Page 1

Please read these instructions before installing or commissioning.

Potterton Solar - Solar Thermal Domestic Hot Water System

should only be installed by a competent person.

Please leave these instructions with the user for safe keeping.

Commissioning, Maintenance & Servicing Guide

Potterton Solar - Solar Thermal Domestic Hot Water System

© Baxi Heating UK Ltd 2007.

Page 2

ndex

I

2 Index

3 Commissioning of system

General information

Flushing and filling the system

5 Commissioning of hydraulic station

Checking/setting pressure

hecking/adjusting flow rate

C

Installation of thermal insulation

Commissioning of solar controller

7

Overview of display

Button function

Operating menu

Menu structure

"Info"

"Programming"

"Manual operation"

"Basic adjustment"

Controller functions

21 Commissioning record

22 Servicing and maintenance record

24 Maintenance

Check heat transfer fluid

Maintenance of the collector

25 Fault finding

Failures with error message

Resistance table

Flow charts

28 Spares

30 Warranty

© BAXI Heating UK Ltd 2007. All rights reserved. No part of this publication may be reproduced

or transmitted in any form or by any means, or stored in any retrieval system of any nature

(including in any database), in each case whether electronic, mechanical, recording or otherwise,

without prior written permission of the copyright owner, except for permitted fair dealing under

Copyrights, Designs and Patents Act 1988.

Applications for the copyright owner’s permission to reproduce or make other use of any part of

this publication should be made, giving any details of the proposed use to the following address:

The Company Secretary,BAXI Heating UK Ltd,The Wyvern Business Park,Stanier Way,Derby DE21 6BF.

Full acknowledgement of author and source must be given.

WARNING: Any person who does any unauthorised act in relation to a copyright work may be

liable to criminal prosecution and civil claims for damages.

Potterton Solar - Solar Thermal Domestic Hot Water System2

Page 3

.0 Commissioning of system

1

1.1 Commissioning - General

The Potterton Solar system uses a sealed system indirect

solar primary circuit which must be filled with the solar

heat transfer fluid provided. This is pre-diluted to the

appropriate strength (40% glycol/60%water) and should

not be diluted further. Use only the fluid supplied.

Additional canisters of solar fluid are available in 10 litre

(5119550) and 20 litre (5119549) bottles.

DO NOT mix the fluid with other types.

The system should be filled when there is no direct

radiation from the sun. If direct radiation occurs the

collector panels should be shaded by covering them

during filling and flushing.

Although the solar heat transfer fluid is non corrosive

and biodegradable appropriate precautions should be

taken when handling.

- Wear protective gloves and goggles.

- Wash with soap and water if the fluid comes into

contact with skin.

- If fluid gets into eyes, immediately rinse with large

quantities of clear running water.

- A full safety and specification sheet can be obtained

by request.

The solar heat transfer fluid must be pumped into the

system.The pump can be electric or manual but must be

capable of producing a pressure of at least 2 bar.

The system should be thoroughly flushed to remove any

contaminants in the solar primary circuit prior to filling

with the heat transfer fluid

Potterton Solar - Solar Thermal Domestic Hot Water System 3

Page 4

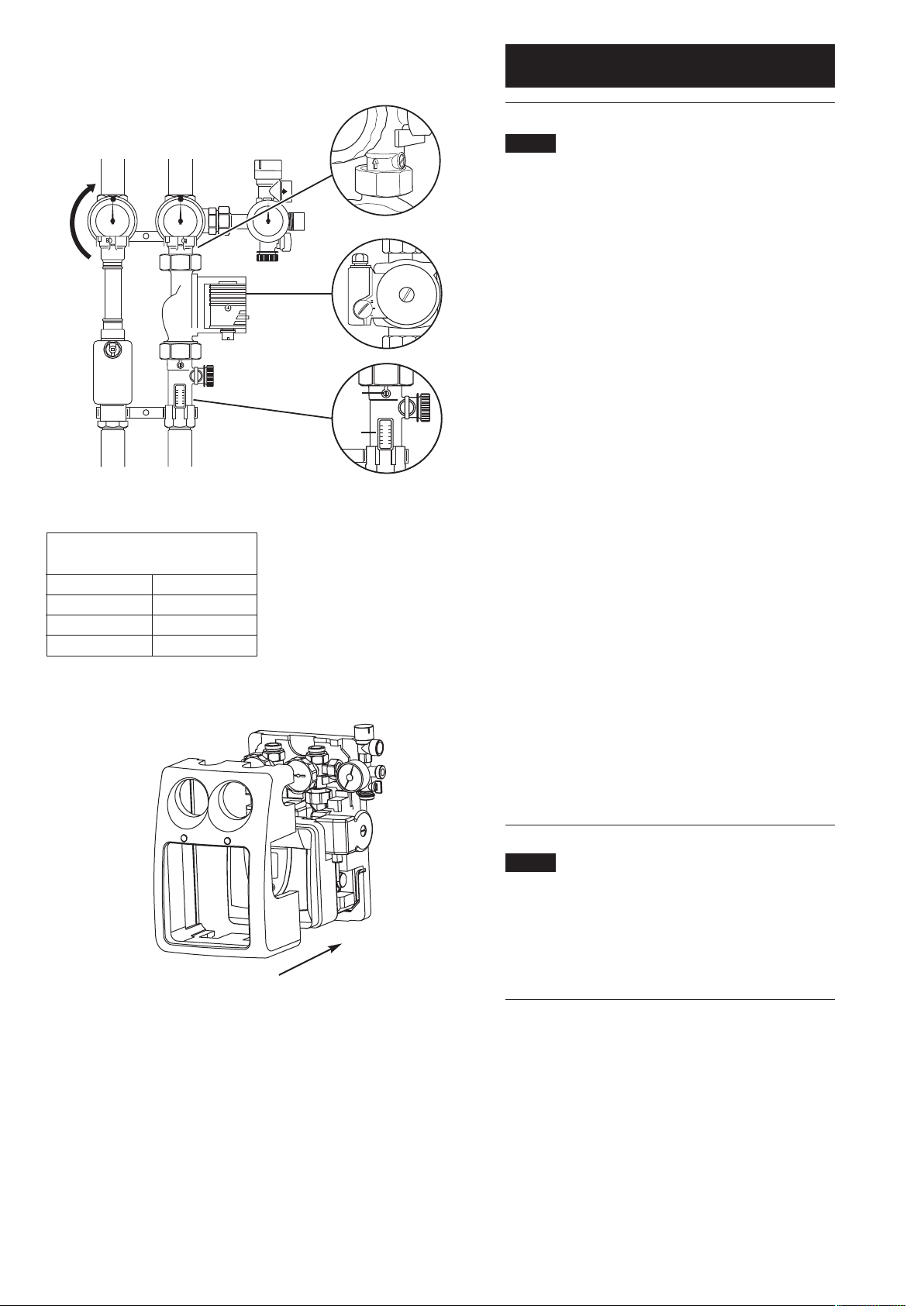

Fig. 1

.0 Commissioning of system

1

3

4

5

1

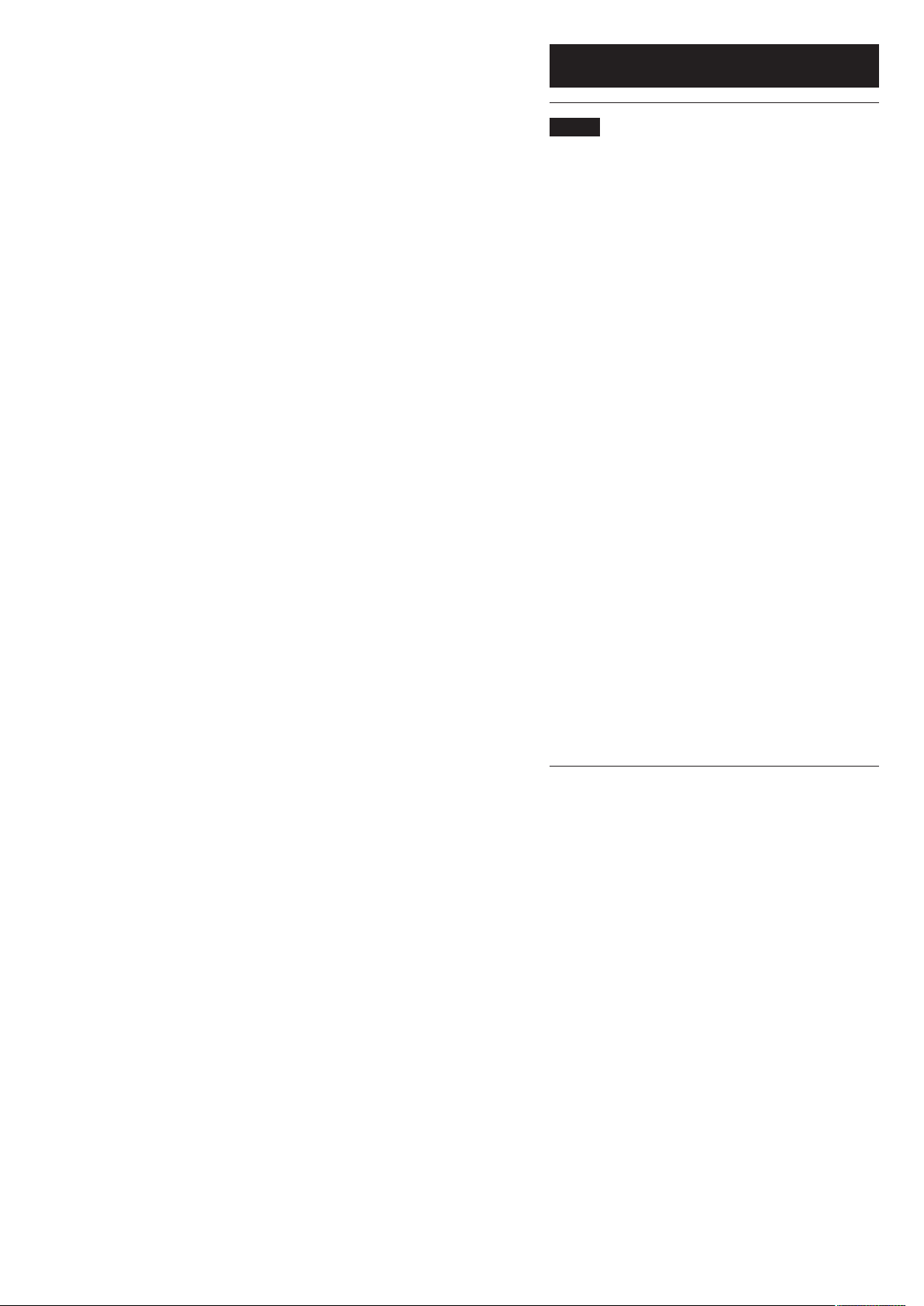

1.2 Flushing the pipework

Before the system is commissioned the pipework must

be flushed to remove any contaminants. It is recommended

that this is done using the solar heat transfer fluid as it

will be impossible to fully drain all parts of the system.

Connect the flushing pipes to the fill & drain valve on

the safety group (Fig. 1 Item 1) and to the fill & drain

valve on the flow meter (Fig. 1 Item 2).

Fig. 2

2

6

7

Filling pump

Filter

Open the fill & drain valves.

Turn the slot of the adjusting screw (Fig. 1 Item 3) in the

return so the slot is vertical to open the non-return

valve.

Turn the left hand isolating valve with integral

thermometer in the flow (Fig. 1 Item 4) in the direction

indicated by the arrow (to a 45° position) to open the

non-return valve.

Ensure that the right hand isolating valve with integral

thermometer in the return (Fig. 1 Item 5) is open

indicated by the dot on the thermometer bezel being

at the top.

Turn the slot of the adjusting screw of the flow meter

(Fig. 1 Item 6) in the return vertically to open the flow

limiter (Fig. 1 Item 7).

Flush the solar primary pump by pumping the fluid into

the system via the fill and drain valve on the safety group.

Close right hand isolating valve (dot on thermometer

bezel at 9 o’clock position). Flush solar primary pipework

and panels via the fill and drain valve on the safety group.

If reusing flushed fluid ensure this is filtered before reintroducing into the system (see Fig. 2).

Fig. 3

Solar fluid Solar fluid

1.3 Filling the pipework

Close the fill and drain valve (Fig. 3 Item 2) on the flow

meter. Open the righthand isolating valve (Fig. 3. Item 1)

with integral thermometer by turning so that the dot on

the bezel is at the top. Fill the solar primary system by

pumping in fluid until the system pressure reads 1.5 to

1

3

2

2.0 bar. Close the fill and drain valve (Fig. 3. Item 3) on

the safety group.

Potterton Solar - Solar Thermal Domestic Hot Water System4

Page 5

2.0 Commissioning of hydraulic station

2.1 Check pressure in the solar primary

pipework

After flushing and filling the solar primary system with

eat transfer fluid the pressure must be checked.

h

Pressure test the system (6 bar). Observe the maximum

pressure ratings of all components concerned.

Check the solar heating system for leaks.

Close the fill and drain valve on the safety group.

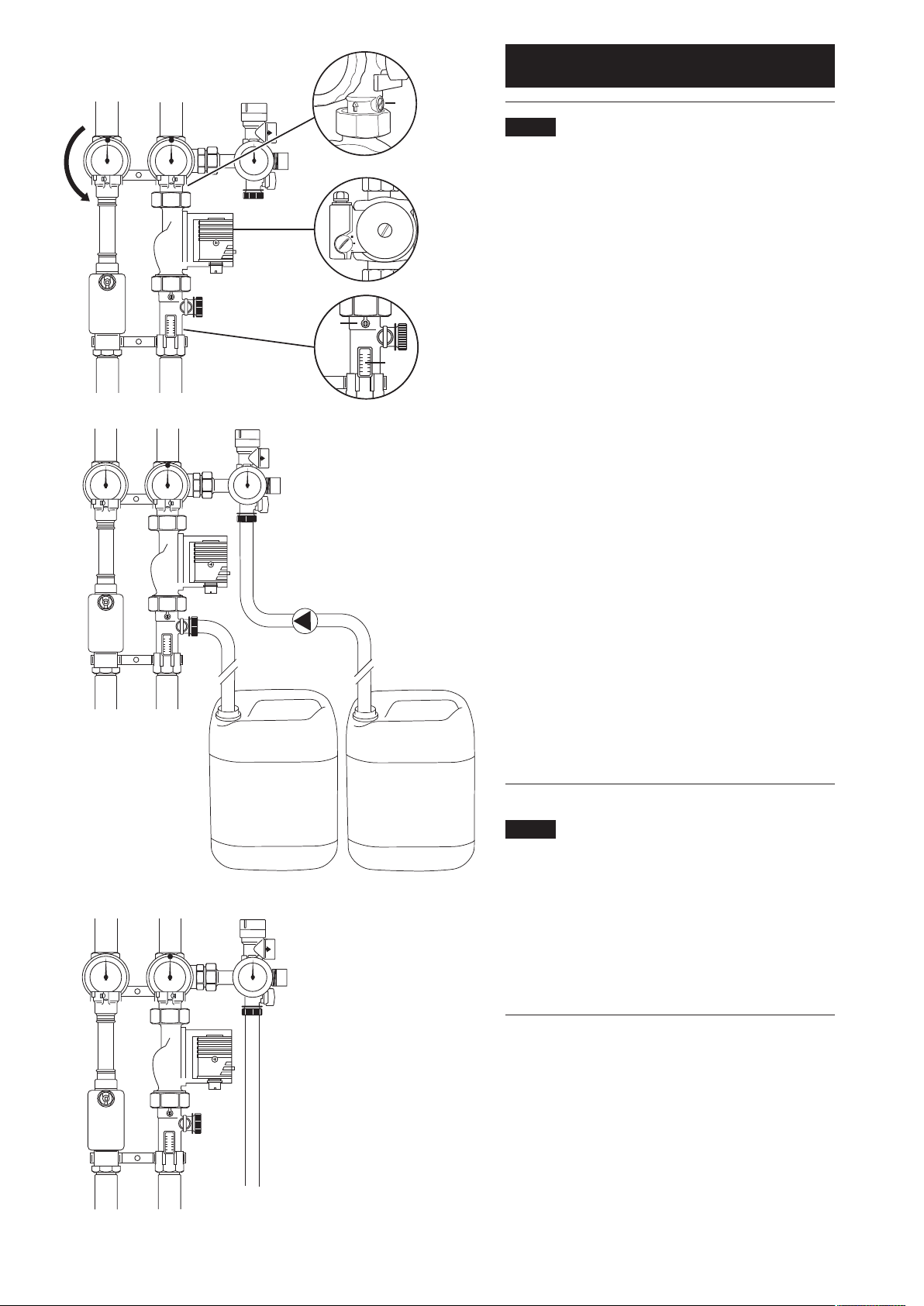

Fig. 4

2.2 Ensure the solar primary system is free

from air

Switch on the power supply to the solar differential

temperature controller.

2

Manually switch the circulation pump ON and OFF

via the solar differential temperature controller

(see section 3.1.7) to pump fluid around the solar

primary system.

1

Turn the pump off and open the airbleed screw on the

air separator (Fig. 4 Item 1). Bleed any air from the air

separator. If the system pressure drops top up by opening

the fill and drain valve (Fig. 4 Item 2) on the safety group

and pumping in more solar fluid to restore the pressure.

This must be repeated until the pressure remains stable.

2.3 Setting the system pressure

During commissioning, the system pressure should be

0.7 bar above the static pressure (1 metre height

differential equals 0.1 bar). However, it must be at least

1.5 bar and no higher than 2.2 bar.

Determine the system pressure when the system is

cold (20°C).This should be recorded on the

Commissioning Record Sheet (page 21).

If the pressure is too low you should pump additional

heat transfer fluid into the system; the fill & drain valve

on the safety group (Fig. 4 Item 2) needs to be opened

for this purpose.When system pressure is correctly set,

ensure the fill and drain valve is closed and remove filling

hose from safety group.

Potterton Solar - Solar Thermal Domestic Hot Water System 5

Page 6

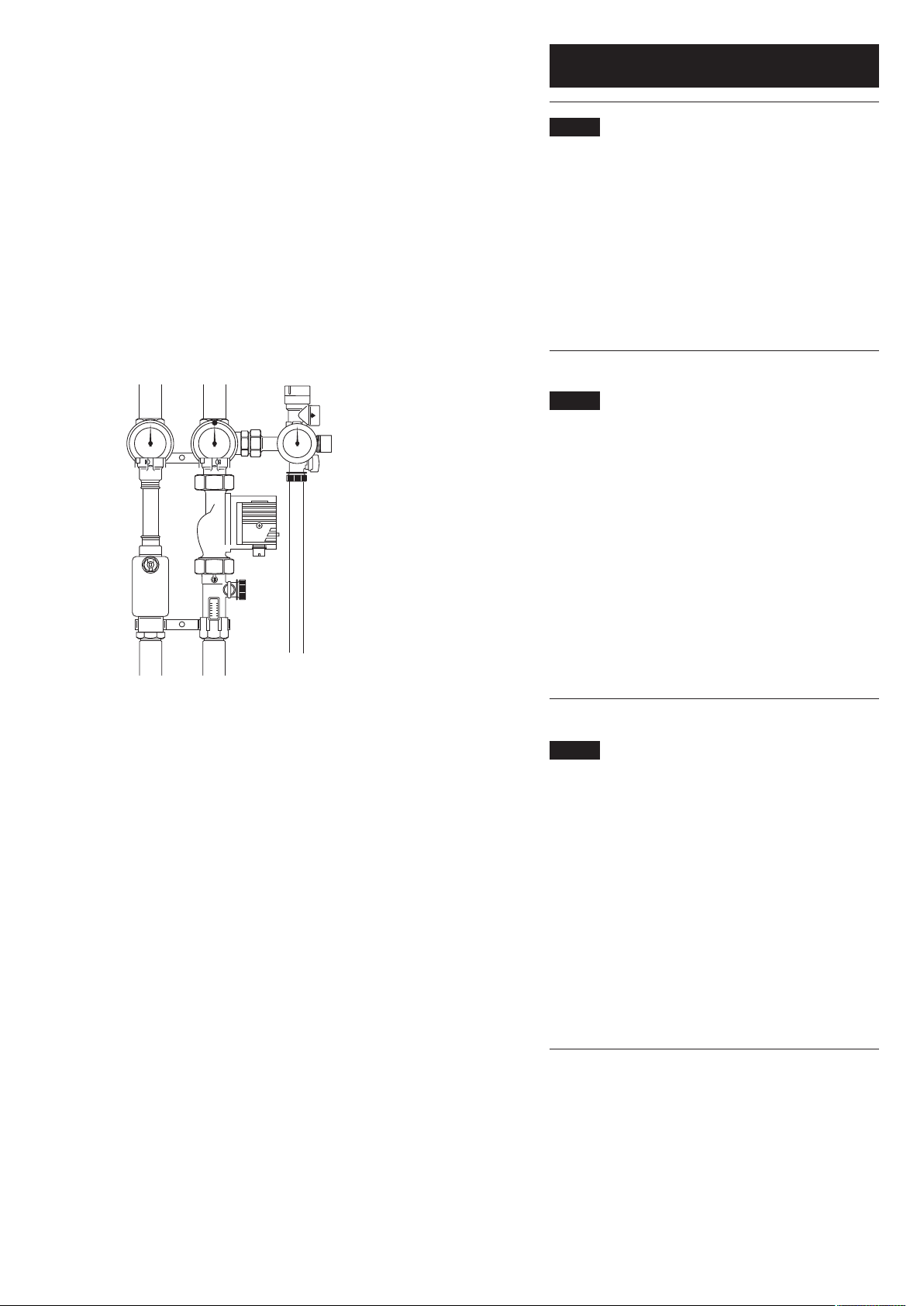

Fig. 5

.0 Commissioning of hydraulic station

2

2

Table 1

Flow rate

(when system is cold)

Collectors l/min

1 approx. 2

2 approx. 4

3 approx. 6

1

2.4 Checking and adjusting the flow rate

Adjust the flow rate when the system is cold (20°C)

(see Fig. 5).

The flow rate should be adjusted to give the optimum

flow rate depending on the number and type of

collector panels connected.

5

3

4

Turn the slot of the adjusting screw (Fig. 5 Item 1) below

the return temperature gauge horizontally to close the

non-return valve.

Turn the l.h. isolating valve with integral thermometer in

the flow (Fig. 5 Item 2) as far as it will go in the direction

indicated by the arrow to close the non-return valve (dot

on bezel on top).

Turn the slot of the adjusting screw (Fig. 5 Item 3) in the

return vertically to open the flow limiter on the flow

meter (Fig. 5 Item 4).

Manually operate the solar pump (see section 3.1.7).

Set the solar pump switch (Fig. 5 Item 5) so that the

required flow rate is achieved or exceeded with the

lowest possible setting.The flow limiter adjusting screw

(Fig. 5 Item 3) can be used to fine-tune the flow rate.

Depending on the number and type of collectors installed,

set the required flow rate from table (SeeTable 1).

Fig. 6

The float in the flow meter will indicate the circulation

flow rate through the flow meter sight glass.

Adjust screw of the flow limiter (Fig. 5 Item 3) with a

screwdriver, until the upper edge of the float in the sight

glass indicates the required flow rate.

Set manual pump operation to off.

1

3

2

2.5 Installation of the thermal insulation

Refit the controller mounting moulding (Fig. 6 Item 1)

onto the rear moulding.

Push the front thermal insulation (Fig. 6 Item 2) against

the rear thermal insulation section (Fig. 6 Item 3) until it

clips into place.

Potterton Solar - Solar Thermal Domestic Hot Water System6

Page 7

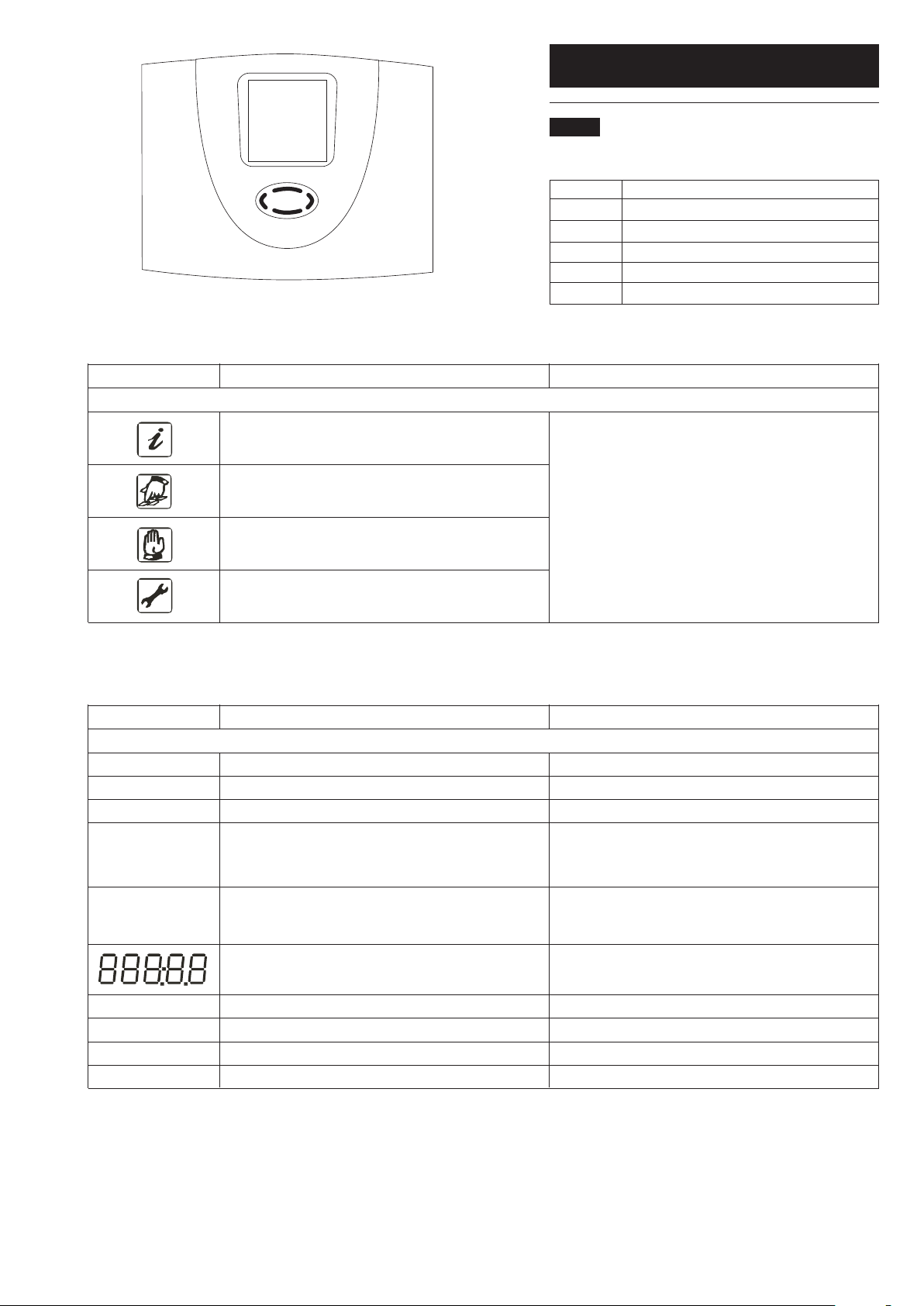

1

2

4

35

Fig. 7

.0 Commissioning of solar controller

3

3.1 Overview of display and operating elements

(see Fig. 7).

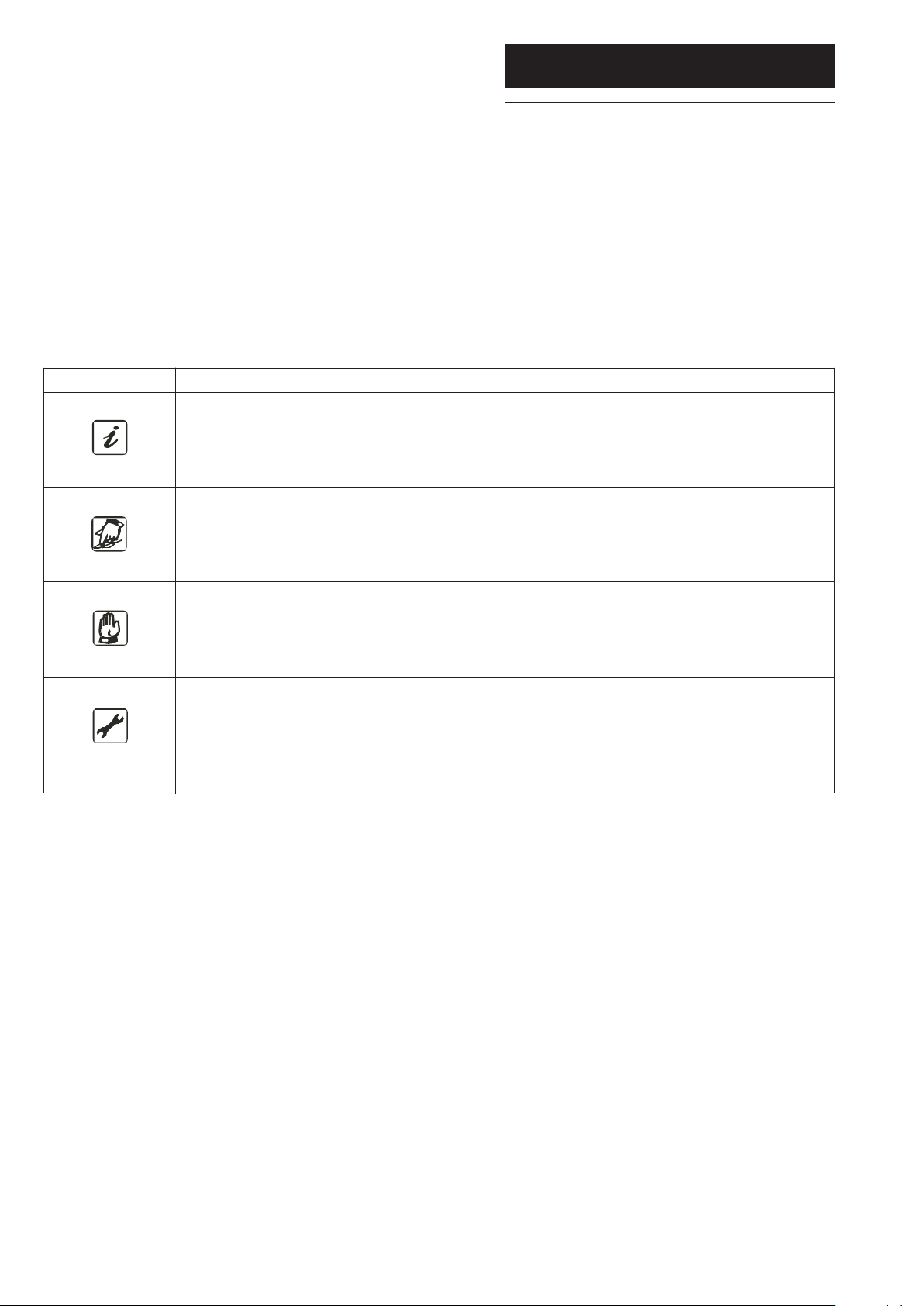

Number Description

1 Display with graphic symbols

2 Control button scroll upwards / +

3 Control button exit / break-off

4

5 Control button choice / confirmation

3.1.1 Explanation of graphic symbols

Graphic symbol Description Indication in operation

Main Menu

Menu "Info"

Control button scroll downwards / –

Menu "Programming"

Menu "Manual operation"

Menu "Basic adjustment"

Graphic symbol Description Indication in operation

Indicator values

dT Temperature difference

min Min value Appears when minimum values are indicated

max Max value Appears when maximum values are indicated

min Timeframe 1 start Appears when the differential controller is active

0:00 (timeframe 1-3) or tube collector is active (timeframe 4)

1

Max Timeframe 1 stop Appears when the differential controller is active

23:59 (timeframe 1-3) or tube collector is active (timeframe 4)

1

5 x 7 segment display. Display of all values, display flashes when

Presentation of figures 00000 to 99999 a value is changed

When symbol flashes it is possible for it to be

selected. If that symbol is chosen by pressing the

button, the symbol remains static (not flashing).

ºC Temperature in Celsius

K Temperature difference in Kelvin

h Operating hours

kWh Productivity indication in kWh

Potterton Solar - Solar Thermal Domestic Hot Water System 7

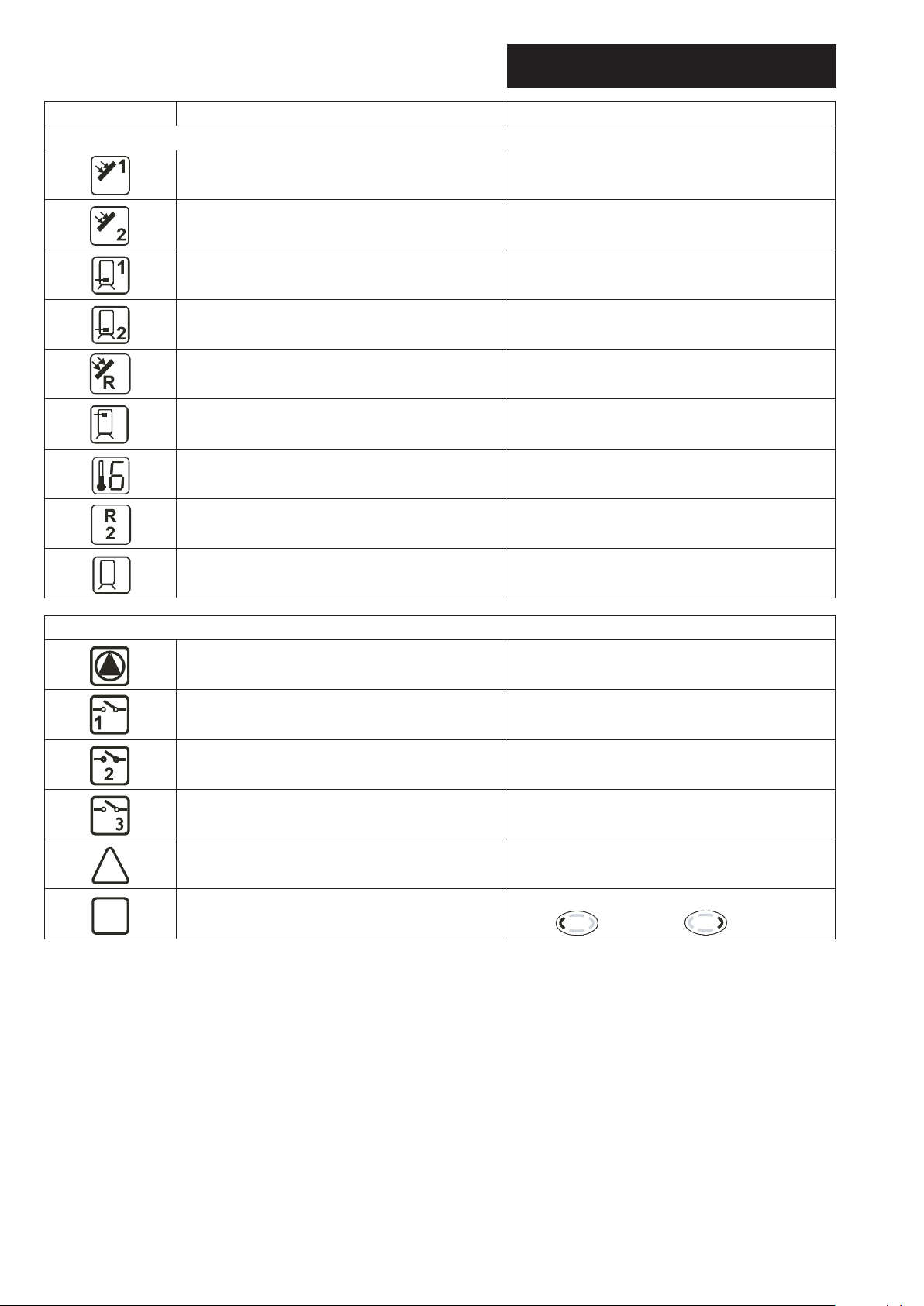

Page 8

.0 Commissioning of solar controller

!

ok?

3

Graphic symbol Description Indication in operation

Measuring points assignment

Temperature measuring point collector array 1

Temperature measuring point collector array 2

Temperature measuring point storage tank 1 lower

(storage tank 1 charging)

Temperature measuring point storage tank lower

(storage tank 2 charging)

Temperature measuring point collector - return

Temperature measuring point storage tank upper

(thermostat function)

Antifreezing sensor or universal temperatures

measuring point (T6) (no sensor monitoring)

2nd temperature differential controller

Operating hours, energy productivity measurement

Status indication

Solar circulation pump Symbol revolves when solar circulation pump is on

Switch output 1 is active Appears when switch output 1 is active (on)

Switch output 2 is active Appears when switch output 2 is active (on)

Switch output 3 is active Appears when switch output 3 is active (on)

Reference to system fault Display flashes when a fault occurs in the system

Safety query for value changes which are to be stored

Input value can be either

rejected or accepted

Potterton Solar - Solar Thermal Domestic Hot Water System8

Page 9

ok?

Button Function Description

"Up" • Step up through menu

"+" • Value change: Increase of the indicated value by 1, holding the button down will

automatically increase values

"Call" • Call up of main menu, step down through menu

"Down" • Value change: Decrease of the indicated value by 1, holding the button down will

automatically decrease values

"Scroll left" • In main menu, scrolls to the left

"Exit" • Exit current menu

• Exit menu point

"Break-off" • Break-off value change without storing

"Scroll right" • In main menu, scrolls to the right

"Choice" • Choosing one menu point

"Confirmation" • Confirmation of value change, stores value change

3.1.2 Button function

Operation and programming of the Potterton Solar

differential temperature controller is by means of 4 operating

buttons.By means of pressing these buttons you can:

• recall display values

• carry out controller adjustments

The graphic symbols on the display step through the

operating structure and show clearly the current menu

oints, display values or parameters.

p

Operating buttons have the following functions:

Example of setting procedure

Button Function Icon after operation step Description

"Exit"

"Scroll right"

"Call"

"Down"

"Choice"

"Up"

"Confirm"

Max

65°C

dT min

3K

dT min

3K

dT min

4K

dT min

4K

Currently selected menu icon will flash

Exit menu's "Info"

Choosing menu "Programming"

Chosen menu icon will flash

Call up menu "Programming", the first menu

point appears

Repeated pressing up to menu point

"S1 dTmin" appears

Choosing presented character

When chosen, value to be changed will flash

Increase of parameter

Confirmation of the character

"ok?" icon will flash

"Confirm"

"Exit"

"Scroll left"

"Call"

Potterton Solar - Solar Thermal Domestic Hot Water System 9

4K

60°C

dT min

Storing of the parameter

When stored, icon will stop flashing

Exit menu "Programming"

Currently selected menu icon will flash

Choosing menu "Info"

Chosen menu icon will flash

Call up menu "Info"

Page 10

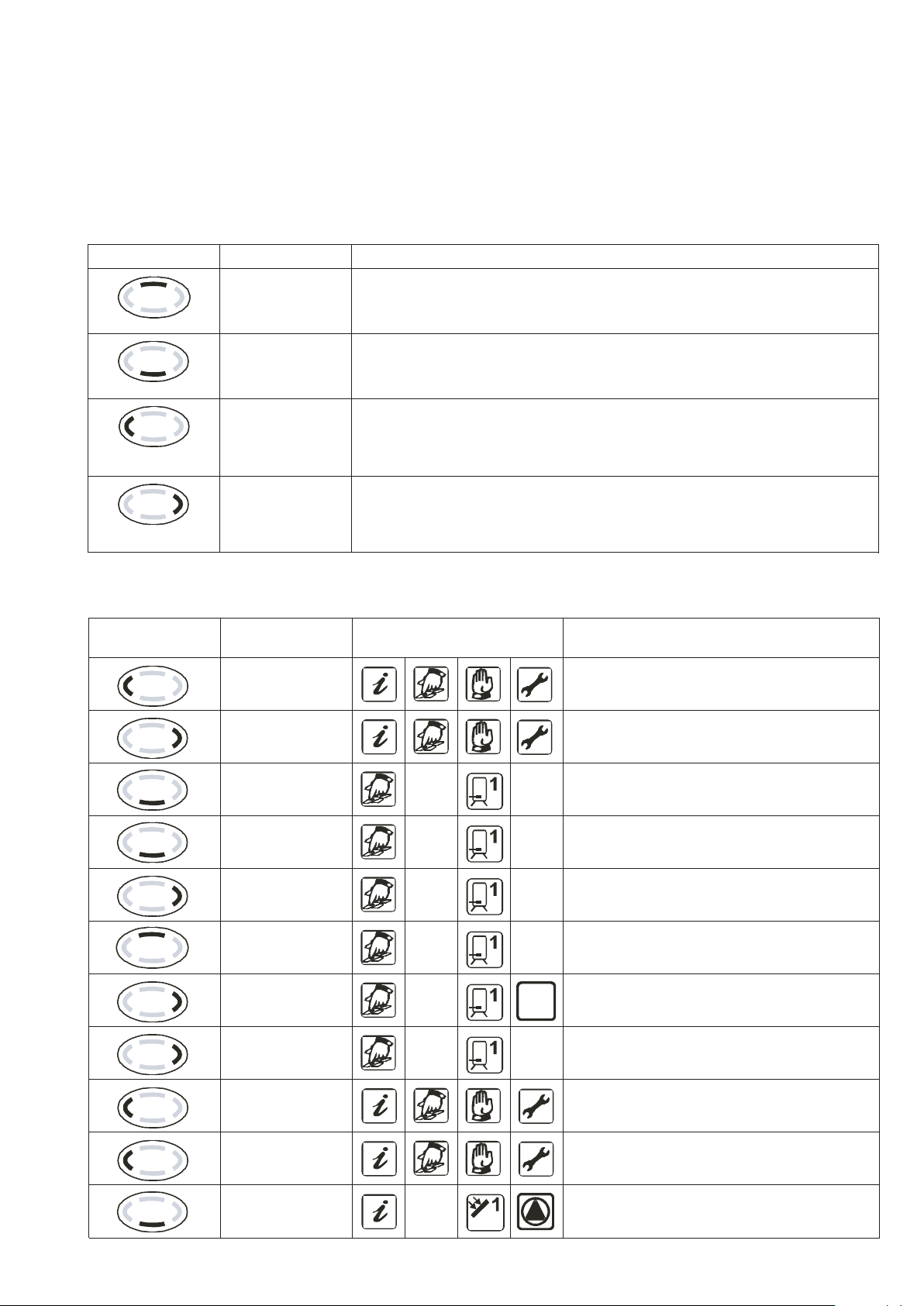

Menu Description

Info Main menu for automatic regulation of solar system

• Indication of current measured values

• Indication of system condition

• Indication of error messages

• Indication of operating hours and energy productivity (if installed)

Programming Changes to programmable values (parameters)

.0 Commissioning of solar controller

3

3.1.3 Operating menu

To make the operation of the controller clear, operating

nd display functions are divided into 4 main menus.

a

These are

• Info

• Programming

• Manual operation

• Basic adjustment

Each active menu is shown in the upper line of the

display by its corresponding icon.

Note: Changes can affect systemfunctions!

Manual operation Switching on and off connected pumps / valves by hand. Overrides automatic regulation.

Basic adjustment Information about basic adjustment for system function

Important

Adjustments and changes in this menu must be carried out only by a competent

installer or service engineer.

Potterton Solar - Solar Thermal Domestic Hot Water System10

Page 11

.0 Commissioning of solar controller

3

3.1.4 Overview: Construction of menustructure

The overview shows the whole menu structure.

ccording to basic adjustment and system type some

A

menu points may not be displayed.

Info Program Manual operation Basic setting

Current collector temperature Maximum temperature Pump1 off / on Collector protection function

/ Collector1 storage cylinder1 off / on

Minimum collector temperature Storage cylinder1 Pump2 / Valve1 Collector protection

/ Collector1 Td max (Td on) off / on temperature

Maximum collector temperature Storage cylinder1 Heating / Cooling / Temperature Re-cooling

/ Collector1 Td min (Td off) differential controller off / on

off / on

Current storage cylinder Maximum temperature of Re-cooling

temperature / storage1 at bottom storage cylinder2 temperature

Minimum storage cylinder Storage cylinder2 Tube collector

temperature / storage1 at bottom Td max (Td on) off / on

Maximum storage cylinder Storage cylinder2 Yield estimation

temperature / storage1 at bottom Td min (Td off) off / on

Current storage cylinder temp / Minimum Glycol type

storage2 at bottom / collector 2 pump rotating speed in %

Minimum storage cylinder temp / Start temperature Glycol percentage

storage2 at bottom / collector 2 Heating / cooling

Maximum storage cylinder temp / Hysteresis temperature Volume flow

storage2 at bottom / collector 2 heating / cooling Td

Current collector Temperature differential Controlling time in

temperature - return line controller: seconds

Maximum temperature of the

heating target Tmax

Current temperature Temperature differential Storage cylinder priority

heating / cooling / controller:

differential controller Minimum temperature of the

heating source heating source Tmin

Current temperature Temperature differential Frost protection

frost protection sensor / controller: off / on

differential controller heating Hysteresis Tdmax

target / universal measuring

point T6

Operating hours pump1 Temperature differential Frost protection sensor

controller: assignment

Hysteresis Tdmin

Yield storage1 Timeframe start 1,2,3 for the Frost protection:

independent controller, 4 for the start temperature

tube collector function

Operating hours pump2 Timeframe stop 1,2,3 for the Independent controller

independent controller, 4 for the assignment: Cooling, heating,

tube collector function temperature differential

controller

Yield storage2 Set time Sensor assignment for the

independent controller

Select basic configuration

Potterton Solar - Solar Thermal Domestic Hot Water System 11

Page 12

.0 Commissioning of solar controller

3

3.1.5 Menu “Info”

In this menu mode all measured values and operating

tates are shown.

s

If the values are marked as “resettable”, they may be

reset in the following way:

Choose the value with buttons and

Reset value by means of the button

Message “OK?” confirm with = no or = yes

Indication Description Reset possible

75ºC Indication of current collector temperature no

min. 12ºC Indication of minimum collector temperature yes

Re-settable to current temperature

max. 105ºC Indication of maximum collector temperature yes

Re-settable to current temperature

52ºC Indication of current temperature storage tank (lower) no

min. 40ºC Indication of minimum temperature storage tank (lower) yes

Re-settable to current temperature

max. 67ºC Indication of maximum temperature storage tank (lower) yes

Re-settable to current temperature

25ºC Indication of universal temperature measuring points (T3) no

55ºC Indication of current temperature storage tank thermostat no

60ºC Indication of current temperature collector return no

60ºC Heating, cooling, temperature differential controller no

heat source. Sensor T1...T6

35ºC Temperature differential controller no

heat target

1234 h Operating hours for charging storage tank Yes

Resettable to 0 h

927 kWh Energy productivity for storage tank Yes

Resettable to 0 kWh

Potterton Solar - Solar Thermal Domestic Hot Water System12

Page 13

.0 Commissioning of solar controller

2

3

3.1.6 Menu “Programming”

All adjustable parameters can be checked in this menu

and, if necessary, changed.The default factory set values

will usually give efficient, problem free operation.

The number of indicated values depends on the

ontroller type and the adjusted additional functions.

c

Only the required values are shown at each menu step:

Indication Description Value range Defaults

max Storage 1/2: 15..95ºC 65ºC

5ºC Maximum temperature

6

dT max Storage 1/2: Hysteresis (Tdon) 3..40 K 7 K

7 K

dT min Storage 1/2: Hysteresis (Tdoff) 2..35 K 3 K

3 K

min Setting the speed control of the pump 30%..100% 100%

100 100% = speed control off

13:21 Clock 0:00...23.59 12:00

min Temperature start for the function 20..90ºC 40ºC

40ºC heating/cooling

dT Hysteresis heating/cooling 1..30K 10K

10K

max Differential controller: Maximum 15..95ºC 65ºC

65ºC temperature of heat target Tmax

min Differential controller: Maximum 0..95ºC 15ºC

15ºC temperature of heat source Tmin

dTmax Temperature differential controller: 3..40K 7K

7 K Hysteresis dTmax

dT min Temperature differential controller: 2..35K 3K

3 K Hysteresis dTmin

min Timeframe 1(2,3): Start 0:00... 00:00

00:00 for the independent controller 23.59

1(2,3)

max Timeframe 1(2,3): Stop 0:00... 23:59

23:59 for the independent controller 23:59

1(2,3)

min Timeframe 1(2,3): Start 0:00... 6:00

6:00 for the tube collector function 23:59

4

max Timeframe 1(2,3): Stop 0:00... 20:00

20:00 for the tube collector function 23:59

4

Potterton Solar - Solar Thermal Domestic Hot Water System 13

Page 14

.0 Commissioning of solar controller

3

.1.7 Menu “Manual operation”

3

For commissioning, service and test purposes the solar

primary system can be manually operated. For this purpose

he switch outputs may be disconnected or connected.

t

During manual operation there is no automatic regulation

of the system.To avoid inadmissible operating states this

mode of operation changes into “Indication” after ca.

8 hours and the automatic regulation is activated again.

Indication Description Value range

Switching on / off switch output A1 (solar circulation pump) by hand 0 = off

1 = on

Switching on / off switch output A2 (pump2 / valve1) by hand 0 = off

1 = on

Switching on / off switch output A3 (cooling, thermostat or 2nd temperature 0 = off

difference controller function) by hand 1 = on

Potterton Solar - Solar Thermal Domestic Hot Water System14

Page 15

.0 Commissioning of solar controller

3

3.1.8 Menu “Basic adjustment”

Adjustments and changes in this menu must be carried

out only by a competent installer or service engineer.

Incorrect adjustments may adversely affect the function

of controller and solar primary system.

To avoid accidental changes in menu “Basic adjustment”,

it is not editable in normal functioning but has only a

display function.To be able to carry out any changes, this

menu must be chosen within the first minute after

switching on the appliance. The basic adjustment menu is

‘blocked’ automatically one minute after if no buttons are

pressed or one minute after switching on the appliance.

Indication Description Value Factory

range set-up

Parameter / value

0 – 0 Collector protection 0 = off 0 = off

1 = on

1 – 120ºC Start temperature for the collector protection 110..150ºC 120ºC

2 – 0 Re-cooling function (only when collector 0 = off 0 = off

protection is on) 1 = on

3 – 40ºC Target temperature for the storage after 30..90ºC 40ºC

collector protection activity

4 – 0 Time controlled circulation with 0 = off 0 = off

tube collectors 1 = on

5 – 0 Yield estimation off/on 0 = off 0 = off

1 = on

6 – 0 Glycol types (see table below) 0...10 0

7 – 50 Glycol percentage 0 ... 100% 50

5% - steps

8 – 1,0 Volume flow: Litre per impulse - flow meter 0,5 ... 25 I/I 1,0

0,5l - steps

9 – 240 Time controlling in s 30...480 240

10 – 1 Storage priority 1...2 1

11 – 0 Frost protection on/off 0 = off 0

1 = on

12 – 6 Sensor assignment - Frost protection 1...6 6

13 – 3 Start temperature for the frost protection function -20ºC ... +7ºC 3

14 – 0 Select cooling thermostat 0 = off 0

or temperature differential controller 1 = cooling

2 = heating

3 = temperature

differential controller

15 – 5 Sensor assignment for the independent controller (source) 1...6 5

16 – 0 System configuration 0...4 0

Glycol types (point 6):

0 Anro 6 Tyfocor L5.5 - supplied

1 IIexan E, Glythermin 7 Dowcal 10

2 Antifrogen L 8 Dowcal 20

3 Antifrogen N 9 Dowcal N

4 IIexan E 10 Tyfocor LS

5 IIexan P

Potterton Solar - Solar Thermal Domestic Hot Water System 15

Page 16

.0 Commissioning of solar controller

3

3.1.9 Controller functions

The Potterton Solar differential temperature controller

contains many functions to regulate and monitor the

olar primary system. Including

s

- controller functions for heating the solar cylinder

- functions for system protection and system monitoring

- additional functions (other accessories may be required

o achieve these functions).

t

3.1.10 General controller functions

he controller collects the temperatures of various

T

measuring points and determines the right time to charge

the storage tank on account of programmed (additional)

functions and controller parameters.

3.1.11 Cylinder heating by solar primary system

Switching action can be adjusted through dTmax (dTon)

and dTmin (dToff), but dTon cannot be set lower than dT

off + 1K .The solar cylinder is heated by operating the

solar pump on output A1 up to the set maximum storage

temperature. Pump operation is allowed as long as the

collector panel temperature exceeds the cylinder

temperature by a set amount.

Corresponding values in menu

“Basic adjustment” “Programming”

--- Maximum temperature

--- dT max (dT on)

Switch-on temperature difference

--- dT min (dT off)

Switch-off temperature difference

3.1.12 Systems with two storage cylinders

For systems with more than one storage cylinder (System

Types 1 and 2) the cylinder heating can be optimised

depending on the energy supply. Usually the cylinder with

lower priority will have a lower temperature than that

with the higher priority. Re-directing the energy to the

lower priority cylinder will lower the temperature in the

collector array. To “reinforce” the collector temperature

the heating of the lower priority cylinder will be

interrupted for a short while at fixed intervals. If the

heating criteria for the higher priority cylinder is fulfilled

then the lower priority cylinder will be heated.

The higher priority cylinder can be selected in the

“Basic Settings” menu point no. 10.

Potterton Solar - Solar Thermal Domestic Hot Water System16

Page 17

3.1.13 Rotational speed regulation

The solar circulation pump on 230V-outputs A1 and

A2 can be operated either in switch-mode (two-point

controller) or in a rotational speed regulated way.

If the rotational speed regulation is activated the pump

power is adjusted by a controller so that switch-on

temperature difference “Storage tank dTmax” is kept

constant as much as possible.At lower deviation of

Storage tank dTmax” the pump is operated with the

“

lowest power till the switch-off wave is reached.

Corresponding values in menu

“Basic adjustment” “Programming”

--- Rotational speed min <100%

3.1.14 Thermostat (heating)

he thermostat is a control circuit that’s independent

T

from the storage loading.Thus an auxiliary heating in

the top area of the storage cylinder is made possible.

The output A3 will be:

• Switched on, when the temperature falls below the

adjusted start level.

• Switched off, when the temperature reaches the

10k

TTh

4

d

0ºC

on

A3

o

hermostat

[ºC]

T

T

ff

T

Storage top)

(

Heating on (A3)

t

adjusted start level + hysteresis.

Corresponding values in menu

“Basic adjustment” “Programming”

14 -- 2 Start temperature max ºC

15 -- 5 Hysteresis Td in K

Timeframe (1…3) Start: min time

Timeframe (1…3) Stop: max time

3.1.15 Thermostat (cooling)

In order to optimise the energy yield, it could be useful

to “redirect” the solar energy, or to take it away from

the storage when the storage temperature reaches a

certain level.

When the sensor reaches the start temperature, output

A3 will be switched on.When the temperature level falls

below the start temperature hysteresis, the output A3

will be switched off.

Corresponding values in menu

“Basic adjustment” “Programming”

14 -- 1 Start temperature max ºC

15 -- 5 Hysteresis Td in K

Timeframe (1…3) Start: min time

Timeframe (1…3) Stop: max time

Potterton Solar - Solar Thermal Domestic Hot Water System 17

Page 18

3.1.16 Temperature difference control

!

!

The temperature difference control manages an output

according to adjustable temperature differential criteria.

The function is independent from all the other functions.

TDiff1 is the temperature of the heating source andTDiff2

of the heating target. Output A3 will be switched on

regarding the conditions below, when a timeframe is active.

Corresponding values in the menu

“Basic Setting” “Programming”

4 -- 3 Maximum temperature heating target max ºC

1

15 -- 5 Minimum temperature heating source min ºC

ysteresis Td max in K

H

Hysteresis Td min in K

Timeframe (1…3) Start: min time

Timeframe (1…3) Stop: max time

A3 on TDiff >= TDiff2 + Diff.Tdmax and

TDiff2 < Diff.Tmax – 1 and

TDiff1>=Diff.Tmin + 1

A3 off TDiff1 < TDiff2 + Diff.Tdmin or

TDiff2 >= Diff.Tmax or

TDiff1<Diff.Tmin

3.1.17 Tube collector

The function “tube collector” can be switched off/on in

the “Basic setting” menu – point 4.The timeframe 4 in the

“Program” menu makes it possible to activate this function

only for a certain period of time (sunshine period).When

activated, the solar pump will be switched on every 30

minutes for a period of 30 seconds.This is necessary, to

measure a temperature change in the collector if there

was no circulating for a long period of time.

Corresponding values in menu

“Basic Setting” “Programming”

4 -- 1 Timeframe (4) Start: min time

Timeframe (4) Stop: max time

3.2.1 Sensor monitoring

The sensors necessary for control functions and their

connecting cables are monitored regarding break and

short circuit. If a faulty sensor is recognised by the

software, the symbol is shown. By scrolling up and

down you can find an error source.

The use of temperature sensors of thewrongtype

can also lead to anerror message

Indication Meaning

X

Potterton Solar - Solar Thermal Domestic Hot Water System18

Short circuit on temperature sensor of the current measuring point

Break on temperature sensor of the current measuring point,

circulation error at activated energy productivity measurement

Page 19

3.2.2 Flow monitoring

!

If the energy productivity measurement option is

deactivated, the temperature difference between

collector and storage tank is checked.

If it exceeds the amount of (60K + dTmax), it is then

interpreted as an error because in the case of normal

system dimensioning and a pump switched on such large

differences cannot take place.

f the energy productivity measurement option is

I

activated, the flow amount when the pump is switched

on is checked. If for 15 minutes no flow is recognised

it is evaluated as an error.

rror message is automatically reset after eliminating

E

the failure.

Indication Meaning

+

Missing circulation in solar circuit

3.2.3 Collector protection / Re-cooling

This function can be switched on/off in the “Basic settings”

menu.

High temperatures can destroy antifreeze liquids.Therefore,

the maximum collector temperature should be restricted.

When all storages have been loaded to the limit, the solar

pump is switched off. If the collector temperature rises

above “T collector max”, the solar pump is switched on,

until the collector temperature drops by 10K. Part of the

energy is lost in the pipes, the rest is loaded in the storage,

which results in increasing the storage temperature above

the adjusted maximum storage temperature. For security

reasons the function will be interrupted if the storage

reaches 95ºC.

If the storage temperature is bigger TStmax+2K and the

collector temperature is 10K below TSt, then the re-cooling

function is activated.The redundant storage energy will be

released through the collector in order to assure reserves

for the next loading cycle.

The re-cooling ends when TSt drops below the value“recooling till…” in the “Basic settings” menu, point 3, or

when the collector temperature >= the storage

temperature – 2K.

The re-cooling function can be active only when the

collector protection function is on.

Corresponding values in menu

“Basic SETTINGS” “Programming”

0 -- 1 ---

1 -- 120ºC

2 -- 1

3 -- 40ºC

3.2.4 System protection function

The system protection function switches the system off if

the “maximum collector temperature” is exceeded by 10K.

As soon as the temperature drops below the “maximum

collector temperature”,the system is started up again.This

function has higher priority and is always active, regardless

of whether the collector protection is on or off.

Potterton Solar - Solar Thermal Domestic Hot Water System 19

Page 20

3.2.5 Frost protection

This function can be switched on/off in the “Basic settings”

menu,point 11 and the start temperature can be adjusted

in point 13. Furthermore, a frost protection sensor can be

selected (T1-T6, point 12).

For systems driven without or with very low amounts of

antifreeze, the pipes and the collector have to be protected

from freezing. For this purpose, the selected frost

rotection sensor measures the temperature at an exposed

p

place,e.g. blank pipes before the collector. If the measured

value is lower than the start temperature, the solar pump

is activated until the adjusted frost protection start

emperature +5K is reached.The minimum runtime of

t

the pump is 5 minutes.

For security reasons the function is deactivated if the

temperature of the priority storage falls below 5ºC.

3.2.6 Energy productivity measurement

or the purposes of energy productivity measurement

F

(solar gain), a sensor on the collector return line and a

flow meter are required. The yield value is calculated

from the values of the temperature difference between

the collector and collector return line and the value

measured by the flow meter. This function is switched on

and off in the “Basic settings” menu.

Corresponding values in menu

“Basic Setting” “Programming” “info”

5 -- 1 --- XXXX kWh

3.2.7 Operating hours meter

So long as the storage tank is charged by a pump, the

operating hours meter records for each separate pump.

The number of operating hours can be read in menu

“info” and for each pump separately reset to 0.

Corresponding values in menu

“Programming” “info”

--- XXXX h

Potterton Solar - Solar Thermal Domestic Hot Water System20

Page 21

Commissioning record

he following chart should be completed during Commissioning of the system.

T

Installer: _______________________________

Contact details: _______________________________

Original installation date: _______________________________

General Commissioning

All pipework correctly installed, identified and ❑

arth bonded

e

Solar primary system filled with heat transfer ❑

fluid supplied

System pressure test carried out ❑

olar expansion vessel charge pressure checked ❑

S

and set bar

Air vented from system ❑

Exposed pipework insulated using high-temp and ❑

weather resistant insulation

Panel fixing bracket positions weatherproofed ❑

where necessary

Panel fixings checked and secure ❑

Hydraulic Station

System pressure when cold bar

Solar primary flow when cold l/min

Solar differential temperature controller - operational parameters

If any factory values are changed please enter the new values in the

table below.

Adjustable in menu Typical Current

"Programming" adjustment adjustment

Storage tank1: 65°C

Maximum storage temperature

Storage tank1: 7 K

switch-on difference (dTon)

Storage tank1: 3 K

switch-off difference (dToff)

Storage tank2: 90°C

Maximum storage temperature

Storage tank2: 7 K

switch-on difference (dTon)

Storage tank2: 3 K

switch-off difference (dToff)

Minimum pump power on 100%

rotational speed regulation

Switch-on temperature of 40°C

thermostat function

Hysteresis of thermostat function 10 K

2nd temperature differential 65°C

controller maximum temperature Tmax

2nd temperature differential controller 7 K

hysteresis dTmax

Isolating/non-return valves (flow and return) in ❑

operating position

Solar Collector Panels

Panels visually inspected for defects ❑

Collector temperature sensor correctly installed ❑

and secured

Pipe entry points to building weatherproof ❑

Solar Differential Temperature Controller

Record all operational parameters set ❑

(see separate table)

Pump operation tested in automatic and manual ❑

modes

All cables correctly installed and secured ❑

Suitably fused isolating device installed ❑

Solar Cylinder

Cylinder installed and commissioned in ❑

accordance with cylinder installation instructions

Adjustable in menu Typical Current

"Basic adjustments" adjustment adjustment

Switching on or off the function 0 = off

collector protection

Temperature at which the collector 120°C

protection function is active

Switching on or off the function 0 = off

recooling (only when the collector

protection is on)

Temperature to which the storage 40°C

tank is recooled when collector

protection function is on

Function for time-controlled 0 = off

circulation in operation with

tube collectors

Switching on or off the function 0 = off

energy productivity measurement

Choice of glycol types used 0 = Anro

Mixture ratio of coolants 50%

Litres per impulse of the flowmeter 1.0 L/I

Switching on or off the function 0 = off

antifreezing

Temperature at which the antifreezing -1°C

is active

Alternative choice of the cooling, 0 = none

thermostat function or the 2nd

temperature differential controller

System type type 0

Time control in secs 240

Storage priority 1

Potterton Solar - Solar Thermal Domestic Hot Water System 21

Page 22

bar bar bar bar bar bar bar bar bar bar bar bar bar

/ / / / / / / / / / / / / / / / / / / / / / / / / /

Date Date Date Date Date Date Date Date Date Date Date Date Date

Concentration ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

Next check date ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

Protection to ºC ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

bar bar bar bar bar bar bar bar bar bar bar bar bar

l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min

____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

Servicing and maintenance record

Please complete the following record after any Servicing or Maintenance of the Baxi Solarflo system. Refer to the Commissioning Record charts for details of the original system for reference. Refer to Maintenance section for recommended Maintenance periods

Check condition of all pipework ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Check condition of insulation ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Check frost protection of solar fluid (every 2 years)

Check solar expansion vessel charge pressure

Check solar primary system pressure (cold)

Check solar primary system flow rate

Check operation of PRV ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Check sensor operation ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

(use resistance/temperature table. See page 22)

manufacturer's instructions

Ensure system is free of air ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Check solar cylinder in accordance with ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Visually check condition of solar collector panels ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Visually check condition of collector panel brackets ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Visually check condition of any waterproofing ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

and fixings (every 2 years)

(around pipe entries to roof and roof fixings)

Engineers initials

Potterton Solar - Solar Thermal Domestic Hot Water System22

Page 23

bar bar bar bar bar bar bar bar bar bar bar bar bar

/ / / / / / / / / / / / / / / / / / / / / / / / / /

Date Date Date Date Date Date Date Date Date Date Date Date Date

Concentration ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

Next check date ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

Protection to ºC ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

bar bar bar bar bar bar bar bar bar bar bar bar bar

l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min l/min

____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

Check condition of all pipework ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Potterton Solar - Solar Thermal Domestic Hot Water System 23

Check condition of insulation ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Check frost protection of solar fluid (every 2 years)

Check solar expansion vessel charge pressure

Check solar primary system pressure (cold)

Check solar primary system flow rate

Check operation of PRV ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Check sensor operation ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

(use resistance/temperature table. See page 22)

manufacturer's instructions

Check solar cylinder in accordance with ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Ensure system is free of air ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Visually check condition of solar collector panels ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Visually check condition of collector panel brackets ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

Visually check condition of any waterproofing ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑

and fixings (every 2 years)

(around pipe entries to roof and roof fixings)

Engineers initials

Page 24

.0 Maintenance

4

4.1 Check heat transfer fluid

The heat transfer fluid must be checked every two years

with regard to its antifreeze and pH value.

- Check antifreeze using antifreeze tester.Target value is

approximately -21 deg C (40% concentration).

Do not allow to fall below 30% concentration.

If necessary replace or replenish the solar heat

transfer fluid.

- Check pH value with a pH indicator rod (target value

approx. pH 7.5). If the limit pH value is less than pH 7,

replace the heat transfer fluid.

4.2 Maintenance of the collector

The collector or the collector array must be inspected

visually, once a year, for any damage, leaks and

contamination.

4.3 Cylinder

Solar fluid concentrations

% volume Density at 20°C g/cu.cm Refractive Index nD20 Frost protection °C

25 1.023 1.3627 -10

30 1.029 1.3690 -14

35 1.033 1.3747 -17

40 1.037 1.3801 -21

45 1.042 1.3855 -26

50 1.045 1.3910 -32

Refer to manufacturers documentation.

Potterton Solar - Solar Thermal Domestic Hot Water System24

Page 25

Error representation on display Possible reasons Measures

!!!

Sensor wire broken • Check wire

•

flashing

lashing

f

Circulation error: no flow

+

flashing

Additionally at energy

productivity measurement:

• Sensor defect • Check sensor resistance, if necessary exchange sensor

• Short circuit in sensor wire • Check wire

• Sensor defect • Check sensor resistance, if necessary exchange sensor

• Error in pump connection • Check cabling

• Pump defect • Exchange pump

• Air in the system • Check the float of the flow meter moves

when the system runs (if visible)

• Connection with flow • Check wire

meter defect

• Sensor wire broken • Check wire

• Sensor defect • Check sensor resistance, if necessary exchange sensor

.0 Fault finding

5

5.1 Failures with error message

Some system failure modes can be recognised by the

solar differential temperature controller and will be

indicated by an error message on the controller display.

Refer to the table below for details of possible errors

and suggested measures to rectify.

Potterton Solar - Solar Thermal Domestic Hot Water System 25

Page 26

Y

ES

No display at solar differential

t

emperature controller

Controller fault

Replace controller

Is the 230/240V~ power

s

upply switched on

YES

Has thermal cutout

on cylinder operated

(

unvented systems only)

NO

NO

Is internal

fuse operational

YES

NO

Replace internal fuse

Check wiring and rectify

Reset thermal cutout.

Investigate cause of operation

and rectify

Is the 230/240V~

power supply at the controller

terminal block

Switch on power supply

I

s the 230/240V~ power

supply correctly wired

Y

ES

NO

YES

NO

Correct any wiring faults

.0 Fault finding

5

Resistance table PT1000.

The correct function of temperature sensors can be

hecked on the basis of the following temperature

c

resistance table with a resistance measuring instrument:

Temperature in ºC Resistance in Ohm

-30 882

-20 921

-10 960

0 1000

10 1039

20 1077

30 1116

40 1155

50 1194

60 1232

70 1271

80 1309

90 1347

100 1385

120 1461

140 1535

200 1758

Potterton Solar - Solar Thermal Domestic Hot Water System26

Page 27

5.0 Fault finding

Y

ES

Pump symbol on controller rotates

b

ut pump does not operate

P

ump fault

Replace pump

Is controller to

pump connection correct

a

nd secure

YES

Is the pump siezed

NO NO

N

O

Y

ES

C

an the impeller be

revolved using a screwdriver

after removing the air

bleed screw

Free impeller and replace

a

ir bleed screw

Check connections and

rectify as necessary

YES

Displayed temperatures on controller

vary greatly over short time intervals

Controller fault

Replace controller

Are sensor cables

laid alongside mains

voltage cables

NO

Have sensor cables

been lengthened with

unshielded cable

NO

NO

Do sensors give

correct temperature

v

resistance readings

YES

YES

NO

Are sensor

connections correctly

made

YES

Sensor fault

Replace sensor

Use shielded cable to extend

sensor cable lengths

Seperate sensor cables from

mains cables (Min. 50mm

recommended) or use

shielded cable

Rectify sensor connections

Potterton Solar - Solar Thermal Domestic Hot Water System 27

Page 28

A

.0 Spares

6

Diagrams not to scale

L

B

C

F

K

M / N

O

I

G

H

J

10 / 20 LITRE

D

PQ

R

E

Potterton Solar - Solar Thermal Domestic Hot Water System28

Page 29

S

6.0 Spares

6.1 Spare parts

A number of Spare Parts are available should any part of

he Potterton Solar system require replacement. Use only

t

genuine parts obtained from Potterton, use of other non

Potterton parts may cause system malfunctions and will

invalidate the warranty. Fitting of any spare parts must

e carried out by a competent installer or authorised

b

T

service engineer or agent.

Description Code No.

A Roof bracket assembly (On roof panels)

comprising roof bracket, roof bracket console,

(

cup square bolt M8 x 25, M8 washer, M8 hex self

securing nut and 2 off self tapping screws No6 x 60 long)

B Collector panels fixings kit (On roof panels)

(comprising 2 off No6 x 60 self tapping screws,

cup square bolt M8 x 25, M8 washer, M8 hex nut,

M8 self securing nut, M8 x 30 hammer head bolt,

ounting part top, clamping piece)

m

C Extension assembly (On roof panels)

(comprising clamping piece extension,

ounting part extension, 2 off M8 hex nut, 2 off M8 washer) 5119534

m

5119532

5119533

D Connection washer (On roof panels)

comprising 2 off flat sealing washer)

U

(

5119535

E Temperature sensor 5119536

F Solar differential temperature controller

(complete) 5122978

G Pressure relief valve 5119538

H Pressure Gauge 5119539

I Safety Group

(complete) 5119540

J Solar primary circulating pump 5119541

K Flow meter assembly 5119542

L Temperature gauge 5119543

V

W

X

M Solar heat transfer fluid 10 litre drum 5119544

N Solar heat transfer fluid 20 litre drum 5119545

O Solar expansion vessel 24 litre 5119548

P Expansion vessel self-sealing connection 5119779

Q Flow Meter (for solar gain module) 5122979

R Sensor (for solar gain module) 5122980

S Connection washers (for in roof panels) 5122981

T Flexible connection hose (2m) + insulation 5122982

Y

U Roof bracket kit for in roof panels

(comprising roof bracket, self tapping screws 5x60

sealed plumbing screws 4.5x35, metal retainer

and roofing nails)

5122983

V Connection adaptor for in roof panels 5122984

W1” BSP male / 3/4” female adaptor fitting 5129783

X1” BSP male / 3/4” male adaptor fitting 5129784

Y Thermostatic blending valve 5122985

NOTE:The solar cylinders have their own set of spare

parts available. Information on these can be found in the

separate cylinder installation instruction manual.

Potterton Solar - Solar Thermal Domestic Hot Water System 29

Page 30

7.0 Warranty

7.1 Standard Warranty Terms & Conditions

olar Collectors 10 Years

S

Solar Control Station 2 Years

To receive your free warranty please complete the form

upplied with the Potterton Solar system within 30 days

s

of installation, or simply call heateam, the service division

of Baxi Heating UK Limited on 08700 603 261

ur promise to you

O

If you experience a fault with your new Potterton Solar

system, we aim to provide a safe and high quality repair

service supported by our dedicated national network of

highly skilled engineers. If your installer can't resolve the

problem for you, we will do everything we can to get an

engineer out to you as quickly as possible. Nothing in this

warranty will affect your statutory consumer rights.

What you need to do if you experience a problemwith

your Potterton Solar system.

You should always contact your installer first because the

fault may not be related to the Potterton Solar system.

If your installer confirms that the fault is within the

Potterton Solar system itself and he/she decides they

cannot repair it our friendly customer service team is

on hand to help. Simply call our service division heateam

on 08700 603 261 to book an engineer visit or for any

general advice that you may need. Our contact centre is

open Monday to Friday 8arn - 6pm, weekends and Bank

Holidays 8.30am - 2pm, excluding Christmas Day and

New Years Day.

When calling heateamyou must have the following

information to hand: -

– Potterton Solar system serial number

– Potterton Solar system model number

– Your installer name, address details and contact details

– Proof of purchase (if you do not have the Potterton

Solar serial number)

Potterton Solar - Solar Thermal Domestic Hot Water System30

Page 31

.0 Warranty

7

What this warranty covers

– Free of charge repair or replacement of components

found to be faulty from manufacture.

– Free of charge replacement of the complete assemblies

provided always that the failure is related to a

manufacturing fault that cannot be repaired or is

beyond repair.

The warranty runs for from the date your product is

installed.

What this warranty does not cover

– Potterton Solar collectors that are installed damaged

or damaged during installation. If a Potterton Solar

collector is found to be damaged on delivery then it

ust not be installed, simply return it to your supplier

m

for replacement under warranty.

– The warranty will become invalid if the failure is due to

frost, transient voltages, lightning strikes or any act of

vandalism or mis use.

– This guarantee does not cover the effects of scale.

– Tampering or modification will invalidate this warranty.

– The installation must be in an appropriate location and

its use is restricted to potable water.

– Due to the varied locations Potterton Solar collector/s

can be installed Baxi Heating UK Ltd will only carry

out warranty repair/replacement to Potterton Solar

collectors which have safe access provided that

meets current Health & Safety working at heights

requirements. Heateam will cover the cost of any safety

equipment required to meet this standard after the first

30 days of installation up to 2 years and will appoint a

contractor to carry this work out. Prior to this contact

your installer. Heateam accept no liability for any third

party damage.

– Repairs to Potterton Solar systems which haven't been

installed and commissioned properly, as set out in the

installation and commissioning instructions.

– Any other defects or failures, either in the connected

system or outside of the Potterton Solar system itself.

– Installations within commercial settings for which this

Potterton Solar system was not designed.

– Reimbursement of any third party repair or

replacement costs that we haven't been told about

and agreed with you in advance.

– Compensation for consequential losses (e.g. loss of

earnings, business losses, stress and inconvenience)

arising from a product breakdown, including repair

delays caused by factors outside our reasonable

control.

Potterton Solar - Solar Thermal Domestic Hot Water System 31

Page 32

All descriptions and illustrations provided in this leaflet have been

carefully prepared but we reser ve the right to make changes and

improvements in our products which may affect the accuracy of the

information contained in this leaflet. All goods are sold subject to

our standard Conditions of Sale which are available on request.

Potterton

A Trading Division of Baxi Heating UK Ltd, a division of Baxi Group.

Brooks House, Coventry Road,Warwick. CV34 4LL

After Sales Service and Technical Enquiries 08700 603261

Our contact centre is open Monday to Friday 8am to 6pm,

Weekends and Bank Holidays 8.30am to 2pm.

We are closed Christmas Day and New Years Day.

Website www.potterton.co.uk

© Baxi Heating UK Ltd 2007.

Comp No 3600 5983 - Issue 1 - 5/07

Loading...

Loading...