Page 1

Not Recommended for New Installations.

Please contact Technical Support for more information.

Strain Gauge/Load Cell Bridge Amplifier

Documentation Number FBDA0797

Designed and Manufactured

of domestic and imported part s by

B&B Electronics Mfg. Co. Inc.

707 Dayton Road -- P.O. Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Model FBDA

This product

In Ottawa, Illinois

USA

Internet:

http://www.bb-elec.com

orders@bb-elec.com

support@bb.elec.com

1997 B&B Electronics

Documentation Number FBDA0797 Manual Cover Page

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 2

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION.................................................................1

F

EATURES ...............................................................................................1

ACKING LIST ..........................................................................................2

P

OFTWARE ..............................................................................................2

S

ALIBRATION ...........................................................................................2

C

FBDA S

CHAPTER 2: CONNECTIONS..................................................................3

P

S

D

CHAPTER 3: GAIN SELECTION..............................................................7

CHAPTER 4: EXCITATION VOLTAGE....................................................9

PECIFICATIONS............................................................................2

OWER SUPPLY CONNECTIONS ................................................................3

ENSOR CONNECTIONS............................................................................3

ATA ACQUISITION CONNECTIONS ............................................................4

Documentation Number FBDA0797 Manual Table of Contents i

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 3

Chapter 1: Introduction

Features

The FBDA is a signal conditioning module that allows you to

measure voltages produced by full-bridge sensors using a data

acquisition module. This module can condition signals from Strain

Gauges, Load Cells, Pressure Sensors, and other Full-Bridge

Transducer Sensors. A number of different gain settings are

available on the FBDA to accommodate a wide variety of voltage

ranges. The FBDA also provides an adjustable excitation voltage for

the full-bridge circuitry. The sensor connections are made using

terminal blocks, and the A/D connections are made through a DB-25

connector. B&B Electronics’ SDAXX, and ADIO12 data acquisition

modules are pin compatible with the FBDA. This allows you to

simply plug one of the data acquisition modules mentioned above

into the FBDA, and the A/D connections are complete. The SPDA

data acquisition modules can also be used with the FBDA.

Figure 1.1: FBDA Module

Documentation Number FBDA0797 Manual 1

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 4

Packing List

Examine the shipping carton and the contents for physical

damage. The following items should be in the shipping carton:

1. FBDA module

2. This instruction manual

If any of these items are damaged or missing, contact B&B

Electronics immediately.

Software

Software is not included with the FBDA module. This device is

used in conjunction with a data acquisition device. All of B&B

Electronics’ data acquisition modules come complete with software

that you can modify to meet your exact needs.

Calibration

The FBDA is calibrated at the factory. The excitation

voltage is set to 5VDC ± 0.05VDC and the gain is calibrated at 80 ±

2. The process of calibrating the FBDA and your sensor will vary

depending on the type of sensor being used. An example calibration

procedure is covered in Chapter 3.

FBDA Specifications

Size: 4.8 x 2.2 x 0.9 in

Maximum Input Voltage from Sensor: 440mV (using Gain = 25)

Output Voltage Range: 0.003V to 11VDC

Gain: 25, 40, 80, 220-1000

Maximum Gain Error: 5% of gain setting max.

Input Offset Voltage: 150

Input Offset Voltage Drift: 1.5

Excitation Voltage: 0.5VDC to +11VDC

Operating Temperature Range: 0 to 70

Power Requirements: 13-18VDC @10mA (does

2 Documentation Number FBDA0797 Manual

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

µV max.

o

µV/

C

o

C

not include current draw

from excitation voltage.)

Page 5

Chapter 2: Connections

Power Supply Connections

The FBDA module requires 13 to 18VDC @ 10mA. Model

232PS2 available from B&B Electronics is recommended. Although

the 232PS2 is a 12VDC power supply, it outputs a voltage above

13VDC when less than 10mA are being drawn from it. The power

supply is connected to the terminal blocks marked +13V and GND.

Make sure the polarity of the power supply is correct (the white

striped wire on the 232PS2 is the positive lead).

Sensor Connections

Most full-bridge sensor circuits require four connections for the

sensor to operate properly. These connections will be made using

the terminal blocks. First, an excitation voltage is required to excite

the bridge circuitry. This can be done using the adjustable excitation

voltage (marked EXV) available on the FBDA, or another voltage

source can be furnished by the user. This excitation voltage is

referenced with respect to ground, which is the second connection

(marked GND). The remaining two leads from the sensor carry the

differential signal voltage that is to be conditioned and read by the

data acquisition module. These two leads are connected to SIG+

and SIG-. Consult your sensor manual to determine the signal lead

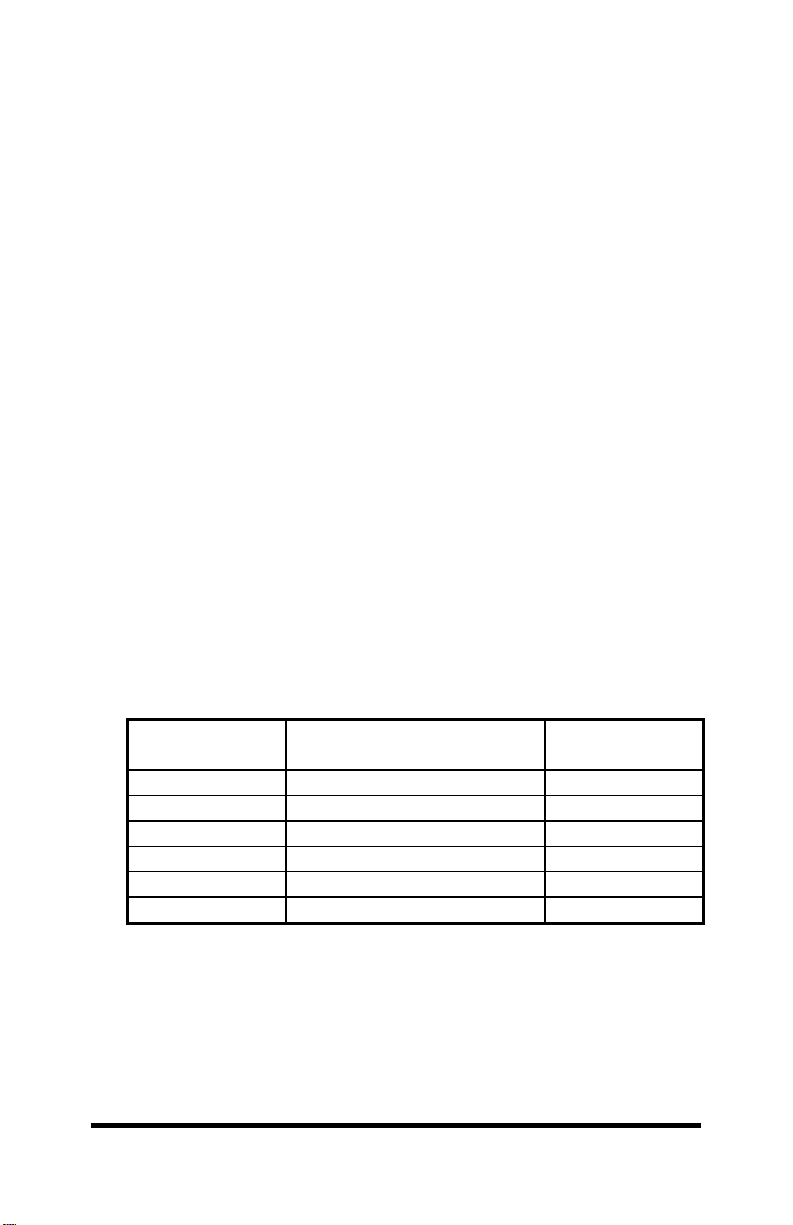

polarity. Table 2.1 shows the terminal block assignments.

Table 2.1: Terminal Block Assignments

Terminal

Block Name

SIG+ Positive Signal Lead Input

SIG- Negative Signal Lead Input

EXV Excitation Voltage Output

A/D 1 A/D Converter channel Input

+13V Power Supply Connection Input

GND Power Supply Connection Input

Note: A/D 1 is connected straight through from the terminal blocks

to DB-25 pin # 9. This allows access to A/D channel 1 on B&B

Electronic’s SDAXX line of A/D converters. This channel can read

voltages between 0 and 5VDC (useful for calibrating the excitation

voltage). This channel has no signal conditioning circuitry. It is

simply connected to A/D 1 on the data acquisition module.

Function I/O

Documentation Number FBDA0797 Manual 3

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 6

Data Acquisition Connections

The connections to the Data Acquisition Module are made

through a DB-25 (male) connector. The FBDA is pin compatible with

B&B Electronics’ SDAXX, and ADIO12 modules. This allows you to

simply plug the FBDA into one of the above data acquisition

modules, and the data acquisition module connections to the FBDA

are complete. Table 2.2 contains the DB-25 (male) pin

assignments.

Table 2.2: DB-25 (Male) Pin Assignments

DB-25 Pin # Function DB-25 Pin # Function

1 GND 14 ------2 ------- 15 ------3 ------- 16 ------4 ------- 17 looped to 18

5 ------- 18 looped to 17

6 ------- 19 GND

7 GND 20 ------8 Vout 21 -------

9 A/D 1 22 ------10 ------- 23 ------11 ------- 24 ------12 ------- 25 ------13 -------

1. ------- denotes no connection.

2. The conditioned sensor signal is available on pin #8 and is

labeled Vout.

3. Pin #9 is connected straight through to terminal block A/D 1 (no

signal conditioning circuitry).

4. Pins #17 and #18 are looped to each other to provide +5V to

REF+ in the SDAXX line of A/D modules.

5. Pin #19 provides 0V to REF- in the SDAXX line of A/D modules.

Figure 2.1 contains a diagram of the connections required to read

the signal produced by a sensor.

4 Documentation Number FBDA0797 Manual

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 7

Note: Conditioned signal is

available on DB-25 pin #8

and is labeled as Vout.

Sensor

A/D 1

+13V

Terminal Blocks

1

SIG-

2

SIG+

3

EXV

4

5

FBDA

Module

DB-25P Connector

1

GND

7

GND

88

Vout

99

171817

1

7

18

+13V REF+

6

19 19

GNDGND

Figure 2.1: Block Diagram of FBDA Connections

GND

GND

A/D 0

A/D 1

+5V

REF-

D

/

A

e

l

u

d

o

M

Documentation Number FBDA0797 Manual 5

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 8

Chapter 3: Gain Selection

The FBDA has several different gain settings to provide the

largest possible voltage range for an A/D converter. The gain of the

FBDA is selected using a jumper, 6 jumper pins (labeled 1-6), and a

potentiometer (labeled P1). The FBDA is calibrated at the factory to

have a gain of 80 ± 2. To change the gain of the FBDA the

following steps should be followed:

1. Remove the cover from the FBDA using a small slotted

screwdriver.

2. There are six jumper pins labeled 1-6. Place the jumper on the

two pins selected from Table 3.1 below. Placing the jumper on

the two selected pins will set a gain near the values listed in

Table 3.1.

3. Make all of the required connections (power supply, A/D

converter, sensor, and excitation voltage), and turn on the

power.

4. Set up your sensor to provide a known input signal for the

FBDA. If you are using a load cell, place a known weight on the

load cell. This will produce a known input signal.

5. The output voltage from the FBDA can be read from DB-25 pin 8

(A/D 0 on B&B Electronics’ SDAXX data acquisition modules).

6. Adjust P1 to trim the gain to an exact value. The gain equation

is shown below. ((SIG+) - (SIG-)) is the input signal.

Table 3.1: Jumper Selection to Choose Gain

Gain Jumper Selection

25 Jumper pin 5 to pin 6

40 Jumper pin 4 to pin 5

80 Jumper pin 2 to pin 3

220-1000 Jumper pin 1 to pin 2

1. The potentiometer (P1) becomes more critical as the gain is

increased.

2. The gain range of 220 to 1000 is entirely decided by P1. When

P1 is turned completely in counter-clock-wise, the Gain will be

close to 220. When P1 is turned completely clock-wise, the

Gain will be greater than 1000.

Documentation Number FBDA0797 Manual 7

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 9

Gain Equation

GAIN = Vout / ((SIG+) - (SIG-))

Sensors that incorporate bridge circuitry usually have

noticeable zero offsets. This should be considered when taking

measurements and determining gain. The easiest way to solve this

problem is to calibrate the system while avoiding zero inputs, and

correct for the zero offset in software.

Example:

If a 10lb. load cell needs to be calibrated, the suggested method

is the following:

1. Make all of the required connections.

2. Place a 1lb. mass on the load cell. Record the voltage on DB-

25 pin 8 as Vouta. Pin 8 is A/D 0 on the SDAXX modules.

3. Add a second 1lb. mass onto the load cell. Record the voltage

on DB-25 pin 8 as Voutb.

4. Subtract Vouta form Voutb. The difference is the voltage, Vout,

which corresponds to 1lb.

5. Calculate what ((SIG+) - (SIG-)) is for 1lb. This is the voltage

produced by the sensor.

6. Use the Gain Equation to calculate the exact gain of the

amplifier.

7. Adjust P1, and repeat process until the desired gain is achieved.

8. Subtract Vouta from Vout. The difference is the zero offset

error. The zero offset error should be included in any equation

conversion equation used in your software.

8 Documentation Number FBDA0797 Manual

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Page 10

Chapter 4: Excitation Voltage

Sensors that are based on a Wheatstone bridge need an

excitation voltage to excite the bridge. The FBDA provides an

adjustable excitation voltage. This excitation voltage is available on

the terminal block labeled EXV. The excitation voltage is set to

5VDC ± 0.05VDC at the factory. This voltage is referenced with

respect to GND. To adjust the excitation voltage, the following steps

should be followed:

1. Remove the cover from the FBDA module using a small slotted

screwdriver.

2. Make all of the required connections except the sensor

connections and turn on the power.

3. Using a voltmeter, measure the voltage on the terminal block

labeled EXV with respect to the GND terminal block. Adjust P2

to change the excitation voltage. The terminal block labeled A/D

1 can be used to measure the excitation voltage.

Sensors that are comprised of Wheatstone bridges usually state

the amount of output per volt of excitation voltage. An example is:

10mV output / 1V of excitation. If a 5V excitation voltage is used,

The full scale output of the sensor will be 50mV. The gain of the

FBDA should then be chosen, so that Vout does not exceed 5V (the

maximum voltage that the SDAXX line of data acquisition modules

can measure).

If for some reason the excitation voltage source in the FBDA

does not meet your needs, you can use an external excitation

voltage. If this is the case, then nothing should be connected to the

EXV terminal block, and the GND lead of the external excitation

voltage source should be connected to the GND terminal block on

the FBDA module.

Documentation Number FBDA0797 Manual 9

B&B Electronics -- PO Box 1040 -- Ottawa, IL 61350

PH (815) 433-5100 -- FAX (815) 433-5105

Loading...

Loading...