BaySeparator

Technical and Design Manual

www.BaySaver.com

BAYSEPARATOR™ SYSTEM

T echnical and Design Manual

© BaySaver Technologies, Inc.

1302 Rising Ridge Road, Unit One

Mount Airy, Maryland 21771

Phone 301-829-6470 • Fax 301-829-3747

i

Table of Contents

Page

CHAPTER 1 – INTRODUCTION……………………………………………. 1

CHAPTER 2 - PRINCIPLES OF OPERATION…………………………….. 2

Hydrodynamic Separators………………………………………………………………………... 2

Mechanisms of Removal…………………………………………………………………………. 2

Overview of the Standard BaySeparator™ System……………...………………………………. 3

Single Structure BaySeparator™ Systems……………...………………………………............... 4

BaySeparator™ System Operation……………………………………………………………….. 5

Single Structure BaySeparator™ Operation…………...………………………………................. 8

CHAPTER 3 - COMPONENTS OF THE BAYSEPARATOR™ SYSTEM 16

BaySeparator™ Unit…………………………………………………………………….….......... 17

Primary and Storage Manholes………………………………………………………………….. 17

System Connections and Miscellaneous Piping…………………………………………………. 17

Single Structure BaySeparator™ Systems………………………………………………….......... 18

CHAPTER 4 – ENGINEERING AND DESIGN…………………………….. 19

Specifying BaySeparator™ Systems………………………………………………………..……. 20

Hydraulic Performance…………………………………………………………………………… 21

System Sizing…………………………………………………………………………………….. 22

Annual Aggregate Removal............................................................................................................ 22

CHAPTER 5 – INSTALLATION, MAINTENANCE AND CLEANING. ... 25

Installation Instructions………………………………………………………………………….. 25

Maintenance………………………………………………………………………………...……. 30

Inspection and Cleaning………………………………………………………………….………. 31

CHAPTER 6 - COST AND AVAILABILITY……………………………….. 33

APPENDICES………………………………………………………………….. 34

A. Specifications………………………………………………………………………………… 35

B. Engineering Drawings……………………………………………………………………….. 40

C. Project Information Sheet.…………………………………………………………………… 52

ii

BAYSAVER TECHNOLOGIES, INC.

Chapter

1

Introduction

Since 1997, BaySaver Technologies™ has been protecting lakes, streams, and waterways

from environmental problems. One of BaySaver Technologies’ most innovative products to control

non-point source pollution has been the BaySaver

installed in over 1,500 locations in commercial, industrial, and residential applications worldwide, and

has been used in projects as varied as parking lots, gas stations, service stations, maintenance

facilities, and highways. This separator has also been used as a pretreatment for other types of

stormwater technologies such as filters, ponds, infiltration systems, etc.

This manual provides an introduction to the BaySeparator™ line of products and the

technical details that will help you meet your stormwater pollution control requirements both now and

in the future.

®

Separation System1. The system has been

The BaySeparator™ was designed based upon the philosophy of the 3E’s: Efficiency, Ease of

Maintenance, and Economy. Through extensive laboratory testing and mathematical modeling we

have developed a separator that delivers predictable, reliable, and scalable performance based on third

party full scale testing.

The BaySeparator™ System makes complying with stormwater treatment regulations

nationwide convenient and cost effective. The BaySeparator™ system is a high performance

separator yet, its unique and simple design keeps it highly affordable, easy to specify, install, and

maintain. The BaySeparator™ is customizable to special project site conditions as either a standalone

or a pretreatment unit, and is ideal for use in retrofit situations. The BaySeparator™ has minimal

footprint requirements when compared to other types of Best Management Practices (BMPs).

The BaySeparator™ system begins operating as soon as runoff enters the system. During a

storm event, flow enters a Primary Manhole for initial separation. The flow is then conveyed to an

offline Storage Manhole where oils, fine suspended solids, and floatables are collected. Since the

water flow is regulated into the secondary manhole, resuspension is eliminated during higher flows.

In addition, the system’s chambers are fully accessible for inspection and maintenance from the

surface without entry to the system, resulting in more efficient maintenance and lower costs.

BaySaver Technologies, Inc. is committed to providing stormwater treatment solutions and

excellent customer service. If you have any questions about the information in this manual, please

contact BaySaver Technologies at 1-800-229-7283 (1-800-BaySaver) or by e-mail at

TechQuestions@BaySaver.com.

1

The BaySaver® Separation System is manufactured in Mount Airy, Maryland, by BaySaver Technologies,

Inc., and is protected by U.S. patent 5,746,911, several patents pending, and international patents. Any

infringement on these patents will be prosecuted to the fullest extent of the law. For detailed information on

specifying, purchasing, or installing a BaySaver

Inc. or an authorized representative directly.

®

Separation System, please contact BaySaver Technologies,

1

BAYSAVER TECHNOLOGIES, INC.

Chapter

2

Principles of Operation

Hydrodynamic Separators

Hydrodynamic separators rely on density differences and gravity to remove suspended solids

and floatables (hydrocarbons, floating debris, etc.) from stormwater runoff. The BaySeparator™

system splits water between two different manholes for optimal removal efficiency, responding to

changes in the influent flow rate. Pollutants are trapped in the two manholes until they are removed

by routine maintenance.

Mechanisms of Removal

The BaySeparator™ system removes pollutants from the stormwater stream through one of

two mechanisms: sedimentation or flotation. Engineers have relied on these two mechanisms in water

and wastewater treatment for years. The BaySeparator™ system applies these time tested principles

to stormwater treatment in a configuration that prevents contaminant release or resuspension during

high flow rates.

Sedimentation is the gravity-driven process by which solids suspended in water fall

downward. Sedimentation is driven by the difference in density between the solid particles and the

water surrounding it, and the size of the settling particles. Because they have more mass, larger

particles settle faster than smaller ones. The effectiveness of sedimentation depends on the size of the

settling particles and the length of time the particles are allowed to settle.

Flotation works the same way as sedimentation, but in the opposite direction. Floatable

pollutants like free oils and debris rise to the surface and are trapped in the storage manhole.

BaySeparator™ systems and other types of similar BMPs are typically sized to provide a

given annual aggregate removal efficiency. While hydrodynamic separators perform better at low

flow rates than they do at high flows, low flows are far more frequent than high flows. When

designed to achieve a specified annual aggregate removal efficiency, the BaySeparator™ system

operates at a high removal efficiency during the frequent, low intensity storms. Because the majority

of the sediment load from a site is contained in these more frequent storms, a BaySeparator™ system

designed in this way can remove 80% or more of the annual sediment load from a given site. The

BaySeparator™ can also be configured as a pretreatment BMP to filters, ponds, and other types of

BMPs as part of a treatment train.

2

BAYSAVER TECHNOLOGIES, INC.

o

Overview of the Standard BaySeparator™

System

The system is comprised of three main components: the BaySeparator™ unit, the Primary

Manhole, and the Storage Manhole. Figure 2.1 displays a simple schematic of the BaySeparator™

system. Influent flow containing pollutants enters the system by first passing through the Primary

Manhole. In this structure, coarse sediment settles while the flow passes over a weir into the

BaySeparator™ Unit and is routed to the Storage Manhole. The influent flow, at this point, still

contains pollutants of concern, such as fine sediments, oil, grease, floating trash, and other debris.

Once in the Storage Manhole floatable trash, oils, and grease float to the surface, while fine sediments

settle out and the influent separated flow returns to the outfall of the system back through the

Separator Unit.

Storage

Manhole

Floatables

Outlet To

Environment

Fine

Sediment

BaySeparator™ Unit

Coarse

Sediment

Primary

Manhole

Inlet Storm

NOTE: Second “Tee” pipe has

been removed for a clearer

view of the weir.

w

Fl

Figure 2.1: The BaySeparator™ System

As the rate of flow increases through the system, the BaySeparator™ unit acts as a dynamic

control to route the influent flow through the most effective flow path for treatment. For example,

under low flow conditions the entire influent flow is treated as described above. Under moderate

flows and up to the maximum treatment flow, water is continuously treated through both the Primary

and Storage Manholes, with a portion of these flows diverted through the T-pipes and the remainder

flowing into the Separator Unit and then to the Storage Manhole. This flow path allows for full

treatment of floatable pollutants, while still treating sediments under moderate flow conditions.

During maximum flow conditions, most of the influent flow passes over the bypass plate and will not

be treated.

3

BAYSAVER TECHNOLOGIES, INC.

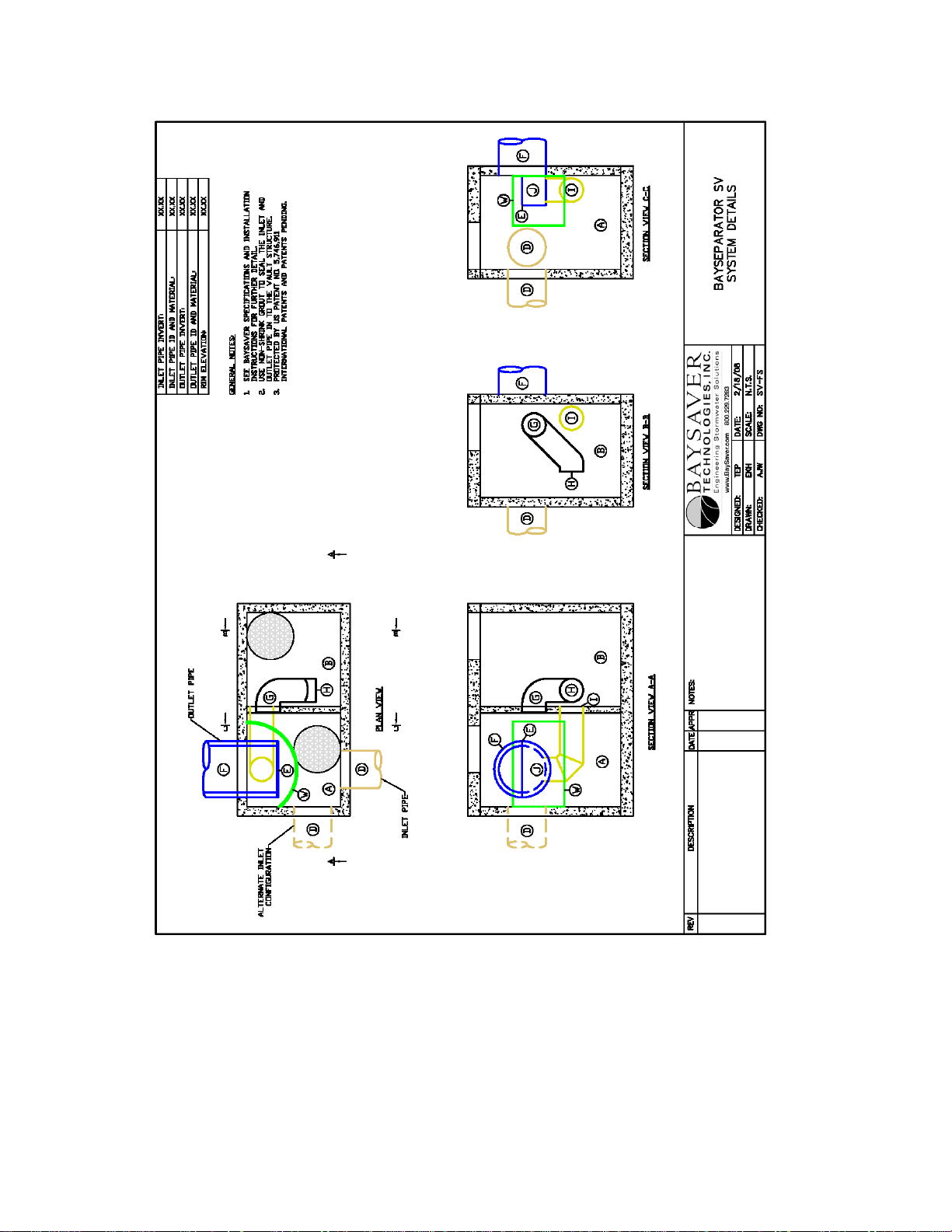

Single Structure BaySeparator™ Systems

For some applications, site conditions or applicable regulations may require a single structure

hydrodynamic separator. For these projects, BaySaver Technologies can provide the BaySeparator™ SV, a

BaySeparator™ system contained in a single precast concrete vault. The BaySeparator™ SV is a selfcontained, single structure BMP that operates on the same principles and in the same manner as the standard

BaySeparator™ systems.

The BaySeparator™ SV is contained in a precast concrete vault. The vault is divided into two

separate chambers: a primary chamber and a storage chamber, which duplicate the functions of the precast

manholes. These two chambers provide a location for sedimentation and flotation to occur, and storage

capacity for the collected pollutants. Fine sediments and floatable pollutants are stored off-line, isolated

from high flows that may enter the system during extreme events, and the accumulated pollutants are

retained in the two chambers until they are removed by routine maintenance.

Internal flow controls divert influent water to achieve the best possible treatment efficiency in

response to the influent flow rate. These controls are constructed of HDPE, PVC, or stainless steel, and

include a surface skimming pipe that conveys influent water from the surface of the primary chamber to the

middle of the storage chamber; a return pipe that delivers treated water from the storage chamber to the

system outfall; a baffle in the primary chamber that prevents design flows from passing directly to the

system outlet; and a weir at the system outfall that allows flows up to the maximum treatment rate to pass

through the system without inundating the storage chamber and resuspending the pollutants collected there.

These flow controls also allow extreme flows to pass through the system unimpeded, thus minimizing the

risk of resuspending collected pollutants.

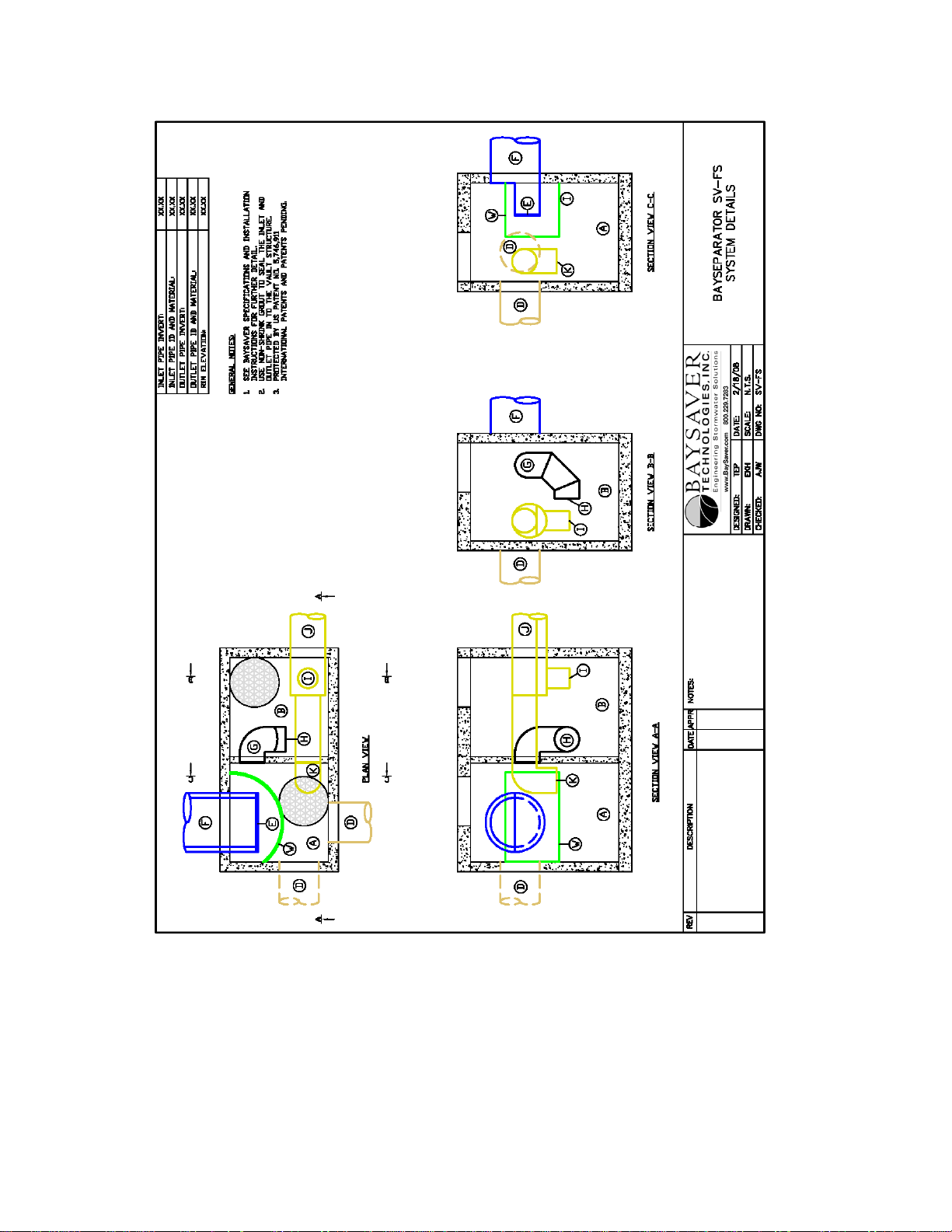

The BaySeparator™ SV is also available with built-in flow splitter design (BaySeparator™ SVFS). This configuration delivers treated effluent to a detention system or another water quality device via a

low flow while also diverting treated secondary flow to the low flow outlet as well. This outlet also allows

high intensity runoff to bypass the system through a separate overflow outlet pipe. The two effluent streams

can be directed to separate outfalls, or combined downstream and directed to a single outfall. Engineering

details for the BaySeparator™ SV-FS system can be found in Appendix B.

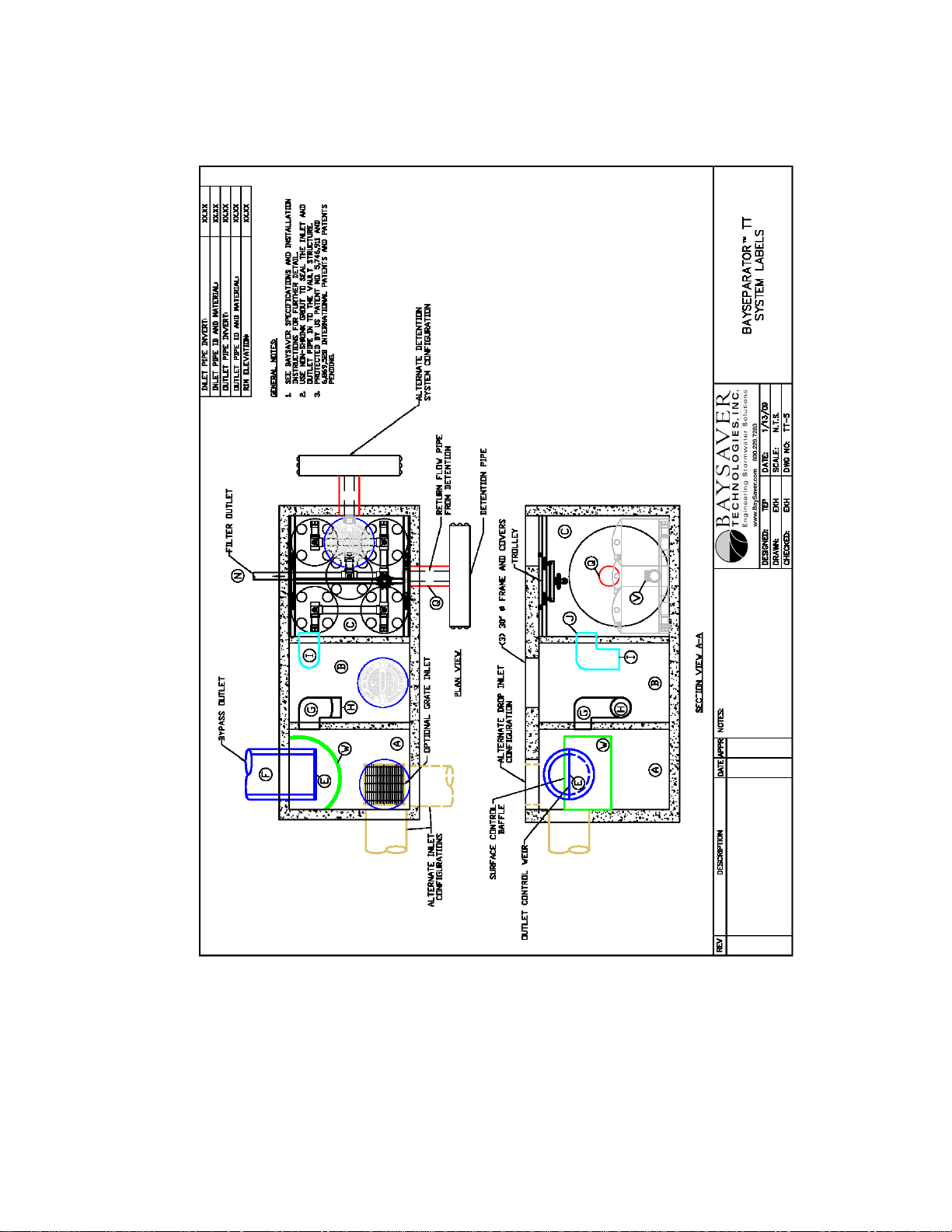

BaySaver Technologies, Inc. also manufactures an additional single structure system,

BaySeparator™ TT. The BaySeparator™ TT is constructed within a precast concrete vault. The

system comprises a modified BaySeparator™ SV-FS system and a third chamber that is used as the

housing structure for a BayFilter™ system. This third chamber also accommodates an attachment of

an underground storage system that retains the water quality volume on site.

4

BAYSAVER TECHNOLOGIES, INC.

y

BaySeparator™ System Operation

Low Flows

During low flows, the BaySeparator™ System treats all the runoff through both manholes.

This occurs during small storms and the beginning of more intense storms.

Outlet Pipe from

Storage Manhole

Primary Manhole

Storage Manhole

Storage Manhole

Storage Manhole

Inlet Pipe to Storage

Manhole

Figure 2.2: Low Flow Operation

Note: Onl

one “T” pipe is shown in this drawing.

As shown in Figure 2.2, water enters the BaySeparator™ system’s Primary Manhole through the

inlet pipe shown on the right side of the figure. Coarse sediments (gravel and sand) immediately fall to the

floor of the Primary Manhole. The influent water, carrying floatables and finer sediments, flows through the

separator and is conveyed into the Storage Manhole (on the left), where it enters the structure below the

water surface. When water enters the Storage Manhole from the submerged inlet pipe, oils and other

floatables rise to the surface, while sediments settle to the floor. These contaminants remain trapped offline

and are not resuspended during larger flows. The influent water displaces clean water from the center of the

column, which is forced back up the return pipe to the system outfall. In this way, all of the water that

reaches the system outfall has been treated in both the Primary and Storage manholes.

5

BAYSAVER TECHNOLOGIES, INC.

Maximum Treatment Flow

During larger storms, flow rates continue to increase. During these events, the

BaySeparator™ unit continues to divert surface flows (containing the majority of suspended

sediments, as well as the oils and other floatables) from

Manhole as described above (Figure 2.3).

the Primary Manhole to the Storage

“Tee” Pipes

Figure 2.3: Maximum Treatment Flow

Additional flows associated with the larger storm are treated by separation in the Primary Manhole.

As the pollutants are separated, the influent water displaces treated water from the center of the column and

forces it up the “Tee” pipes to the system outfall.

6

BAYSAVER TECHNOLOGIES, INC.

Peak Design Flow

The BaySeparator™ system also has an internal bypass to prevent flooding of the drainage area.

Influent flows with flood potential are directed over the bypass plate and directly through the unit. The

BaySeparator™ system uses the weir plate to limit flows into the Storage Manhole, minimizing the risk of

resuspending captured pollutants such as fine sediments, oils, and floatables that are stored offline. By

storing pollutants offline, the BaySeparator™ system hydraulically isolates these contaminants from

the high energy influent flows, effectively eliminating the risk of resuspending accumulated

contaminants

.

Figure 2.4 Peak Design Flow

Figure 2.4 shows the BaySeparator™ system near peak design flow. The open top “Tee”

pipes are engineered to minimize resuspension risks in the Primary Manhole. When the flow rate is

high enough to present the possibility of resuspension, water is allowed to flow into the top of the

“Tee” pipe. This limits the flow from the bottom of the pipe and minimizes turbulence in the center

of the Primary Manhole.

7

BAYSAVER TECHNOLOGIES, INC.

Single Structure BaySeparator™ Operation

BaySeparator™ SV Operation

During low flow conditions, influent water enters the BaySeparator™ SV through the Inlet pipe

(labeled D in Figure 2.5). It flows directly into the primary chamber (A), causing the water level in that

chamber to rise. When the water level in the primary chamber rises, water is skimmed from the surface of

that chamber by a pipe (G) that penetrates the wall between the two chambers. This pipe delivers that water

to the storage chamber (B), where it enters horizontally below the water surface through a 90 degree fitting

(H). When the water enters the storage chamber, the entrained sediments, floatables (oils, trash, debris)

separate from the water stream – sediments settle to the structure floor and floatables rise to the water

surface. The additional water in the storage chamber displaces clean water from the center of the column,

which enters the return pipe (I) and flows to the system outlet assembly (J). From here, the treated water

leaves the BaySeparator™ system.

When the flow rate into the BaySeparator™ system increases an additional flow path is created.

During this design treatment rate water in the primary chamber flows beneath the surface baffle plate (W).

The water that passes beneath this baffle is free of oils and floatable pollutants, which will continue to be

removed in the storage chamber. When the water level in the primary chamber rises high enough, this

cleaner water will flow over the weir (E) shown in the outlet assembly (J).

In extreme storm events, the flow rate into the BaySeparator™ system exceeds the maximum

treatment rate (MTR) of the SV unit. Under these rare conditions, the excess flow passes over the surface

baffle plate (W) and flows directly to the outlet assembly (J). Because the water level in the primary is

higher than the top of the weir, the weir no longer limits the flow to the system outlet. Instead, the high

flows pass directly over the walls of the outlet assembly (J) and enter the outlet pipe (F) directly.

8

BAYSAVER TECHNOLOGIES, INC.

g

ure 2.5: BaySeparator SV

Fi

9

BAYSAVER TECHNOLOGIES, INC.

BaySeparator™ SV-FS Operation

pipe (labeled D in Figure 2.6), in the same manner as it does in the standard BaySeparator™ SV system. It

flows directly into the primary chamber (A), causing the water level in that chamber to rise. When the water

level in the primary chamber rises, water is skimmed from the surface of that chamber by a pipe (G) that

penetrates the baffle wall between the two chambers. This pipe delivers that water to the storage chamber

(B), where it enters horizontally below the water surface through a 90 degree fitting (H). When the water

enters the storage chamber, the entrained sediments and oils begin to separate from the water stream –

sediments settle to the structure floor and oils rise to the water surface. The additional water in the storage

chamber displaces clean water from the center of the column, which enters the return pipe (I) and flows to

the treated flow outlet assembly (J).

When the flow rate into the BaySeparator™ system increases an additional flow path is created.

When the water level in the primary chamber rises to a point higher than the horizontal invert of the tee-pipe

(K), water begins to flow into the tee-pipe (K) from below the water surface of the primary chamber. This

water is free of oils and other floatable pollutants, and it is conveyed through the tee-pipe to the treated water

outlet assembly (J). The geometry of the tee pipe limits the flow rate through this path in such a way as to

continue sedimentation in the primary chamber throughout design conditions.

In extreme storm events, the flow rate into the BaySeparator™ system exceeds the maximum

treatment rate of the SV-FS unit. Under these rare conditions, the excess flow passes over the surface baffle

plate (W) and flows directly to the overflow outlet pipe (F). The overflow outlet assembly (E) prevents

water from entering the overflow outlet during design flow conditions. When the water level in the primary

chamber rises high enough, however, excess water flows over the outlet assembly walls (E) and leaves the

system through the overflow outlet pipe (F).

During low flow conditions, influent water enters the BaySeparator™ SV-FS through the influent

10

BAYSAVER TECHNOLOGIES, INC.

Figure 2.6: BaySeparator™ SV-FS

11

BAYSAVER TECHNOLOGIES, INC.

BaySeparator™ TT Operation

(labeled D in Figure 2.7), in the same manner as it does in the BaySeparator™ SV. It flows directly into the

primary chamber (A), causing the water level in that chamber to rise. When the water level in the primary

chamber rises, water is skimmed from the surface of that chamber by a pipe (G) that penetrates the wall

between the two chambers. This pipe delivers the storage inflow water to the storage chamber (B), where it

enters horizontally below the water surface through a 90 degree fitting (H). When the water enters the

storage chamber, the entrained sediments and floatables separate from the water stream – sediments settle to

the structure floor and oils rise to the water surface. The additional water in the storage chamber displaces

clean water from the center of the column, and this storage outflow enters the return pipe (I) and flows into

the filtration chamber (C). The treated water enters the filtration chamber horizontally through a 90 degree

fitting on the end of the pipe (J).

When the flow rate into the BaySeparator™ system increases a second flow path is utilized. When

the water level in the primary chamber rises to a point higher than the horizontal invert of the secondary flow

pipe, water begins to flow into the secondary flow pipe from below the water surface of the primary

chamber. This secondary treatment flow is free of oils and other floatable pollutants, and it is conveyed

through the storage chamber via the secondary flow pipe. The geometry of the pipe limits the flow rate

through this path in such a way as to continue sedimentation in the primary chamber throughout design

conditions as well as to accommodate the low flow paths as outlined above.

During low flow conditions, influent water enters the BaySeparator™ TT through the inlet pipe

The low flow is released into the filtration chamber so as to ensure that the first flow is used to

“prime” the BayFilter™ cartridges to enable full cartridge flow to occur immediately. There is a one-way

(flap) valve (V) that prevents water from flowing into the detention pipes until after the water has reached a

depth that is sufficient to prime the filter cartridges. As water enters the filtration chamber, the valve will be

held shut by the pressure difference between this chamber and the water in the extended detention pipes

(This seal does not need to be “perfect”, a restricted condition is all that is necessary.) Once the water

elevation has reached 28”, the filters are primed and flow at the design rate will occur. At this point excess

water flow goes in to the extended detention pipe via an upper connecting pipe (Q). After the storm subsides

and the filter chamber drains down, the cartridges go into siphon, and the flap valve opens and releases the

water in the extended detention chamber into the filtration chamber.

For runoff flow rates up to the design treatment flow rate, 100% of the water that enters the

BaySeparator™ TT system is treated by both the physical processes of the BaySeparator™ itself and the

media filtration of the BayFilter™ system. When the influent flow rate is greater than the filtration capacity

of the BaySeparator™ TT system, but below the maximum treatment flow rate of the BaySeparator™ TT

unit, the excess water is diverted to the extended detention system, where it is stored until it can be released

to the filtration chamber at the lower flow rate. In the filtration chamber, the water is passed through the

BayFilter™ cartridges, and then collected in an under drain manifold and discharged through the outlet pipe

(N). Once the extended detention system is full, the treatment continues because as the water enters the

primary chamber (A), it must flow below the baffle (W) and then over the outlet weir (E) to the outlet pipe

(F).

12

BAYSAVER TECHNOLOGIES, INC.

Figure 2.7: BaySeparator™ TT

13

BAYSAVER TECHNOLOGIES, INC.

In extreme storm events, the flow rate into the BaySeparator™ system exceeds the maximum treatment rate

of the BaySeparator™ TT unit. Under these rare conditions, the excess flow passes over the surface baffle

plate (W) and flows directly to the overflow outlet pipe (F).

The BaySeparator™ TT-SO offers a slight variation from the “standard” TT unit.

Functionally, both units operate in a similar fashion, but the SO unit has a single outlet (F) instead of

two separate outlets. This single outlet (F) is located at the vault floor level of the primary chamber.

In the TT-SO unit, the filter outlet pipe (N) is connected directly to a standpipe (E), which is open at

the top, in the primary chamber. The elevation of this opening is the same as the elevation of the weir

in the standard TT unit. All effluent flows (both treated and bypass flows) from the TT SO unit enter

into a single outlet pipe (F). This TT SO unit may be used on sites where a single discharge point is

advantageous.

14

BAYSAVER TECHNOLOGIES, INC.

Figure 2.8: BaySeparator™ TT-SO

15

BAYSAVER TECHNOLOGIES, INC.

C

hapter

3

Components of the

BaySeparator™ System

The BaySeparator™ system comprises two standard precast manholes and the

BaySeparator™ unit. The two manholes allow the removal and storage of pollutants, while the

separator unit directs the flow of water to provide the most efficient treatment possible. Figure 3.1

shows a cutaway view of the complete BaySeparator™ system with flow patterns.

Figure 3.1: BaySeparator™ Flow Patterns

16

BAYSAVER TECHNOLOGIES, INC.

BaySeparator™ Unit

The BaySeparator™ unit is the heart of the BaySeparator™ system. The BaySeparator™ unit

controls the influent flow through the two manholes. This device is manufactured by BaySaver

Technologies’, and can be purchased through our locally authorized sales representative. Contact

BaySaver Technologies, Inc. for additional sales information.

The BaySeparator™ unit is fabricated entirely of high density polyethylene (HDPE) infused

with UV-resistant carbon-black. HDPE is a non-brittle, chemically inert material known for its

corrosion-resistant properties. It is commonly used in applications that expose it to harsh conditions

(landfills and chemical plants, for example) and is used in storm drains throughout the world.

The BaySeparator™ unit is constructed using state-of-the-art technology and the best materials

available ensuring quality construction. All parts are joined together with extrusion welding. The

BaySeparator™ unit is light, easy to install, and is provided with the connecting pipes and couplers needed

for a complete system (less the manholes)

Primary and Storage Manholes

The Primary Manhole is a standard precast structure used to remove coarse sediments. This

manhole is generally installed inline with the storm drain and can be used as a multiple inlet structure.

The precast manholes are purchased from local concrete distributors.

The Storage Manhole acts as a secondary treatment device for the collection and offline storage of

oils, fine sediments and floatables. It is also a standard precast manhole that is purchased locally. The

Storage Manhole is a key component that sets the BaySeparator™ system apart from other systems. The

BaySeparator™ system stores the pollutants offline to prevent resuspension.

System Connections and Miscellaneous Piping

The BaySeparator™ unit is connected to each of the two manholes with standard storm drain

pipe connections. The connecting pipes entering and leaving the storage manhole are submerged

during normal operation. Those joints must be watertight, and are typically made using flexible pipeto-manhole connectors (rubber boots) installed in the storage manhole by the precast manufacturer.

These connecting pipes are joined to the BaySeparator™ unit using Fernco® seals with shear rings.

The shear rings provide additional structural strength and rigidity to this joint. The BaySeparator™

unit is joined to the system outfall pipe with a custom made reducer/adapter provided by BaySaver

Technologies, Inc.

The connecting pipes are joined to the BaySeparator™ unit via a flanged connection. The

connecting pipe orientation (left or right hand) can be easily changed by removing the bolts in the

flange and rotating the connecting pipe to the desired unit orientation.

17

BAYSAVER TECHNOLOGIES, INC.

Single Structure BaySeparator™ Systems

BaySeparator™ XK systems, BaySeparator™ SV systems, and BaySeparator™ TT systems

contain internal components supplied by BaySaver™ Technologies, Inc. In BaySeparator™ XK

systems, these components are fabricated from stainless steel, and are joined to the walls of the

concrete vault structure using standard hardware provided by BaySaver™ Technologies. BaySaver™

supplies both mounting hardware and watertight seals (where necessary) for these installations.

BaySeparator™ SV and TT systems contain internal flow controls fabricated from HDPE and

PVC. Like the components of the XK systems, these flow controls are provided by BaySaver™

Technologies with the necessary mounting hardware and watertight seals. The component mounting

hardware and seals utilize standard utility connections, and are selected to meet all storm drain

construction specifications. The flow controls are designed to be easy for any experienced utility

contractor to install.

18

BAYSAVER TECHNOLOGIES, INC.

Chapter

4

Engineering and Design

BaySeparator™ units are manufactured in five (5) standard sizes (see Table 4.1). The

BaySeparator™ is also available in a custom configuration XK model for sites requiring higher flow

rates than the standard units, SV configurations for constrained sites that require a compact, single

structure unit, and a TT (treatment train) single structure unit that incorporates an SV BaySeparator™

coupled with an integral extended detention structure, and a BayFilter™ system with controlled

release.

The sizes of both the Primary and Storage Manholes in the BaySeparator™ may be varied to

suit specific site conditions and treatment requirements as necessary. By selecting the appropriate

separator unit size and determining the manhole diameters, the design engineer has the freedom to

adapt the BaySeparator™ unit to the needs of a particular site. The entire system can easily be

customized and hydraulically scaled to treat a wide array of stormwater flows varying from 1.1 cfs to

21.8 cfs with standard units. BaySaver Technologies can also accommodate significantly larger flows

by using the BaySeparator™ XK model.

Table 4.1: BaySeparator™ Hydraulic Performance

Characteristics

Standard

BaySeparator™

Model

Designation

1/2K

1K

3K

5K

10K

SV

SV-FS

TT-5 (TT-SO-5)

TT-8 (TT-SO-8)

XK

Note: cfs = cubic feet per second

BaySeparator™

Nominal

Diameter

(in inches)

24 1.1 8.5 48 6

24 2.4 10 48 8

36 7.8 30 60 8

48 11.1 50 72 8

60 21.8 100 120 8

24 5.3-23.1 16.0-101.8 48-96 4-6

24 5.3-23.1 16.0-101.8 48-96 4-6

24 2.8*/0.33** 16.0 48 4

24 2.9*/0.53** 16.0 48 4

Please contact BaySaver Technologies for design assistance

Maximum

Treatment

Rate

(MTR)

(in cfs)

*Maximum flow to extended detention, ** Maximum filtration rate

Maximum

Hydraulic

Rate

(MHR)

(in cfs)

Manhole

Diameter/

Length

Flow Based

Systems

(inches)

Manhole/

Vault

Depth

(in ft)

19

BAYSAVER TECHNOLOGIES, INC.

Specifying BaySeparator™ Systems

Location

The first step in specifying a BaySeparator™ system is determining where to place it. One of

the advantages of the BaySeparator™ system is its flexibility in site placement. The BaySeparator™

system can be configured as either a right- or left-hand unit to design around existing structures and

can be placed under load bearing surfaces or in green spaces. Looking downstream through the

system, if the Storage Manhole is placed to the left of the Primary Manhole, then a left-hand unit is

needed, and if the Storage Manhole is placed to the right of the Primary Manhole, then a right-hand

unit is needed.

For either pretreatment or full treatment flows that exceed the hydraulic capacities and/or

performance capability of the 60″ BaySeparator™, BaySaver Technologies BaySeparator™ XK

custom product line can accommodate higher hydraulic capacities and treatment flows to match a

special application. Call BaySaver’s Engineering Department at 1.800.229.7283 for sizing and design

information.

One of the most important considerations in specifying the site of the BaySeparator™ system

is choosing a location where inspection and maintenance access is readily available. The

BaySeparator™ systems can be designed downstream of multiple inlets or catch basins to reduce the

number of devices needed onsite, thus decreasing regulatory and maintenance costs.

BaySeparator™ systems are typically shown on site plans as shown in Figure 4.1.

BaySeparator™

System

Figure 4.1: Site Plan Example

The location of the BaySeparator™ on the site is determined by several factors. Maintenance

access, the unit’s footprint, available drop, available depth, and the surface elevation of the receiving

waters must be considered when selecting the system’s location.

The BaySeparator™ system must be installed in an area that is accessible to maintenance

equipment. The annual maintenance of a BaySeparator™ system requires a vacuum truck, and the

20

BAYSAVER TECHNOLOGIES, INC.

manhole covers of the BaySeparator™ must be placed in locations that can be easily reached by such

a vehicle.

The BaySeparator™ should be placed in a location that minimizes its interference with

existing or planned underground utilities.

Hydraulic Performance Characteristics of the

BaySeparator™

The BaySeparator™ system has two characteristic flow rates: the maximum treatment rate

(MTR) and the maximum hydraulic rate (MHR). The MTR is the maximum flow rate that can be

fully treated by the BaySeparator™ unit without any bypass. The MHR is the maximum flow rate that

can be conveyed through the BaySeparator™. The MHR, or bypass flow capacity, allows

BaySeparator™ systems to be installed online, without the need for a separate diversion structure.

Table 4.1 shows the MTR and MHR for each of the BaySeparator™ units.

BaySeparator™ systems can be designed for pretreatment (50% sediment annual aggregate

removal efficiency), for standalone / full treatment (80% annual aggregate removal efficiency), or for

other values of annual aggregate removal efficiencies. The design criteria used for each project will

depend on the applicable regulations of the jurisdiction in which the project site is located. Please

consult BaySaver Technologies’ Engineering Department at 1.800.229.7283 for special sizing

requirements or questions.

21

BAYSAVER TECHNOLOGIES, INC.

System Sizing

BaySeparators™ can be sized following different criteria which include:

1. Flow Based Sizing: This applies when a locality specifies the required treatment flow (MTR)

the separator has to treat together with the maximum hydraulic rate (MHR) associated with a

peak design storm. In some cases a treatment volume is given which then needs to be

converted to a flow using approved methods.

2. Annual Aggregate Removal (AAR) Based Sizing: This is a very common criteria used to size

hydrodynamic separators to a given suspended solids removal performance.

3. Other Sizing Criteria: Certain jurisdictions might have special sizing criteria that do not fit

the sizing criteria 1 or 2. In this case, BaySaver Technologies will work with the design

engineer and regulators to design a system meeting these local regulations or concerns.

Sizing by Flow Rate

To size the BaySeparator™ unit, the design maximum flow through the storm drain must first

be calculated. Compare that flow rate to the Peak Design Flow Rate listed in Table 4.1. Select a unit

with a Peak Design Flow Rate equal to or higher than the design flow. The unit selected and all larger

BaySeparator™ units have the capacity to convey the design flow without backup.

Local regulations may specify that a certain flow rate must be treated. In that case, compare the

Maximum Treatment Flow Rate with the treatment flow specified by the local regulations. Again, the

BaySeparator™ unit must have a maximum treatment flow rate (MTR) that is greater than or equal to the

determined treatment flow rate. This ensures that the BaySeparator™ unit will meet the local regulations.

Contact BaySaver Technologies for the recommended manhole sizes for flow based systems at

1.800.229.7283.

Example

:

Stormwater treatment is needed for a 3.2 acre site located in the US East Coast. The site has an

imperviousness coefficient of 0.85.

For this jurisdiction, the peak design flow is the 10-year 1-hour storm which is 2.6 inches. Using

the Rational Method, this translates into calculated peak flow of 7.07 cfs of runoff to be conveyed.

Using Table 4.1, we cross-reference this value against the Peak Design Flow Rates. The smallest

unit that can convey this peak design flow is a 1/2K BaySeparator™.

If local regulations require full treatment of the 1-year 1-hour storm which is 1.1 inches for this

location, this yields an average rainfall intensity of 1.1 inches per hour that need full treatment

resulting in a treatment requirement of 2.99 cfs. Again, using Table 4.1, we cross-reference this

value against the Peak Design Flow Rates. The smallest unit that can convey both the peak design

flow and the required treatment rate is a 3K BaySeparator™.

Annual Aggregate Removal

The performance of the BaySeparator™ system is dependent on not only the BaySeparator™

unit size, but also the diameter and depth of the Primary and Storage manholes. As described above,

hydrodynamic separators operate at varying efficiencies, depending on the treatment flow rate through

the separator. The sizing of the manholes is done by BaySaver Technologies, Inc, or the designer

using the BaySeparator™ Sizing Program. A general explanation of the procedure followed by the

sizing program is given next.

22

BAYSAVER TECHNOLOGIES, INC.

In the BaySeparator™ system, the removal efficiency is related to the flow rate by a general

logarithmic function shown below in Equation 1.

Q

MTR

⎞

b

⎟

⎠

⎛

mE +

∗= ln Equation 1

⎜

⎝

In Equation 1, E is the suspended solids removal efficiency of the system at the given flow

rate Q, (≤MTR) and the parameters m and b are characteristics of the particular BaySeparator™ unit.

To size BaySeparator™ systems to meet AAR efficiencies, more information about the site is

required. This sizing is done using the BaySeparator™ Sizing Program. In addition to the

characteristics of the BaySeparator™ system, the drainage area, runoff coefficient for the site, the

target TSS removal efficiency, and the maximum hydraulic rate (MHR) must be considered. The site

location must be entered to determine which precipitation record to use as the basis for AAR

calculations.

To calculate the AAR efficiency of a BaySeparator™ system, rainfall intensity is calculated

to correspond to the MTR for the chosen system (100% of fraction of MTR in Table 4.3). The

fraction of the total rainfall falling at or below that intensity is calculated for that maximum intensity

based on historical precipitation records. Increments (10%) of that intensity and a runoff flow rate are

then calculated for each of these increments. The fraction of the rainfall that generates a given runoff

flow rate is multiplied by the removal efficiency at that flow rate to find the fraction of the total

sediment removed under those conditions. Finally, the load reductions for each increment up to the

MTR of the BaySeparator™ unit are added together to give the AAR efficiency of the system. An

example of AAR calculations is shown in Table 4.3.

Scarsdale, New York

Drainage Area: 0.76 Acres

m = -0.3913

b = 0.3466

Fraction

of MTR

(percent)

10 99.0 0.11 43.6 43.1

20 97.6 0.22 23.5 23.0

30 81.8 0.33 12.3 10.1

40 70.5 0.44 6.7 4.7

50 61.8 0.55 5.5 3.4

60 54.6 0.66 2.5 1.4

70 48.6 0.77 1.4 0.7

80 43.4 0.88 1.2 0.5

90 38.8 0.99 0.9 0.3

100 34.7 1.10 0.7 0.2

Table 4.3: Calculation Example Annual Aggregate Removal Efficiency (AAR)

Removal

Efficiency

(percent)

Rainfall Intensity

(in/hr)

Aggregate Removal Efficiency: 87.4

Fraction of Rainfall

below Intensity

(percent)

Incremental

Efficiency

(percent)

23

BAYSAVER TECHNOLOGIES, INC.

Because AAR sizing calculations require precipitation data that may not be available to

designers, BaySaver staff can perform these calculations whenever they are required.

AAR-based BaySeparator™ designs take into account the typical precipitation patterns

throughout the United States. In most locations, the vast majority of precipitation falls at low

intensities, generating low runoff flow rates. In Baltimore, Maryland, for example, 80% of the total

precipitation falls at an hourly intensity of 0.37 inches per hour or less, and 95% of the total rainfall

comes at hourly intensities below 1 inch per hour.

Hydrodynamic separators usually function better at low flow rates, and the performance

degrades as the flow rate through the separator increases. Since the vast majority of precipitation falls

at low intensity and generates low runoff flow rates, this runoff is treated at a high efficiency. The

small fraction of the total precipitation that falls at higher intensities is still treated, but not with the

same efficiency that the majority of the runoff was treated.

When the majority of the runoff is treated to greater than 80% efficiency, and a small fraction is

treated less effectively, the end result is the net removal of still over 80% of the total sediment load.

24

BAYSAVER TECHNOLOGIES, INC.

Installation, Maintenance and

Cleaning

Installation Instructions

Overview

Chapter

5

BaySeparator™ systems are installed as part of the stormwater treatment system. The

BaySeparator™ unit and the system inlet pipe are grouted into the Primary Manhole using standard

storm drain connections. The connecting pipes entering and leaving the Storage Manhole require

watertight connections. These connections are made using standard boots or other locally approved

seals. Flexible couplers join the BaySeparator™ unit to the parallel inlet and outlet pipes (connecting

pipes) from the storage manhole. These flexible couplers account for differential settlement between

the two structures.

The pipes extending down from the separator (connecting pipes) must be backfilled with a free

flowing and self-compacting material such as pea gravel or 3/4" minus crushed stone. The remaining fill

material must be a Class I, II or III backfill and should be taken to at least 6" over the crown of the separator

unit.

The following Table 5.1 provides the minimum burial depths for the different separator models.

Table 5.1: Minimum Burial Depths

BaySeparator™ Diameter

(in inches)

24 12

36 12

48 12

60 24

Minimum Cover

For H-20 Load

(in inches)

25

BAYSAVER TECHNOLOGIES, INC.

Figure 5.1: BaySeparator™ Installation at a Typical Site

Contact the local utility and follow any special requirements regarding installation of

manholes and/or underground structures such as the BaySeparator™ unit. To demonstrate the

configuration of a standard BaySeparator™ System, an exploded view of the entire system is shown

below in Figure 5.2.

26

BAYSAVER TECHNOLOGIES, INC.

Figure 5.2: Exploded View of Standard BaySeparator™ System Components

27

BAYSAVER TECHNOLOGIES, INC.

Installation Instructions

1. Contact utility locator to mark underground utilities and to make certain it is safe to excavate.

2. Reference the site plan to determine the location of the BaySeparator™ system. Determine the

separator configuration (right-handed or left-handed), and compare it to the configuration

specified on the BaySeparator™ Detail Sheet. Looking downstream from the Primary Manhole,

determine whether the Storage Manhole is on the left or right side of the BaySeparator™ unit, and

determine whether the unit is properly configured as delivered. If the unit is not properly

configured, the stub pipes must be repositioned (see instruction 3). If correct, go to instruction 6.

3. Beginning with one flange, unscrew the nuts from each of the bolts. With the nuts removed,

lift the stub pipe vertically away from the body of the separator unit.

4. Turn the stub pipe 180 degrees from its original configuration.

5. Before placing the stub pipe back down on the unit, make sure that the gasket located between the

flanged end of the stub pipe and the flanged end of the separator unit, is sitting flush on the

separator unit flange, void of any wrinkles.

6. Place the stub pipe back down onto the unit. The bolts will pass directly back up through the holes

in the stub pipe flange.

7. In order to ensure a watertight seal between the stub pipe flange and the separator unit flange, the

bolts must be tightened in the following pattern and to the appropriate torque. Always use a

crisscross pattern for tightening. For example, tighten 1 to 20% of final torque, then tighten 2 to

20% of final torque, then tighten 3 to 20% of final torque, then tighten 4 to 20% of final torque,

and so on and forth until all bolts are tightened to 100% of the final torque. All bolts should be

tightened to a torque of 30 foot pounds.

Figure 10: Crisscross Pattern Diagram

8. Excavate to proper depth, length, and width in accordance with regulations to ensure safe site

conditions.

9. Level subgrade to the proper elevation and check against finished grade and structure dimensions

to ensure adequate depth.

10. Set the base of the Primary Manhole on approved subgrade.

11. Set the base of the Storage Manhole downstream as specified by dimensions on the

BaySeparator™ standard detail sheet and offset to either the left or right side as specified by

dimensions on the BaySeparator™ standard detail sheet.

12. Check the level of both the Primary and Storage Manhole bases and correct level if needed before

adding additional risers.

13. Add watertight seal (either mastic rope or rubber gasket) to the base of each manhole.

14. Set riser section on the base of each structure.

4

3

28

BAYSAVER TECHNOLOGIES, INC.

15. Add additional riser sections as previously detailed, until structures reach grade. Be sure to install

water tight seals.

16. Align the opening in the Primary Manhole for the separator unit with the proposed outlet to the

storm drain.

17. Align the inlet and outlet holes in the Storage Manhole so that they will be 90 degrees on center to

the separator unit.

18. Once the inlets and outlets for the Primary and Storage Manholes are properly aligned, backfill to

the bottom of the inlet and outlet of the Storage Manhole.

19. Insert the BaySeparator™ unit into the Primary Manhole. Be sure of the following:

A - The BaySeparator™ unit penetrates the inside wall of the Primary Manhole to a depth of

at least 1 corrugation.

B - The tee pipes of the BaySeparator™ unit are vertical and not skewed.

20. Support the body of the BaySeparator™ unit and level the unit so that there is no slope from the

front to the back of the separator unit.

21. Once the BaySeparator™ is level, insert the two connecting pipes into the inlet and outlet of the

Storage Manhole. Be sure the end of the connecting pipe labeled “IN” is inserted into the Storage

Manhole.

22. Line up the connector pipes with the stub pipes coming out of the bottom of the BaySeparator™

unit.

23. Tighten the watertight boots in the Storage Manhole onto on the connector pipes.

24. Tighten Fernco® couplers and shear rings on the joint between the stub pipes and the connector

pipes. (The 10K BaySeparator uses MarMac couplers to make this connection)

25. Backfill around the connector pipes up to the bottom of the separator unit using free flowing, selfcompacting material such as pea gravel or 3/4"or smaller crushed stone without fines

26. If the outlet pipe that is to be attached to the BaySeparator™ unit is of a different diameter than

the BaySeparator™, then a reducer/adapter (supplied by others) must be used to make the

connection.

27. Align reducer/adapter such that the small end of the reducer/adapter is in alignment with the outlet

pipe.

28. Use the larger Mar Mac (supplied by others) to couple the BaySeparator™ to the reducer/adapter.

Use the smaller Mar Mac (supplied by others) to couple the reducer to the outlet pipe. For further

information see instructions included with Mar Macs.

29. Using non-shrinking grout, seal the separator unit into the primary manhole.

30. Continue to back fill with Class I, II, or III material to at least 1’ above the crown of the 1/2K, 1K,

3K, and 5K; and 2’ over the crown for the 10K BaySeparator™ unit.

31. Install additional grade riser as needed and install frame and covers.

32. Backfill to grade using Class I, II or III backfill or other suitable material. Compact the backfill

according to geotechnical recommendations.

29

BAYSAVER TECHNOLOGIES, INC.

Maintenance

One of the advantages of the BaySeparator™ systems is the ease of maintenance. Like any

system that collects pollutants, the BaySeparator™ systems must be periodically maintained for

continued effectiveness. Maintenance is a simple procedure performed using a vacuum truck or

similar equipment. The systems were designed to minimize the volume of water removed during

routine maintenance, reducing disposal costs.

Contractors can access the pollutants stored in each manhole through a 30″ manhole cover.

This allows them to gain unobstructed access to the full depth of the system. There is no confined

space entry necessary for inspection or maintenance.

Vacuum hoses can reach the entire sump area of both manholes to remove sediments and

trash. The entire maintenance procedure typically takes less than an hour.

Local regulations may apply to the maintenance procedure. Safe and legal disposal of

pollutants is the responsibility of the maintenance contractor. Maintenance should be performed only

by a qualified contractor. Contact BaySaver Technologies Inc. at 1-800-229-7283 for a list of

approved contractors in your area.

30

BAYSAVER TECHNOLOGIES, INC.

Inspection and Cleaning

Periodic inspection is required to determine the need for and frequency of maintenance.

Inspections should be performed initially every six (6) months. Typically, the system needs to be

cleaned every 12 to 36 months, depending on site conditions. The system needs to be cleaned when 2

feet of sediment (1.5 feet for the 1/2K model) has accumulated in the bottom of either structure or

when visual inspection shows a large accumulation of debris or oil.

Measuring Sediment Depth

You can determine the sediment depth by lowering a pole into the manhole until it hits the

sediment and measuring the distance from the bottom of the pole to the water line mark on the pole. If

this is less than 6 feet (4.5 feet for the 1/2K model), the system needs to be cleaned.

Maintenance Instructions

1. For each BaySeparator™ system, there are 2 manholes to clean: the Primary Manhole and

Storage Manhole.

2. Remove the manhole covers to provide access to the pollutant storage.

3. Storage Manhole: Use a vacuum truck or other similar equipment to remove all water,

debris, oils, and sediment.

4. Storage Manhole: Use a high pressure hose to clean the manhole of all the remaining

sediment and debris. Then, use the vacuum truck to remove the rinse water.

5. Primary Manhole: Use a submersible pump to pump the bulk of the water from the Primary

Manhole into the clean Storage Manhole. Stop pumping when the water surface falls to one

foot above the accumulated sediments.

6. Primary Manhole: Use a vacuum truck or other similar equipment to remove all remaining

water, debris, and sediment.

7. Primary Manhole: Use a high pressure hose to clean the manhole of all the remaining

sediment and debris. Then, use the vacuum truck to remove the rinse water.

8. Both Manholes: On sites with a high water table or other conditions which may cause

flotation, it is necessary to fill the manholes with clean water after maintenance

9. Replace the two manhole covers.

10. Dispose of the polluted water, oils, sediment, and trash at an approved facility.

• Most local regulations prohibit the discharge of solid material into the sanitary

system. Check with the local sewer authority for any required permits and/or

conditions to discharge the liquid.

• Many places require the pollutants removed from BaySeparator™ systems to be

treated in a leachate treatment facility. Check with local regulators about disposal

requirements.

11. Additional local regulations may apply to the maintenance procedure.

This procedure is intended to remove all the collected pollutants from the system while

minimizing the volume of water that must be disposed. Additional local regulations may apply to the

maintenance procedure. Safe and legal disposal of pollutants is the responsibility of the maintenance

contractor; therefore maintenance should be performed only by a qualified contractor.

31

BAYSAVER TECHNOLOGIES, INC.

Summary

• Access the pollutants through the two manhole covers.

• See the entire floor/sump area of each manhole from the surface.

• No confined space entry for inspection or maintenance.

• During maintenance, transfer “clean” water from the Primary to the Storage Manhole,

minimizing the amount of water for disposal.

BaySaver

Technologies can assist in coordinating a maintenance contractor in the installation area,

or work directly with owners who wish to perform their own maintenance. Contact BaySaver Technologies

at 1-800-229-7283 (1-800-BaySaver) for more information

32

BAYSAVER TECHNOLOGIES, INC.

Chapter

6

System Cost and Availability

BaySeparator™ systems are available throughout the United States from BaySaver Technologies,

Inc. or from an authorized representative. Material, installation, and maintenance costs may vary

throughout the country. The BaySeparator™ System is your best value per treated CFS

regardless of your geographic location. For BaySeparator™ pricing in your area, please contact

BaySaver

directly.

Technologies Inc. at 1-800-229-7283 (1-800-BAYSAVE) or an authorized representative

The BaySeparator™ unit and materials can be shipped anywhere in the continental United States

within two weeks or less. Custom systems may require additional time. The system’s precast manholes need

to be ordered locally to arrive in conjunction with the BaySeparator™ Unit.

33

BAYSAVER TECHNOLOGIES, INC.

Appendices

Appendix A Stormwater Treatment Unit(s) Specification — Online System

Appendix B Engineering Drawings

Appendix C Project Information Sheet

34

BAYSAVER TECHNOLOGIES, INC.

A

Appendix

Stormwater Treatment

Unit(s) Specification —

Online System

35

BAYSAVER TECHNOLOGIES, INC.

STORMWATER TREATMENT UNIT(S) SPECIFICATION –

ONLINE SYSTEM

PART 1.00 GENERAL

1.1 DESCRIPTION

A.

Work Included:

The manufacturer selected by the Contractor and approved by the

Engineer, shall furnish all labor, materials, equipment and incidentals

required to manufacture the stormwater treatment system(s) specified

herein in accordance with the attached Drawing(s) and these

specifications.

1.2 QUALITY CONTROL INSPECTION

A. The quality of materials, the process of manufacture, and the finished

sections shall be subject to inspection by the Engineer. Such inspection

may be made at the place of manufacture, or on the worksite after

delivery, or at both places, and shall be subject to rejection at any time if

material conditions fail to meet substantially any of the specification

requirements. If a Stormwater Treatment Unit is rejected after delivery to

the site, it shall be marked for identification and removed from the site.

The Stormwater Treatment Unit(s) which have been damaged beyond

repair during delivery will be rejected and, if already installed, shall be

repaired to the Engineer’s and manufacturer’s acceptance level, if

permitted.

B. All sections shall be field inspected for general appearance, dimensions,

soundness, etc.

1.3 SUBMITTALS

A. Plan, elevation, and profile dimensional drawings shall be submitted to the

Engineer for review and approval. The Contractor shall be provided with

the approved plan, elevation, and profile dimensional drawings.

36

BAYSAVER TECHNOLOGIES, INC.

PART 2.00 PRODUCTS

2.1 MATERIALS AND DESIGN

Concrete structures shall be designed for H-20 traffic loading and

A.

applicable soil loads or as otherwise determined by a Licensed

Professional Engineer. The materials and structural design of the devices

shall be per ASTM C857 and ASTM C858.

1.

The minimum compressive strength of the concrete in the manhole

base, riser, and top sections shall be 4000 psi.

2.

The minimum wall thickness shall be one twelfth of the internal

diameter of the riser or largest cone diameter.

3.

Cement shall conform to the requirements for Portland cement of

Specification C150.

4.

Aggregates shall conform to Specification C33, except that the

requirement for gradation shall not apply.

5.

Reinforcement shall consist of wire conforming to Specification

A82 or Specification A496, of wire fabric conforming to

Specification A185 or Specification A497, or of bars of Grade 40

steel conforming to Specification A615/A615M.

6.

The access cover shall be designed for HS20-44 traffic loading and

shall provide a minimum 30 inch clear opening.

7.

All joints shall be waterproof with wrapped gaskets or sealed with

a mastic treatment.

8.

Any grout used within the system shall meet the ASTM C 1107

“Standard Specification for Packaged Dry, Hydraulic-Cement

Grout (Non-Shrink)”. Grades A, B and C at a pourable and plastic

consistency at 70ºF. CRD C 621 “Corps of Engineers

Specification For Non-Shrink Grout.”

9.

Storage manhole connector pipes shall be equipped with a seal

gasket that meets or exceeds material specifications of ASTM C923 or other locally approved methods.

B.

The separator structure shall be substantially constructed of HDPE or

equivalent corrosion resistant material meeting ASTM D330, ASTM

F412, and ASTM C-425.

C.

Pipes within the unit, (i.e., tee pipes, connector pipes and down pipes)

shall be constructed of at least SDR 32.5 HDPE pipe of standard ASTM

F412.

D. Pipe and fitting material shall be high-density polyethylene meeting

ASTM D330 minimum cell classification 335400C for 24-inch through

60-inch diameters. The 24- through 60- inch pipe material shall be slow

37

BAYSAVER TECHNOLOGIES, INC.

crack resistant HDPE material, evaluated using the single point notched

constant tensile load (SP-NCTL) test.

E.

The reducer/adaptor to the mainline shall be installed with an exterior

joining coupler. The joint coupler shall be Polyseal Pipe Coupler as

manufactured by Mar Mac Manufacturing Company or an approved equal

and shall be installed according to the manufacturer’s recommendations.

F.

The connector pipes shall be connected with the down pipes using

Fernco® Flexible Couplings that have been manufactured to conform to

ASTM C-425.

2.2 PERFORMANCE

A.

The stormwater treatment unit shall be an online unit capable of

conveying 100% of the design peak flow.

B.

The BaySeparator™ unit shall be designed to remove at least 80% of the

suspended solids load on an annual aggregate removal basis. Said removal

shall be based on full-scale third party testing using F-95 media gradation

(manufactured by US Silica) or equivalent. Said full scale testing shall

have included sediment capture based on actual total mass collected by the

Stormwater Treatment Unit (s).

C.

The stormwater treatment unit shall consist of one (1) prefabricated

separator structure, one (1) online coarse sediment capture structure, and

one (1) offline sediment and floatable capture structure. The separator

structure shall be substantially constructed of HDPE or equivalent

corrosion resistant material. The offline sediment storage structure must

provide for offline sediment storage of sediments and floatables that are

isolated from high intensity storms.

D.

The stormwater treatment unit(s) head loss at the Peak Design Flow Rate

shall not exceed the head loss specified by the Engineer.

E.

The unit shall be designed to remove sediment particles as well as floating

oils and debris.

2.3 MANUFACTURER

A. The stormwater treatment unit(s) shall be of a basic design that has been

installed and used successfully for a minimum of 5 years.

B. Each stormwater treatment system shall be a BaySeparator™ system as

manufactured by BAYSAVER

Mount Airy, MD 21771, Phone: (301) 829-6470, Fax: (301) 829-3747,

Toll Free: 1-800-229-7283 (1-800-BaySaver), E-mail: Info@BaySaver

Protected under U.S. Patent Number 5746911.

PART 3.00 EXECUTION

®

, INC., 1302 Rising Ridge Rd, Unit 1,

.

38

BAYSAVER TECHNOLOGIES, INC.

3.1 INSTALLATION

A. Installation of the Stormwater Treatment Unit(s) shall be performed per

manufacturer’s Installation Instructions. Such instructions can be obtained

by calling BaySaver Technologies, Inc. at 1.800.229.7283 or by login to

www.BaySaver.com

.

39

BAYSAVER TECHNOLOGIES, INC.

Appendix

B

Engineering Drawings

40

BAYSAVER TECHNOLOGIES, INC.

41

BAYSAVER TECHNOLOGIES, INC.

42

BAYSAVER TECHNOLOGIES, INC.

43

BAYSAVER TECHNOLOGIES, INC.

44

BAYSAVER TECHNOLOGIES, INC.

45

BAYSAVER TECHNOLOGIES, INC.

46

BAYSAVER TECHNOLOGIES, INC.

47

BAYSAVER TECHNOLOGIES, INC.

48

BAYSAVER TECHNOLOGIES, INC.

49

BAYSAVER TECHNOLOGIES, INC.

50

BAYSAVER TECHNOLOGIES, INC.

51

BAYSAVER TECHNOLOGIES, INC.

Appendix

C

Project Information Sheet

52

Loading...

Loading...