Page 1

4. Hydraulic Theory

TABLE OF CONTENTS

4. HYDRAULIC THEORY ..................................................3

4.1 Overview............................................................ 3

4.2 Dialysate Circuit................................................ 4

4.2.1 Incoming Water Pressure Regulator ............4

4.2.2 Water On/Off Valve.....................................5

4.2.3 Heat Exchanger............................................5

4.2.4 Heater, Thermistor, Safety Thermostat........5

4.2.5 Concentrate Line Regulator(s) and

Concentrate Central Delivery Systems

(optional)...................................................6

4.2.6 Volumetric Proportioning System ...............6

4.2.7 Supply Manifold ..........................................6

4.2.8 Air Removal System ....................................9

4.2.9 "A" & "B" Rinse Fittings .............................9

4.2.10 Supply Pump Recirculation Loop..............9

4.2.11 Input Pressure Equalizer, Flow Equalizer,

and Output Pressure Equalizer................12

4.2.12 End-of-Stroke Sensors .............................12

4.2.13 Dialysate Monitoring Manifold ................14

4.2.14 Dialysate Bypass Valve and Sensor.........16

4.2.15 Rinse Block..............................................17

4.2.16 Dialysate Sample Ports .............................17

4.3 Ultrafiltration System ..................................... 17

4.4 Blood Leak Detector....................................... 18

4.5 Other Components ......................................... 18

4.5.1 Rinse Valve................................................18

4.5.2 Heat Disinfection Recirculation Valve ......19

4.5.3 Citric Acid Valve Manifold (optional) ......19

Standard Hydraulics Flow Diagram ..................... 21

157-1278-893 Rev A 4-1

January 2004

Page 2

Arena Service Manual

4-2 157-1278-893 Rev A

January 2004

Page 3

4. HYDRAULIC THEORY

4.1 OVERVIEW

The Arena Instrument is designed to heat incoming water to

approximately human body temperature, mix the water with

dialysate concentrate in physiologically correct proportions and

infuse the dialysate through an artificial kidney to effect

hemodialysis therapy. In doing this, it also accurately measures

the amount of fluid entering and exiting the artificial kidney and

can adjust these volumes to control the fluid removal from the

patient. Operation of the hydraulic components is controlled by

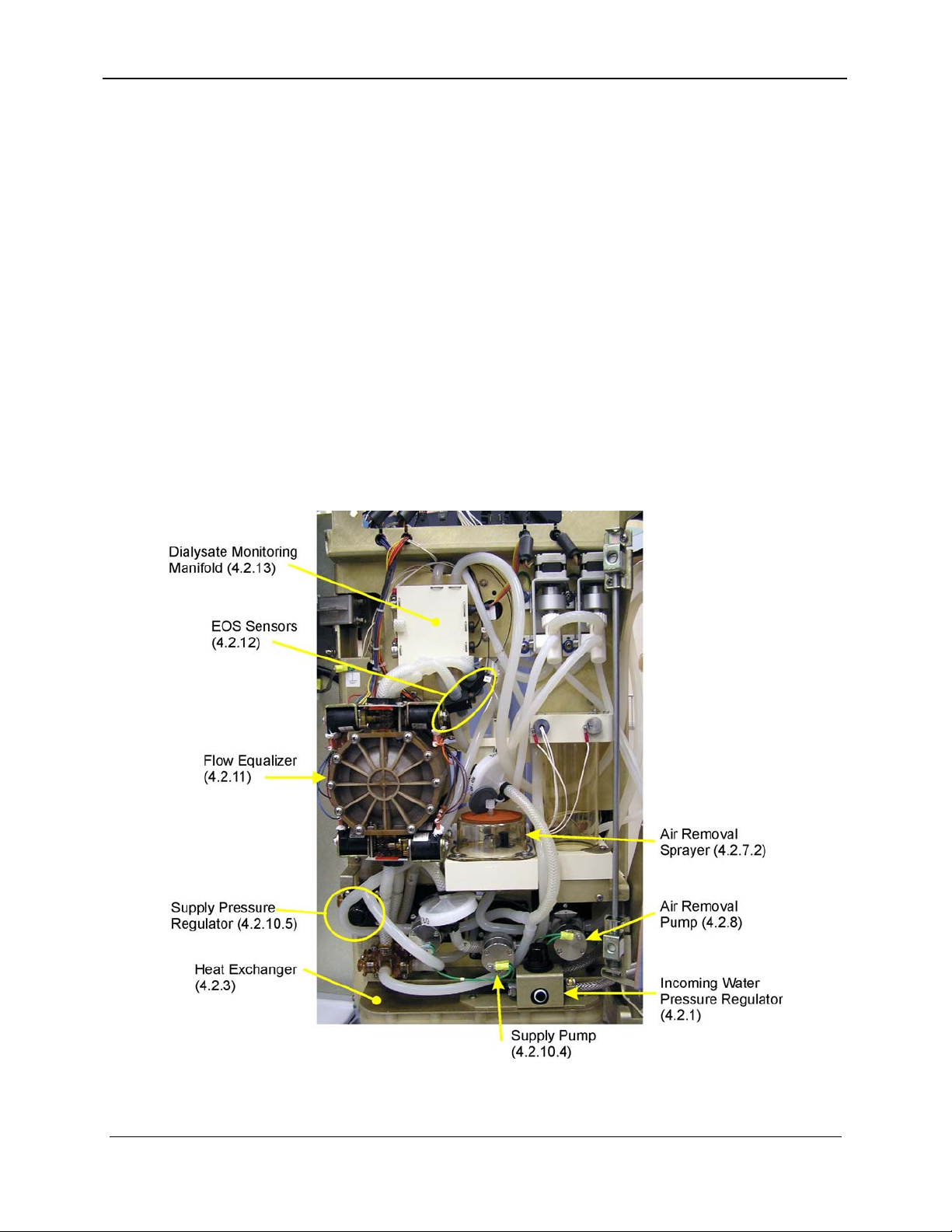

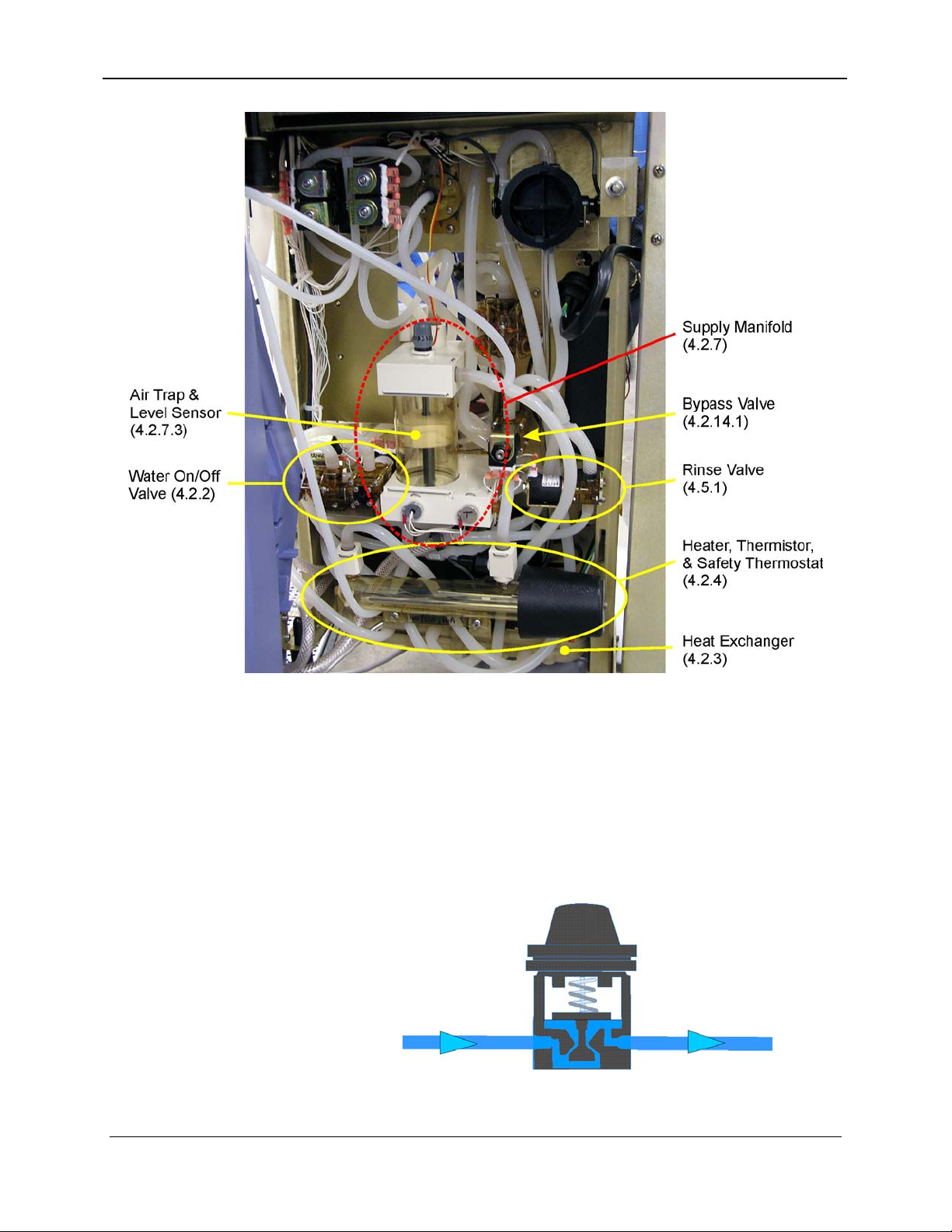

several microprocessors. Refer to Figures 4-1 and 4-2 for the

location of components in the Instrument and to the standard

hydraulics diagram (157-1278-587) at the end of this section for

thier sequence in the flow path.

4. Hydraulic Theory

Figure 4-1. Standard Hydraulics Module, Front View

157-1278-893 4-3

January 2004

Page 4

Arena Service Manual

Figure 4-2. Standard Hydraulics Module, Rear View

4.2 DIALYSATE CIRCUIT

4.2.1 Incoming Water Pressure Regulator

The pressure of the incoming water is reduced and stabilized by

the adjustable water pressure regulator to the factoryrecommended level (see Section 18, Calibration Procedures).

Figure 4-3. Incoming Water Pressure Regulator

4-4 157-1278-893 Rev A

January 2004

Page 5

4. Hydraulic Theory

4.2.2 Water On/Off Valve

This valve is actuated through a coil using unregulated +24 VDC.

When the power is off, the valve is closed preventing water from

entering the Instrument. When power is on, the on/off valve

operation is controlled by the supply manifold level sensor signal.

During heat cleaning, the valve is closed. This valve can be

monitored using the DS1 “Flow Control” LED on the I/O

Hydraulics Power board (see Section 5, Electronic Theory).

4.2.3 Heat Exchanger

Incoming water flows through a hydraulic channel on one side of a

stainless steel plate. On the other side of the plate, the spent

dialysate flows in a countercurrent direction in an identical

hydraulic channel before draining out of the Instrument.

Heat is transferred from the spent dialysate to the incoming water

through the plate. This heat transfer preheats the incoming water,

shortening dialysate warm up time. By reducing the time the

heater is on, the heat exchanger saves energy.

The heat exchanger allows the Instrument to be used with a wider

range of incoming water temperatures since this preheating of the

incoming water reduces these variations.

Figure 4-4. Heat Exchanger

4.2.4 Heater, Thermistor, Safety Thermostat

The water is heated to the desired temperature by a heater. On the

output of the heater is a thermistor. The thermistor resistance

changes in inverse proportion to temperature changes. The

thermistor sends a signal to the UF-Proportioning Power board,

which then turns the heater on or off to maintain or increase the

temperature.

Next to the heater is a resettable thermostat, which prevents the

heater from exceeding a temperature of approximately 107°C

157-1278-893 4-5

January 2004

Page 6

Arena Service Manual

4.2.5 Concentrate Line Regulator(s) and Concentrate

4.2.6 Volumetric Proportioning System

(225°F). The thermostat turns off power to the heater to prevent

damage in case of a runaway temperature circuit failure.

For testing purposes, the heater has a resistance of approximately

10-20 Ω when cold. The thermistor has a resistance of

approximately 3 KΩ at 37 to 38°C and 5 KΩ at 25°C.

Central Delivery Systems (optional)

Concentrate Line Regulators are recommended when a central

delivery system is used to feed concentrates into the Instrument.

Refer to Section 7, Dialysate Preparation, for more information.

The Instrument's volumetric proportioning system consists of fixed

volume pumps for concentrates and a fixed volume metering

device (Flow Equalizer) for dialysate. They are linked

electronically through the Ultrafiltration Controller to provide a

fixed ratio proportioning system.

Refer to Section 7, Dialysate Preparation, and Section 8,

Ultrafiltration, for more information.

4.2.7 Supply Manifold

The supply manifold controls the incoming water flow, mixes the

“A” dialysate concentrate component, removes the dissolved air

from the water, and monitors the “A” concentrate and water

conductivity. The supply manifold is composed of four

components:

• “A” Mix Chamber and Air Gap

• Air Removal Sprayer

• Air Trap and Level Sensor

• “A” Conductivity Probe/Thermistor Set

This manifold also contains the connections for the air removal

pump, and the “A” and “B” rinse fittings that connect through a

common line to the supply manifold and draw rinse water from

this source.

The “A” concentrate pump is described in Section 7, Dialysate

Preparation.

4-6 157-1278-893 Rev A

January 2004

Page 7

4. Hydraulic Theory

Figure 4-5. Supply Manifold

4.2.7.1 “A” Mix Chamber and Air Gap

As the name implies, the “A” mix chamber mixes the water and

“A” concentrate into a uniform solution.

The air gap at the top of this chamber is at atmospheric pressure,

which helps to limit proportioning errors. The air gap also acts as

a barrier preventing back flow in the event of a drop in the

incoming water pressure.

4.2.7.2 Air Removal Sprayer

The sprayer is part of the air removal system. Refer to Section 7,

Dialysate Preparation, for more information.

4.2.7.3 Air Trap and Level Sensor

The air trap and level sensor control the flow of water into the

hydraulic system by causing the water on/off valve to open when

the level drops and by closing the valve when the level rises.

The level sensor consists of a float with magnet and a Hall-effect

switch. When the water level float magnet is below the sensor, the

condition indicates the need for more water, opening the incoming

157-1278-893 4-7

January 2004

Page 8

Arena Service Manual

water on/off valve. When the magnet is above the sensor, the

condition indicates the air trap is full, closing the incoming water

on/off valve.

In normal operation, as the supply pump draws solution from the

air trap chamber to fill the flow equalizer, the liquid level in the

chamber is lowered along with the float causing the water on/off

valve to open so water again fills the chamber.

When the air trap level rises, the level sensor signal shuts off the

water on/off valve. This cycle is repeated during every fill phase

of the flow equalizer.

4.2.7.4 "A" Conductivity Probe/Thermistor Set

This is one of three conductivity probe sets. The other two are

described in Section 4.2.10.3, "B" Conductivity Probe/Thermistor

Set, and Section 4.2.13.1, Dialysate (Primary) Conductivity

Probe/Thermistor Set.

Figure 4-6. "A" Probe/Thermistor Set

Conductivity is used as a measure of the electrolyte composition of

dialysate. The hardware for measuring conductivity is always a

cell for measuring changing resistance as the amount of dissolved

salt changes and a thermistor for measuring temperature changes.

Electronic circuits are used to equate these changing resistances to

the standard measuring conditions of a 1 cm cell at 25 Celsius.

The information from these devices can be used to give us

conductivity in the units of milliSiemens/cm (mS/cm) @ 25°C.

The “A” conductivity thermistor is not used to control or monitor

the temperature of the dialysate. It is calibrated with the other

thermistors during temperature calibration.

4-8 157-1278-893 Rev A

January 2004

Page 9

4. Hydraulic Theory

4.2.8 Air Removal System

The air removal system removes dissolved gases that are trapped

in the water used to make up dialysate. The air removal system

consists of the air removal sprayer, the air removal pump, and the

vented air trap.

The air removal sprayer nozzle restricts the flow so that a partial

vacuum of approximately 500 to 650 mmHg is created in the air

removal sprayer chamber. The fluid that passes through the air

removal sprayer is deflected into a conical spray pattern. By

developing a spray pattern, a larger surface area is exposed to the

500 to 650 mmHg vacuum. The vacuum pulls the air out of the

solution. Due to the large surface area of fluid exposed to the

vacuum, the rate at which the air comes out of the water is

increased, enhancing the air removal function.

The air removal pump (also known as the deaeration pump) runs at

a constant speed of approximately 1500 mL/min for all flow rates,

pulling the solution through the air removal sprayer nozzle.

The vented air trap provides an opening for air to leave the system.

For more information, refer to Section 4.2.7 and Section 7,

Dialysate Preparation.

4.2.9 "A" & "B" Rinse Fittings

The “A” and “B” rinse fittings are located on the right side panel

of the Instrument. Both fittings are connected to a source of water

in the supply manifold. This water is used to rinse the concentrate

lines and concentrate pumps.

A proximity sensor built into each of the rinse fittings senses when

the concentrate lines are attached. The rinse fittings are keyed so

that the “A” concentrate line will not fit into the “B” concentrate

fitting and vice versa. When the “B” concentrate line is not in use

during acetate dialysis or during rinse, it is connected to its rinse

fitting.

4.2.10 Supply Pump Recirculation Loop

The supply pump recirculation loop mixes the “B” concentrate,

monitors the total conductivity, regulates the pressure, and pumps

dialysate to the flow equalizer. This loop contains the inlet for the

“B” concentrate pump, the "B" (bicarbonate) mix chamber, the

157-1278-893 4-9

January 2004

Page 10

Arena Service Manual

“B” conductivity probe, the supply pressure pump, and the supply

pressure regulator. Figure 4-7 describes this loop.

The loop configuration helps to mix the bicarbonate concentrate by

recirculating the solution through the “B” mix chamber. The loop

also acts as a conduit for flow that is diverted by the supply

pressure regulator at the end of each flow equalizer fill cycle.

Figure 4-7. Supply Pump Recirculation Loop

4.2.10.1 "B" Mix Point

Bicarbonate concentrate enters the water-acid concentrate mixture

at the “B” mix point.

4.2.10.2 "B" Mix Chamber

During hemodialysis therapy, the solution that enters the “B” mix

chamber from the supply manifold contains water and acetate

concentrate, or water and the acid and bicarbonate components of

bicarbonate dialysate (depending on the concentrates selected).

This chamber mixes the solution before it is monitored by the “B”

conductivity probe.

4.2.10.3 "B" Conductivity Probe/Thermistor Set

This is one of three conductivity probe sets. The other two are

described in Section 4.2.7.4, "A" Conductivity Probe/Thermistor

Set, and Section 4.2.13.1, Dialysate (Primary) Conductivity

Probe/Thermistor Set.

4-10 157-1278-893 Rev A

January 2004

Page 11

4. Hydraulic Theory

Figure 4-8. "B" Probe/Thermister Set

The second conductivity probe in the flow path is located at the

outlet of the “B” mix chamber in the dialysate supply recirculation

loop. The probe/thermistor set is identical to the “A” conductivity

probe/thermistor set. In addition to compensating for temperature

effect on the conductivity reading, the “B” thermistor is also the

source of the temperature reading for the redundant high

temperature alarm as well as fine-tuning the dialysate temperature

control. Refer to Section 6, Temperature Control, for more

information on temperature control.

The “B” probe monitors the total conductivity of the dialysate

solution after both concentrates are mixed. The UF-Proportioning

Controller board subtracts the “A” conductivity probe reading

from the “B” conductivity probe reading and compares the

difference to the expected result. In the acetate therapy mode, the

result of this calculation should be zero and is used to recheck the

“A” conductivity probe reading. When bicarbonate dialysate is

used, the UF-Proportioning Controller board calculates whether

the conductivity contribution of the “B” portion of the solution is

acceptable for the type of bicarbonate concentrate used.

4.2.10.4 Supply Pump

The supply pump fills the flow equalizer with fluid. The supply

pump pumps at a rate slightly higher than the dialysate flow rate

set by the operator. This extra flow ensures an adequate supply of

solution to fill the flow equalizer. For more information on the

speed control of the supply pump, refer to Section 7, Dialysate

Preparation.

157-1278-893 4-11

January 2004

Page 12

Arena Service Manual

4.2.11 Input Pressure Equalizer, Flow Equalizer, and

4.2.12 End-of-Stroke Sensors

4.2.10.5 Supply Pressure Regulator

The supply pressure regulator controls the peak input pressure to

the "pre" side of the input pressure equalizer. When the flow

equalizer cavity is filled, the pressure in the pressure regulator

increases to its maximum value (16 psi ±1), overcoming the spring

force of the regulator spring allowing the dialysate to recirculate

back to the “B” mix chamber. The Supply Pressure Regulator is

equivalent to an adjustable pressure relief valve. See also Section

8, Ultrafiltration.

Output Pressure Equalizer

Refer to Section 8, Ultrafiltration, for a detailed description of

these components.

The end-of-stroke (EOS) sensors are infrared optical devices

located in the flow path after the Flow Equalizer and before the

Output Pressure Equalizer. These sensors verify when the Flow

Equalizer compartments have reached the end of the fill cycle.

When the compartments are full, the sensor sends a signal to the

UF-Proportioning Power board. The EOS sensors are used to

minimize the end-of-stroke time of the Flow Equalizer by

controlling the flow rate of the supply pump via feedback from the

sensors.

The Instruments that have temperature-dependent EOS sensors,

work with self-heating thermistors. The temperature of these

thermistors will rise when the flow through them stops.

The Instrument may have optical EOS sensors like the one shown

in Figure 4-9. (The diagrams in this section show the optical

sensor.) The main components are two small PCBs, one on each

side of the assembly, and one diaphragm right in the middle of the

assembly. One PCB has the circuitry for the LED, and the other

for the Detector. On the body of the assembly, the orientation of

the diaphragm is indicated by a raised alignment symbol.

4-12 157-1278-893 Rev A

January 2004

Page 13

4. Hydraulic Theory

Figure 4-9. Optical Sensor Assembly

The diaphragm has four flaps that will open under a pressure of 0.5

PSI, allowing the light from the LED to go across the assembly

and reach the Detector (see Figure 4-10). This will indicate that

dialysate is flowing. When the flow stops, the diaphragm will

close, blocking the light from the LED, which indicates that the

flow stopped.

A green LED on the Detector PCB will turn on when the Detector

does not get any light.

157-1278-893 4-13

January 2004

Page 14

Arena Service Manual

Figure 4-10. Optical/Diaphragm Sensors for EOS

4.2.13 Dialysate Monitoring Manifold

The purpose of this assembly is to house the components to

monitor the dialysate temperature, conductivity and pressure. This

manifold contains:

The dialysate (primary) conductivity probe/thermistor set

The dialysate pressure transducer

The bypass valve flow sensor

4-14 157-1278-893 Rev A

January 2004

Page 15

4. Hydraulic Theory

Figure 4-11. Dialysate Monitoring Manifold

4.2.13.1 Dialysate (Primary) Conductivity Probe/Thermistor

Set

This is one of three conductivity probe sets. The other two are

described in Section 4.2.7.4, "A" Conductivity Probe/Thermistor

Set, and Section 4.2.10.3, "B" Conductivity Probe/Thermistor Set.

Figure 4-12. "Primary" Probe /Thermistor Set

The third conductivity probe/thermistor set is located in the

Dialysate Monitoring Manifold at the outlet of the output pressure

157-1278-893 4-15

January 2004

Page 16

Arena Service Manual

4.2.14 Dialysate Bypass Valve and Sensor

equalizer. This probe set is identical to the other conductivity

probe sets. It measures the total conductivity of the dialysate

before it enters the artificial kidney. This temperaturecompensated conductivity value is displayed in the

CONDUCTIVITY window. The primary conductivity alarm

circuit also uses the signal from this probe.

As mentioned previously, a thermistor is built into one of the

electrodes. This thermistor supplies information for the

temperature display and the primary high and low temperature

alarm limits. For more information on temperature monitoring,

refer to Section 6, Temperature Control.

4.2.13.2 Dialysate Pressure Transducer

This pressure transducer senses the dialysate pressure and changes

the pressure reading into an analog electrical signal proportional to

pressure. This signal is used for the transmembrane pressure

display and alarms.

4.2.14.1 Bypass Valve

The bypass valve protects the patient in the event of a temperature

or conductivity alarm by diverting unacceptable dialysate away

from the dialyzer. The diverter is a +24 VDC three-way solenoid

valve, controlled by the I/O Hydraulics Power board. During a

dialysate temperature or conductivity alarm, an electronic signal

causes the bypass valve to close the fluid path leading to the

dialyzer and shunt the dialysate to the drain.

On the I/O Hydraulics Power Board, LED DS6 indicates Bypass

(off) or Flow (on). See Figure 4-13 for location.

Figure 4-13. Bypass/Flow LED

4-16 157-1278-893 Rev A

January 2004

Page 17

While in Rinse Mode, the Instrument will automatically go into

Bypass Mode periodically.

There is also a manual Bypass Mode that permits the operator to

put the Instrument in bypass when a dialyzer is connected or

sequential ultrafiltration therapy is performed. This manual

Bypass Mode is activated via the Bypass switch located on the

Membrane Switch Panel.

4.2.14.2 Bypass Valve Flow Sensor

A temperature-dependent flow sensor connected (see Figure 4-11)

to the dialysate monitoring manifold after the bypass valve is used

to monitor dialysate flow. When the Instrument is in bypass, the

bypass valve diverts the dialysate flow away from the dialyzer;

therefore this sensor verifies the correct functioning of the bypass

valve by detecting that no flow is going through the sensor. The

Instrument generates a shutdown alarm in the event of a bypass

valve failure.

The signal from the Flow Sensor is also used to indicate dialysate

flow or bypass on the touchscreen display. Refer to Section 4.2.12

for more information on the sensor assembly.

4. Hydraulic Theory

4.2.15 Rinse Block

When the Instrument is not being used for a patient treatment and a

dialyzer is not in use, the dialysate lines are attached to a rinse

block. The rinse block has proximity sensors that are used to

determine the placement of the dialyzer connectors and are used as

interlocks for mode changes.

4.2.16 Dialysate Sample Ports

The sample ports (pre- and postdialyzer) are provided as an

opening for the operator to obtain a sample of the dialysate to test

for conductivity or residual disinfectant.

4.3 ULTRAFILTRATION SYSTEM

The ultrafiltration (UF) system allows the operator to remove a

precise amount of fluid from a patient in a controlled manner. By

controlling exactly how much dialysate is going to and returning

from the dialyzer, accurate fluid removal is achieved.

The main components of the UF system are (as they appear in the

flow path):

Supply Pump

150µ Particle Filter

157-1278-893 4-17

January 2004

Page 18

Arena Service Manual

Supply Pressure Regulator

Input Pressure Equalizer

Flow Equalizer

Output Pressure Equalizer

Dialyzer Connectors and Dialyzer

Check Valve

Dialysate Pressure Pump

Flow Restrictor

UF Removal Regulator

UF Flow Meter

Refer to Section 8, Ultrafiltration Control, for more information on

the UF System.

4.4 BLOOD LEAK DETECTOR

Spent dialysate expelled from the flow equalizer passes through

and is monitored for the presence of blood in the blood leak

detector. There is a light source and a photocell which monitors

the light transmitted through the solution present in the cavity. If

blood leaks through the dialyzer membrane, the blood passing

through the blood leak detector will absorb a portion of the light,

preventing it from reaching the photocell. The dimmed light then

sets off a blood leak alarm and protects the patient by stopping the

blood pump, clamping the venous line, and warning the operator.

For more information, refer to Section 14, Blood Leak Detector.

4.5 OTHER COMPONENTS

4.5.1 Rinse Valve

The rinse valve (also called the dialysate pressure relief valve)

connects to the fluid path immediately after the flow sensor on the

downstream side of the dialyzer. When the Instrument is in the

Rinse Mode, the electronics control the UF flow meter to meter 3.6

L/h of fluid out of the flow path. Fluid must be added to the

system to prevent a vacuum from being built up in the flow path.

The rinse valve allows fluid from the drain line to replace the

volume removed by the UF flow meter.

4-18 157-1278-893 Rev A

January 2004

Page 19

4. Hydraulic Theory

The rinse valve is open in the Rinse and Prime Modes, in Self Test

(except UF test) and in the Calibration Mode when the UF Flow

Meter is being calibrated. Therefore, when the dialyzer connectors

are not connected to the Instrument, the rinse valve must be closed.

4.5.2 Heat Disinfection Recirculation Valve

The heat disinfection recirculation valve diverts the effluent water

back into the input side of the heater (with the water on/off closed)

in order to heat the water to above 84°C and maintain that fluid

path temperature for the time set by the service technician. For

more information, refer to Section 9, Disinfection.

4.5.3 Citric Acid Valve Manifold (optional)

This manifold is part of the Citric Acid option. It consists of a

normally-closed two-way valve, which opens during the Citric

Acid Heat Clean Mode if the dialyzer connectors are on the rinse

block and citric acid is to be infused.

If the dialyzer connectors are removed from the rinse block during

citric acid infusion, the citric acid valve will close, citric acid

infusion will stop, and the message PLACE DIALYZER LINE ON

RINSE BLOCK will be displayed.

For more information on the Citric Acid option, refer to Section 2,

Physical Description, and Section 9, Disinfection.

Figure 4-14. Citric Acid Option Hardware

157-1278-893 4-19

January 2004

Page 20

Arena Service Manual

4-20 157-1278-893 Rev A

January 2004

Loading...

Loading...