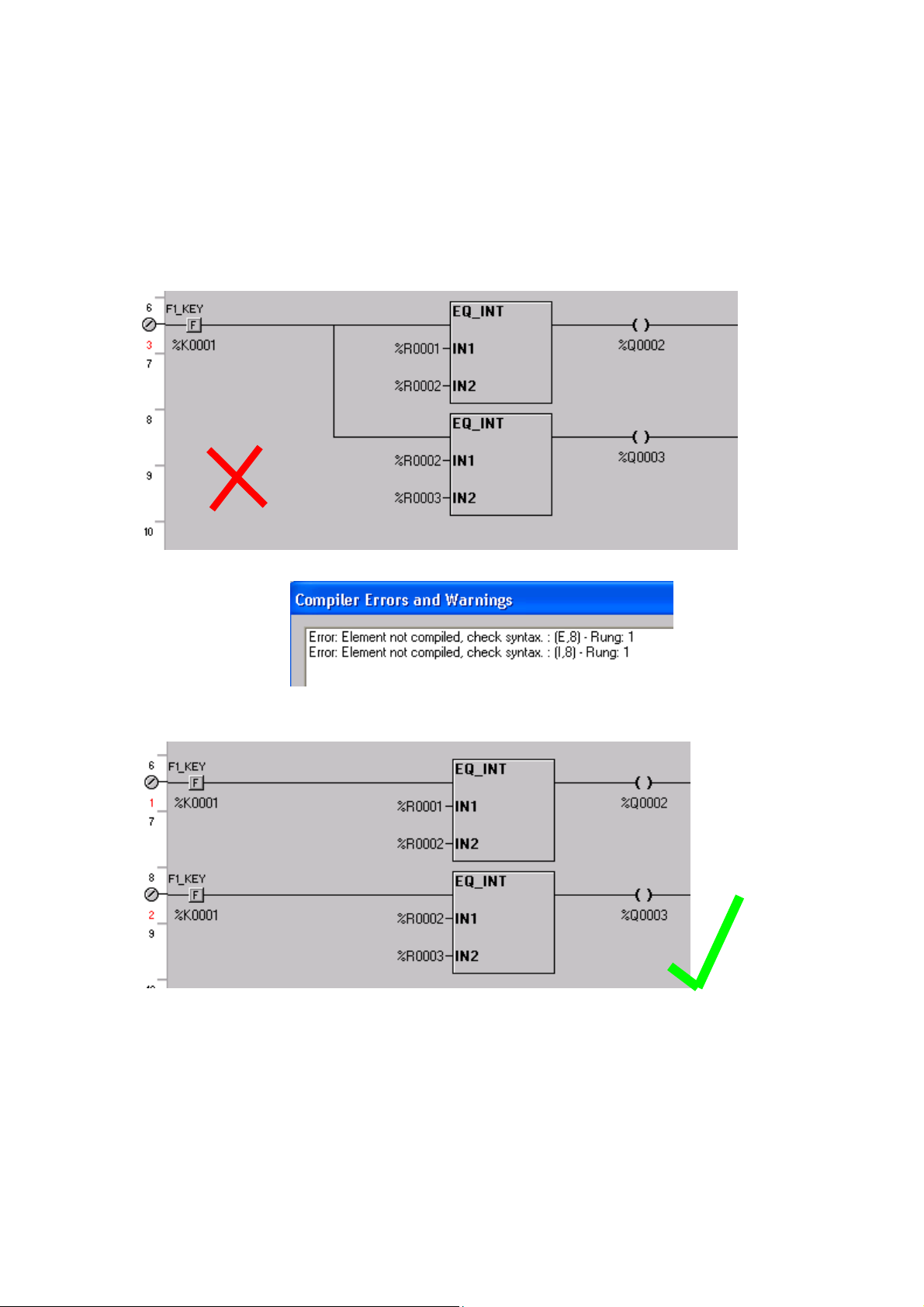

Function Blocks

All function blocks have an enable input and a Boolean output. Other I/O parameters

are dependent on the individual function block and are required to be set up when

inserting the block.

Nesting function blocks will create an error.

© IMO Precision Controls ltd. 13

Page 13

Timers and Counters

Timers and counters require two consecutive registers to store their data in memory.

The first register contains the current value and the second contains the status bits of

the counter or timer.

Register 1 = Accumulated value

Register 2 .15 = Function Enabled

Register 2 .16 = Function Completed i.e. timing elapsed, preset value met.

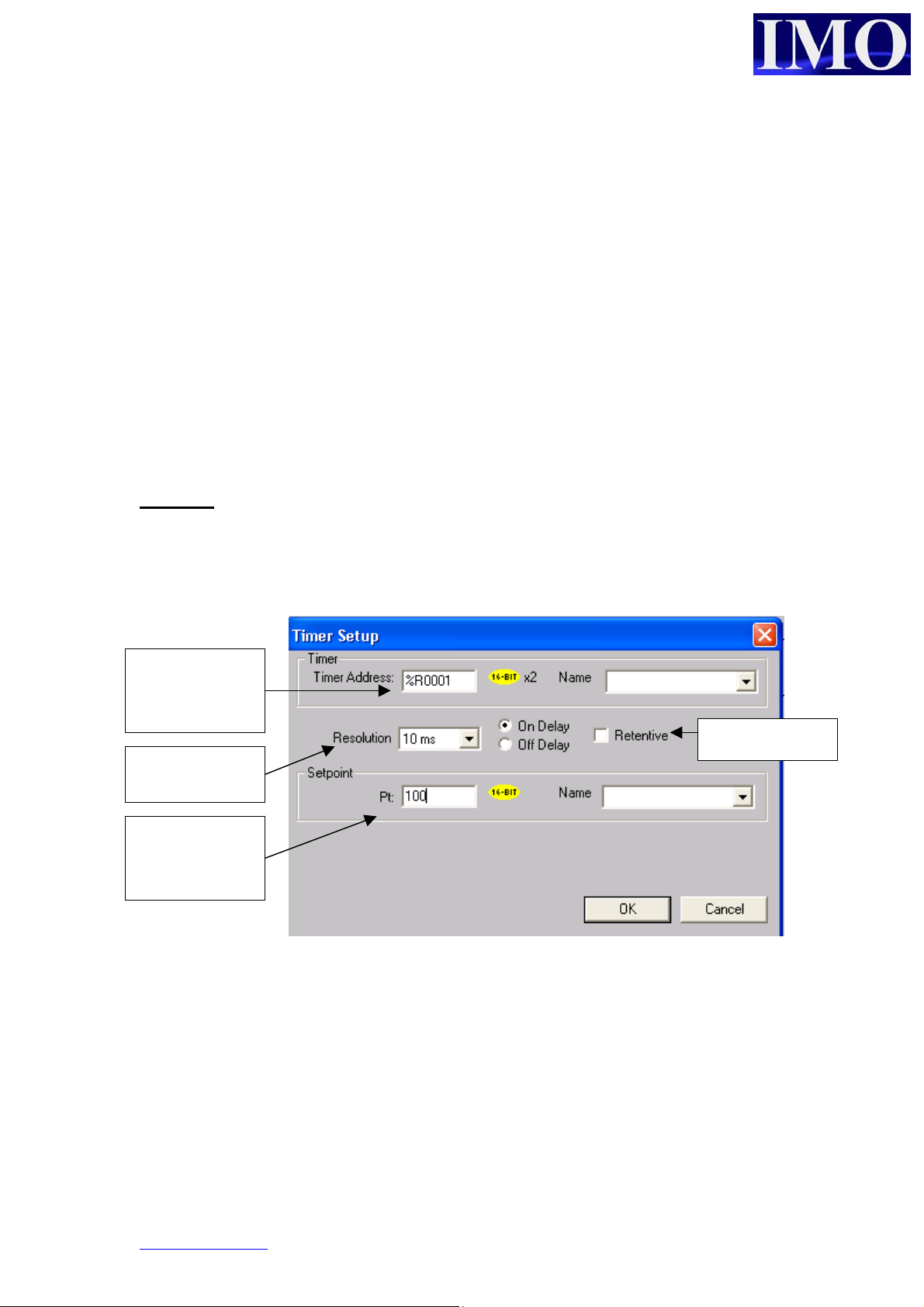

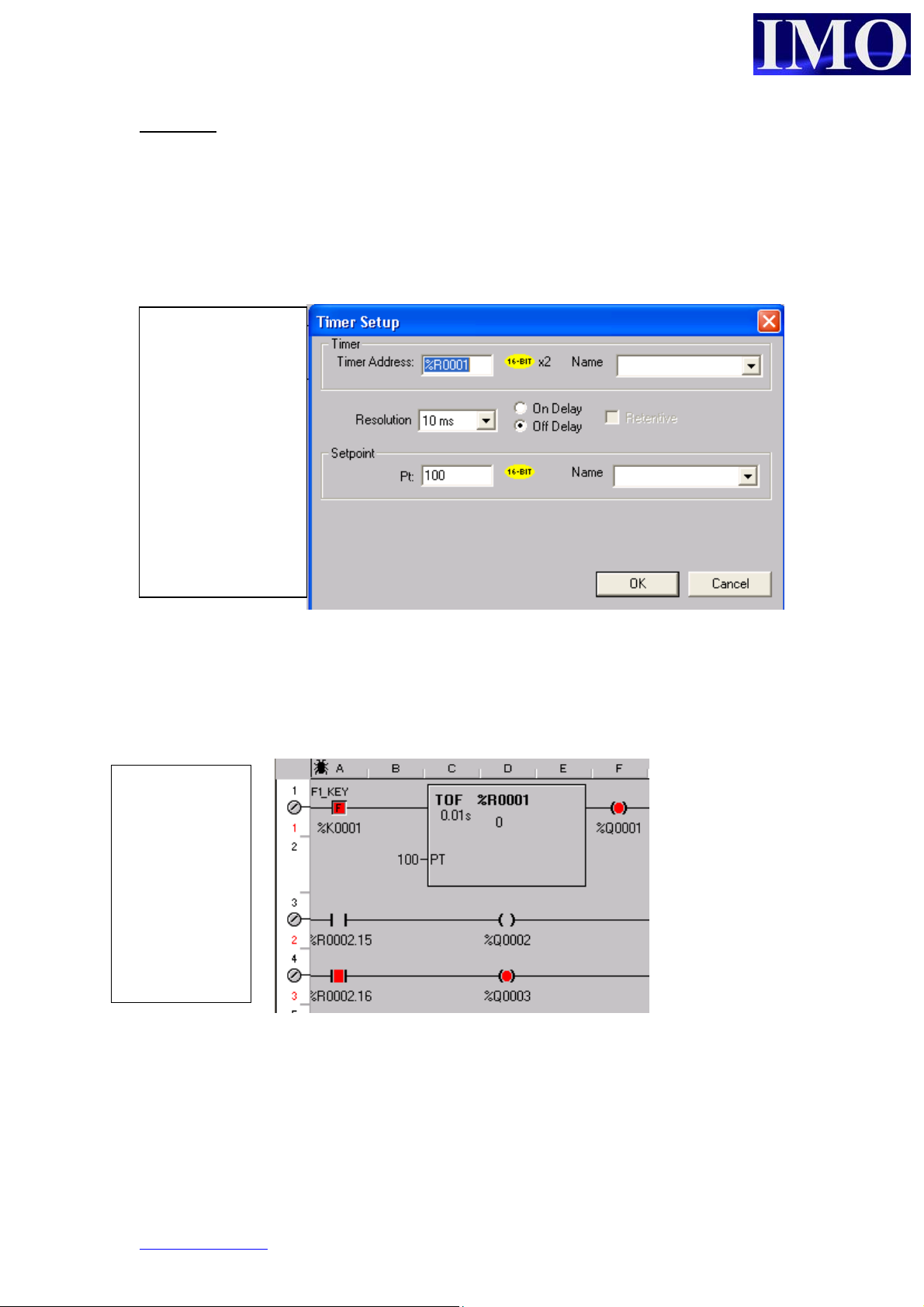

Timer Set up

There are two types of timer, on delay and off delay. The On delay timers can be

retentive.

On Delay

Delays before the output goes high. On being enabled the timer starts. When elapsed

time reaches the Preset the output will energise. The output will remain energised

until the input to the timer has been removed.

Consecutive

registers %R01

and R02

Either 10ms or

100ms

Set point can

be a register or

a constant

Timer options

www.imopc.com 14

Page 14

Basic Operation

p

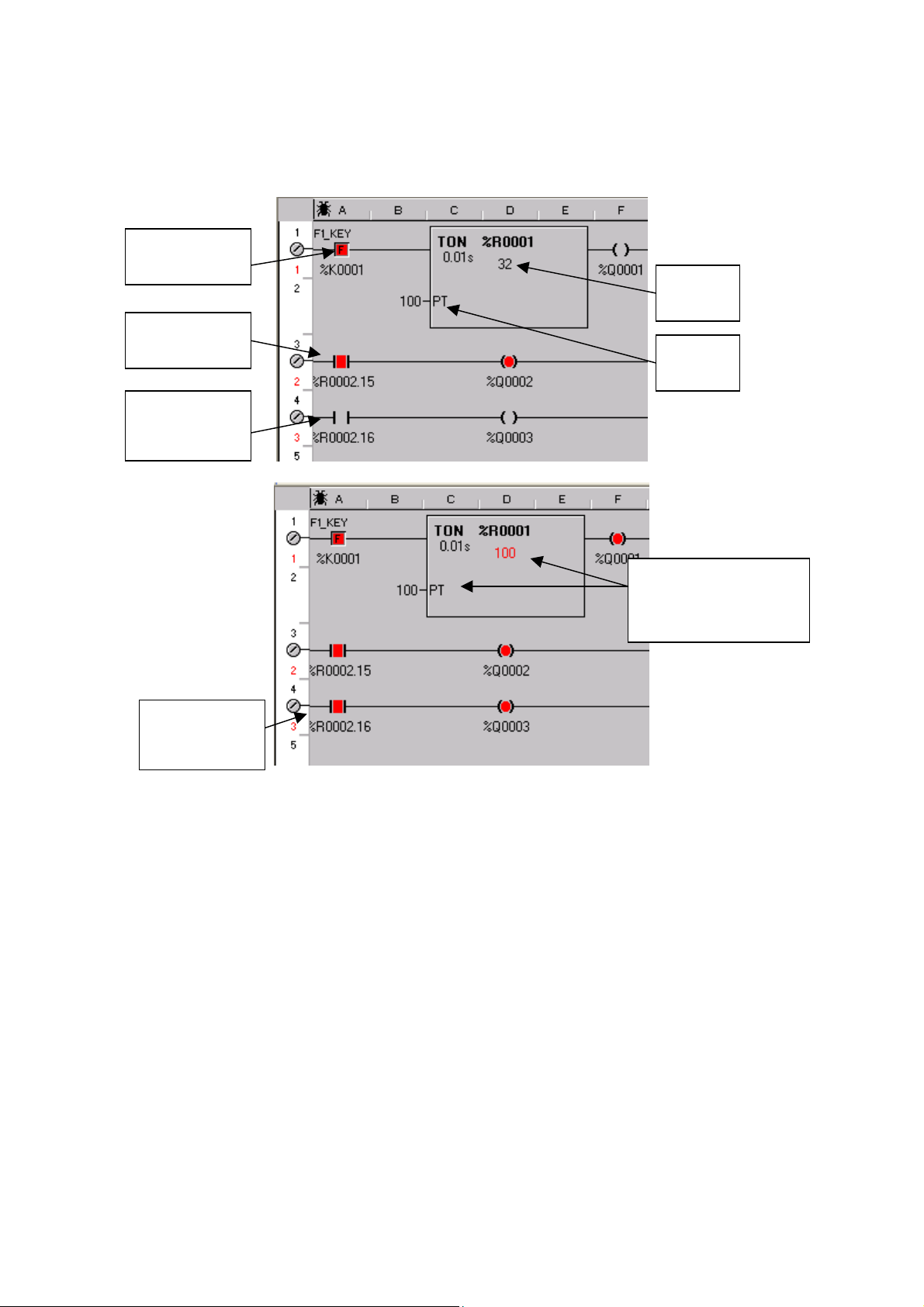

Example 4:

This is an example of a 1s On delay timer.

F1 enables

the timer

Timer

enabled

Timer is not

complete

Current

value

Preset

value

Timer output

is energised.

Current value =

reset value and the

output is high

© IMO Precision Controls ltd. 15

Page 15

p

b

f

N

Off Delay

The Off delay timer provides a delay before switching the output off when the input is

enabled. When the input is removed the timing will begin, when the elapsed time

equals the preset the output will reset.

The setup window

is the same as the

revious example

ut the “Of

Delay” button is

checked.

otice that the

Retentive button is

no longer available

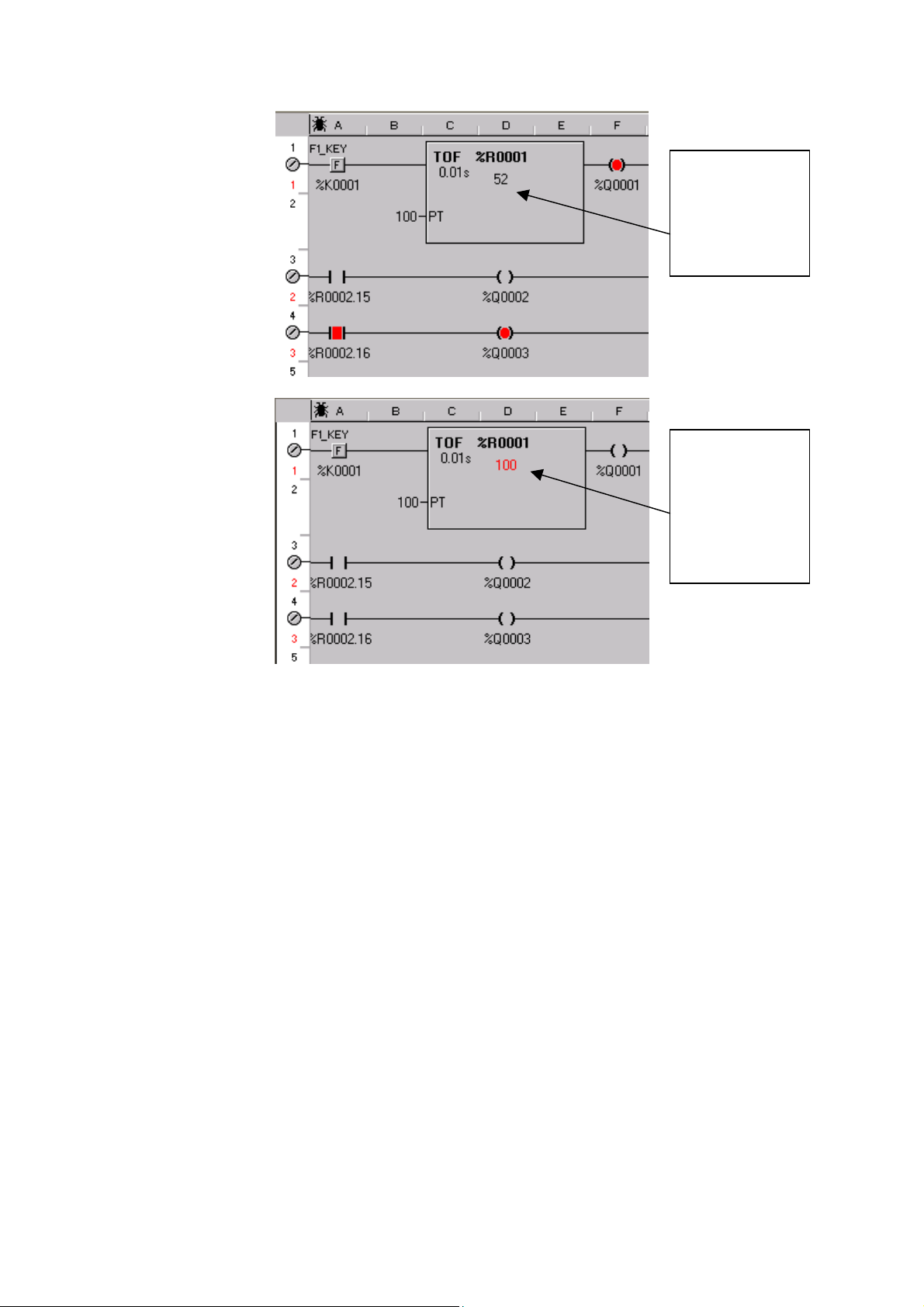

Example 5:

This is a 1 second Off-delay Timer. The output (%R0002.16) is energised when the

input (%K0001) is made and will remain energised for 1 second after the input is

removed.

The input to

the timer has

been enabled

and the output

is high.

When the input

is remove the

timing begins.

www.imopc.com 16

Page 16

Basic Operation

p

The output

remains high,

whilst the

current value is

accumulating.

The current

value now

equals the

reset value

and the timer is

now off.

© IMO Precision Controls ltd. 17

Page 17

p

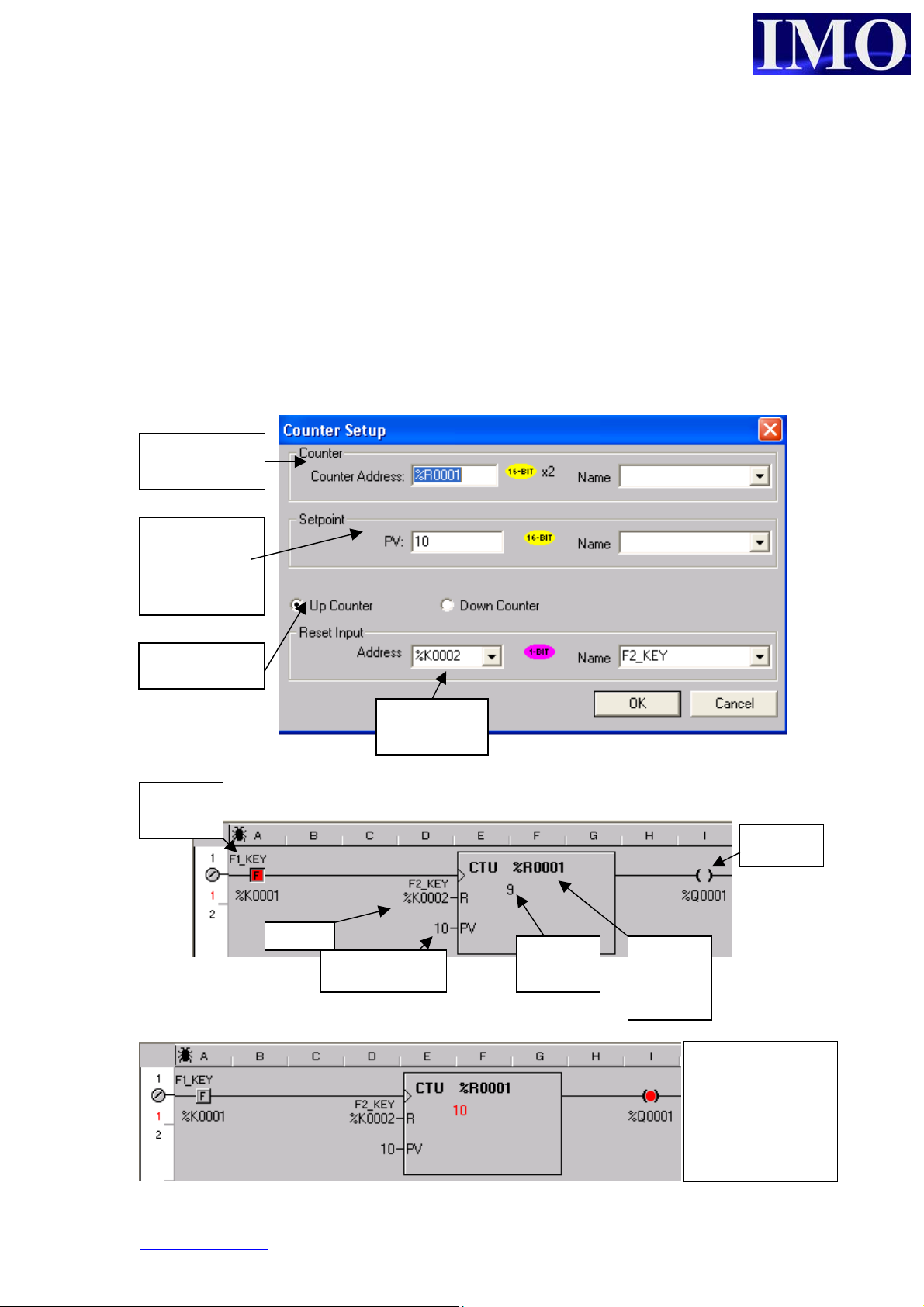

Counter Set up

There can be two types of counters, Up Count and Down Count. All the counters

increment / decrement the current value on the positive edge of a defined input and

require a Reset input.

An up counter will increment its current value from 0 to the preset value at which

point the output is energised. A down counter will decrement its current value

(starting at a value equal to the Preset) until the current value reaches 0 at which point

the output is energised. Both counters will overtake the preset if input pulses continue

to be applied to the counter after the output is energised.

Consecutive

registers (2)

Set point can

be a register

or a constant

Counter type

Input to

counter

reset

Select the

Reset input

Preset value

output

Current

value

Starting

counter

register

The count value

has reached the

reset energising

the output.

www.imopc.com 18

Page 18

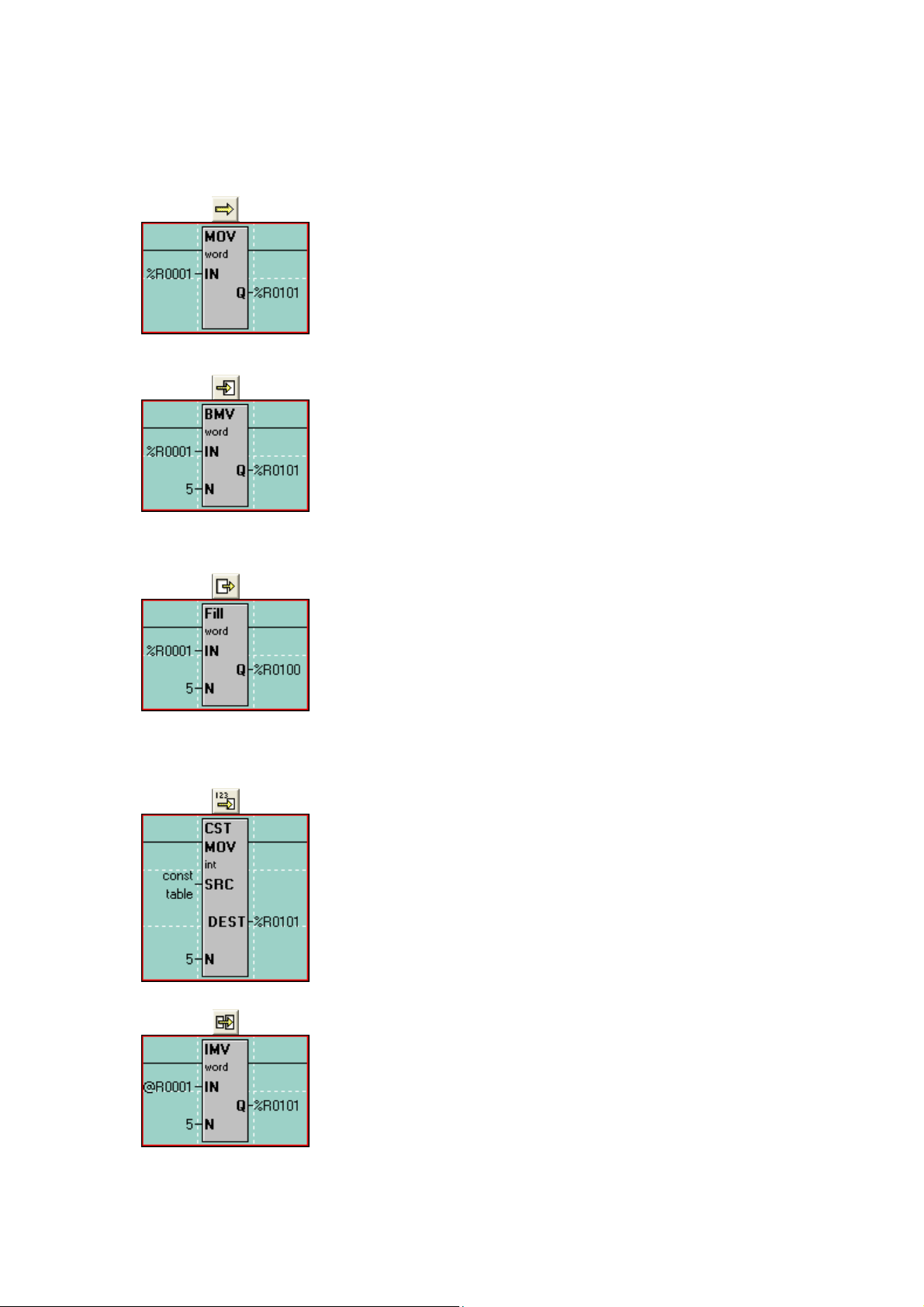

Move Functions

Basic Operation

used to copy a single byte, word or double-word from one

location to another. The count is locked at 1. In the case of the

example to the left, the value in %R1 is copied into %R101.

This only happens when the ladder rung receives power. The

value in %R101 is NOT taken back out when power is lost to

The first type of Move is the ‘Move Word’, or ‘MOV’. It is

the rung. The IN can be either a register or a constant value.

The next type of Move is the ‘Move Data Block’, or ‘BMV’.

It is used to copy a group of bytes, words or double-words to

another location. The count (N) determines how many

registers are to be copied. In the example to the left, %R1%R5 are copied into %R101-%R105. Again, this only

happens when the ladder rung receives power. The IN must be

a register reference and constant values are not allowed.

The next type of Move is the “Fill WORD”, or “Fill”. It is

used to copy the contents of a single register or value into

multiple other registers, thus filling that one value into a group

of registers. The count (N) determines how many registers to

fill that single value into. In the example to the left, the value

in %R1 is copied into %R101-%R105 so that %R101-%R105

all will have the same value in them. This can be used to zeroout a group of registers. The IN can be either a register or a

constant value.

The ‘Constant Move’, or ‘CST MOV’, it is used to move a group of

constant values into a group of consecutive registers. If, for

example, you want to move the values 1, 2, 3, 4 and 5 into %R101,

%R102, %R103, %R104 and %R105, respectively, then you can use

the Constant Move function. The count (N) is automatically

determined by how many constant values you enter into the

configuration for this function. The source data can ONLY be

constant data and cannot be register references.

The ‘Indirect Move’, or ‘IMV’, it is used to move data from variable

positions or to variable positions or both. It functions, for the most

part, like the Block Move function. If specified as Indirect, the IN

and/or the Q are used as pointers to where in the %R registers to get

data from or put data to. When looking at the ladder logic, the @

symbol will appear next to the IN or Q address if it is specified as

Indirect. This function is used in data logging applications.

© IMO Precision Controls ltd. 19

Page 19

Indirect Move Examples

In this example, the IN is specified as Indirect. This means the

controller will look at %R1 and see a value within it. If %R1 has a

value of 501 in it, the controller will go to %R501 to get the source

data. 5 registers will then be moved from %R501-%R505 to

%R101-%R105.

In this example, the Q is specified as Indirect. This means the

controller will look at %R101 and see a value within it. If %R101

has a value of 851, the controller will take the data in %R1-%R5 and

move it into %R851-%R855.

In this example, both the IN and the Q are specified as Indirect. This

means the controller will look at %R1 and see a value. Let’s say it is

241. The controller also looks at the value in %R101. Let’s say it is

341. The controller will then take the values in %R241-%R248 and

move them into %R341-%R348.

www.imopc.com 20

Page 20

Basic Operation

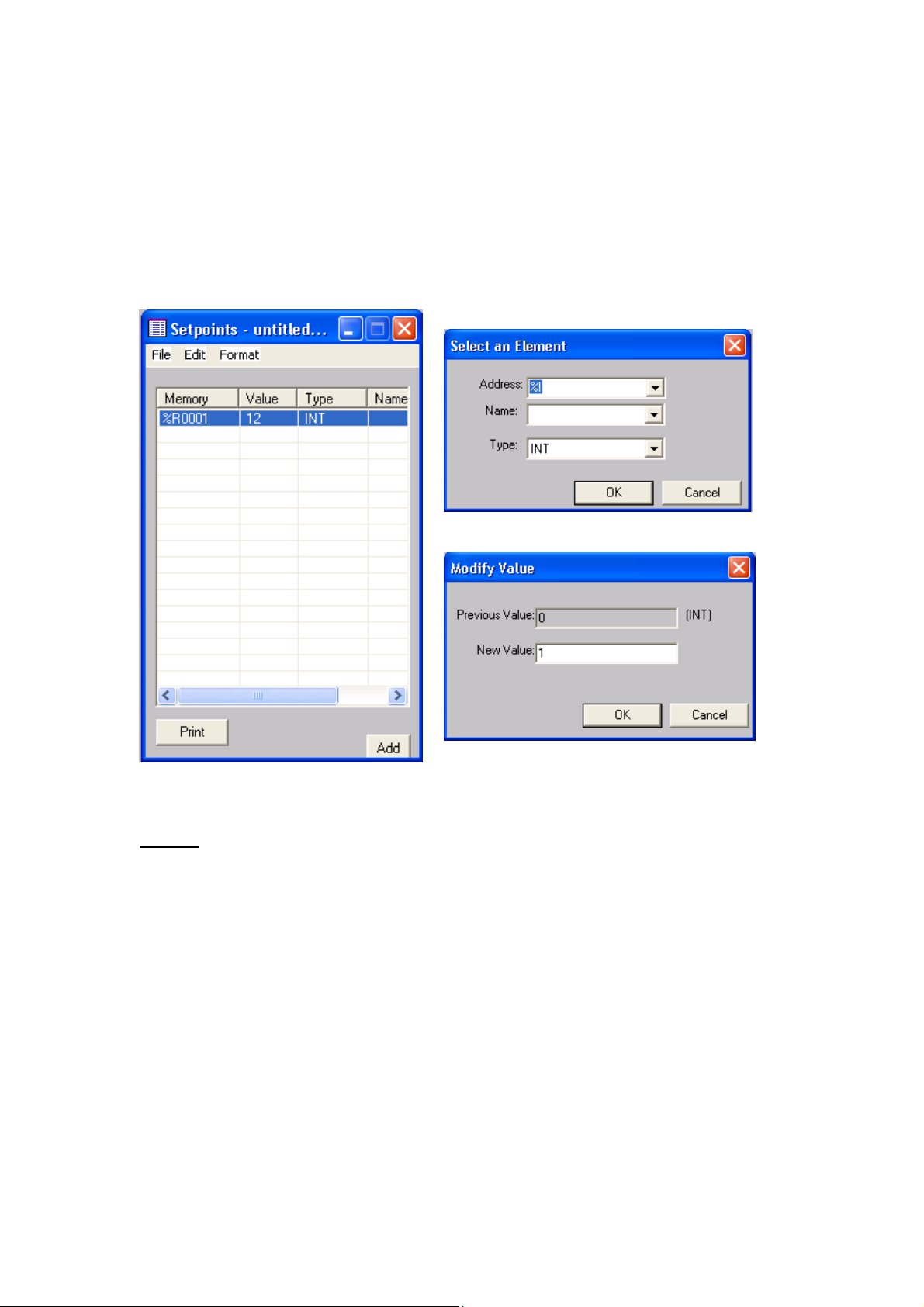

Set Points

It is possible to set registers with initial values by using the set point editor. To open

it, select the Setpoint option from the program menu.

From within the editor we can “Add” a new register. Double click on the Value

column to enter a Setpoint.

NOTE:

The Setpoint button must be selected in the Download Options when you are ready to

3

i

download the application program into the

.

© IMO Precision Controls ltd. 21

Page 21

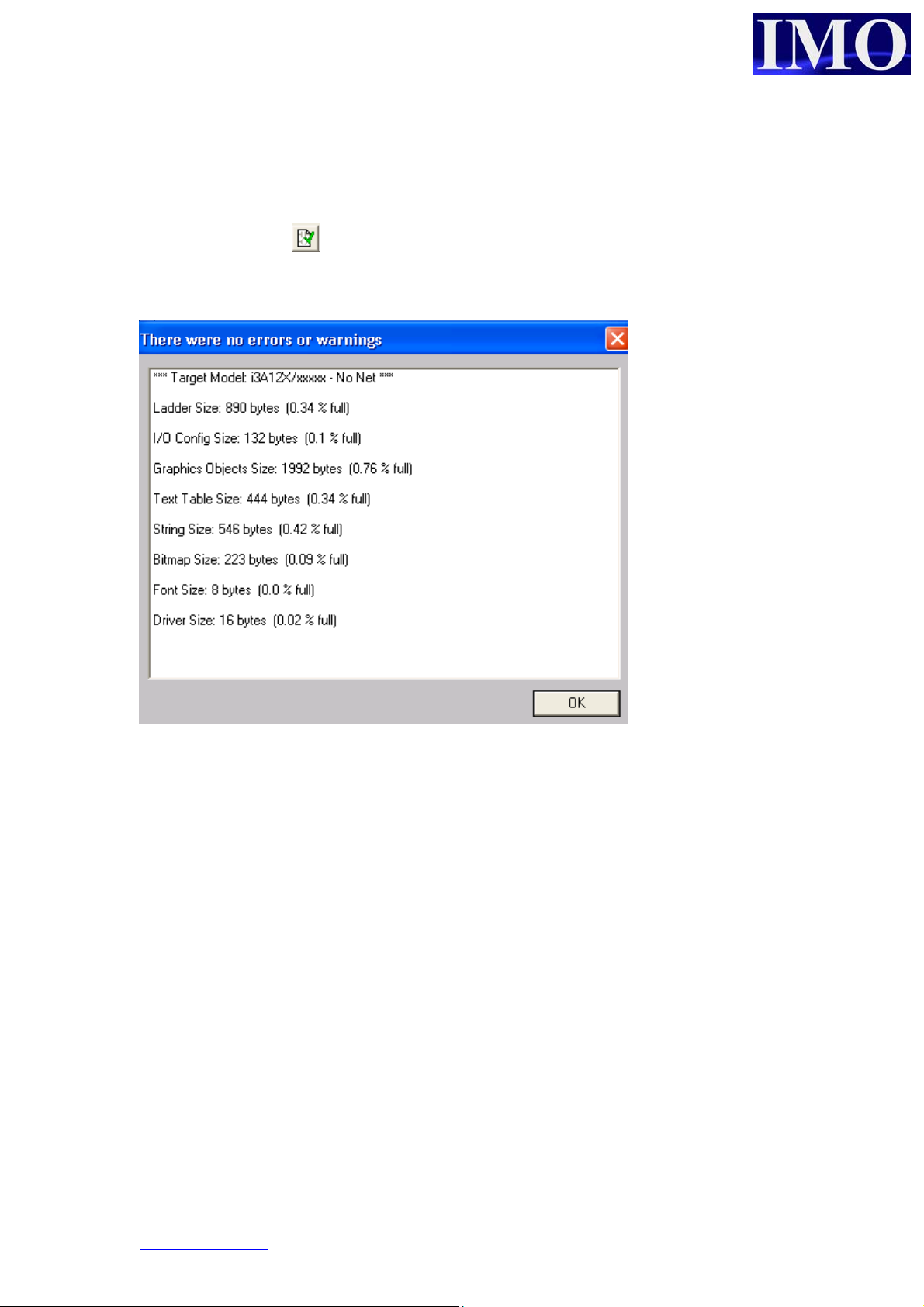

Download Options

Once you have created the Ladder logic and user screens the program can be verified

by clicking the icon . This will check the program for any errors. If there no errors

are detected in the program or configuration of the i3 the download can proceed.

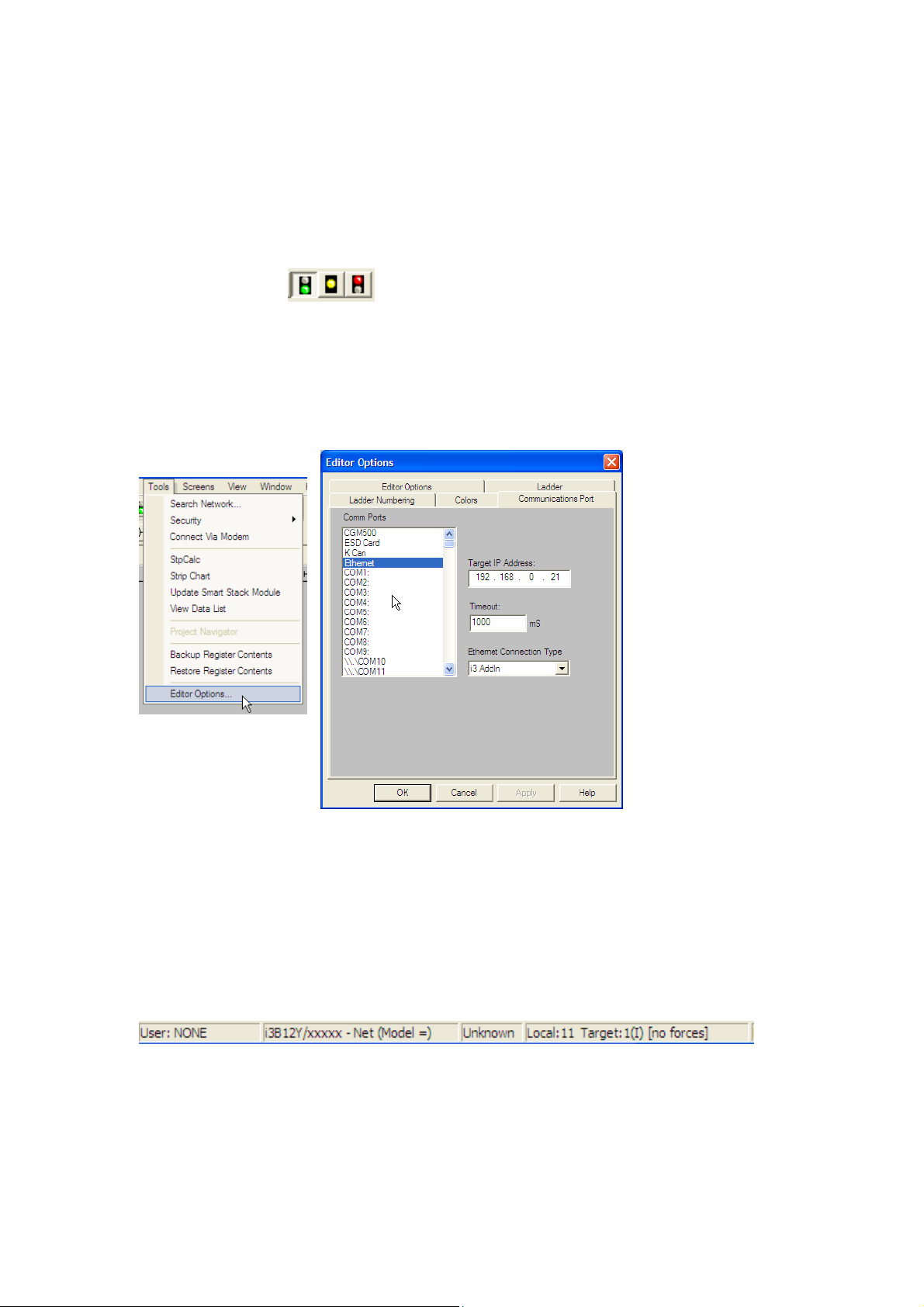

Connecting to your i3

It is important to understand a little of how the

designed in order to do this correctly. The Configurator is also a complete Project

Management System capable of connecting to multiple i3 Controllers simultaneously

to debug an entire iCAN network. This means that you may have as many as 252 i3

Controllers linked together via the CAN port. Then by linking your PC via an

Ethernet, Serial, or Modem link to just one of them; you can debug and monitor them

all. So therefore, each project has the Network ID for that device stored as one of the

settings.

3

i

that does not have a CAN port, such as the basic 10A01 model, has a default

An

network ID of 253 (above the usable range of 1 – 252) as it will never be part of a

network. When creating a new project for a device without CAN the

defaults the network ID to 253. When creating a new project for a device with CAN

the software defaults the network ID to 1 – as is the default setting of a CAN enabled

3

i

. Problems can occur if a project is started with the device configured for one option,

3

i

Configurator software has been

3

i

Configurator

www.imopc.com 22

Page 22

Basic Operation

then switched to the other at a later time. The result will be a mismatch in the network

ID settings between the Configurator project and the i3 (it is trying to communicate

with ID 253 when the device is set at 1, or communicate with ID 1 when the device is

set to 253).

Also, the comms engine of the i3 Configurator constantly runs in the background as

soon as the software is started. The first indicator that Comms are established is that

the ‘Traffic Lights’ will show the status of the connected i3, as one of the

buttons will appear depressed.

If this does not occur then the comms settings can be verified as shown below. This

shows an Ethernet connection. Care must be taken if using a USB to Serial Adapter

that the Com port assigned to the adapters matches the one selected through these

options.

At the bottom of the Configurator screen we can see the status bar. This is showing

that we are Locally connected to the i3 of Network ID 11. This is the device that we

are physically connected to. But, it is showing the Target ID of 1. So, despite being

connected to ID 11; we are actually configuring/debugging/monitoring the i3 with an

ID of 1. It is showing us that this is an i3B model with CAN Net, but no I/O

configuration as yet (/xxxxx).

© IMO Precision Controls ltd. 23

Page 23

Configuring the correct model.

Before downloading the program it must be configured to match the model of i3 to be

used.

Select the I/O

configure from

the controller

menu.

Then click the

“Auto Config System”

button ensuring the i

3

is connected to the PC

with an i3PC45 cable.

When

configured

3

the i

part

number will

match the

unit.

www.imopc.com 24

Page 24

Basic Operation

p

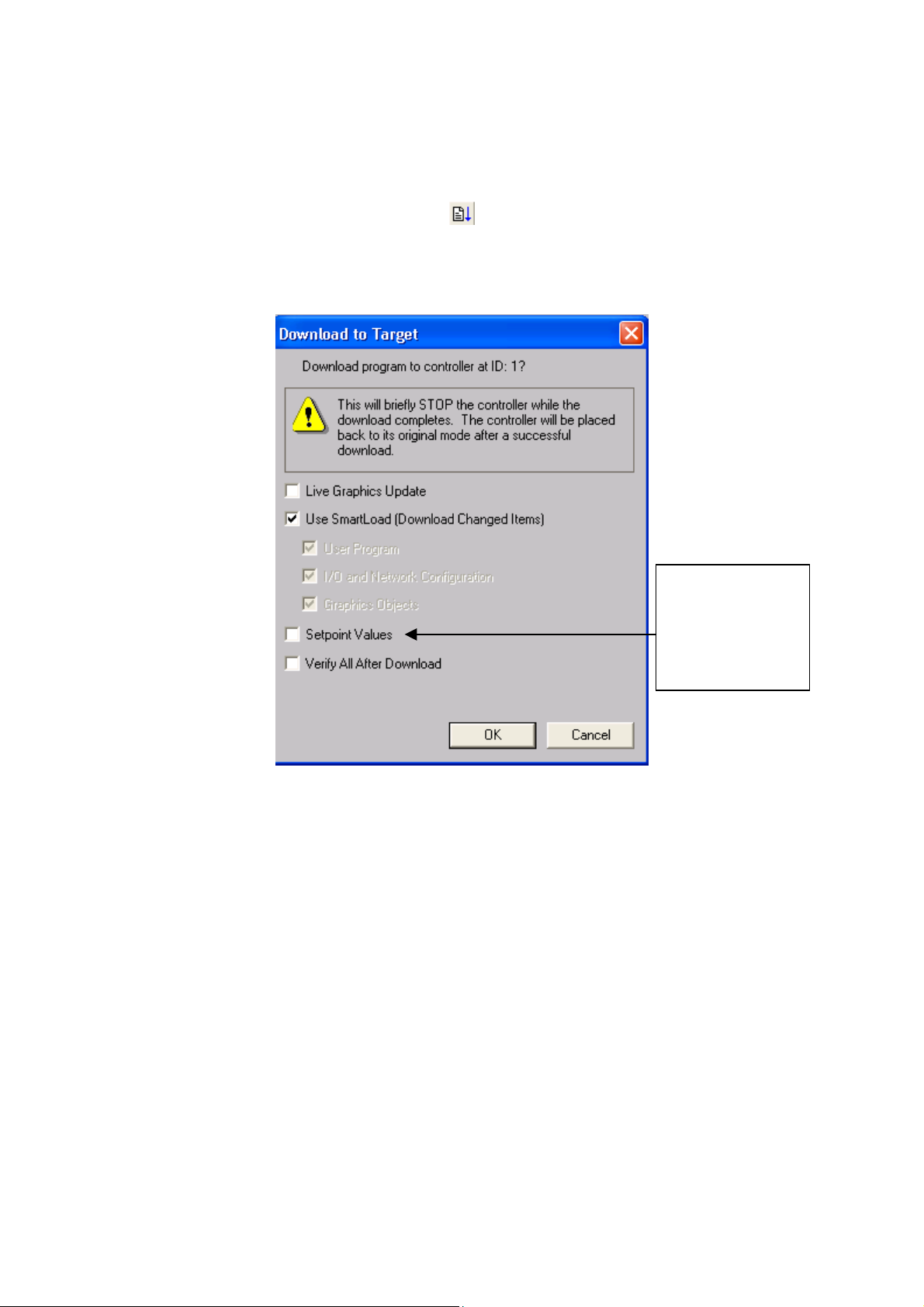

Downloading the Program

Then to download to the i3 click the icon or select Download from the Program

Menu.

The “Download to Target” menu will appear.

If you want to

download set

oints, ensure

that this option is

checked.

© IMO Precision Controls ltd. 25

Page 25

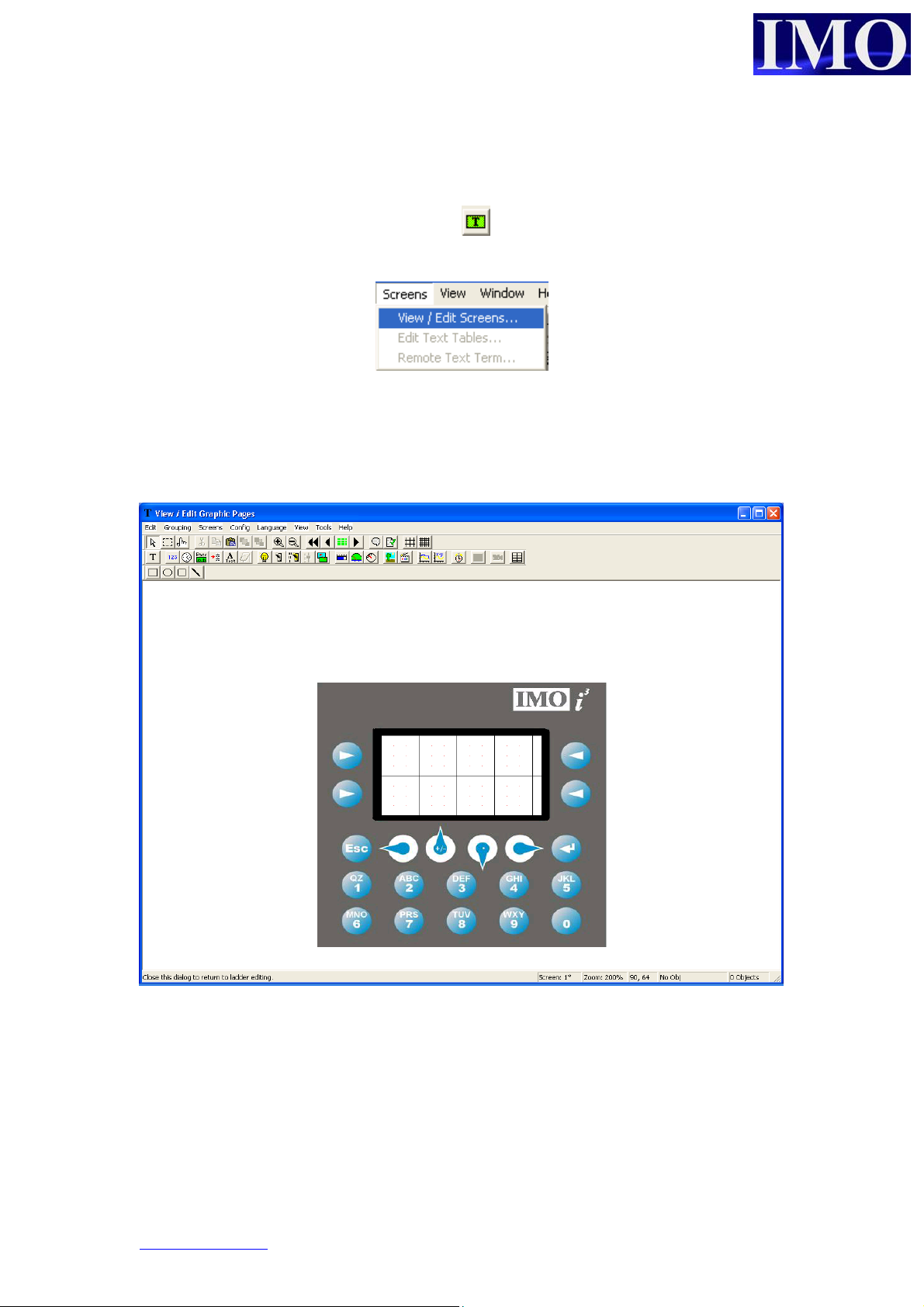

Screen Editor

To open the screen editor click on the icon or select the option from the screens

menu.

Please note that a default screen needs to be configured before a program can be

downloaded to an i3.

Before editing screens it is important to configure the I/O as previously described.

The screen editor program shows the i3 in the middle with the programming functions

at the top and screen information in the bottom right corner. To exit click the top right

corner where the X is.

www.imopc.com 26

Page 26

Screen Editor Tool Bar.

r

d

r

r

N

r

p

umeric data

Static text

RTC data

Text table

Passwor

otepad (i3B Models)

ASCII data

Menu Item

Lamp

Basic Operation

Switch & Selecto

Slider (i3B Models)

Bar Graphs, Gauges

Screen Jump

& meters

Static Bitmap

&Animation

Trends and XY Graphs

Removable Media

Alarm Handle

Menu (option)

e Edit

Reci

Selectors

Operator Stimulato

Cut, Copy,

Paste

Screen Ordering

Zoom

Scroll through

screens

View Screen

Drawing Tools

Bottom right corner of Editor

Screen

numbe

Zoom view

Cursor location

on screen in i3Object location

3

on screen in i

screen

3

umber of objects

in i

Check code

documentation

Snap to Grid lines

© IMO Precision Controls ltd. 27

Page 27

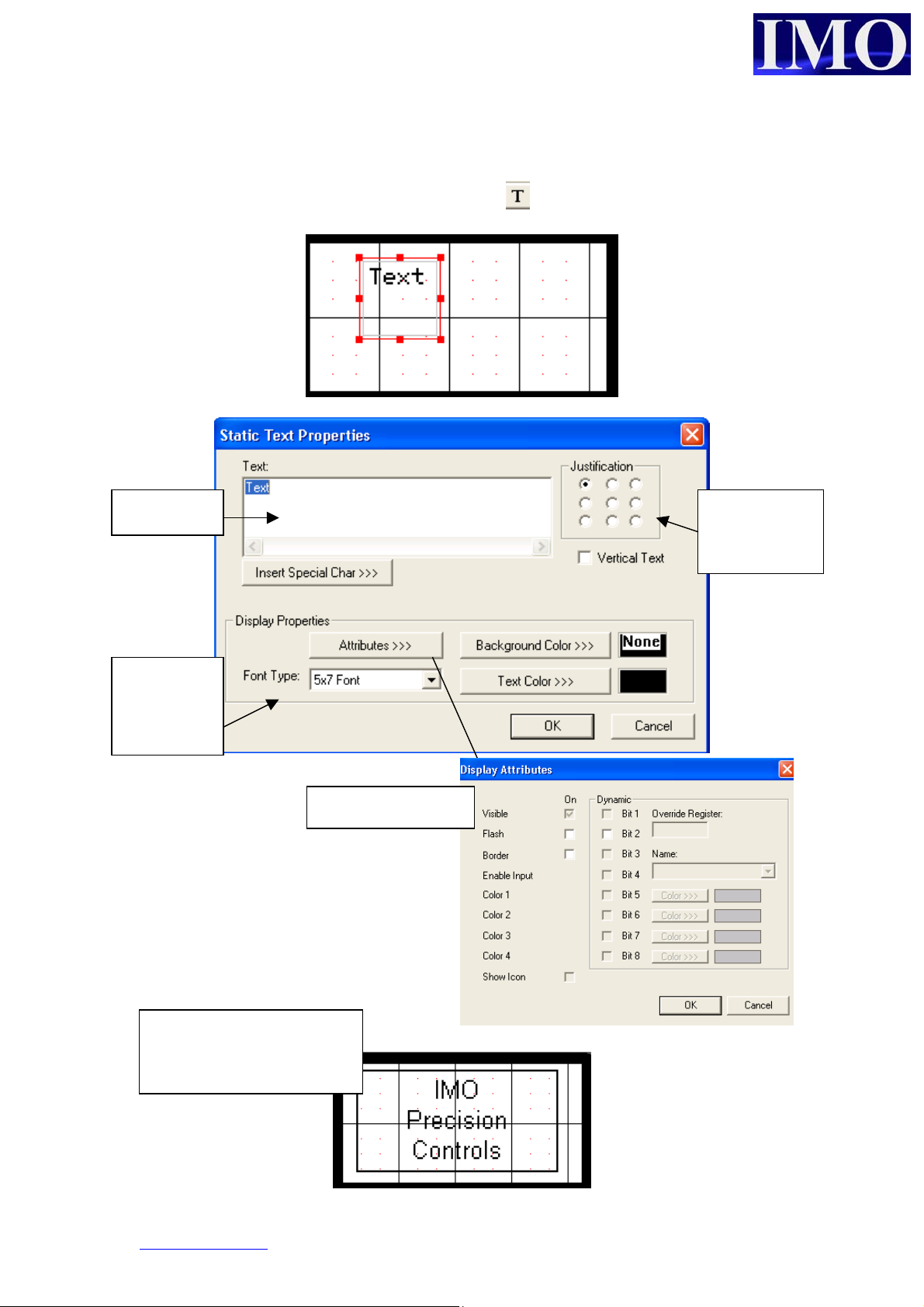

Static Text

To insert a Static Text message click on the icon and click it to the screen.

The box can be

resized as required.

To enter the text to

be displayed double

click on the box.

Insert your

text here.

Select Font

type from

the menu.

Once you have correctly

set up the static text, click

OK to confirm and exit

Display Attributes.

Justification

within the

text box

www.imopc.com 28

Page 28

Basic Operation

Numeric Data

To insert a numeric data display click on the icon and click it into the screen.

The box can be resized as

required. To Enter the

details of the numeric data

double click on the box.

The Legend of the Numeric

Field can be modified as

required.

The address of

the data to be

displayed

display

Editable

allow the

user to

enter data

through the

screen

© IMO Precision Controls ltd. 29

Page 29

R

Time Data

To insert a time data display click on the icon and click it into the screen. Double

click the box to edit the properties.

The system

time is stored

in

consecutive

SR registers

from %SR44

It may simpler to

select the RTC

registers by

choosing their S

register name

www.imopc.com 30

Page 30

Basic Operation

p

d

Password

To insert a Password display, click on the icon and click it into the screen.

The password

box is similar to

the numeric data

display but the

numbers are

hidden.

Address where the

assword will be

entered.

Simple password logic uses

a Compare Function block.

When the Password Number

entered is equal to the store

value an additional control

condition can be unlocked.

© IMO Precision Controls ltd. 31

Page 31

N

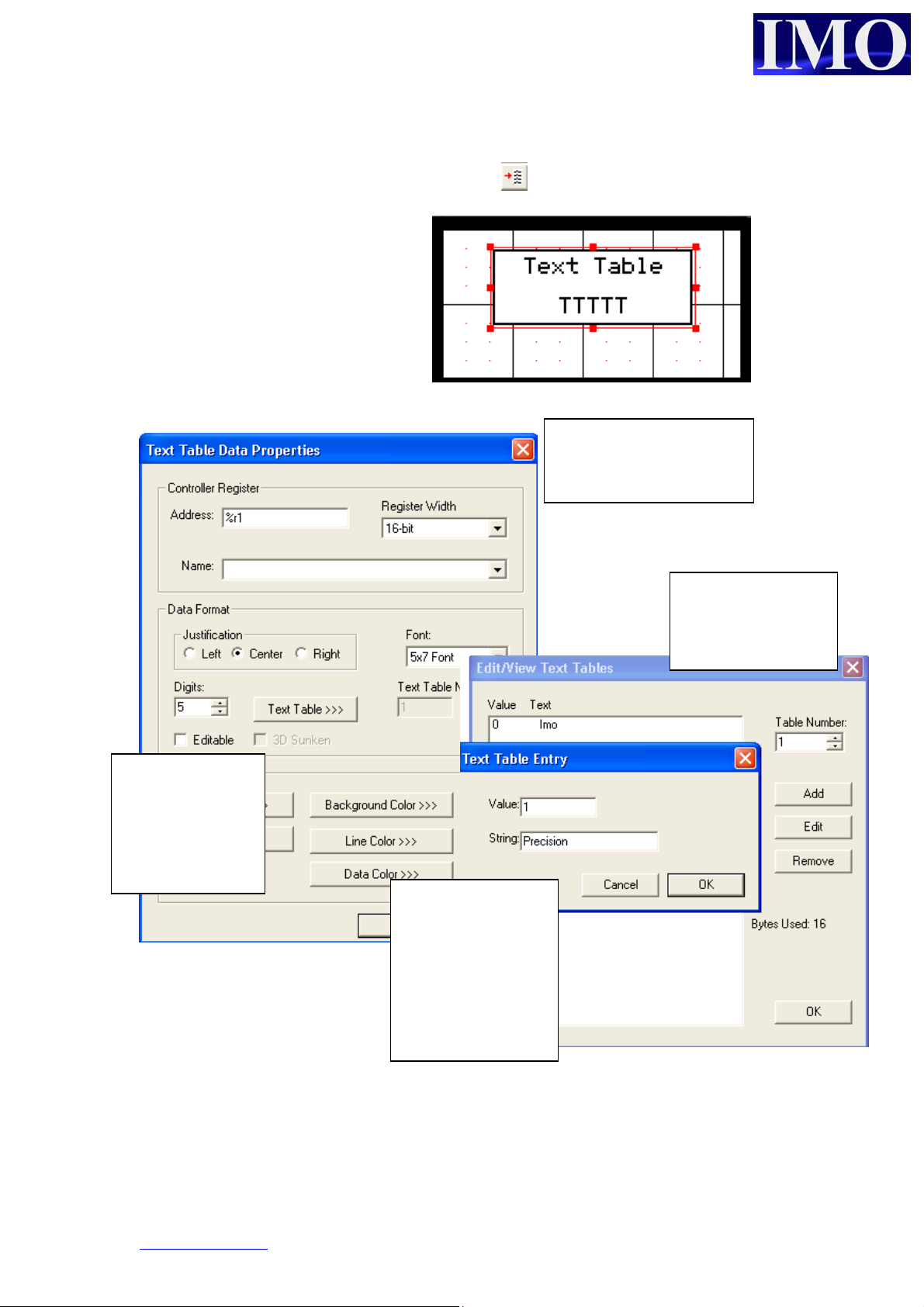

Text Table data

To insert a Text Table display, click on the icon and click it into the screen.

The text table can be used to

display text messages instead of

numeric data for a given register.

A message table can be

selected for a word, byte

or a bit.

There can be up to

255 tables and one

can be used more

than once.

The number of

digits to display

must match the

maximum length

of message to

display.

Select a value and

enter a message to

correspond to it.

ow the message

will be displayed

instead of the

numeric value.

www.imopc.com 32

Page 32

Basic Operation

N

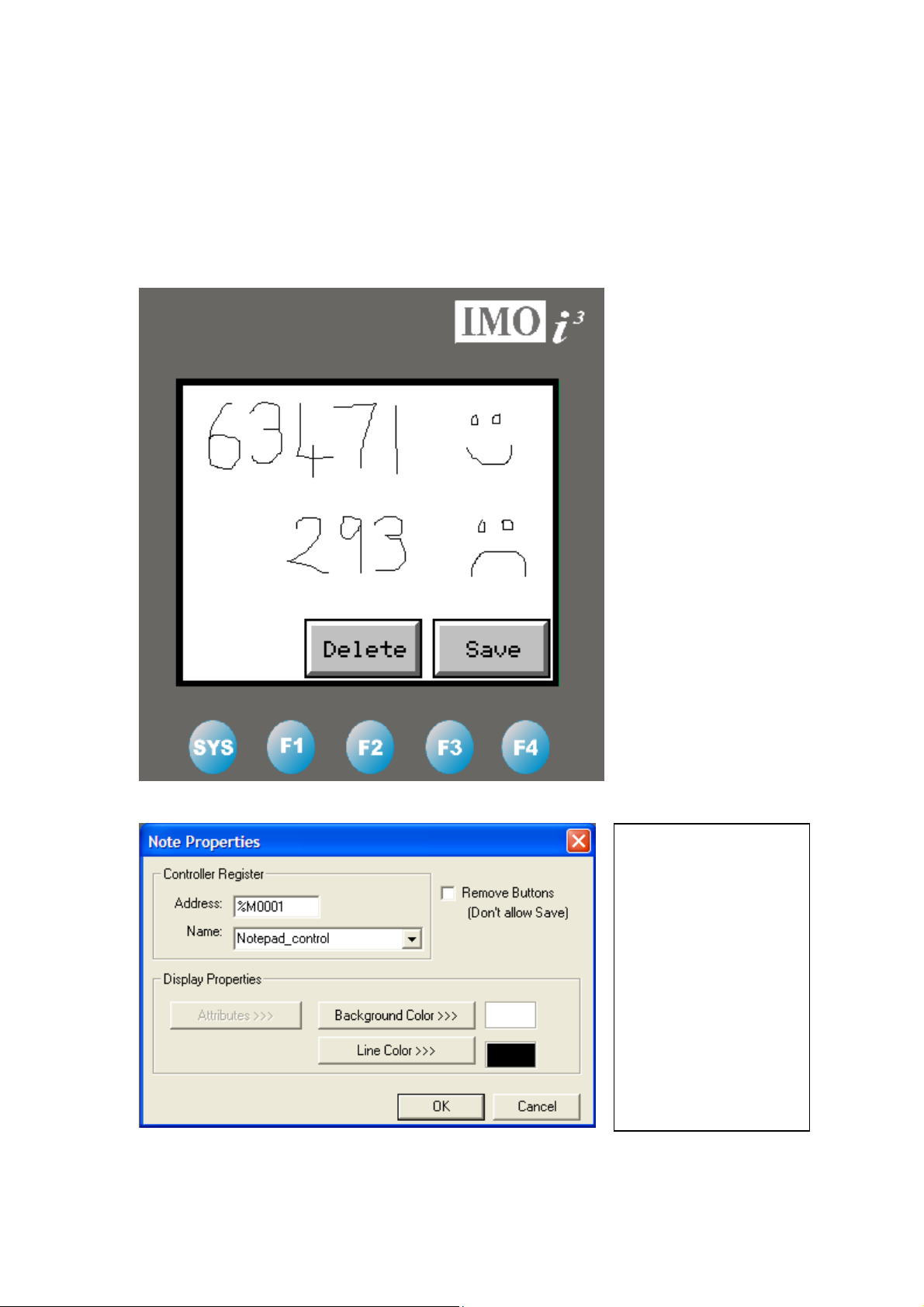

Notepad

This is function is only for touch-screen models such as the i3B12Y range. It provides

the operator with a screen upon which they can write or draw a simple diagram. This

data can then be stored into the HMI memory for recall at a later date. A useful

feature should an operator find themselves without a pen and in need of writing down

batch numbers.

The Controller

Register enables or

disables the Note

Object. The Remove

Buttons checkbox

removes the ‘Delete’

and ‘Save’ buttons

from the Note object

making sure it is

erased every time the

ote screen is exited.

© IMO Precision Controls ltd. 33

Page 33

p

i

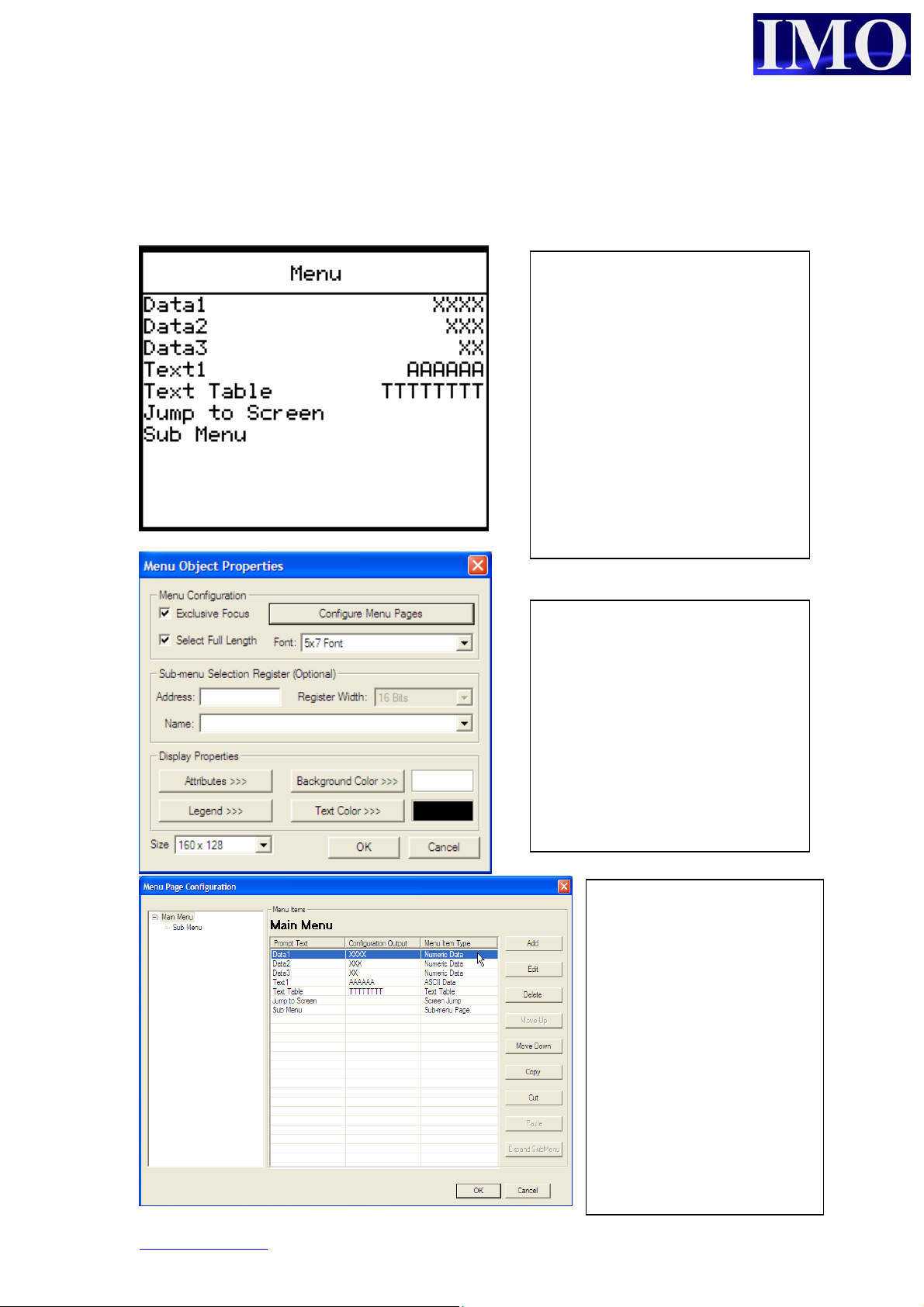

Menu Item

A Menu Item allows many settings and screens to be configured through one single

object.

Inside the Menu Item it is

ossible to easily configure

groups of Numeric Data Items,

Text Tables, ASCII text Items,

Passwords, Screen Jumps and

also Sub-menu items.

The Sub-Menus allow more pages

of configurable data to be

displayed, allowing an operator to

make many changes from within

a single screen.

The menu object is navigated via

the soft keys or touch screen.

If the Exclusive Focus is selected

then no other objects on the

screen can be activated.

Clicking on the Configure Menu

Pages button opens the window

below.

The ‘Size’ of the Menu must be

selected when using on a Touch-

3

Screen

.

Menu Items can be added,

then, configured in a similar

way to how they are outside

of a Menu Object by

specifying the Control

Register, Data Format, and

Display Properties. The

only difference is that

‘Prompt Text’ is used

instead of a Legend.

Sub-Menus can also be

added, to partition the data

into different areas as

required.

www.imopc.com 34

Page 34

Basic Operation

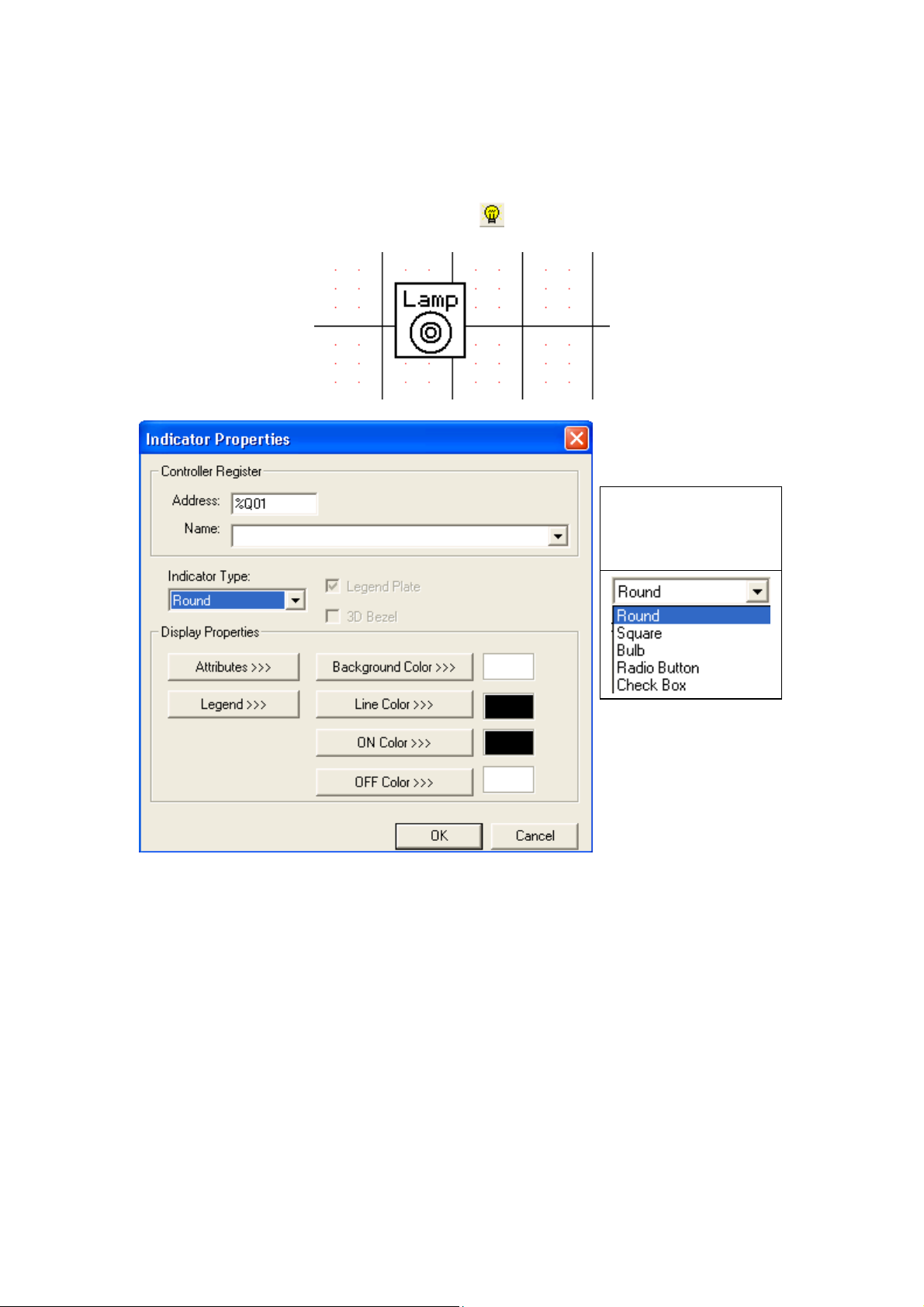

Indicator Lamp

To insert an indicator lamp, click on the icon and click it into the screen.

The indicator

lamp can only be

assigned to a bit

(Q, M, S or T).

There are several

different options for

display of lamp.

© IMO Precision Controls ltd. 35

Page 35

p

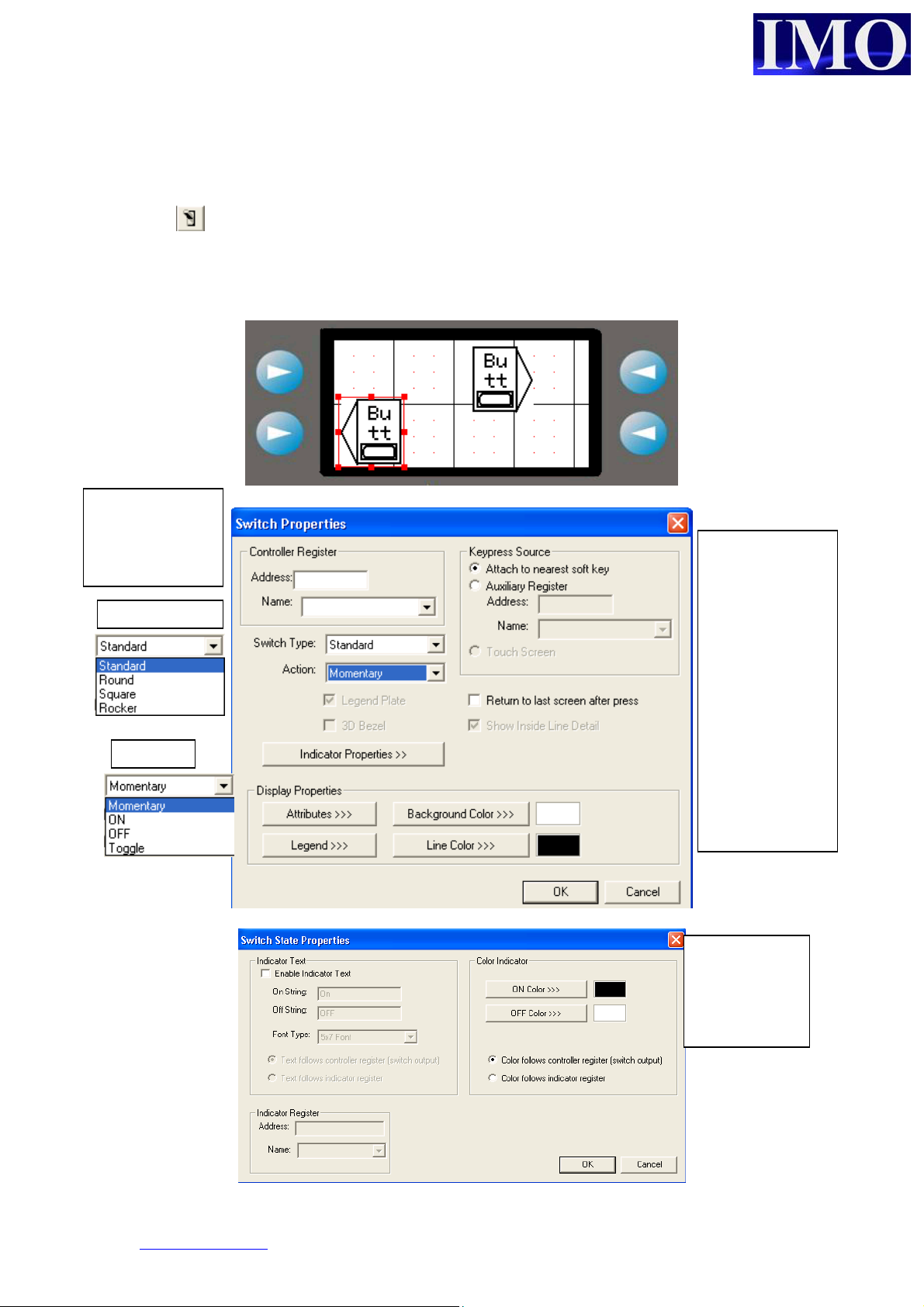

Button

There are four buttons that can be programmed through the screen editor, the

remaining keys are programmed in the ladder editor. To insert a button, click on the

icon and click it into the screen.

The button will then allocate itself to the nearest key next on the side of the screen.

Only one button can be assigned to a single key per screen.

The buttons are

binary and can

only be assigned

to a bit

Switch type

The Keypress

source defaults

at the nearest

softkey (4 keys

either side of

the screen.

However they

can be set to

another

address in the

3

i

.

We can also

edit the

indicator

roperties

www.imopc.com 36

Page 36

Basic Operation

Selector Switch

To insert a selector switch, click on the icon and click it into the screen.

It will then select the nearest buttons to it on either side of the screen. With the

selector switch the maximum the i3 can have is two positions.

A selector

switch will

be either one

of two states.

The

address

can be a

bit or a

register.

The items

can be

given

meaningful

names

© IMO Precision Controls ltd. 37

Page 37

Slider

This is an option only for touch-screen models such as the i3B12Y range. It is a quick

way to change a value inside a 16-bit register. The object can be configured with or

without extra buttons for fine control, and automatically changes it orientation from

horizontal to vertical depending how it is sized – similar to the Bar Chart Item.

The Slider has configurable

scale limits. It also has two

checkboxes that allow the

graphic of the slider to be

turned off along with the

Inc/Dec buttons.

www.imopc.com 38

Page 38

Basic Operation

Screen Jump

Screen jumps are allocated like buttons but are for jumping between screens in a

menu fashion. To insert a screen jump, click on the icon and click it into the

screen.

The jump

button will

allocate itself

to the nearest

key at either

side.

Select what screen number to jump to and the display properties of the button.

The Keypress

source defaults

at the nearest

softkey (4 keys

either side of

the screen.

However they

can be set to

another

address in the

i3 or can even

be selected

using the

cursor and

arrow keys

© IMO Precision Controls ltd. 39

Page 39

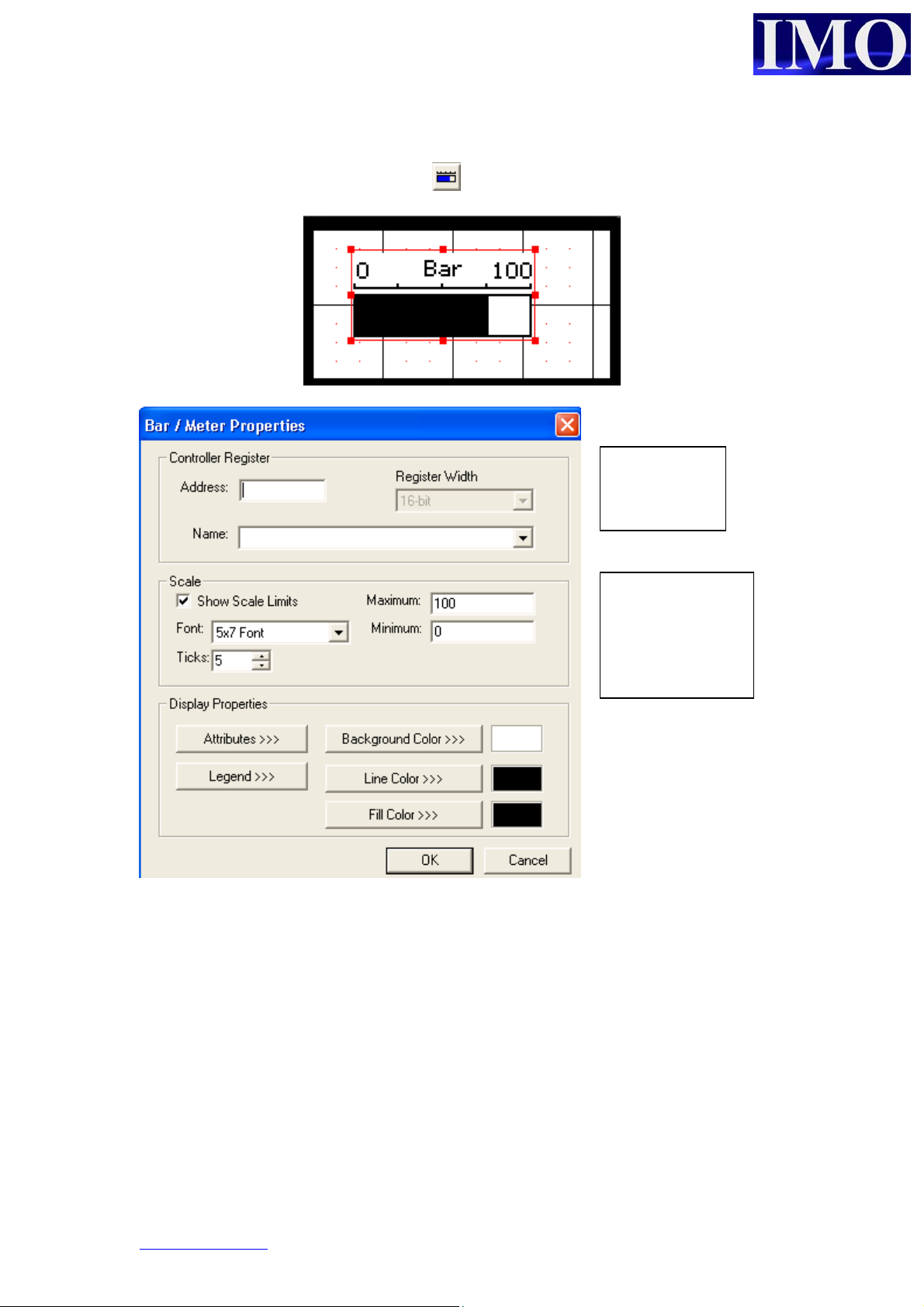

Bar Graph

To insert a bar graph, click on the icon and click it into the screen.

To graphically display

a register value on the

screen. Click on the

edge of the box and

drag to make the bar

graph bigger.

The bar

graphs must

be a word.

The bar graph

has to be scaled

and this can be

shown on the

screen.

www.imopc.com 40

Page 40

Basic Operation

b

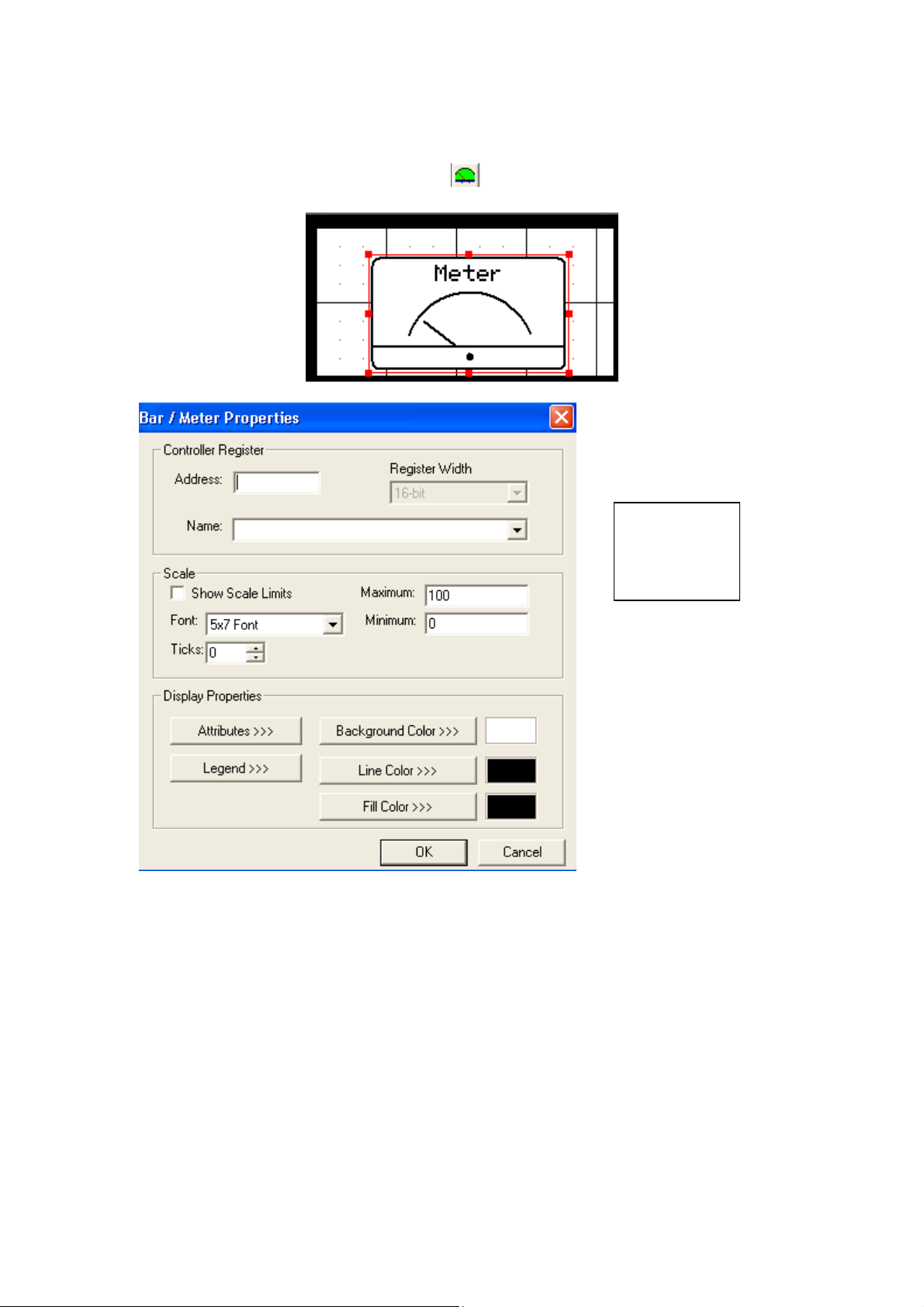

Meter

To insert a meter graph, click on the icon and click it into the screen.

Another option

to the bar

graph is o

display the data

as a meter.

The details

are the same

as with the

ar graph.

© IMO Precision Controls ltd. 41

Page 41

p

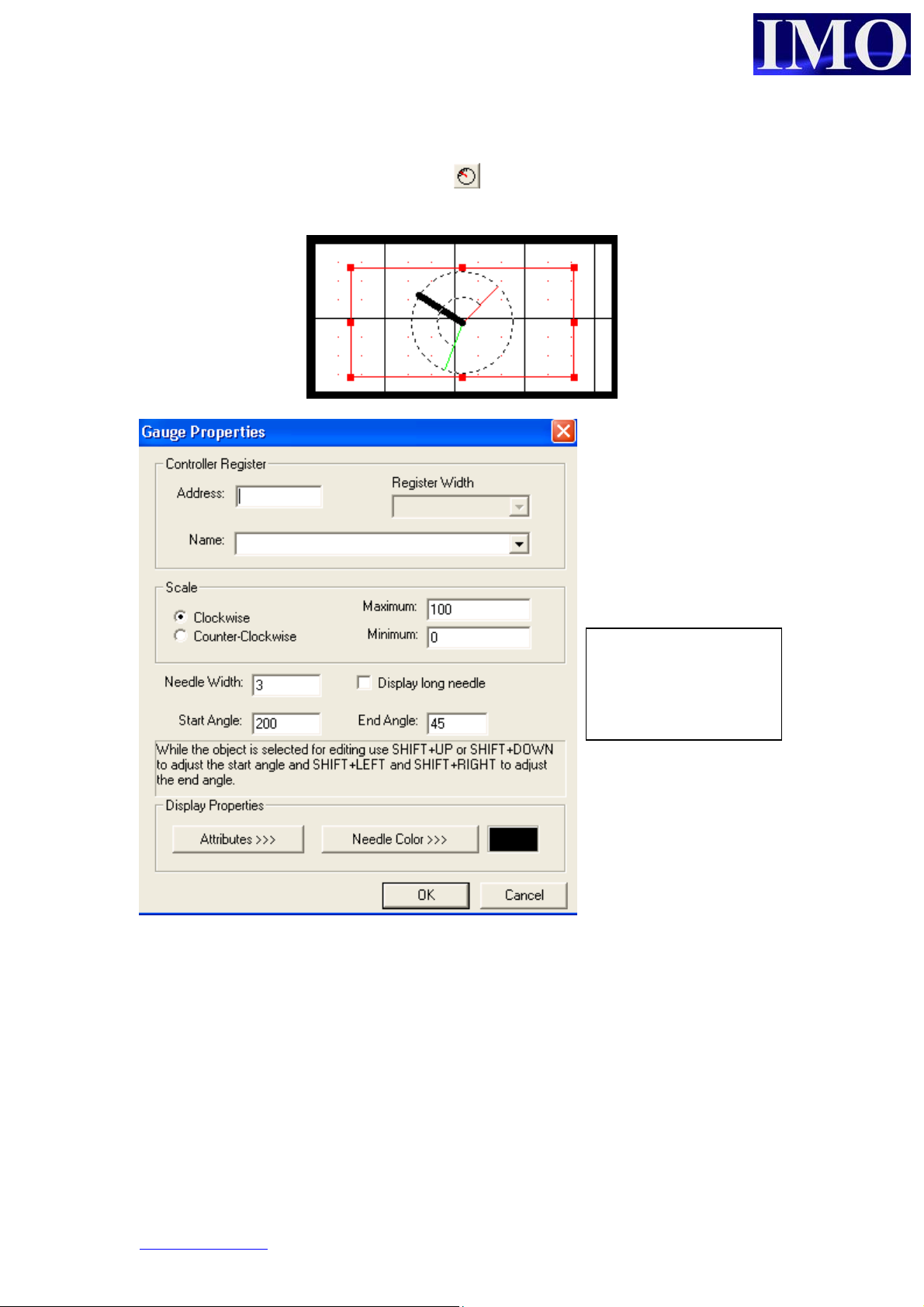

Gauge

To insert a gauge graph, click on the icon and click it into the screen.

The Gauge is more

complex than a bar /

meter. This gauge is

an automotive style

gauge and can be

laced over bitmaps.

Select starting and

ending angle and the

needle will rotate

within the set scale.

www.imopc.com 42

Page 42

Basic Operation

Static Bitmap

A bitmap can be used as a screen back drop, where a company logo can be inserted.

To insert a static bitmap, click on the icon and click it into the screen.

The i3 has a

mono screen,

therefore the

bitmap must

comply to these

restrictions.

Bitmaps can be created in simple packages like MS Paint.

© IMO Precision Controls ltd. 43

Page 43

b

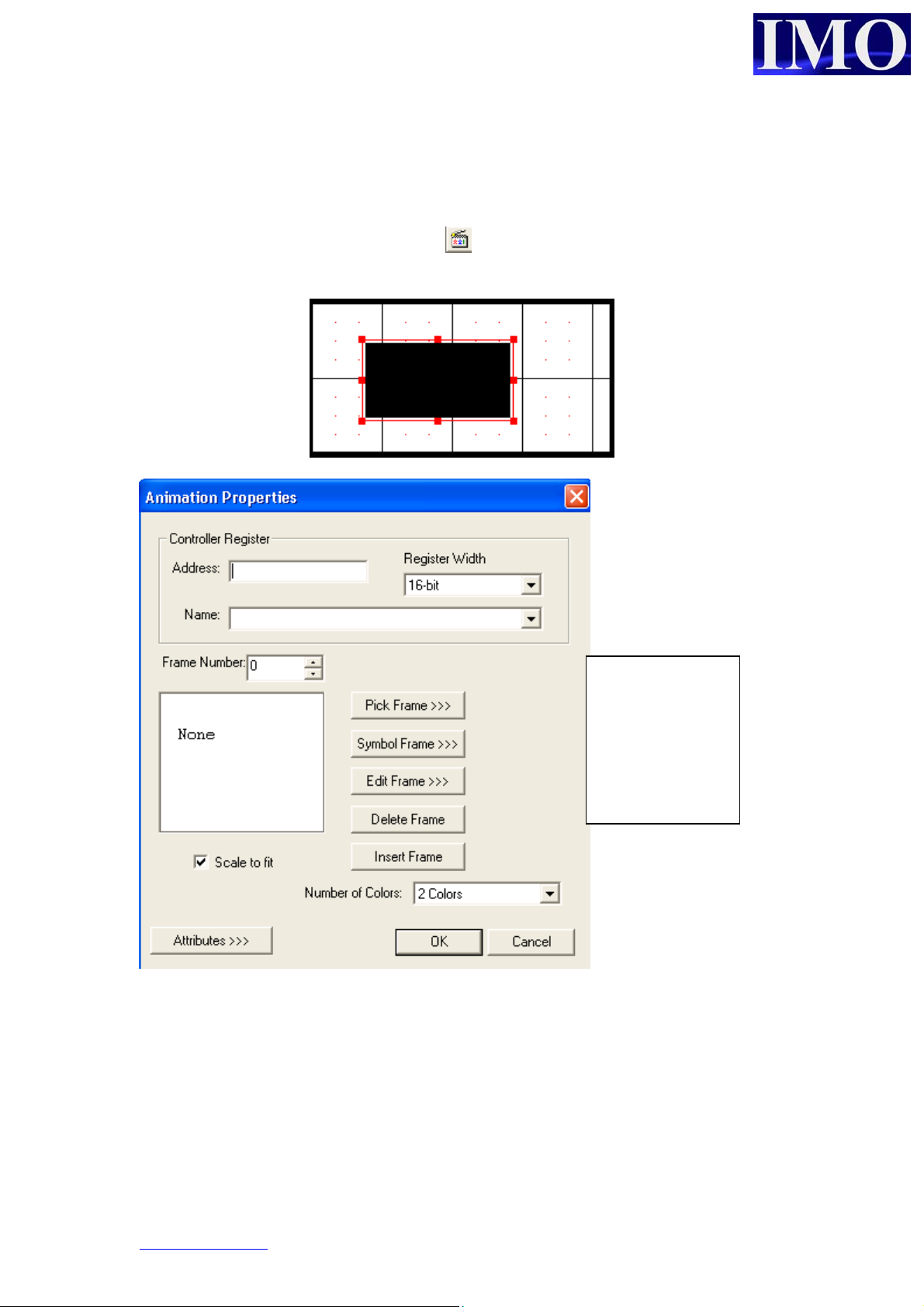

Animation

The animation displays a series of bitmaps depending on the value of a register,

double word, word, byte or bit.

To insert an animation, click on the icon and click it into the screen.

Select the

bitmaps for the

frames to match

the value in the

registers, i.e. a

it will have two

frames.

www.imopc.com 44

Page 44

Basic Operation

p

Trend

The data trend tracks data over a period of time. To insert a trend, click on the icon

and click it into the screen.

A data trend can

track up to four

registers over a

set period of

time.

The sample can be in

seconds, minutes or

hours

The trigger address

is required to

activate the trend.

The trend can be 1 of

4 different types, see

the help file for

detailed information

Up to 4

ens per

trend can

be edited.

i.e. 4 data

registers.

The axis titles

can be edited

to something

more

meaningful,

and the scale

can be adjusted

© IMO Precision Controls ltd. 45

Page 45

p

p

X – Y Data Graph

To insert an X – Y Graph, click on the icon and click it into the screen. The X-Y

graph represents variation of a variable in comparison to variations in one or more

variables.

The trigger

address is

required to

reset and

refresh the

lotting

rocess.

www.imopc.com 46

Page 46

Basic Operation

Alarms

To insert an Alarm Log, click on the icon and place it into the screen. There are

two types of alarm: Summary and History. Summary only displays the alarm when it

is currently active and History logs the alarm. There are two steps to setting up the

alarm, first the button needs to be set up then the log itself.

The alarm will

display a

message and

time stamp it

for when it

occurred.

Type of

alarm log

Details to

display

There can be

up to 16

different

alarm groups

© IMO Precision Controls ltd. 47

Page 47

Configure the Alarm Log

Select Alarm from

the Config Menu

drop down, to open

the Alarm Log

editor.

The alarm

trigger can

be 1

register or

consecutive

Choose what

to display in

the History

log

www.imopc.com 48

Alarm

message to

display and

group

related to.

Page 48

Basic Operation

q

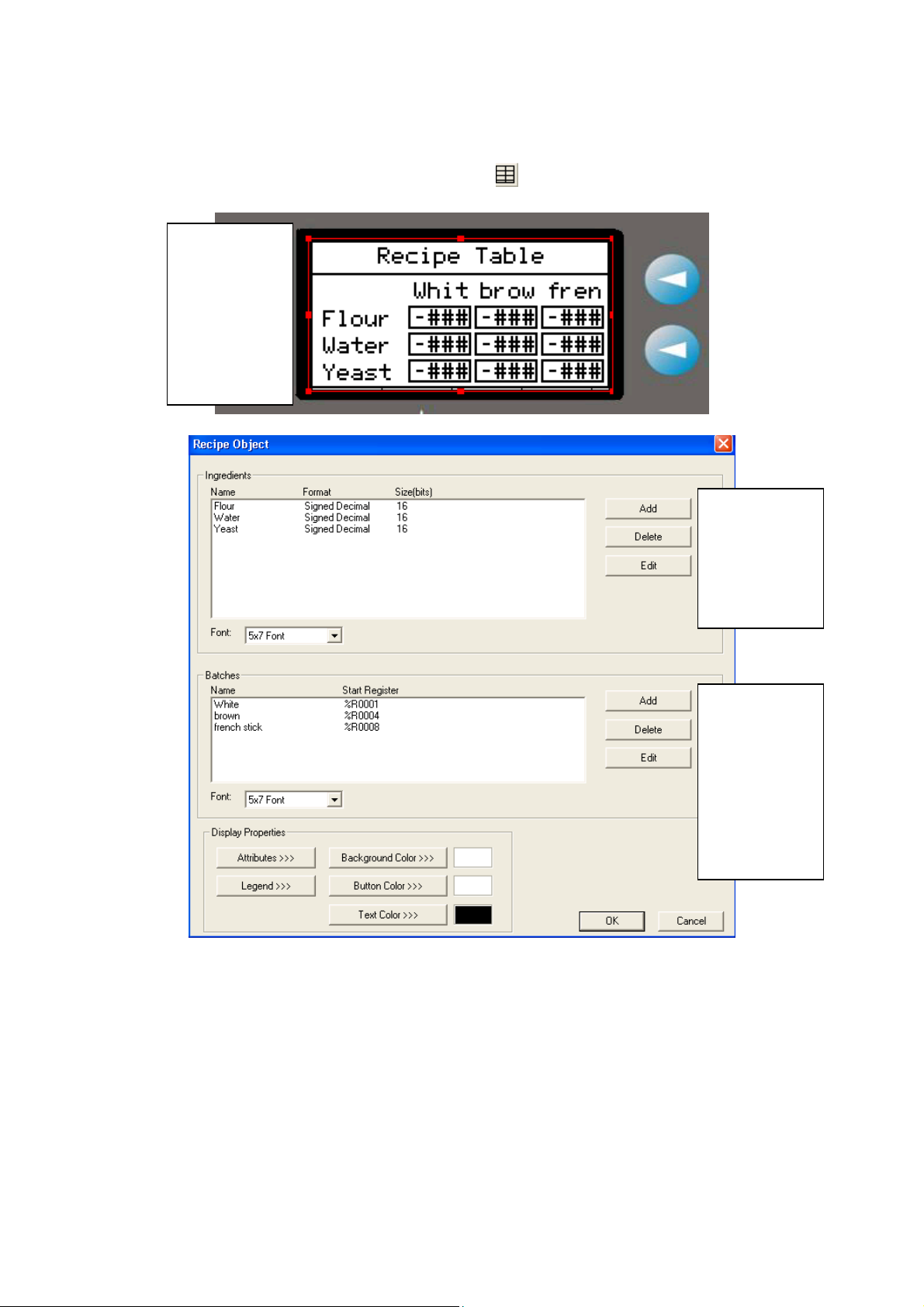

Recipe Editor

To insert a Recipe Editor Object, click the icon on to the screen.

A recipe can

be created to

store the

values of

variables for

different

batch

uantities.

Add the

ingredients

table. These

will be stored

in consecutive

registers.

Add the

different

batches, to

store the

different

rates of

ingredient

quantities

© IMO Precision Controls ltd. 49

Page 49

p

Set up the

ingredient

display and

scales.

Add the

batch

roperties

and storage

register.

This recipe function can be used in conjunction with move function blocks, to move

recipe data from one location to another.

www.imopc.com 50

Page 50

Basic Operation

© IMO Precision Controls ltd. 51

Loading...

Loading...