Baxi Bermuda 45/4 M, Bermuda 45/4 E, Bermuda 57/4 M, Bermuda 57/4 E Installation And Servicing Instructions

Baxi Bermuda 45/4 & 57/4 Boilers

Gas Fired Central Heating Unit

Gas Type G20 (Natural Gas)

Comp N

Baxi Bermuda 45/4 M - G.C.No 44 077 71

Baxi Bermuda 57/4 M - G.C.No 44 077 72

Baxi Bermuda 45/4 E - G.C.No 44 077 73

Baxi Bermuda 57/4 E - G.C.No 44 077 74

These Instructions must be read in conjunction with those

for the separate Firefront.

o

241794 - Iss 9 - 6/00

Installation

And

Servicing

Instructions

Natural Gas

Baxi Bermuda 45/4 M

G.C.No. 44 077 71

Baxi Bermuda 57/4 M

G.C.No. 44 077 72

Baxi Bermuda 45/4 E

G.C.No. 44 077 73

Baxi Bermuda 57/4 E

G.C.No. 44 077 74

These Instructions must be read in

conjunction with those for the

separate Firefront.

Baxi UK Limited is one of the leading manufacturers

of domestic heating products in the UK.

Our first priority is to give a high quality service to our

customers. Quality is built into every Baxi product -products

which fulfil the demands and needs of customers, offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the products

that customers want to buy.

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we know

that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If not,

please let us know.

Baxi is a BS-EN ISO 9001

Accredited Company

The boiler meets requirements of Statutory Instrument “The

Boiler (Efficiency) Regulations 1993 No 3083” and is

deemed to meet the requirements of Directive 92/42/EEC on

the efficiency requirements for new hot water boilers fired

with liquid or gaseous fuels.

Type test for purpose of Regulation 5 certified by:

Notified Body 0086.

Product/production certified by: Notified Body 0086.

CONTENTS - Page 3

Introduction

Technical Data

System Details

Site Requirements

PAGE 4

PAGE 5

PAGE 6 - 8

Water Circulating Systems

Treatment of Water Circulating Systems

Pipework

System Controls

Fully Pumped System

Overheat Kit & Sealed Systems

Storage Systems

Pumped Heating & Gravity Hot Water

PAGE 9 - 12

Builders & Fireplace Opening

Location

Fireplace Surround

Flue

Ventilation

Gas Supply

Electrical Supply

Installation

Commissioning the Appliance

Annual Servicing

Changing Components

Short Parts List

Fault Finding

PAGE 13 - 22

Initial Preparation

Siting the Boiler

Securing the Boiler

Water Connections

Fully Pumped Systems

Overheat Thermostat

Pumped Heating & Gravity Hot Water

Gas Connection

Electrical Connection

Making the Electrical Connection

Refilling the Controls

Flue Connection

Completion

PAGE 23 - 24

PAGE 25 - 28

Removal of Firefront

Removal of Controls

Cleaning the Lint Arrestor

Cleaning the Burner & Main Injector

Cleaning the Pilot / A.S.D. Assembly

Cleaning the Heat Exchanger

PAGE 29 - 34

Removal of Firefront

Flame Sensing Lead

Ignition Lead

Gas Valve

Burner & Main Injector

Pilot / A.S.D. Assembly

Thermostat

Piezo Igniter Unit

Suppression Capacitor

Thermostat Sensor

Thermostat Potentiometer

Printed Circuit Board

PAGE 35

PAGE 36 - 40

INTRODUCTION - Page 4

Description

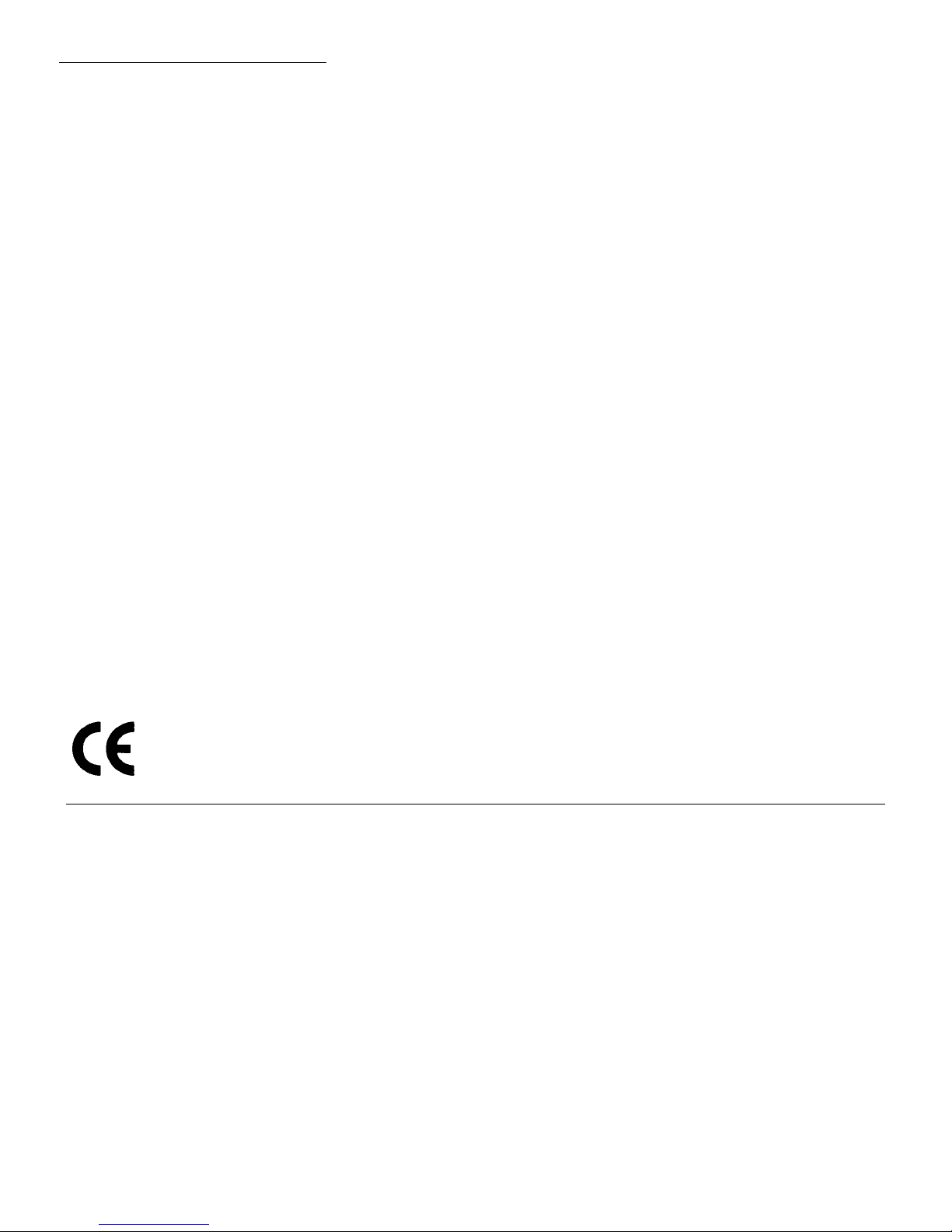

The Baxi Bermuda is a combined central heating boiler and

gas fire designed for installation within a builders opening in

the living space of a dwelling.

These installation and servicing instructions cover all natural

gas models. There are two physical sizes of boiler, the

Bermuda 45 being the smaller. Both Bermuda 45 and 57 are

available with either electronic or manual controls. The

appliance is fitted with an Atmospheric Sensing Device

which will shut the boiler down in the event of adverse flue

conditions. All installation and servicing procedures are the

same for each size of boiler. Any differences in procedure

between electronic and manual control versions are covered

in this booklet.

These instructions relate to the central heating boiler section

of the appliance.

The two models of the boiler have range rated outputs

as shown.

Each appliance is preset at its MIDRANGE heat input rate

and is designed for use on NATURAL GAS only. The boilers

are suitable for fully pumped and pumped central heating

with gravity hot water systems. The propane back boiler is

covered by its own instructions supplied with it. An optional

overheat thermostat kit is available for sealed systems or

where additional system protection is required.

“Benchmark” Log Book

As part of the industry-wide “Benchmark” initiative all Baxi

boilers now include an Installation, Commissioning and

Service Record Log Book. Please read the Log Book

carefully and complete all sections relevant to the appliance

and installation. These include sections on the type of

controls employed, flushing the system, burner operating

pressure etc. The details of the Log Book will be required in

the event of any warranty work. Also, there is a section to be

completed at each subsequent regular service visit.

Baxi Part No 235565 for 45/4E & 57/4E

Baxi Part No 234885 for 45/4M & 57/4M

Installation

The installation must be carried out by a CORGI Registered

Installer or other Competent Person and be in accordance

with the relevant requirements of GAS SAFETY (Installation

and Use) REGULATIONS, the BUILDING REGULATIONS

(Scotland) (Consolidation), the LOCAL BUILDING

REGULATIONS, the current I.E.E. WIRING REGULATIONS

and the bye laws of the LOCAL WATER UNDERTAKING.

Where no specific instructions are given, reference should

be made to the relevant B.S. CODES OF PRACTICE.

All systems must be thoroughly flushed and treated with

inhibitor (see System Details).

B.S. Codes of Practice

STANDARD

BS 6891

BS 5546

BS 5449

BS 6798

BS 5440 Pt 1

BS 5440 Pt 2

BS 5871 Pt 1

BS 6500

SCOPE

Gas Installation.

Installation of hot water supplies

for domestic purposes.

Forced circulation hot water

systems.

Installation of gas fired hot water

boilers.

Flues.

Air Supply.

Installation of fire/back boilers,

gas appliances.

Cables

TECHNICAL DATA - Page 5

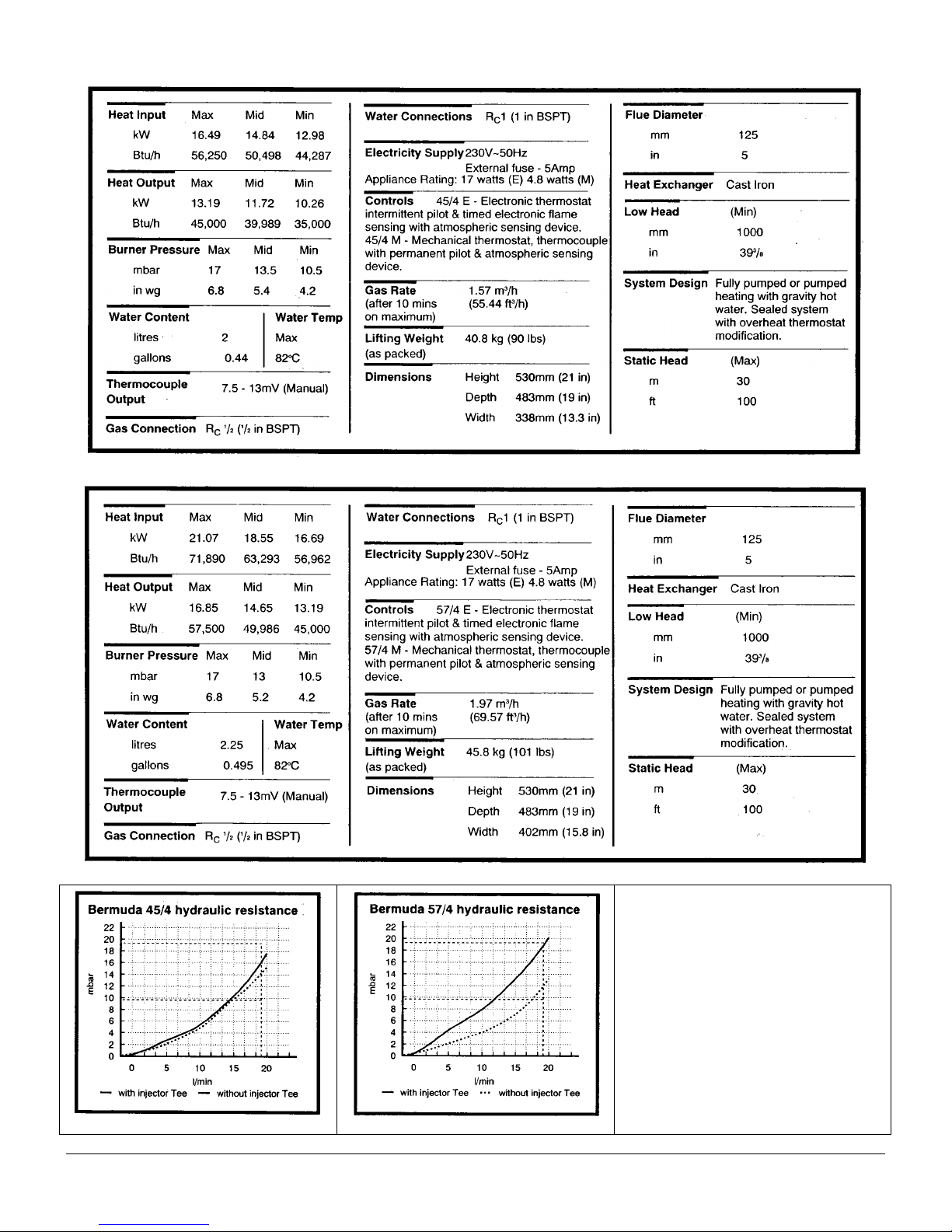

Bermuda Boiler 57/4

Bermuda Boiler 45/4

Sedbuk Declaration For Bermuda

45/4 and 57/4 Boilers

The seasonal efficiency (SEDBUK) are

45/4M 72.7%

45/4E 76.8%

57/4M 71.8%

57/4E 75.8%

This value is used in the UK

Government’s Standard Assessment

Procedure (SAP) for energy rating of

dwellings. The test data from which it

has been calculated has been certified

by 0086.

SYSTEM DETAILS - Page 6

Water Circulating Systems

The appliance is suitable for open vented systems which are

either fully pumped or pumped central heating with gravity

domestic hot water.

An overheat thermostat modification kit is available where

additional control protection is required and for sealed

system applications. This must not be used on gravity

systems

The following conditions should be observed at all

times:

The static head must not exceed 30m (100ft) of

water.

The boiler must not be used with a direct cylinder.

Drain cocks should be fitted to all system low points.

All gas and water pipes and electrical wiring must

be installed in such a way that it does not restrict the

servicing of the boiler. Position isolating valves as

close as possible to the circulating pump

Treatment of Water Circulating Systems

For optimum performance after installation, this boiler and its

associated central heating system must be flushed in

accordance with the guidelines given in B57593: 1992

‘Treatment of water in domestic hot water central heating

systems’.

This must involve the use of a proprietary cleanser, such as

BetzDearborn’s Sentinel X300 or X400, or Fernox’s

Superfloc. Full instructions are supplied with the products,

but for immediate information, please contact BetzDearborn

on 0151 420 9563, or Fernox on 01799 550811.

For long term protection against corrosion and scale, after

flushing, it is recommended that an inhibitor such as

BetzDearborn’s Sentinal X100, or Fernox’s MB-1 or Copal is

dosed in accordance with the guidelines given in B5S593:

1992.

Failure to flush and add inhibitor to the system may

invalidate the appliance warranty.

Pipework

The sizes of the flow and return pipes from the boiler should

be determined by normal methods according to the

requirements of the system (BS 5449).

It is recommended that the system is designed for an

11ºC (20ºF) drop in temperature across the system.

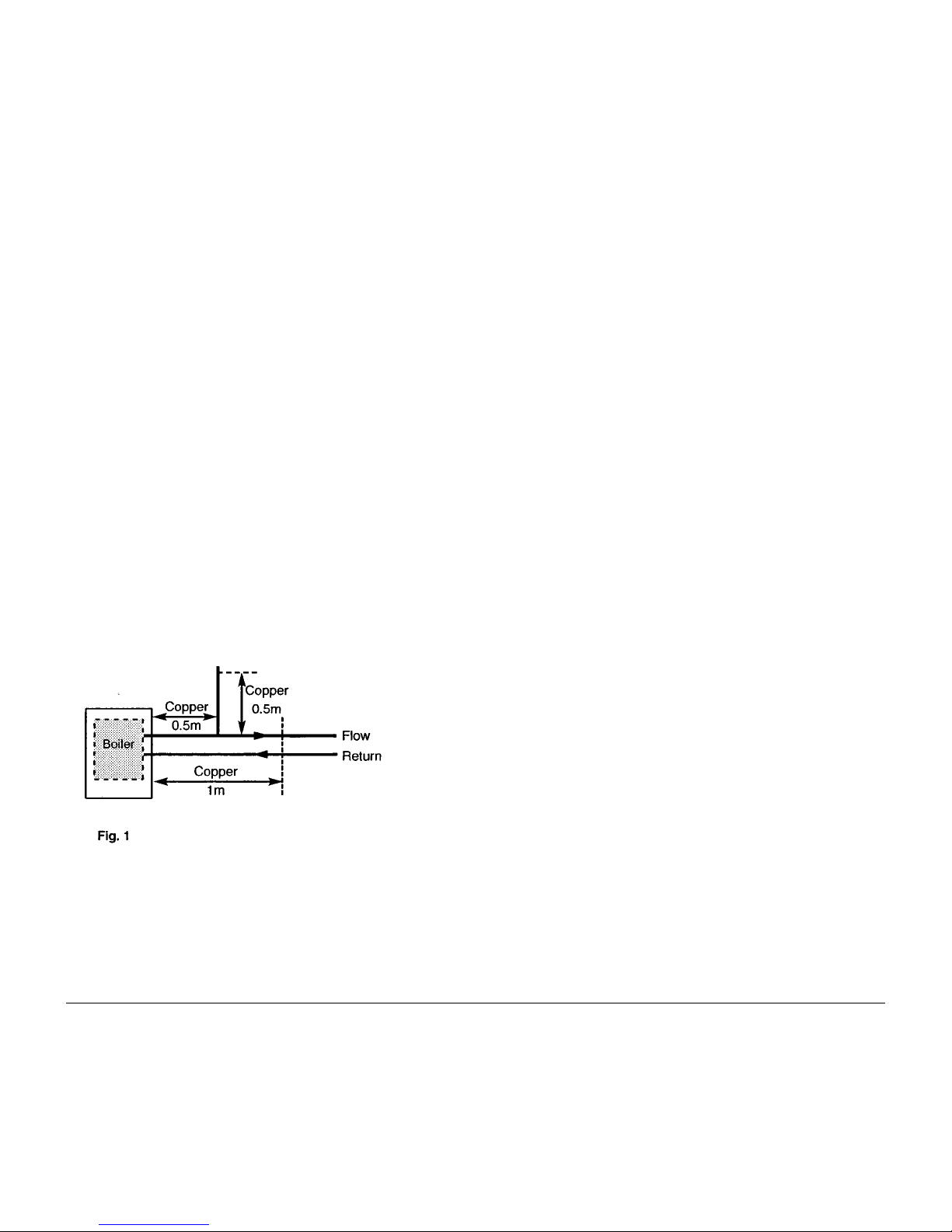

In systems using non-metallic pipework it is necessary to

use copper pipe for the boiler Flow and Return. The copper

must extend at least 1 metre from the boiler and include any

branches. The copper pipe must not be insulated (Fig. 1).

SYSTEM DETAILS - Page 7

System Controls

For optimum operating conditions, the heating system into

which the appliance is installed should include a control

system.

Such a system would comprise a timer control and a

separate room and/or cylinder thermostat as appropriate.

The boiler should be controlled so that it operates on

demand only.

It is not economical to rely on the boiler thermostat to

control operation of the system.

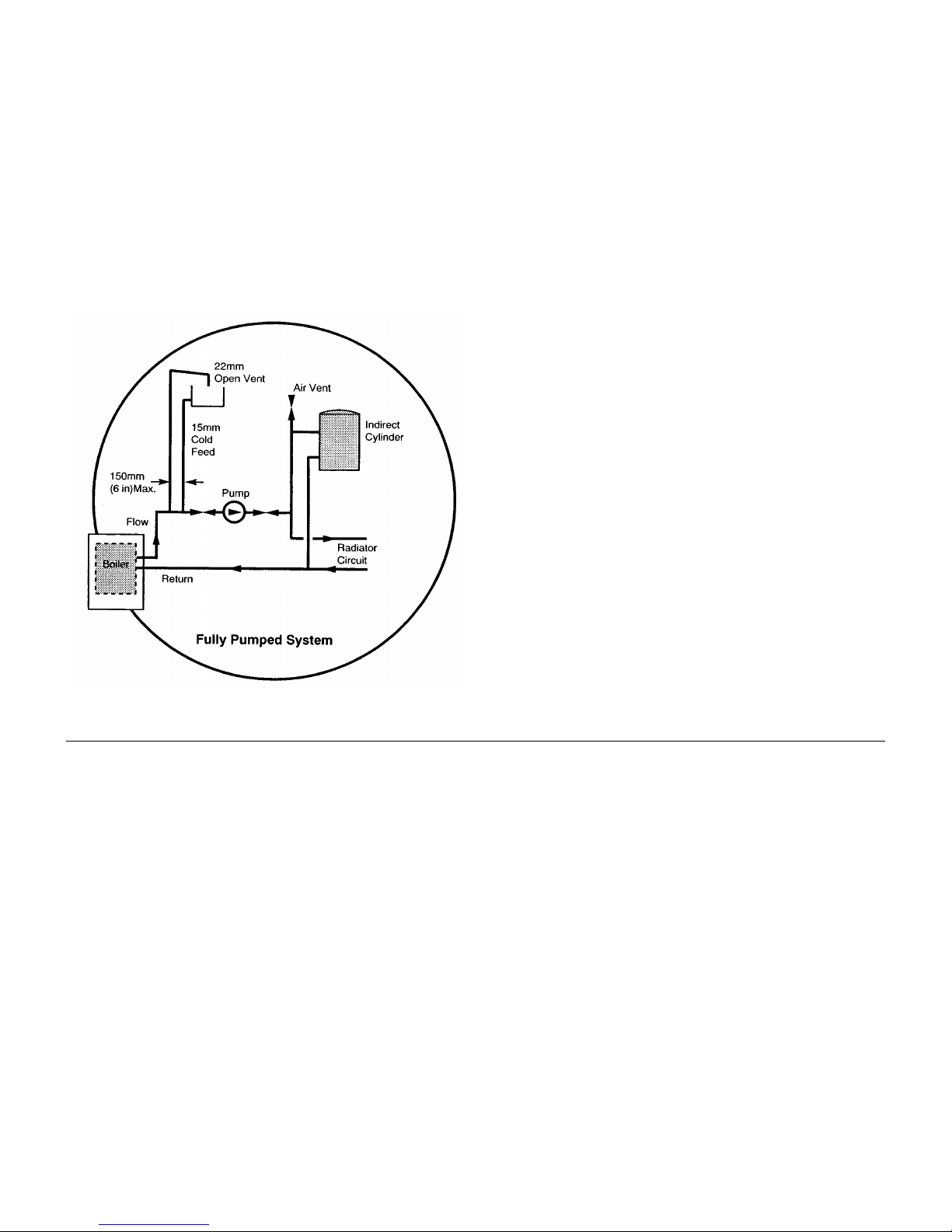

Fully Pumped System

The sizes of the system pipes should be determined by

normal methods (BS 5449).

The open vent pipe should be a minimum of 22mm and must

rise continuously to a point above the feed and expansion

tank.

The flow pipe from the boiler may form part of the vent pipe.

No part of the open vent should contain a valve.

The cold feed pipe (15mm mm) should preferably be

connected to the boiler return.

Close coupling of the cold feed pipe to the flow pipe at a

maximum of 150mm (6 in) from the vent pipe is permissible

but there must always be an open cold water path to the

boiler return connection.

SYSTEM DETAILS - Page 8

Overheat Kit And Sealed Systems

An overheat thermostat modification kit is available to

facilitate the installation of a Bermuda boiler to systems

incorporating a combined feed and vent and to flats and

dwellings where the building design prevents the boiler vent

pipe rising continuously to the feed and expansion tank.

(This must not be used on gravity systems.)

Baxi Part No 235565 for Electronic Controls

Baxi Part No 234885 for Manual Controls

The boiler can be applied to a sealed system with the

use of the overheat kit.

Information regarding the application of the overheat

thermostat is included with the kit.

Storage Systems

For information regarding the use of a Bermuda boiler with.a

storage system, contact the appropriate storage system

manufacturer.

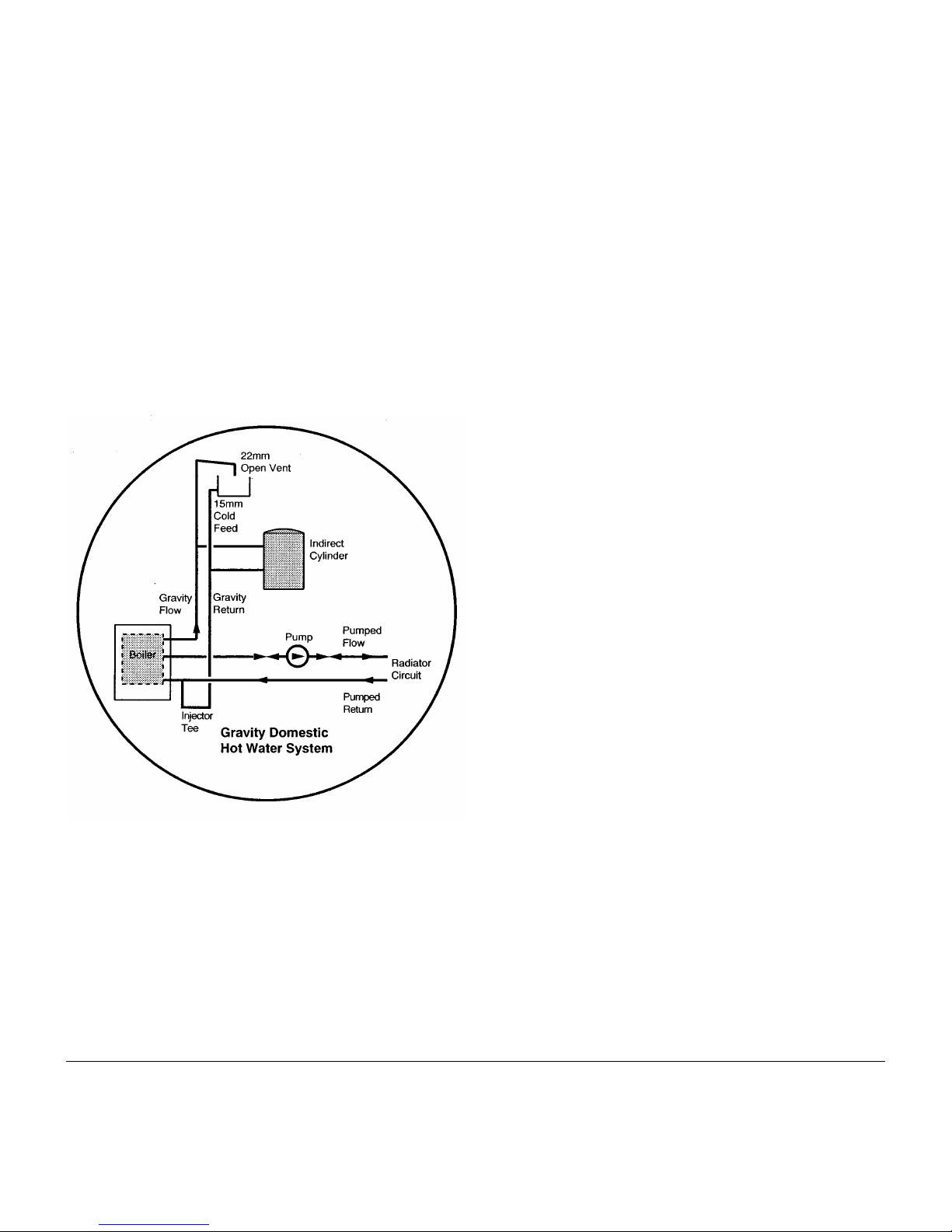

Pumped Heating & Gravity Hot Water

The sizes of system pipes should be determined by normal

methods (BS 5449). 28mm pipe is recommended for the

gravity circuits.

The gravity flow pipe should rise vertically as close as

possible to the boiler, avoiding sharp bends and tight

elbows.

The open vent pipe should be a minimum of 22mm and must

rise continuously to a point above the feed and expansion

tank.

The flow pipe from the boiler may form part of the vent pipe.

No part of the open vent should contain a valve.

The cold feed pipe (15mm mm) should be connected to the

boiler return pipework.

The brass injector tee must be fitted to the boiler return

on all systems incorporating a gravity circuit.

The circulating head should not be less than 1 m (3ft.) with a

maximum horizontal run of 3m (10ft.) when using 28mm

pipes. Smaller pipe sizes and longer horizontal runs are

acceptable with suitably increased circulating heads.

The gravity circuit should be designed with a minimum of

restriction, avoiding possible air traps and long horizontal

runs.

The system should be designed to prevent gravity circulation

in the heating system when the pump is not running.

SITE REQUIREMENTS - Page 9

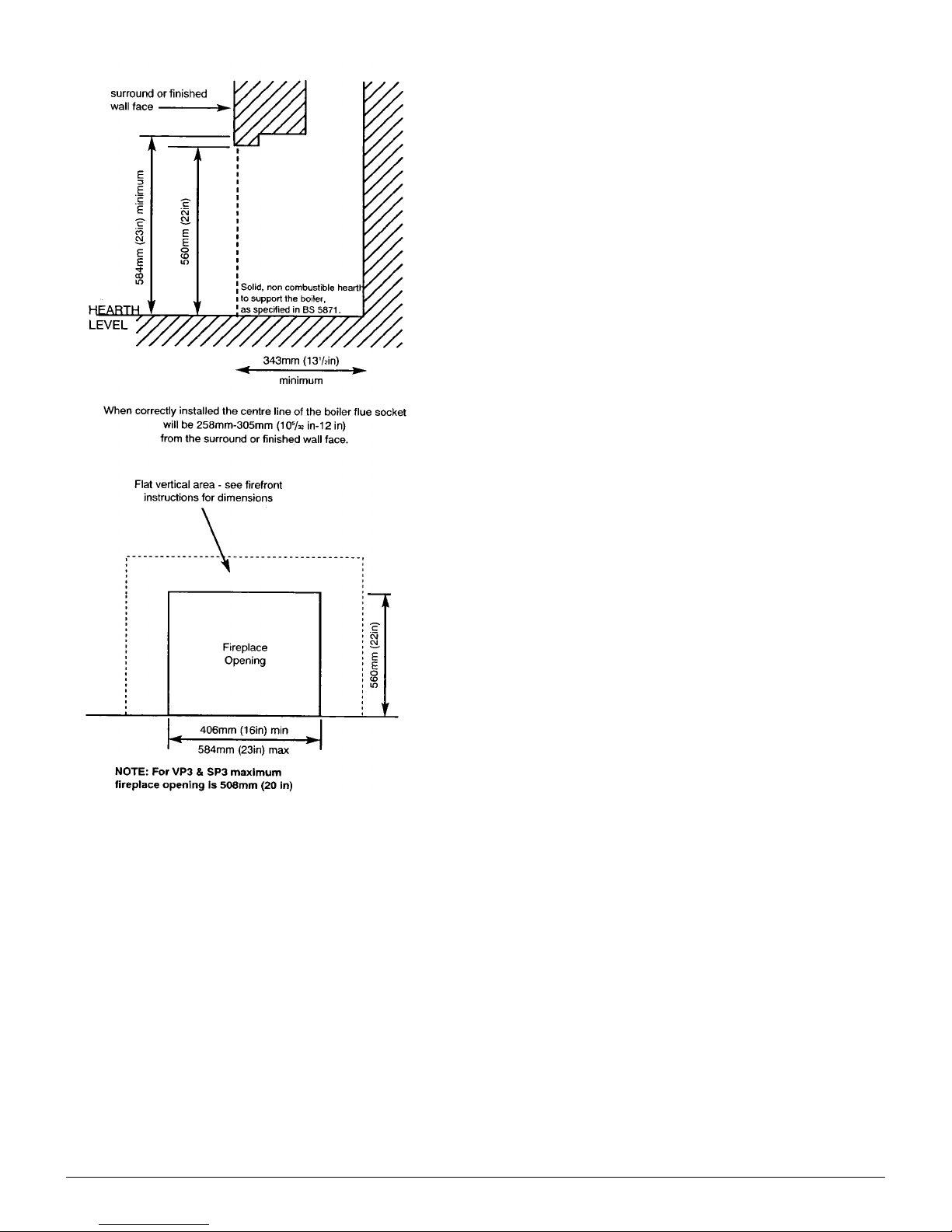

Builders & Fireplace Opening

The boiler unit is designed to fit within a standard builders

opening cavity, the minimum dimensions of which are

343mm(13½in) deep x 584mm(23in) wide x 584mm(23in)

high.

The opening should be soundly constructed of brick, precast concrete or be a proprietary builders opening. The base

of the opening should be sound and non-combustible and

must be flat and level.

The base of the builders opening should be at the same

height as the finished level of the hearth or be the required

height of 100-125mm (4-5 in) above floor level for a wall

mounted firefront installation.

The fireplace opening (i.e. the opening into the cavity) must

be 560mm (22in) high and between 406mm (16in) and

584mm (23in) wide.

Maximum fireplace opening sizes are preferable for ease of

installation and service.

Location

The appliance must be installed in the living space of a

dwelling.

Restrictions to the siting of the appliance are covered by BS

5546. The appliance may not be installed in bathrooms,

shower rooms, bedrooms or bed sitting rooms.

Fireplace Surround

If a fireplace surround is to be used, it must be centrally

placed and have opening sizes and a vertical flat area as

shown in the firefront Installation and Servicing Instructions.

Maximum fireplace opening sizes are preferable for ease of

installation and service.

NO SURROUND

The appliance can be fitted without a surround.

The fireplace opening and vertical flat areas as per above

still apply.

Maximum fireplace opening sizes are preferable for ease of

installation and service.

HEARTH MOUNTING

All Bermuda Firefronts are suitable for hearth mounting. The

hearth must be on the same level as the builders opening.

The hearth must be non-combustible and comply with BS

5871: Pt 1.

WALL MOUNTING

A number of Bermuda Firefronts are aesthetically suitable for

wall mounting above the level of the room floor in instances

where there is no hearth.

The base of the builders opening on which the boiler rests

should be 100-125mm (4-5 in) above floor level.

The following firefronts are suitable for wall mounting:

Bermuda 5P3 Bermuda PW5 Deluxe

Bermuda CS Bermuda RG3

Bermuda C5W Bermuda LFE5 Super

SITE REQUIREMENTS - Page 10

FLUE

Prior to installation it is important to establish that the

flue will perform satisfactorily. Do not proceed with the

installation if the flue does not operate correctly.

The Bermuda is fitted with an Atmospheric sensing

Device that will automatically shut the appliance down

under adverse flue conditions and where insufficient

flue pull exists.

The flue installation must conform to BS 5440 Pt 1. The flue

must have a minimum vertical height of 3m (10ft) measured

from the boiler flue outlet socket and have an internal cross

section area of 12,700 mm2 (20in2), this is satisfied by a flue

of 125mm (5in) internal diameter. If the flue system contains

any bends the vertical height must be increased accordingly.

An approved terminal is required for all installations.

9in X 9in BRICK

Flues previously used for other fuels must be thoroughly

swept. The flue must be protected with a 125mm (5in)

flexible liner. The bottom of the liner should terminate

500mm (20in) above the base of the builders opening. The

flue must be sealed between the liner and the brickwork at

both the top and bottom.

An approved terminal must be installed.

ACID RESISTANT LINERS

A flue constructed of acid resistant liners is satisfactory

provided the size requirements are met.

The boiler flue outlet can be connected to the flue by

means of a short length of 125mm (5in) of flue pipe.

A seal must be made in the annular space between the outer

face of this flue pipe and the acid resistant liner.

An approved terminal must be installed.

PRECAST FLUES

These must conform to BS 5440 Pt 1 and be correctly

designed and installed without intrusion of cement into the

flue passage.

An approved terminal must be installed.

PROPRIETARY FLUES

A flue of this type must meet the size requirements specified

and be installed in accordance with the flue manufacturers

recommendation and relevant codes of practice.

An approved terminal must be installed.

SITE REQUIREMENTS - Page 11

Ventilation

Ventilation air supply to BS 5440 Pt 2 is required.

The permanent ventilation area size requirements are

given in the firefront Installation and Servicing

Instructions.

The permanent vent may be directly into the room containing

the appliance. The vent may also be sited in another room

provided an interconnecting vent is used.

The vent must not be installed inside the builders opening.

The vent should be sited following good practise for a

habitable room. We recommend the use of the Stadium

BM720 “Black Hole” ventilator which is available from your

local merchant.

Gas Supply

The gas installation should be in accordance with BS

6891. The connection at the appliance is Rc ½ (½in

BSPT internal) located at the rear of the gas cock.

Ensure the pipework from the meter to the appliance is of

adequate size and suitably protected. It is preferable to route

the gas supply pipe to the right hand side of the builders

opening. It must be routed so as not to restrict the

installation and servicing of the appliance.

Electrical Supply

External wiring must be correctly earthed, polarised and in

accordance with current lEE wiring regulations. The mains

supply is 230V ~ 50Hz

fused at 5 A.

NOTE: The method of connection to the electrical

supply must facilitate complete electrical isolation of the

appliance, connection may be made via a fused double

pole isolator with a contact separation of at least 3mm

on all poles and serve the appliance and system

controls only.

The cable within the builders opening should be 0.75 mm2 to

lEC 53 Code 227 (heat resistant).

The cable must be routed to avoid contact with the

metal combustion box and hood.

PERMANENT LIVE

A permanent live electrical supply is required for all firefronts

with lighting effects i.e. VP3, 5P3, RG3, 5L3, LFE5 Super

and GF3 Super. The permanent live is also required to

operate the electronic ignition on VP3, 5P3 and RG3

models.

SITE REQUIREMENTS - Page 12

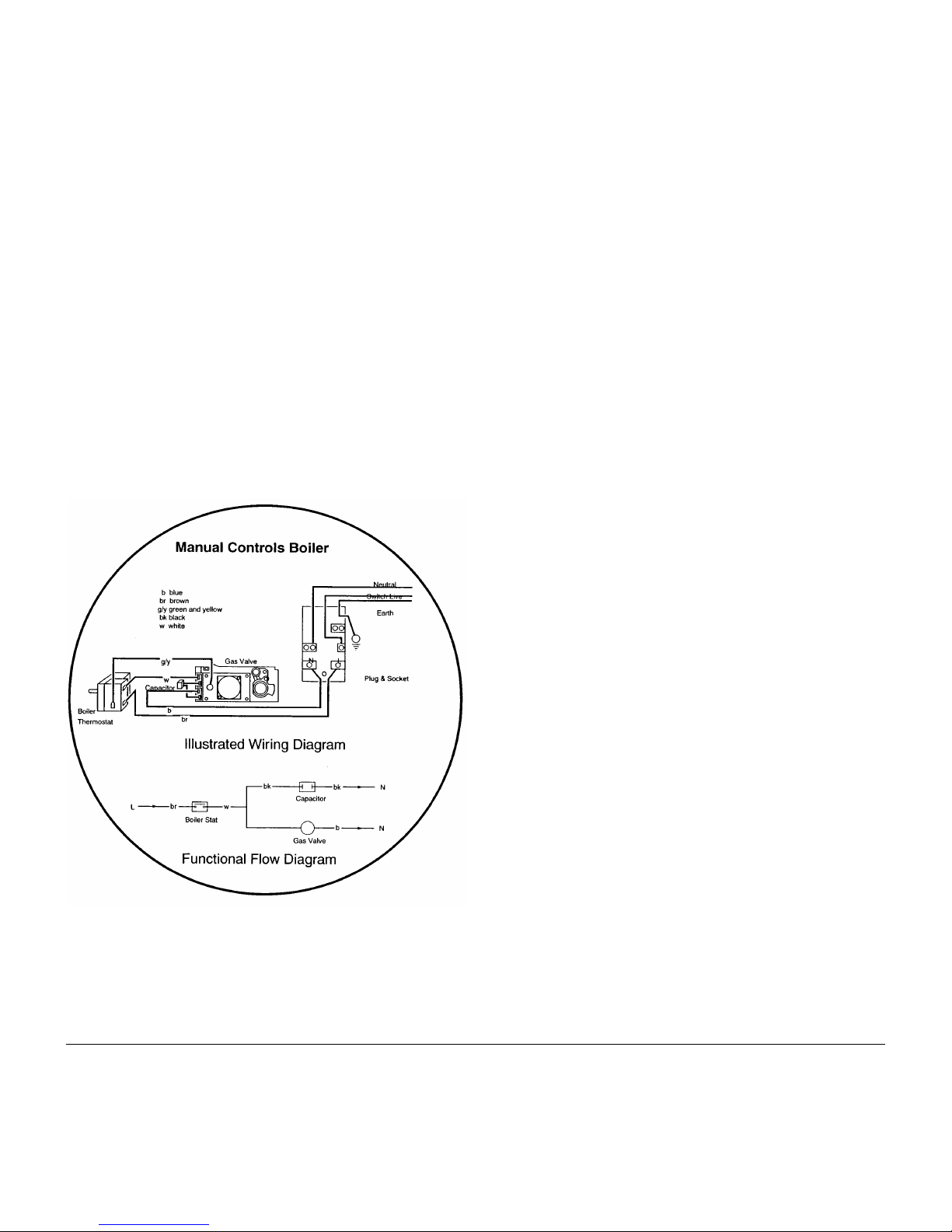

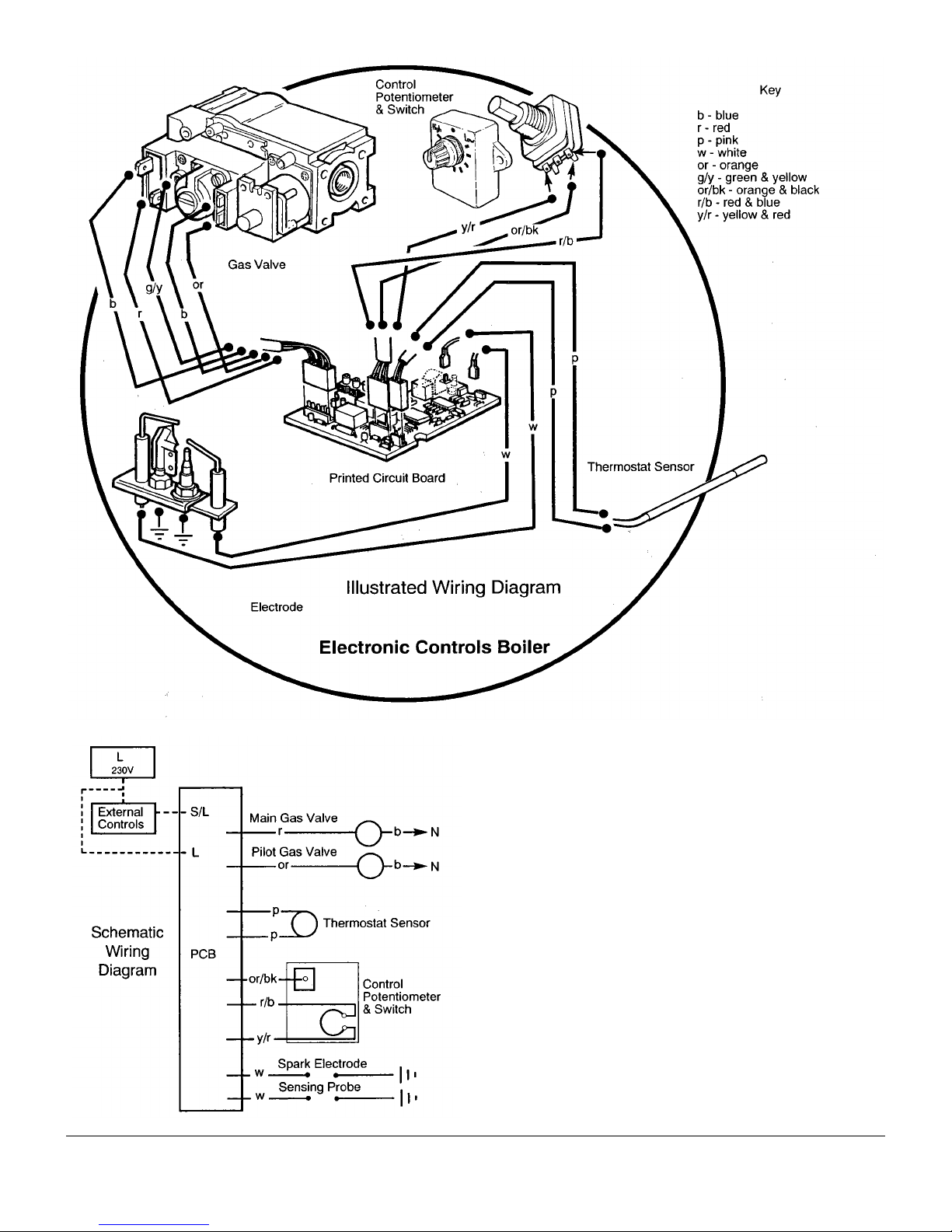

Functional Flow Diagram

It is preferable to route the input cable from the left hand side

of the builders opening.

The cable can be secured to either the boiler base or fire

support plate using the ‘P’ clip supplied in the kit.

NOTE: Polarity of the appliance MUST be correct otherwise

the appliance will not operate correctly.

Loading...

Loading...