Page 1

WWW.BB-LOCKS.COM

INSTRUCTION MANUAL - A1 SERIES

Page 2

CHARACTERISTICS:

24V DC stabilized (+/- 5%)consumption:

2,2 A activationcurrent(<0,2sec)

130 mA holding current

controlledandmanageableaccess

immediatelylocked(onthemainboltwithathrow of 20mm) when the door closes

mechanical opening with the cylinder is alwayspossible

from the inside the lock (HX and HE) can always be opened mechanically

using the handle or panic bar (emergency exit)

integrated signalisation of the bolt position (unlocked/ locked)

integrated signalisation of the door position (open / closed)

integrated signalisation of the use of the cylinder

integrated signalisation of the use of the handle

stainlesssteellockingcomponents, cylinder block, baseplate and striker plate

the locking components are mounted on the solid baseplate using 6mm axes,

which improvesthefreemovementofthecomponents and the lifespanofthelock

integratedmicroprocessor controlledintelligence

anti-saw pin in the bolt

strikerplates (standardoradjustable)withcast on strikercup

PCB protectedinapolyurethanecasted resin

door detection by 3 Hall-sensors

testedtoachieve1.000.000cycles

testedtoafrequencyof600cycles a day

bolt resistanceupto40.000Nlateralforce

unlocking under considerablelateral pressureispossible

specially designed security escutcheons (SE-17, SE-22, SEK-17, SEH-17, SEH-22 and

SEHK-17) are available (optional)

availableforboth17mmand22mmcylinders

availableinbacksetsof25,30,35,50&60mm(SA,SX&SEmodels)

availableinbacksetsof35&60mm(HX&HEmodels)

availablewith2cylinderopenings(PSX,PSE&PMEmodels)

distancefromhandletocylinderis72mm(HX&HEmodels)

tumbler 9 mm (completeboltretraction at 30° tumbler rotation)-(HX&HEmodels)

DESCRIPTION:

The B&B Locks A1-series are electrical security locks of superior quality. Because of their very

solid construction, these locks offer an extreme high resistance against all forms of agression

and burglary attempts and are suitable for intensif use. To ensure a fast and precise action, the

hardened locking components are driven by a powerful solenoid. This solenoid was especially

designed to have the best possible balance between activation and holding current. A low

power consumption and very little heating are additional advantages thereof. Unlocking is

done by giving animpulse with a push button, card reader, code, fingerprint or any other type of

impulse generator. Mechanical unlocking is always possible using a key. The automatic locking

mechanism guarantees that the door will be locked as soon as it closes, which makes a closed

door automaticallyasecureddoor.

A1 ELECTRO-MECHANICAL SECURITY LOCK

Description & Characteristics

Page 3

Certificates EN14846

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

Certificates:

EN14846:2008

CERTIFICATE:

SKG-IKOB -ITT(report nr.):

Declarationof Performance (doc.nr.):

PRODUCT AND DESCRIPTION:

3

M

9

C

0

L

7

1

1

0960-CPR-SKGIKOB.009752.01.EN

13.00921

DoP1011

:

A1B__SX, A1B__SE, A1B__PSX,A1B__PSE

A1B__HX, A1B__HE

A1SRC__SX, A1SRC__SE, A1SRC__PSX, A1SRC__PSE

A1SRC__HX, A1SRC__HE

(availableon our website)

A1 fail secure series

Category of use High frequency of use in public buildings

Durability and load on latchbolt 200'000 cycles with 25N sideload

Door mass and closing force Above 200 Kg, closing force max. 15N

Suitebility for use on fire/smoke doors Suitable for use on smoke/fire doors (30 min.)

Safety -

Corrosion resistance, temperature and humidity High resistance (96h), -25°C to +70°C, level 2

Security Very high security with drill resistance

Security - electrical function Status indication

Security - electrical manipulation Electrostatic discharge EN 61000-4-2 level 2

CERTIFICATE:

SKG-IKOB - ITT(report nr.):

PRODUCT AND DESCRIPTION:

3

M

9

0

0

L

7

1

1

SKGIKOB.009753.01.EN

13.00921

:

A1B__SANOCYL, A1B__SA, A1B__PSA

A1SRC__SANOCYL, A1SRC__SA, A1SRC__PSA

A1 fail safe series

Category of use High frequency of use in public buildings

Durability and load on latchbolt 200'000 cycles with 25N sideload

Door mass and closing force Above 200 Kg, closing force max. 15N

Suitebility for use on fire/smoke doors Not intended for use on smoke/fire doors

Safety -

Corrosion resistance, temperature and humidity High resistance (96h), -25°C to +70°C, level 2

Security Very high security with drill resistance

Security - electrical function Status indication

Security - electrical manipulation Electrostatic discharge EN 61000-4-2 level 2

Page 4

A1 ELECTRO-MECHANICAL SECURITY LOCK

Certificates EN179

Certificates:

EN179:2008

CERTIFICATE:

IFT - ITT(report nr.):

Declarationof Performance (doc.nr.):

PRODUCT AND DESCRIPTION:

3

7

6

B

1

4

5

2

A

B

0960-CPR-SKGIKOB.009758.01.EN

13-000057-PR05

DoP1013

A1B__HX, A1B__HE, A1B__HA

A1SRC__HX, A1SRC__HE, A1SRC__HA

(availableon our website)

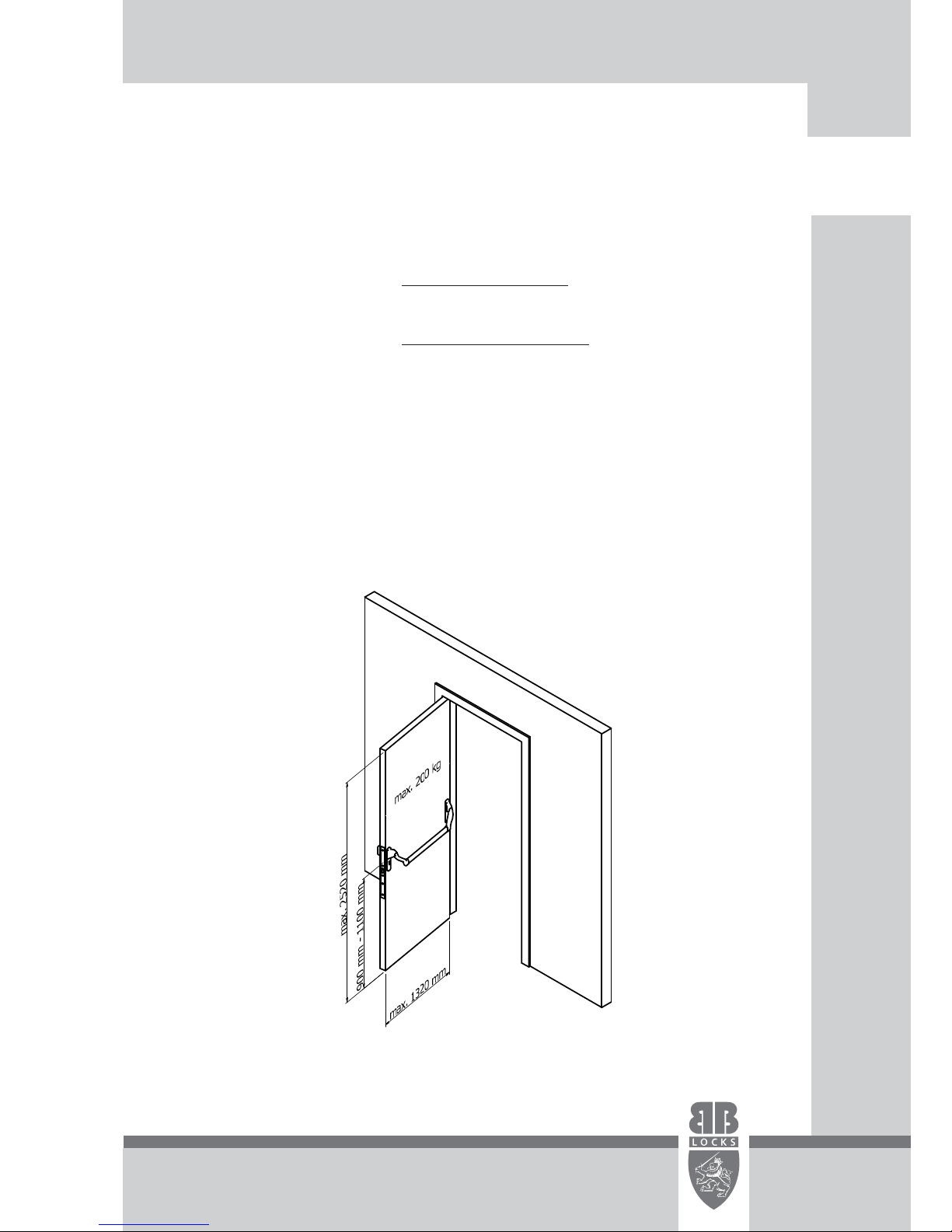

A1 lock series with handle:

In combination with one of the following lever handles:

SEH-17

SEH-22

Category of use High frequency of use (little care + chance of incidence and misuse)

Durability 200'000 test cycles

Door mass up to 200 Kg

Suitebility for use on fire/smoke doors Suitable for use on smoke/fire doors (EN1634-1)

Safety Safety function

Corrosion resistance 240 h (very high resistance)

Security 5000 N

Projection of operating element projection up to 100mm (standard projection)

Type of operation Emergency exit device with "lever handle" operation

Field of door application Outwardly opening single exit door only

Page 5

Certificates EN1125 and DIN18251

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

Certificates:

EN1125:2008

DIN18251 - part 1

40'000N resistance to lateral force on the bolt.

CERTIFICATE:

IFT - ITT(report nr.):

Declarationof Performance (doc.nr.):

PRODUCT AND DESCRIPTION:

3

7

6

B

1

4

2

2

A

B

0960-CPR-SKGIKOB.009760.01.EN

13-000057-PR06

DoP1014

A1B__HX, A1B__HE, A1B__HA

A1SRC__HX, A1SRC__HE, A1SRC__HA

Push-bar ECO EPN900 II-IV

Push-bar ECO EPN950

(availableon our website)

A1 lock series with handle:

In combination with Push-bar:

Category of use High frequency of use (little care + chance of incidence and misuse)

Durability 200'000 test cycles

Door mass up to 200 Kg

Suitebility for use on fire/smoke doors Suitable for use on smoke/fire doors (EN1634-1)

Safety Safety function

Corrosion resistance 240 h (very high resistance)

Security Grade 2, only one grade

Projection of operating element projection up to 100mm (standard projection)

Type of operation Panic exit device with "push-bar" operation

Field of door application Single door only

Page 6

Standard Striker Plate with

striker cup

3mm

Adjustable Striker Plate with

striker cup

6mm

Both the standardstriker plate (SSP)

and the adjustable striker plate

(ASP) have a cast on striker cup

protecting the bolt. The ASP has the

big advantage of being easily

adjustable in case the lock and the

striker plate need to get aligned

better.

Models without handle

A1 ELECTRO-MECHANICAL SECURITY LOCK

SA SANOCYL P P P&SX SXSE SE ME

AVAILABLE BACKSETS : 25, 30, 35, 50 & 60 mm AVAILABLE BACKSETS : 35 & 60 mm

SANOCYL

SA

SX

SE

:

:

:

:

unlocked without power - without cylinder block

unlocked without power - with cylinder block (mechanical opening always possible with key)

locked without power - with cylinder block (mechanical opening always possible with key)

locked without power ( ) - with cylinder block (mechanical opening

always possible with key)

: locked without power - with 2 cylinder holes

: locked without power ( ) - with 2 cylinder holes

: mechanical version - unlocking by cylinder; automatic locking when door closes

only when door is closed

only when door is closed

PSX

PSE

PME

Page 7

Models with handle

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

HHX E

AVAILABLE BACKSETS : 35 & 60 mm

Standard Striker Plate with

striker cup

3mm

Adjustable Striker Plate with

striker cup

6mm

Both the standard striker plate (SSP) and the adjustable striker

plate (ASP) have a cast on strikercup protectingthe bolt. The ASP

has the big advantage of being easily adjustable in case the lock

and the striker plate need toget aligned better.

HX :

HE :

Lockedwithout power. Mechanical opening withkeyis always possible fromboth sides.

Mechanical opening withthe handle isalwayspossible from thesecureside.

Lockedwithout power ( ). Mechanical openingwith key is always

possible from bothsides. Mechanical openingwith the handle isalways possiblefromthe

secure side.

The handle on the inside mechanically retracts the locking components, always granting you an authorised exit.

These HX and HE versions of the A1 locks are therefore suitable for emergency exit doors and are certified for

and European standards.

In some cases it might be desirable to prevent people from exiting a building freely. In that case a master-slave

combination (of different A1 locks) can be installed. The „slave“ will need an unlock impuls from an authorised

person or alarm; the „master-lock“ will be unlucked with the handle. Please contact us for more detailed

informationregardingpossible combinations.

only when thedoor is closed

EN179 EN1125

Page 8

Installation instructions

A1 ELECTRO-MECHANICAL SECURITY LOCK

Please make sure the following installation requirements are met to ensure the correct functioning of

your B&B A1 electro-mechanical lock :

Use BB25LSZH cable (2 x 1,5mm² + 5 x 0,22mm² - shielded).

Use 24V DC regulated POWER SUPPLYof minimum 2,5A per lock.

Makesure the distance between the power supply and the lock is maximum 25m.

Measure the voltage coming to the lock and make sure that this never drops below 22,8V (24V DC +/-

5%) - important especially when the solenoid is activated! In case of a voltage drop on the line

one can increase the TRIM 2 on the PS24D52 power supply (factory setting = 2 ).

Makesure the distance between the lock and strikerplate is min. 2mm and max. 6mm.

Make sure the lock and striker plate are installed in a proper matter where the 2 are perfectly aligned

(in closed door position they should be straight across from each other, both laterally and in

height).

Makesure that there is no friction on the bolt when being ejected and retracted (this should be tested

after installation of the rubbers on the profile).

Make sure the holes for inserting the cylinder are large enough so the cylinder can be easily installed

without being forced.

Only cylinders with the lever at 5 and 7 (o’clock)can be used:

Filings that end up in or around the lock will be attracted

when the solenoid is activated and will eventually damage the lock. Compressed air can be used

to clean out the lock if necessary.

Do not use grease or oil in the locks. The necessary areas have been libricated during the assembly at

the factory.

A standard revision is recommended aftre 300'000 cycles or 5 years.

Make sure the door is equipped with adequate hinges (according to door size and weight) to avoid

„hanging“ of the door.

Makesure the door is equipped with an adequate door closer (according to door size and weight) !

DO NOT FILEwith the lockalready installed!

Please note that in order for the lockto functioncorrectly the above mentioned specifications need to

be strictly followed. B&B LOCKS b.v.b.a. can not be held accountable for on-site interventions and

reparationsunder warranty if the installation was notdone according tothese specific instructions!

min. 2mm

max. 6mm

Page 9

Mounting possibilities

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

Sanocyl

SA

SX

SE

Sanocyl

SA

Sanocyl

SA

SX

SE

HX

HE

BASEPLATE FIXATION BLOCKS

(BFB)

SURFACE MOUNT BRACKETS

(SMB)

A1 locks can of course also be

installed in existing doors. Since

it is not always easy to make very

accurate adaptions to a door

when you are on site, we have

developed Baseplate Fixation

Blocks ( ). Using these

blocks the A1 lock will end up

flush mounted on the profile

(when profile used is 2mm).

BFB-1

In case it is impossible to

install the A1 lock in the door

or the door frame because of

its dimensions, a surface

mount apllication may be

considered. The Surface

Mount Bracket (SMB) consists

of 2 mounting blocks and 1

stainless steel cover (these

need to be ordered

seperately for the lock AND

forthestrikerplate).

Installation is on the secure

side!

Page 10

Notes

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

......................................................................................................

A1 ELECTRO-MECHANICAL SECURITY LOCK

Page 11

A1 BASIC - connection diagram

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

CONNECTOR 1 (2-pole):

CONNECTOR 2 (5-pole):

pin 1 = (red,

GND (blue,

,

pin 4 = BOLT SIGNAL

(brown,

(yellow,

pin 6 = KEY SIGNAL

(green,

(grey,

+24Vdc +/- 5%, 2.5A 1.5 mm²)

pin 2 = 1.5 mm²)

pin 3 = UNLOCK - opening impulse - NO contact connects pin 2 (GND) and pin 3 to unlock

(black 0.22 mm²)

0.22 mm²)

0.22 mm²)

0.22 mm²)

0.22 mm²)

- transistorswitch to GND when bolt is locked - max. charge 100mA

pin 5 = DOOR SIGNAL - transistorswitch to GND when door is closed - max. charge 100mA

- transistorswitch to GND when key is used - max. charge 100mA

pin 7 = HANDLE SIGNAL - transistorswitch to GND when handle is used - max. charge 100mA

handle OUT

unlock impulse

bolt OUT

door OUT

key OUT

power GND

power +24V

-Unlock

Internal GND (+0V)

Internal power (+24V)

Page 12

A1 BASIC - connection diagram with REL-4

A1 ELECTRO-MECHANICAL SECURITY LOCK

The REL-4 interface is available to turn the

signals coming from the lock into potential

free contacts. It also facilitates the

connection of the access control.

In order to guarantee the correct

functioning of the lock, 24Vdc (+/- 5%) /

2.5A has to reach the lock. We suggest

using our PS24D52 power supply and

BB25LSZH cable (2x1.5mm² + 5x0.22mm²).

The maximum distance between the power

supply and the lock is 25m.

Page 13

REL-4 - connection diagram

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

REL-4 interface:

CONNECTOR 1 (2-pole) - connection to the power supply:

CONNECTOR 2 (2-pole) - unlocking impulse:

CONNECTOR 3 (7-pole) - connection to the lock:

CONNECTOR 1 (12-pole) - potential free outputs:

DIN Rail box with user friendly Phoenix plug-in screwconnectors.

pin 1 = (red,

GND (blue,

pin 2

pin 1 = (red,

GND (blue,

(black,

pin 4 = BOLT SIGNAL brown,

(yellow,

pin 6 = KEY SIGNAL (green,

(grey,

pin 1 = BOLT common

pin 2 = BOLT locked (NO)

pin 3 = BOLT unlocked (NC)

pin 4 = DOOR common

pin 5 = DOOR closed (NO)

pin 6 = DOOR open (NC)

pin 7 = KEY common

pin 8 = KEY in use (NO)

pin 9 = KEY not in use (NC)

pin 10 = HANDLE common

pin 11 = HANDLE in use (NO)

pin 12 = HANDLE not in use (NC)

Inputs:

Outputs:

+24Vdc +/- 5%, 2.5A 1.5 mm²)

pin 2 = 1.5 mm²)

pin 1

+24Vdc +/- 5%, 2.5A 1.5 mm²)

pin 2 = 1.5 mm²)

pin 3 = UNLOCK - unlocking impulse 0.22 mm²)

0.22 mm²)

0.22 mm²)

0.22 mm²)

0.22 mm²)

(

pin 5 = DOOR SIGNAL

pin 7 = HANDLE SIGNAL

UNLOCK - NO contact connecting pin 2 (GND) to pin 3 to unlock

Page 14

A1 BASIC - connection diagram without REL-4

A1 ELECTRO-MECHANICAL SECURITY LOCK

Connection without REL-4 interface:

The unlock impulse is a NO contact, which

bridges pin 2 and 3 on the lock.

In order to guarantee the correct

functioning of the lock 24Vdc (+/-5%) / 2.5A

has to arrive at the lock. We recommend

using our PS24D52 power supply and

BB25LSZH cable (2x1.5mm² + 5x0.22mm²).

The maximum distance between the power

supply and the lock is 25m.

Page 15

A1 master-slave connection

w w w . b b - l o c k s . c o m

A1 ELECTRO-MECHANICAL SECURITY LOCK

Openen 3x A1 sloten met kruk uitgang

Voeding +24V

Voeding massa

Ontgrendel ingang

Schoot uitgang

Deur uitgang

Sleutel uitgang

Kruk uitgang

Voeding +24V

Voeding massa

Ontgrendel ingang

Schoot uitgang

Deur uitgang

Sleutel uitgang

Kruk uitgang

Voeding +24V

Voeding massa

Ontgrendel ingang

Schoot uitgang

Deur uitgang

Sleutel uitgang

Kruk uitgang

SLOT MET KRUK

It is possible to mount multiple A1 locks on 1 door in a „master-slave“ configuration

to obtain a multi-point locking system:

handle output

key output

door output

bolt output

opening impulse input

Power Supply GND

Power Supply +24V

handle output

key output

door output

bolt output

opening impulse input

Power Supply GND

Power Supply +24V

handle output

key output

door output

bolt output

opening impulse input

Power Supply GND

Power Supply +24V

Page 16

Production and sales:

Uilenbaan 88 unit 3

2160 Wommelgem

Belgium

Tel.: +32.3.326.36.30

Fax: +32.3.326.38.33

E-mail: info@bb-locks.com

B&B LOCKS b.v.b.a.

Loading...

Loading...