Please leave these instructions with the user

Baxi Bermuda

Inset 2 Boiler 50/4

Fireside Gas Central Heating Unit

Comp N° 238983 - Issue 4 - 10/99

Installation and

Servicing Instructions

Page 2

Natural Gas

Baxi Bermuda Inset 2 Boiler 50/4

G.C. No. 44 075 01

For use with the following firefronts:

Baxi Bermuda Inset 2 TS

G.C. No. 37 075 12

Baxi Bermuda Inset 2 BS

G.C. No. 37 075 13

Baxi Bermuda Inset 2 FS

G.C. No. 37 075 15

Baxi Bermuda Inset 2 KS

G.C. No. 37 075 14

Baxi Bermuda Inset 2 TS Deluxe

G.C. No. 37 075 28

Baxi Bermuda Inset 2 BS Deluxe

G.C. No. 37 075 29

Baxi Bermuda Inset 2 FS Deluxe

G.C. No. 37 075 30

Baxi Bermuda Inset 2 KS Delux

G.C. No. 37 075 31

Baxi Limited is one of the leading manufacturers of domestic

heating products in the UK.

Our first priority is to give a high quality service to our

customers. Quality is built into every Baxi product - products

which fulfil the demands and needs of customers, offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the products

that customers want to buy.

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we know

that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If not,

please let us know.

Baxi is a BS-EN ISO 9001

Accredited Company

Contents - Page 3

Section

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

Introduction

Technical Data

System Details

Water Circulating Systems

Treatment of Water Circulating Systems

Pipework

System Controls

Fully Pumped System

Overheat Kit & Sealed Systems

Storage Systems

Pumped Heating & Gravity Hot Water

Site Requirements

Builders Opening

Location

Fireplace Opening & Surround

Frame Extension Kit

Flue

Ventilation

Gas Supply

Electrical Supply

Installation

Initial Preparation

Right Hand Water Connections

Connecting the Sensing Pipe

Siting the Boiler

Securing the Boiler

Water Connections

Fully Pumped Systems

Overheat Thermostat

Pumped Heating & Gravity Hot Water

Gas Connection

Electrical Connection

Making the Electrical Connection

Overheat Thermostat

Flue Connection

Completion

CommissionIng the Appliance

Annual ServicIng

Annual Servicing

Removal of Firefront

Removal of Controls

Cleaning the Lint Arrestor

Cleaning the Burner & Main Injector

Cleaning the Pilot/A.S.D. Assembly

Cleaning the Heat Exchanger

Changing Components

Changing Components

Removal of Firefront

Lint Arrestor

Suppression Capacitor

Thermostat

Piezo Igniter Unit

Removal of Controls

Gas Valve

Burner & Main Injector

Pilot/A.S.D. Assembly

Ignition Lead

Fault Finding

Short Parts List

Page

4

5

6

9

12

18

19

22

26

28

1.0 Introduction - Page 4

The boiler meets requirements of Statutory Instrument

“The Boiler (Efficiency) Regulations 1993 N° 3083” and

is deemed to meet the requirements of Directive

92/42/EEC on the efficiency requirements for new hot

water boilers fired with liquid or gaseous fuels.

Type test for purpose of Regulation 5 certified by:

Notified Body 0086.

Product/production certified by: Notified Body 0086.

“Benchmark” Log Book

As part of the industry-wide “Benchmark” initiative all

Baxi boilers now include an Installation, Commissioning

and Service Record Log Book. Please read the Log

Book carefully and complete all sections relevant to the

appliance and installation. These include sections on

the type of controls employed, flushing the system,

burner operating pressure etc. The details of the Log

Book will be required in the event of any warranty work.

Also, there is a section to be completed at each

subsequent regular service visit.

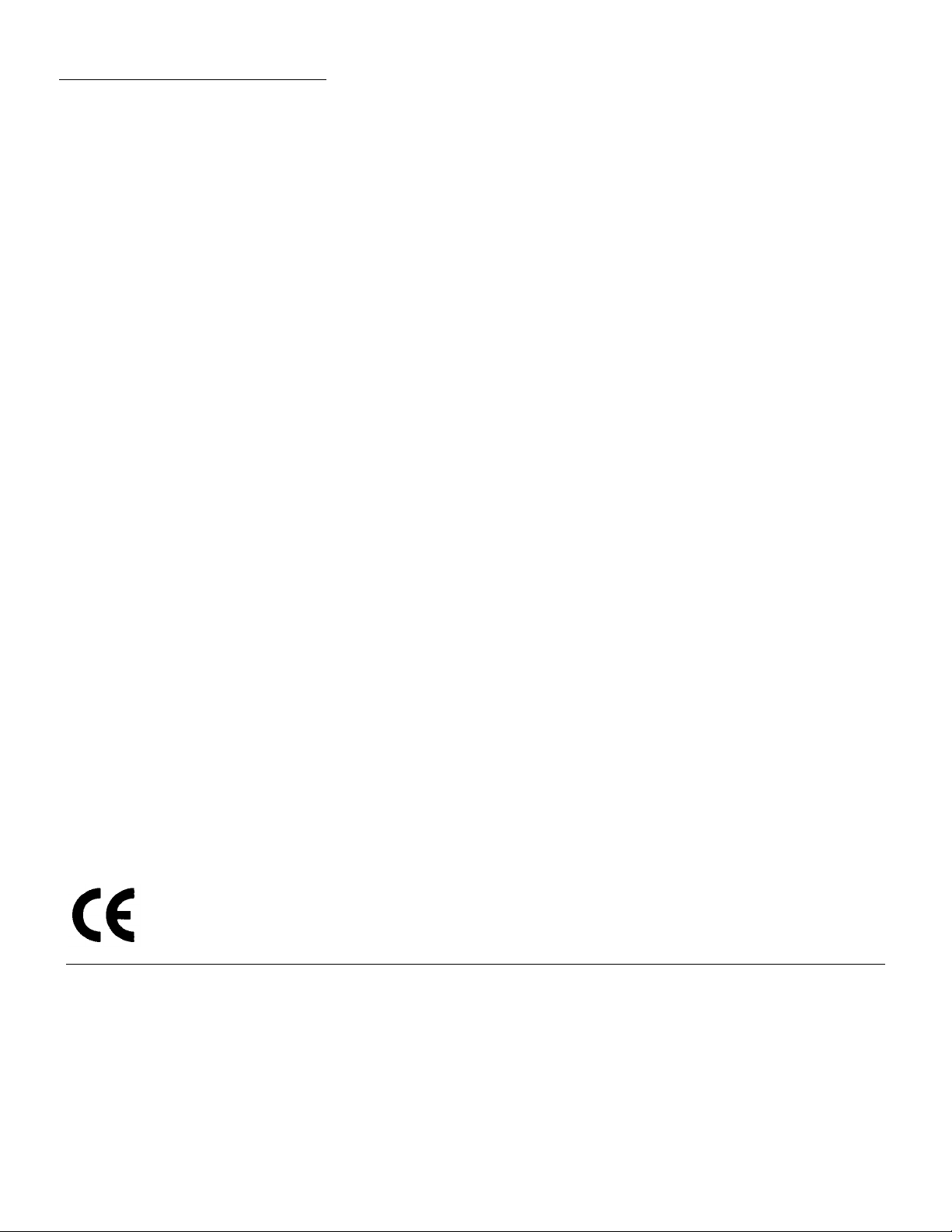

1.1 Description

1. The Baxi Bermuda Inset 2 is a combined central heating

boiler and gas fire designed for installation within a builders

opening in the living space of a dwelling.

2. The firefront is intended for hearth mounting.

3. These instructions relate to the central heating boiler

section of the appliance (Fig. 1).

4. The boiler is range rated, with outputs as shown:

5. The appliance is preset at its MIDRANGE heat input rate

and is designed for use on NATURAL GAS only. The boiler

is suitable for fully pumped and pumped central heating with

gravity hot water systems.

6. Sealed System applications require an optional overheat

thermostat kit.

1.2 Installation

1. The appliance is suitable for installation only in G.B. and

I.E. and should be installed in accordance with the rules in

force. For Ireland install in accordance with l.S. 813

“Installation of Gas Appliances”.

2. The installation must be carried out by a CORGI

Registered Installer or other competent person and be in

accordance with the relevant requirements of Gas Safety

(Installation and Use) Regulations, the Building Regulations

(Scotland) (Consolidation), the Local Building Regulations,

the Current I.E.E. Wiring Regulations and the bye laws of the

Local Water Undertaking. Where no specific instructions are

given, reference should be made to the relevant B.S.

CODES OF PRACTICE.

3. All systems must be thoroughly flushed and treated

with inhibitor (see section 3.2).

1.3 B.S. Codes of Practice

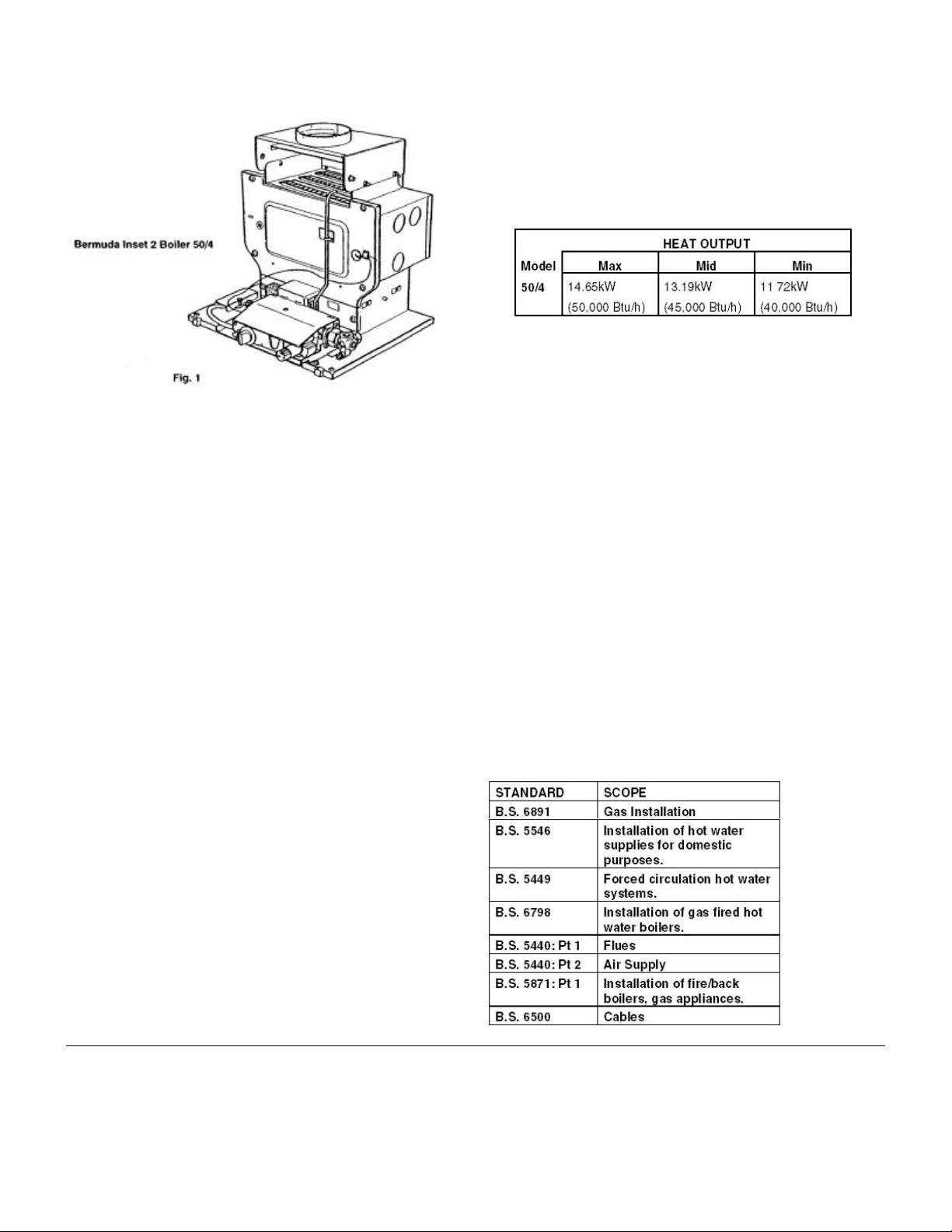

2.0 Technical Data - Page 5

Bermuda Inset 2 Boiler 50/4

The Boiler is for use with Natural Gas only.

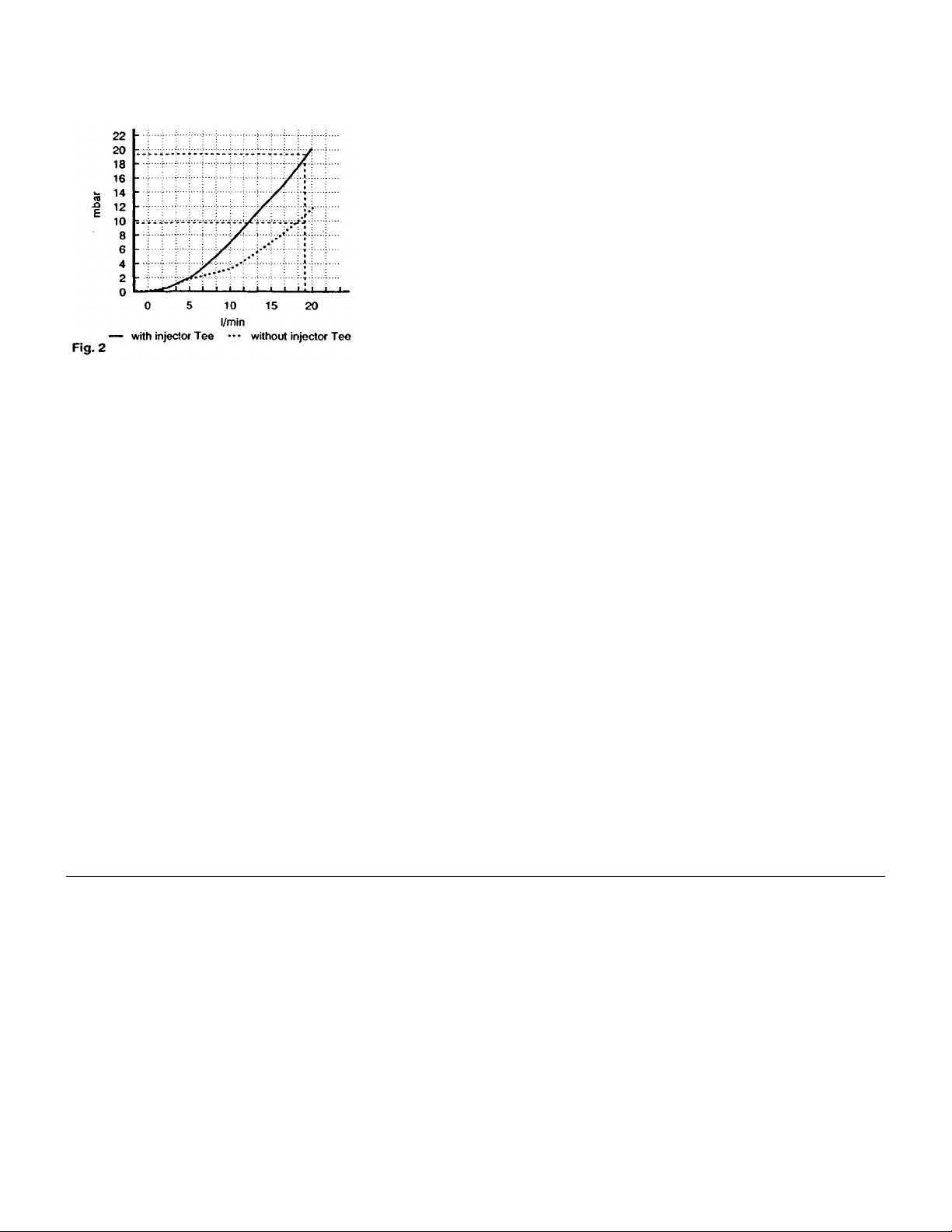

Inset 2 50/4 hydraulic resistance

SEDBUK Declaration For Inset 2 50/4

The seasonal efficiency (SEDBUK) is 72 %

This value is used in the UK Government’s Standard

Assessment Procedure (SAP) for energy rating of

dwellings.

The test data from which it has been calculated have

been certified by 0086.

Heat Input

kW

Btu/h

Heat Output

kW

Btu/h

Burner Pressure

mbar

in wg

Water Content

litres

gallons

Thermocouple

Output

Gas Connection

Water Connections

Electricity Supply

Controls

Gas Rate

(after 10 mins)

Max

18.79

64,100

Max

14.65

50,000

Max

17

6.8

Max

1 6

0.35

9.5 - 11 5mv

Rc ½ (½ in BSPT)

3 x 1 in BSP

230V ~ 50Hz

External fuse - 3 Amp

Appliance Rating - 4.8 watt

Multi-functional gas valve, mechanical thermostat,

thermocouple with permanent pilot & atmospheric

sensing device

1.8m3/h

(63.57ft3/h)

Mid

17

58,070

Mid

13.19

45,000

Mid

14

5.6

Min

15.2

51,850

Min

11.72

40,000

Min

11

4.4

Lifting Weight

Dimensions

Flue Diameter

mm

in

Heat Exchanger

Low Head

mm

in

Water Content Fully pumped or pumped heating with gravity hot

32.1 kg (70.7 Ibs)

Height

Width

Depth

125

5

Cast Iron

(Min)

1000

393/

8

water. Sealed system with optional overheat

thermostat

516mm

440mm

368mm

3.0 System Details - Page 6

3.1 Water Circulating Systems

1. The appliance is suitable for open vented systems which

are either fully pumped or pumped central heating with

gravity domestic hot water.

2. An optional overheat thermostat kit is available where

additional control protection is required and for sealed

system applications. This must not be used on gravity

systems.

3. The following conditions should be observed at all

times:

• The static head must not exceed 30m (100ft)

of water.

• The boiler must not be used with a direct

cylinder.

• Drain cocks should be fitted to all system low

points.

• All gas and water pipes and electrical wiring

must be installed in such a way that they do

not restrict the servicing of the boiler.

• Position isolating valves as close as possible

to the circulating pump.

3.2 Treatment of Water Circulating Systems

For optimum performance after installation, this boiler and its

associated central heating system must be flushed in

accordance with the guidelines given in BS7593: 1992

“Treatment of water in domestic hot water central heating

systems”. This must involve the use of a proprietary

cleanser, such as BetzDearborn’s Sentinel X300 or X400, or

Fernox’s Superfloc.

Full instructions are supplied with the products, but for

immediate information please contact BetzDearbom (0151

420 9563) or Fernox (01799 550811).

For long term protection against corrosion and scale, after

flushing it is recommended that an inhibitor such as

BetzDearborn’s Sentinel X100, or Fernox’s MB-1 or Copal is

dosed in accordance with the guidelines given in

BS7593:1992.

Failure to flush and add inhibitor to the system will

invalidate the appliance warranty.

It is important to check the inhibitor concentration after

installation, system modification and at every service in

accordance with the manufacturer’s instructions. (Test kits

are available from inhibitor stockists.)

For information or advice regarding any of the above contact

the Baxi Helpline.

3.0 System Details - Page 7

3.3 Pipework

1. The sizes of the flow and return pipes from the boiler

should be determined by normal methods according to the

requirements of the system.

2. It is recommended that the system is designed for an

11°C (20° F) drop in temperature across the system.

3.4 System Controls

1. For optimum operating conditions, the system in which

the appliance is installed should include a control system.

2. Such a system would comprise a timer control and a

separate room and/or cylinder thermostat as appropriate.

3. The boiler should be controlled so that it operates on

demand only.

4. It is not economical to rely on the boiler thermostat to

control operation of the system.

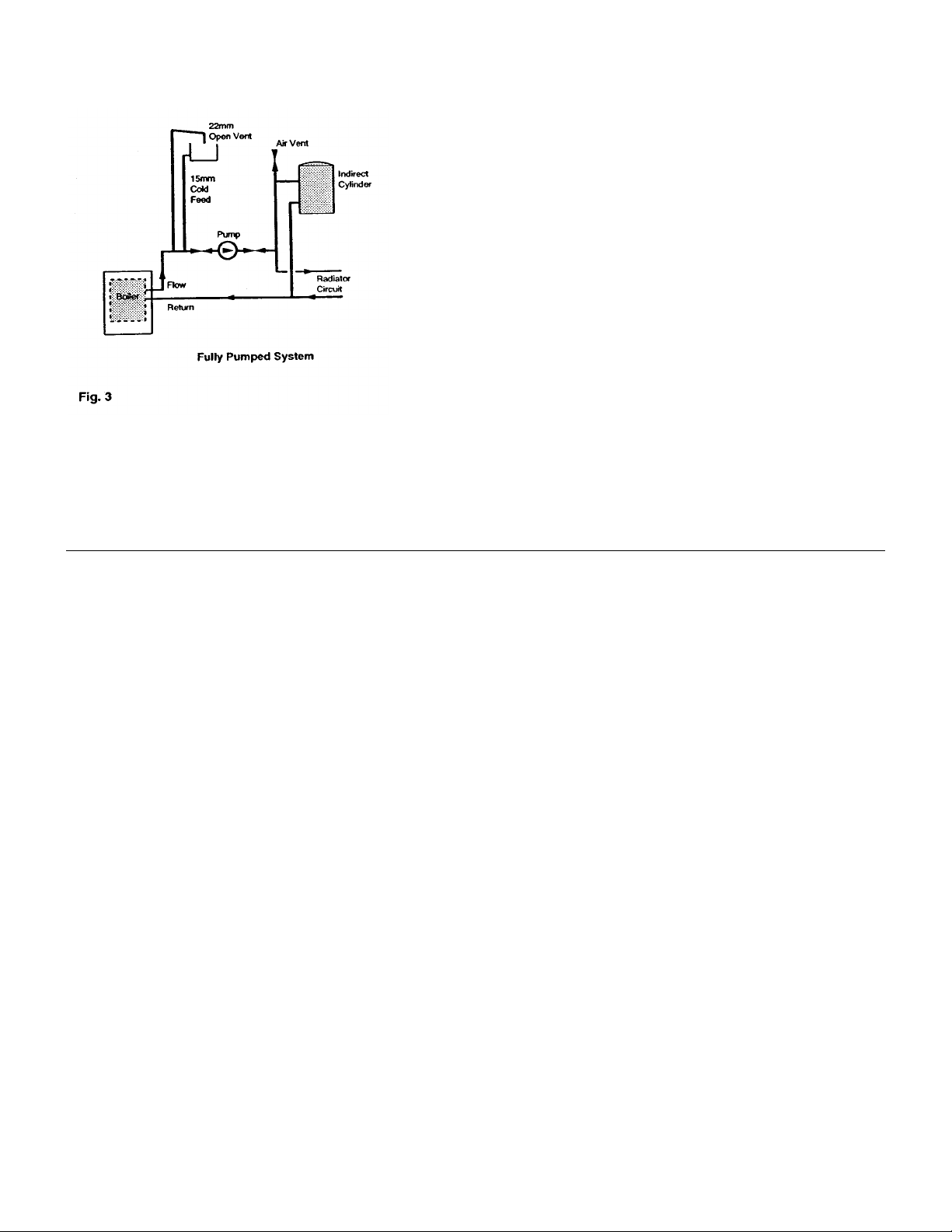

3.5 Fully Pumped System (Fig. 3)

1. The sizes of the system pipes should be determined by

normal methods.

2. The open vent pipe should be a minimum of 22mm and

must rise continuously to a point above the teed and

expansion tank.

3. The flow pipe from the boiler may form part of the vent

pipe. No part of the open vent should contain a valve.

3.0 System Details - Page 8

3.6 Overheat Kit & Sealed Systems

1. An overheat thermostat kit is available to facilitate the

installation of a Bermuda Inset 2 boiler to systems

incorporating a combined feed and vent and to flats and

dwellings where the building design prevents the boiler vent

pipe rising continuously to the feed and expansion tank.

(This must not be used on gravity systems.) Baxi Part N°

234885.

2. The boiler can be applied to a sealed system with the use

of the overheat kit.

3. Information regarding the application of the overheat

thermostat is included with the kit.

3.7 Storage Systems

1. For information regarding the use of a Bermuda Inset 2

boiler with a storage system, contact the appropriate storage

system manufacturer.

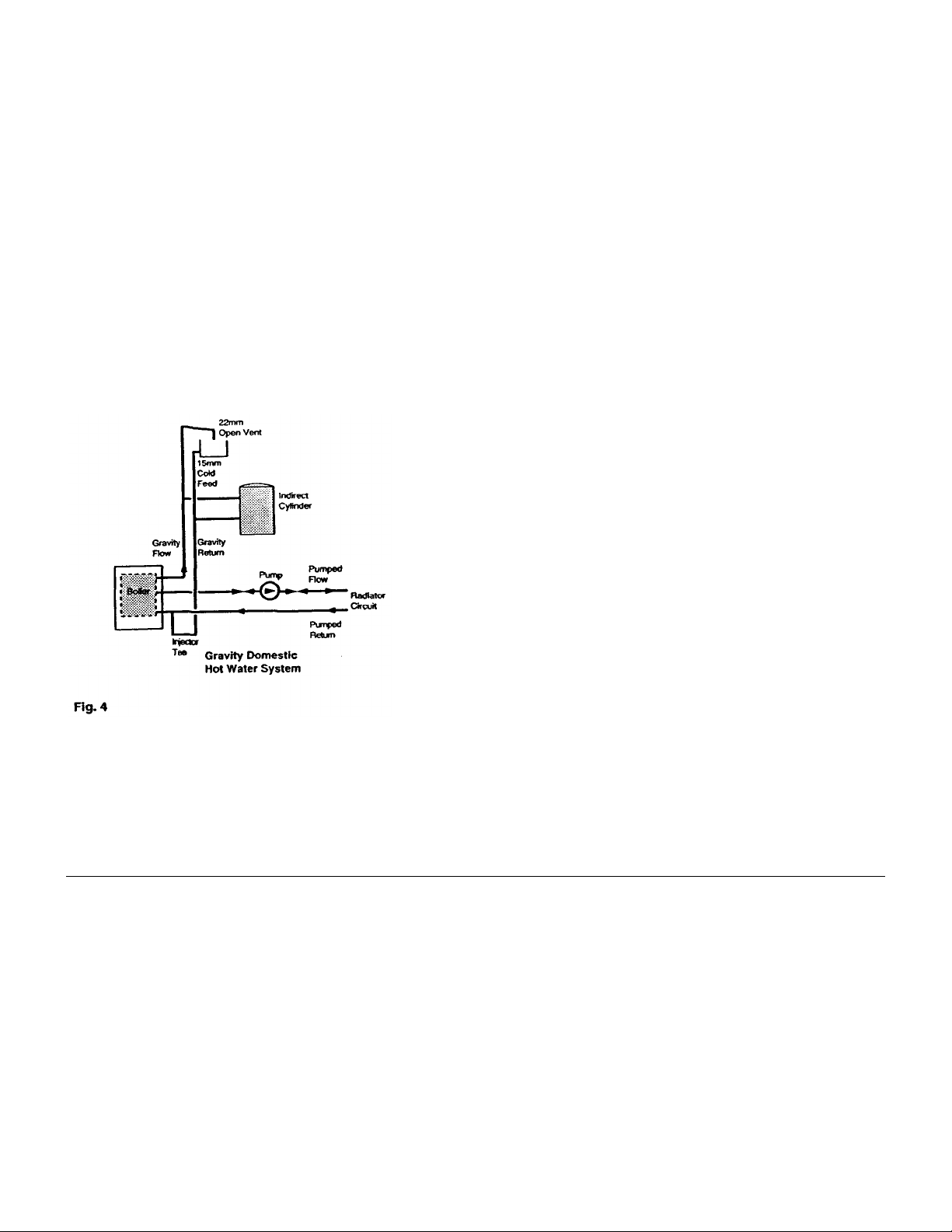

3.8 Pumped Heating & Gravity Hot Water (Fig. 4)

1. The sizes of system pipes should be determined by

normal methods.

2. The gravity flow pipe should rise vertically as close as

possible to the boiler, avoiding sharp bends and tight

elbows.

3. The open vent pipe should be a minimum of 22mm and

must rise continuously to a point above the feed and

expansion tank.

4. The flow pipe from the boiler may form part of the vent

pipe.

5. No part of the open vent should contain a valve.

6. The brass injector tee must be fitted to the boiler return

on all systems incorporating a gravity circuit.

7. The circulating head should not be less than 1 m (3ft)

with a maximum horizontal run of 3m (10ft) when using

28mm pipes. Smaller pipe sizes and longer horizontal runs

are acceptable with suitably increased circulating heads.

8. The gravity circuit should be designed with a minimum of

restriction, avoiding possible air traps and long horizontal

runs.

9. The system should be designed to prevent gravity

circulation in the heating system when the pump is not

running.

4.0 Site Requirements - Page 9

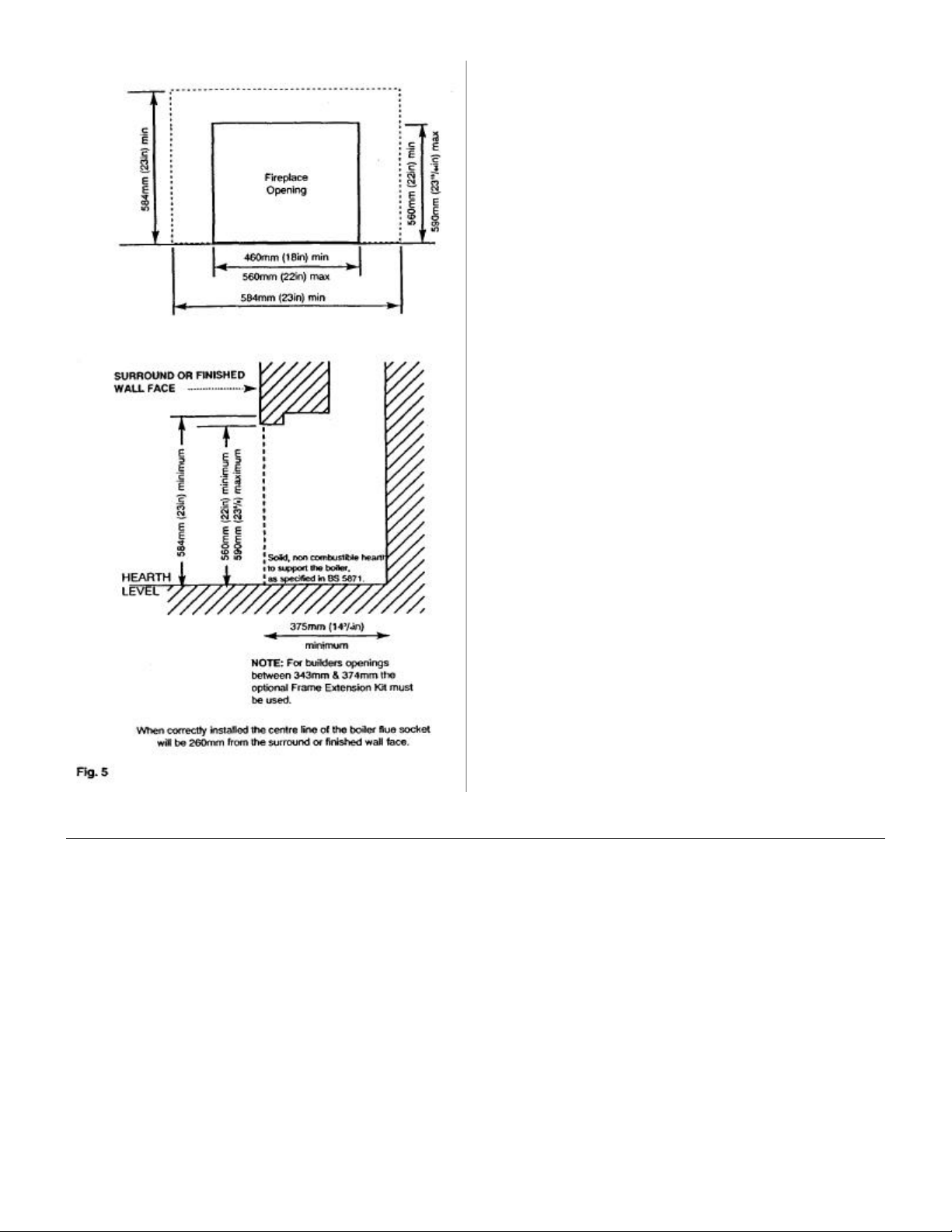

4.1 Builders Opening (Fig 5)

1. The boiler unit is designed to fit within a standard builders

opening, the minimum dimensions of which are as shown.

Height 584mm (23in)

Width 584mm (23in)

Depth 375mm (14¾in)

2. The opening should be soundly constructed of brick, precast concrete or be a proprietary builders opening.

3. The base of the opening should be sound and noncombustible and must be flat and level.

4. The base of the builders opening should be at the same

height as the finished level of the hearth.

IMPORTANT: If a false chimney breast is intended to

house the boiler, a simulated builders opening, within

the breast, must be provided.

5. The builders opening must not communicate with voids,

pipe ducts or spaces other than the room in which the

appliance is situated.

4.2 Location

1. The appliance must be installed in the living space of a

dwelling.

2. Restrictions to the siting of the appliance are covered by

BS 5546. The appliance may not be installed in bathrooms,

shower rooms, bedrooms or bed sitting rooms.

4.3 Fireplace Opening & Surround

1. If a fireplace surround is to be used, it must be centrally

placed and have opening sizes and a vertical flat area as

detailed in the Installation and Servicing Instructions for the

fire.

4.4 Frame Extension Kit

1. If the depth of the builders opening is less than the

375mm minimum specified, it can be increased by the use of

the Frame Extension Kit.

2. Kit N° 234887 is suitable for use with Inset 2 TS, BS and

FS models.

For Inset 2 KS, Kit N” 239341 must be used.

3. Full installation details are included in the kit.

Loading...

Loading...