Page 1

Zlinx

series

Wireless Modbus I/O Modules

Models:

RT12-0044-ZP-12

RT12-2222-ZP-12

RT12-4444-9T-W20

Documentation Number: RT-12 series-4006m (pn#7331)

This product designed and manufactured in Ottawa, Illinois USA

of domestic and imported parts by

707 Dayton Road -- P.O. Box 1040 -- Ottawa, IL 61350 USA

Phone (815) 433-5100 -- General Fax (815) 433-5105

Phone (815) 433-5100 -- General Fax (815) 433-5105

Website: www.bb-elec.com

Sales e-mail: orders@bb-elec.com

Technical Support e-mail: support@bb.elec.com

European Headquarters

Westlink Commercial Park -- Oranmore, Co. Galway, Ireland

Phone +353 91-792444 -- Fax +353 91-792445

Website: www.bb-europe.com

Sales e-mail: sales@bb-europe.com

Technical Support e-mail: support@bb-europe.com

B&B Electronics Mfg. Co. Inc. -- October 2006

-- Fax (815) 433-5109

-- Fax (815) 433-5104

B&B Electronics

DO NOT OPERATE ANY EQUIPMENT UNTIL THIS MANUAL

IS READ IN ITS ENTIRETY

2006 B&B Electronics. No part of this publication may be reproduced or transmitted in any form or by any

©

means, electronic or mechanical, including photography, recording, or any information storage and retrieval

system without written consent. Information in this manual is subject to change without notice, and does not

represent a commitme n t on the part of B&B Electroni c s .

B&B Electronics shall not be liable for incidental or consequential damages resulting from the furnishing,

performance, or use of this manual.

All brand names used in this manual are the registered trademarks of their respective owners. The use of

trademarks or other designations in this publication is f or reference purposes only and does not constitute an

endorsement by the trademark holder.

This document contains information that is proprietary and confidential to B&B Electronics Mfg. Co. Inc. The

methods described herein are for the exclusive use of B&B Electronics authorized per sonnel. Any unauthorized

use or dissemination of the information contained in the document is strictly forbidden.

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: RT-12 series-4006m

Page 2

Wireless I/O Modules – from B&B Electronics

We value our customers. If you have any suggestion to improve o ur system please

contact us at: support@bb-elec.com

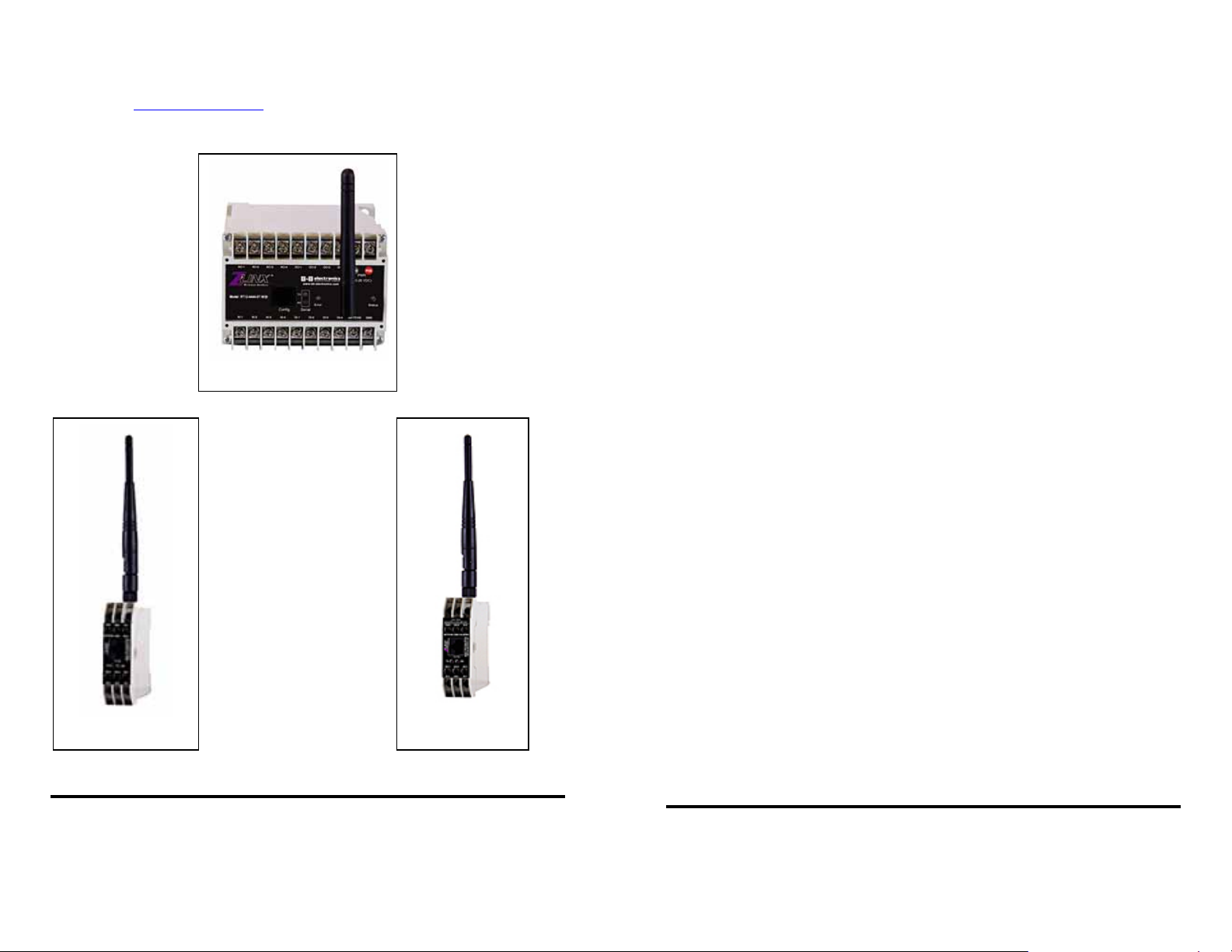

RT12-4444-9T-W20

RT12-0044-ZP-S12

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: RT-12 series-4006m

RT12-2222-ZP-S12

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Manual Documentation Number: RT-12 series-4006m

Page 3

Table of Contents

Chapter 1 – Introduction............................................................................................1

THEORY OF OPERATION..............................................................................................1

MODBUS OVERVIEW...................................................................................................3

MODBUS FUNCTIONS SUPPORTED...............................................................................5

MODBUS REGISTER MAPS ..........................................................................................6

PEER TO PEER OVERVIEW...........................................................................................8

Chapter 2 – System Identification...........................................................................10

RT12-4444-9T-W20 – FRONT PANEL IDENTIFICATION............................................10

RT12-4444-9T-W20 – EXTERNAL BATTERY BACK-UP............................................13

RT12-2222-ZP-S12 – FRONT PANEL IDENTIFICATION .............................................14

RT12-2222-ZP-S12 – EXTERNAL BATTERY BACK-UP.............................................17

RT12-0044-ZP-S12 – FRONT PANEL IDENTIFICATION .............................................18

RT12-0044-ZP-S12 – EXTERNAL BATTERY BACK-UP.............................................21

HARDWARE SET-UP ..................................................................................................22

Typical Application: Peer-to-Peer......................................................................22

Typical Application: Modbus..............................................................................24

Typical Application: Well Monitor and Control (Peer-to-Peer)........................25

Typical Application: Well Monitor and Control (Mo dbus) ...............................26

Typical Application: 4-20 mA to Voltage Conversion........................................27

Configuration Cable Description........................................................................28

Chapter 3 – Configuration & Programming..........................................................29

CONFIGURATION/MONITORING SOFTWARE SYSTEM MAP........................................29

CONFIGURATION/MONITORING SOFTWARE MAIN PAGE...........................................30

CONTROLLER CONFIGURATION ................................................................................31

CURRENT CONTROLLER SETTINGS ...........................................................................32

CONNECTING / DISCONNECTING...............................................................................35

Master, Slave, Modbus, Peer-to-Peer.................................................................36

MODBUS CONFIGURATION........................................................................................37

DIGITAL INPUT TYPES ..............................................................................................38

RTU ALARMS...........................................................................................................39

ANALOG OUTPUTS RESTING VOLTAGE.....................................................................42

UPDATING/SENDING CONFIGURATION TO RTU........................................................45

THIRD PARTY COMMUNICATIONS PROTOCOL SUPPORT ...........................................46

STATUS BAR.............................................................................................................47

DIGITAL OUTPUTS ....................................................................................................48

Manual Documentation Number: RT-12 series-4006m Table of Contents i

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

ii Table of Contents Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 4

Chapter 1 – Introduction

Theory of Operation

This manual will refer to two types of SCADA communications to pologies, Peer to

Peer (P2P) and Modbus.

The Peer to Peer topology

and digital I/O is communicated between the Master and Slave.

The Modbus topology

Modbus slaves. The Modbus master is responsible for requesting data from a

respective Modbus slave.

The ‘RT’ serie s RTU’s have se veral unique functions and features and has been

designed to replicate a wired sensor system. Transmission distances of up to 40 miles

(64 km), (depending on the radio type and with modified antennas), user

programmable sample/polling rates from 10 sam ples/sec to one sample every 20

seconds, programmable transmission retries, user programmable “full scale”

engineering units allow users to enter full scale for a respective sensor, just to name a

few.

The hardware architecture for RT series RTU’s are identical. Number of analog or

digital I/O depends on the type of RTU. Each respective RTU has Bi-directional

analog signal flow.

Other features include:

-Battery backup and in -circuit charging sys tem,

-MODBUS-RTU-Slave Enhancements,

-Programmable main voltage failure alarm,

-Low and high input voltage alarm,

-Communications failure alarm,

-Programmable resting voltages on communication failure,

-Programmable Output to Active High or Low during Communications Failure,

-Report by exception if a respective input changes by a +/- percentage,

-Configurable Inputs to Digital, Frequency or Accumulato r/Total.

An enhanced monitoring and configuration windows based program, allows you to

configure each controller as well as monitor data.

consists of one “Master” and one “Slave” RTU. Analog

consists of one Modbus Master, and as many as 255

Your system may consist of two RT type wireless analo g bridges or RTU. In Peer to

Peer mode, one controller must be programmed as the master and the other as the

slave. It is critical that your system be programmed properly. Confi rm your system

configuration before using your system.

All configuration parameters may be retrieved by connecting to the respective

device’s serial configuration port. The wireless type and other parameters may be

adjusted or viewed.

For Peer-to-Peer mode, check and confirm the following:

___ Your system consists of one MASTER and one SLAVE. Do not allow two

masters or two slaves to communicate with each other. The devices may communicate

but a systems failure will occur.

___ Make sure the system ID’s and RF-Network ID’s match.

WARNING:

ID numbers for the Master and Slave must match and must not be repeat ed with

any other Master/Slave pairs with the same RF-Network ID within the radio

range of each respective wireless pair. Doing so will cause cross talk between

master/slave pairs.

___ Make sure both Master and Slave have an antenna attached and installed correctly.

___ Make sure that the input power supply doe s NOT exceed 28 Vdc.

___ Make sure that the input power supply does N OT fall below 8.5 Vdc.

___ When power is applied to both the master and slave both units will communicate

with each other.

For Modbus Slave RTU mode, check and confirm the following:

___ Your system does not consist of two RT RTU/devices with the same Slave ID

numbers.

___ Each RTU/device has the same Radio ID and RF-Network ID numbers. Your

Modbus Master device will need to be connected to our Packaged Modbus Modem

(PMM) and will need to be configured with the same Radio ID and RF-Network ID

numbers as the Modbus Slave devices. The PMM may be configured to allow for an

RS-232 or RS-485 communications port.

Manual Documentation Number: RT-12 series-4006m 1

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

2 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 5

Modbus Overview

This section is written for the person who will use the RT series RTU’s with Modicon

Modbus protocols for communication in Modicon programmable controller

applications. It describes the different types of Modbus registers supported. The RT

Series RTU’s support Modbus, Slave RTU mode.

The Modbus protocol provides the internal standard that the Modicon controllers use

for parsing messages. During communications on a Modbus network, the protocol

determines how each controller will know its device address, recognize a message

addressed to it, determine the kind of action to be taken, and extract any data or other

information contained in the message.

All of the RT series RTU’s use a common Modbus communications protocol. All data

is sent and received raw units.

Engineering Note: It may be necessary to force your PLC or Modbus master device

to delay between Modbus packet transmissions. Some devices transmit without a

break in data packets. Because of the nature of half-duplex radio you may need to

configure or program your device with a 30-50 mS delay between packets and a 1.5-

2.0 second timeout.

Modbus Data: Some Modbus devices send data differently than others. This example

shows Slave address 9, using fu n ction 3 and 16. It also shows he full data address of

40001. The RT series RTU’s do not send the full address. The Modbus protocol

allows a system to assume the data address based on the function type. This is true of

all Modbus functions for the RT series RTU’s.

09 03 9C 40 00 01 91 7E

09 10 9C 40 00 01 02 00 00 9E 54

09 = Slave 9

03 = Read Holding Registers

9C = Starting Address High -\

40 = Starting Address Low -/ 40001

00 = Number of Points High-\

01 = Number of Points Low -/ Read 1 Point

91 = Check Sum

7e = Check Sum

This is an example showing what data would look like for

the RT series RTUs.

09 = Slave 9

03 = Read Holding Registers

00 = Starting Address High -\

00 = Starting Address Low -/ 40001

00 = Number of Points High-\

01 = Number of Points Low -/ Read 1 Point

91 = Check Sum

7e = Check Sum

Manual Documentation Number: RT-12 series-4006m 3

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

4 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 6

Modbus Functions Supported

01 Read Coil Status: Reads the ON/OFF status of discrete outputs (0X references,

coils) in the slave. Broadcast is not supported.

02 Read Input Status: Reads the ON/OFF status of discrete inputs (1X references) in

the slave. Broadcast is not supported.

03 Read Holding Registers: Reads the binary contents of holding registers (4X

references) in the slave. Broadcast is not supported.

04 Read Input Registers: Reads the binary contents of input registers (3X references)

in the slave. Broadcast is not supported.

05 Force Single Coil: Forces a single coil (0X reference) to either ON or OFF.

06 Preset Single Register: Presets a value into a single holding registe r (4X

reference).

15 (0F Hex) Force Multiple Coils: Forces each coil (0X reference) in a sequence of

coils to either ON or OFF.

16 (10 Hex) Preset Multiple Registers: Presets values into a sequence of holding

registers (4X references).

Modbus Register Maps

RT12-4444 Modbus Map

Function 1

00001 Digital Input 1

00002 Digital Input 2

00003 Digital Input 3

00004 Digital Input 4

Function 2

10001 Digital Input 1

10002 Digital Input 2

10003 Digital Input 3

10004 Digital Input 4

Function 3 (Holding Reg)

40001 AO 1

40002 AO 2

40003 AO 3

40004 AO 4

40005 Freq Input 1

40006 Freq Input 2

40007 Totalize 1 Low

40008 Totalize 1 High

40009 Totalize 2 Low

40010 Totalize 2 High

40011 Time to Save Counter

Function 4 (Inputs)

30001 AI 1 12bit

30002 AI 2 12bit

30003 AI 3 12bit

30004 AI 4 12bit

30005 Vin 10bit

RT12-0044 Modbus Map

Function 1

00001 Digital Input 1

00002 Digital Input 2

00003 Digital Input 3

00004 Digital Input 4

Function 2

10001 Digital Input 1

10002 Digital Input 2

10003 Digital Input 3

10004 Digital Input 4

Function 3 (Holding Reg)

40001 FQ1 (Input-1)

40002 FQ2 (Input-2)

40003 Totalize 1 Low

40004 Totalize 1 High

40005 Totalize 2 Low

40006 Totalize 2 High

40007 Time To Save Counter

Function 4 (Inputs)

30001 Main Vin 10Bit

30002 Batt Vin 10Bit

Manual Documentation Number: RT-12 series-4006m 5

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

6 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 7

RT12-2222 Modbus Map

Function 1

00001 Digital Input 1

00002 Digital Input 2

Function 2

10001 Digital Input 1

10002 Digital Input 2

Function 3 (Holding Reg)

40001 AO 1

40002 AO 2

40003 Freq Input

40004 Freq-2/Input 1

40005 Freq-3/Input 2

40006 Total Count 1_Low

40007 Total Count 1_High

40008 Total Count 2_Low

40009 Total Count 2_High

40010 Time To Next Save

Function 4

30001 AI 1

30002 AI 2

30003 Battery Input

30004 Main Input

Manual Documentation Number: RT-12 series-4006m 7

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Peer to Peer Overview

Peer to Peer mode can be described as a Wireless Signal Re plicator. The product line

of RT series RTU’s can be configured as a Peer to Peer device. Two of the same type

RTU’s are required to create a peer to peer system, one Master and one Slave.

The master or slave is determined by the way It is

configured. The only difference between a master and

slave is, the master is responsible for starting the

communication process.

Both the master and slave must contain the same Radio ID

and Subnet Value. Only the respective peer-to-peer

systems may have the same Radio ID and RF-Network

numbers. Failure to do so will cause erratic output

voltages, AO’s or Digital Outputs, DO’s.

Each respective “RT” RTU device has the same number of Analog Inputs (AI’s),

Analog Outputs (AO’s), Digital Inputs (DI’s) and Digital Outputs (DO’s).

The number and type of I/O will depend on the type of RTU. Each RTU, including

I/O, is described in this manual.

Peer to Peer mode will allow you to transmit a 0-5 Vdc analog input, or a Digital

Input, from a Master device to a Slave device and vice-versa. A master’s analog or

digital inputs, become a slave’s analog or digital outputs, and vice-versa. This allows

for a full-duplex, looped system.

An application example would be a remote PLC with the RT12-2222’s analog and

digital I/O connected to it, this RTU will be conf igured as a Master. The Slave device

would monitor and control a water well system and would be connected to several

sensors, pump status indicators, current sensor, etc.

The PLC will view the analog and digital signals from the slave device as if the PLC

was connected directly to the several sensors, pump status indicators, current sensor,

etc. See “Typical Application – Well Monitor and Control, Peer-to-Peer” in this

manual.

8 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 8

Note: This section assumes that your computer is equipped

with a serial port and you have installed the RT series

configuration software.

To Connect to a Controller:

1) Install the configuration software (setup.exe).

2) Apply Power to the controller. The heartbeat/sanity LED will begin to FLASH.

3) Connect the programming cable to your PC’s serial Port.

4) Launch the “Configuration” software.

5) You must select a communications port. Select “Comm”, “Serial” then the desired

serial port.

6) The “Connect” box will be Red.

7) Press the “Connect” Button. The “Asserting” check box will become checked.

8) If the software successfully connects to the controller,

9) The “Connect” check box will become checked and the “Connect” butt on will turn

Green.

10) The software will begin retrieving configuration data from the controller you are

connected to. If all data boxes are not filled in refer back to step #6 in this section.

11) The software will indicate the type of device, Master or Slave.

12) For further programming features see, “Configuration/Programming Software

Setup.”

Chapter 2 – System Identification

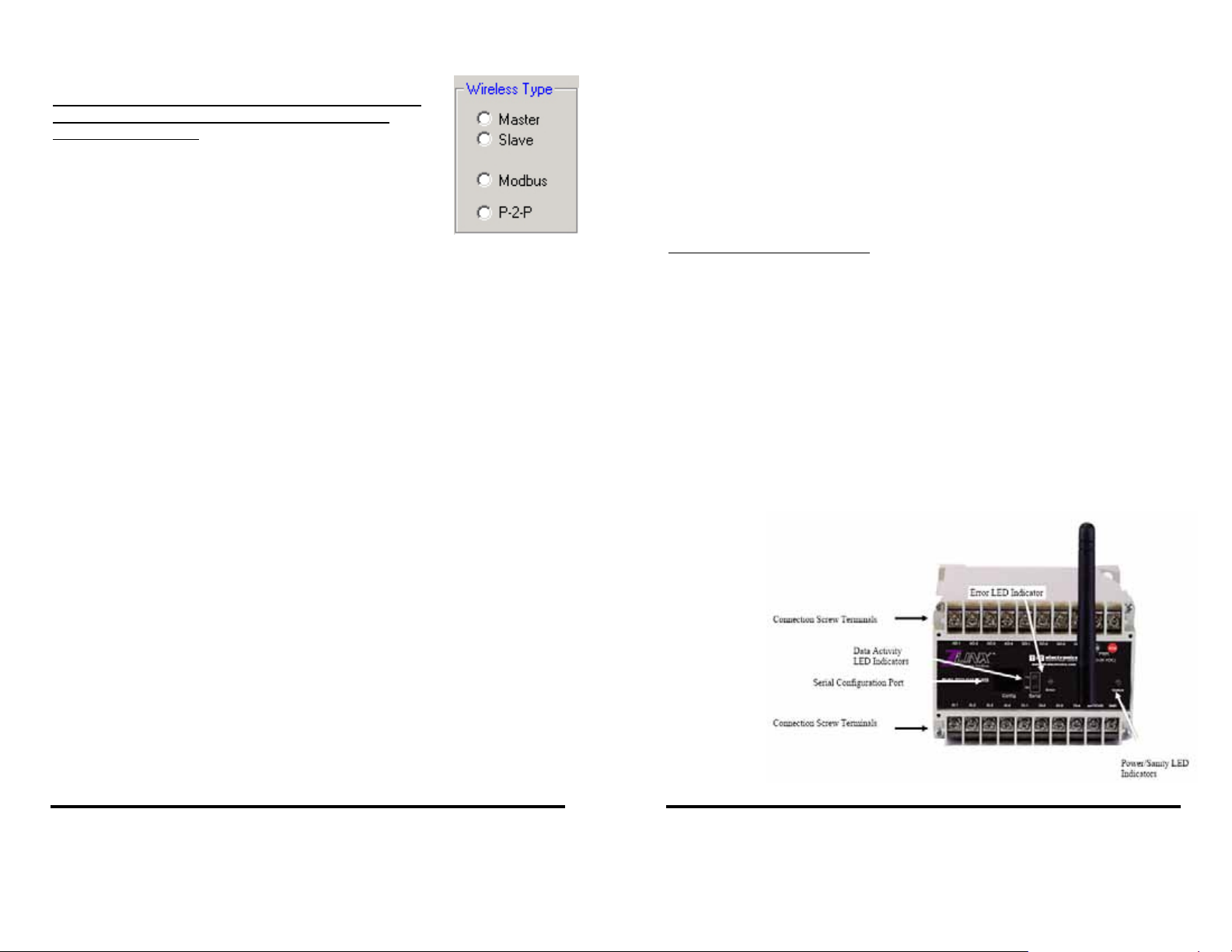

RT12-4444-9T-W20 – Front Panel Identification

All analog voltage inputs and outputs are 12-bit, 0- 5 Vdc. All digital inputs are from 0

to 12 Vdc. Digital inputs must fall to 0 Vdc as a LOW. Digital o utputs are Open

Drain.

Connection Screw Terminal Description

PIN NAME DESCRIPTION

1 AO 1 Analog Output-1

2 AO 2 Analog Output-2

3 AO 3 Analog Output-3

4 AO 4 Analog Output-4

5 DO 1 Digital Output-1

6 DO 1 Digital Output-2

7 DO 1 Digital Output-3

8 DO 1 Digital Output-4

9 GND (-) Power Input. Ground.

10 PWR (+) Power Input. 10-28 Vdc.

11 AI 1 Analog Input-1

12 AI 2 Analog Input-2

13 AI 3 Analog Input-3

14 AI 4 Analog Input-4

15 DI 1 Digital Input-1

16 DI 2 Digital Input-2

17 DI 3 Digital Input-3

18 DI 4 Digital Input-4

19 BAT (+) Battery I/O. 10.5-28 Vdc.

20 GND (-) Battery.

Manual Documentation Number: RT-12 series-4006m 9

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

10 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 9

Power: 10.5~28 Vdc

Most DC power supplies rated from 10.5 to 28 Vdc @ 1000mA, will work with the

RT12-4444-9T-W20. Do not use a power supply rated less than 1000mA. Doing so

may cause the RT12-4444-9T-W20 to continuously reset. Make sure that the power

supply voltage is maintained between the programmable HIGH and LOW supply

voltage limits or an alarm may occur. If a rechargeable battery is used or if you ar e

supplying voltage to a sensor using the same power used to power the RT12-4444-9TW20, then the input volt age will need to be adjusted to th e proper voltage to mainta i n

respective equipment. Never exceed 28 Vdc. Damage by overheating to the controller

will occur causing the system to malfunction.

Data Activity LED Indicators

The RT12-4444-9T-W20 RTU is equipment with four LED indicators. The

RED/GREEN pair labeled “SERIAL”, indicate data transmit and data received. The

RED LED will blink when data is being transmitted The GREEN LED will blink any

time data is received, this is true for the MASTER and SLAVE.

Link/Sanity LED Indicators

The yellow LED indicator labeled “Status” indicates proper system operation. The

second yellow LED indicator, labeled “Error”, will flash any time an alarm is

programmed and the respective alarm is active.

Serial RS-232 Interface

Used to configure the RTU. See “Software Setup”.

The RT12-4444-9T-W20 has two rows of 10, screw type, connections. Using a

common type screwdriver, loosen the respective te rminal screw, insert the respective

wire and tighten.

The front panel is stenciled with each Connection number. Listed below are the

respective Connection numbers and Connection description.

Connection Screw Terminals Description

Pin 1: “AO 1” (+) Analog Output - 1, 0-5 Vdc

Pin 2: “AO 2” (+) Analog Output - 2, 0-5 Vdc

Pin 3: “AO 3” (+) Analog Output - 3, 0-5 Vdc

Pin 4: “AO 4” (+) Analog Output - 4, 0-5 Vdc

Pin 5: “DO 1” (+) Digital Output - 1, Open Drain, Act ive Low, Output

Pin 6: “DO 2” (+) Digital Output - 2, Open Drain, Act ive Low, Output

Pin 7: “DO 3” (+) Digital Output - 3, Open Drain, Act ive Low, Output

Pin 8: “DO 4” (+) Digital Output - 4, Open Drain, Act ive Low, Output

Pin 9: “GND” (-) Main Supply GROUND

Pin 10: “VIN+” (+) Main Supply 10.5 to 28.0, Must be > 13.0 to Charge

External Battery. Do Not Exceed 28 Vdc

Pin 11: “AI 1” (+) Analog Input - 1, 0-5 Vdc

Pin 12: “AI 2” (+) Analog Input - 2, 0-5 Vdc

Pin 13: “AI 3” (+) Analog Input - 3, 0-5 Vdc

Pin 14: “AI 4” (+) Analog Input - 4, 0-5 Vdc

Pin 15: “DI 1” (+) Digital Input - 1, Active Low, 0~12 Vdc

Pin 15: “DI 2” (+) Digital Input - 2, Active Low, 0~12 Vdc

Pin 15: “DI 3” (+) Digital Input - 3, Active Low, 0~12 Vdc

Pin 15: “DI 4” (+) Digital Input - 4, Active Low, 0~12 Vdc

Pin 19: “Batt” (+) Battery Charge During Normal Main Power Input.

Battery Backup during Main Power Fa ils.

Pin 20: “GND” (-) Battery Ground

Manual Documentation Number: RT-12 series-4006m 11

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

12 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 10

RT12-4444-9T-W20 – External Battery Back-up

Connecting an Optional External Backup Battery to RT12-4444-9T-W20

!WARNING: Use Caution When Connecting Any Rechargeable Battery to any

of the RT series RTU’s. Make sure that the BATTERY is NOT connected until

the connection is made to the controller first. This will minimize the chance of

damage to the controller if the charging wiring harness is connected incorrectly.

Use only Nickel Cadmium 12Vdc and a minimum of 1.5 Amp Hour batteries.

Use only fused cable. The RTU is internall y fused as well.

RT12-2222-ZP-S12 – Front Panel Identification

All analog voltage inputs and outputs are 12-bit, 0-5 Vdc. All digital inputs are from 0

to 12 Vdc. Digital inputs must fall to 0 Vdc as a LOW. Digital o utputs are Open Drain.

Connection Screw Terminal Description

PIN NAME DESCRIPTION

1 BATT (+) Battery I/O. 10.5~28 Vd c

2 GND (-) Battery

3 DI 3 Frequency Input. <5 KHz

4 PWR (+) Power Input. 10~28 Vdc

5 DO 2 Digital Output-2

6 DI 2 Digital Output-2

7 DO 1 Digital Output-1

8 AO 2 Analog Output-2

9 AO 1 Analog Output-2

10 DI 1 Digital Input-1

11 AI 2 Analog Input-2

12 AI 1 Analog Input-1

1) Connect the RED wire from the Charging wiring harness to pin 19, “BATT”

of the respective RTU device. The Master and Slave controllers are identical

in wiring, features and programming. Be sure a 1 Amp FAST blow fuse is

installed.

2) Connect the BLACK wire from the Charging wiring harness to pin 20,

,“Gnd”, of the respective device.

3) Confirm the above instructions. If the connectio ns are c orrect, connect the

RED wire to the (+) of the battery and the black wire to the (-). The RTU will

begin to operate.

Manual Documentation Number: RT-12 series-4006m 13

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

14 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 11

Power: 10.5~28 Vdc

Most DC power supplies rated from 10.5 to 28 Vdc @ 200mA, will work with the

RT12-2222-ZP-S12. Do not use a power supply rated less than 200 mA, doing so may

cause the RT12-2222-ZP-S12 to continuously reset. Make sure that the power supply

voltage is maintained between the programmable HIGH and LOW supply voltage

limits or an alarm may occur. If a rechargeable battery is used or if you are supplying

voltage to a sensor using the same power used to power the RT12-2222-ZP-S12, then

the input voltage will need to be adjusted to the proper voltage to maintain respective

equipment. Never exceed 28 Vdc damage, overheating to the controller will occur

causing the system to malfunction.

Data Activity LED Indicators

The RT12-2222-ZP-S12 RTU is equipment with three LED indicators. The

RED/GREEN pair labeled “RX” and ”TX”, indica te data transmit and data received.

The RED LED will blink when data is being transmitted The GREEN LED will blink

any time data is received.

Link/Sanity LED Indicators

The yellow LED indicator is locate internally and indicates proper system operation.

The second yellow LED indicator, labeled “Error”, will flash any thing an alarm is

program and the respective alarm is active. The Status LED indicator may be seen

through a small hole on the top of enclosure.

Serial RS-232 Interface

Used to configure the RTU. See “Software Setup”.

The RT12-2222-ZP-S12 has two rows of 6, screw type, connections. Using a common

type screwdriver, loosen the respective terminal screw, insert the re spective wire and

tighten.

The front panel is stenciled with each Connection PIN number. Listed below are the

respective Connection numbers and Connection description.

Connection Screw Terminals Description

Pin 1: “Batt” (+) Battery Charge During Normal Main Power Input.

Battery Backup during Main Power Fails

Pin 2: “GND” (-) Power and Battery Ground

Pin 3: “DI 3” (+) Frequency Input. Do Not Exceed 5 KHz

Pin 4: “PWR” VIN(+) Main Supply 10.5 to 28.0, Must be > 13.0 to Charge

External Battery. Do Not Exceed 28 Vdc

Pin 5: “DO 2” (+) Digital Output - 2, Open Drain, Active Low, Output

Pin 6: “DI 2” (+) Digital Input - 2, Active Low, 0~12 Vdc

Pin 7: “DO 1” (+) Digital Output - 1, Open Drain, Active Low, Output

Pin 8: “AO 2” (+) Analog Output - 2, 0-5 Vdc

Pin 9: “AO 1” (+) Analog Output - 1, 0-5 Vdc

Pin 10: “DI 1” (+) Digital Input - 1, Active Low, 0~12 Vdc

Pin 11: “AI 2” (+) Analog Input - 2, 0-5 Vdc

Pin 12: “AI 1” (+) Analog Input - 1, 0-5 Vdc

Manual Documentation Number: RT-12 series-4006m 15

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

16 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 12

RT12-2222-ZP-S12 – External Battery Back-up

Connecting an Optional External Backup Battery to RT12-2222-ZP-S12

!WARNING!

Use Caution When Connecting Any Rechargeable Battery to any of the

RT series RTU’s. Make sure that the BATTERY is NOT connected until the

connection is made to the controller first. This will minimize the chance of damage to

the controller if the charging wiring harness is connected incorrectly. Use only Nickel

Cadmium 12Vdc and a minimum of 1.5 Amp Hour batteries. Use only fused cable.

The RTU is internally fused as well.

1) Connect the RED wire from the Charging wiring harness to pin 19, “BATT” of

the respective RTU device. The Master and Slave controllers are identical in

wiring, features and programming. Be sure a 1 Amp FAST blow fuse is installed.

2) Connect the BLACK wire from the Cha rg in g wiring harness to pin 20 ,“Gnd”, of

the respective RTU.

3) Confirm the above in structions. If the connections are correct, conn e ct the RED

wire to the (+) of the battery and the black wire to the (-). The RTU will begin to

operate.

RT12-0044-ZP-S12 – Front Panel Identification

All analog voltage inputs and outputs are 12-bit, 0- 5 Vdc. All digital inputs are

from 0 to 12 Vdc. Digital inputs must fall to 0Vdc as a LOW. Digital outputs are

Open Drain.

Connection Screw Terminal Description

PIN NAME DESCRIPTION

1 BATT (+) Battery I/O. 10.5~28 Vdc

2 GND (-) Battery

3 DO 4 Digital Output-4

4 PWR (+) Power Input. 10~28 Vdc

5 GND Ground

6 DI 4 Digital Input-4

7 DO 3 Digital Output-3

8 DO 2 Digital Output-2

9 DO 1 Digital Output-1

10 DI 3 Digital Input-3

11 DI 2 Digital Input-2

12 DI 1 Digital Input-1

Manual Documentation Number: RT-12 series-4006m 17

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

18 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 13

Power: 10.5~28 Vdc

Most DC power supplies rated from 10.5 to 28 Vdc @ 200 mA, will work with the

RT12-0044-ZP-S12. Do not use a power supply rated less than 200 mA, doing so may

cause the RT12-0044-ZP-S12 to continuously reset. Make sure that the power supply

voltage is maintained between the programmable HIGH and LOW supply voltage

limits or an alarm may occur. If a rechargeable battery is used or if you are supplying

voltage to a sensor using the same power used to power the RT12-0044-ZP-S12, then

the input voltage will need to be adjusted to the proper voltage to maintain respective

equipment. Never exceed 28 Vdc damage, overheating to the controller will occur

causing the system to malfunction.

Data Activity LED Indicators

The RT12-0044-ZP-S12 RTU is equipment with three LED indicators. The

RED/GREEN pair labeled “RX” and ”TX”, indica te data transmit and data received.

The RED LED will blink when data is being transmitted The GREEN LED will blink

any time data is received.

Link/Sanity LED Indicators

The yellow LED indicator is locate internally and indicates proper system operation.

The second yellow LED indicator, labeled “Error”, will flash any thing an alarm is

program and the respective alarm is active. The Status LED indicator may be seen

through a small hole on the top of enclosure.

Serial RS-232 Interface

Used to configure the RTU. See “Software Setup”.

The RT12-0044-ZP-S12 has two rows of 6, screw type, connection s. Using a common

type screwdriver, loosen the respective terminal screw, insert the re spective wire and

tighten.

The front panel is stenciled with each Connection number. Listed below are the

respective Connection numbers and Connection description.

Connection Screw Terminals Description

Pin 1: “Batt” (+) Battery Charge During Normal Main Power Input.

Battery Backup during Main Power Fails

Pin 2: “GND” (-) Power and Battery Ground

Pin 3: “DO 4” (+) Digital Output 4. Open Drain, Active Low, Output

Pin 4: “PWR” VIN(+) Main Supply 10.5 to 28.0 Vdc, Must be > 13.0 to Charge

External Battery. Do Not Exceed 28 Vdc

Pin 5: “GND” (-) Main Supply GROUND

Pin 6: “DI 4” (+) Digital Input - 4, 0-12 Vdc

Pin 7: “DO 3” (+) Digital Output - 3, Open Drain, Active Low, Output

Pin 8: “DO 2” (+) Digital Output - 2, Open Drain, Active Low, Output

Pin 9: “DO 1” (+) Digital Output - 1, Open Drain, Active Low, Output

Pin 10: “DI 3” (+) Digital Input - 3, 0-12 Vdc

Pin 11: “DI 2” (+) Digital Input - 2, 0-12 Vdc

Pin 12: “DI 1” (+) Digital Input - 1, 0-12 Vdc

Manual Documentation Number: RT-12 series-4006m 19

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

20 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 14

RT12-0044-ZP-S12 – External Battery Back-up

Connecting an Optional External Backup Battery to RT12-0044-ZP-S12

!WARNING! Use Caution When Connecting Any Rechargea ble Battery to any of the

RT series RTU’s. Make sure that the BATTERY is NOT connected until the

connection is made to the controller first. This will minimize the chance of damage to

the controller if the charging wiring harness is connected incorrectly. Use only Nickel

Cadmium 12Vdc and a minimum of 1.5 Amp Hour batteries. Use only fused cable.

The RTU is internally fused as well.

1) Connect the RED wire from the Charging wiring harness to pin 19, “BATT” of

the respective RTU device. The Master and Slave controllers are identical in

wiring, features and programming. Be sure a 1 Amp FAST b low fuse is in stalled.

2) Connect the BLACK wire from the Ch a r ging wiring harness to pin 20 ,

“Gnd”, of the Respective RTU.

3) Confirm the above in structions. If the connections are correct, conn e ct the RED

wire to the (+) of the battery and the black wire to the (-). The RTU will begin

to operate.

Hardware Set-up

Typical Application: Peer-to-Peer

Below is a typical overview of the communications method for the MASTER and

SLAVE allow analog data to be passed from the master to the slave and vise-versa.

Manual Documentation Number: RT-12 series-4006m 21

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

22 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 15

Typical Application: Peer-to-Peer

Typical Application: Modbus

This typical application shows the INPUT voltage signals from the Master

controller is sent to the Slave controller. The save output voltages reflect the

Masters input voltages.

The Slave INPUT voltage signals are sent to the Master and converted to the Master’s

OUTPUT voltages signals and reflect the SLAVE inputs voltages.

This typical application shows two Slave Modbus controllers. Modbus slave controller

can be address from 1 to 255.

Manual Documentation Number: RT-12 series-4006m 23

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

24 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 16

Typical Application: Well Monitor and Control (Peer-to-Peer)

Below is a typical Peer to Peer monitoring and control a pplication.

Typical Application: Well Monitor and Control (Modbus)

Below is a typical Modbus monitoring and control application.

Manual Documentation Number: RT-12 series-4006m 25

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

26 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 17

Typical Application: 4-20 mA to Voltage Conversion

This section will describe how a typical system is converted from a 4-20mA or 020mA current signal to a 1-5Vdc or 0-5Vdc voltage signal.

The RT series RTU’s do not allow for a direct 4-20mA connection. A s imple 250

Ohm, 1%, ¼ Watt, resistor from the input of the respective terminal to ground will

convert the current signal to a voltage signal. If a 250 Ohm resistor is not available a

249 Ohm, 1%, ¼ Watt, resistor will work.

The same example is true for a 0-20mA current signal. The only exception is the

voltage will swing from 0-5Vdc. If a current source is applied to a respective input

without a resistor the data will not be correct and a signal error will occur.

The example below shows analog Input 1 converted from 4-20 to 1-5Vdc. Keep in

mind, if an RTU is used in Peer to Peer mode, the receiving device will output a 15Vdc voltage on the respective output.

Configuration Cable Description

Serial cable used in configuration and connectivity of B&B Electronics’ RT-series

controllers.

Pin# Connection (color) Description

DB9-Pin#2 Green TX

DB9-Pin#3 Red RX

DB9-Pin#5 Yellow GND

DB9-Pin#7 Black CTS

-Use a straight-through, common, Category 5 cable (available from B&B Electronics) for

connection to the RT-series RTU’s.

Manual Documentation Number: RT-12 series-4006m 27

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

28 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 18

Chapter 3 – Configuration & Programming

Configuration/Monitoring Software System Map

Programmable and monitoring features may be accessed using the configuration software.

Programmable features such as polling rates, id number, subnets, labels, full scale

engineering units, etc, may be easily changed. This section will show you many of the RT

series features.

The configuration and monitoring software will allow you to save and load configuration

profiles. The profile may be uploaded to the respective RTU.

To load a profile, from the task bar, select “Profile” --> “Load Profile” --> then select the

desired file. The default file is “default_rt_config.cff”, It is recommended that you do not

over-write this file.

To save a profile, from the task bar, select “Profile” --> “Save Profile” --> Name the file

you wish to save, --> select “Save”.

The status bar at bottom of the main window shows what profile data is being displayed.

“Profile = RTU ” mea n s t he da ta be ing displaye d was retrieved from the respect i v e RTU.

“Profile = File” means the data being displayed was retrieved from a file.

Note: Remember to ALWAYS confirm programming changes by pressing “Disconnect”

then “Connect”. This will retrieve the programmed data from the respective RTU. Confirm

each field within the main window “Controller Programming Parameters.”

Configuration/Monitoring Software Main Page

During the initial start-up process you will need to select a serial port. Refer to your

PC’s users guide to select a valid serial port. The most common port selected is COM1

or COM2 but may differ on your computer. This will set the correct communications

port for configuring, displaying or monitoring the controller.

!WARNING!

This will cause a communications failure on the opposing link. Depending on features

selected, a communications error may cause your system to malfunction.

Note: The system must be connected to perform most of the functions described in

the following sections.

!WARNING!

connecting after a change or changes. This will allow the system to retrieve data from

any RTU you’re connected to and confirm changes.

Features supported are:

-Comm (Communications) -Third Party Communications

-About -Support

-Profiles -About

-Communications WDT -MODBUS Slave

Connecting to a RTU device will disrupt the wireless communications.

Always confirm any changes that you make by disconnecting and re-

Manual Documentation Number: RT-12 series-4006m 29

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

30 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 19

Controller Configuration

Selecting the “Get Setup Information From Device” button will allow you to view

existing setup parameters saved by the master or slave controller. The task bar on the

bottom of the Main screen should indicate “Profile = RTU”

This section will identify each parameter as well give a descrip tion of it respective

function. This section assumes that the Monitoring software is loaded and running.

To capture/display data from the Master or Slave controller:

a) Connect the serial programming cable into your computer’s serial

communications port.

b) Connect the remaining end of the programming cable into the programming jack

labeled “Program”. Make sure the controller has powered applied.

c) Press the “Connect” button. Keep in mind that the data flow between the

controller being configured and its respectiv e mate will stop. If the “Set Rest

Voltage on Comm Error” is set on the mating controller, it will alarm and set the

outputs to its programmed resting voltage.

d) You may need to disconnect and connect several times to make a valid

connection.

e) When the software makes a connection with the controller the “Connec ted”

indicator will show as “Marked”, the “Controller Time” and date will b e

displayed as well as all other data listed in each box. The “Connect” button will

also turn green.

Manual Documentation Number: RT-12 series-4006m 31

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

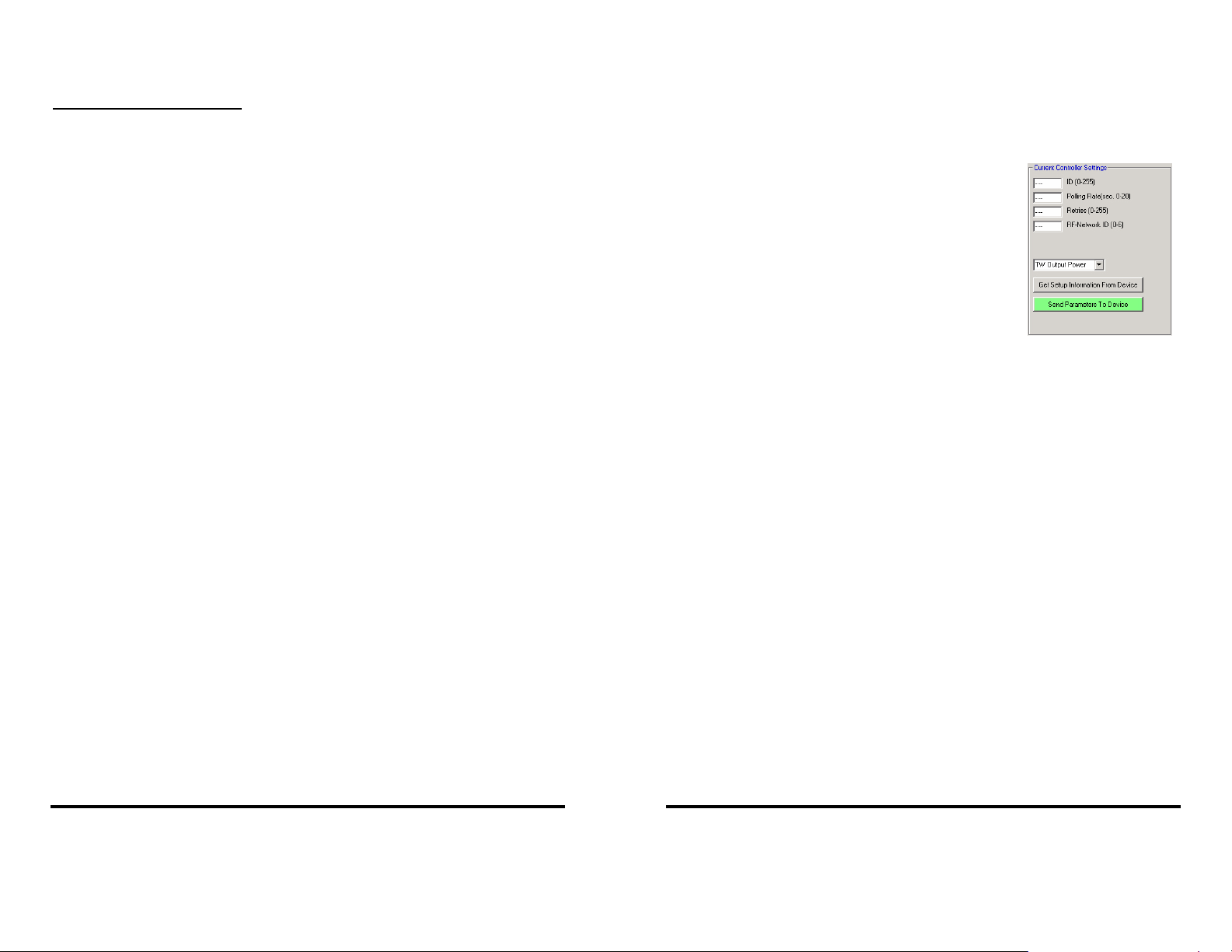

Current Controller Settings

This configuration block will allow you to set the res pective RTU parameters such as

ID, subnet, polling rate, etc. These setting are vital

to the operation and performance

of your wireless system.

Parameters not set correctly may cause the system to malfunction or not communicate.

This block will affect different fields depending on the Wireless Type.

ID: Displays the current controller ID number between 0 and 255.

!WARNING! In Peer-to-Peer Mode, the ID numbers for the Master and Slave must

match and must not be repeated with any other Master/Slave Pairs with the same RFNetwork ID within the radio range of each respective wireless pair. Doing so will cause

cross talk between master/slave pairs and may cause harm to the equipment attached.

Polling Rate: In Peer-to -Peer mode, this parameter determines the sampling rate of

data passed between the Master and Slave controllers. It is also the update rate for the

Master and Slave’s analog and digital I/O. This parameter has no affect in Modbus

mode. The Master is responsible for starting the communications process. Therefore the

Polling rate is only configured on the Master controller.

32 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 20

If your system is configured on Peer-to-Peer mode, by default, if the Slave unit does not

receive a response from the master within 20 seconds of any polling seque nce, and if the

”Set Rest Voltage On Comm Error” is enabled, an alarm will sound on the Slave unit

and depending on alarm parameters set, would cause the Slave’s outputs to be set with

the user defined resting voltages.

Retries: In Peer-to-Peer mode, this parameter

determines the number of consecutive failed polling

attempts before a communications failure occurs. It

is not recommended to set the number of retries

higher than 10 attempts. Large numbers may cause

an unnecessary delay in communications failure

response time; a low number may cause the system

to prematurely fail. This parameter has no affect in

Modbus mode.

Output Power: This parameter determines the RF

Power output on some RTU’s. If a respective RTU

does not support a variable RF power out the

parameter will continue to display “Output Power”.

The “ID” field has a dual purpose, as the controller number when in peer-to-peer

mode and the Modbus slave address field when in MODBUS mode.

If Modbus is selected, the Radio ID will automatically appear and the “ID” field will

automatically change to “MODBUS ID.”

If your controller is programmed in Modbus mode, the ID field will change to the

Modbus Slave address. Valid addresses are from 1 to 255. Keep in mind that the

Modbus master you are interfacing to may not support the full spectrum of slave

address IDs. Please refer to your device user’s manual.

Manual Documentation Number: RT-12 series-4006m 33

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

34 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 21

Connecting / Disconnecting

Connect: Pressing the “Connect” button will force the software

to make an attempt to connect to the controller your PC. The

programming cable must be connected. The connect button will

start RED and will remain RED until a connection is made.

The “Assert” check box will indicate “Checked” whe n the

software makes the attempt to connect.

Once connected, the “Connected” check box will indicate,

“Checked” and the “Connect” button will turn gre en.

Disconnect: Pressing the “disconnect” button will force the

software to disconnect from the controller your PC is connected

to. Both the “Assert” and “Connected” check boxes will indicate

“Unchecked”.

NOTE: The controller must be “Disconnected” for the master

and slave to communicate with each other.

You may need to make several attempts to connect. Make sure the “Connected” box is

check and the “Connect” button is GREEN, before pr oceeding.

During the “Connect” process you will notice a series a check marks, in the “Update”

configuration Block, located next to each of the subsystems. This is confirmation that

the configuration software is collecting data from the respective RTU.

Master, Slave, Modbus, Peer-to-Peer

Master: If the controller you are connected to is a Master Peer to

Peer device, the Wireless type will indicate “Master”.

Slave: If the controller you are connected to is a Slave Peer to Peer

device, the Wireless type will indicate “Slave”.

MODBUS: If the controller you are connected to is in MODBUS

mode the Wireless type will indicate “MODBUS”.

P-2-P: P-2-P is also Peer to Peer.

If your system is configured as a Peer to Peer system,

the system must consist of one Master and one Slave.

The Master controller is responsible for starting the

polling sequence.

If your controller is configured as a MODBUS

controller then typical Modbus, Slave, RTU, protocol

applies. Do not allow for duplicate Slave address

within the same system, unless It is on a separate

Radio Id and/or RF-Network ID.

Manual Documentation Number: RT-12 series-4006m 35

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

36 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 22

Modbus Configuration

The Modbus configuration menu will allow you to

adjust the base address for the I/O to be displayed

or controlled. When in Modbus mode, the radio ID

number is within the Modbus configuration menu.

Digital Input Types

The RT series RTU’s support the ability

to configure DI-1 and DI-2 as Digital or

Frequency/Accumulator inputs. Some

RTU have an additional, dedicated,

“Freq” input.

Clicking on a respective “Input” box,

will check and uncheck, the respective

input box.

If a respective Input Box is Checked,

the input will be configured as a digital

discrete input. To save this setting to

the respective RTU, press the “Send

Parameters To Device” button.

If a respective Input Box is Unchecked, the input will be

configured as a Counter/Accumulator/Freq uency input.

To save this setting to the respective RTU, press the

“Send Parameters To Device” button.

The Counter/ Accumulator/Frequency mode is rese rved

for Modbus mode. The Accumulator and Frequency

values are held in separate registers.

The RT12-4444 is equipped with a configurable communications watch dog timer.

The timer was designed to detect the absence of data traffic will attempt to reset the

communications system. Setting the timer to “0” will d isable the timer. The timer is in

seconds. To set the timer, make sure you are connected to the respective device, enter

a timer value from 1 to 65535 and press “Send Parameters To Device”. It is not

recommended to enter a value smaller than 60.

Manual Documentation Number: RT-12 series-4006m 37

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

38 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 23

RTU Alarms

The RT series RTU’s have several types of

alarms. Below is a description of each alarm. To

modify or change any of the alarms, click on the

respective box or boxes, and press the “Send

Parameters To Device”. Make sure you are

“Connected”. Alarms are local to the RTU. Each

RTU has a built in beeper alarm. Most alarms

will sound at the master as well as the slave units.

Most of the alarms apply even in Modbus mode.

Update On Change: Not used at this time and is used

for future enhancements.

Alarm On Comm Fail: If enabled, will sound an

alarm on a Local RTU Level. If in peer to peer mode,

the alarm may sound at the Master as well as the Slave.

A communications failure is determined by repeated,

consecutive, failed attempts made by the Master to

contact the Slave unit. The number of at tempts made

depends on the parameter “Retries”. The slave unit

defaults to a 20 second time out if it does not make

contact with the Master.

Set Rest Voltage on Comm Error: If enabled, will cause a local and remote alarm if

a communications failure occurs. This will also force the analog outputs to the

programmed “Analog Resting Voltages” and if enabled will cause the discrete output

to be set to an active high or active low state. “Alarm On Comm Fail” must also be

enabled. In Modbus mode, the comm. fail delay time is 2 minutes.

This parameter also applies if the respective RTU is configured as a Modbus Slave

device.

Alarm On Input Voltage Limit Error: If enabled will cause a local and remote

alarm if the main input voltage falls below or rises abo ve your set limits. These limits

are located in the same section “Analog Resting Voltages”. This alarm will not affect

any of the outputs; the alarm will cause an audible alarm.

Alarm On Main Power Supply Failure: If enabled will cause a local and remote

alarm if the main input voltage completely fails. The backup battery MUST be

connected for this function to operate properly or a communications failure will occur.

This alarm will not affect any of the outputs; the alarm will cause an audible alarm.

Discrete Output-1 Comm Fail Output: If enabled and a communications alarm occurs,

this parameter will cause DO-1, on all RT series RTU’s, to become “Active High” or

“Active Low”. The Output level will depend on how the output is configured. If

enabled, this output can not be controller in peer to peer or Modbus mode. This feature

was added to notify other equipment of a communications failure. This feature may

also be used to activate an external auditable or visual alarm, such as a Horn or Light.

Manual Documentation Number: RT-12 series-4006m 39

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

40 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 24

Input Voltage Alarm Limits

Analog Outputs Resting Voltage

(Note: Four analog outputs available on specific RT-12 series models.)

The RT series RTU’s is capable of monitoring its input voltage. This section w ill

describe how to set and enable the “Input Voltage Alarm Limits”.

If the “Alarm On Input Voltage Limit Error” is enabled and the INPUT supply voltage

rises above the “High Limit” or falls below the “Low Limit” the respective RTU will

sound an alarm.

The alarm will stop sounding when the input suppl y voltage returns to ”normal” by

returning between the +/- limits determined by the “High /Low Limit Dead Band”. The

“Normal” +/- limits are calculated by subtracting the “High/Low Limit Dead Band”

from the “High limit” and adding the “High/Low Limit Dead Band” to the “Low Limit”

The configuration shown above will cause a HIGH alarm if the input supply voltage

rises above 28.0 VDC and will return to normal when the inpu t s upply voltage falls to

26.01 VDC.

The configuration above will cause a LOW alarm if the i nput supply voltage falls below

9.99 VDC and will return to normal when the input supply voltage rises to 11.98 VDC.

Manual Documentation Number: RT-12 series-4006m 41

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

(Note: Four analog outputs available on specific RT-12 series models.)

This section applies to Peer to Peer and Modbus systems. In peer to peer mode, the

master and slave communicate with each other and during the comm unication p rocess

they share information. In the event of a communication failure, the updating process

will stop and if the Communications alarm is disabled the analog outputs for the

master and slave will be the last valid update.

A communications error will occur if the number of consecutive failed polling

attempts exceeds the programmed number of re tries. This count is reset if even one

valid communications update occurs before the number of retries expires and if the

RTU is a Modbus device, a communications of 2 minutes must laps.

The analog output resting voltages provide a means to program the voltage outputs in

the event of a communications error.

Due to the nature of wireless systems, communication failures may occur. The RT

series RTU’s allow you to program each of the analo g outputs with a preset level in

the event of a communications failure. Each ana log output can be programmed with

independent levels from 0 volts to 5 Vdc.

If the RTU is programmed to respond to a communications ala rm and a

communications failure occurs, the respective RTU will force the outputs with your

preset levels. The outputs will return to normal once communications is reestablished.

To program the RTU to respond to communications failures select t he “Set Rest

Voltage on Comm Error” and update the configuration by pressing the “Send Changes

To Device”.

42 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 25

(Note: Four analog outputs available on specific RT-12 series models.)

To program each analog resting output voltage, enter a voltage from 0.0 to 5.0, into

each box representing Analog Output 1, Analog Output 2, Analog Output 3, and

Analog Output 4. Then press “Send Resting and Limits Æ Device”. This data is saved

and remains resident within the respective RTU. This process is valid ONLY if the

RTU is “Connected”.

The respective RTU is also equipped with the ability to turn on or off its output if a

Communications error occurs. This is true for the Master and Slave.

The output is an Open Drain output and should be used to sink not s ource current,

1Amp MAX. This typically means that the Output will supply a “Ground” to the

device to turn it on or off.

The respective RTU also has the ability to control its respective Out put during a

communications failure. The output may be configu red to an ACTIVE HIGH or

ACTIVE LOW state during a communications failure. This can be useful as an alarm

output or to turn a device on or off. A “Check” mark next to the “Discrete Output Comm

Fail Enable” will force the output to an active HIGH or LOW, (depending on what is

selected for an Active High or Active Low), during a communications failure. If you

use the output to respond during a communicatio ns failure, you will not have control

using the Modbus protocol. If you wish to use the output for something other than a

comm. failure you will need to disable the “Discrete Output Comm Fail Enable”.

Manual Documentation Number: RT-12 series-4006m 43

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

44 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 26

Updating/Sending Configuration to RTU

This section assumes the system is connected.

Pressing the “Get Setup Information From Device” w ill request information from the

respective RTU you are connected to.

Once pressed, the MAIN form will remove data from all respective data fields and

replace them with refreshed data.

Pressing the “Send Changes To Device” will force the information located within the

data fields into the respective RTU’s internal configuration.

!WARNING!

Be sure that all the respective data fields are filled with the correct

data. If a parameter is left blank the system will interpret the data as a ZERO “0”. This

may cause your system to fail if parameter such as the ID or RF network is set

incorrectly. Confirm all configuration data by requesting data from the respective

RTU or Press the Disconnect then Connect to update and view the most current data.

Third Party Communications Protocol Support

Third party communications support was added to allow for different type of

communications protocols such as Modbus RTU, etc. As we develop and enhance

support of other protocols we will

To select a communications type, click on the communications type bar, select the

type of communications then “Send Parameters To Device”.

Communications Type

Manual Documentation Number: RT-12 series-4006m 45

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

46 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 27

Status Bar

The status bar is a quick view of system status. Functions such as connection status,

communications port, number of event saved by the master or slave, profile type, time

and date, etc.

Profile status is an indicator of where data is being retrieved from, a file or the

respective RTU.

Digital Outputs

Note: Third party communications protocols available as custom modifications.

(Contact B&B Electronics Mfg. Co. Inc.)

Depending on the RT12 you are configuring or using, it may be equipped with one or

more digital outputs, (DO’s). These outputs are typically high current outputs that

will sink current, also known as “Low Side Drivers”.

Typically, each digital output can sink up to 500 milliamps of current. Below is a

typical digital output application.

Manual Documentation Number: RT-12 series-4006m 47

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

48 Manual Documentation Number: RT-12 series-4006m

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics – Westlink C ommercial Park – Oranmore, Ga lway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Loading...

Loading...