Baxi Solo 3 30 PF System, Solo 3 40 PF System, Solo 3 60 PF System, Solo 3 50 PF System, Solo 3 70 PF System Installation And Servicing Instructions

...

Please leave these instructions with the user

Baxi Solo 3PF System

Wall Mounted Powered Flue System Boiler

Gas Fired Central Heating Unit

Comp No 245443 - Issue 1 - 9/99

Installation and

Servicing Instructions

Page 2

Natural Gas

Baxi Solo 3 30 PF System

G.C.No. 41 075 12

Baxi Solo 3 40 PF System

G.C.No. 41 075 13

Baxi Solo 3 50 PF System

G.C.No. 41 075 14

Baxi Solo 3 60 PF System

G.C.No 41 075 15

Baxi Solo 3 70 PF System

G.C.No. 41 075 16

Baxi Solo 3 80 PF System

G.C.No 41 075 17

Baxi Heating Ltd is one of the leading manufacturers of

domestic heating products in the UK.

Our first priority is to give a high quality service to our

customers. Quality is built into every Baxi product -products

which fulfil the demands and needs of customers, offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the products

that customers want to buy.

The boiler meets requirements of Statutory Instrument “The

Boiler (Efficiency) Regulations 1993 No 3083” and is deemed

to meet the requirements of Directive 92/42/EEC on the

efficiency requirements for new hot water boilers fired with

liquid or gaseous fuels:-

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we know

that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If not,

please let us know.

Baxi is a BS-EN ISO 9001

Accredited Company

Type test for purpose of Regulation 5 certified by:

Notified Body 0086.

Product/Production certified by:

Notified Body 0086.

For use in GB / IE only.

Contents - Page 3

Page4668111432343536

Section

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

Introduction

General Layout

Technical Data

System Details

Site Requirement

Installation

Commissioning the Appliance

Fitting the Outercase

Overheat Cut-Off Device

Annual Servicing

Changing Components

Short Parts List

Fault Finding

38

43

44

1.0 Introduction - Page 4

B.S. Codes of Practice

1.1 Description

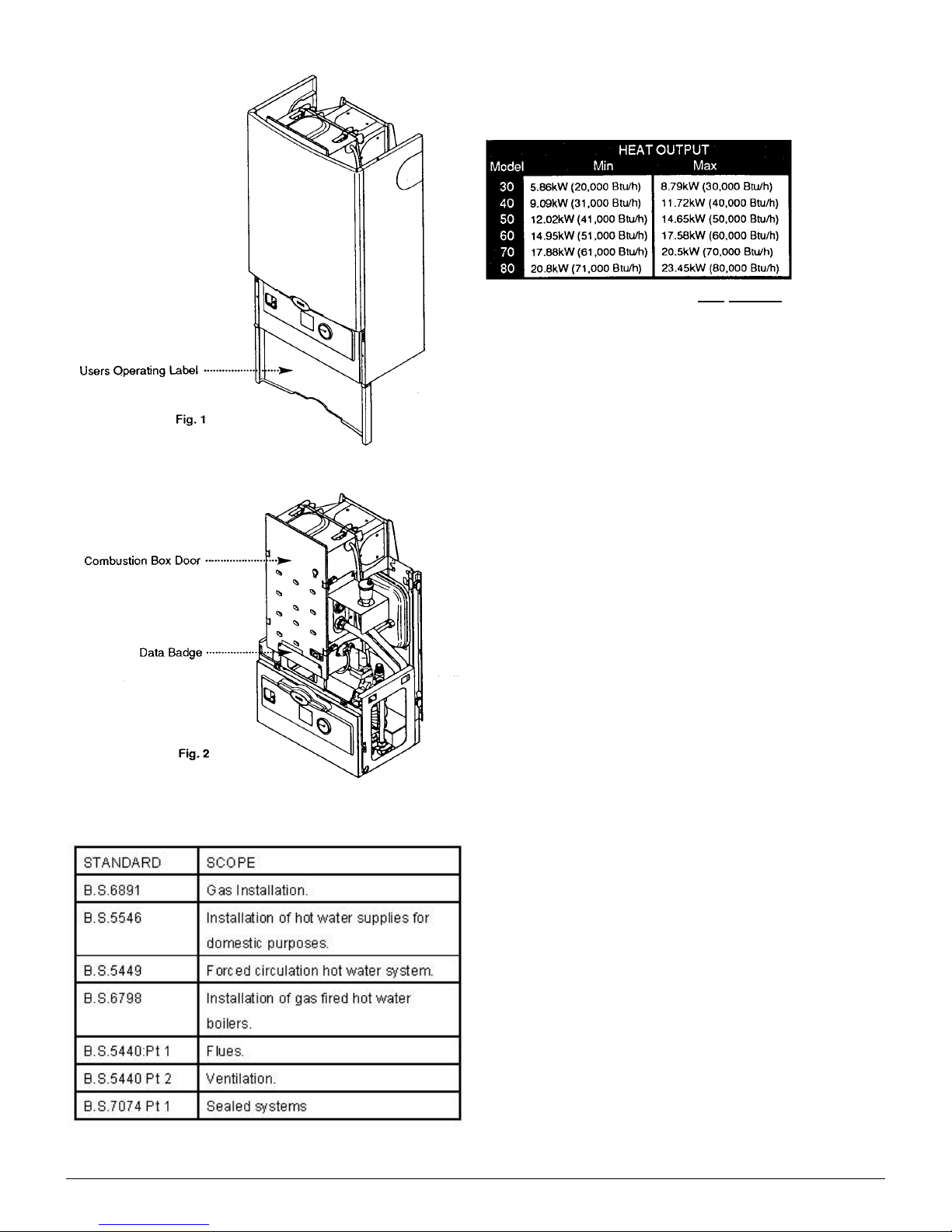

1. The Baxi Solo 3 PF System is a gas fired room sealed

fan assisted central heating system boiler with range rated

outputs as shown in the table below.

2. Each appliance is preset at a MID RANGE heat input

rating and is designed for use on NATURAL GAS only.

3. All boilers are suitable for sealed fully pumped systems

only.

4. The appliance incorporates a circulating pump and

expansion vessel.

5. The appliance data badge is fitted to the combustion box

door, an abbreviated version is on the inside of the front

panel.

6. All illustrations show the Solo 50 3 PF System boiler.

1.2 Installation

1. The appliance is suitable for installation only in G.B. and

I.E. and should be installed in accordance with the rules in

force. For Ireland install in accordance with I.S.813

“INSTALLATION OF GAS APPLIANCES”. The installation must be

carried out by a CORGI Registered Installer or other

competent person and be in accordance with the relevant

requirements of the current GAS SAFETY (Installation and

Use) REGULATIONS, the BUILDING REGULATIONS (Scotland)

(Consolidation), the LOCAL BUILDING REGULATIONS, the

CURRENT I.E.E. WIRING REGULATIONS and the bye laws of the

Local Water Undertaking. Where no specific instructions are

given, reference should be made to the relevant BRITISH

STANDARD CODES OF PRACTICE.

2. All systems must be thoroughly flushed and treated

with inhibitor (see Section 4.2).

1.3 Important Information

COSHH Regulations

This product contains Refractory Ceramic Fibres (R.C.F.)

which are man-made vitreous silicate fibres. Excessive

exposure to these materials may cause temporary irritation

to eyes, skin and respiratory tract. Care must be taken when

handling these articles to ensure the release of dust or fibres

is kept to a minimum.

To ensure that the release of fibres from these articles is

kept to a minimum, during installation and servicing it is

recommended that a H.E.P.A. filtered vacuum is used to

remove any dust, soot or other debris accumulated in and

around the appliance. This should be performed before and

after working on the installation.

It is recommended that any replaced item(s) are not broken

up but sealed within heavy duty polythene bags and clearly

labelled “R.C.F. waste”. This is not classified as “hazardous

waste” and may be disposed of at a tipping site licensed for

the disposal of industrial waste. Protective clothing is not

required when handling these articles but it is recommended

that gloves are worn and the normal hygiene rules of not

smoking, eating or drinking in the work area are followed and

always wash hands before eating or drinking.

2.0 General Layout - Page 5

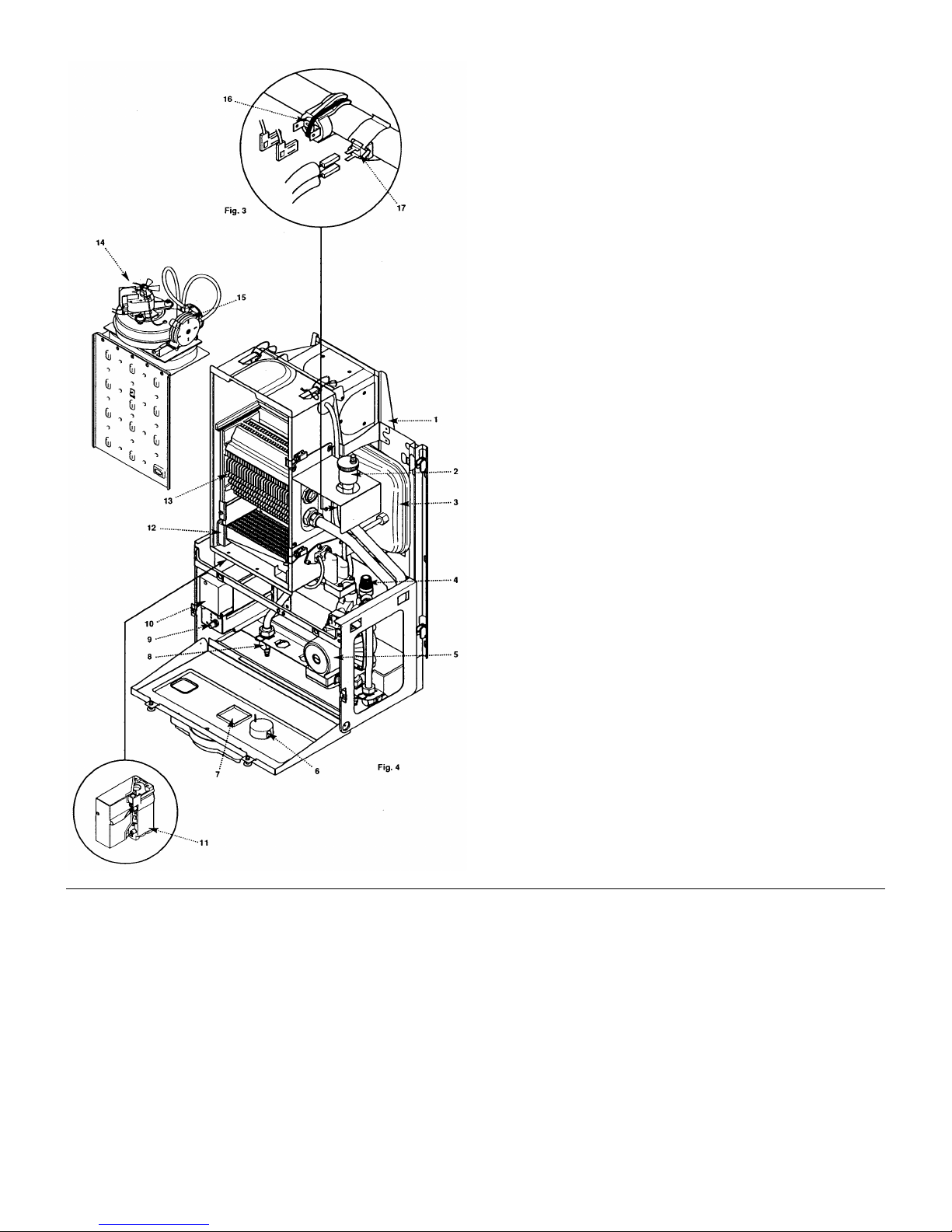

2.1 Layout (Figs. 3 & 4)

1. Wall Plate

2. Automatic Air Vent

3. Expansion Vessel

4. Pressure Relief Valve

5. Circulation Pump

6 Water Pressure Gauge

7. Position of Optional Timer

8. Gas Tap

9. Control Knob

10. Electronics Housing

11. Gas Valve

12. Burner

13. Heat Exchanger

14. Fan Assembly

15. Pressure Switch

16. Overheat Thermostat

17. Thermostat Sensor

3.0 Technical Data - Page 6

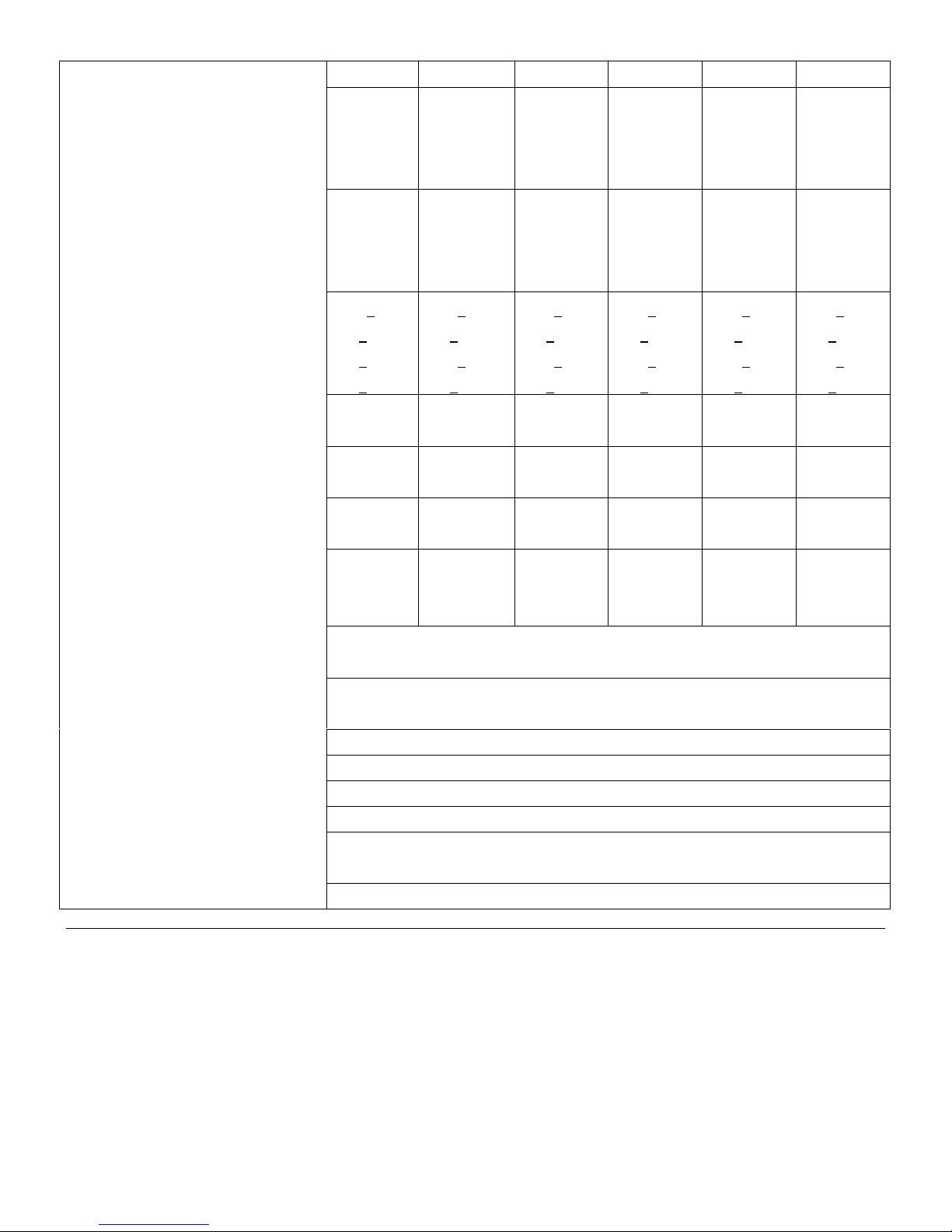

Model 30 40 50 60 70 80

Heat Output (Max) kW 8.9 11.72 14.65 17.58 20.5 23.45

Btu/h 30,000 40,000 50,000 60,000 70,000 80,000

Heat Output (Min) kW 5.86 9.09 12.02 14.95 17.88 20.8

Btu/h 20,000 31,000 41,000 51,000 61,000 71,000

Heat Input (Max) kW 10.99 14.65 18.32 21.98 25.64 29.31

Btu/h 37,500 50,000 62,500 75,000 87,500 100,000

Heat Input (Min) kW 7.33 11.36 15.02 18.68 22.35 26.01

Btu/h 25,000 38,750 51,250 63,750 76,250 88,750

Burner Pressure (Max) mbar 16.0 + 0.5 16.0 + 0.5 16.0 + 0.5 16.0 + 0.5 16.0 + 0.5 16.0 + 0.5

in wg 6.4 + 0.2 6.4 + 0.2 6.4 + 0.2 6.4 + 0.2 6.4 + 0.2 6.4 + 0.2

Burner Pressure (Min) mbar 8.0 + 0.5 10.0 + 0.5 11.5 + 0.5 11.5 + 0.5 12.1 + 0.5 11.5 + 0.5

in wg 3.2 + 0.2 4.0 + 0.2 4.4 + 0.2 4.4 + 0.2 4.8 + 0.2 4.4 + 0.2

Gas Rate CV38MJm

(after 10 mins) 36.86ft3/h 49.0ft3/h 61.3ft3/h 73.5ft3/h 86.75ft3/h 98.1ft3/h

Lifting Weight kg 40 40 40 49.1 49.1 49.1

Water Content litres 2.1 2.1 2.1 2.6 2.6 2.6

3

1.04m 3/h 1.39m 3/h 1.74m 3/h 2.08m 3/h 2.43m 3/h 2.78m 3/h

lbs 88 88 88 108 108 108

pints 3.2 3.2 3.2 4.5 4.5 4.5

Outercase Height 850mm 850mm 850mm 850mm 850mm 850mm

Dimensions Width 490mm 490mm 490mm 490mm 490mm 490mm

Depth 320mm 320mm 320mm 320mm 320mm 320mm

Flue Terminal Diameter 100mm

Dimensions Depth 70mm

Connections Flow 22mm Cu tail

Return 22mm Cu tail

Heat Exchanger Cast iron monobloc

System Design fully pumped sealed systems only

Gas Connection 22m Cu tail

Electrical Supply 230V ~ 50 Hz fused 5A - 90W

Controls boiler thermostat, intermittent pilot & electronic flame sensing,

timed pump over-run, frost protection thermostat

Internal Fuse 4AF 250V to BS4256 situated on control board

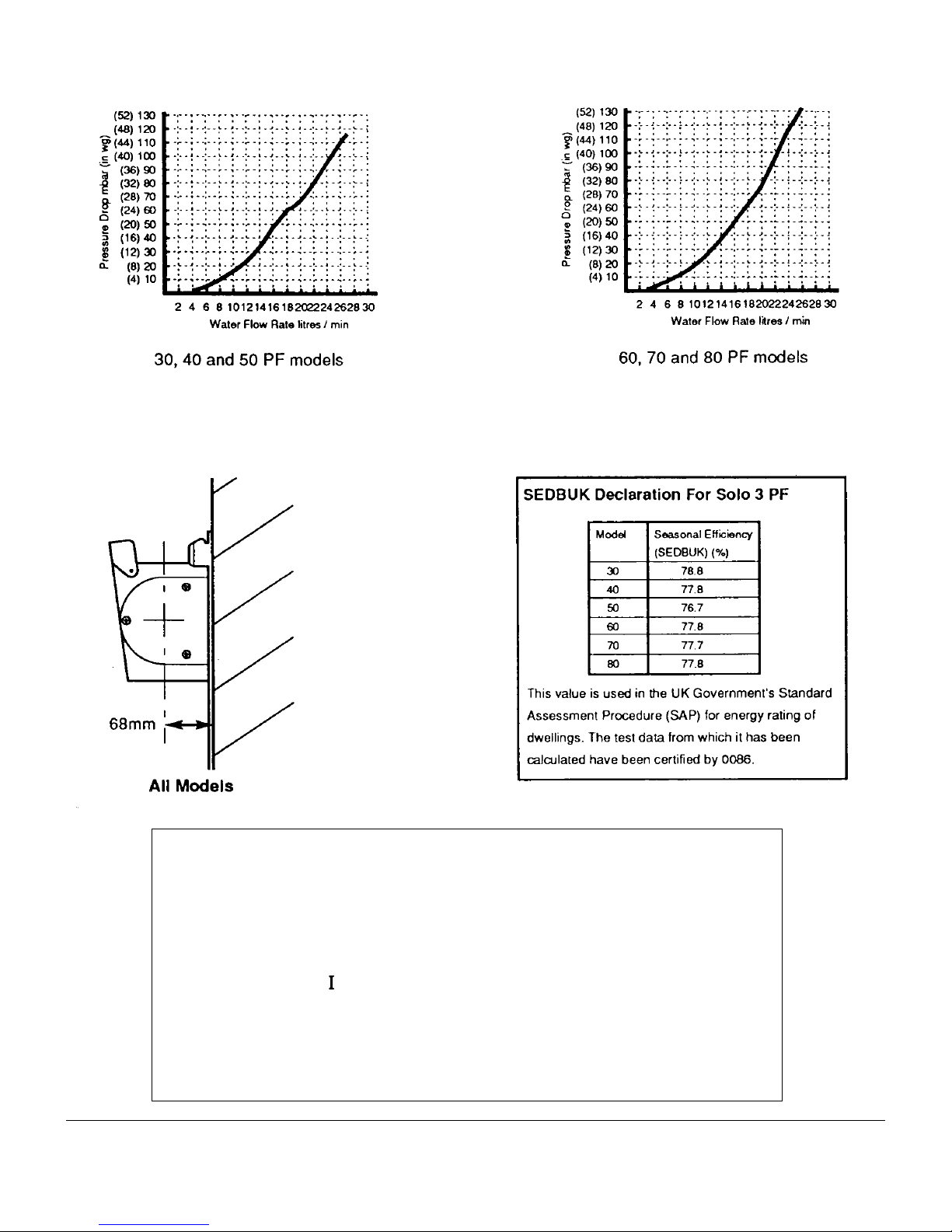

3.0 Technical Data - Page 7

Hydraulic Resistance Charts

• This appliance is only intended for installation on a governed supply.

• PMS = 3 bar pressure class 2

• Max CH water pressure 3 bar

• Type C12 C

32

• Nox class 2

• Appliance category

• Ret: 86/AU/588

• Burner Injector Sizes: 30=B31 40=B32 50=B33 60=B34 70=B35 80=B36

• This boiler is designed to operate at a maximum water temperature of 85º C.

2H - G20 - 20mbar

2H

4.0 System Details - Page 8

4.1 Water Circulating Systems

Water Circulating Systems

1. The appliance is suitable for fully pumped sealed systems

only.

The following conditions should be observed on all

systems:

• The boiler must not be used with a direct cylinder.

• Drain cocks should be fitted to all system low points.

• All gas and water pipes and electrical wiring must be

installed in a way which would not restrict the servicing of the

boiler.

• Air vents should be fitted to all system high points.

• All components used in the system must be suitable for

operation at 110ºC (230ºF).

4.2 Treatment of Water Circulating Systems

• All recirculatory water systems will be subject to

corrosion unless an appropriate water treatment is applied.

This means that the efficiency of the system will deteriorate

as corrosion sludge accumulates within the system, risking

damage to pump and valves, boiler noise and circulation

problems.

• For optimum performance after installation this boiler

and its associated central heating system must be flushed in

accordance with the guidelines given in BS 7593:1992

“Treatment of water in domestic hot water central heating

systems”.

• This must involve the use of a proprietary cleanser, such

as BetzDearborn Sentinel X300 or X400, or Fernox

Superfloc. Full instructions are supplied with the products,

but for immediate information please contact BetzDearborn

(0151 420 9563) or Fernox (01799 550 811) directly.

• For long term protection against corrosion and scale,

after flushing it is recommended that an inhibitor such as

BetzDearbom Sentinel X100, or Femox MB-1 or Copal is

dosed in accordance with the guidelines given in BS

7593:1992.

Failure to flush and add inhibitor to the system may

invalidate the appliance warranty.

• It is important to check the inhibitor concentration after

installation, system modification and at every service in

accordance with the manufacturers instructions. (Test kits

are available from inhibitor stockists.)

• For information or advice regarding any of the above

contact the Baxi Helpline.

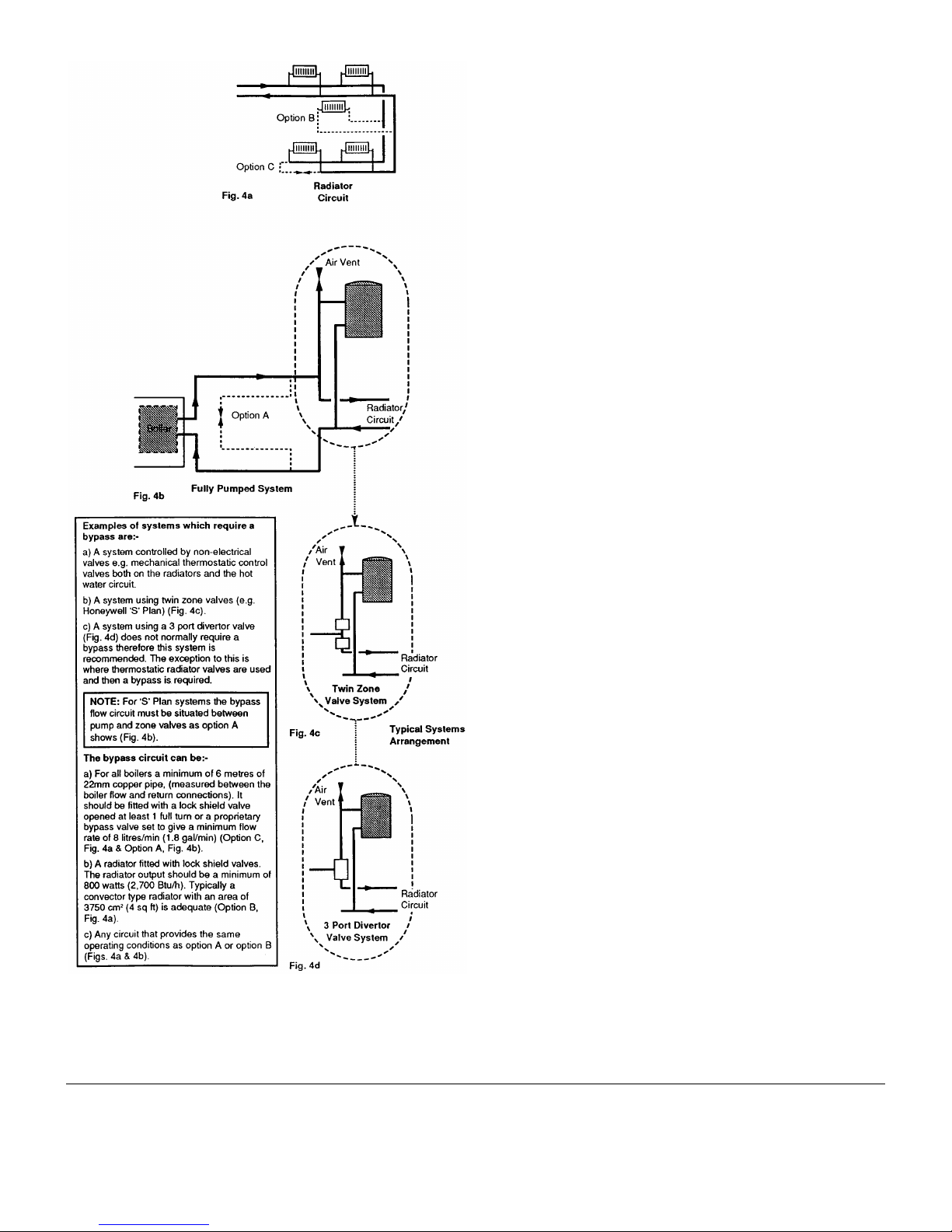

4.3 Bypass Requirements

1. The boiler is fitted with a pump overrun device which

allows the removal of residual heat from the boiler.

NOTE: The pump overrun will operate for approximately

8 minutes. The system design must therefore always

provide an open circuit for water to circulate between

the boiler flow and return.

4.0 System Details - Page 9

4.4 Pipework

1. The sizes of flow and return pipes from the boiler should

be determined by normal methods, according to the

requirements of the system.

2. The connections to the boiler are 22mm copper tails.

4.5 System Controls

1. For optimum operating conditions, the heating system

into which the boiler is installed should include a control

system.

2. Such a system will comprise of a timer control and

separate room or cylinder thermostats as appropriate. (An

integral twin channel programmer is available as an optional

extra).

3. The boiler should be controlled so that it operates on

demand only.

4. Operation of the system under control of the boiler

thermostat & TRV’s only does not produce the best results

4.6 Thermal Stores & Heat Stores

1. If a thermal store or heat store is being used, it should be

one approved for use with the Baxi Solo 3 PF System Boiler.

4.0 System Details - Page 10

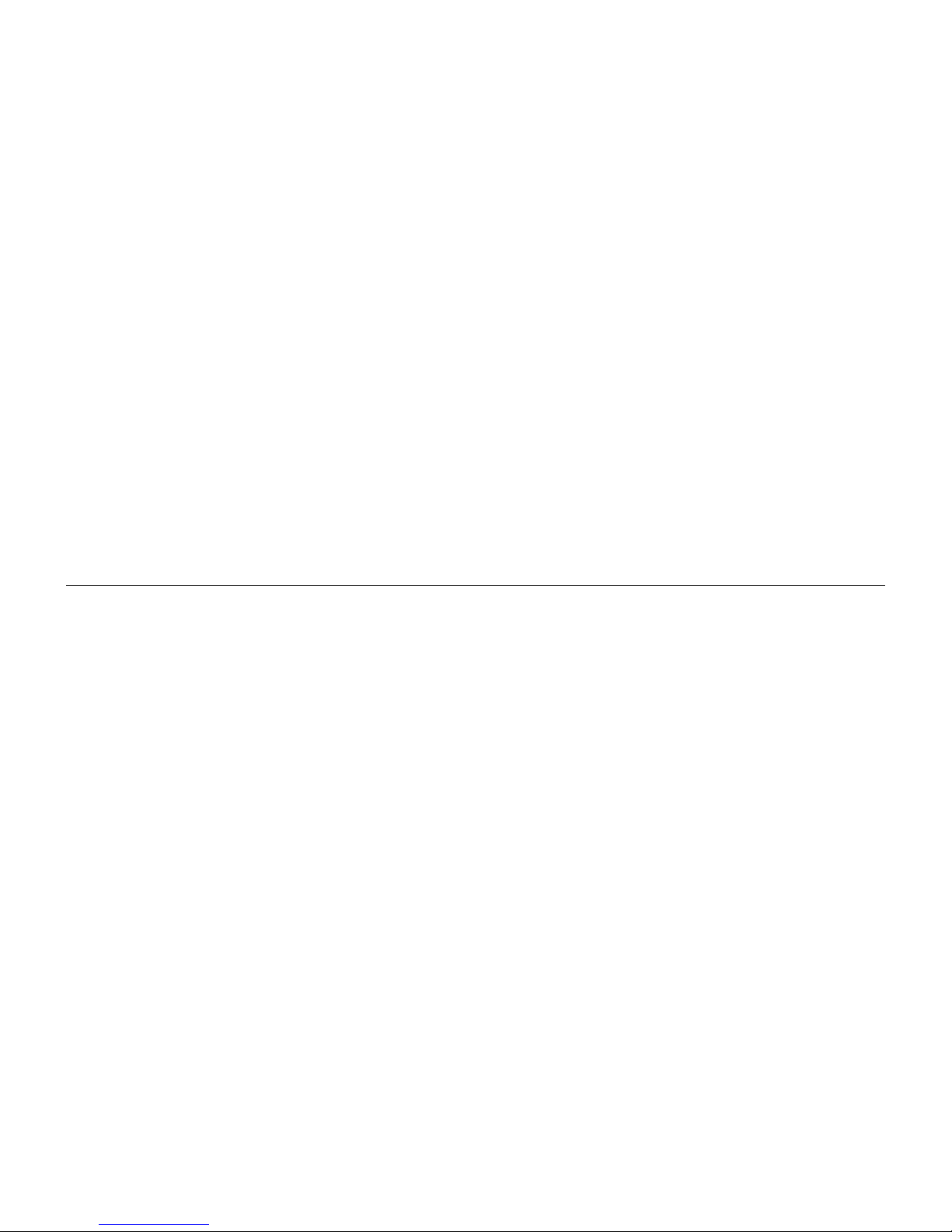

4.7 System Filling and Pressurising

1. A filling point connection on the central heating return

pipework must be provided to facilitate initial filling and

pressurising and also any subsequent water loss

replacement/refilling.

2. The filling method adopted must be in accordance with all

relevant water supply bye-laws and use approved

equipment.

3. Your attention is drawn to: RN 302 and Byelaw

14.

4. The sealed primary circuits may be filled or replenished

by means of a temporary connection (Filling Loop) between

the circuit and a supply pipe, provided a WRC approved

double check valve or some other no less effective backflow

prevention device is permanently connected at the inlet to

the circuit and the temporary connection (Filling Loop) is

removed after use (Fig. 5).

4.8 Expansion Vessel

1. The appliance expansion vessel is pre-charged to 1 bar

(10 lb/in2). Therefore, the minimum cold fill pressure is 1 bar.

The vessel is suitable for correct operation for system

capacities up to 125 litres (27.5gal). For greater system

capacities an additional expansion vessel must be fitted refer to BS 7074 Pt 1.

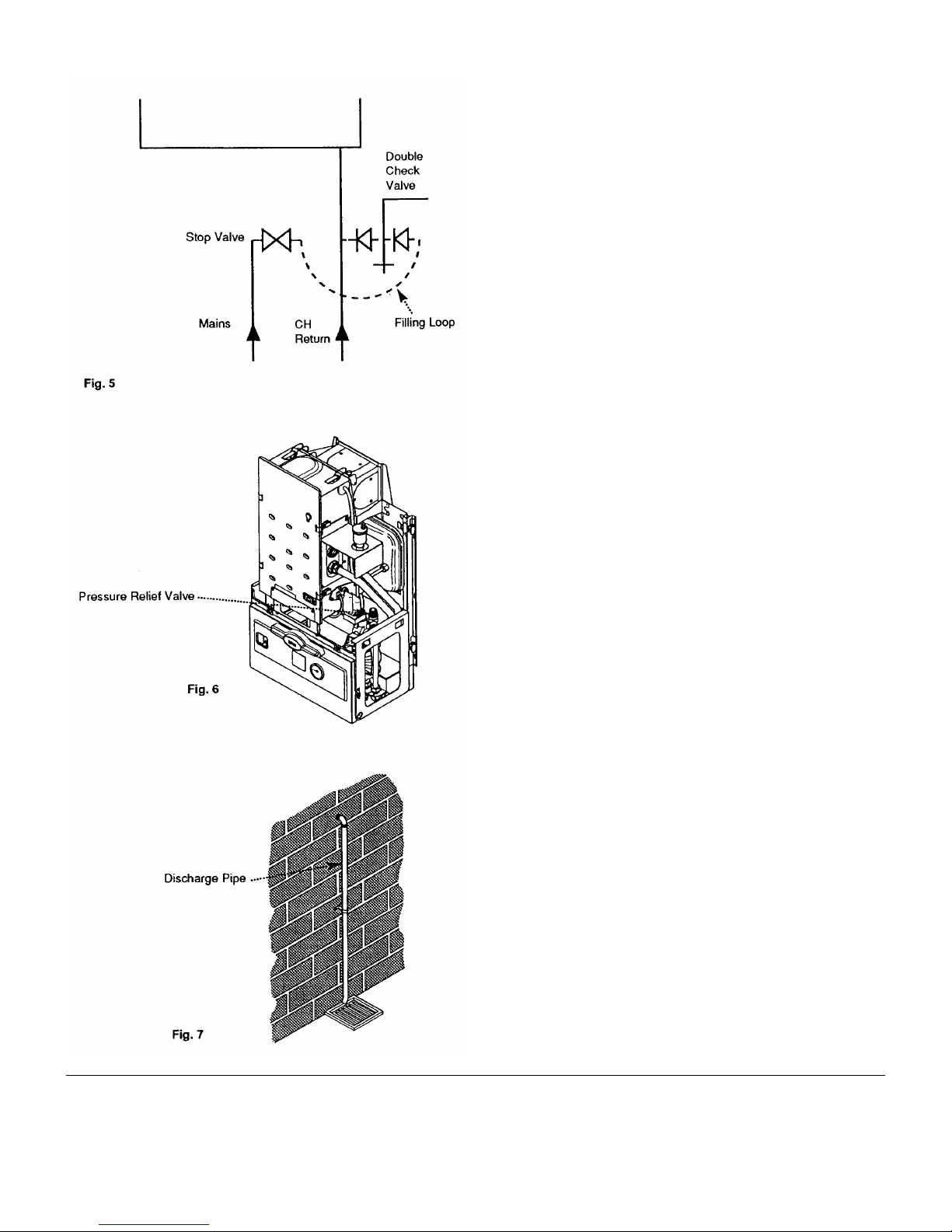

4.9 Pressure Relief Valve (Figs. 6 & 7)

1. The pressure relief valve is set at 3 bar, therefore all

pipework, fittings, etc. should be suitable for pressures in

excess of 3 bar.

2. The pressure relief discharge pipe should be not less

than 15mm dia, run continuously downward, and discharge

outside the building, preferably over a drain. It should be

routed in such a manner that no hazard occurs to occupants

or causes damage to wiring or electrical components. The

end of the pipe should terminate facing down and towards

the wall.

3. The discharge must not be above a window, entrance or

other public access. Consideration must be given to the

possibility that under fault conditions boiling water/steam

could discharge from the pipe.

4. The pressure relief valve must not be used for draining

the system/boiler.

5.0 Site Requirements - Page 11

5.1 Location

1. The appliance may be fitted to any suitable wall with the

flue passing through an outside wall and discharging to

atmosphere in a position permitting satisfactory removal of

combustion products and providing an adequate air supply.

The appliance should be fitted within the building unless

otherwise protected by a suitable enclosure ie. garage or

outhouse. (The appliance may be fitted inside a cupboard.

Cooling ventilation and insulation of the cupboard are not

required, see section 5.5.)

2. If the appliance is fitted in a room containing a bath or

shower reference must be made to the Current l.E.E. Wiring

Regulations and Building Regulations. If the appliance is to

be fitted into a building of timber frame construction then

reference must be made to the Institute of Gas Engineers

document UP7 (“Guide for Gas Installation in Timber

Framed Dwellings”).

3. Recommendations for flues are given in BS 5440 Part 1.

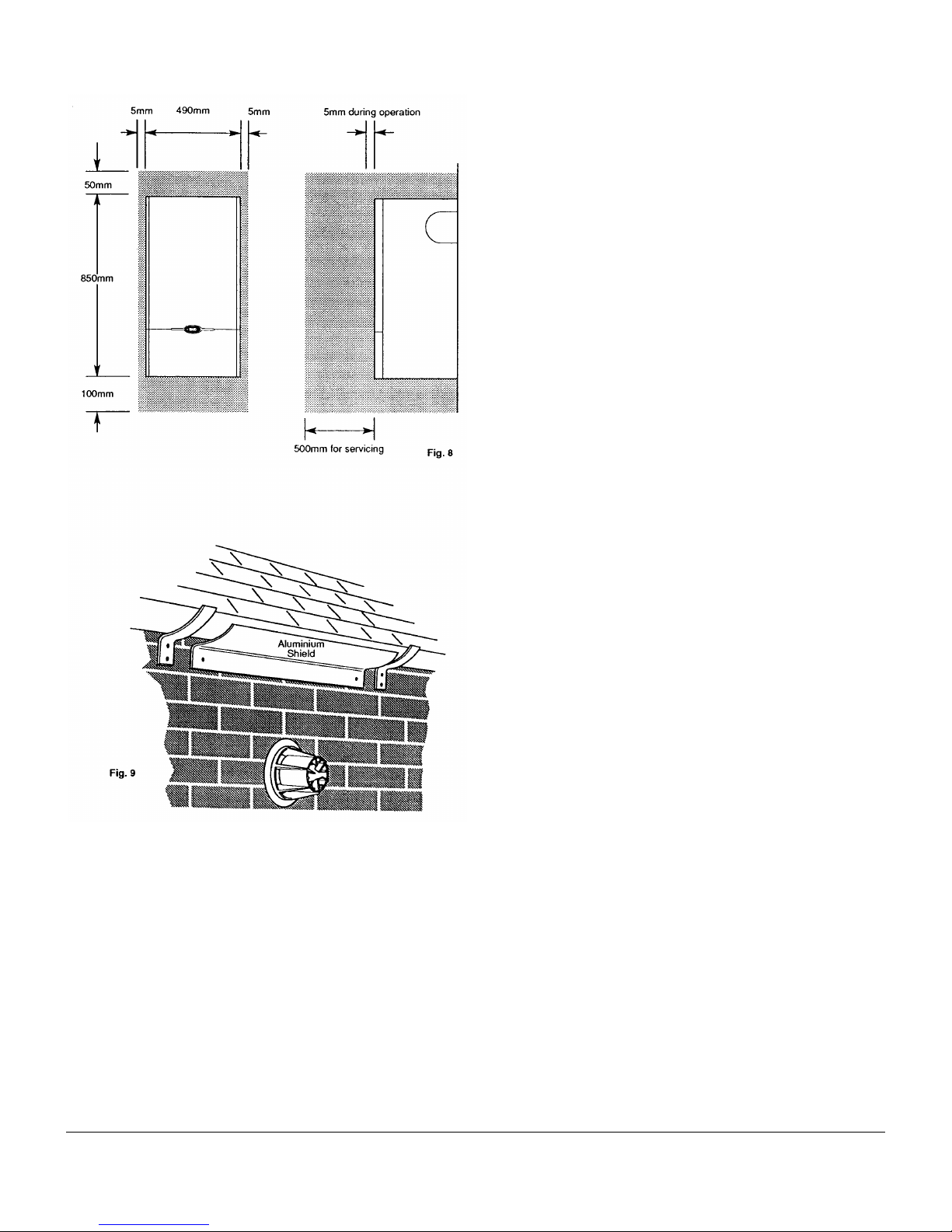

5.2 Minimum Clearances (Fig. 8)

1. A flat vertical area is required for the installation of the

boiler.

2. These dimensions include the necessary clearances

around the appliance for case removal, spanner access and

air movement. Additional clearances may be required for the

passage of pipes around local obstructions such as joists

running parallel to the front face of the appliance.

3. If fitted inside a cupboard the clearance of 500mm shown

is only necessary when the cupboard door is open. A

clearance of 5mm (3/16 in) is required when the door is

closed.

5.3 Flue Position

1. For installations where the flue terminal is inaccessible

from the outside, an internal fitting kit is available. This can

be obtained free of charge from your local merchant.

2. The following guide lines indicate the general

requirements for siting balanced flue terminals.

3. If the terminal is fitted within 1 metre (39in) of a plastic

gutter, within 500mm (19½ in) of a painted eave or a painted

gutter, an aluminium shield of at least 1 metre (39in) long

should be fitted to the underside of the gutter or painted

surface. An air space of 5mm (3/16 in) should be left between

shield and gutter (Fig. 9).

4. If the terminal discharges onto a pathway or passageway,

check that combustion products will not cause a nuisance

and that the terminal will not obstruct the passageway.

5. If the outer surface of an outside wall is of combustible

material, it should be protected by fitting the flue film

provided.

5.0 Site Requirements - Page 12

5.3 Flue Position (Cont)

WARNING - The addition of anything that may interfere

with the normal operation of the appliance (e.g. FLUE

DAMPERS, ECONOMISERS,etc.) without the express

written permission of Baxi Heating Ltd could invalidate

the appliance warranty and Infringe the GAS SAFETY

(Installation and Use) REGULATIONS.

If a terminal is less than 2 metres (78¾ in) above a

balcony, above ground or above a flat roof to which

people have access then a suitable terminal guard must

be provided.

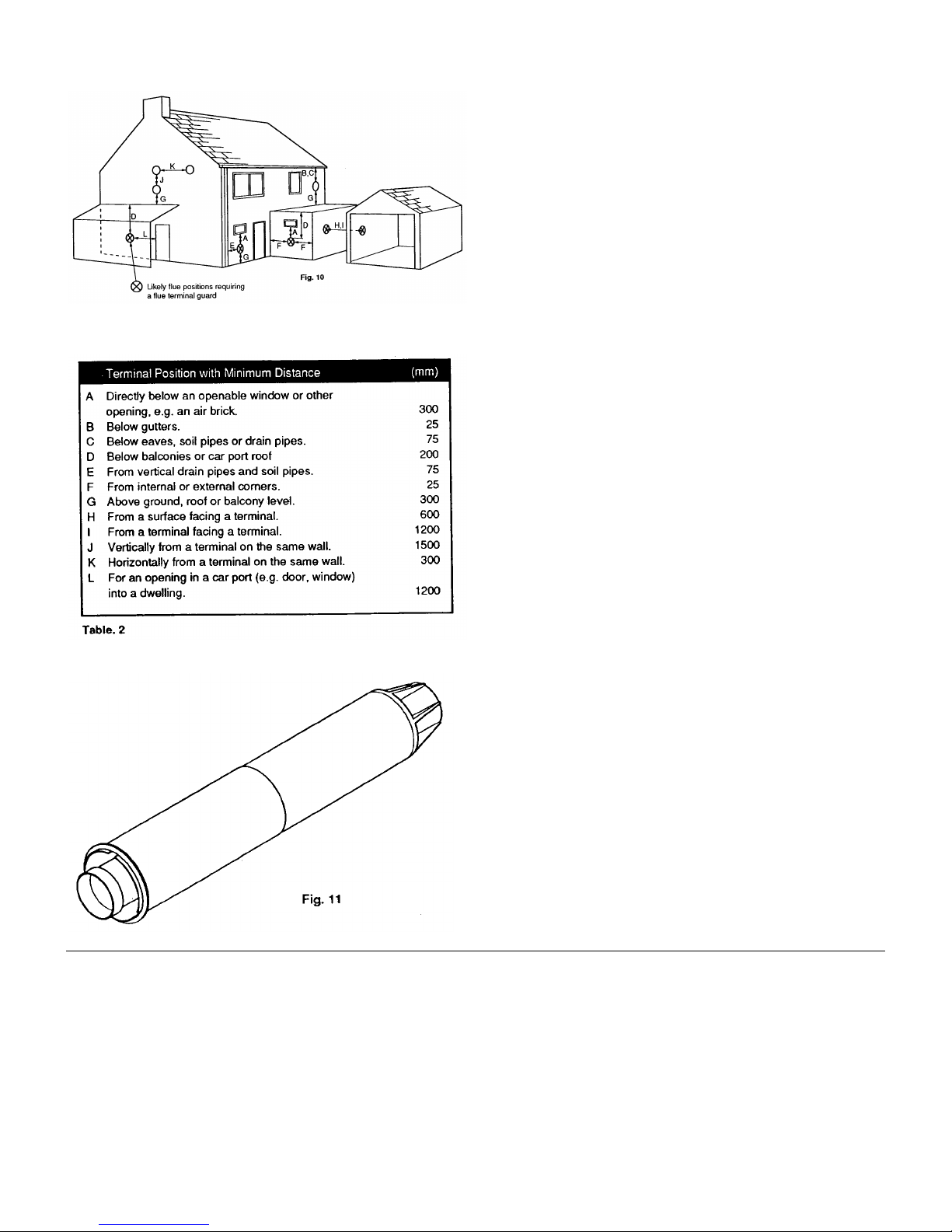

6. Table 2 and Fig. 10 show the positioning of the flue

terminal relative to buildings and other structures.

7. The dimensions of the flue terminal are shown on page 6.

5.4 Flue Dimensions

1. Flue extensions are available as optional extras for

installations up to 3 metres (1181/8 in) horizontal.

2. Vertical flue kits are available up to 4 metres in

length. Vertical twin flue kits are available up to 15

metres In length.

3. The standard flue supplied with the appliance is suitable

for use with flue lengths between 100mm (4in) and 500mm

(195/8 in).

NOTE: Maximum flue length when flued to the left or

right is

350mm - Left Hand Flue

330mm - Right Hand Flue

4. Where it is intended to pass the flue through a

combustible wall or timber framed dwelling, reference should

be made to the Institute of Gas Engineers document UP7 Guide for Gas Installations in Timber Framed Dwellings.

5. If the flue is more than 1 metre (393/8 in) long, it is

required that it is supported.

6. All above dimensions are taken from the respective

faces of the outer case.

5.0 Site Requirements - Page 13

5.5 Ventilation of Compartments

1. Where the appliance is installed in a cupboard or

compartment, no air vents are required.

NOTE: The ventilation label on the front of the outer

case MUST NOT BE REMOVED when the appliance is

installed in a compartment or cupboard.

2. B.S. 5440 Part 2 Clause 4.2 refers to room sealed

appliances installed in compartments. This appliance will run

sufficiently cool without ventilation.

5.6 Gas Supply

1. The gas installation should be in accordance with BS

6891.

2. The connection of the appliance is a 22mm copper tail on

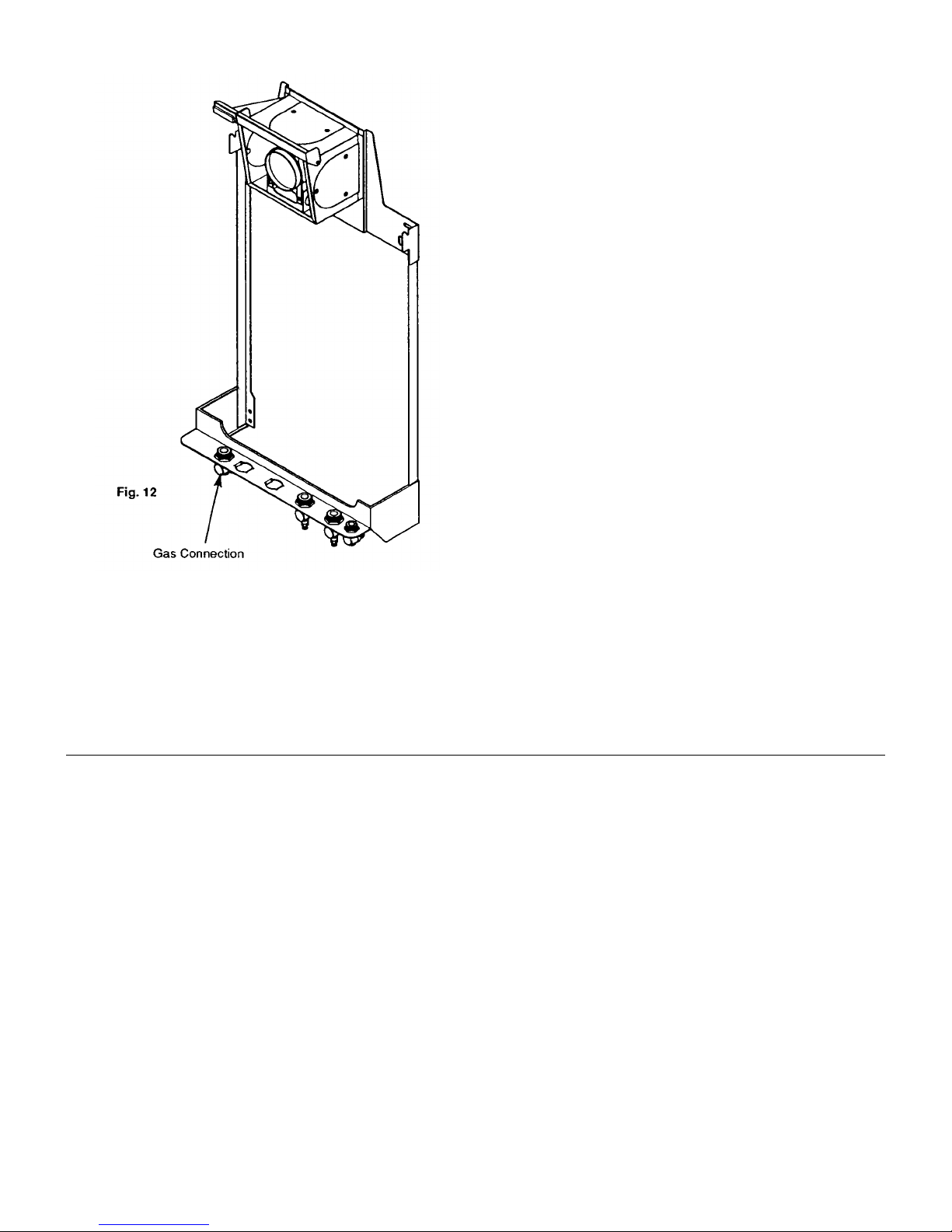

the tap rail (Fig. 12).

3. The pipework should be sized to account for the distance

of the appliance from the meter, the pipe routing and

maximum input of the appliance.

5.7 Electrical Supply

External wiring must be correctly earthed, polarized and in

accordance with CURRENT I.E.E. WIRING REGULATIONS.

The mains supply is 230V ~ 50Hz fused at 5A.

NOTE: The method of connection to the electricity

supply must facilitate complete electrical isolation of the

appliance.

Connection may be made via a fused double-pole isolator

with a contact separation of a least 3mm in all poles and

serving the appliance and system controls only.

6.0 Installation - Page 14

6.1 Initial Preparation

1. Remove the hinged lower door panel from the outer case

by opening it to 90º and pulling forwards (Fig. 13).

2. Remove the 2 screws holding the outer case to the

combustion box (Fig. 13).

3. Place the outer case in a safe place until required.

4. Remove the R clip from the latch securing the

combustion box to the back plate and release the latches

(Fig. 14a & 14b).

5. Lift and remove the combustion box and backplate from

the wall plate (Fig. 14). Place the combustion box and

backplate on its back.

IMPORTANT - When installing a Solo 3 System with a

rear flue see section 6.2 Fan Outlet Restrictor before

continuing the installation.

6. Proceed to the relevant section for flueing the appliance

either to the Rear, Left, Right or Vertically.

NOTE: For Vertical flueing or flue lengths greater than

standard, the relevant optional extra kits must be

obtained and their instructions followed.

Loading...

Loading...