Baxi Sirius FS 90, Sirius FS 105, Sirius FS 130, Sirius FS 160 Installation, Operation & Maintenance Manual

Page 1

Working towards

a cleaner future

Sirius FS

90-105-130-160

Floor Standing Condensing Gas Boilers

Installation, Operation & Maintenance Manual

To be kept by the user October 2010

heating specialists

Page 2

2

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

Dear Customer,

We are sure your new boiler will comply with all your requirements.

Do not dispose of this booklet. This manual contains the information, which will help you to

run your boiler correctly and efciently.

POTTERTON COMMERCIAL boilers bear the CE mark in compliance with the basic

requirements as laid down in the following Directives:

- Gas Directive 90/396/EEC

- Efciency Directive 92/42/EEC

- Electromagnetic Compatibility Directive 2004/108/EEC

- Low Voltage Directive 2006/95/EC

Do not leave any parts of the packaging (plastic bags, polystyrene, etc.) within children’s reach as they are a

potential source of danger.

ATTENTION

This boiler can only be installed and operate

in permanently, ventilated rooms in accordance with

BS6644

Page 3

3

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

1. Instructions prior to installation 4

2. Instructions prior to commissioning 4

3. Commissioning of the boiler 5

4. Filling the boiler 12

5. Switching the boiler off 12

6. Prolonged standstill of the system. Frost protection 12

7. Servicing instructions and gas change 12

8. General information 13

9. Instructions prior to installation 13

10. Boiler installation and dimensions 14

11. Chimney ue connection 21

12. Connecting the mains supply 23

13. Adjusting the gas valves and gas change 29

14. Setting the boiler parameters 33

15. Control and operation devices 34

16. Positioning of the ignition and ame sensing electrode 35

17. Check of combustion parameters 35

18. Activating the chimney-sweep function 36

19. Annual service 36

20. Boiler schematic 37

21. Illustrated wiring diagram 38-39

22. Technical data 40

CONTENTS

INSTRUCTIONS PERTAINING TO THE USER

INSTRUCTIONS PERTAINING TO THE INSTALLER

Page 4

4

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

This boiler is designed to heat water at a lower than boiling temperature at atmospheric pressure. The boiler must be

connected to a central heating system and/or to a domestic hot water supply system in compliance with its performances

and output power.

The boiler must be installed by a Qualied Service Engineer and ensure the following operations are carried out:

a) Check that the boiler is t for operation with the type of gas available. For more details see the notice on the packaging

and the label on the appliance itself.

b) Careful checking that the ue terminal draft is appropriate; that the terminal is not obstructed and that no other appliance

exhaust gases are expelled through the same ue duct, unless the ue is especially designed to collect the exhaust gas

coming from more than one appliance, in conformity with the standards and regulations in force.

c) Careful checking that, in case the ue has been connected to pre-existing ue ducts, thorough cleaning has been carried

out in that residual combustion products may come off during operation of the boiler and obstruct the ue duct.

d) To ensure correct operation of the appliance and avoid invalidating the warranty, observe the following precautions:

1. Heating circuit

1.1. New system

Before proceeding with installation of the boiler, the system must be cleaned and ushed out thoroughly to eliminate

residual thread-cutting swarf, solder and solvents if any, using suitable proprietary products.

To avoid damaging metal, plastic and rubber parts, use only neutral cleaners, i.e. non-acid and non alkaline. The

recommended products for cleaning are:

SENTINEL X300 or X400 and FERNOX heating circuit restore. The use of this product must be strictly in accordance

with the maker’s directions. Finally the system must be dosed with a suitable inhibitor at 1% system volume.

1.2. Existing system

Before proceeding with installation of the boiler, the system must be cleaned and ushed out to remove sludge and

contaminants, using suitable proprietary products as described in section 1.1.

To avoid damaging metal, plastic and rubber parts, use only neutral cleaners, i.e. non-acid and non-alkaline such

us SENTINEL X100 and FERNOX heating circuit protective. To use this product proceed strictly in accordance with

the maker’s directions. Dose with inhibitor.

Remember that the presence of foreign matter in the heating system can adversely affect the operation of the boiler

(e.g. overheating and noisy operation of the heat exchanger).

Failure to observe the above will render the warranty null and void.

1. INSTRUCTIONS PRIOR TO INSTALLATION

Initial lighting of the boiler must be carried out by a qualied service engineer. Ensure the following operations are carried

out:

a) compliance of boiler parameters with (electricity, water, gas) supply systems settings.

b) compliance of installation with the standards and regulations in force.

c) appropriate connection to the power supply and earthing of the appliance.

Failure to observe the above will render the warranty null and void.

The instructions shall state the substance of the following:

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

2. INSTRUCTIONS PRIOR TO COMMISSIONING

Page 5

5

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

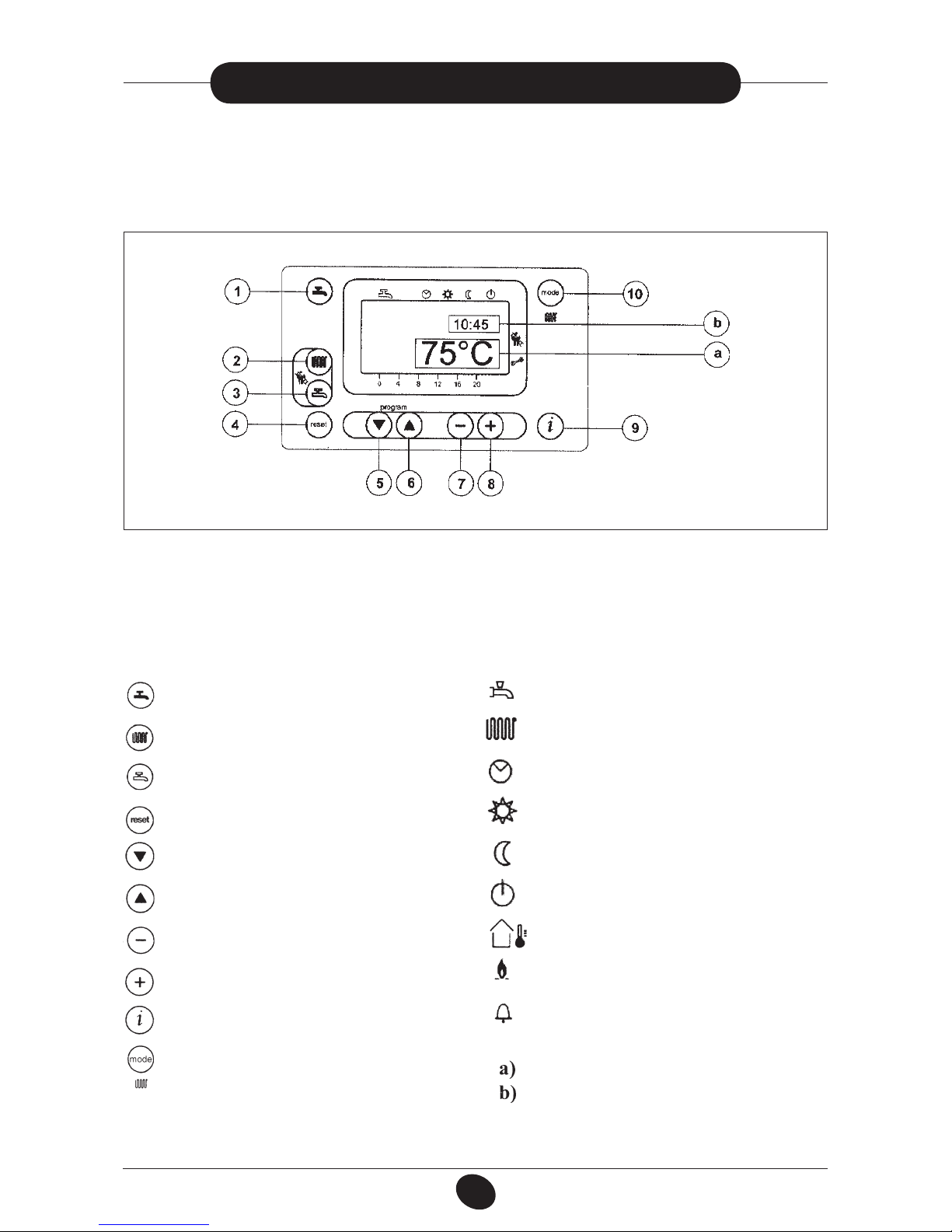

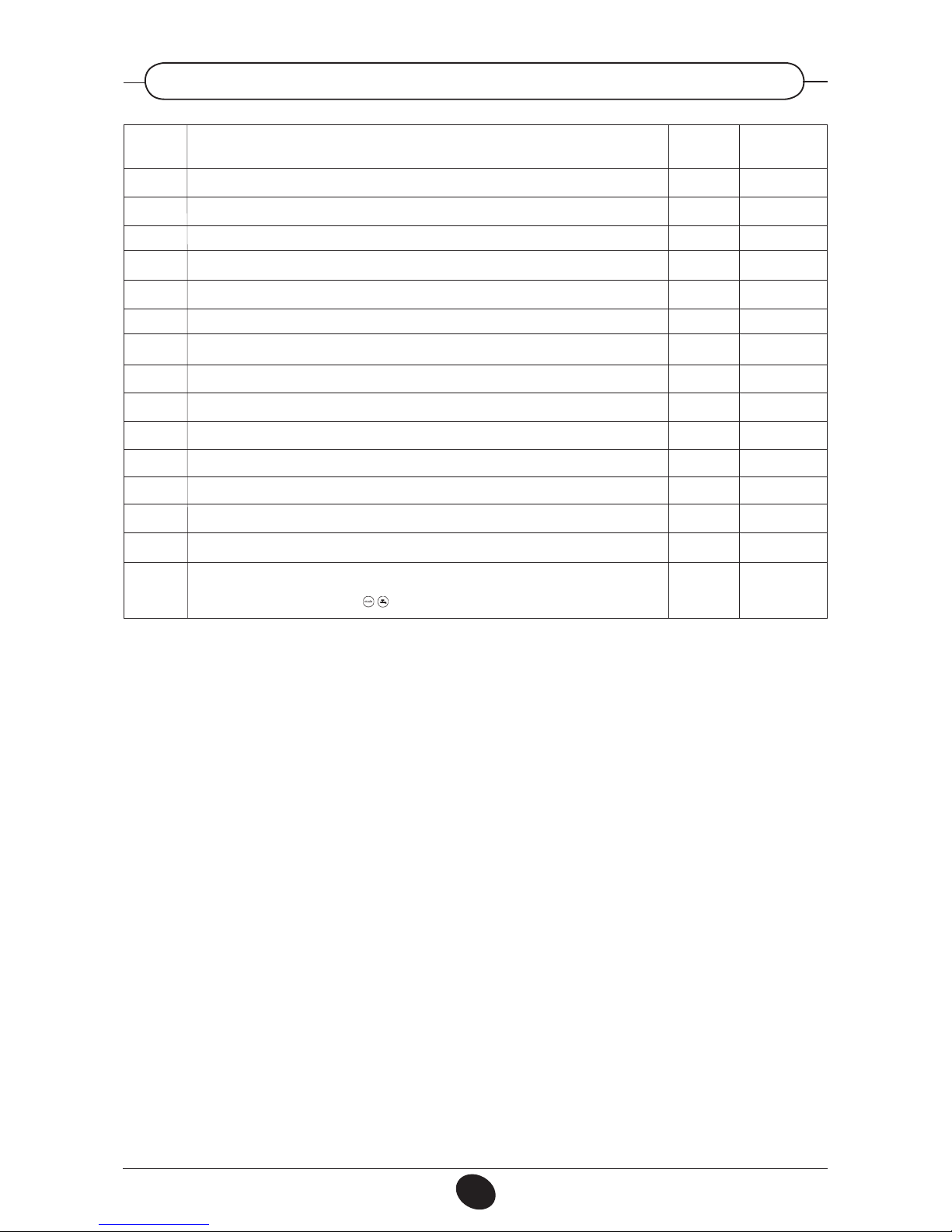

KEYS DISPLAY SYMBOLS

Central heating mode setting key

Data display reset key

Parameter setting key (increase value)

Parameter setting key (decrease value)

Program access and scroll key

Program access and scroll keys

Reset key

Domestic hot water temperature setting key

Central heating water temperature setting key

Domestic hot water on/off key

Resettable alarm warning

MAIN display

SECONDARY display

Flame present (on)

Outdoor temperature

Standby (off)

Operation in manual mode at minimum temperature

Operation in manual mode at the maximum

temperature set

Operation in automatic mode

Operation in central heating mode

Operation in domestic hot water mode

020503_1100

Figure 1

IMPORTANT: Domestic Hot Water (D.H.W.) instructions discribed here, are to be taken into account only

if the boiler is connected to a D.H.W. production system.

To correctly light the burner proceed as follows:

1) Provide power supply to the boiler;

2) Open the gas cock;

3) Follow the directions given below regarding the adjustments to be made at the boiler control panel.

3. COMMISSIONING OF THE BOILER

Page 6

6

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

020503_0800

Figure 2

•

Automatic operation. Operation of the boiler is controlled by the timed program as described

in point 3-5.1 “Daily timed program for operation of the central heating system”;

•

Manual operation at the maximum temperature set. The boiler comes into operation regardless

of the timed program set. The operating temperature is that set using the key (point 3-3:

“Setting the maximum central heating temperature”);

•

Manual operation at minimum temperature. The operating temperature is that set in point

3-6: “setting the minimum central heating temperature”.

•

Standby. The boiler does not work in central heating mode, although the antifreeze function is

still enabled.

(1) Domestic hot water on/off key: This key can be pressed to activate or deactivate this function,

which is identied on the display by a black cursor line under the symbol .

(4) Reset key. In case of a fault, referred to in point 3-7 “Faults and resetting the boiler”, the boiler can

be restarted by pressing this key for at least two seconds (see 3-8).

If this key is pressed with no fault present, the display will show the message “E153”, and the same key

has to be pressed again (for at least two seconds) to restart the boiler.

(9) Data key. This key can be pressed repeatedly to display the following information:

- Temperature (°C) of the domestic hot water ( );

- outdoor temperature (°C) ( ); only provided with the outdoor temperature sensor probe connected.

Press either of the keys to return to the main menu.

Dash

“Automatic mode”

active

(2)

Central heating water temperature setting key.

This key can be pressed to set the central heating

water output temperature as described in point 3-3.

(3) Domestic hot water temperature setting key. This key can be pressed to set the domestic hot

water temperature as described in point 3-4.

(10) Central heating mode operating key

.

The key can be pressed to activate four boiler central heating operating modes; these modes are

identied by a black cursor line underneath the relative symbol on the display, and are as follows:

3.1 DESCRIPTION OF KEYS

Page 7

7

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

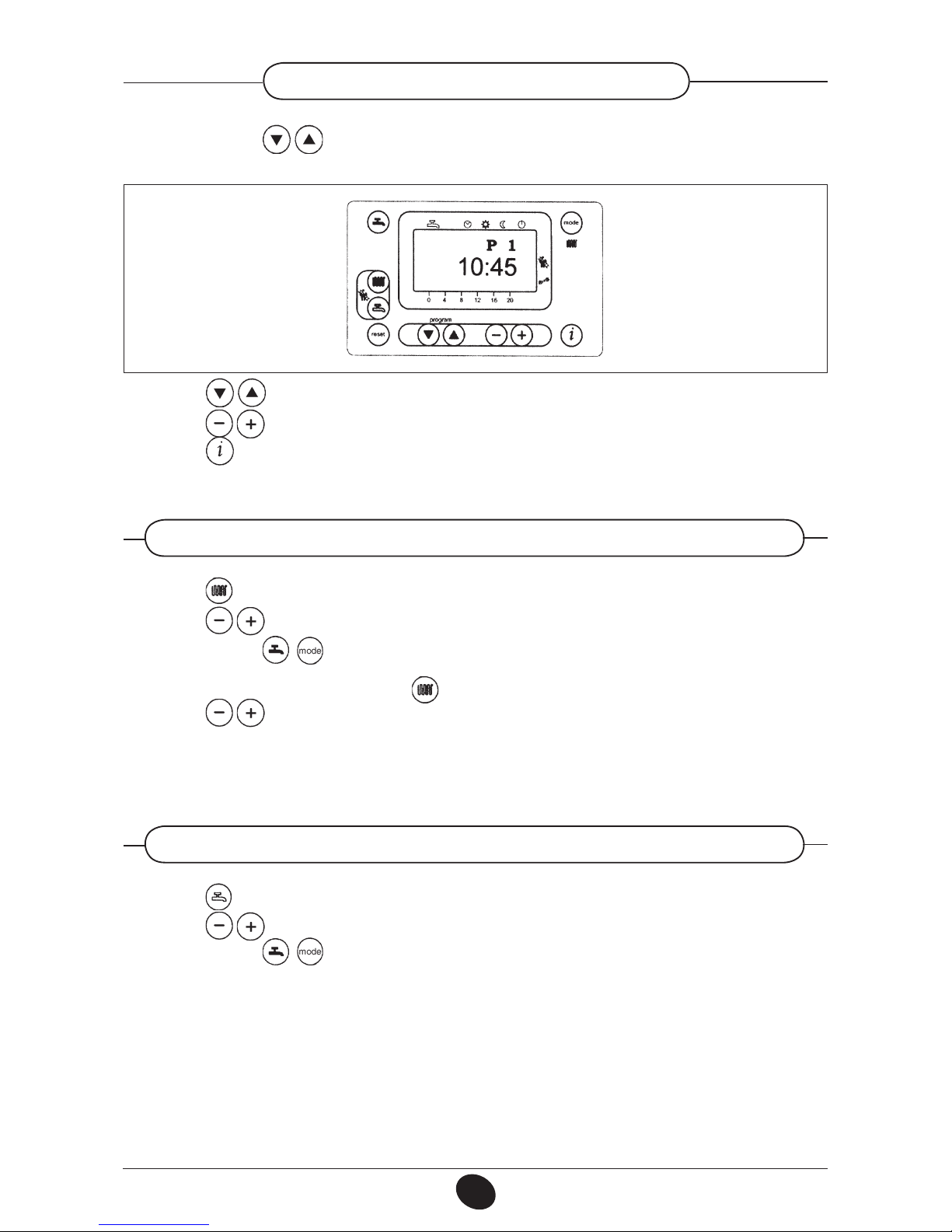

•

Press either of the keys to access the programming function;

the display will show the letter P followed by a number (program line);

•

Press the keys until the display shows P1, referring to the time to be set;

•

Press the keys to set the time; on the display, the letter P will start to ash;

•

Press the key to save and exit the programming function;

020503_0700

Figure 3

3.2 SETTING THE TIME

- Press the key (2-gure 1) to set the central heating water temperature;

- Press the keys to set the temperature required;

- Press either of the keys (1 or 10 - gure 1) to save and return to the main menu.

N.B – With the outdoor sensor connected, the key (2 - gure 1) can be used to shift the central heating curve.

Press the keys to decrease or increase the room temperature in the premises to be heated.

3.3 SETTING THE MAXIMUM CENTRAL HEATING TEMPERATURE

- Press the key (3-gure 1) to set the maximum domestic hot water temperature;

- Press the keys to set the temperature required;

- Press either of the keys (1 or 10 - gure 1) to save and return to the main menu.

3.4 SETTING THE MAXIMUM DOMESTIC HOT WATER TEMPERATURE

Page 8

8

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

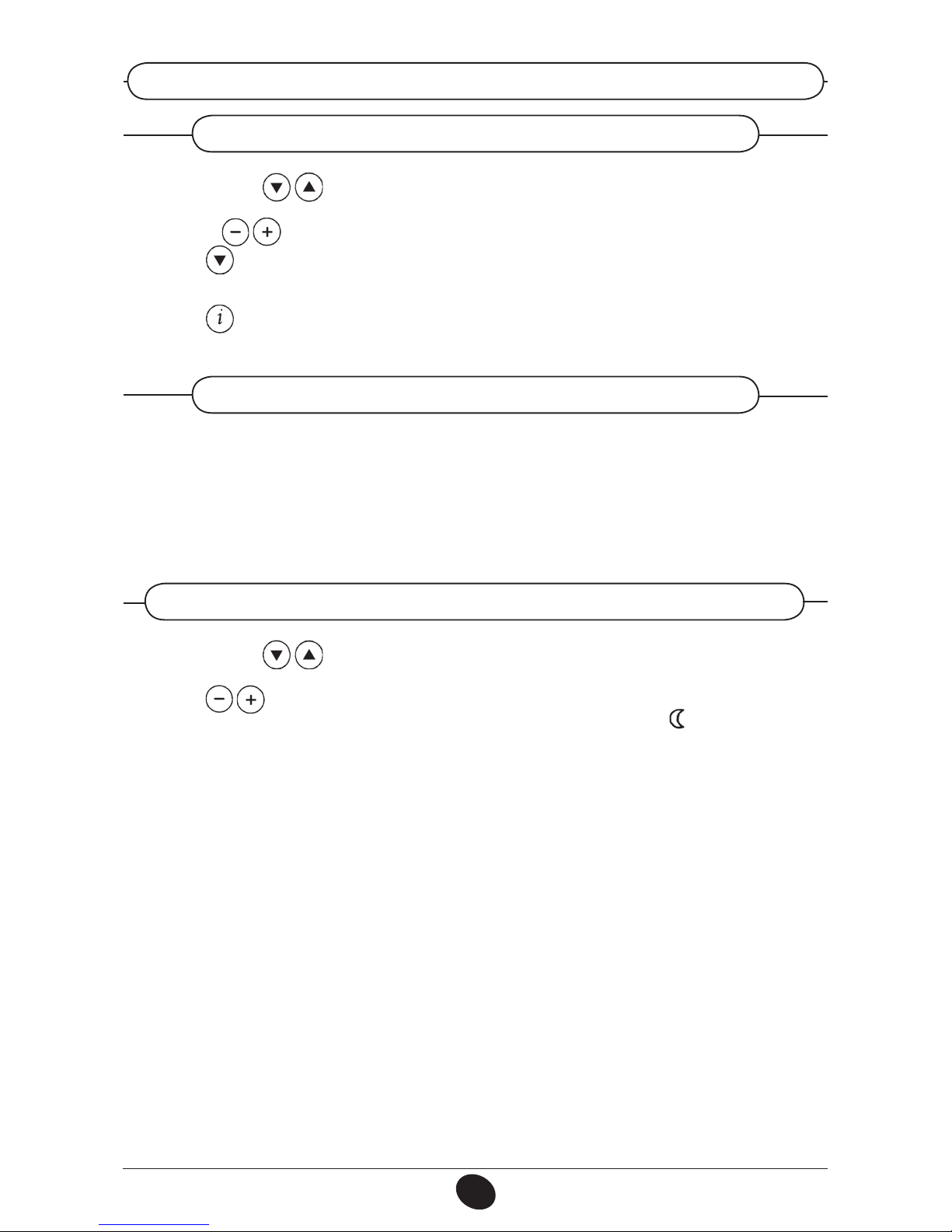

- Press either of the keys to access the programming function;

a) press these keys until the display shows P11, referring to the program start time;

b) press the keys to set the time;

- Press the key; the display will show P12, referring to the program end time;

- Repeat the operations described in points a and b until the third and last cycle is reached (program line

P16);

- Press the key to save and exit from the programming function.

3.5 SETTING THE DAILY PROGRAM FOR OPERATION IN CENTRAL HEATING AND DOMESTIC HOT WATER MODES

3.5.1 Setting the daily times for central heating mode operation

3.5.2 Setting the daily times for domestic hot water mode operation

- Factory setting of D.H.W. function is enable (ON) while is disabled D.H.W. daily times program. To enable

D.H.W. daily times program see section 14 (parameter H91).

Setting the daily times for domestic hot water mode operation-Carry out the operations described in section

3.5.1 for program lines 31 to 36.

3.6 SETTING THE MINIMUM CENTRAL HEATING TEMPERATURE

- Press either of the keys to access the programming function;

- Press these keys until the display shows P5, referring to the temperature to be set;

- Press the keys to set the temperature required.

This operating mode is enabled when minimum temperature central heating mode “ ” is activated or when

the daily central heating program does not require heat.

N.B – With the outdoor sensor connected, parameter P5 can be used to set the minimum room temperature in the premises to be heated (night set-back).

Page 9

9

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

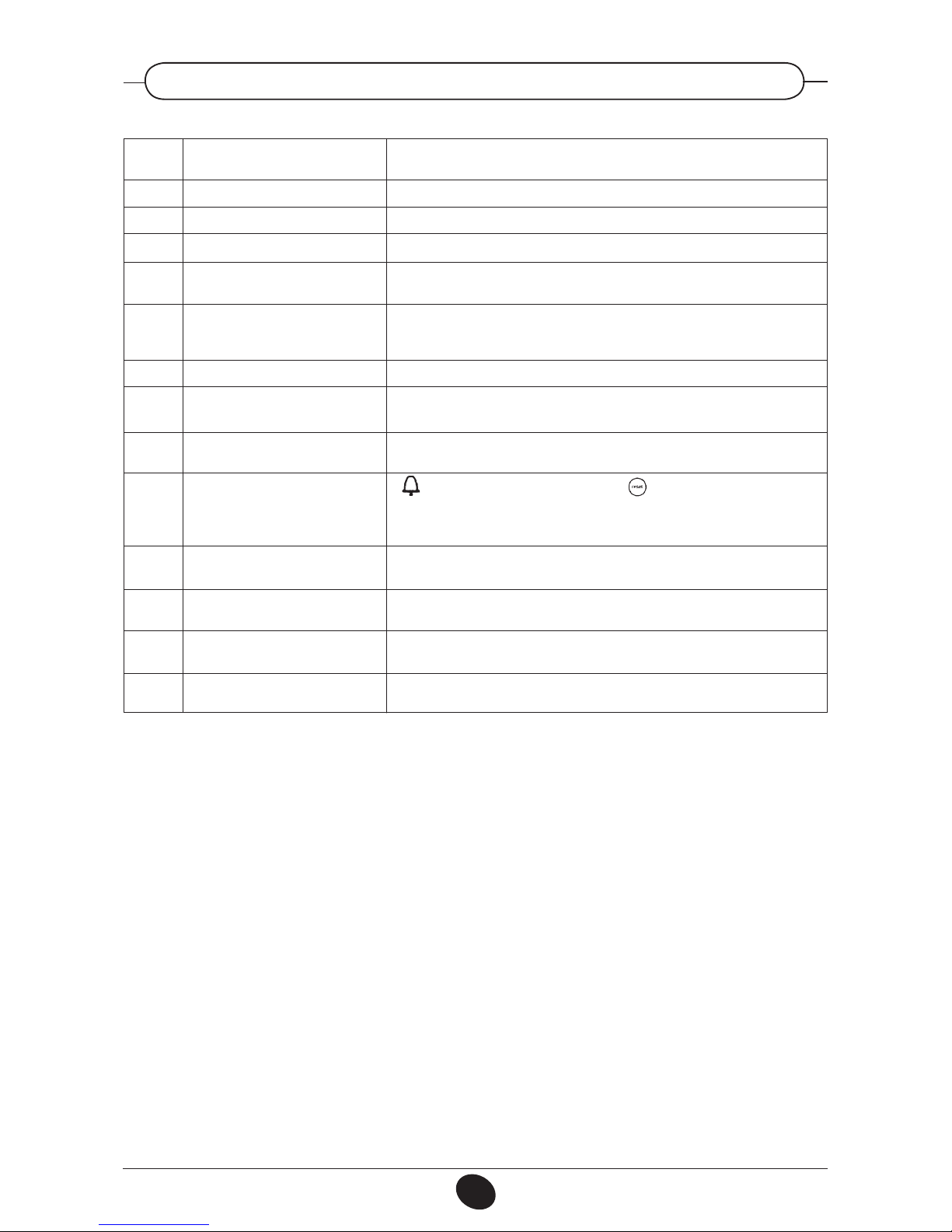

Range

0…23:59

25..80

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

00:00…24:00

0...1

Factory

setting

———-

25

6:00

22:00

0:00

0:00

0:00

0:00

0:00

24:00

0:00

0:00

0:00

0:00

0

Parameter description

Time of day setting

Minimum central heating temperature setting (°C)

Start of rst daily period of automatic central heating

End of rst daily period of automatic central heating

Start of second daily period of automatic central heating

End of second daily period of automatic central heating

Start of third daily period of automatic heating

End of third daily period of automatic central heating

Start of rst daily period of domestic hot water production

End of rst daily period of domestic hot water production

Start of second daily period of domestic hot water production

End of second daily period of domestic hot water production

Start of third daily period of domestic hot water production

Fine End of third daily period of domestic hot water production

Reset of daily central heating and domestic hot water production programs (factory settings).

Press the - + keys together for about 3 seconds; the number 1 appears on the display.

Conrm by pressing either of the keys

Parameter

N.

P1

P5

P11

P12

P13

P14

P15

P16

*

P31

*

P32

*

P33

*

P34

*

P35

*

P36

P45

*

Parameters for program lines P31 to P36 are displayed only if Domestic Hot Water (D.H.W.) program (parameter H91 see section 14) is activated.

3.7 TABLE FOR USER-SETTABLE PARAMETERS

Page 10

10

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

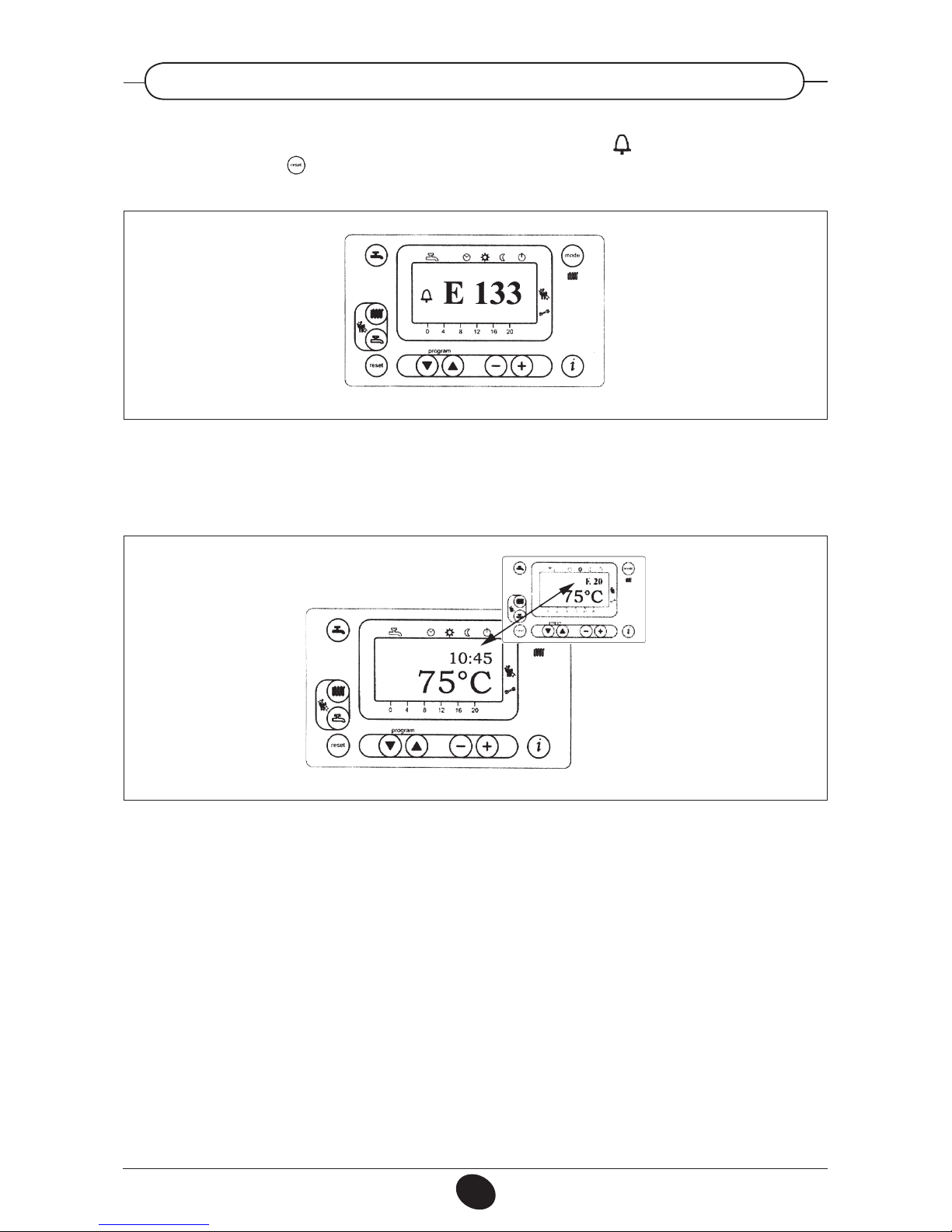

If a fault occurs, a ashing warning code appears on the display.

The fault warnings appear on the main display (gure 1 a) together with the symbol (Figure 4).

To reset, press the reset button for at least two seconds.

020503_0500

Figure 4

020503_0600

Figure 4.1

Fault warnings appear on the secondary display (gure 1 b) alternating with the time, both of them ashing

(gure 4.1). It is not possible to reset malfunction warnings which appear on the secondary display as the cause

of the alarm has rst to be removed.

3.8 FAULT WARNINGS AND RESETTING THE BOILER

Page 11

11

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

(*) Auotoreset when fault disappears.

All the faults are displayed in order of importance; if several faults occur simultaneously, the rst to be displayed

is the one with highest priority. After the cause of the rst fault has been removed, the second one will be

displayed, and so on.

If any given fault occurs frequently, contact the authorised Service Centre.

3.9 TABLE OF FAULTS AND ERROR MESSAGES

Corrective action

Call an authorised service centre (*).

Call an authorised service centre (*).

Call an authorised service centre (*).

Press the reset key (for about 2 seconds: if this device is triggered repeatedly, call

the authorised service centre)

Call an authorised service centre.

Call an authorised service centre.

Call an authorised service centre to check the gas pressure.

Press the reset key (for about 2 seconds); if the fault persists, call the authorised

service centre to check polarity of ignition electrodes, ionisation current.

If symbol is displayed, press the reset button otherwise switch off the

electricity supply to the boiler for at least 10 seconds; if the fault persists, call the

authorised service centre.

Check the positioning of the ignition and ame sensing electrode (see section 16).

Press the key again (about 2 seconds)

Press and hold reset button (2 seconds approx.) then press again when warning

E153 appears

Call an authorised service centre.

Check that the system is at the rated pressure. (Refer to the section on lling the

system). If the fault persists, call the authorised service centre.

Description of fault

Outdoor temperature sensor fault

NTC output sensor failure

Hot water NTC sensor failure

Safety or ue gas thermostat tripped

Loss of ame during operation (the

ionization current has fallen below

the limit)

Minimum fan speed limit not reached

Gas pressure switch tripped / external

thermostat tripped

No ame detected

Boiler circuit board error

The reset key h as been pressed

inappropriately

Internal error on boiler circuit module

Fan speed threshold not reached

Low water pressure

Error

code

E10

E20

E50

E110

E128

E129

E132

E133

E151

E153

E154

E160

E164

Page 12

12

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE USER

To shut down the boiler switch off the electrical supply to the appliance.

IMPORTANT: Regularly check that the pressure displayed by the pressure gauge is 1 ÷ 4 bar when the central

heating system is cold. Open the boiler drain cock to reduce pressure if it is too high. Open the lling cock to

increase pressure if it is too low.

Always open the lling cock very slowly to allow any air to bleed off.

If the pressure in the system drops frequently, contact an authorised service centre to have the system checked.

We recommend you avoid draining the whole system as raw water makeup will lead to harmful limestone deposits inside the boiler and on the heating elements.

In case the boiler is not operated during wintertime and is therefore exposed to danger of frost we suggest you

add some specic-purpose anti-freeze to the water contained in the system (e.g.: propylene glycole coupled

with corrosion and scaling inhibitors).

The electronic management of the boilers includes a “frost protection” function in the central heating system

which operates the burner to reach a heating ow temperature of 30° C when the system heating ow temperature drops below 5°C.

The frost protection function is enabled if:

* electrical supply to the boiler is on;

* the gas service cock is open;

* the system pressure is as required;

* the boiler is not isolated.

To maintain efcient and safe operation of your boiler have it checked by a Qualied Service Engineer at the

end of every heating season.

Careful servicing will ensure economical operation of the system.

Do not clean the outer casing of the appliance with abrasive, aggressive and/or easily ammable cleaners

(i.e.: gasoline, alcohol, and so on). Always isolate the electrical supply to the appliance before cleaning it (see

section 5 Turning off the boiler).

These boilers are produced for natural gas and can be converted to work with LPG (G 31).

Any gas change must be effected by a Qualified Service Engineer.

4. FILLING THE SYSTEM

5. SWITCHING THE BOILER OFF

6. PROLONGED STANDSTILL OF THE SYSTEM. FROST PROTECTION

7. SERVICING INSTRUCTIONS AND GAS CHANGE

Page 13

13

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

This boiler is designed to heat water at a lower than boiling temperature at atmospheric pressure. The boiler

must be connected to a central heating system and/or to a domestic hot water supply system in compliance

with its performances and output power.

IMPORTANT! The following components are not installed in the boiler as supplied. It is the installer’s

responsibility to provide them:

• Expansion vessel;

• Pressure safety valve;

• Circulation pump;

• Filling system cock.

Before connecting the boiler ensure the following operations have been completed:

a) Check that the boiler is t for operation with the type of gas available. For more details see the notice on the

packaging and the label on the appliance itself.

b) Check that the ue terminal draft is appropriate; that the terminal is not obstructed and that no other applian-

ce exhaust gases are expelled through the same ue duct, unless the ue is especially designed to collect

the exhaust gas coming from more than one appliance, in conformity with the standards and regulations in

force.

c) Check that, in case the ue has been connected to pre-existing ue ducts, thorough cleaning has been carried

out in that residual combustion products may come off during operation of the boiler and obstruct the ue

duct.

The following remarks and instructions are addressed to Service Engineers to help them carry out a faultless

installation. Instructions regarding lighting and operation of the boiler are contained in the ‘Instructions pertaining to the user’ section.

Note that installation, maintenance and operation of the gas appliances must be performed exclusively by

qualied personnel in compliance with current standards.

Please note the following:

• Install the boiler in a permanent ventilated central heating boiler room.

• This boiler can be connected to any type of convector plates, radiators, thermoconvectors. Design the system

sections as usual though taking into account the available output / pump head performances, as shown in

chapter 10.4.

• Do not leave any packaging components (plastic bags, polystyrene, etc.) within children’s reach as they are

a potential source of danger.

• Initial lighting of the boiler must be effected by a Qualied Service Engineer.

• Make sure that the room where the boiler is installed has a sufcient supply of air to ensure complete combu-

stion of the gas consumed by the appliance. Install unblockable ventilation grilles as necessary in accordance

with the Rules in force.

• Connect the boiler directly to an efcient ue to vent all fumes and combustion gases outdoors. Make sure

that the pipe connecting the boiler to the ue is not smaller in diameter than the boiler’s ue outlet. Make

sure that the ue is in good condition and free from holes or cracks that could reduce draw.

Failure to observe the above will render the warranty null and void.

8. GENERAL INFORMATION

9. INSTRUCTIONS PRIOR TO INSTALLATION

Page 14

14

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

10. BOILER INSTALLATION AND DIMENSIONS

Install the boiler in a position that ensures easy maintenance. You must be able to fully open the front access

door and have adequate access to the rear of the boiler.

If possible, install the boiler on a raised base of 200 mm in height to facilitate drainage of ue condensate.

When calculating the weight of the boiler on the oor, bear in mind the weight of the water in the heat exchanger

(see table 1).

Adjust the levelling feet to compensate for any unevenness in the oor.

Install the necessary utility connections starting from the water and gas connections on the rear of the boiler

(see table 1 for tting type and size).

These appliances do not have any circulation pump, expansion tank or safety valve. These devices

must therefore be provided elsewhere in the system, and must be sized to suit the system’s thermal

capacity.

Connect the ue condensate drain pipe to a suitable water drain, ensuring an adequate slope.

To drain the boiler, use the drain tap at the rear.

To ensure correct operation of the appliance and avoid invalidating the warranty, observe the following

precautions:

1. Heating circuit

1.1. New system

Before proceeding with installation of the boiler, the system must be cleaned and ushed out thoroughly to

eliminate residual thread-cutting swarf, solder and solvents if any, using suitable proprietary products.

To avoid damaging metal, plastic and rubber parts, use only neutral cleaners, i.e. non-acid and non

alkaline. The recommended products for cleaning are:

SENTINEL X300 or X400 and FERNOX heating circuit restore. The use of this product must be strictly

in accordance with the maker’s directions. Finally the system must be dosed with a suitable inhibitor at

1% system volume.

1.2. Existing system

Before proceeding with installation of the boiler, the system must be cleaned and ushed out to remove

sludge and contaminants, using suitable proprietary products as described in section 1.1.

To avoid damaging metal, plastic and rubber parts, use only neutral cleaners, i.e. non-acid and non-

alkaline such us SENTINEL X100 and FERNOX heating circuit protective. To use this product proceeding

strictly in accordance with the maker’s directions.

Remember that the presence of foreign matter in the heating system can adversely affect the operation

of the boiler (e.g. overheating and noisy operation of the heat exchanger). Dose with inhibitor.

Failure to observe the above will render the warranty null and void.

Page 15

15

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Figure 5

Table 1

Model Depth Height Width Gas Fitting Fitting Water contents

(mm) (mm) (mm) tting F R ( l )

A (CH) (CH)

FS 90 801 850 450 G 3/4” G 1 1/4’’ G 1 1/4’’ 13,7

FS 105 871 850 450 G 1” G 1 1/2” G 1 1/2” 21

FS 130 1024 850 450 G 1” G 1 1/2” G 1 1/2” 23,3

FS 160 1132 850 450 G 1” G 1 1/2” G 1 1/2” 25,3

Insert the flue-gas union

and fasten the connector

to the flue-gas thermostat

CT_0804 / 0906_2501

F CH: heating ow

R CH: heating return

GAS: gas inlet to the boiler

SC: condensate drain

SIZE = EXTERNAL 25 mm

INTERNAL 18 mm

CLEARANCE

FRONT = 700 mm

REAR = allow room to make

connections

SIDE = 10 mm

TOP = 500 mm

Page 16

16

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Figure 6

10.1 HYDRAULIC SYSTEM 1

(Pumped heating circuits with remote control QAA73 or Room Thermostat, including hot-water tank,

with primary loop)

Applications and Installation Details

- TS: Tank Sensor (QAZ36)*

- B3: Room Control Module (QAA73)*

- B1: Room Thermostat*

- B9: Outdoor Temperature Sensor (QAC34) supplied with the boiler

- P1: Heating Pump

- PDHW: Hot Water Pump

- PLP: Primary Pump

(*) Available Optional Extra

- Pumps, Hot Water Cylinder, Low Loss Header , Non return valve (Not supplied)

- Installer Wiring ---------------

Applications (pumps, sensor, remote control ...) have to be connected to terminal as follows (see also section 12):

WITH QAA73 WITH

REMOTE CONTROL ROOM THERMOSTAT

APPLICATION

TERMINAL BOARD TERMINAL BOARD

PRIMARY PUMP PLP M1: A – B M1: A – B

DHW PUMP PDHW M3: 13 – 14 M3: 13 – 14

HEATING PUMP P1 M3: 11 – 12 M3: 11 – 12

DHW SENSOR TS M2: 7 – 8 M2: 7 – 8

REMOTE CONTROL QAA73 M2: 1 – 2 NO

ROOM THERMOSTAT M2: 3 – 4 OPEN M2: 3 – 4

CT_0664 / 0906_2202

Page 17

17

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Parameter changes requires (see also section 14):

PCB Description Setting Parameter

PARAMETER

H552 Hydraulic system H552 = 2 (*)

H553 KongHKS H553 = 21 (*)

H615 KongAusgang H615 = 9 (*)

H632 WANFO Q8 H632 = 00001100 (*)

(*) factory set

10.2 HYDRAULIC SYSTEM 2

(Pumped heating circuits with Room Thermostats and compensated circuit with remote control QAA73,

including hot-water tank, with primary loop)

Applications and Installation Details

- TS:Tank Sensor (QAZ36)*

- B3: Room Control Module (QAA73)*

- B1: Room Thermostat*

- B9: Outdoor Temp Sensor (QAC34) supplied with the boiler

- AGU2.500: Zone controller (Clip-in AGU2.500)*

- FS: Flow Sensor (QAD36: supplied with the AGU2.500)*

- P1: CTC Heating Pump

- P DHW: Hot Water pump

- PLP: Primary Pump

- 3WV: 3-Way Valve (power open / power close)

- P2: VTC Pump

(*) Available Optional Extra

- Pumps , Hot Water Cylinder, Low Loss Header, Non return valve (Not supplied)

- Installer Wiring --------------

Figure 7

CT_0663 / 0906_2203

Page 18

18

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Applications (pumps, sensor, remote control ...) have to be connected to terminal as follows (see also section 12):

APPLICATION

TERMINAL BOARD

PRIMARY PUMP PLP M1: A – B

DHW PUMP PDHW M3: 13 – 14

HEATING PUMP P1 M3: 11 – 12

DHW SENSOR SB M2: 7 – 8

REMOTE CONTROL QAA73 (LOW TEMPERATURE) M2: 1 – 2

ROOM THERMOSTAT M2: 3 – 4

HEATING PUMP P2 CLIP IN AGU 2.500

3 WAY VALVE 3WV CLIP IN AGU 2.500

FLOW SENSOR FS CLIP IN AGU 2.500

Parameter changes requires

(see also section 14)

:

PCB PARAMETER Description Setting Parameter

H552 Hydraulic system H552 = 50

H553 KongHKS H553 = 12

H615 KongAusgang H615 = 9

H632 WANFO Q8 00001111

10.3 HYDRAULIC SYSTEM 3

(Cascade with pumped heating circuits, Room Thermostats, primary loop)

Applications and Installation Details

- RT: Room Thermostat*

- B9: Outdoor Temperature Sensor (QAC34) supplied with the boiler

- OCI 420: Cascade interface controller (Clip-in OCI 420)*

- RVA 47: Cascade controller (RVA 47)*

- FS: Flow/return Sensor (QAD21)*

- P1: Heating Pump

- PLP: Primary Pump

(*) Available Optional Extra

- Pumps , Hot Water Cylinder, Low Loss Header, Non return valve (Not supplied)

- Installer Wiring --------------

Page 19

19

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Figure 8

Applications (pumps, sensor, remote control ...) have to be connected to terminal as follows (see also section 12):

APPLICATION

TERMINAL BOARD

PRIMARY PUMP PLP M1: A – B

HEATING PUMP P1 RVA 47

ROOM THERMOSTAT RVA 47

FLOW/ RETURN SENSOR QAD 21 RVA 47

Parameter changes requires

(see also section 14)

:

PCB PARAMETER Description Setting Parameter

H552 Hydraulic system H552 = 80

H553 KongHKS H553 = 21

H615 KongAusgang H615 = 9

H632 WANFO Q8 00001111

If DHW circuit is required then DHW pump and DHW sensor have to be connected to terminal of RVA 47

Cascade Controller.

For more details refer to the instruction provided with the accessories RVA 47 and RVA 46 (compensated

circuit).

CT_0665 / 0906_2204

Page 20

20

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

10.4 EXCHANGERS PRESSURE DROP

Exchanger pressure drop (mH

2

O)

WATER FLOW RATE (l/h)

Graph 1

Exchanger pressure drop (mH

2

O)

WATER FLOW RATE (l/h)

Graph 1.1

FS 90 - 105

EXCHANGER

PRESSURE DROP.

FS 130 - 160

EXCHANGER

PRESSURE DROP.

0512_19010512_1902

90

105

130

160

kPa Lit/sec kPa Lit/sec kPa Lit/sec kPa Lit/sec

FS 90 76,49 1,85 36,29 1,35 23,54 1,02 10,79 0,68

FS 105 74,53 2,17 40,21 1,59 22,56 1,19 12,75 0,80

FS 130 53,94 2,61 31,38 1,91 22,56 1,43 10,79 0,96

FS 160 49,03 3,26 31,38 2,39 19,61 1,79 10,79 1,19

Boiler Hydraulic Resistance and Water Flow Rates

11°K ∆T 15°K ∆T 20°K ∆T 30°K ∆T

FS 90 0,52

FS 105 0,58

FS 130 0,72

FS 160 0,91

Boiler Minimum Water Flow Rates

Lit/sec

Page 21

21

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Connect the boiler to the ue using a pipe made of stainless steel or plastic material with an internal diameter

of 100 mm, capable of resisting normal mechanical stresses over time, as well as high temperatures (<120°C)

and the chemical effects of fuel gases and their condensates. Insert the flue-gas union and fasten the

connector to the flue-gas thermostat before hooking up to the flue.

Whenever possible use a ue connection that can be disconnected for maintenance.

Important! Horizontal flue sections must have a minimum slope of 3° towards the boiler.

Flue accessories made of plastic material for cascade or single installations are available.

11. CHIMNEY FLUE CONNECTION

Figure 7a

CT_0809 / 0902_2705

CT0667 / 0903_1601

In case exhaust and intake flues not supplied by POTTERTON COMMERCIAL have been installed, these must

be certified for the type of use and must have a maximum pressure drop in according to the values reported in

the table.

To ensure the correct rated heat input to the maximum and minimum heat input, it is necessary to update the speed (rpm)

of the fan, it depends on the lenght of the pipes, in accordance with the installation of ue and air pipes as indicated in

the tables below. The factory-set value is referred to the minimum length of ue pipe (0÷10 m). To carry such updating,

changing the speed of the fan at the (rpm and pwm%) , refer to par. 13-14.

Max. length of ue duct (L) : 20 m

Each 90° bend reduces the duct max. length by : 1 m

Each 45° bend reduces the duct max. length by : 0.5 m

FLUE PRESSURE TABLE AVAILABLE

Cascade solution

∆P available

ue duct B23 Ø 100

∆P available with

single non-return valve

Ø 110/110

∆P available with

double non-return valve

Ø 110/110

FS 90 110 110 -

FS 105 150 110 -

FS 130 170 - 80

FS 160 280 - 120

Page 22

22

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

The kit is used to introduce combustion air from outside the installation area and comprises a hose to be

installed in the mixer body.

Please consult the instructions supplied with the kit.

For air ducts (diameter and length), see the kit manual.

11.2 CONNECTOR WITH C53 TYPE

CT_0813 / 0903_0601

Page 23

23

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

12. MAKING THE ELECTRICAL CONNECTIONS

Electrical safety of the appliance is only guaranteed by correct earthing, in accordance with the current standards and regulations.

Connect the boiler to a 230V by means of the three-pin cable supplied with it make sure that the polarities are

correctly connected.

Use a double-pole switch with a contact separation of at least 3mm in both poles.

In case you replace the power supply cable t a HAR H05 VV-F’ 3x0.75mm2 cable with an 8mm diameter

maximum outer sheath.

IMPORTANT: Check that the overall current drawn by accessories connected to the appliance is less

than 2 amp. If the value is greater, a relay must be wired between the boiler control circuit board and

the accessories drawing the higher current.

12.1 TERMINAL BLOCKS ACCESS

• Isolate power to the boiler with the two-pole switch.

• Remove the top facia panel cover (which is held by magnets).

• Unscrew the two screws holding the facia panel in place.

• Swing the facia panel forwards.

Main terminal block M1

• Remove the clip-on cover from terminal strip M1.

• The main terminal block incorporates a fast blow 3.15 A fuse (gure 10). Remove the black fuse holder to

check and/or replace the fuse.

Terminal block M2

• Unscrew the xing screw and remove the cover from terminal block M2.

Terminal block M3

• Unscrew the xing screws and remove the main cover.

Figure 10

020523_0400

Terminal Block M1

Terminal Block M2

Cover

Cover

Facia panel

Page 24

24

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

12.2 CONNECTING THE PUMPS

Figure 11

Turn the control box downward to access terminal boards M1 and M3 used for the electrical connections by

removing the protective covers (see gure 11).

Terminals M1 a – b: connection of the Primary loop pump for the heating system (Plp)

Check the correct size and rating of the pump by referring to graph n° 1, which shows the boiler pressure

losses.

Terminals M3 11 – 12: connection for heating pump (P1)

Terminals M3 13 – 14: connection for hot water tank pump (PDHW)

The electrical specications of the pump must be as follows:

230 V AC; 50 Hz; 1 A max; cos f > 0.8.

If the specications of the installed pump are different, a relay must be wired between the boiler control circuit

board and the pump.

It is advisable not to adopt any electrical connection other than those described.

Connect earth to earth strip

Remove the resistor from terminals 9-10 of terminal strip M2 (gure 12), and connect the hot water priority

NTC sensor, which is supplied as an accessory.

The sensing element of the NTC device must be located in the recess provided on the storage tank (gure 12).

The temperature and on-off programming of the domestic hot water supply are selected directly from the

boiler control panel, as described in this manual under the user instruction headings.

12.3 CONNECTING THE HOT WATER TANK SENSOR

CG_1763 / 0906_2205

Page 25

25

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Figure 12

Figure 13

0602_0707/CG1764

0602_0708/CG1765

safety

contact

room thermostat

Page 26

26

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Turn the control box downward to access terminal blocks M1 and M2 used for the electrical connections by

removing the two protective covers (see gure 10).

Terminals 1-2: connections for the optional SIEMENS QAA73 (optional extra) room temperature regulator.

These connections do not have any specic polarity.

Remove the bridge between terminals 1-2 “TA” on terminal block M1.

Read the instructions provided with the temperature regulator to ensure correct installation and programming.

Terminals 3-4: room temperature thermostat “TA”. Thermostats with integral accelerator resistor must not be

used. Check that there is no voltage across the ends of the two thermostat connection wires.

Terminals 5-6: external safety contact (commercially available device).

Terminals 7-8: connections for the optional SIEMENS QAC34 outdoor temperature sensor supplied with the

boiler. Read the instructions provided with the outdoor temperature sensor to ensure correct installation.

Terminals 9-10: connections for the optional domestic hot water priority sensor, for connecting single system

boilers to external DHW boilers.

CLIP-IN AGU 2.511

Terminals 3-4 L-N OUT: connection to signal lamp (230 V - 0,5 A max) for lockout alarm.

Terminals 5-6 L-N OUT: connection to signal lamp (230 V - 0,5 A max) for run mode.

For low voltage signal lamp remove the internal wiring and feed with an external low voltage power supply.

12.4 DESCRIPTION OF THE ELECTRICAL CONNECTIONS TO THE BOILER

12.5 CONNECTING THE QAA73 ROOM TEMPERATURE REGULATOR

The SIEMENS model QAA73 room temperature regulator, if required (optional accessory) must be connected

to terminals 1-2 of terminal block M2 in gure 12.

The link across terminals 3-4, provided for connection of a room temperature thermostat, must be removed.

The settings of the domestic hot water temperature and domestic hot water production schedule must be made

using this device.

The timed program of the central heating circuit must be set on the QAA73 if there is a single zone, or in relation

to the zone controlled by the QAA73 device.

The timed program for the central heating circuit of the other zones can be set directly on the boiler control

panel.

See the instructions provided with the QAA73 temperature regulator for the user parameter programming

procedure.

QAA73: parameters which can be set by the installer (service)

By pressing the two PROG buttons together for at least three seconds it is possible to access the list of parameters that the installer can display and/or set.

Press either of these buttons to change the parameter to display or change.

Press the [+] or [-] key to change the value displayed.

Press either of the PROG buttons again to save the change.

Press the information button (i) to quit programming.

Here follows a list of the most commonly used parameters:

Page 27

27

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

- Fault messages

In the event of fault, the display panel on the QAA73 shows the ashing symbol . Press the information key

( ) to display the error code and a description of the fault (see table on paragraph 3.9).

Line no.

70

72

74

75

77

78

79

80

90

91

Default value

15

85

Light

On HC1

On

0

0

—.-

10

24 h/day

Range

2.5…40

25…85

Light, Heavy

on HC1

on HC2

on HC1+HC2

nil

On - off

0…360 min

0…360 min

2.5…40

—.- = not active

10…58

24 h/day

TSP HC-1h

TSP HC

TSP DHW

Parameter

HC1 gradient heating curve

Selection of central heating circuit temperature curve “kt”

HC1 max. output

Central heating system maximum output temperature

Type of building

Room compensation

Activation/deactivation of the inuence of the room temperature. If it is

deactivated, the outdoor temperature sensor must be installed.

Automatic adaptation of the temperature curve “kt” in relation to the room

temperature.

Opt Start Max

Maximum time the boiler is switched on ahead of the timed program to optimise

the temperature in the premises.

Opt Stop Max

Maximum time the boiler is switched off ahead of the timed program to optimise

the temperature in the premises.

HC2 gradient heating curve

DHW Red Setp

Minimum temperature of the domestic domestic hot water

DHW program

Selection of the type of timed program for domestic hot water.

24 h/day = always on

PROG HC-1h = as HC1 central heating program less one hour

PROG HC = as central heating program

PROG DHW = specic domestic hot water program

(see also program lines 30-36)

Page 28

28

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

The SIEMENS model QAC34 outdoor temperature sensor must be connected to terminals 7-8 of terminal board

M2 in gure 12.

The procedures for setting the gradient of the temperature curve “kt” vary depending on the accessories connected to the boiler.

a) Without QAA73 room temperature regulator:

The temperature curve “kt” must be selected by setting parameter H532 as described in section 14 “setting the

boiler parameters”.

See graph 2 for selecting the curve referred to a room temperature of 20°C.

The chosen curve can be shifted by pressing the (2), button (2) on the boiler control panel, and modifying

the value displayed by pressing the and . keys. See graph 3 for curve selection. (The example show

in graph 3 refers to the curve Kt=15).

Increase the value displayed if the room temperature required is not reached inside the premises for central heating.

b) With QAA73 room temperature regulator:

The temperature curve “kt” must be selected by setting parameter 70 “HC1 curve” of the QAA73 room temperature control device as described in section 12.4 “QAA73: parameters which can be set by the installation

(service) engineer”.

See graph 4 for selecting the curve referred to a room temperature of 20°C.

The curve is shifted automatically on the basis of the room temperature set using the QAA73 climate control.

If the system is divided into zones, the temperature curve “kt” relating to the part of the system not controlled by the

QAA73 must be selected by setting parameter H532 as described in section 14 “setting the boiler parameters”.

Graph 2 Graph 3

TM = Flow temperature

Te = Composite outside temperature

Sth = Kt Curve

TM = Flow temperature

Te = Composite outside temperature

020523_0600

020523_1000

12.6 CONNECTING THE OUTDOOR TEMPERATURE SENSOR PROBE

Graph 4

c) With AGU2.500 for control of a low temperature system:

Refer to the instructions provided with the AGU2.500 accessories for connection and control of a variable

temperature zone.

Page 29

29

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

0502_2108

Figure 14a

LEGEND:

Pi: Gas supply pressure

connection point

P out: Pressure connection point for

measurement of the OFFSET

Pl: Air signal input from fan

V: Gas ow adjuster screw (high)

K: OFFSET adjuster screw (low)

13. ADJUSTING THE GAS VALVES

0502_2109

Figure 14b

FS 90 - 105 models have a single gas valve (gure 14 a).

FS 130 - 160 models have a double gas valve (gure 14 b).

Gas nozzle

Gas nozzle

Page 30

30

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

13.1 SINGLE GAS VALVE MODELS (FS 90 - 105) FIGURE 14a

Proceed as follows to adjust the single gas valve:

• Insert the ue analysis probe into the ue sampling hole as instructed in section 17 (gure 17).

• Press and hold the and keys on the control panel simultaneously for 7 seconds until the symbols

appear on the display in the position shown in gures 15a and 15b . You are now in ‘calibration

mode’.

• Press the key to set the maximum heat output, with the display showing 100% (gure 15a).

Caution: in the event of the boiler failing to ignite, or when replacing the gas valve, the recommended

procedure is to tighten the adjuster screw (V) fully and then back off 3 turns, repeating the steps

described above.

• Turn the adjuster screw V on the gas valve until you achieve the CO2 levels shown in

table 2.1 for natural

gas (G20) and in table 2.2 for propane (LPG):

- Turn the screw anti-clockwise to increase the CO2 level.

- Turn the screw clockwise to decrease the CO2 level.

• Press the key to set the minimum heat output, with the display showing 0% (gure 13b).

• Turn the adjuster screw K on the gas valve until you achieve the CO2 levels shown in table 2:

- Turn the screw clockwise to increase the CO2 level.

- Turn the screw anti-clockwise to decrease the CO2 level.

Proceed as follows to adjust the double gas valve:

• Connect a pressure gauge to the P1OUT pressure measurement hole on valve 1.

• Insert the probe of the ue gas analyzer in the sampling port as indicated in heading 17 - gure 17.

• Switch on the boiler, activating the “setting function” from the control panel by pressing and holding the

and keys simultaneously until the symbols are displayed, positioned as illustrated in gures

15a and 15b . You are now in ‘calibration mode’.

• Press the key to set the maximum heat output, with the display showing 100% (gure 15a).

Caution: in the event of the boiler failing to ignite, or when replacing the gas valves, the recommended

procedure is to tighten the adjuster screws (V1) and (V2) fully and then, depending on the model, back

off 2¼ turns (FS 130) or 2½ turns (FS 160), repeating the steps described above.

• Turn both gas valve adjuster screws (V1) and (V2) so as to set the CO2 values as indicated in table 2.1 for

natural gas (G20) and in table 2.2 for propane (LPG):

- Turn the screw clockwise to decrease the CO2 level.

- Turn the screw anti-clockwise to increase the CO2 level.

• Press the key to set the minimum heat output, with the display showing 0% (gure 15b).

• Turn the adjuster screw K1 of gas valve 1 so as to set the pressure value (Pout) as indicated in table 2.1

for natural gas (G20) and in table 2.2 for propane (LPG):

c. Turn the screw clockwise to increase pressure (CO2 increasing).

13.2 DOUBLE GAS VALVE MODELS (FS 130 - 160) FIGURE 14b

Page 31

31

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

d. Turn the screw anti-clockwise to decrease pressure (CO2 decreasing).

• Remove the pressure gauge from the P1OUT port and connect to the P2OUT port of gas valve 2.

• Turn the adjuster screw K2 of gas valve 2 so as to set the pressure value (Pout) as indicated in table 2.1

for natural gas (G20) and in table 2.2 for propane (LPG):

• Check that the CO2 value at minimum heat output is as indicated in table 2.1 or 2.2. The value can be

optimized by making the necessary ne adjustment to screw K2.

13.3 GAS CONVERSION

IMPORTANT: in the event of converting the boiler from natural gas (G20) to propane (LPG), the following

operation must be carried out before proceeding to adjust the gas valve as described above:

• For models with one valve, replace the diaphragm on the gas valve outlet (gure 14a).

To replace the diaphragm, disassemble the gas valve by undoing the inlet and outlet ttings, then unscrew

the nozzle with a pair of straight round nose pliers.

Check the uid-tightness of the gas ttings removed previously.

• For models with two gas valves, replace the diaphragm located at the venturi inlet (gure 14b).

To enable this operation, the gas valve manifold must rst be removed.

Check the uid-tightness of the gas ttings removed previously.

• Set parameters H536 - H541 - H608 - H609 - H610 - H611 - H612 - H613 by way of the display on the

control panel.

The values to be set are given in tables 2.1 and 2.2. The programming methods are described in chapter 14.

Figure 15a

0307_2201

Figure 15b

⇑

⇑

0502_2110

Page 32

32

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Table 2.1

Table 2.2

Gas consumption at

15 °C

1013 mbar

Gas G31 - 3P - 37 mbar

FS 90 FS 105 FS 130 FS 160

PCI (NET) MJ/Kg 46,34 46,34 46,34 46,34

Consumption at max. heat output

Kg/h 6,77 7,97 9,56 11,95

Consumption at min. heat output

Kg/h 2,57 2,86 3,10 3,22

Gas nozzle

mm 7,8 7,8 7,8 7,8

CO2 max. heat output

% 10,2 10,2 10,2 10,2

CO2 min. heat output

% 9,3 9,8 10,2 10,2

Pout pressure at

minimum power

Pa - - -7 -8

Parameters H536-H613 (rpm) at maximum power

4600 5150 4300 5350

Parameters H541-H610 (

pwm

%)

at maximum power

90 100 55 100

Parameter H612 (rpm) at minimum power

1900 1950 1450 1450

Parameter H609

(pwm)

at minimum power

14,5 14,5 10 9,5

Parameter H611 (rpm) ignition load

4200 4200 2600 2900

Length of exhaust flue : 0 ÷ 10 m

Parameter H608

(pwm)

ignition load

40 40 15 15

Length of exhaust flue : 10 ÷ 20 m

Parameter H608

(pwm)

ignition load

50 50 20 20

Cascade solution with single non-return valve Ø 110/110

Parameters H536-H613 (rpm) at maximum power

5000 5500 - -

Parameter H612 (rpm) at minimum power

2200 2100 - -

Parameter H609

(pwm)

at minimum power

16,5 15 - -

Parameter H608

(pwm)

ignition load

50 50 - -

Gas consumption at

15 °C

1013 mbar

Gas G20 - 2H - 20 mbar

FS 90 FS 105 FS 130 FS 160

PCI (NET) MJ/m

3

34,02 34,02 34,02 34,02

Consumption at max. heat output

m3/h 9,26 10,9 13,08 16,35

Consumption at min. heat output

m3/h 3,50 3,89 4,23 4,39

Gas nozzle

mm 11,5 12 11 11,5

CO2 max. heat output

% 8,7 8,7 8,7 8,7

CO2 min. heat output

% 8,6 8,6 8,4 8,4

Pout pressure at

minimum power

Pa - - -4 -5

Parameters H536-H613 (rpm) at maximum power

5100 5650 4650 6000

Parameters H541-H610 (

pwm

%)

at maximum power

90 100 55 100

Parameter H612 (rpm) at minimum power

1900 2100 1600 1550

Parameter H609

(pwm)

at minimum power

15 15 10 9,5

Parameter H611 (rpm) ignition load

3600 3600 2600 2900

Length of exhaust flue : 0 ÷ 10 m

Parameter H608

(pwm)

ignition load

30 30 15 15

Length of exhaust flue : 10 ÷ 20 m

Parameter H608

(pwm)

ignition load

40 40 20 20

Cascade solution with single non-return valve Ø 110/110

Parameters H536-H613 (rpm) at maximum power

5500 6000 - -

Parameter H612 (rpm) at minimum power

2200 2250 - -

Parameter H609

(pwm)

at minimum power

16,5 16

Parameter H608

(pwm)

ignition load

40 40

Page 33

33

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

( * ) For these parameters see section 10.1 - 10.2 - 10.3 (hydraulic system).

If the electronic circuit board is replaced, make sure that the parameters set are those specic to the boiler

model, as indicated in the documentation available from the authorised Service Centre.

Parameter

N.

Description

Factory setting

H90 Minimum D.H.W. temperature setting (°C).

10

H91

D.H.W. activation program

(0=active; 1=not active)

1

H505

Maximum temperature (°C) of the central heating circuit HC1 corresponding to:

- the main circuit in systems with just one zone;

- the circuit of the zone where the QAA73 room temperature control device is installed in case

of systems with more than one high-temperature zone;

- the high temperature zone circuit in mixed systems and if the SIEMENS AGU2.500 accessory

is used.

80

H507

Maximum temperature (°C) of the central heating circuit HC2 of a system with more than one

zone, corresponding to the circuit of the low-temperature zone if the SIEMENS AGU2.500

accessory is used.

80

H516 Automatic Summer / Winter switching temperature (°C). 20

H532 Selection of temperature curve of central heating circuit HC1 (see Graph 2) 15

H533 Selection of temperature curve of central heating circuit HC2 (see Graph 2) 15

H608 PWM (%) Setting: Ignition load

See table 2

H611 Speed setting (rpm) : Ignition load

H609 PWM Setting (%) : minimum power

H541-H610 PWM Setting (%) : maximum power Central heating / Domestic hot water

H612 Speed setting (rpm) : minimum power

H536-H613 Speed setting (rpm) : maximum power Central heating / Domestic hot water

H544 Pump post-circulation time in central heating mode (min) 10

H545 Burner operating pause time between two start-ups (s) 180

H552

( * )

Hydraulic system setting (see instructions provided with the SIEMENS AGU2.500 accessory)

H552 = 50 with AGU2.500 and QAA73

H552 = 80 with RVA 47

2

H553

( * )

Conguration of heating circuits

H553 = 12 with AGU2.500

21

H615 Programmable function: 9

H632

( * )

Heat demand to be supported by the system pump

H632 = 00001111 with AGU2.500 and RVA 47

00001100

H641 Fan overrun time setting (s) 10

H657

Setpoint of autonomous ANTILEGIONELLA function

60...80 °C = setting temperature range

0 = function inactive

0

Table 3

The boiler parameters may only be modied by professionally qualied staff proceeding as follows:

a) Press the , keys on the boiler’s front panel together for about 3 s until the parameter H90 appears on the display;

b) Press the keys to select the parameter for modication;

The boiler parameters may only be modied by professionally qualied staff proceeding as follows:

a) Press the , keys on the boiler’s front panel together for about 3 s until the parameter H90 appears on the display;

b) Press the keys to select the parameter for modication;

c) Press the and keys to modify the parameter;

d) Press the key to exit the programming function.

The following are the parameters generally used:

14. SETTING THE BOILER PARAMETERS

Page 34

34

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

The boiler has been designed in full compliance with European reference standards and in particular is equipped

with the following:

• Overheatsafetythermostat

This thermostat interrupts the gas ow to the main burner in case the water contained in the circuit has ove-

rheated. Under these conditions the boiler locks out and can only repeat the ignition procedure by pressing

of the reset button on the boiler after the cause of the trip has been rectied.

It is strictly forbidden to disable this safety device.

• Fluethermostat

This device, positioned on the ue inside the boiler, interrupts the ow of gas to the burner if the temperature

exceeds 90 °C. After verifying the cause of the trip, press the reset button positioned on the thermostat

itself, then press the reset button on the boiler.

It is forbidden to disenable this safety device

• Flameionizationdetector

The ame sensing electrode guarantees safety of operation in case of gas failure or incomplete interlighting

of the main burner.

Under such conditions the boiler is locked out.

You must press the reset button on the boiler to restore the normal operating conditions.

• Pumpoverrun

The electronic control system keeps the pump operating for 10 minutes in central heating mode after the

room temperature thermostat has switched off the main burner.

• Frostprotectiondevice

The boilers electronic management includes a “frost protection” function in the central heating system which

operates the burner to reach a heating ow temperature of 30°C when the system heating ow temperature

drops below 5 °C.

This function is enabled as long as the boiler is connected to the a.c. power supply gas supplies and the

pressure in the system is as specied.

• Pump-blockingprevention

In case there is no call for heat either from the central heating system or from the DHW system for 24 hours

continous the pump will automatically switch on for 10 seconds.

• Hydraulicpressuresensor

This device enables the main burner only to be switched on if the system pressure is over 0.5 bar.

• Gaspressureswitch

This device enables the burner only to be switched on if the gas pressure is over 12 mbar.

15. CONTROL AND OPERATION DEVICES

Page 35

35

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Drill a hole in the ue at a distance from the boiler equivalent to twice the diameter of the ue to measure

combustion efciency and combustion ue composition in accordance with the rules in force. Use this hole to

measure the following parameters:

• Combustion ue temperature

• Oxygen (O2) or carbon dioxide (CO2) concentration.

• Carbon monoxide (CO) concentration.

Measure the temperature of combustion air near the air inlet to the boiler. The necessary hole must be made by

the technician responsible for the heating system when the system is rst started up, and must then be closed

to ensure that the ue remains properly sealed during normal operation.

17. CHECK OF COMBUSTION PARAMETERS

Figure 17

Figure 16

16. POSITIONING OF THE IGNITION AND FLAME SENSING ELECTRODE

0503_2204

Important! Close the ue test point

hole on completion of measurements.

BOILER FLUE TEST

POINT HOLE

0811_1703 / CT_0782

Page 36

36

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

To facilitate measurement of the combustion efciency and improve the cleanliness of the production products,

the chimney sweep function can be activated by proceeding as described below:

1) Press the (2-3) together until the pointer “ ” appears on the display alongside the symbol (about 3

seconds but no more than 6 seconds). In these conditions, the boiler operates at the maximum heat output

in central heating mode.

2) Press either of the buttons to exit the function

020429_0200

Figure 18

To ensure the boiler operates at peak efciency, the following checks must be performed every year:

• Check on the appearance and tightness of the gas and combustion circuit gaskets;

• Check on the condition and position of the ignition and ame sensing electrodes (see section 16);

• Check on the condition of the burner and its xing to the aluminium ange;

• Check for any dirt in the combustion chamber. Use a vacuum-cleaner for this cleaning operation;

• Check that the gas valve is calibrated correctly (see section 13);

• Check that there is no dirt in the siphon;

• Check on the central heating system pressure;

• Check on the central heating expansion vessel pressure.

18. ACTIVATING THE CHIMNEY SWEEP FUNCTION

19. ANNUAL SERVICE

Page 37

37

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Figure 19

Key:

1 Water pressure gauge

2 Siphon (condensate)

3 Central heating ntc sensor

4 105°C overheat safety thermostat

5 Gas valve

6 Heat exchanger

7 Flame detector electrode (ionisation probe)

8 Burner

9 Ignition electrode

10 Mixer with venturi

11 Gas injector

12 Fan

13 Flue joint

14 Automatic air vent

15 Hydraulic pressure sensor

16 Boiler drain point

17 Joint ue with ue thermostat

18 Flue thermostat

19 Gas pressure switch

20 Seat of air intake pipe

20. BOILER SCHEMATIC

CT_0818 / 0907_0101

Page 38

38

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

21. ILLUSTRATED WIRING DIAGRAM

21.1 FS 90 - 105

CT_0660 / 0907_0102

Page 39

39

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

21.2 FS 130 - 160

CT_0661 / 0907_0103

Page 40

40

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Boiler model FS 90 105 130 160

Category II

2H3P

II

2H3P

II

2H3P

II

2H3P

Maximum heat input (net/gross) kW 87,2-96,7 102,7-113,8 123,2-136,6 154-170,7

Minimum heat input (net/gross) kW 33,1-36,7 36,8-40,8 40-44,3 41,5-46,02

Maximum heat output 75/60°C kW 85 100 120 150

kcal/h 73100 86000 103200 129000

Maximum heat output 50/30°C kW 91,6 107,8 129,7 162

kcal/h 78776 92708 111542 139320

Minimum heat output 75/60°C kW 32,2 35,8 39 40,4

kcal/h 27692 30788 33540 34744

Minimum heat output 50/30°C kW 34,9 38,8 42,1 43,7

kcal/h 30014 33368 36206 37582

Useful efciency according to 92/42/CEE directive — ★★★★ ★★★★ ★★★★ ★★★★

Central heating system max. pressure bar 4 4 4 4

Heating circuit temperature range °C 25÷80 25÷80 25÷80 25÷80

Flue type —

B23 - B23P - C53*

Flue duct diameter mm 100 100 100 100

Max. ue mass ow rate kg/s 0,041 0,049 0,058 0,073

Min. ue mass ow rate kg/s 0,016 0,018 0,019 0,020

Max. ue temperature °C 78 80 77 75

NOx class — 5 5 5 5

Type of gas used — G20 G20 G20 G20

— G31 G31 G31 G31

Natural gas feeding pressure 2H mbar 20 20 20 20

Propane gas feeding pressure 3P mbar 37 37 37 37

Gas Consumption (NG) m3/hr 9,26 10,9 13,8 16,35

Minimum Operating Pressure Bar 1 1 1 1

High Level Ventilation to BS6644 boiler room cm2 174,4 205,4 246,4 308

Low Level Ventilation to BS6644 boiler room cm2 348,8 410,8 492,8 616

Mechanical inlet to BS6644 m3/sec 0,067 0,08 0,1 0,12

Water Flow at 20°K Δt lit/sec 1,02 1,19 1,44 1,80

Hydraulic Resistance at 20°K Δt kPa 25 25 22 21

Cold Feed Size to BS6644 mm 25 25 25 32

Safety valve size to BS6644 (open vent) mm 19 19 19 19

Open vent BS6644 mm 32 32 32 32

Maximum Flow Temperature °C 85 85 85 85

Water Content lit 13,7 21 23,3 25,3

Power supply voltage V 230 230 230 230

Power supply frequency Hz 50 50 50 50

Rated power supply W 100 160 135 235

Net weight kg 75 83 95 103

Dimensions height mm 850 850 850 850

width mm 450 450 450 450

depth mm 801 871 1014 1132

* C53 (only with air intake kit)

22. TECHNICAL DATA

Page 41

41

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Page 42

42

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Page 43

43

912.823.1 - GB

INSTRUCTIONS PERTAINING TO THE INSTALLER

Page 44

Baxi Commercial Division

Wood Lane, Erdington,

Birmingham B24 9QP

Email: potterton.commercial@baxigroup.com

www.pottertoncommercial.co.uk

Sales:

0845 070 1056

Technical:

0845 070 1057

heating specialists

Commercial sales

technical & service enquiries

Tel: 0845 070 1055

Fax: 0845 070 1059

Sales hotline: 0845 070 1056

Technical helpline: 0845 070 1057

Service hotline: 0845 070 1058

e-mail: potterton.commercial@baxigroup.com

web: www.pottertoncommercial.co.uk

Spares

Potterton Commercial spares are available nationwide

through the interpart network of approved stockists.

Alternatively please contact:-

Interpart

Brooks House

Coventry Road

Warwick CV34 4LL

Tel: 0844 871 1540

Applications & Installations

Our experienced technical support team are available to offer

advice on any aspect of heating system design and boiler

installation.

Please contact: 0845 070 1057

Commercial service offices

Our service organisation covers the whole of the UK to look after

your needs for all Potterton Commercial products.

Our service office offers a wide range of specialised services

including:

• Burner commissioning for all fuels

• Boiler service contracts

• Breakdown and repair services

• Burner and boiler replacement

• Oil/gas conversions

• Water treatment and descaling

• Packaged units

All descriptions and illustrations contained within this leaflet have

been carefully prepared, but we reserve the right to make

changes and improvements in our products which may affect

the accuracy of the information in this leaflet.

Loading...

Loading...