Page 1

Supplied By www.heating spares.co Tel. 0161 620 6677

Please leave these instructions with the user

Baxi Arena Super

Baxi Baroque Super

Living Flame Effect Gas Fires

Natural Gas

Comp N° 235317 - Issue 8 - 11/99

Installation and

Servicing Instructions

Baxi Arena Super - G.C.N° 32 077 34

Baxi Baroque Super - G.C.N° 32 077 35

Page 2

Supplied By www.heating spares.co Tel. 0161 620 6677

Contents - Page 2

Introduction

PAGE 3

Technical Data

Site Requirements

Installation

Commissioning the Fire

Fitting the Outer Case

Annual Servicing

PAGE 4

PAGE 5-6

Fireplace Opening

Hearth Mounting

Wall Fixing

Existing Chimneys

Pre-Cast Flues

Gas Supply

Electrical Supply

PAGE 7-9

Initial Preparation

Fitting the Fire

Electrical Connections

PAGE 10-12

Spillage Detection

PAGE 13-14

Baxi Baroque

Baxi Arena

PAGE 15-19

Cleaning the Pilot Assembly

Cleaning the Burner/Injectors

Changing Components

Fault Finding

Short Parts List

PAGE 20-27

Glass Frame

Frame Sealing Rope

Coal Bed

Burners and Injectors

Light Switch

Electrode Lead

Spark Generator

Resistor

Pilot Assembly

Electro-Magnetic Unit

Control Tap and Micro-switch

PAGE 28-29

PAGE 30

Page 3

Supplied By www.heating spares.co Tel. 0161 620 6677

INTRODUCTION - Page 3

Description

The Baxi Baroque Super and Baxi Arena Super are living

flame effect gas fires with a heat input of 5.57 kW (19,000

Btu/h) and an output of 3.40 kW (11,590 Btu/h) at its

maximum setting. The fires are available for use with Gas

Type G20 (Natural Gas) at 20mbar supply pressure. The

fires are suitable for either hearth or wall mounting and are

designed to be used on NATURAL GAS ONLY. NOTE: The

data and spillage test labels are located on the inner fire

support feet behind the fender front.

Electronic ignition is provided to light the pilot. The fire is

controlled by a control knob positioned on the right hand side

of the case. This control knob has six positions giving a

choice of four output settings.

Position - OFF

Position - PILOT

Position 1 - LOW

Position 2 - MEDIUM

Position 3 - MEDIUM/HIGH

Position 4 - HIGH

The artificial coal bed may be illuminated by concealed bulbs

as and when required. The light effect is operated by a

switch situated below the control knob. It may be used

whether the fire is ON or OFF.

NOTICE

DISCOLOURATION OF WALL SURFACES

Most heating appliances generate warm air convection

currents and transfer heat to any wall surface against

which they are situated.

Some soft furnishings (such as blown vinyl wallpapers)

may not be suitable for use where they are subject to

temperatures above normal room levels and the

manufacturer’s advice should be sought before using

this type of wall covering adjacent to any heating

appliance.

The likelihood of wall staining from convected air

currents will be increased in environments where high

levels of cigarette smoke or other contaminants exist.

WARNING

The addition of anything that may interfere with the

normal operation of the appliance (e.g. FLUE DAMPERS,

ECONOMISERS etc.) without the express written

permission of BAXI LIMITED could invalidate the

appliance warranty and infringe the GAS SAFETY

(Installation and Use) REGULATIONS.

The fire is manufactured to British Standards 5258 Part 5

and 6332 Part 2.

Installation

The installation must be carried out by a CORGI Registered

Installer or other competent person and be in accordance

with the relevant requirements of the GAS SAFETY

(Installation and Use) REGULATIONS, the BUILDING

REGULATIONS (Scotland) (Consolidation), the LOCAL

BUILDING REGULATIONS and the CURRENT I.E.E.

WIRING REGULATIONS. It should also be in accordance

with the relevant BRITISH STANDARD CODES OF

PRACTICE.

Important Information

This product contains Refractory Ceramic Fibres (R.C.F.)

which are man-made vitreous silicate fibres. Excessive

exposure to these materials may cause temporary irritation

to eyes, skin and respiratory tract. Care must be taken when

handling these articles to ensure the release of dust or fibres

is kept to a minimum.

To ensure that the release of fibres from these articles is

kept to a minimum, during installation and servicing it is

recommended that a H.E.P.A. filtered vacuum is used to

remove any dust, soot or other debris accumulated in and

around the appliance. This should be performed before and

after working on the installation.

It is recommended that any replaced item(s) are not broken

up but sealed within heavy duty polythene bags and clearly

labelled “R.C.F. waste”. This is not classified as “hazardous

waste” and may be disposed of at a tipping site licensed for

the disposal of industrial waste.

Protective clothing is not required when handling these

articles but it is recommended that gloves are worn and the

normal hygiene rules of not smoking, eating or drinking in

the work area are followed and always wash hands before

eating or drinking.

Page 4

Supplied By www.heating spares.co Tel. 0161 620 6677

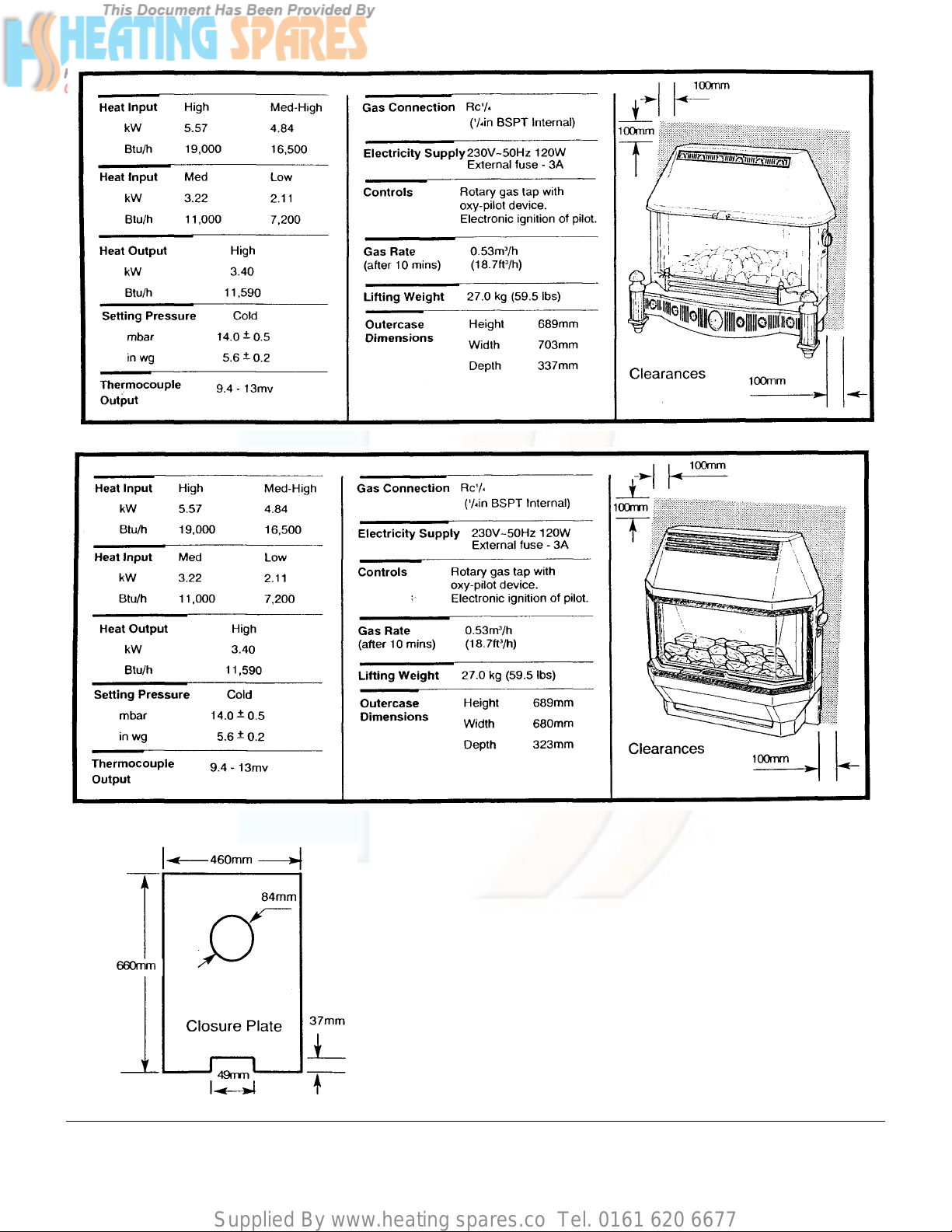

TECHNICAL DATA - Page 4

Baxi Baroque Super

Baxi Arena Super

B.S. Codes of Practice

STANDARD

B.S. 6891

B.S. 5871

B.S. 5440: Part 1

B.S. 5440: Part 2

SCOPE

Gas Installation

Installation of gas fires, convectors and

fire/back boilers.

Flues.

Air Supply

Page 5

Supplied By www.heating spares.co Tel. 0161 620 6677

SITE REQUIREMENTS - Page 5

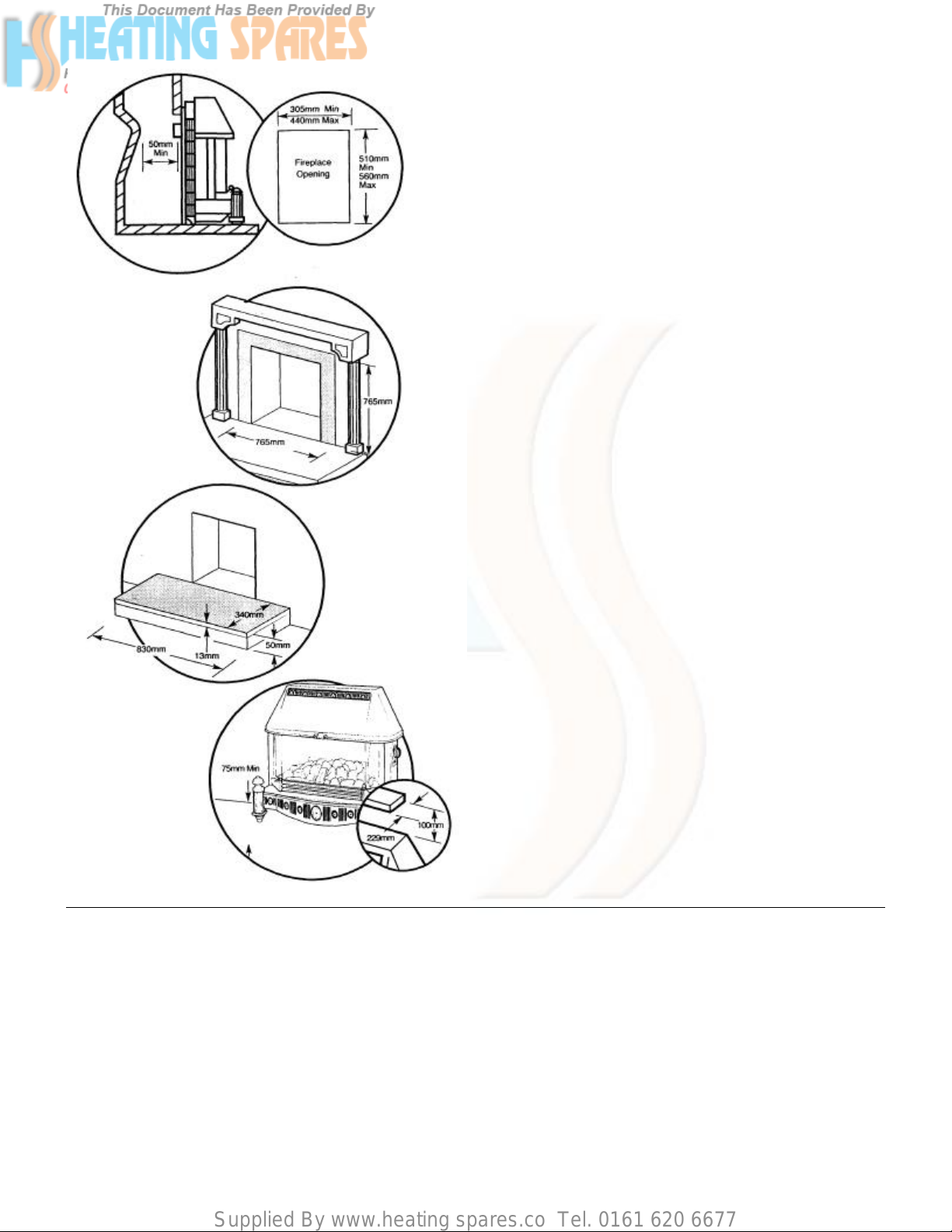

Fireplace Opening

The installation requires a fireplace opening as illustrated. At

the height of the flue spigot the opening shall be no less than

100mm (4in) deep, measured from the front face of the

opening to the fireplace back brick. There must be a

minimum of 412mm (167/32in) between the base of the

fireplace opening and the bottom of the flue spigot.

NOTE: Where possible the fireplace opening should be

to the minimum dimensions, particularly for wall

mounted installations.

The fireplace must be built from non-combustible materials

and have a flat vertical surface measuring 765mm (301/8in)

wide x 765mm (301/8in) high around the fireplace opening. If

a fire surround is to be used then its rear section must meet

the same requirements.

Any gaps between the wall and the surround must be

sealed.

HEARTH MOUNTING

If the fire unit is to be hearth mounted then the hearth must

be of a non-combustible material at least 13mm (½in) thick,

measuring at least 340mm (133/8in) deep by 830mm (32¾in)

wide. It must be fitted central to the fireplace opening. The

top surface of the hearth should be a minimum of 50mm

(2in) above floor level.

On no account should the fire be fitted directly onto a

combustible floor or carpet.

WALL FIXING

If the fire is to be wall mounted, then the wall must be noncombustible and the base of the fire must be no less than

75mm (3m) above floor level.

A shelf may be fitted above the fire, provided that it is at

least 100mm (4in) above the fire canopy and not more than

229mm (9in) in depth.

Page 6

Supplied By www.heating spares.co Tel. 0161 620 6677

Site Requirements - Page 6

Existing Chimneys

A chimney which has previously been used to burn solid fuel

MUST be swept before beginning the installation and any

restrictions such as dampers or register plates must be

removed. The chimney must be at least 3.10m (10ft) in

height and also meet the following requirements:

1) It must not be cracked.

2) It must serve one room only.

3) It must not be joined with any void, space or any

room other than that in which the fire is fitted.

4) It must not be blocked by paper or rubble etc.

5) It must have a positive flue pull up the chimney.

6) It must have a standard 229mm x 229mm (9in x

9in) section or a 127mm(5in) flue liner.

If there is no positive airflow up the chimney DO NOT FIT

THE FIRE. Seek expert advice before continuing with the

installation. A positive flue pull can be detected by holding a

lighted match or taper near to the fireplace opening.

PRE-CAST FLUES

The fire is suitable for fitting into properly designed and

constructed pre-cast flues, complying with BS 1289. The flue

must be at least 3.10m (10ft) in height and have a flue way

of at least 197mm x 67mm (7¾in x 25/8in) or equivalent

cross-sectional area.

NOTE: It is important to ensure that the mortar between

the blocks has not been forced into the flue way. If there

is mortar in the flue way, then it must be removed. If

raking blocks are used, they must be fitted according to

the manufacturer’s instructions.

Gas Supply

The gas installation should be in accordance with BS 6891.

The connection to the appliance is Rc¼ (¼in BSPT internal)

and is located at the centre (rear) of the fire, permanently

fixed to the bottom of the back plate. Ensure that the

pipework from the meter to the appliance is of adequate

size. Do not use pipes of a smaller diameter than the

appliance gas connection.

Electrical Supply

THIS APPLIANCE MUST BE EARTHED The mains supply

required is 230V ~ 50Hz fused at 3A.

NOTE: The method of connection to the electricity

supply must facilitate complete electrical isolation of the

appliance, preferably by the use of a fused three pin

plug and unswitched shuttered socket outlet, both

complying with the requirements of BS 1363.

Alternatively, connection may be made via a fused

double-pole isolator with a contact separation of at least

3mm (1/8in) in all poles and serving the appliance only.

Page 7

Supplied By www.heating spares.co Tel. 0161 620 6677

INSTALLATION - Page 7

Initial Preparation

To unpack the fire, remove the packing piece complete with

fitments and the pack containing the canopy and hearth

assembly. Place to one side. Remove the plastic bag and

remaining packing piece. Lift the fire from its carton.

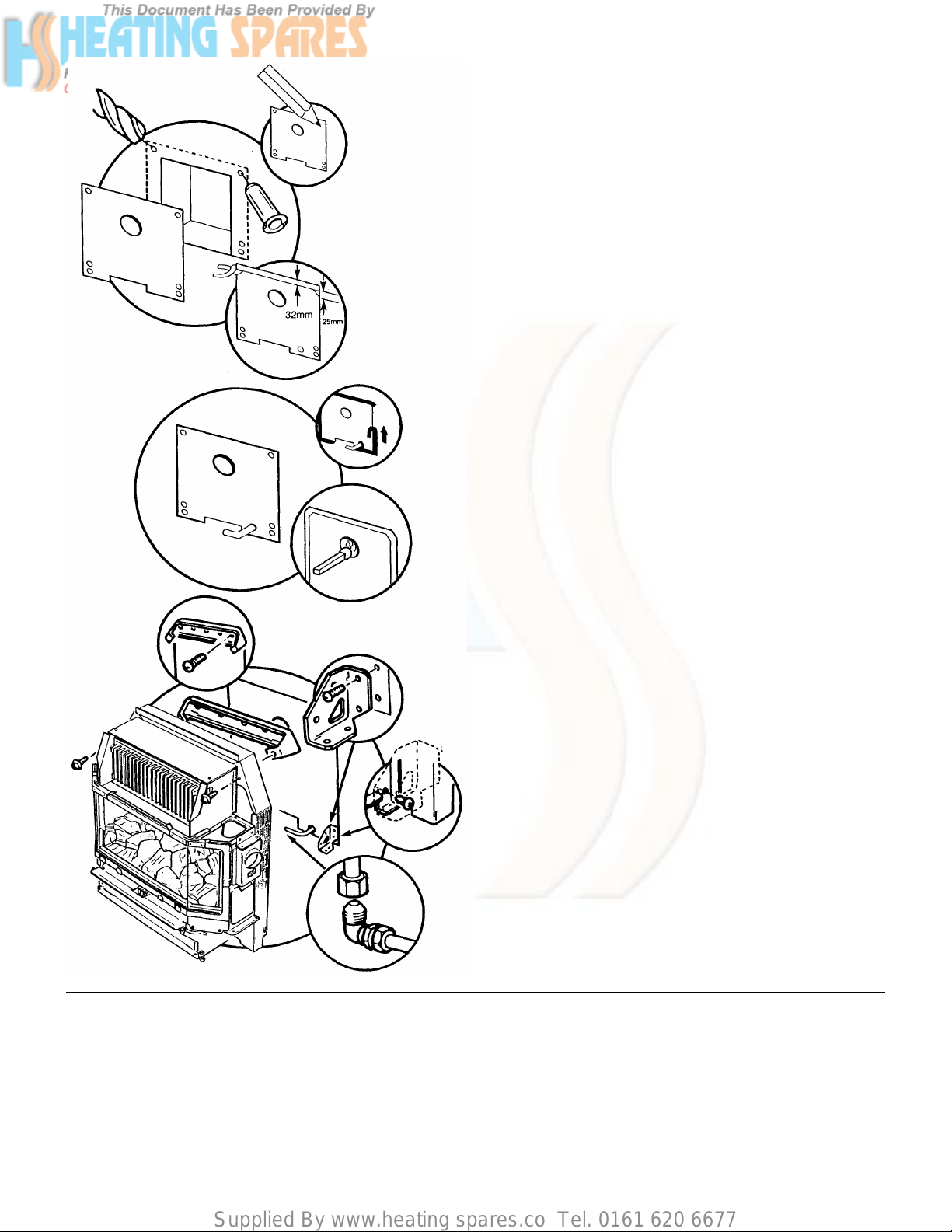

Fitting the Fire

HEARTH MOUNTING

Take the closure plate provided and hold centrally across the

fireplace opening with the bottom edge resting on the hearth.

NOTE: Where the closure plate is more than adequate

to cover the fireplace opening and to prevent the sealing

tape from becoming visible, it is advisable to trim the

closure plate as follows:

Cut 32mm (1¼in) off the top of the closure plate (i.e.

through the centre line of the top two fixing holes) and

then trim the top corners at an angle of 45° to a depth of

25mm (1in). If necessary, cut a hole in the closure plate

for the gas supply pipe.

Seal all edges of the closure plate with a suitable tape. DO

NOT COVER THE AIR RELIEF OPENING IN ANY WAY. If

the closure plate has been cut for the gas supply pipe, seal

around this opening too.

Hold a lighted taper or match to the spigot hole in the closure

plate. If the flame is pulled into the opening, proceed with the

installation. If the flame is NOT pulled into the opening, preheat the chimney for a few minutes then re-check for flue

pull. If there is still no definite flow into the spigot opening,

the chimney may need attention. DO NOT CONTINUE WITH

THE INSTALLATION - SEEK EXPERT ASSISTANCE.

Take the backing plate from the fittings pack and secure to

the fire using the two N° 8 x 5/8in self tapping screws

provided.

Locate the flue spigot in the hole in the closure plate and

push the fire backwards as far as possible.

NOTE: A flue spigot extension may be used with this

appliance, but must not exceed 150mm (6in) when

measured from the back of the fire.

Level the fire by adjusting the front feet.

Make the gas connection to the union elbow and tighten the

flared joint.

Page 8

Supplied By www.heating spares.co Tel. 0161 620 6677

INSTALLATION - Page 8

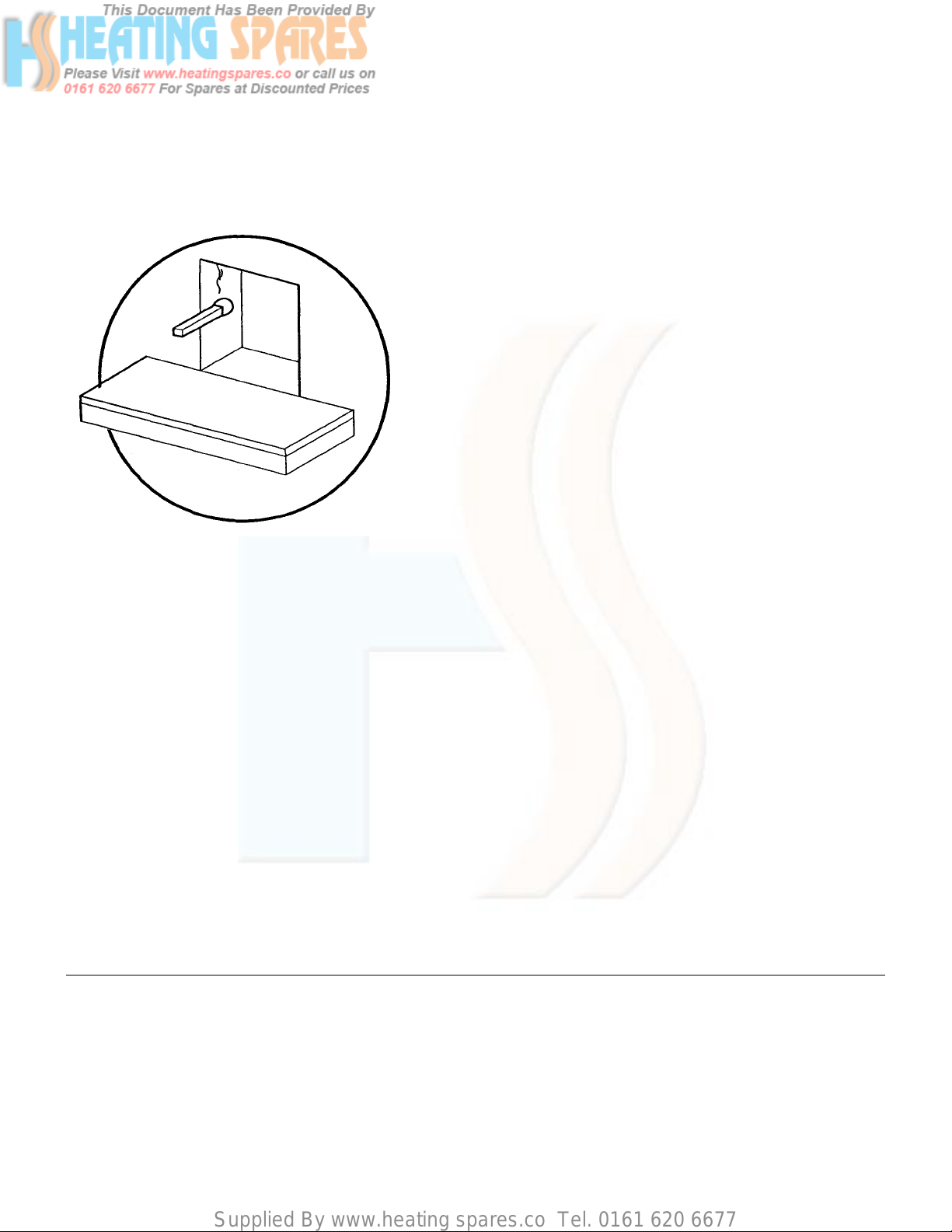

Wall Fixing

Using the closure plate supplied as a template, hold it

centrally across the fireplace opening with the bottom edge

level with the base of the fireplace opening. Mark out the six

hole positions. Remove the closure plate and drill the fixing

holes using a 6mm drill to accept the wall plugs provided.

NOTE: Where the closure plate is more than adequate

to cover the fireplace opening and to prevent the sealing

tape from becoming visible, it is advisable to trim the

closure plate (after marking the fixing holes) as follows:Cut 32mm (1¼in) off the top of the closure plate (i.e.

through the centre line of the top two fixing holes) and

then trim the top corners at an angle of 45° to a depth of

25mm (1in). If necessary, cut a hole in the closure plate

for the gas supply pipe.

Replace the closure plate, making sure to line it up with the

holes previously drilled and plugged and seal all edges with

a suitable tape. DO NOT COVER THE AIR RELIEF

OPENING IN ANY WAY.

If the closure plate has been cut for the gas supply pipe, seal

around this opening too.

Hold a lighted taper or match to the spigot hole in the closure

plate. If the flame is pulled into the opening, proceed with the

installation. If the flame is NOT pulled into the opening, preheat the chimney for a few minutes then re-check for flue

pull. If there is no definite flow into the spigot opening, the

chimney may need attention.

DO NOT CONTINUE WITH THE INSTALLATION -SEEK

EXPERT ASSISTANCE.

Take the backing plate from the fittings pack and fix it to the

wall as shown using the 1½in wood screws provided.

Fix the two wall mounting brackets in position using the four

1½in wood screws provided.

Take the fire, two N° 8 x 5/8in self tapping screws,

screwdriver and locate the flue spigot in the hole in the

closure plate, push the fire backwards as far as possible,

ensuring that the rear feet locate positively on the wall

mounting brackets. Whilst holding the fire in position, secure

the fire to the backing plate with the screws.

Fix the fire firmly to the wall mounting brackets as shown

using the two N° 8 x 5/8in self tapping screws provided.

Make the gas connection to the union elbow and tighten the

flared joint.

Page 9

Supplied By www.heating spares.co Tel. 0161 620 6677

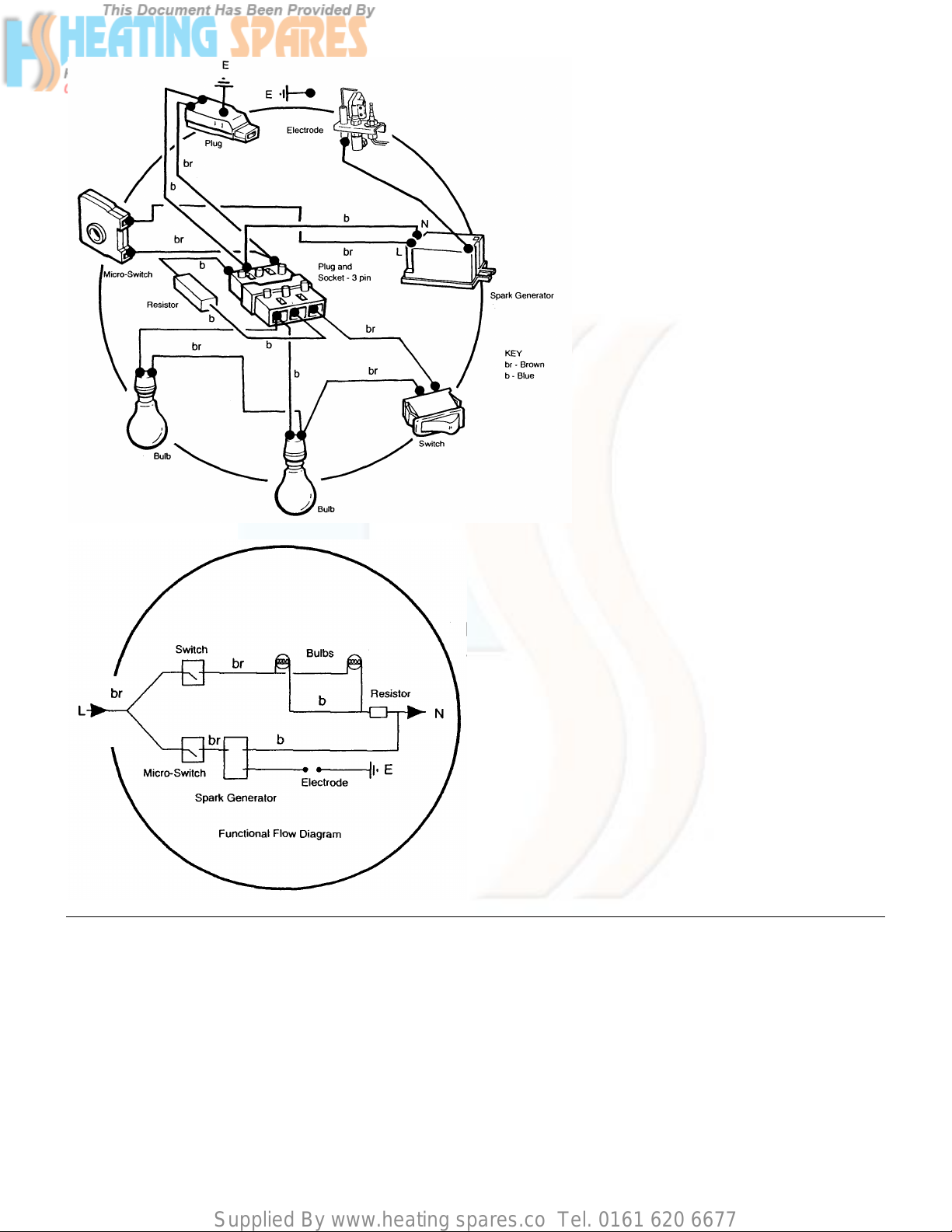

Electrical Connections - Page 9

Electricity is supplied to the fire unit via

the plug-and-cable assembly provided

with the appliance.

WARNING

THIS APPLIANCE MUST BE EARTHED.

3 core input cable for connection to the

mains input must NOT be less than

0.5mm2 (16 x 0.2mm) PVC heat resistant

to 70°C grade 1 to BS 6500 table 15 or

16.

Page 10

Supplied By www.heating spares.co Tel. 0161 620 6677

COMMISSIONING THE FIRE - Page 10

Purge any air from the gas inlet and make good the gas

connection. Switch on the gas. Check for gas soundness.

Remove the glass frame by disengaging the retaining

clamps and lifting away. Remove the polystyrene packing

piece securing the coal bed in position.

Remove the coal bed from its plastic bag and carefully

replace in position on the burner.

CAUTION: The coal bed is extremely fragile and must

be handled accordingly. Gloves should be worn and any

inhalation of the dust should be avoided. Keep the coals

away from children at all times. Please read the

Important Information section on page 3.

Remove any labels fixed to the glass frame assembly

and clean both sides of the glass panels before

replacing the glass frame.

Replace the glass frame and lock in place by engaging the

retaining clamps.

Take the lead provided and fit the plug into the socket on the

fire. Connect to the electricity supply, taking care to route the

cable so that it will not come into contact with any hot

surface.

Page 11

Supplied By www.heating spares.co Tel. 0161 620 6677

COMMISSIONING THE FIRE - Page 11

Check the electricity supply to the fire unit by switching on

the illumination bulbs to the coal bed. If the bulbs light,

switch off and continue with commissioning the fire. If the

bulbs do not light, isolate the electricity supply and perform

preliminary electrical system checks before proceeding i.e.

earth continuity, polarity, resistance to earth etc.

Isolate the electricity supply.

Remove the electrical cover on the right hand side of the

chassis as shown, by removing the fixing screw.

Release the pressure test point sealing screw and connect a

pressure gauge in position.

Reconnect the electricity supply.

Push in the control knob, turn to the IGNITION position ( )

and hold in. Sparking will commence at the ignition electrode

and the pilot will ignite.

Continue to hold the control knob in for a further 15 seconds

then release. The sparking will stop and the pilot will stay

alight. If the pilot does not stay alight, repeat the process

after waiting for 3 minutes. (If the pilot still fails to remain

alight, refer to the fault finding chart).

Page 12

Supplied By www.heating spares.co Tel. 0161 620 6677

COMMISSIONING THE FIRE - Page 12

Turn the control knob slowly to position 4, looking for

complete cross-lighting of the burner.

Check the setting pressure at position 4. No adjustment to

the setting pressure is possible.

(See Technical Data).

Turn the control knob to the ‘OFF’ ( )position.

Isolate the electricity supply.

Disconnect the pressure gauge, taking care not to touch any

hot surfaces and replace the pressure test point sealing

screw, ensuring a gas-tight seal.

Refit the electrical cover and reconnect the electricity supply.

SPILLAGE DETECTION

Check that the fire is fitted correctly.

Ensure that all the doors and windows in the room are

closed.

IMPORTANT NOTE: If there is an extractor or ceiling fan

in the room or any adjoining room, the check for

spillage must be performed with the fan turned on and

any interconnecting doors open.

Light the fire, turn to the full rate and leave for 5 minutes.

The fire should be checked visually for clearance of

products. Fit a lighted smoked match in a suitable holder and

position it in the downdraught diverter at either side of the

fire. Ensure that the majority of the smoke is drawn into the

chimney.

If there is any doubt, repeat the test after a further 10

minutes.

If there is any indication of spillage then the chimney may be

faulty. The cause of the fault must be identified and

corrected before the installation can proceed.

IF THE FAULT CANNOT BE RECTIFIED, TURN OFF AND

DISCONNECT THE GAS SUPPLY TO THE FIRE. SEEK

EXPERT ADVICE.

Page 13

Supplied By www.heating spares.co Tel. 0161 620 6677

FITTING THE OUTER CASE - Page 13

Baxi Baroque Super

Turn off the fire and fit the outer case components as

follows:

Remove the fender front from the hearth assembly by pulling

forward.

Engage the hearth assembly on the side ledges as shown

and push home as far as possible. Adjust the feet to touch

the fireplace hearth. Fix the hearth assembly in position

using the two N° 8 x 5/8in screws in the front and the two M4

x 8mm thread former screws in the sides.

Hang the left and right hand side doors on the fittings as

shown and close the doors, ensuring that they lock in

position.

Fix the canopy by lowering it into position over the top edge

and then by gently easing the sides inwards, push home to

lock in place.

Locate the fender front in position at the front of the hearth

assembly and push home.

lnstruct the user in the operation of the fire controls and hand

over the user’s instructions and installation instructions,

giving advice on the necessity of regular servicing.

Page 14

Supplied By www.heating spares.co Tel. 0161 620 6677

Fitting the Outer Case - Page 14

Baxi Arena Super

Turn off the fire and fit the outer case components as

follows:

Engage the hearth by guiding the locating pins through the

holes in the innercase and sliding forward on the side ledges

as far as possible. Fix the hearth in position using the two

3

/8in screws in the sides.

Hang the left and right hand side doors on the fittings as

shown leaving them open.

Fix the canopy by guiding the bottom edge onto the door

pins and then by tilting the back edge over the locating lip on

the innercase. Close the doors ensuring they lock in place.

Instruct the user in the operation of the fire controls and

hand over the user’s instructions and installation instructions,

giving advice on the necessity of regular servicing.

Page 15

Supplied By www.heating spares.co Tel. 0161 620 6677

ANNUAL SERVICING - Page 15

Baxi Baroque Super

IMPORTANT: Always check for gas soundness before and

after servicing the fire particularly gas carrying joints which

may have been disturbed. At least once a year remove the

fire and check behind the closure plate for any accumulation

of rubble. Reseal the four edges of the closure plate and any

opening between the closure plate and any rear entrance

gas supply but ensure that the ventilation hole at the bottom

of the closure plate is not covered. Before servicing please

read the Important section on page 3.

For economy and safety reasons, it is important to service

the fire annually.

NOTE: Before attempting to service the appliance,

ensure that the fire is COLD.

All Electrical Servicing MUST comply with ‘THE

ELECTRICITY AT WORK REGULATIONS 1989’.

Important: It is possible that some soot may be deposited

on the coals after use. This is acceptable providing it is not

allowed to accumulate.

CAUTION: The coal bed is extremely fragile and must

be handled accordingly. Gloves should be worn and any

inhalation of the dust should be avoided.

Keep the coals away from children at all times.

ISOLATE THE ELECTRICITY SUPPLY TO THE FIRE

Remove the canopy by gently easing the sides inwards and

pulling the bottom edge forward, then lift the canopy

upwards and away from the locating lip.

Remove the left and right hand side doors firstly by opening

them and then lifting away from their mountings.

Remove the fender front by forward.

Remove the hearth assembly by removing the fixing screws

and sliding it forward and away from the chassis.

Page 16

Supplied By www.heating spares.co Tel. 0161 620 6677

Annual Servicing - Page 16

Baxi Arena Super

IMPORTANT: Always check for gas soundness before and

after servicing the fire particularly gas carrying joints which

may have been disturbed. At least once a year remove the

fire and check behind the closure plate for any accumulation

of rubble. Reseal the four edges of the closure plate and any

opening between the closure plate and any rear entrance

gas supply but ensure that the ventilation hole at the bottom

of the closure plate is not covered. Before servicing please

read the Important Information section on page 3.

For economy and safety reasons, it is important to service

the fire annually.

NOTE: Before attempting to service the appliance,

ensure that the fire is COLD.

All Electrical Servicing MUST comply with ‘THE

ELECTRICITY AT WORK REGULATIONS 1989’.

Important: It is possible that some soot may be deposited

on the coals after use. This is acceptable providing it is not

allowed to accumulate.

CAUTION: The coal bed is extremely fragile and must

be handled accordingly. Gloves should be worn and any

inhalation of the dust should be avoided. Keep the coals

away from children at all times.

ISOLATE THE ELECTRICITY SUPPLY TO THE FIRE

Remove the canopy, firstly by opening the left and right hand

side doors, then lift the canopy by the bottom edge upwards

and away from the locating lip.

Remove the left and right hand side doors by lifting away

from their mountings.

Remove the hearth by removing the fixing screws and sliding

the hearth assembly forward and away from the chassis.

Page 17

Supplied By www.heating spares.co Tel. 0161 620 6677

Annual Servicing - Page 17

Disconnect the 3-pin plug from the socket beneath the fire.

Isolate the gas supply.

Disconnect the fire inlet pipe from the fire inlet.

HEARTH MOUNTING

Pull the fire forward until the flue spigot is clear of the closure

plate and lift away.

Inspect the fireplace for damage and blockages.

WALL FIXING

Remove and retain the screws securing the fire to the wall

mounting brackets.

Whilst holding the fire in position, remove and retain the

screws securing the fire to the backing plate. Pull the fire

forward until the flue spigot is clear of the closure plate and

lift away.

Inspect the fireplace for damage and blockages.

Page 18

Supplied By www.heating spares.co Tel. 0161 620 6677

Annual Servicing - Page 18

Ensuring that the glass frame is cold, disengage the

retaining clamps and lift the frame away.

Remove the coal bed by carefully lifting away from the

locating pins and place to one side.

Cleaning the Pilot, Electrode & Thermocouple Assembly

Examine and clean the electrode and thermocouple,

ensuring that the gap between electrode and target is 2.5 -

4.0mm.

Ensure that the pilot burner aeration hole is free from lint,

debris etc.

Page 19

Supplied By www.heating spares.co Tel. 0161 620 6677

Annual Servicing - Page 19

Cleaning the Burner / Injectors

Remove the burner as follows:

Remove the locating pins (these also secure the burner to its

support brackets).

Disconnect the compression nuts from the injectors. Remove

the burner from the fire.

Using a soft brush remove any dirt or debris from the top of

the burner and ensure that the ports and aeration openings

are free from obstruction.

Release and remove the injectors from the burner. Examine

and clean carefully then replace with the flat end of the

injector in the burner.

BEFORE RE-ASSEMBLING ALL COMPONENTS

Examine the glass frame, if the glass is in any way

damaged, then it must be replaced.

NOTE: This is a heat resistant glass and must not be

replaced by “ordinary” glass.

The glass may be cleaned with a cream cleansing agent if

required.

Examine the glass frame sealing rope on the fire and replace

it if in any way damaged.

Examine the coal bed and replace it if any major damage

has occurred.

Re-assemble all components in reverse order, ensuring that

the flue spigot is engaged into the hole in the closure plate.

Make good all gas and electrical connections and check for

gas soundness.

Recommission the fire before use, then re-assemble the

outer components in the reverse order of dismantling.

Page 20

Supplied By www.heating spares.co Tel. 0161 620 6677

CHANGING COMPONENTS - Page 20

Baxi Baroque Super

When changing components ensure that the gas and

electricity supplies are isolated before the work is started.

Before changing any components please read the Important

Information section on page 3.

To change the GLASS FRAME, FRAME SEALING ROPE,

COAL BED, BURNER, INJECTORS and LIGHT SWITCH,

remove the canopy and side doors as shown.

To change a LIGHT BULB refer to the User’s Instructions for

this appliance.

To change the ELECTRODE LEAD, SPARK GENERATOR

and RESISTOR, remove the canopy, side doors, fender front

and hearth assembly as shown.

To change the CONTROL TAP, PILOT / ELECTRODE /

THERMOCOUPLE ASSEMBLY, ELECTRO-MAGNETIC

UNIT and MICRO-SWITCH, remove the canopy, side door,

electrical cover, fender front and hearth assembly. The fire

must then be disconnected from the gas supply and

removed from the fire place to give access to the rear of the

unit as follows:

1. Isolate the gas supply.

2. Disconnect the 3-pin plug from the socket beneath the

fire.

3. Disconnect the inlet pipe from the fire inlet.

HEARTH MOUNTING

Pull the fire forward until the flue spigot is clear of the closure

plate and lift away.

WALL FIXING

4. Remove and retain the screws securing the fire to the

wall mounting brackets.

5. Whilst holding the fire in position, remove and retain the

screws securing the fire to the backing plate.

Pull the fire forward until the flue spigot is clear of the closure

plate and lift away.

Page 21

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 21

Baxi Arena Super

When changing components ensure that the gas and

electricity supplies are isolated before the work is started.

Before changing any components please read the Important

Information section on page 3.

To change the GLASS FRAME, FRAME SEALING ROPE,

COAL BED, BURNER, INJECTORS and LIGHT SWITCH,

remove the canopy and side doors as shown.

To change a LIGHT BULB refer to the User’s Instructions for

this appliance.

To change the ELECTRODE LEAD, SPARK GENERATOR

and RESISTOR, remove the canopy, side doors and hearth

as shown.

To change the CONTROL TAP, PILOT / ELECTRODE /

THERMOCOUPLE ASSEMBLY, ELECTRO-MAGNETIC

UNIT and MICRO-SWITCH, remove the canopy, side door

hearth and electrical cover. The fire must then be

disconnected from the gas supply and removed from the fire

place to give access to the rear of the unit as follows:

1. Isolate the gas supply.

2. Disconnect the 3-pin plug from the socket beneath the

fire.

3. Disconnect the inlet pipe from the fire inlet.

HEARTH MOUNTING

Pull the fire forward until the flue spigot is clear of the closure

plate and lift away.

WALL FIXING

4. Remove and retain the screws securing the fire to the

wall mounting brackets.

5. Whilst holding the fire in position, remove and retain the

screws securing the fire to the

backing plate.

Pull the fire forward until the flue spigot is clear of the closure

plate and lift away.

Page 22

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 22

Glass Frame

1. Ensure that the glass panel is cold. Disengage the

retaining clamps.

Lift the frame away.

Fix the new glass frame in position and engage the retaining

clamps. Re-assemble the components in the reverse order

to dismantling.

Frame Sealing Rope

1. Ensure that the glass panel is cold. Disengage the

retaining clamps.

2. Pull the old rope seal out of the locating channel and

release the glass locating brackets.

Fit the new seal, starting at the centre, tuck well into the

locating channel. Ensure that there is an equal amount of

seal free at either end of the channel. Secure the glass

locating brackets.

Fix the glass frame in position and engage the retaining

clamps. Re-assemble the components in the reverse order

to dismantling.

Check that the seal between the rope and the glass frame is

good.

Coal Bed

1. Ensure that the glass panel is cold. Disengage the

retaining clamps.

Lift the frame away.

3. Lift the coal bed away from the locating pins.

CAUTION: The coal bed is extremely fragile and must

be handled accordingly. Gloves should be worn and any

inhalation of the dust should be avoided. Keep the coals

away from children at all times.

Carefully fit the new coal bed in position on the locating pins.

Fix the glass frame in position and engage the retaining

clamps. Re-assemble the components in the reverse order

to dismantling.

Page 23

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 23

Burner and Injectors

1. Ensure that the glass panel is cold.

Disengage the retaining clamps and lift the frame away.

2. Lift the coal bed away from the locating pins and place to

one side.

3. Remove the locating pins securing the burner to its

support brackets.

4. Disconnect the compression nuts from the injectors and

remove the burner, being careful not to damage the pilot

assembly.

5. Remove the injectors from the old burner and fit them into

the new burner or if required fit new injectors (flat end in the

burner) taking care not to over tighten them in their

mountings.

Re-assemble the components in the reverse order to

dismantling.

Page 24

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 24

Light Switch

Ensure that the electricity supply to the fire unit is

isolated.

Remove the control knob by pulling from the spindle.

Remove the two screws holding the bezel in place.

Note the orientation of the two electrical connections and

disconnect from the switch. Remove the bezel.

Press together the retaining arms on the rear of the switch

and remove from the bezel.

Fit the new switch in place, ensure that the orientation of the

switch is correct. (i.e. with the ‘O’ symbol towards the front of

the fire.) and make good the electrical connections.

Re-assemble the components in the reverse order to

dismantling.

Page 25

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 25

Electrode Lead

1. Remove the insulating sleeve from the body of the

electrode. Disconnect the electrode lead from the electrode.

2. Disconnect the electrode lead from the spark generator.

Undo the screw holding the orange panel to the chassis. Lift

the panel upwards and withdraw the sleeve and lead.

Thread the new electrode lead through the insulating sleeve.

Fit the new electrode lead to the spark generator and

electrode.

Re-assemble the components in the reverse order to

dismantling.

Spark Generator

Remove the front screw holding the spark generator in

place, and release the rear screw, enabling the generator to

be removed. Disconnect the electrical connections and

electrode lead.

Fit the new spark generator and re-assemble all components

in the reverse order to dismantling.

Resistor

Remove the two screws securing the light shield bracket.

Unclip the resistor from the side frame.

Disconnect the two resistor wires from terminal strip.

Replace resistor and refit in reverse order.

Page 26

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 26

Pilot, Electrode & Thermocouple Assy

Note: The thermocouple cannot be changed as an individual

component. The complete assembly must be changed in the

event of one or other component failure(s).

1. Remove the lead from the electrode.

2. Undo the pilot feed pipe from the assembly.

4. Undo the thermocouple from the gas tap.

3. Remove the screws holding the pilot assembly bracket to

the fire chassis. Unclip the thermocouple from the fire

chassis. Withdraw the pilot assembly and bracket.

Remove the screw holding the assembly to the bracket.

Re-assemble all components in the reverse order to

dismantling.

Electro-Magnetic Unit

4. Release the thermocouple from the control tap by

unscrewing the retaining nut.

5. Release the Electro-Magnetic Unit retaining nut and

remove the unit from the control tap.

Fit the new Electro-Magnetic Unit and replace the retaining

nut.

Fix the thermocouple in position taking care not to

overtighten the retaining nut. Re-assemble all components in

reverse order to dismantling.

Page 27

Supplied By www.heating spares.co Tel. 0161 620 6677

Changing Components - Page 27

Control Tap and Micro-Switch

Remove the control knob by pulling from the spindle.

Remove the two screws holding the bezel in place.

Disconnect the two electrical connections from the light

switch, taking note of their orientation. Remove the bezel.

Release the thermocouple from the control tap by

unscrewing the retaining nut.

Disconnect the two electrical connections from the micro

switch.

Release the nut-and-olive connections on the control tap

body and disconnect the bundy tubing from the control tap.

Disconnect the gas inlet at the control tap by releasing the

compression fitting.

Release the locknut fixing the control tap to the chassis.

Access to the locknut may be gained through the bezel

location.

Withdraw the control tap from the fire.

At this point change the micro-switch if required by removing

the circlip holding it in position on the control tap.

Fit the new micro-switch or the new control tap in reverse

order.

Make good all gas and electrical connections. Temporarily

reconnect electricity supply. Light the fire, turn off the

electricity supply and check all joints for gas soundness.

Turn the fire off. Re-assemble all components in reverse

order to dismantling.

Page 28

Supplied By www.heating spares.co Tel. 0161 620 6677

28-29

Page 29

Supplied By www.heating spares.co Tel. 0161 620 6677

SHORT PARTS LIST - Page 30

Key

No.

G.C.

No.

Description

Manufacturers

Part No.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

0

156 036

156 431

156 233

156 063

378 912

156 300

E01 617

156 095

156 094

156 432

397 681

156 230

378 916

386 129

205 723

Glass and Frame Assy

Knob Control - Baroque

Knob Control - Arena

Seal Frame Glass Rope

Oxy-pilot Assembly

Gas Tap

Electro Magnetic Unit

Micro Switch Assy

Burner

Coal Bed

Injector Burner FO3 (2 off)

Spark Generator Kit

Electrode Lead

Resistor 68 Ù

Pilot Filter

225391

236394

233466

226876

235601

234098

239413

227761

225400

236103

227348

232804

236184

228955

082412

Page 30

Supplied By www.heating spares.co Tel. 0161 620 6677

Page 31

Baxi Limited is one of the leading manufacturers of domestic

heating products in the U.K.

Our first priority is to give a high quality service to our

customers. Quality is built into every Baxi product - products

which fulfil the demands and needs of customers, offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the products

that customers want to buy.

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we know

that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If not,

please let us know.

Baxi is a BS - EN ISO 9001 Accredited Company

Click here for Helplines

Loading...

Loading...