Page 1

GW-7553 PROFIBUS/Modbus TCP Gateway

User's Manual

High Quality, Industrial Data Acquisition, and Control Products

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 1

Page 2

Warranty

All products manufactured by ICP DAS are under warranty regarding

defective materials for a period of one year from the date of delivery to the

original purchaser.

Warning

ICP DAS assumes no liability for damages resulting from the use of this

product. ICP DAS reserves the right to change this manual at any time

without notice. The information furnished by ICP DAS is believed to be

accurate and reliable. However, no responsibility is assumed by ICP DAS

for its use, or for any infringements of patents or other right of third parties

resulting from its use.

Copyright

Copyright 2008 by ICP DAS. All rights are reserved.

Trademark

The names used for identification only may be registered trademarks of

their respective companies.

List of Revision

Date Author Version Revision

2008/12/31 Raiden 1.00 Release

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 2

Page 3

Table of Contents

1. Introduction…………………………………………………………. 4

1.1 Features…………………………………………………………………………………... 5

1.2 Modules Support…………………………………………………………………………. 5

1.3 Specification……………………………………………………………………………… 5

2. Hardware……………………………………………………………. 7

2.1 Block Diagram of GW-7553…………………………………………………………….. 7

2.2 Pin Assignment…………………………………………………………………………... 7

2.3 Wiring……………………………………………………………………………………. 9

2.4 Setting the PROFIBUS Address………………………………………………………. 12

2.5 LED status indicator……………………………………………………………………. 13

2.6 Normal/Setting DIP switch…………………………………………………………….. 14

3. Communication protocol transfer theorem……………………… 16

3.1 PROFIBUS data exchange…………………………..…………………………………. 16

3.2 Modbus data exchange…………………………………………………………………. 19

3.3 Communication protocol transfer………………………………………………………. 22

4. Communication……………………………………………………. 26

4.1 Field of application…………………………………………………………………….. 26

4.2 GSD file………………………………………………………………………………… 27

4.3 The Configuration of the common parameters…………………………………………. 30

4.4 The Configuration of the modules……………………………………………………… 31

4.5 Diagnostic messages……………………………………………………………………. 34

4.6 I/O data exchange……………………………………………………………………….. 35

4.7 Establish connection with GW-7553……………………………………………………. 37

4.8 Data exchange example—Modbus RTU……………………………………………….. 39

4.9 Data exchange example—Modbus TCP………………………………………………... 49

5. Application of Utility………………………………………………. 60

5.1 Install Utility……………………………………………………………………………. 60

5.2 Utility introduction……………………………………………………………………… 63

5.3 Memory address configuration of the module………………………………………….. 65

5.4 Safe value setting……………………………………………………………………….. 67

5.5 IP setting………………………………………………………………………………… 69

5.6 Establish connection with GW-7553……………………………………………………. 70

6. Troubleshooting……………………………………………………. 73

7. Dimensions…………………………………………………………. 74

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 3

Page 4

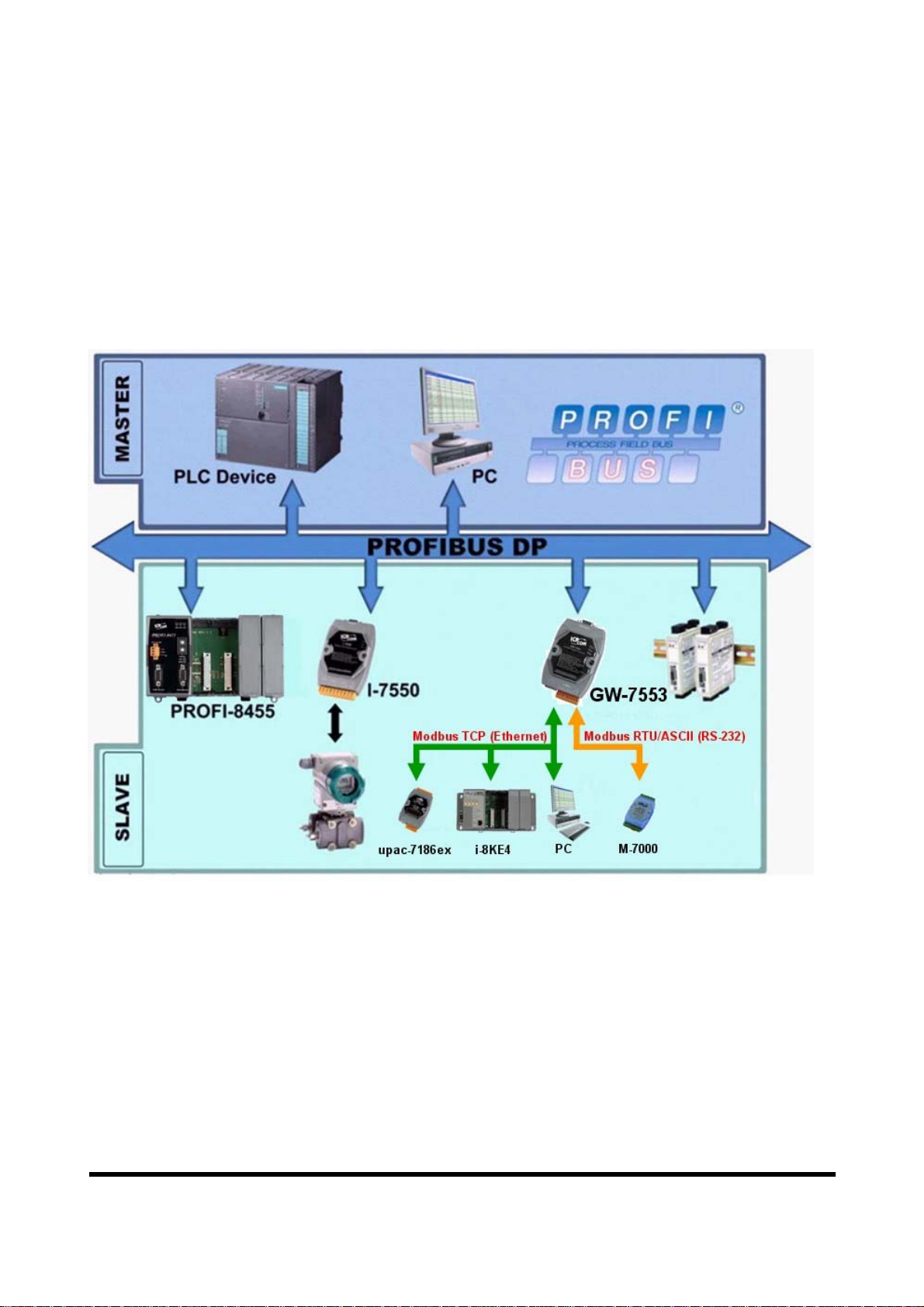

1. Introduction

PROFIBUS and Modbus are two kinds of famous protocols and are wildly used in

the fields of factory and process automation. The GW-7553 is a PROFIBUS to

Modbus TCP gateway. By using this module, users can easily put the Modbus TCP

devices into PROFIBUS network.

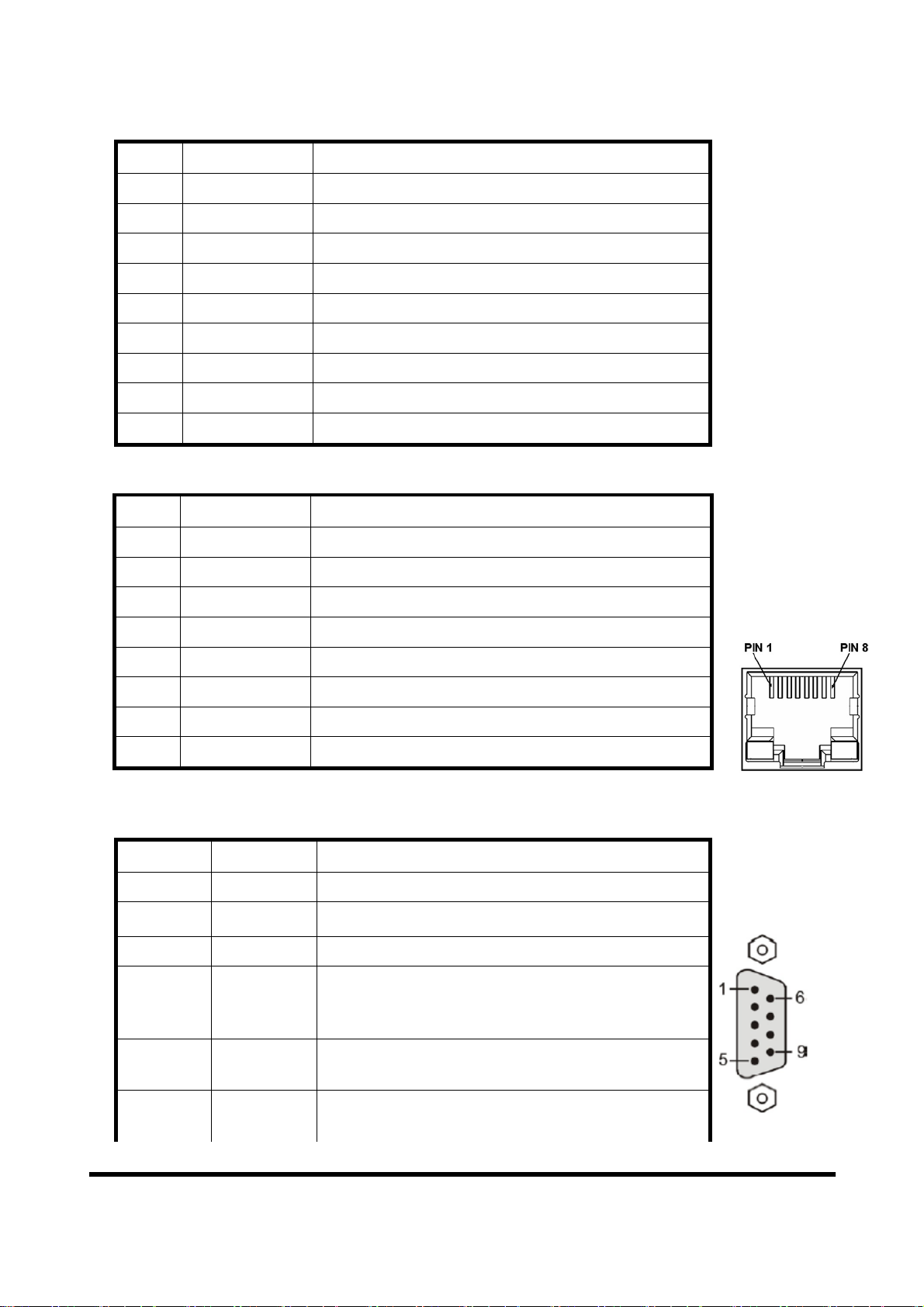

Figure 1 shows an application example for the GW-7553 module.

Figure 1 Application architecture of the GW-7553 module

The GW-7553 Gateway is specially designed for the slave device of PROFIBUS DP

protocol. In the Modbus protocol application, the GW-7553 can be a Modbus Master

device or Slave device. The Modbus devices can exchange data with the PROFIBUS

Master device via the GW-7553 module.

The main features and specification of GW-7553 are described as below:

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 4

Page 5

1.1 Features

● 16-bit Microprocessor inside with 80MHz

● Profichip VPC3+C PROFIBUS controller

● Support PROFIBUS DP-V0 slave

● PROFIBUS transmission rate detect automatically

● Max transmission speed up to 12 Mbps for PROFIBUS and 115.2 kbps for

COM Port

● Support Modbus RTU, ASCII and TCP format

● Support Modbus Master/Slave mode

● Support safe value setting

● COM Port driver has 1K bytes QUEUE input buffer & 512 bytes QUEUE

output buffer

● Max length of output/input data is 131/128 Bytes

● Ethernet Port: 10/100 Base-TX

● 2500Vrms High Speed iCoupler Isolation Protection for PROFIBUS network

● 3000VDC Isolation Protection on the PROFIBUS side

● Provide LED indicators

● Built-in Watchdog

● Mountable on DIN Rail

1.2 Modules Support

Only the following Modbus commands are supported by the gateway.

Table 1: Modbus function codes

Code Name Description

01 Read Coil Status Read the ON/OFF status of discrete outputs in the slave

02 Read Input Status Read the ON/OFF status of discrete inputs in the slave

03 Read Holding Registers Read the binary contents of holding registers in the slave

04 Read Input Registers Read the binary contents of input registers in the slave

05 Force Single Coil Write a single output to either ON or OFF in the slave

06 Preset Single Register Write an integer value into a single register in the slave

15 Force Multi. Coils

Write each coil in the sequence of coils to either ON or

OFF in the slave

16 Preset Multi. Registers Write a block of contiguous registers in the slave

1.3 Specification

COM Port specs:

● Serial port - RS-232

● Serial port interface: screw terminal block

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 5

Page 6

● Baud Rate:2400/4800/9600/19200/38400/57600/115200 bps

● Data Format: 7/8 data bits, None/Odd/Even parity bit, 1/2 stop bit

PROFIBUS specs:

● PROFIBUS interface connector: D-Sub 9-pin female

● Baud Rate: 9.6k/19.2k/45.45k/93.75k/187.5k/500k/1.5M/3M/6M/12Mbps

● Address Setting: 0~126 (set by DIP switch or EEPROM)

Ethernet specs:

● 10/100Base-TX (Auto-negotiating, Auto_MDIX, LED indicator)

Power requirement:

● Unregulated +10 ~ +30 VDC

● Power reverse protection, Over-Voltage brown-out protection

● Power consumption 2.5W

Module specs:

● Dimensions: 119mm x 72mm x 33mm

● Operating temperature: -25 ~ 75 ºC

● Storage temperature: -30 ~ 85 ºC

● Humidity:5 ~ 95% RH, non-condensing

● LED Status Indicators(Table 2)

Table 2: LED status indicator

− Show the power state

PWR LED

− Show data state

ERR LED

RUN LED

− Show error state

− Show communication state of PROFIBUS

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 6

Page 7

2. Hardware

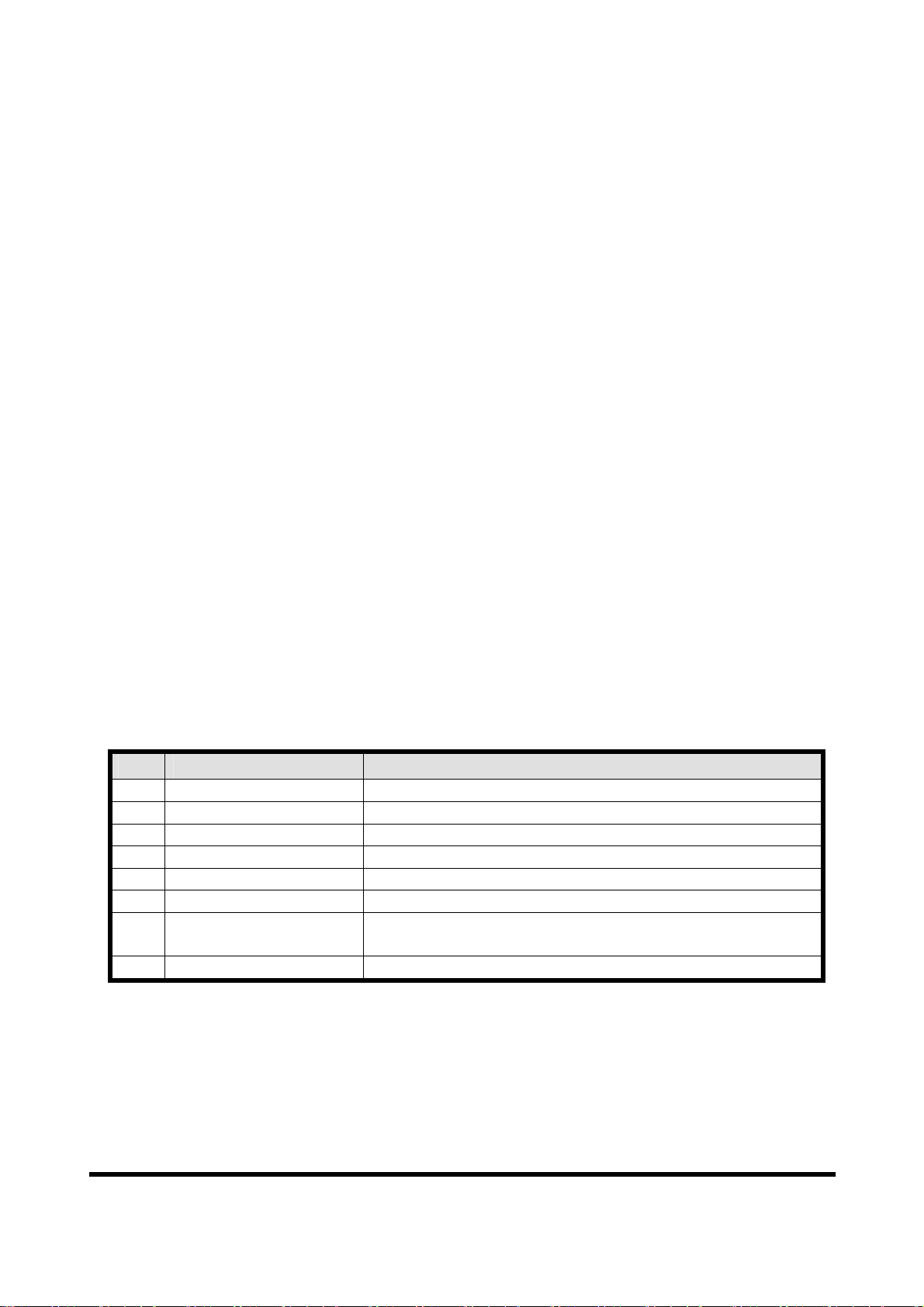

2.1 Block Diagram of GW-7553

Figure 2 Block diagram of GW-7553

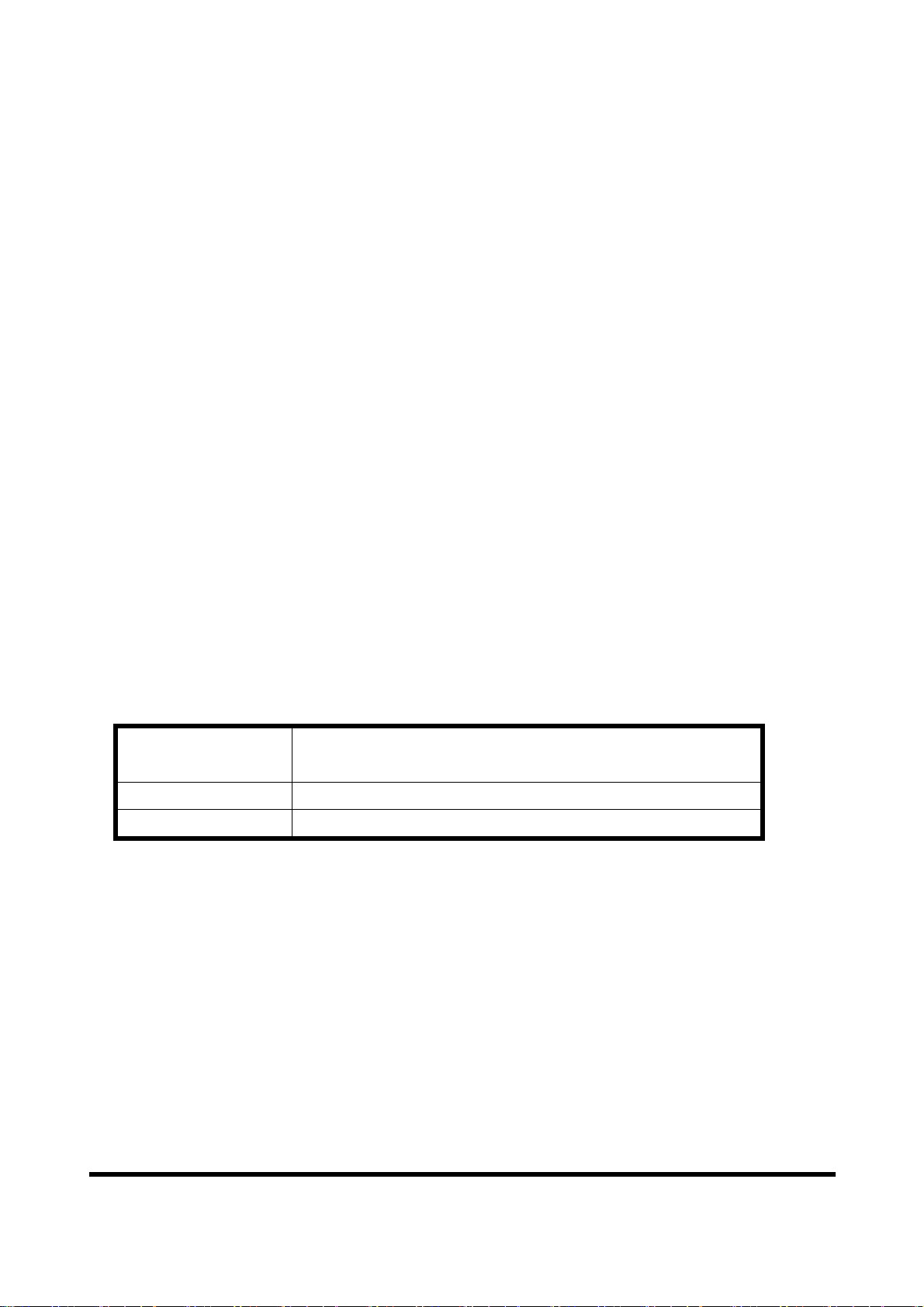

2.2 Pin Assignment

Figure 3 Pin assignment of GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 7

Page 8

Table 3 9-pin screw terminal block

Pin Name Description

1 CTS Clear to Send of RS-232

2 RTS Request to Send of RS-232

3 RX Receive Data of RS-232

4 TX Transmit Data of RS-232

5 GND GND of RS-232

6 - N/A

7 - N/A

8 +VS V+ of Power Supply(+10 ~ +30 VDC)

9 GND GND of Power Supply

Table 4 RJ-45 socket

Pin Name Description

1 TX+ TX+ output

2 TX- TX- output

3 RX+ RX+ input

4 - N/A

5 - N/A

6 RX- RX- input

7 - N/A

8 - N/A

Table 5 PROFIBUS DB9 Female Connector

Pin Name Description

1 - N/A

2 - N/A

3 B Non-inverting Bus Line

4 ISODE Isolated DE output for use in PROFIBUS

applications where the state of the isolated drive

enable node needs to be monitored.

5 GND Power supply ground for the first node and the last

node

6 VP +5V Power Supply for the first node and the last

node

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 8

Page 9

Pin Name Description

port

7 - N/A

8 A Inverting Bus Line

9 - N/A

2.3 Wiring

GW-7553 supports PROFIBUS to Serial or Ethernet communication. It is

recommended to use only one communication interface (RS-232 or Ethernet) of

the Gateway at the same time. The following section describes the connection

interface of GW-7553.

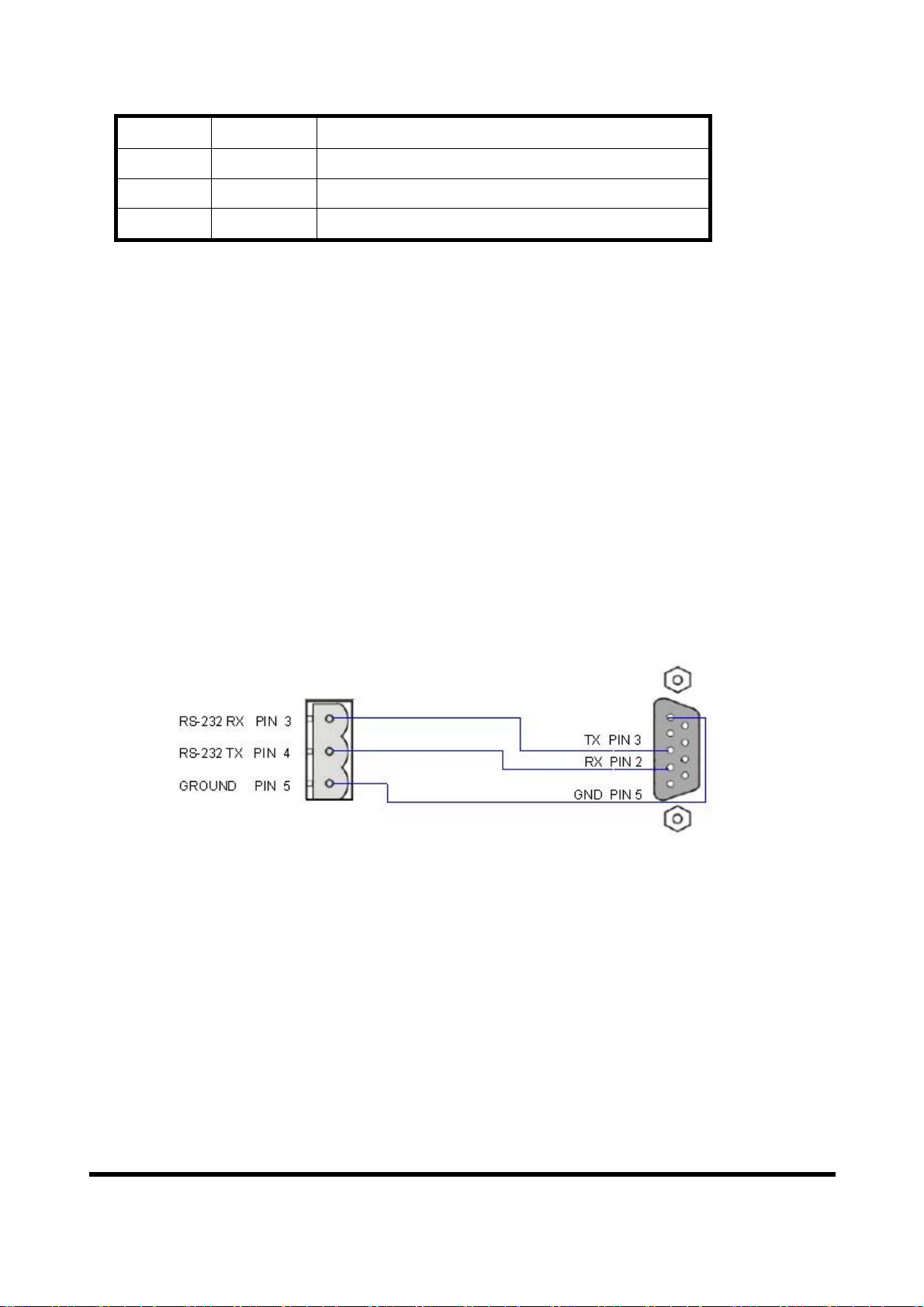

2.3.1 RS-232 connection

The RS-232 port of the GW-7553 has got three pins. The wiring of the RS-232

device with the RS-232 port of the GW-7553 is shown in figure 4.

GW-7553

RS-232

RS-232 device

Figure 4 RS-232 wiring diagram

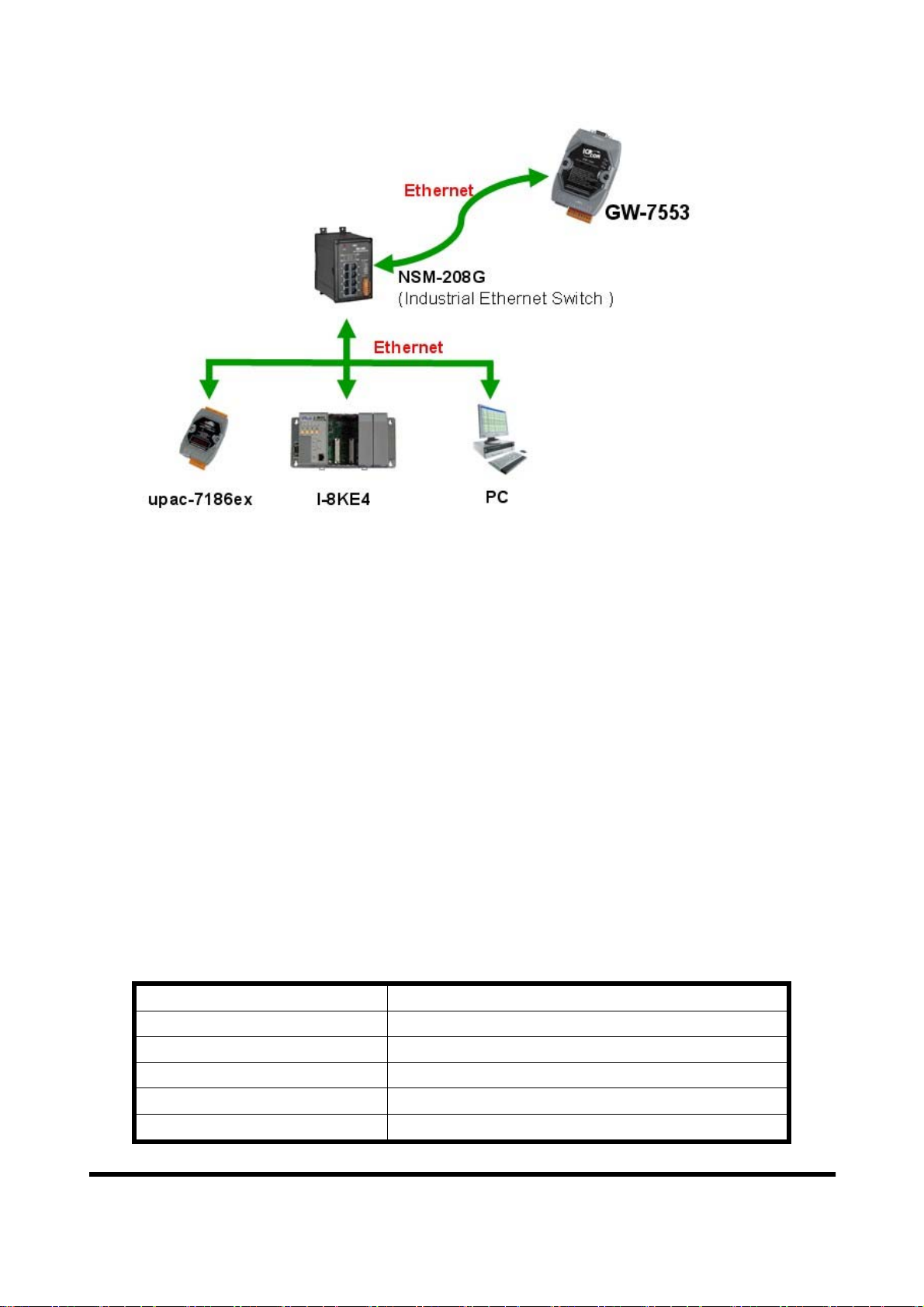

2.3.2 Ethernet connection

The user can connect GW-7553 with the other device to the same sub network

or same Ethernet Switch, as shown in figure 5.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 9

Page 10

Figure 5 Ethernet connection

2.3.3 PROFIBUS Connection

The PROFIBUS interface of the GW-7553 is a DB9 female connector. The

connector uses the standard PROFIBUS 9 pin assignment. It is recommended to

use a standard PROFIBUS cable and connector (DB9 male). As with every

serial bus the rate of safe data transmission in a PROFIBUS network decreases

with increasing distance between Master and Slave. Table 6 shows the

transmission rate and range for a cable with the following properties:

1. Impedance :135~165 Ω

2. Capacity : lower than 30 pF/m

3. Loop resistance : lower than 110 Ω/km

4. Wire diameter : greater than 0.65 mm

5. Core cross-section : greater than 0.34 mm

Table 6 Transmission rate decreasing with increasing transmission distance

2

Transmission Rate(kbps) Transmission Distance per Segment (meter)

9.6, 19.2, 45.45,93.75 1200

187.5 1000

500 400

1500 200

3000, 6000, 12000 100

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 10

Page 11

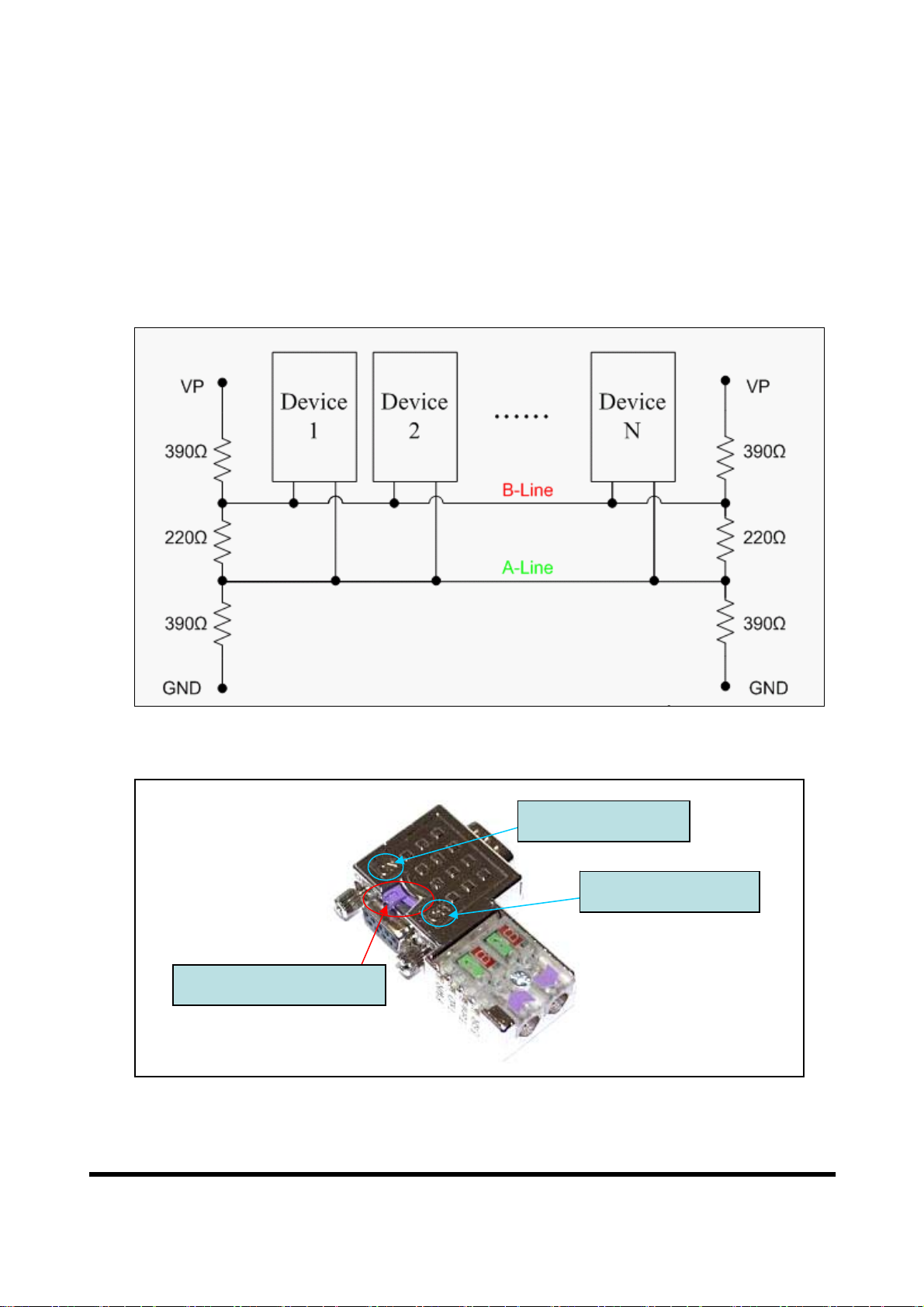

In order to minimize the reflection effect of signal transmission, both ends (first

node and last node) of a PROFIBUS segment needs to be equipped with an

active terminal resistor as shown in figure 6. A standard PROFIBUS connector

is usually already equipped with a terminal resistor. The user therefore only has

to switch on the resistor of the devices stationed at the ends of a segment as

shown in figure 7.

Figure 6 PROFIBUS connection

Terminator Switch

Figure 7 PROFIBUS connector

Terminator ON

Terminator OFF

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 11

Page 12

The number of stations in a PROFIBUS network is restricted to 126. According

to the PROFIBUS specification up to 32 stations are allowed per segment. A

repeater has to be used to link the bus segments.

2.4 Setting the PROFIBUS Address

The station address of GW-7553 can be set by using either the DIP switch or by

writing it directly to the EEPROM. The DIP switch covers a range from 0 to 255.

The valid address range of a PROFIBUS station spans from 0 to 126. Table 7

shows three examples of setting the station address by using the DIP switch. The

DIP switches are accessed by opening the modules housing (Figure 8). Table 8

explains which address will be used by the module after power on, if the DIP

switch address setting differs from the address stored in the EEPROM.

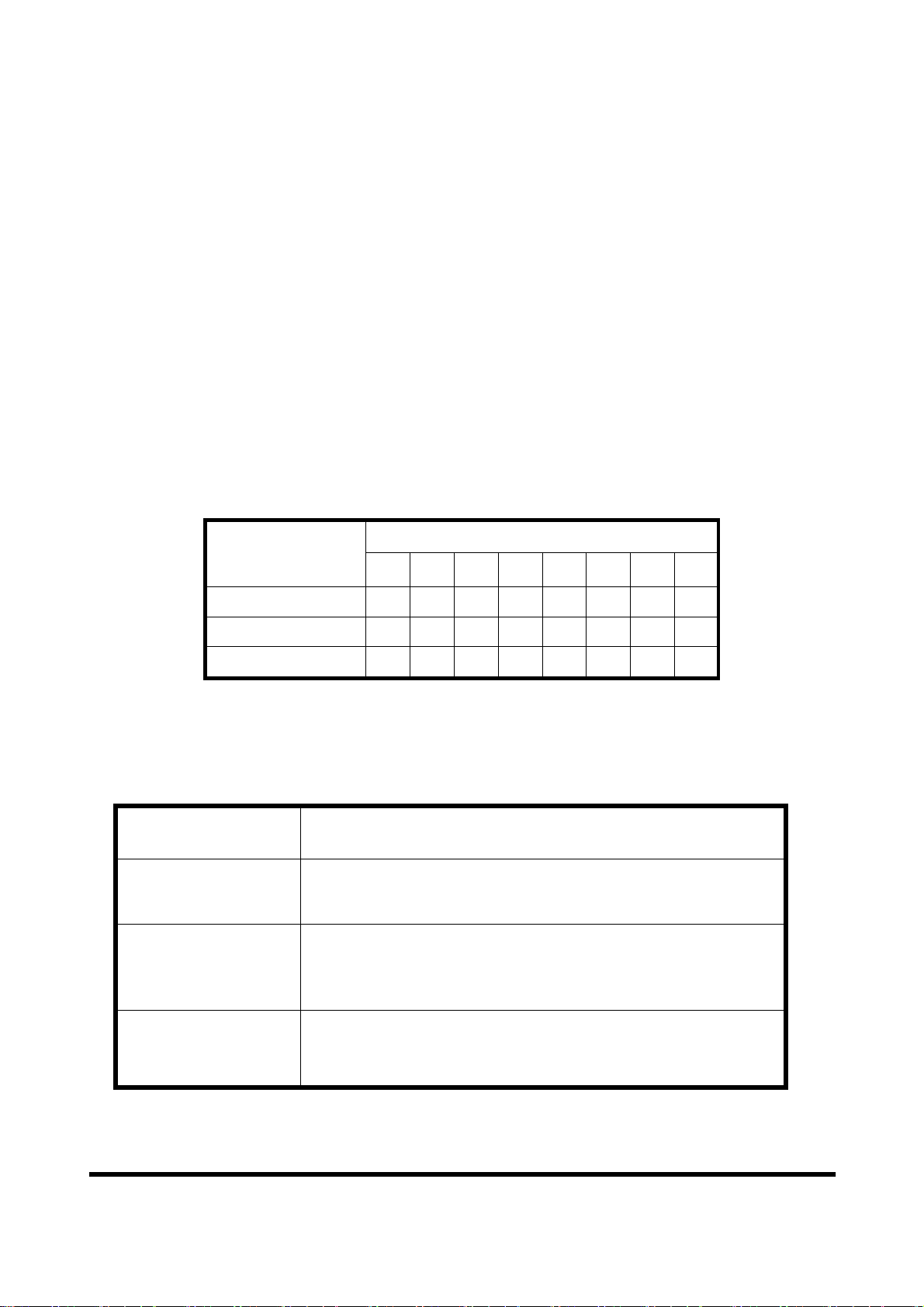

Table 7: DIP switch setting example

Station address

1 2 3 4 5 6 7 8

1 1 0 0 0 0 0 0 0

10 0 1 0 1 0 0 0 0

126 0 1 1 1 1 1 1 0

DIP switch (SW1)

Note: 1=>ON, 0=>OFF

Table 8: The Address setting of the GW-7553

DIP switch Setting Description

1. The address setting of the EEPROM is ignored.

0~125

126-254

2. The address can not be set by the PROFIBUS configuration

tool.

1. The address setting of the DIP switch is ignored.

2. If the address in the EEPROM is 126, the PROFIBUS

configuration tool can set a new address and save it to the

EEPROM.

255 1. Slave address in the EEPROM is set to 126.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 12

Page 13

Figure 8: DIP switch

Each Slave must have a unique valid address (1 to 125) in order to be able to

communicate with the Master. To change the address by using the configuration

tool it is necessary to first set the address stored in the EEPROM to 126. This is

done by setting the DIP switch to 255 in the power off state. Switching the

module on is forcing the module to change its address in the EEROM to 126. In

the next step switch the module off and change the DIP switch setting to any

value from 126 to 254. This step is necessary in order to prevent the module to

change its address in the EEPROM to 126 every time it is powered on. The

configuration tool can now assign the Slave a new address.

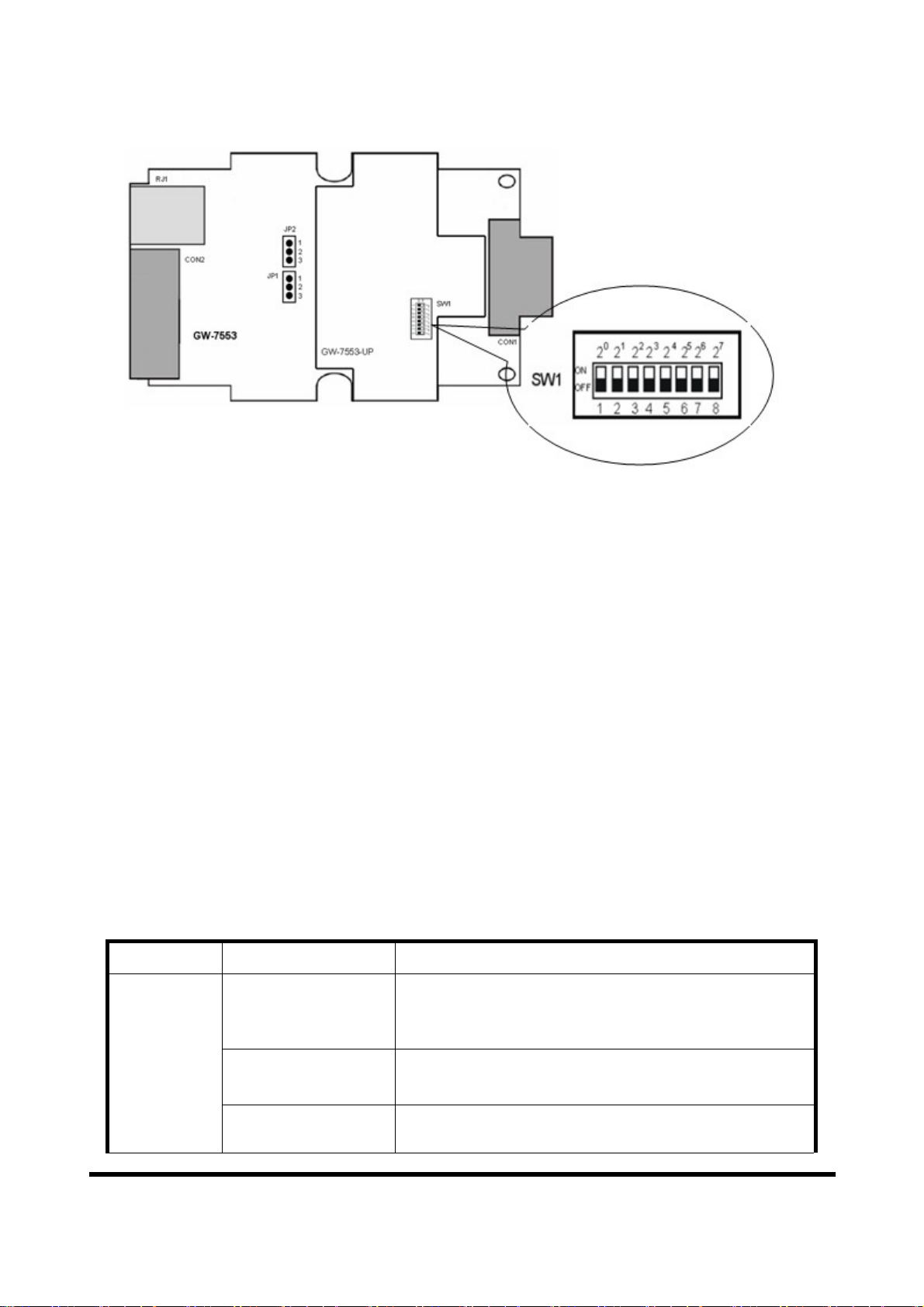

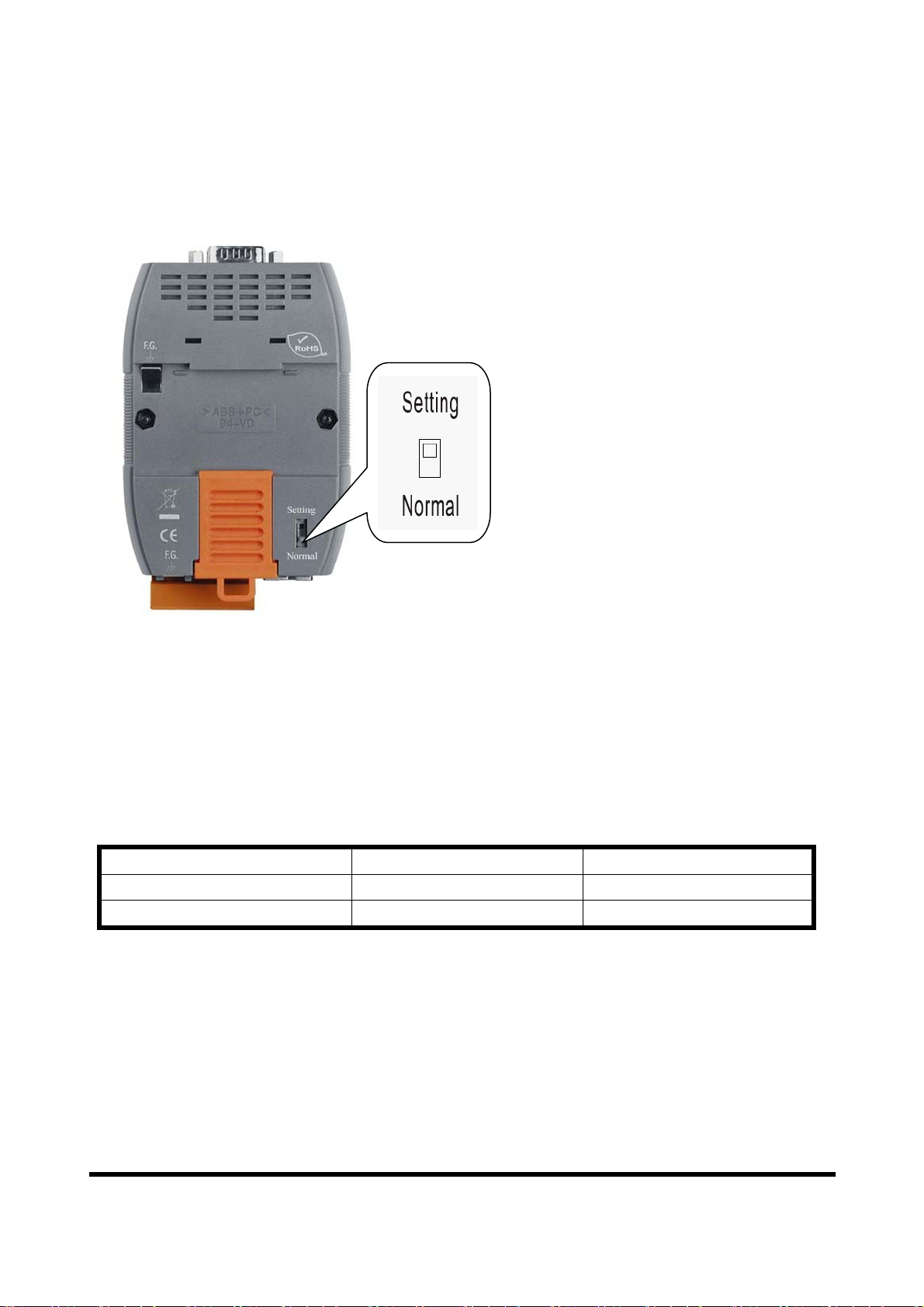

2.5 LED status indicator

The GW-7553 provides three LEDs to indicate the statuses of the GW-7553

module. The position of LEDs and descriptions are shown in table 9 and figure 9.

Table 9: LED status description

LED Name Status Description

When the GW-7553 acts as a Modbus Slave device

flash

PWR

on

off Power supply has failed.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 13

and receiving query message form Modbus Master

device, PWR led will flash.

Power supply is ok.

The firmware has loaded.

Page 14

LED Name Status Description

When the GW-7553 connects with the utility tool, it

flash

will flash fast (flash once about 55ms).

When the GW-7553 has diagnostic message, it will

flash slowly (flash once about 220ms).

ERR

RUN

− Connection error between PROFIBUS Master and

on

off

on

off GW-7553 module is not in a data exchange mode.

Slave or

− PROFIBUS system has not been configured

correctly.

Normal operation

PROFIBUS system has been configured correctly

Data exchange mode

Normal operation.

Figure 9 LED position

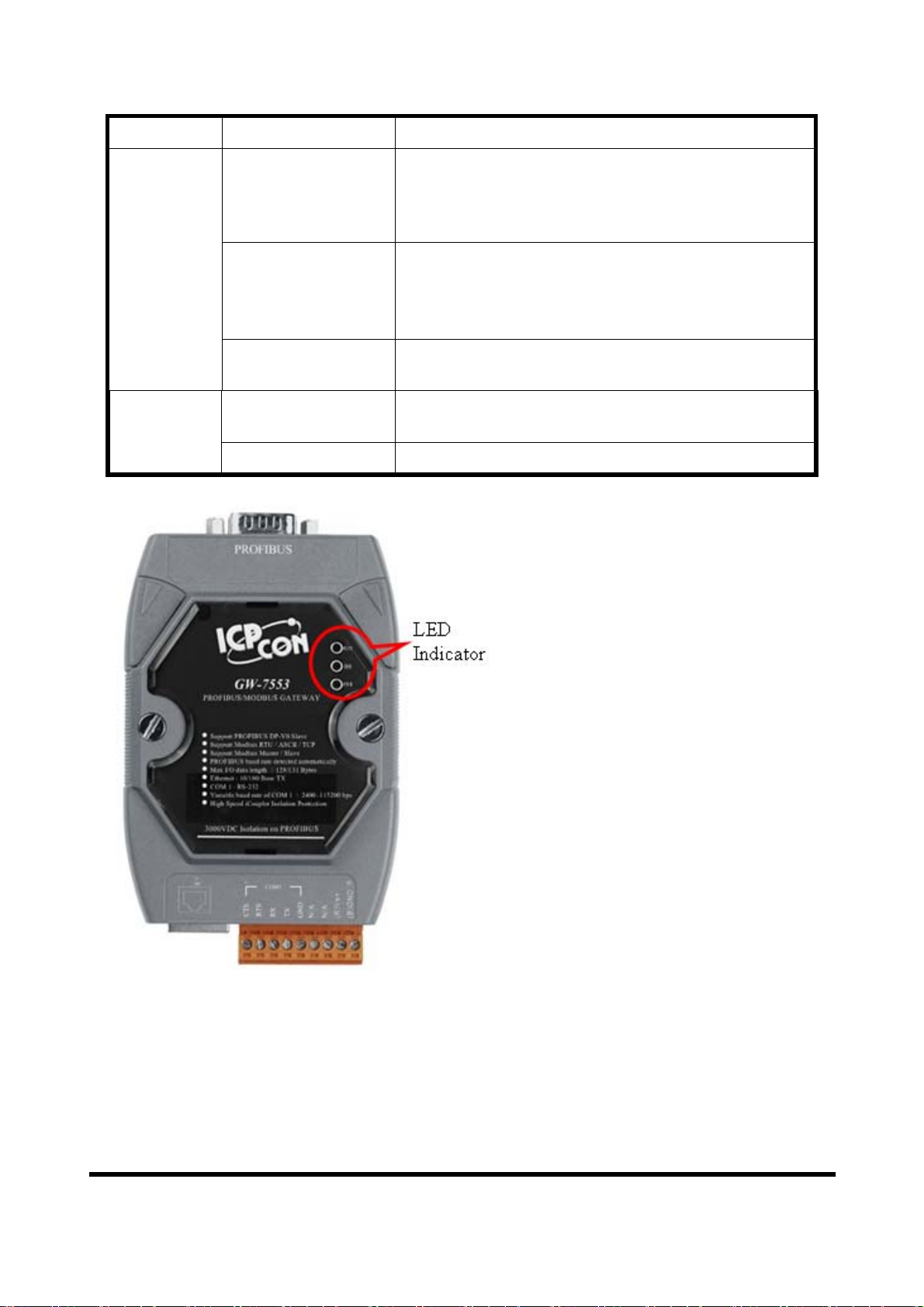

2.6 Normal/Setting DIP switch

There is a DIP switch on the back of the GW-7553 module, as shown in Figure 10.

The DIP switch is used to set the GW-7553 module works in operation mode or

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 14

Page 15

setting mode. In the normal situation, it needs to set the DIP switch to the “Normal”

position. In this case, the GW-7553 module can communicate with Modbus devices.

When the user sets the DIP switch to the “Setting” position, the GW-7553 module can

communicate with the utility to set the safe value and network configuration.

Figure 10 DIP switch of the GW-7553

PS:

There are two kinds of methods to enable the setting mode of the GW-7553. The user

can change the position of the DIP switch or set the control bit (please refer section

4.6.2 Output data area and communication command) to enable the setting mode of

the GW-7553, as shown in table 10.

Table 10 Mode of GW-7553

Mode SM(control bit)=0 SM(control bit)=1

DIP switch=Normal operation mode setting mode

DIP switch =Setting setting mode setting mode

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 15

Page 16

3. Communication protocol transfer theorem

3.1 PROFIBUS data exchange

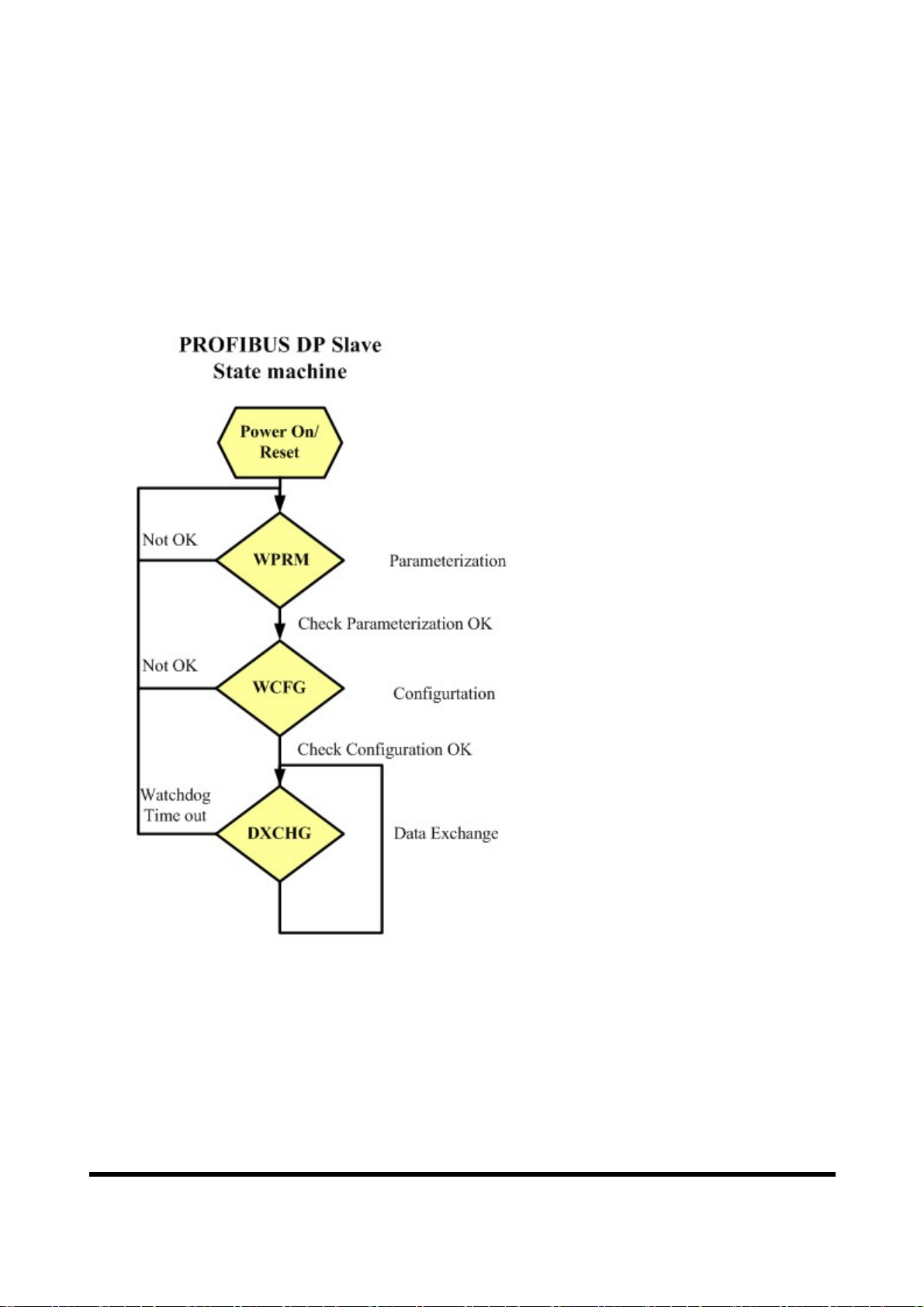

The GW-7553 is a PROFIBUS DP Slave device. The GW-7553 is first

parameterized then configured and finally it goes into the data exchange mode

(Figure 11).

Figure 11 State machine of PROFIBUS DP Slave device

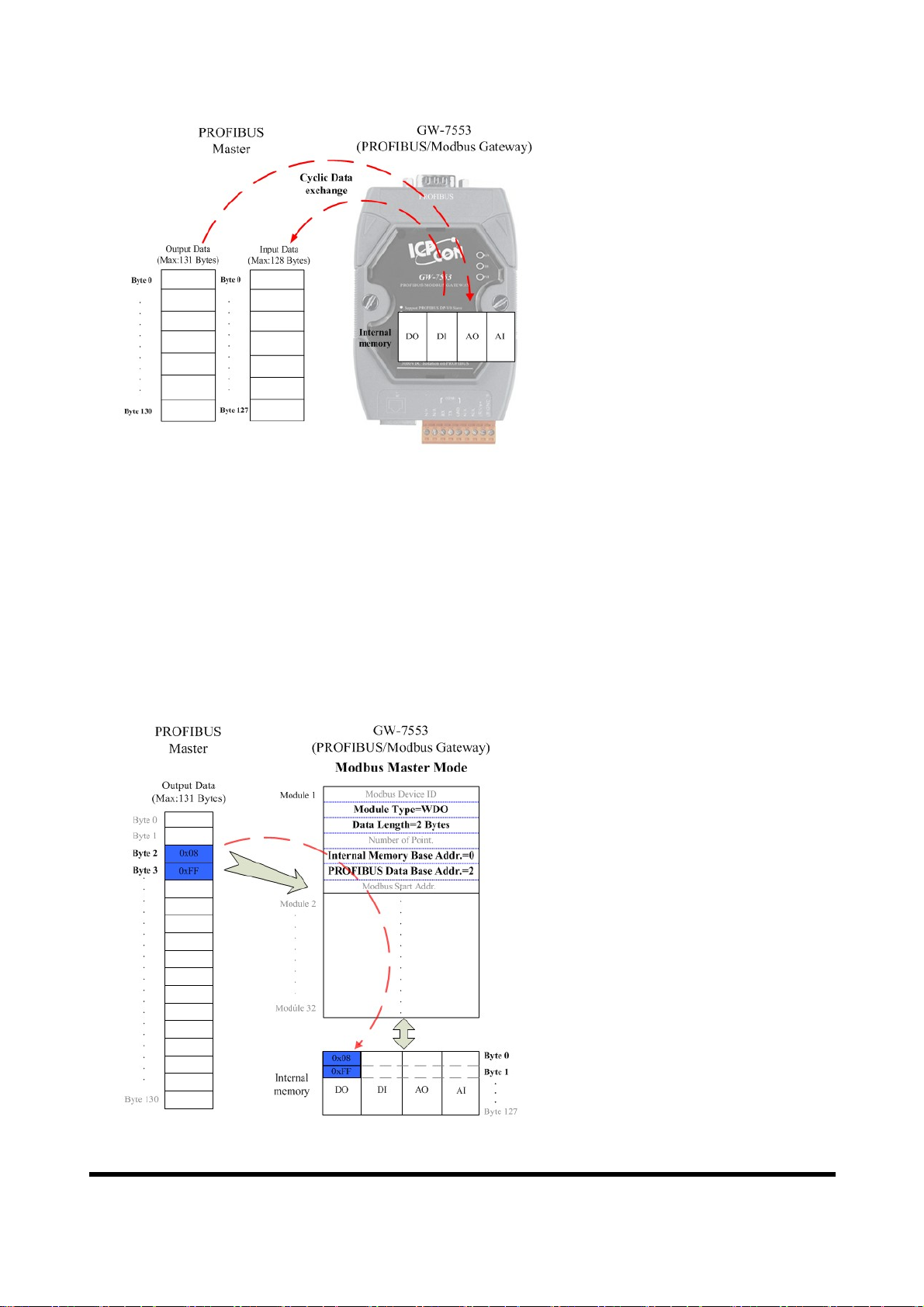

The GW-7553 exchanges data cyclically between internal DI、DO、AI、AO

data and PROFIBUS Master device in data exchange mode, as shown in figure 12.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 16

Page 17

Figure 12 Data exchange between PROFIBUS Master device and GW-7553

The GW-7553 downloads the parameter and configuration from PROFIBUS

Master device to be the module parameters. The GW-7553 and PROFIBUS

Master device have different data type and data address, the GW-7553 can transfer

different data format to PROFIBUS Master device through module parameters.

When the GW-7553 acts as a Modbus Master device, it will send DI、AI data to

input data area of PROFIBUS Master device and it will save data that receives

from PROFIBUS Master device to internal DO、AO memory space, as shown in

、

figure 13

14.

Figure 13 The output data of PROFIBUS Master device send to the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 17

Page 18

Figure 14 The input data of PROFIBUS Master device receive from the GW-7553

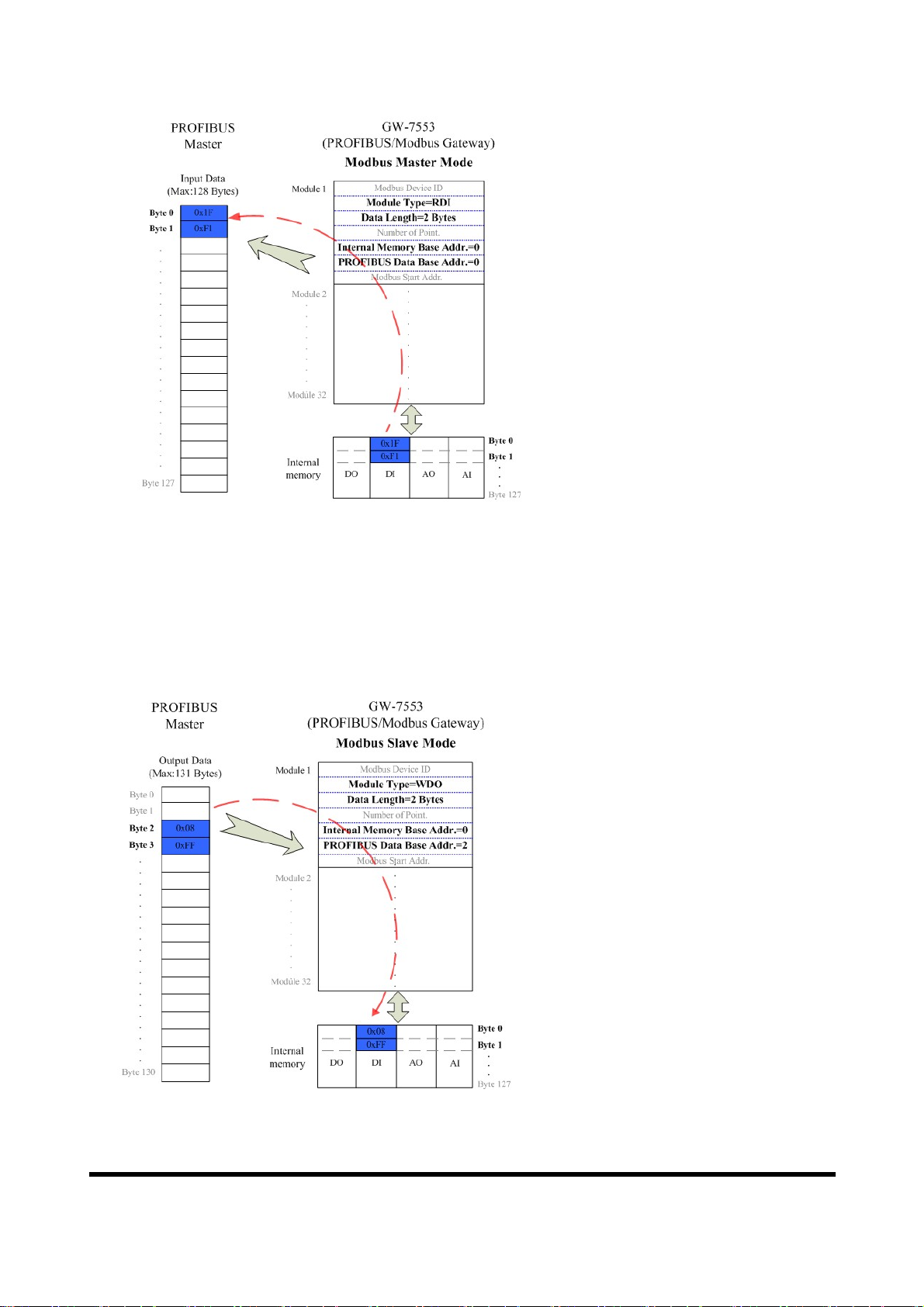

When the GW-7553 acts as a Modbus Slave device, it will send DO、AO data to

input data area of PROFIBUS Master device and it will save data that receives

from PROFIBUS Master device to internal DI、AI memory space, as shown in

figure 15

、

16.

Figure 15 The output data of PROFIBUS Master device send to the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 18

Page 19

Figure 16 The input data of PROFIBUS Master device receive from the GW-7553

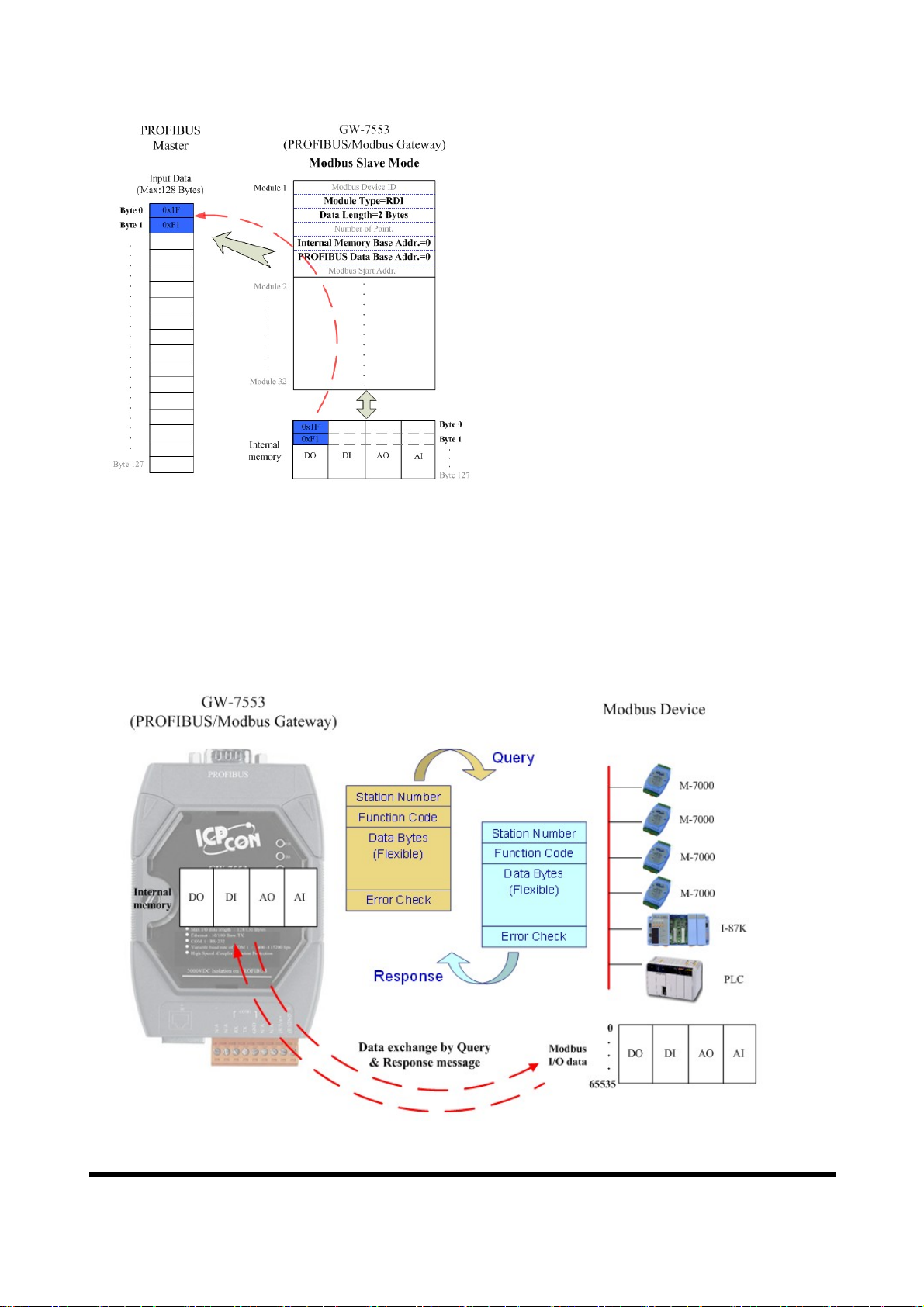

3.2 Modbus data exchange

Modbus protocol belongs to Master-Slave communication and it uses query and

response message to arrive at data exchange and device control, as shown in

figure 17.

Figure 17 Data exchange between the Modbus devices and the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 19

Page 20

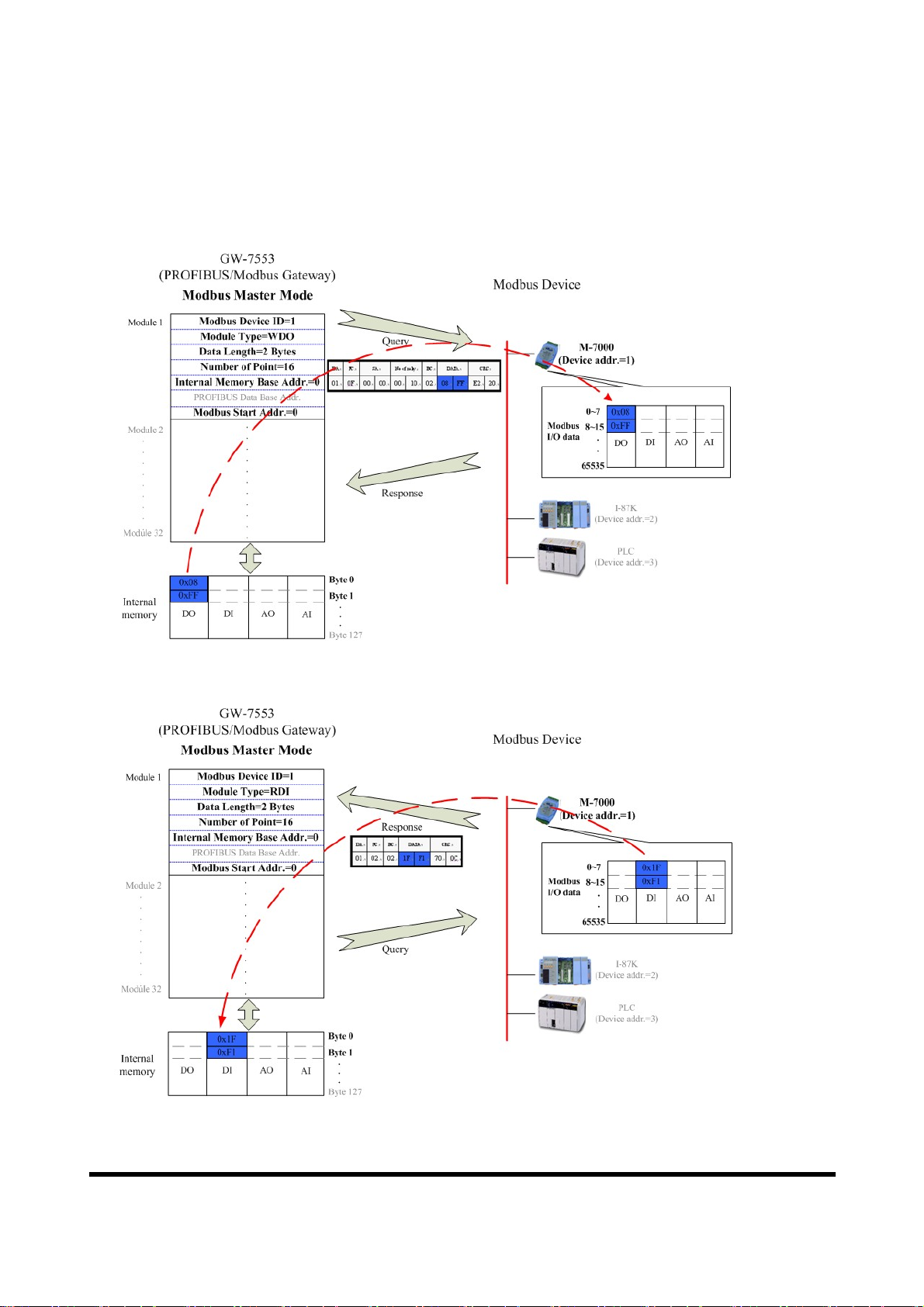

When the GW-7553 acts as a Modbus Master device, it can get query message

through module parameter and DO、AO data and send query message to Modbus

Slave device. It can also receive response message form Modbus Slave device and

then saving to internal DI、AI memory space, as shown in figure 18

、

19.

Figure 18 GW-7553 output data to Modbus Slave devices

Figure 19 GW-7553 receive data from Modbus Slave devices

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 20

Page 21

hen the GW-7553 acts as a Modbus Slave device, it can receive query message

W

from Modbus Master device and then saving to internal DO、AO memory space.

It can also send response message to Modbus Master device through internal DI、

AI data, as shown in figure 20

、

21.

Figure 20 The GW-7553 receive data from Modbus Master device

Figure 21 The GW-7553 output data to Modbus Master device

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 21

Page 22

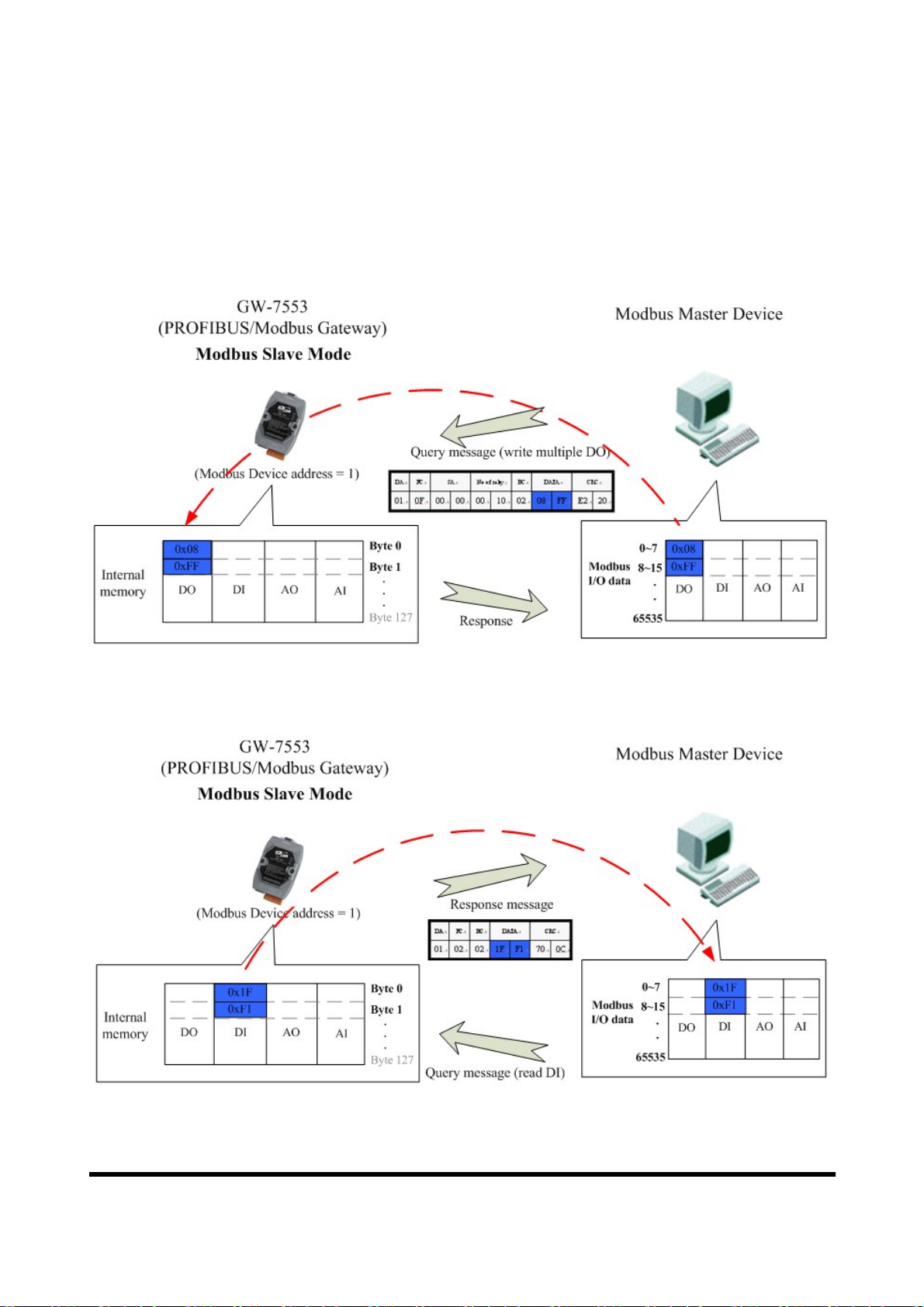

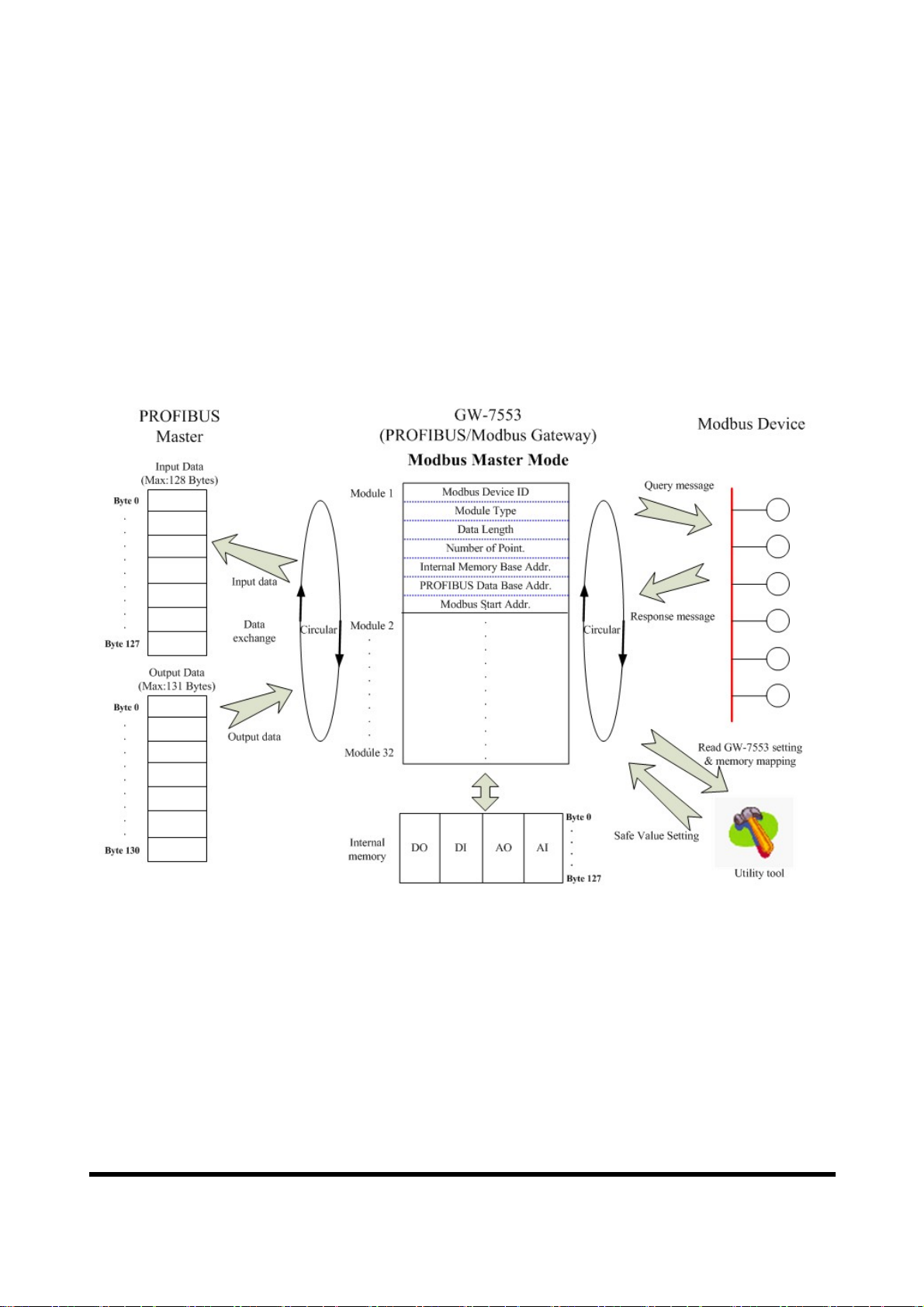

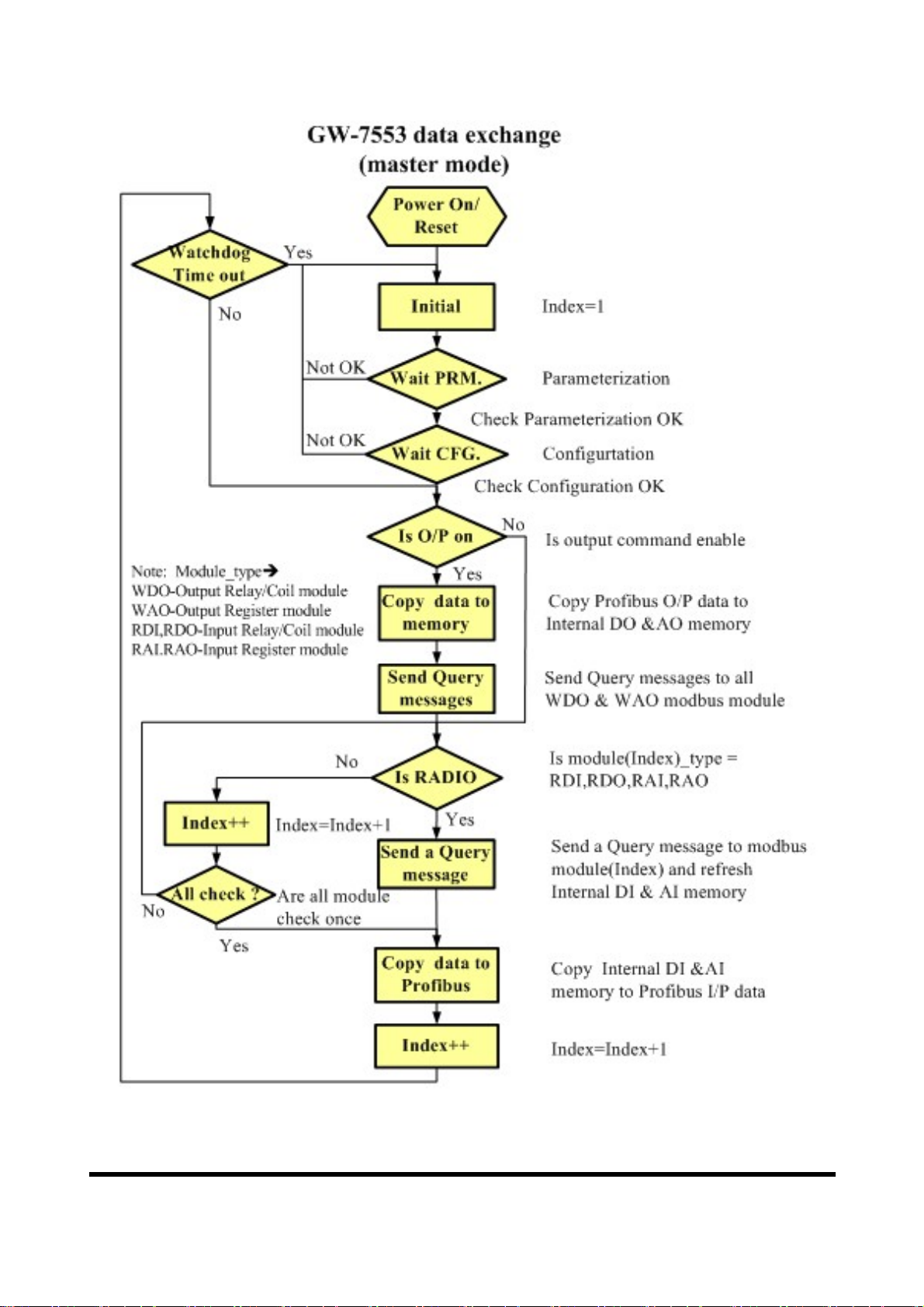

3.3 Communication protocol transfer

In section 3.1 and 3.2, we can understand that data exchange is through DI、

DO、AI、AO memory space of the GW-7553 between PROFIBUS Master、

Modbus and the GW-7553. When the GW-7553 acts as a Modbus Master device,

the data exchange runs continuously between PROFIBUS Master、Modbus and

the GW-7553, as shown in figure 22

、

23.

Figure 22 GW-7553 (master mode) communication protocol transfers

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 22

Page 23

Figure 23 GW-7553 (master mode) flowchart

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 23

Page 24

When the GW-7553 acts as a Modbus Slave device, the data exchange runs

continuously between PROFIBUS Master and the GW-7553 and the data

exchange runs between Modbus Master device and the GW-7553, when GW-7553

、

receive query message from Modbus Master device, as shown in figure 24

25.

Figure 24 GW-7553 (slave mode) communication protocol transfer

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 24

Page 25

Figure 25 GW-7553 (slave mode) flowchart

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 25

Page 26

4. Communication

4.1 Field of application

A master station can be a PLC, PC or any other smart device. The system can be a

mono-master system (Figure 26) or a multi-master system (Figure 27). The GW-

7553 enables the integration of the Modbus devices into a PROFIBUS DP

network.

Figure 26 Mono-master system

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 26

Page 27

Figure 27 Multi-master system

4.2 GSD file

The characteristic (ex: baud rate, message length, number of input / output data.....)

of each PROFIBUS DP device is described in the GSD file. The GSD file of the

GW-7553 is in the ICP DAS companion CD-ROM (PATH--> CD:

\profibus\gateway\gw-7553\gsd\). The user can copy GSD file ( IPDS0C0D.gsd )

and the Bitmap file ( ICP_7553.bmp,GW_7553.bmp ) to the PROFIBUS

configuration tool.

4.2.1 The example of how to load GSD file

In the following examples the CIF50-PB PROFIBUS Master card from Hilscher

is used. The configuration and communication is done by the program “SyCon”

provided by Hilscher.

Step 1: Copy the GSD file (IPDS0C0D.gsd) and the Bitmap file

(ICP_7553.bmp,GW_7553.bmp) from CD of the GW-7553 module

into the PROFIBUS configuration tool.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 27

Page 28

File->CopyGSD

(Directory: --> CD: \profibus\gateway\gw-7553\gsd\)

Step 2: Click “insert slave” button in the PROFIBUS configuration tool.

Figure 28 Insert PROFIBUS Slave device

Step 3: Select GW-7553 and click “Add” button to assign the GW-7553.

Figure 29 Assign the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 28

Page 29

Step 4: Set the address of the GW-7553 and click “OK” button.

Figure 30 Set the address of the GW-7553

Step 5: The GW-7553 icon is shown in the window. It adds the GW-7553

successfully in the software.

Figure 31 Finish adding the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 29

Page 30

4.3 The Configuration of the common parameters

GW-7553 has twelve common parameters. The user can configure the common

parameters to set the communication mode and data format by the PROFIBUS

configuration tool. The common parameters are described below.

● COM Port baud rate:2400/4800/9600/19200/38400/57600/115200

● COM Port parity:None/Even/Odd

● COM Port data length:7/8 data bit

● COM Port stop bit:1/2 stop bit

● Modbus Type:Master/Slave

● Modbus Format:RTU/ASCII/TCP

● I/O Safe Mode:Retain last value/Switch safe value

● Byte Order : Little-Endian/Big-Endian

● Modbus Device ID(S):1~247

● Polling Modbus Device Interval(ms) (M):1~65535ms

● Query Message Timeout Value(ms)(M):1~65535ms

PS:

● TCP_Connect_Num(T)(M):1~8

a. When stop bit of COM Port is 2, data bit of COM Port must be 7 or else stop bit

of COM Port will be set to 1.

b. I/O Safe Mode

When GW-7553 acts as a Modbus Master (Modbus Type=Master):

i. Data exchange between PROFIBUS Master and GW-7553 is interrupted

“I/O Safe Mode” will be activated when the data exchange between

PROFIBUS Master and GW-7553 is interrupted (e.g. no physical

connection, PROFIBUS Master leaves the data exchange mode, etc.).

• I/O safe mode = “Switch Safe Value”

The GW-7553 will set internal DIO and AIO data to safe value and

send the safe values to the Modbus Slave device.

• I/O safe mode = “Retain Last Value”

Internal DIO and AIO data retain last value

ii. Connection between Modbus Slave and the GW-7553 is interrupted

• I/O safe mode = “Switch Safe Value”

The GW-7553 will set the internal DI and AI data to safe value and send

safe values to PROFIBUS Master device.

• I/O safe mode = “Retain Last Value”

Internal DIO and AIO data retain last value

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 30

Page 31

When GW-7553 acts as a Modbus Slave (Modbus Type=Slave):

i. Data exchange between PROFIBUS Master and GW-7553 is interrupted

“I/O Safe Mode” will be activated when the data exchange between

PROFIBUS Master and GW-7553 is interrupted.

• I/O safe mode = “Switch Safe Value”

The GW-7553 will set internal DIO and AIO data to safe value.

• I/O safe mode = “Retain Last Value”

Internal DIO and AIO data retain last value

ii. Connection between Modbus Master and the GW-7553 is interrupted

Internal DIO and AIO data retain last value received

Please refer section 5.4 about the safe value settings

c. Byte order is an important factor related to the memory allocation. Big-

endian byte order (Motorola format) allocates more significant byte in lower

memory address. On the other hand, little-endian byte order (Intel format)

allocates more significant byte in higher memory address.

d. Modbus device ID is a Modbus address of the GW-7553, when the GW-7553

acts as a Modbus Slave device.

e. We recommend the user to set the “query message timeout value” bigger than

3ms in order to identify the response message.

f. The user can set the maximum number of Modbus TCP Slave device by

“TCP_Connect_Num”. These Modbus TCP Slave devices can have different

IP Address for connection.

g. (M) means the parameter is effective, when Modbus Type of GW-7553 is

Master.

(S) means the parameter is effective, when Modbus Type of GW-7553 is

Slave.

(T) means the parameter is effective, when Modbus Format of GW-7553 is

TCP.

4.4 The Configuration of the modules

The user can set the number and size of the I/O modules in the PROFIBUS

configuration tool. The settings of the modules are described below.

● Max. I/O modules:32 modules

● System setting module:3 byte out

● Output module:Output Relay/Coil => 1~32 Bytes

Output Register => 1~64 Words

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 31

Page 32

● Input module:Input Relay/Coil => 1~32 Bytes

Input Register

● Max. length of I/O data:259 Bytes

● Output length:0~131 Bytes

● Input length:0~128 Bytes

=> 1~64 Words

The modules have module parameters about the communication settings. The

module parameters are shown in the below:

A. Output Relay/Coil module parameters:

● Modbus Slave Device ID(M):0~247

● Start Address(M):0~65535

● NO. of Relay/Coil(M):8*(n-1)+1 ~ 8*n Bits

n=Module size/Byte

● TCP_Connect_Index(T)(M):1~8

B. Output Register module parameters:

● Modbus Slave Device ID (M):0~247

● Start Address(M):0~65535

● TCP_Connect_Index(T)(M):1~8

C. Input Relay/Coil module parameters:

● Modbus Slave Device ID (M):0~247

● Start Address(M):0~65535

● NO. of Relay/Coil(M):8*(n-1)+1 ~ 8*n Bits

● Module Type(M):Read DI/DO

n=Module size/Byte

● TCP_Connect_Index(T)(M):1~8

D. Input Register module parameters:

● Modbus Slave Device ID (M):0~247

● Start Address(M):0~65535

● Module Type(M):Read AI/AO

● TCP_Connect_Index(T)(M):1~8

Example 1:

If the user wants to read a Modbus digital input module (DI module), Device ID is

1, data address is 10010~10019, and data count is 10 via the first TCP connection.

In this case, the user can select an “Input Relay/Coil=> 2 Bytes module”, module

parameters are shown in the below:

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 32

Page 33

Input Relay/Coil module parameters:

● Modbus Slave Device ID(M):1

● Start Address(M):9

● NO. Of Relay/Coil(M):10

● Module Type(M):Read DI

● TCP_Connect_Index(T)(M):1

Example 2:

If the user wants to write a Modbus analog output module (AO module), Device

ID is 2, data address is 40001~ 40004 and data count is 4 via the second TCP

connection.

In this case, the user can select an “Output Register => 4 Words module”, module

parameters are shown in the below:

Output Register module parameters:

● Modbus Slave Device ID(M):2

● Start Address(M):0

● TCP_Connect_Index(T)(M):2

PS:

a. Relay/Coil module is digital module (DI/DO module), the unit is Byte;

Register module is analog module (AI/AO module), the unit is Word.

b. Modbus Slave Device ID:It is a Modbus Slave device address.

c. Start Address:The GW-7553 and Modbus Slave device exchange data

from this starting address.

d. NO. of Relay/Coil:It is data size that the GW-7553 and Modbus Slave

device exchange.

e. Module type:The user can select data type for data exchange by this

setting.

Write DO(WDO)-- Write Digital Output

Write AO(WAO)-- Write Analog Output

Read DI(RDI)- Read Digital Input

Read DO(RDO)- Read Digital Output

Read AI(RAI)-Read Analog Input

Read AO(RAO)-Read Analog Output

f. TCP_Connect_Index:The user can select TCP connection of the module.

The module will transmit and receive data from this connection.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 33

Page 34

4.5 Diagnostic messages

The GW-7553 can show maximally 10 diagnostic messages at the same time. If

the number of the diagnostic messages is bigger than 10, the GW-7553 will not

process other diagnostic message. The diagnostic messages have four types. They

are “Module Error”, “System Setting Module Error”, “EEPROM Error” and

“Input Data Error”. The diagnostic messages are shown in table 11.

Table 11 Diagnostic messages

Messages Description Note

ILLEGAL FUNCTION!

ILLEGAL DATA ADDRESS!

ILLEGAL DATA VALUE!

SLAVE DEVICE FAILURE!

ACKNOWLEDGE!

SLAVE DEVICE BUSY!

NEGATIVE ACKNOWLEDGE!

Module 1~32 Error *

MEMORY PARITY ERROR!

Please refer

Modbus

Exception

Code

definition for

detail.

System setting module

Error

EEPROM Error

Data Error

Modbus NOT DEFINED ERROR!

GATEWAY PATH UNAVAILABLE!

GATEWAY TARGET DEVICE FAILED

TO RESPOND!

CRC (LRC) Error!

Response Message Timeout!

Response Message error!

Connection error!

Not find System setting module.

Position is not correct!

Read safe value error.

Read IP error!

Write IP error!

PROFIBUS lose input data.

Lose PROFIBUS output data.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 34

Page 35

“*” These error messages are not supported when the GW-7553 act as a Modbus

Slave.

PS:

Data Error:

a. GW-7553 acts as a Modbus Master

If the polling speed between the GW-7553 device and the Modbus Slave is

faster than the data exchange rate between PROFIBUS Master and the GW7553 then the PROFIBUS Master will not get all the data from the Modbus

Slave and therefore a diagnostic message (“PROFIBUS lose input data”) will be

send by the GW-7553 to the PROFIBUS Master

b. GW-7553 acts as a Modbus Slave

If the GW-7553 receives more telegram from the Modbus Master than it

transmits to the PROFIBUS Master then a diagnostic message (“PROFIBUS

lose input data”) will be send by the GW-7553 to the PROFIBUS Master.

c. When the GW-7553 receives a “data output command” (output byte 0) from

system setting module, and this command didn’t increase in order (ex: 0->1, 1>2,…, 255->0), the GW-7553 will think that it lose some output data of the

PROFIBUS Master and a diagnostic message (“Lose PROFIBUS output data”)

will be sent by the GW-7553 to the PROFIBUS Master.

4.6 I/O data exchange

The I/O data exchange is decided by Modbus type of the GW-7553 (please refer

section 4.3 The Configuration of the common parameters) between PROFIBUS

Master device and the GW-7553. Output data area of PROFIBUS Master device is

mapped into DO/AO memory of the GW-7553 and input data area of PROFIBUS

Master device is mapped into DI/AI memory of the GW-7553, when Modbus type

is Master. In the other way, Output data area of PROFIBUS Master device is

mapped into DI/AI memory of GW-7553 and input data area of PROFIBUS

Master device is mapped into DO/AO memory of GW-7553, when Modbus type

is Slave (please refer section 3.1 PROFIBUS data exchange ).

4.6.1 Input data area

The maximum length of input data is 128 bytes. Before arrange the input

module, the user must arrange and configure the system setting module. The

user can get data and control I/O of Modbus Slave device or get DI/DO/AI/AO

of the GW-7553 by read input module.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 35

Page 36

Table 12 Input data area

Module Byte Data Description

Input

module

0~127 Data Receive data

4.6.2 Output data area and communication command

The maximum length of output data is 131 bytes. Before arrange the output

module, the user must arrange and configure the system setting module. The

first three bytes belong to communication commands, as shown in table 13. The

user can change data and I/O state of Modbus Slave device or DI/DO/AI/AO

data of GW-7553 by modify data of output module.

Table 13 Output data area

Module Byte

0

System

setting

module

1

7 6 5 4 3 2 1 0

Data output command

- - - - - - SM DC Control bit

Bit Position

Description

Output module select

Output data

Output

module

2

3~130

● Data output command(byte 0)

a. When Modbus type is Master

When this byte is changed, PROFIBUS Master device will send data

of output module to DO/AO data of GW-7553 and then GW-7553

will send query message to Modbus Slave device for change data or

output state of Modbus Slave device.

b. When Modbus type is Slave

When this byte is changed, PROFIBUS Master device will send data

of output module to DO/AO data of GW-7553.

PS: When the user use this byte to trigger “data output command”, the

user must increase this byte in order (ex: 0->1, 1->2,…, 255->0) or else

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 36

Page 37

the GW-7553 will send a diagnostic message to the PROFIBUS Master

(please refer section 4.5 Diagnostic messages).

● Control bit(byte 1)

DC(bit 0):When this bit is set (DC=1), diagnostic messages sent by the

GW-7553 module will all be cleared.

SM(bit 1):When this bit is set (SM=1), the GW-7553 will enter setup

mode. The utility can communicate with the GW-7553 in

this mode.

When this bit is ''0'' (SM=0), the GW-7553 will enter normal

operation mode. The GW-7553 can communicate with

Modbus device in this mode.

Bit 2~7:The remaining bits have to be set to zero.

● Output module select(byte 2)

When this byte is ‘0’ and the user change data output command(byte 0),

it will trigger all data output command of output modules.

When this byte isn’t ‘0’ and the user change data output command(byte

0), it will trigger single data output command of the output module and

this byte

represent that the user want to trigger data output command of the third

module )

represent module address of the output module (ex: “byte 2”=3, it

4.7 Establish connection with GW-7553

Before establishing a connection between the DP-Master and the GW-7553, user

should execute the following steps first.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 37

Page 38

Figure 32 Establish connection with GW-7553

First, users must load the electronic device description file (GSD file) of the GW7553 into the DP-Master, and then set the parameters. Finally change your DPMaster from Offline state to Operate state. While DP-Master changes to operate

mode, GW-7553 will initial the modules. Then GW-7553 allocates the memory

space and waits for Set_Prm telegram. The next step is waiting for Check_Cfg

telegram in order. If there is no error occurs, GW-7553 proceeds into data

exchange state. Users can observe the status indicator LED to know the state of

GW-7553. At the meantime, if there is any error occurs, GW-7553 will return to

wait parameterization.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 38

Page 39

4.8 Data exchange example—Modbus RTU

In this example a Modbus Master device simulated by a PC program sends query

message and receives response message from a PROFIBUS Master via the GW7553 gateway.

In the following examples the CIF50-PB PROFIBUS Master card from Hilscher is

used. The configuration and communication is done by the program “SyCon”

provided by Hilscher.

Step 1: Copy the GSD file and assign the GW-7553 a valid station address

(Please refer to the section 4.2 GSD file).

Step 2: Connect the RS-232 port of the GW-7553 module to a COM port of

the PC and the PROFIBUS port to a PROFIBUS Master (Figure 33).

Figure 33 Wiring diagram between PC and GW-7553

Step 3: Set the parameters of the GW-7553. We just need to change

“Modbus Type” to Slave and the default setting is being used in the

other parameters for this example. Please refer to section 4.3 the

Configuration of the common parameters. The users can set

parameters as shown in the below.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 39

Page 40

Figure 34 Double click the GW-7553 icon to open the

“Slave configuration” window

Figure 35 Click “Parameter Data…” button to open the

“Parameter Data” window

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 40

Page 41

Figure 36 The user needs to change “Modbus Type” to

Slave for this example and click “OK” button

Step 4: Set the GW-7553 modules, as shown in figure 37 and 38.

− Select “System setting” module: “System setting” module always has

to be selected otherwise no communication can be established

between the gateway and the Modbus network.

− Select “Output Relay/Coil” module: In this example a “Output

Relay/Coil--2 Byte” module is selected.

− Select “Input Relay/Coil” module: In this example a “Input

Relay/Coil--2 Byte” module is selected.

Figure 37 Double click the GW-7553 icon to open the

“Slave configuration” window

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 41

Page 42

Figure 38 Select modules

Step 5: Close the “Slave Configuration” window by clicking the “OK”

button.

Step 6: Now the setting done by the configuration tool has to be

downloaded to the PROFIBUS Master.

Click on the Master area in the graphic window then

Online -> Download…

Figure 39 Click “Online->Download” to download the

setting into PROFIBUS Master

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 42

Page 43

4.8.1 Receiving data from a Modbus Master device

-- Start the test utility “MBRTU” (figure 40) on the PC.

This utility simulates a Modbus Master device and is on the web site in the

following directory:

http://ftp.icpdas.com.tw/pub/cd/8000cd/napdos/modbus/modbus_utility/

(1) Set the COM Port number of the PC

(2) Set the Baud rate to 115200

(3) Set the Line control to N,8,1

(4)Open the connection

Figure 40 MBRTU Utility

--Send Command to write DO of the GW-7553

The user needs to input command (” 01 0F 00 00 00 10 02 FF FF”) here and

click <Send Command> button to send Modbus command: “01 0F 00 00 00

10 02 FF FF E3 90” and then MBRTU can receive response message (” 01 0F

00 00 00 10 54 07”). The user can find byte 0, 1 of the input data area in the

configuration program “SyCon” have changed into “0xFF” at this time, as

shown in the below.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 43

Page 44

Figure 41 Send Modbus command (output data: 0xFF, 0xFF)

Figure 42 Receive “0xFF” in the input data area

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 44

Page 45

Table 14 Receive “0xFF” in the input data area

Module Byte Data type Representation Value

Input module

PS:

Modbus command:

Query message

SA

DA FC

(Hi)

01 0F 00 00 00 10 02 FF FF E3 90

Response message

SA

DA FC

(Hi)

01 0F 00 00 00 10 54 07

Input 0 Byte Hex 0xFF

Input 1 Byte Hex 0xFF

SA

NO

NO

BC DATA

(Lo)

SA

(Lo)

(Hi)

NO

(Hi)

(Lo)

NO

(Lo)

CRC

check

CRC

check

z DA: Device Address-0x01

z FC: Function Code-0x0F=>Write multi-DO

z SA(Hi): Start Address(Hi byte)-0x00

z SA(Lo): Start Address(Lo byte)-0x00

z NO(Hi): No. Of points (Hi byte)-0x00

z NO(Lo): No. Of points (Lo byte)-0x10

z BC: Byte Count-0x02

4.8.2 Receiving data from the PROFIBUS Master device

--Send Command to read DI of the GW-7553

The user needs to input command (” 01 02 00 00 00 10”) in MBRTU and

click <Send Command> button to send Modbus command: “01 02 00 00 00

10 79 C6” and then MBRTU can receive response message (” 01 02 02 00 00

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 45

Page 46

B9 B8”). In this message, the user can know the value of DI0 & DI1 is “0” in

the GW-7553.

--Send output data to write DI of the GW-7553 by the PROFIBUS Master

The user needs to set “0xFE” & “0xDC” in byte 3 & byte 4 of output data

area in the configuration program “SyCon” and then set the value of the first

byte from 0 to 1 to trigger the data output command.

--Send Command to read DI of the GW-7553 again

Now the user can input command (” 01 02 00 00 00 10”) in MBRTU and

click <Send Command> button to send Modbus command: “01 02 00 00 00

10 79 C6” again. Then MBRTU can receive response message (” 01 02 02 FE

DC F8 41”). In this message, the user can know the value of DI0 & DI1 have

changed into “0xFE” & “0xDC” in the GW-7553, as shown in figure 43, 44,

45 & table 15.

Figure 43 Send Modbus command to read DI of the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 46

Page 47

Figure44 Set output data and trigger output data command in

the output data area

Table 15 Set output data and trigger output data command

Module Byte Data type Representation Value

System

module

Output

module

Output 0 Byte Hex

Output 1 Byte Hex 0x00

Output 2 Byte Hex 0x00

Output 3 Byte Hex

Output 4 Byte Hex

0x00 → 0x01

0x00→ 0xFE

0x00→ 0xDC

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 47

Page 48

Figure 45 Send Modbus command to read DI of the GW-7553 and

receive data (0xFE, 0xDC)

PS:

Modbus command:

Query message

SA

SA

NO

NO

CRC

DA FC

(Hi)

(Lo)

(Hi)

(Lo)

check

01 02 00 00 00 10 79 C6

Response message

CRC

DA FC BC DATA

check

01 02 02 FE DC F8 41

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 48

Page 49

z DA: Device Address-0x01

z FC: Function Code-0x02:read DI

z SA(Hi): Start Address(Hi byte)-0x00

z SA(Lo): Start Address(Lo byte)-0x00

z NO(Hi): No. Of points(Hi byte)-0x00

z NO(Lo): No. Of points (Lo byte)-0x10

z BC: Byte Count-0x02

4.9 Data exchange example—Modbus TCP

In this example a Modbus Master device simulated by a PC program sends query

message and receives response message from a PROFIBUS Master via the GW7553 gateway.

In the following examples the CIF50-PB PROFIBUS Master card from Hilscher is

used. The configuration and communication is done by the program “SyCon”

provided by Hilscher.

Step 1: Copy the GSD file and assign the GW-7553 a valid station address

(Please refer to the section 4.2 GSD file).

Step 2: Connect GW-7553 and PC by Figure 46.

Figure 46 Wiring diagram between PC and GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 49

Page 50

Step 3: Set the parameters of the GW-7553. We need to change “Modbus

Type” to Slave and “Modbus Format” to Modbus TCP. The default

setting is being used in the other parameters for this example. Please

refer to section 4.3 the Configuration of the common parameters.

The users can set parameters as shown below.

Figure 47 Double click the GW-7553 icon to open the

“Slave configuration” window

Figure 48 Click “Parameter Data…” button to open the

“Parameter Data” window

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 50

Page 51

Figure 49 The user needs to change “Modbus Type” to

Slave and “Modbus Format” to Modbus TCP for this

example and click “OK” button

Step 4: Set the GW-7553 modules, as shown in figure 50 and 51.

− Select “System setting” module: “System setting” module always has

to be selected otherwise no communication can be established

between the gateway and the Modbus network.

− Select “Output Relay/Coil” module: In this example a “Output

Relay/Coil--2 Byte” module is selected.

− Select “Input Relay/Coil” module: In this example a “Input

Relay/Coil--2 Byte” module is selected.

Figure 50 Double click the GW-7553 icon to open the

“Slave configuration” window

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 51

Page 52

Figure 51 Select modules

Step 5: Close the “Slave Configuration” window by clicking the “OK”

button.

Step 6: Now the setting done by the configuration tool has to be

downloaded to the PROFIBUS Master.

Click on the Master area in the graphic window then

Online -> Download…

Figure 52 Click “Online->Download” to download the

setting into PROFIBUS Master

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 52

Page 53

Step 7: Set the network settings of the GW-7553 by PROFIBUS/Modbus

gateway utility (please refer section 5.5 & 5.6). The settings of the GW7553 must have the same domain and different IP with the PC (ex: PC’s

IP=192.168.0.106, MASK=255.255.0.0; GW-7553’s IP=192.168.0.107,

MASK=255.255.0.0).

Step 8: Reset the power of the GW-7553 for an active setting.

4.9.1 Receiving data from a Modbus Master device

-- Start the test utility “MBTCP” (figure 53) on the PC.

This utility simulates a Modbus Master device and is on the web site in the

following directory:

http://ftp.icpdas.com.tw/pub/cd/8000cd/napdos/modbus/modbus_utility/

(1) Set the IP address of the GW-7553

(2) Click the connect button

Figure53 MBTCP Utility

--Send Command to write DO of the GW-7553

The user needs to input command (” 01 0F 00 00 00 10 02 FF FF”) here and

click <Send Command> button to send Modbus command: “01 0F 00 00 00

10 02 FF FF” and then MBTCP can receive response message (” 01 0F 00 00

00 10”). The user can find byte 0, 1 of the input data area in the configuration

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 53

Page 54

program “SyCon” have changed into “0xFF” at this time, as shown below.

Figure 54 Send Modbus command (output data: 0xFF, 0xFF)

Figure 55 Receive “0xFF” in the input data area

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 54

Page 55

Table 16 Receive “0xFF” in the input data area

Module Byte Data type Representation Value

Input module

PS:

Modbus command:

Query message

SA

DA FC

(Hi)

01 0F 00 00 00 10 02 FF FF

Response message

SA

DA FC

(Hi)

01 0F 00 00 00 10

Input 0 Byte Hex 0xFF

Input 1 Byte Hex 0xFF

SA

NO

NO

BC DATA

(Lo)

SA

(Lo)

(Hi)

NO

(Hi)

(Lo)

NO

(Lo)

z DA: Device Address-0x01

z FC: Function Code-0x0F=>Write multi-DO

z SA(Hi): Start Address(Hi byte)-0x00

z SA(Lo): Start Address(Lo byte)-0x00

z NO(Hi): No. Of points (Hi byte)-0x00

z NO(Lo): No. Of points (Lo byte)-0x10

z BC: Byte Count-0x02

4.9.2 Receiving data from the PROFIBUS Master device

--Send Command to read DI of the GW-7553

The user needs to input command (” 01 02 00 00 00 10”) in MBTCP and click

<Send Command> button to send Modbus command: “01 02 00 00 00 10”

and then MBTCP can receive response message (” 01 02 02 00 00”). In this

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 55

Page 56

message, the user can know the value of DI0 & DI1 is “0” in the GW-7553.

--Send output data to write DI of the GW-7553 by the PROFIBUS Master

The user needs to set “0xFE” & “0xDC” in byte 3 & byte 4 of output data

area in the configuration program “SyCon” and then set the value of the first

byte from 0 to 1 to trigger the data output command.

--Send Command to read DI of the GW-7553 again

Now the user can input command (” 01 02 00 00 00 10”) in MBTCP and click

<Send Command> button to send Modbus command: “01 02 00 00 00 10”

again. Then MBTCP can receive response message (” 01 02 02 FE DC”). In

this message, the user can know the value of DI0 & DI1 have changed into

“0xFE” & “0xDC” in the GW-7553, as shown in figure 56, 57, 58 & table 17.

Figure 56 Send Modbus command to read DI of the GW-7553

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 56

Page 57

Figure 57 Set output data and trigger output data command

in the output data area

Table 17 Set output data and trigger output data command

Module Byte Data type Representation Value

System

module

Output

module

Output 0 Byte Hex

Output 1 Byte Hex 0x00

Output 2 Byte Hex 0x00

Output 3 Byte Hex

Output 4 Byte Hex

0x00 → 0x01

0x00→ 0xFE

0x00→ 0xDC

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 57

Page 58

Figure 58 Send Modbus command to read DI of the GW-7553 and

receive data (0xFE, 0xDC)

PS:

Modbus command:

Query message

SA

SA

NO

NO

DA FC

(Hi)

(Lo)

(Hi)

(Lo)

01 02 00 00 00 10

Response message

DA FC BC DATA

01 02 02 FE DC

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 58

Page 59

z DA: Device Address-0x01

z FC: Function Code-0x02:read DI

z SA(Hi): Start Address(Hi byte)-0x00

z SA(Lo): Start Address(Lo byte)-0x00

z NO(Hi): No. Of points(Hi byte)-0x00

z NO(Lo): No. Of points (Lo byte)-0x10

z BC: Byte Count-0x02

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 59

Page 60

5. Application of Utility

5.1 Install Utility

Step 1:

Download the PROFIBUS/Modbus gateway utility setup file from the

CD-ROM disk following the path of “CD:\profibus\gateway\gw7553\utilities\” or the web site

“

ftp://ftp.icpdas.com.tw/pub/cd/fieldbus_cd/profibus/gateway/gw-

7553/utilities/”

Step 2:

Execute the Setup.exe file to install the PROFIBUS/Modbus Gateway

Utility.

Figure 59 Install the utility

Step 3:

Click the “Next” button to continue. If you want to change the installation

destination, click “Browse” button to set the installation path.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 60

Page 61

Step 4:

Figure 60 Set the installation path

Click the “Next” button to confirm installation

Figure 61 Confirm installation

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 61

Page 62

Step 5:

Step 6:

Click the “Close” button to finish and exit the installation program

Figure 62 Installation complete

After finishing the installation of the PROFIBUS/Modbus Gateway

Utility, users can find the Utility as shown in the following screen shot.

Figure 63 The path of Utility

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 62

Page 63

5.2 Utility introduction

By this utility, the user can understand the module address of PROFIBUS、

Modbus and the GW-7553. The utility also support users set safe value and

network setting easily. It introduces main window of the utility first as shown in

figure 64.

Figure 64 Main window of the utility

Main window of the utility has 6 parts, they are (1)Menu、 (2)COM Port

settings、(3)Module state、(4)Module parameters、(5)Connection status of GW7553 and COM Port、(6) Status bar, as shown in the below.

5.2.1 Menu:

1. Communication =>

a. Connect:Open COM Port and connect with the GW-7553

b. Disconnect:Close COM Port and disconnect with the GW-7553

c. Exit:Exit from the utility

2. IP Setting =>

a. New Setting:Open a new IP setting.

b. Load from file:Load a IP setting from the file.

c. Load from device:Load a IP setting from the GW-7553.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 63

Page 64

3. Safe Value Setting =>

a. New Setting:Open a new safe value setting.

b. Load from file:Load a safe value setting from the file.

c. Load from device:Load a safe value setting from the GW-7553.

4. View =>

a. Space configuration in device:Display memory address configuration

of select module in the GW-7553.

b. Space configuration in PROFIBUS:Display memory address

configuration of select module in PROFIBUS Master station.

c. Space configuration in Modbus:Display memory address

configuration of select module in the Modbus.

5. Help =>

a. Get Firmware Version From Module:Show firmware version of the

GW-7553.

b. About Utility:Show about version of the utility.

5.2.2 COM Port settings:

1. Port: COM1~COM8

2. Baud rate: 2400/4800/9600/19200/38400/57600/115200

3. Parity: None/Odd/Even

4. Data bit: 8 data bit

5. Stop bit: 1 stop bit

5.2.3 Module state:

It can display the number of modules in the GW-7553 and display module

parameters in the window of the module parameter by click the module’s icon.

5.2.4 Module parameters:

Display module parameters of the GW-7553.

5.2.5 Connection status of device and COM Port:

Module state:Display connection status between the utility and the GW-7553.

The green color means connected and the red color means

disconnected.

COM Port state:Display state of the PC’s COM Port. The green color means

COM Port is open and the red color means COM Port is close.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 64

Page 65

5.2.6 Status bar:

Display messages about COM Port connection、the GW-7553 connection and

the progress of data transmission.

5.3 Memory address configuration of the module

There are 3 kinds of memory address configuration. They are (1)Space

configuration in device 、 (2) Space configuration in PROFIBUS 、(3)Space

configuration in Modbus, as shown in figure 65.

Figure 65 The menu of space configuration

5.3.1 Space configuration in device:

The user can select check box of the module to show memory address

configuration of DI/DO/AI/AO in the GW-7553, as shown in figure 66.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 65

Page 66

Figure 66 Space configuration in device

5.3.2 Space configuration in PROFIBUS:

The user can select check box of the module to show memory address

configuration of I/O data area in the PROFIBUS Master station, as shown in

figure 67.

Figure 67 Space configuration in PROFIBUS

5.3.3 Space configuration in Modbus:

The window of “Space Configuration in Modbus” divided into 3 parts to explain,

as shown in figure 68.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 66

Page 67

) Select module:

(1

The user can select

check box of the module to show memory address

configuration of DI/DO/AI/AO in Modbus network.

(

2) Display interface:

The user can click “W

rite Output” button to show DO/AO memory

address configuration of output modules in Modbus network, click “Read

Input” button to show DI/AI memory address configuration of input

modules in Modbus network, click “Read Output” button to show DO/AO

memory address configuration of input modules in Modbus network.

(

3) Color display:

The user can disc

riminate states of Modbus address configuration by

different color. White means the address is not used. Light blue means the

address was configured by a module. Mazarine means the address was

configured by many modules, but Modbus ID is not repeat in these

modules. Red means the address was configured by many modules and

Modbus ID is repeat in these modules. The data may be read and written

by different modules at this time, it may make the data transmit and

device control error easy because address configuration and Modbus ID

overlap.

Figure 68 Space configuration in Modbus

5.4 Safe value setting

There are 3 kinds of safe valu

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 67

e setting. They are (1) Open a new setting、(2)Load

Page 68

from file、(3)Load from device, as shown in figure 69.

Figure 69 The menu of safe value setting

The window of “Safe Value Setting” divided into 6 parts to explain, as shown in

figure 70.

1) Select module:

(

The user can sele

ct check box of the module to know memory address

configuration of the module for set safe value of the module.

(2) DI/O table:

The user can do

uble click left button of mouse at the value of DI/DO to change

the value from “H” to “L” or “L” to “H”.

(3) All DI/O setting:

The user can click “A

ll set to H” button to set all of DI/DO to “H” and click “All

set to L” button to set all of DI/DO to “L”.

(4)AI/O table:

The user can d

ouble click left button of mouse at the value of AI/AO to change

the value into 0x0000~0xFFFF.

(5) All AI/O setting:

The user can click “A

ll set to F” button to set all of AI/AO to “0xFFFF” and click

“All set to 0” button to set all of AI/AO to “0x0000”.

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 68

Page 69

(6) Display and Save interface

The user can click “Output” b

“Input” button to show safe value setting of DI/AI, click “Save to File” button to

open “save file dialog” to save safe value setting for backup, click “Save to

Device” button to save safe value setting to EEPROM of the GW-7553.

utton to show safe value setting of DO/AO, click

Figure 70 Safe value setting

5.5 IP setting

There are 3 kinds o

file、(3)Load from device, as shown in figure 71.

f IP setting. They are (1) Open a new setting、(2)Load from

Figure 71 The menu of IP setting

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 69

Page 70

3 parts to explain, as shown in figure 72.

The window of “IP Setting” divided into

1) Local IP Setting:

(

The user can set local

(2) Rem

The user can set IP add

TCP Slave in this part. When GW-7553 acts as a Modbus TCP Master, these

settings are effective. GW-7553 can connect Modbus TCP Slave devices by these

IP settings and the maximum of Modbus TCP Slave device is 8.

(3

) Save interface

The user can click

setting for backup, click “Save to Device” button to save IP setting to EEPROM

of the GW-7553.

ote IP Setting:

IP setting of GW-7553 in this part.

ress, time out value and reconnecting time of the Modbus

“Save to File” button to open “save file dialog” to save IP

Figure 72 IP setting

5.6 Establish connection with GW-7553

he connection of Utility and GW-7553 is shown in figure 73. Please follow the

T

steps to establish connection.

S

tep 1:

ire COM Port of PC to RS-232 port of GW-7553.

W

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 70

Page 71

Step 2:

C

onnect PROFIBUS cable between PROFIBUS Master station and GW7553 and enter data exchange mode (please refer step 1~6 of section 4.8

PROFIBUS and Modbus data exchange demo for detail). The RUN LED

of GW-7553 is going to light at this time.

Figure 73 The connection of Utility and GW-7553

Step 3:

S

et bit 2 of byte 1 to High in output data area of the PROFIBUS Master

station (set the GW-7553 to setting mode; please refer section 4.6.2

Output data area and communication command) or turn the switch on the

back of the GW-7553 to setting mode (please refer section 2.6

Normal/Setting DIP switch).

Step 4:

Open Utility.exe on PC.

Figure 74 Open Utility

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 71

Page 72

Step 5:

Step 6:

Set COM Port communication setting of Utility (please refer section 5.2.2

COM Port settings) the same as COM Port setting of GW-7553(please

refer section 4.3 The Configuration of the common parameters)

Click “Communication=>Connect” button in menu.

Step 7:

Figure 75 Communication menu

Module state shows green in the Utility now, it means the connection is

complete.

Figure 76 Display connection state

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 72

Page 73

6. Troubleshooting

The troubleshooting list can help users to resolve the problems when using the GW-

7553. If the problem still can't be solved, please contact with technical staff of ICP

DAS.

Table 18 Errors and solutions

Item Trouble state Solution

'PWR' LED indication of

1

the GW-7553 is always

turned off

'ERR' LED indication of the

2

GW-7553 is always turned

on

'ERR' LED indication of the

3

GW-7553 is flashing fast

'ERR' LED indication of the

4

GW-7553 is flashing slow

PROFIBUS Master station

can not communicate with

the Modbus device, when

5

“RUN LED” of the GW7553 is light and “ERR

LED” of the GW-7553 is

dark.

The power supply of GW-7553 has some problems. Please check

the wire connection of the power and the voltage is between

10~30V

That means the GW-7553 isn't connecting to the PROFIBUS

Master station. Please check the wire connection and the

PROFIBUS Master s

GW-7553 in the PROF

It means the GW-7553 is in setting mode and connects with

Utility. Please close Utility and set the GW-7553 to operation

mode (please refer section 2.6 Normal/Setting DIP switch and

section 4.6.2 Output data area and communication command).

It means the GW-7553 has diagnostic messages. Please check

diagnostic messages in the PROFIBUS Master station.

a. Please confirm the GW-7553 is working in operation mode

b. Please confirm the connection between the GW-7553 and

c. Please confirm COM Port setting (please refer section 4.3

d. Please confirm module ID of the GW-7553 (please refer

e. Please confirm Setting of Start Address and NO. of

f. Please confirm the output data put in correct address and have

DC.

tation. T configuration and address of

IBUS Master station are not correct.

and avoid clearing diagnostic message by communication

command (please refer section 2.6 Normal/Setting DIP

switch and section 4.6.2 Output data area and communication

command).

Modbus device.

The Configuration of the common parameters) or IP setting

(please refer section 5.5 IP setting) of the GW-7553 the same

as the Modbus device.

section 4.3 The Configuration of the common parameters and

section 4.4 The Configuration of the modules) the same as

Modbus address of Modbus device.

Relay/Coil is correct (please refer section 4.4 The

Configuration of the modules).

changed value of byte 0 to trigger the output command, when

output data can not send to Modbus device in output data area

of PROFIBUS Master (please refer section 4.6.2 Output data

area and communication command).

he

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 73

Page 74

7. Dimensions

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 74

Page 75

GW-7553 PROFIBUS/Modbus TCP Gateway User Manual (Version 1.00, Dec/2008) PAGE: 75

Loading...

Loading...