Page 1

Baxi Barcelona

Wall Mounted Powered Flue Condensing Boiler

Gas Fired Central Heating Unit

Installation and

Servicing Instructions

BAXI

Page 2

Page 2

Natural Gas

Baxi Barcelona

G.C.Nº 41 075 02

Baxi Limited is one of the leading manufacturers of domestic

heating products in the UK.

Our first priority is to give a high quality service to our

customers. Quality is designed into every Baxi product products which fulfil the demands and needs of customers,

offering choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the products

that customers want to buy.

The boiler meets the requirements of Statutory Instrument

“The Boiler (Efficiency) Regulations 1993 Nº 3083” and is

deemed to meet the requirements of Directive 92/42/EEC on

the energy efficiency requirements for new hot water boilers

fired with liquid or gaseous fuels:-

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we know

that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If not,

please let us know.

Baxi is a BS-EN ISO 9001

Accredited Company

Type test for purpose of Regulation 5 certified by:

Notified Body 0086.

Product/Production certified by:

Notified Body 0086.

For GB/IE only.

Page 3

Contents – page 3

Section

Page

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

Introduction

General Layout

Appliance Operation

Technical Data

Dimensions and Fixings

System Details

Site Requirements

Installation

Electrical

Commissioning the Boiler

Fitting the Outer Case

4

5

6

7

8

9

12

16

22

24

25

12.0

13.0

14.0

15.0

Servicing the Boiler

Changing Components

Short Parts List

Fault Finding

26

28

35

36

Page 4

1.0 Introduction – page 4

Fig.1

Fig. 2

Baxi Limited declare that no substances harmful to health

are contained in the appliance or used during appliance

manufacture.

NOTE: This appliance must be installed in accordance with

the manufacturer’s instructions and the regulations in force,

and only used in a suitably ventilated location.

All systems must be thoroughly flushed and treated

with inhibitor (see Section 6.2).

Read the instructions fully before installing or using the

appliance

1.1 Description

1. The Baxi Barcelona is a gas fired room sealed fan

assisted condensing central heating boiler.

2. The maximum output of the boiler is preset at 80,000

Btu/hr. The boiler will automatically adjust down to

30,000 Btu/hr according to the system load. If required,

the output can be set to 100,000 Btu/hr. Please refer to

section 8.8.

3. It is designed for use on Natural Gas (G20).

4. The boiler is suitable for fully pumped open vented

central heating and domestic hot water systems and

sealed systems.

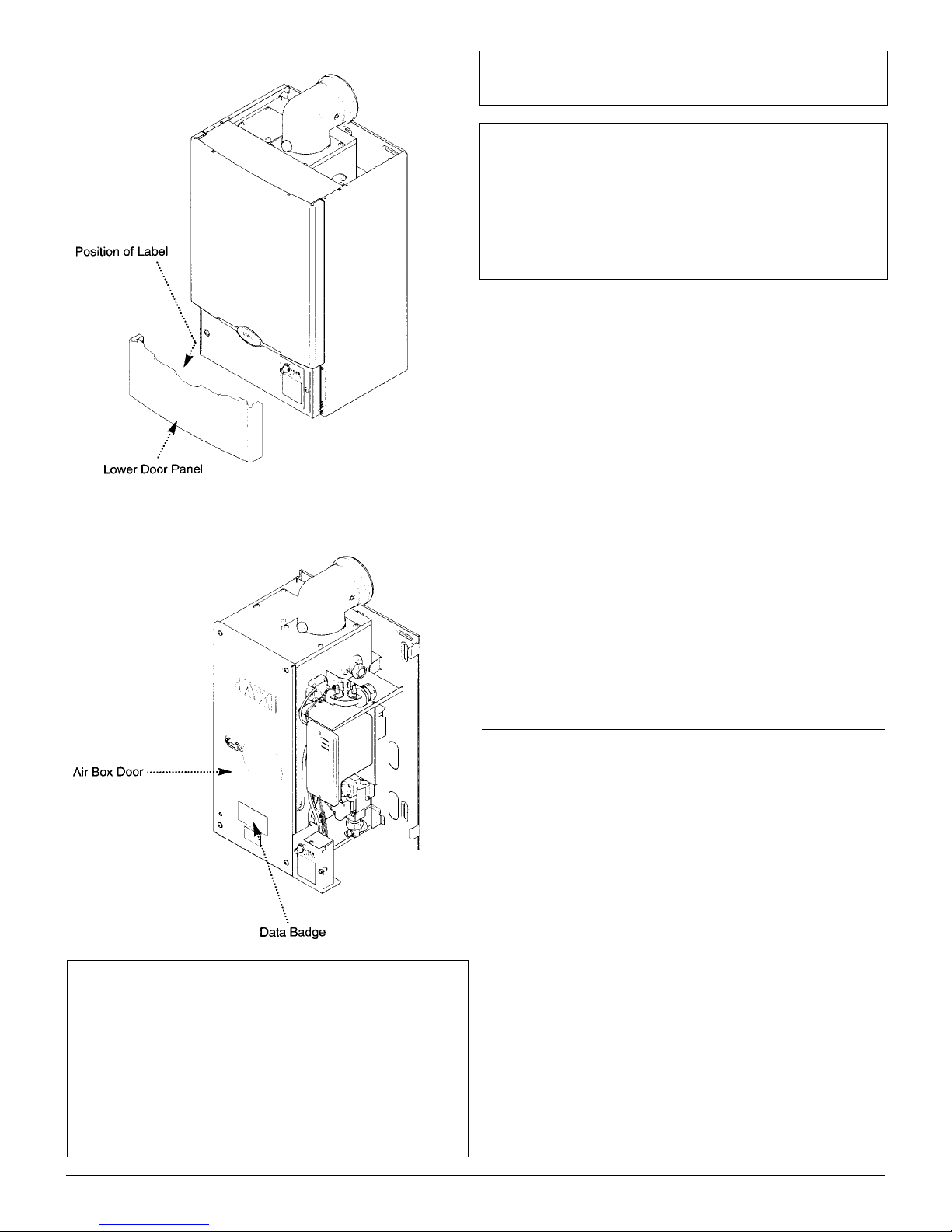

5. A label giving details of the model, serial number and

Gas Council number is situated on the rear of the lower

door panel (Fig. 1).

6. The boiler data badge is positioned on the air box door

(Fig. 2).

7. The boiler is intended to be installed in residential /

commercial / light industrial E.M.C. environments on a

governed meter supply only.

8. The boiler must be installed with one of the purpose

designed flues such as the standard horizontal flue kit,

part nº 236921.

“Benchmark” Log Book

As part of the industry-wide “Benchmark” initiative all Baxi

boilers now include an Installation, Commissioning and

Service Record Log Book. Please read the Log Book

carefully and complete all sections relevant to the

appliance and installation. These include sections on the

type of controls employed, flushing the system, burner

operating pressure etc. The details of the Log Book will be

required in the event of any warranty work. Also, there is a

section to be completed at each subsequent regular

service visit.

1.2 Important Information

This product contains Refractory Ceramic Fibres (R.C.F.)

which are man-made vitreous silicate fibres. Excessive

exposure to these materials may cause temporary irritation

to eyes, skin and respiratory tract. Care must be taken when

handling these articles to ensure the release of dust or fibres

is kept to a minimum.

To ensure that the release of fibres from these articles is

kept to a minimum, during installation and servicing it is

recommended that a HEPA. filtered vacuum is used to

remove any dust, soot or other debris accumulated in and

around the appliance. This should be performed before and

after working on the installation.

It is recommended that any replaced item(s) are not broken

up but sealed within heavy duty polythene bags and clearly

labelled “R.C.F. waste”. This is not classified as “hazardous

waste” and may be disposed of at a tipping site licensed for

the disposal of industrial waste.

Protective clothing is not required when handling these

articles but it is recommended that gloves are worn and the

normal hygiene rules of not smoking, eating or drinking in

the work area are followed and always wash hands before

eating or drinking.

Page 5

2.0 General Layout – page 5

2.1 Layout (Figs. 3,4 & 5)

1. Wall Plate

2. Flue Elbow

3. Heat Exchanger

4. Burner

5. Air Box

6. Fan Protection Thermostat

7. Fan Assembly

8. Condensate Trap

9. User Interface (optional timer available)

10. Gas Tap

11. Gas / Air Ratio Valve

12. Electronics Housing

13. Transformer

14. Flow Pipe Connection

15. Return Pipe Connection

16. Flow Temperature Safety Thermostat - Black

17. Flow Temperature Thermistor - Red

18. Flow Switch (dry fire protection)

2.2 Optional Extras

KIT PART Nº

FLUE EXTENSION KITS (110/70)

Flue Extension 0.25M 241692

Flue Extension 0.5M 241694

Flue Extension 1 M (Use two kits for 2M etc.) 241695

Flue Bend x 2 – 45º (Reduce overall length

of flue by 0.5m when fitting this bend) 241689

Flue Bend – 90º (Reduce Overall length of

flue by 1m when fitting each bend) 241687

VERTICAL FLUE (110/70)

Vertical Flue Terminal 242802

Vertical Boiler Connection 242886

CONTROL ACCESSORIES

Integral Electronic Twin Channel Timer Kit 242834

Page 6

3.0 Appliance Operation – page 6

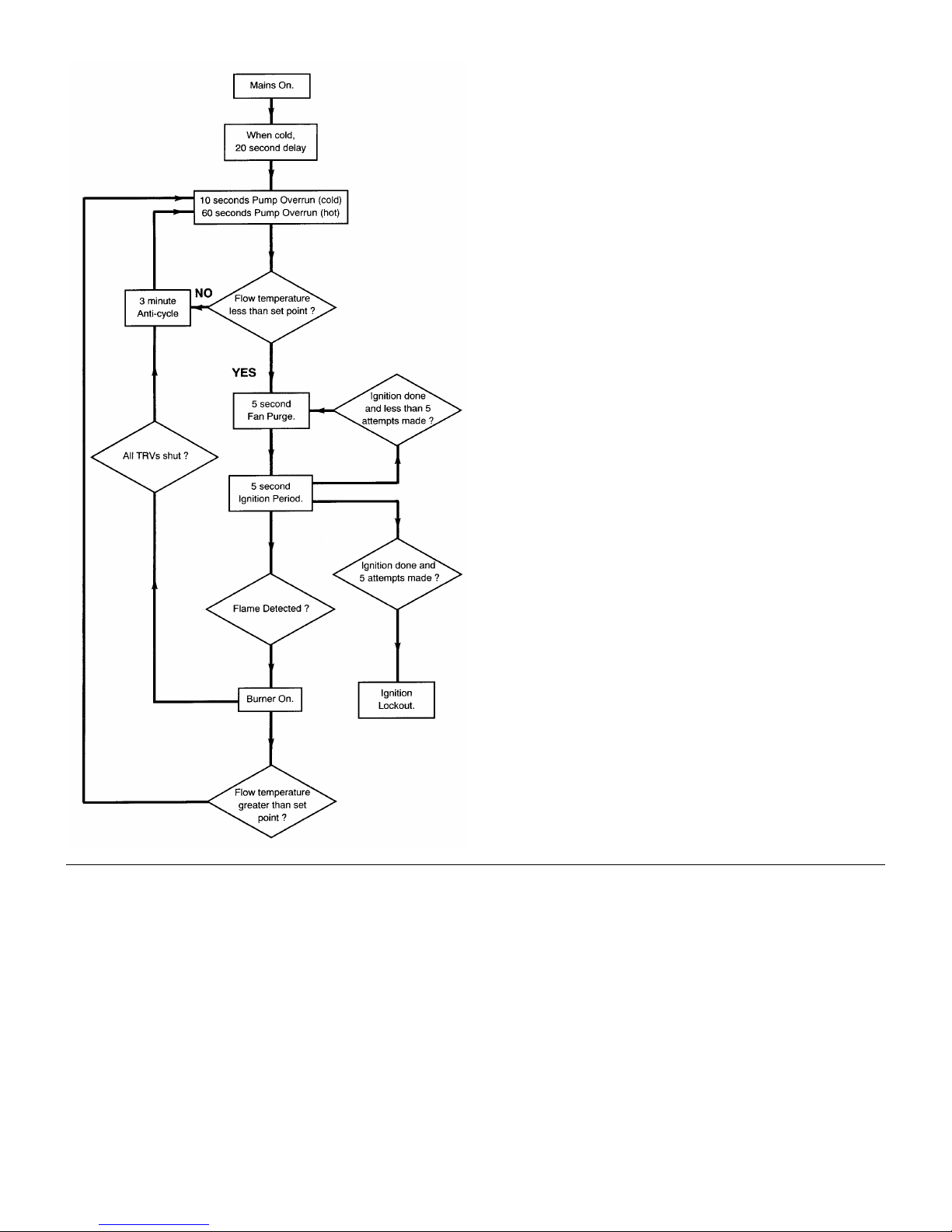

3.1

1. Pump Overrun: When the switched live to the boiler

switches on or the flow temperature is greater than the

set point or anti-cycle finishes then Pump Overrun

occurs for 10 seconds (cold) or 60 seconds (hot). The

pump is on while the fan, spark generator and gas

valve are off.

2. Fan Purge: When pump overrun has finished if the flow

temperature is less than that set on the thermostat

knob then Fan Purge occurs. The pump and fan are on

while the spark generator and gas valve are off.

3. Ignition: When fan purge has finished Ignition occurs.

The pump, fan, spark generator and gas valve are on.

The burner ignites at mid rate.

4. Burner On: When a flame is detected during the

ignition period then Burner On occurs. The pump, fan

and gas valve are on while the spark generator is off.

Flow temperature is controlled by varying the fan speed

(and thereby the gas rate) to achieve optimum

operation.

5. Anti-cycle: When all the TRVs shut down during

Burner On or Pump Overrun finishes and flow

temperature is greater than set point then Anti-cycle

occurs. The pump, fan, spark generator and gas valve

are switched off.

6. Ignition Lockout: When 5 ignition attempts have been

made without a flame being detected then Ignition

Lockout occurs. The pump, fan, spark generator and

gas valve are switched off. The lockout light flashes

once a second. The boiler can only be reset manually

using the thermostat knob.

7. No Water Flow: When there is No Water Flow through

the boiler (indicated by the flow switch) then a

continuous cycle of Pump Overrun and Anti-cycle

occurs.

Page 7

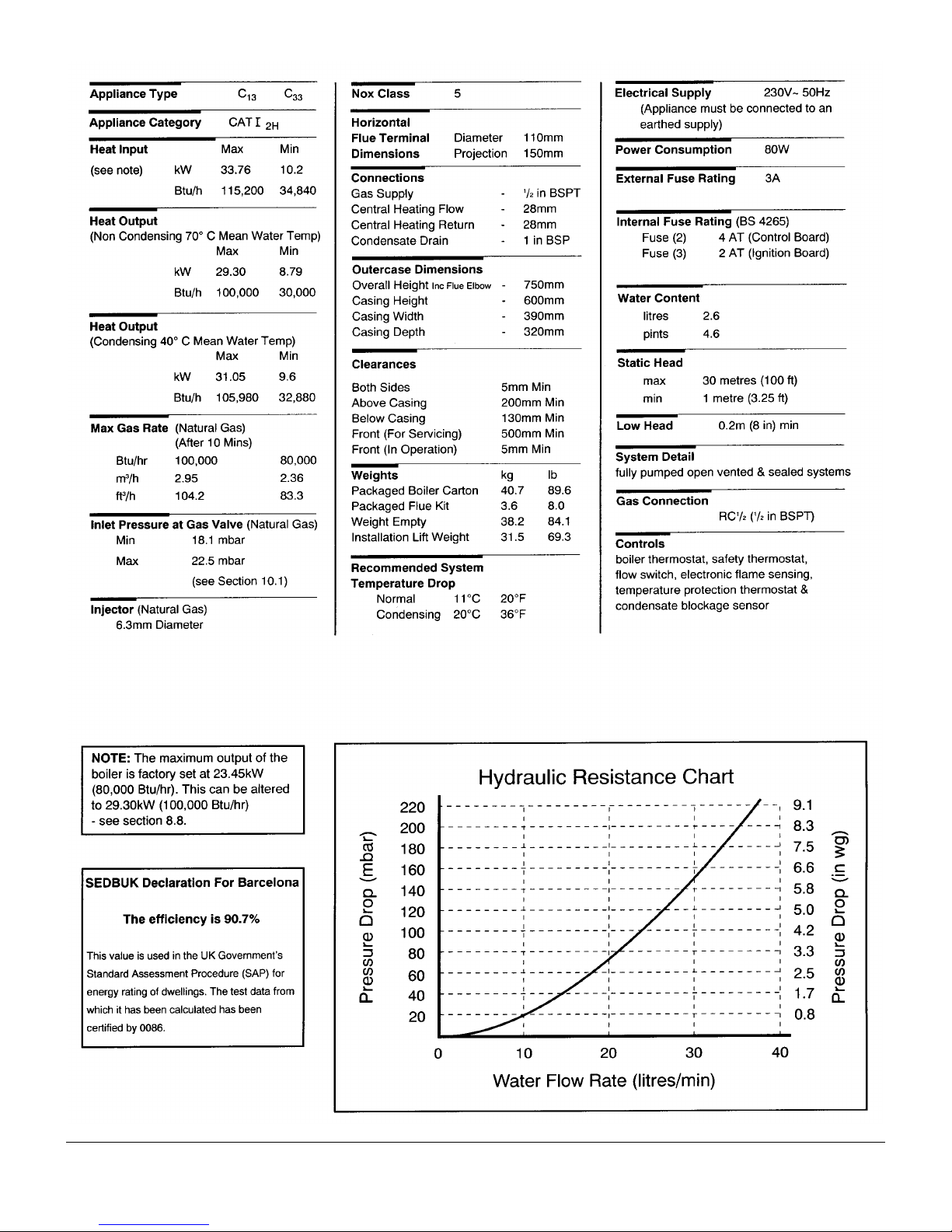

4.0 Technical Data – page 7

Page 8

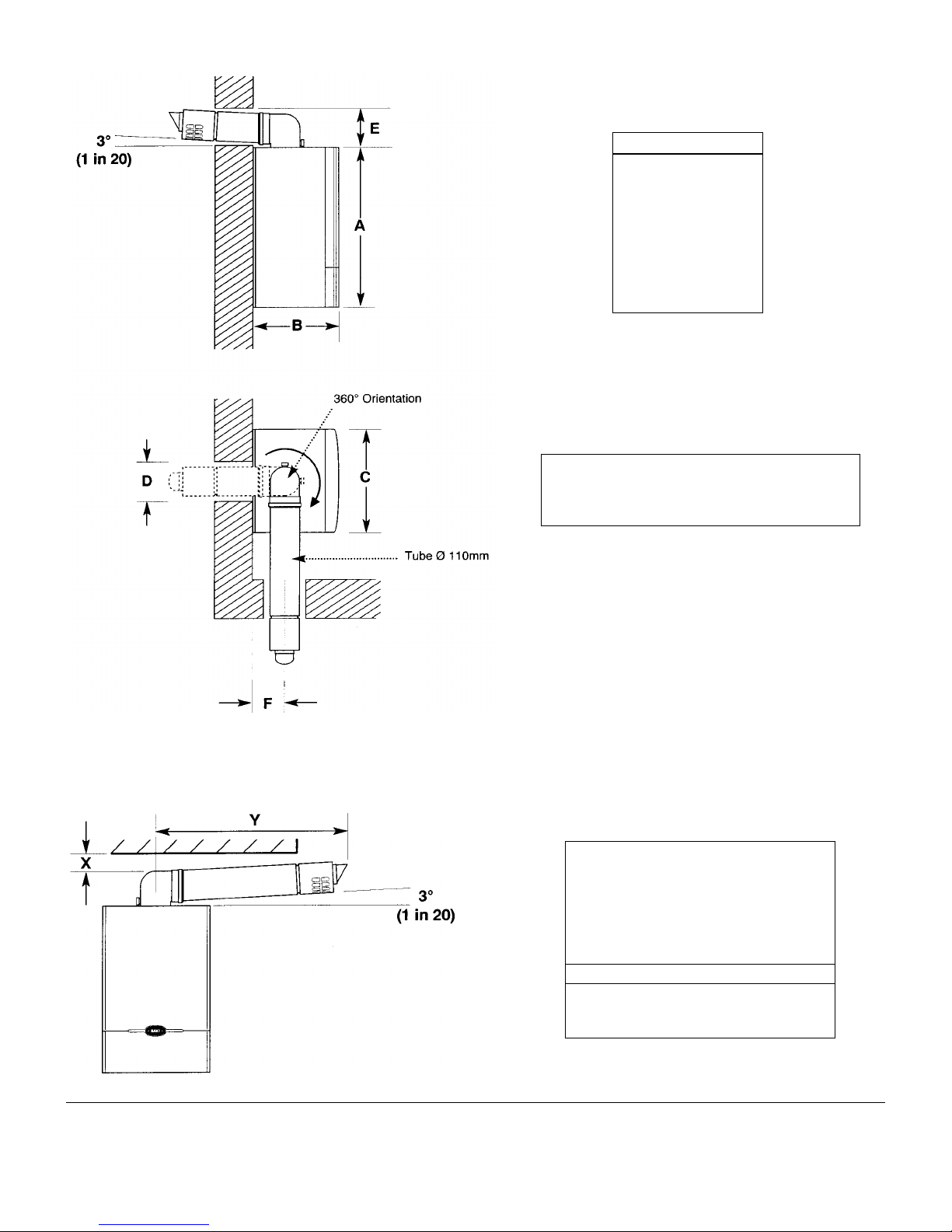

5.0 Dimensions and Fixings – page 8

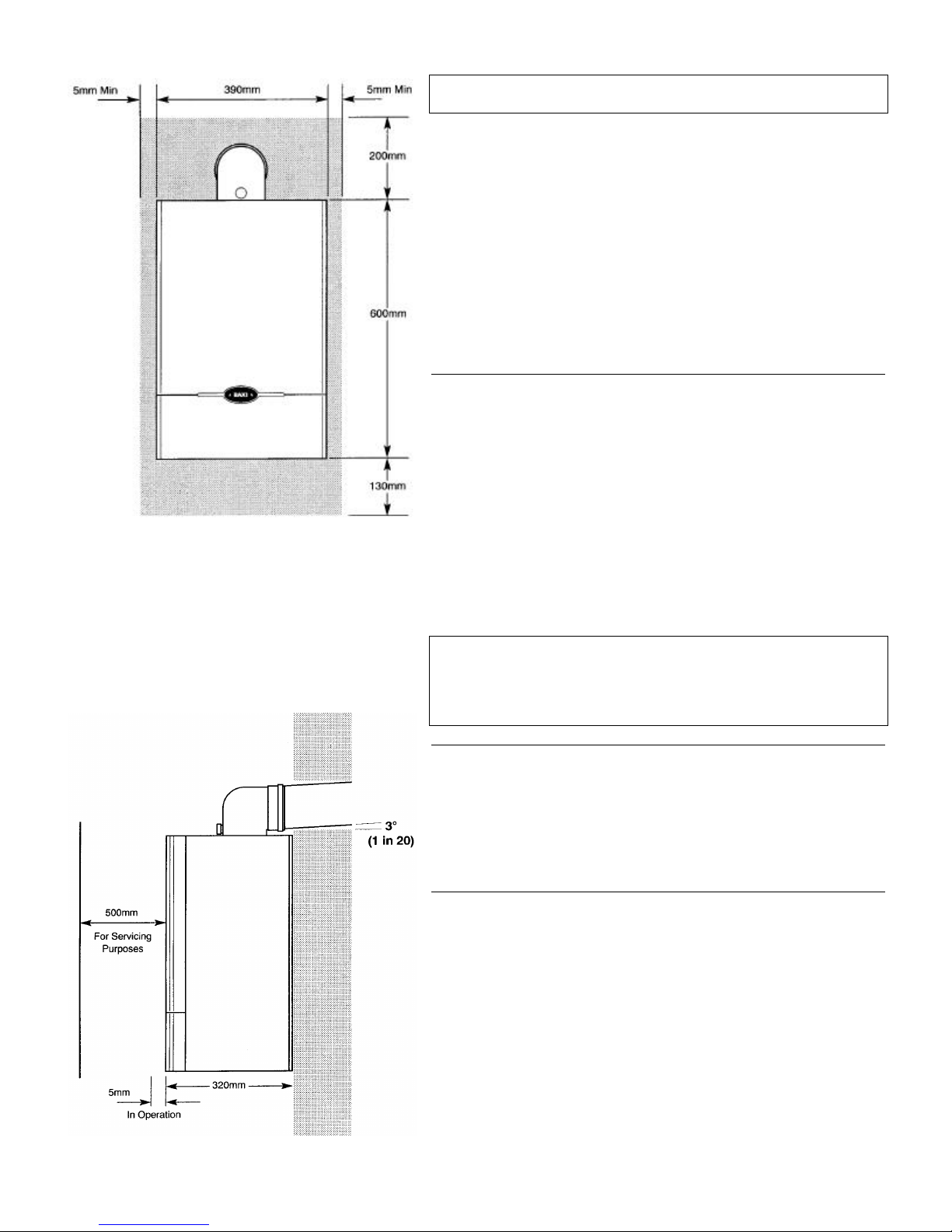

Fig. 6

DIMENSIONS

A 600mm

B 320mm

C 390mm

D l25mm Ø Min.

E 150mm

F 125mm

The 3º (1 in 20) fall provided by the elbow is

to allow condensate to run back to the boiler,

for disposal through the condensate

discharge pipe.

Fig 7

SIDE FLUE (left and right)

For every 1 m of horizontal flue length,

the clearance above the top of the flue

elbow should be 55mm to incorporate

the 3º (1 in 20) fall in the flue from the

terminal to the elbow.

Flue length (Y) Clearance (X)

Up to1m 55mm

1m-2m 110mm

2m-3m 165mm

Page 9

6.0 System Details – page 9

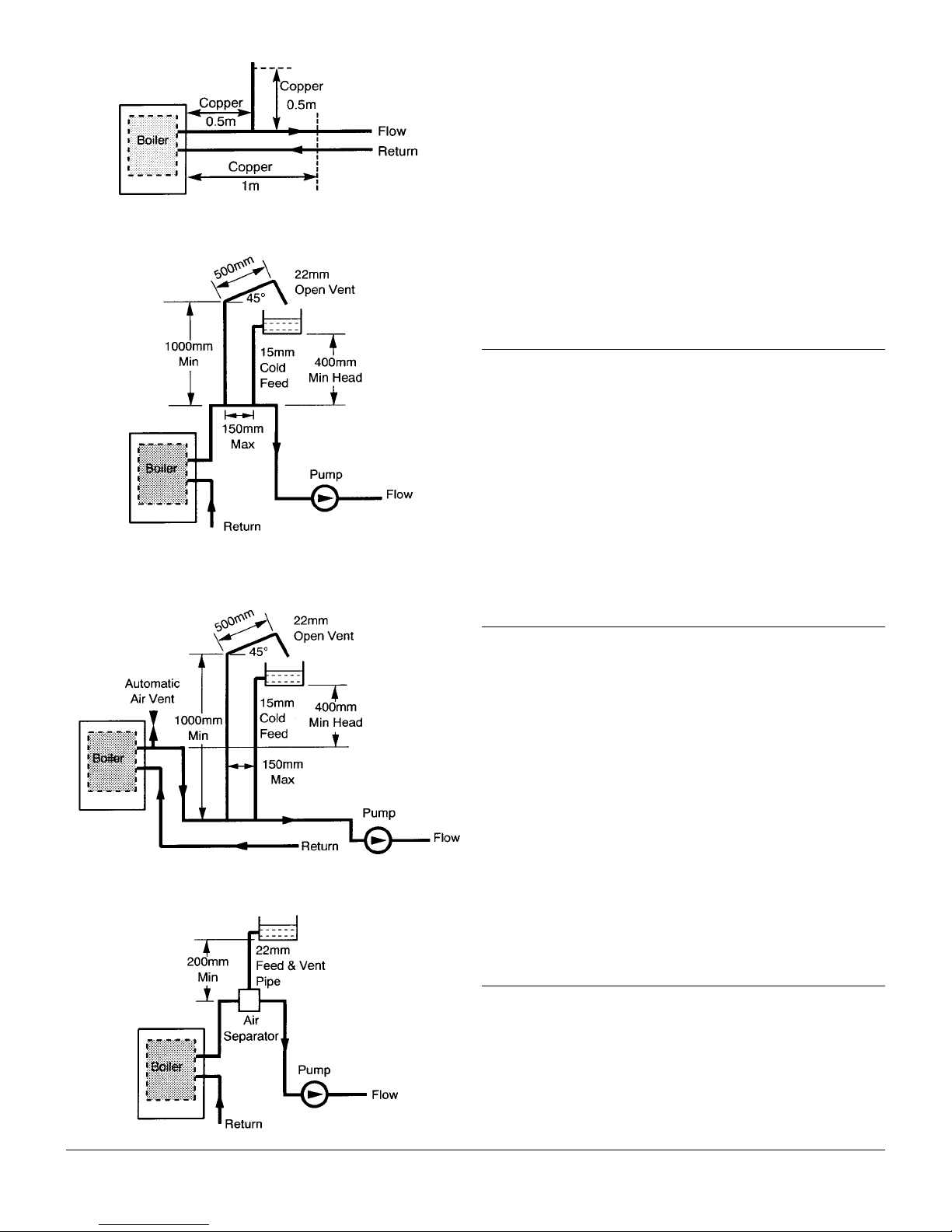

Fig. A Wiring to the pump feed connection of boiler

6.1 Water Circulating Systems

1. The appliance is suitable for use with open vent fully

pumped systems and sealed systems.

The following conditions should be observed on all

systems:

• The static head must not exceed 30m (100ft) of water.

• The boiler must not be used with a direct cylinder.

• Drain cocks should be fitted to all system low points.

• All gas and water pipes and electrical wiring must be

installed in a way which would not restrict the servicing

of the boiler.

• Position isolating valves as close to circulating pump as

possible.

• It is recommended that the return pipe is fitted with an

automatic air vent as close to the boiler as is practical.

NOTE: Full TRV Systems (refer to section 6.4) Where all

the radiators are controlled by TRV’s then pump protection

will be required. This can be done by either of the options

opposite (see Fig A & B). The option shown in Fig. A

should only be used on a full TRV system without a

bypass. Fig. B shows a system with a bypass that must

be capable of allowing a flow of at least 3 l/mm.

Fig. B Providing a 3 l/mm bypass

6.2 Treatment of Water Circulating Systems

• All recirculatory water systems will be subject to

corrosion unless an appropriate water treatment is

applied. This means that the efficiency of the system

will deteriorate as corrosion sludge accumulates within

the system, risking damage to pump and valves, boiler

noise and circulation problems.

• When upgrading existing systems that exhibit evidence

of sludging, it is advisable to clean the system prior to

treatment in order to remove any sludge and reduce the

likelihood of these deposits damaging new

components.

• When fitting new systems flux will be evident within the

system, which can lead to damage of system

components.

• All systems must be thoroughly drained and flushed

out. The recommended flushing and cleansing agents

are Betz-Dearborn Sentinel X300 or X400 and Fernox

Superfloc Universal Cleanser which should be used

following the flushing agent manufacturer’s instructions.

• System additives - corrosion inhibitors and flushing

agents/descalers should be suitable for aluminium and

comply to BS7593 requirements. The only system

additives recommended are Betz-Dearborn Sentinel

X100 and Fernox-Copal which should be used following

the inhibitor manufacturer’s instructions.

Failure to flush and add inhibitor to the system will

invalidate the appliance warranty.

• It is important to check the inhibitor concentration after

installation, system modification and at every service in

accordance with the manufacturer’s instructions. (Test

kits are available from inhibitor stockists.)

• For information or advice regarding any of the above

contact the Baxi Helpline.

Page 10

6.0 System Details – page 10

Fig. 7a

Fig. 8 Typical Low Head Installation

Fig. 9 If Conditions Require,

This System Possible

6.3 Pipework

1. The sizes of flow and return pipes from the boiler

should be determined by normal methods, according to

the requirements of the system. The connection to the

boiler is 28mm (compression).

2. Due to space requirements within the boiler outercase,

pipework should comprise of solder fittings.

3. A 20ºC (36ºF) drop in temperature across the system is

recommended for condensing boilers. Existing radiators

may be oversized and so allow this, but where radiator

sizing is marginal it may be advisable to retain a system

temperature drop of 11ºC (20ºF).

4. In systems using non-metallic pipework it is necessary

to use copper pipe for the boiler Flow and Return. The

copper must extend at least 1 metre from the boiler and

include any branches (Fig. 7a).

6.4 System Controls

1. For optimum operating conditions, the heating system

into which the boiler is installed should include a control

system.

2. Such a system will comprise of a timer control and

separate room or cylinder thermostats as appropriate.

(An integral twin channel programmer is available as an

optional extra).

3. The boiler should be controlled so that it operates on

demand only.

4. Operation of the system under control of the boiler

thermostat & TRV’s only does not produce the best

results.

Fig. 10 Alternative Low Head Installation

6.5 Low Head Installation

1. Using a close couple arrangement the minimum head is

as shown in the diagrams (Figs. 8 & 9) subject to the

following conditions:

a) The pump being adjusted to give an 20ºC drop across

the boiler.

b) The pump must be fitted on the flow.

c) The pump must be fitted in accordance with the pump

manufacturers instructions.

d) The open vent pipe must be taken up from a tee in a

horizontal section of the flow pipe.

An alternative Low Head Installation (Fig. 10)

2. For heads below 400mm then a combined vent and

feed pipe may be connected. This must be a minimum

of 22mm diameter. It is recommended that an air

separator is fitted when using a combined feed and

vent pipe.

6.6 Thermal Stores

1. The Barcelona must not be fitted to thermal stores

which override the boiler control system.

Page 11

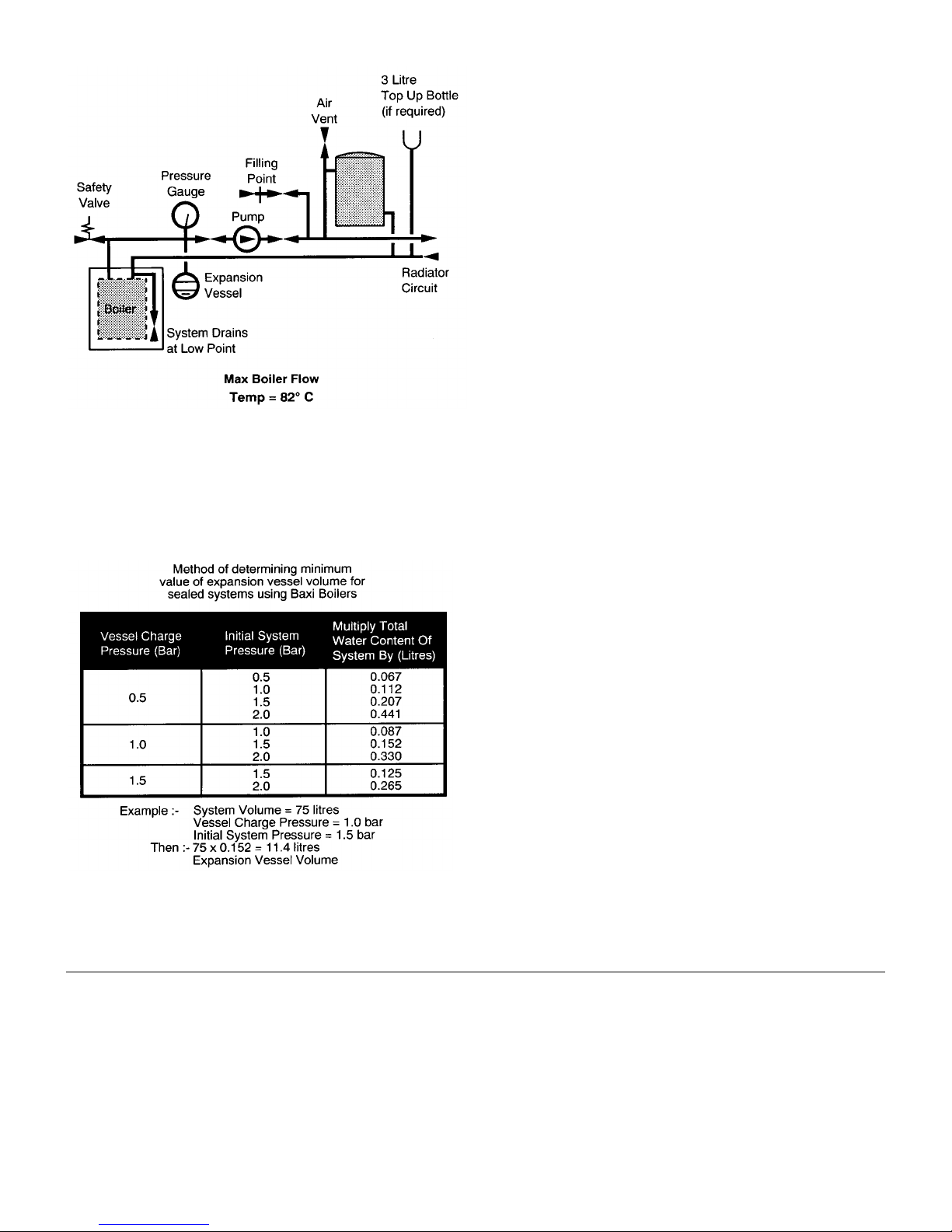

6.0 System Details – page 11

Fig 11

6.7 Sealed Systems (Fig. 11)

1. SAFETY VALVE - A safety valve complying with the

requirements of BS 6750 Part 1 must be fitted close to

the boiler on the flow pipe by means of a horizontal or

vertically upward connection with no intervening valve

or restrictions and should be positioned to facilitate

testing. The valve should be pre-set and non-adjustable

to operate at a pressure of 3 bar (45 lbf/in²). It must be

arranged to discharge any water or steam through a

pipe to a safe outlet position.

2. PRESSURE GAUGE - A pressure gauge of minimum

range 0-4 bar (0-60 lbf/in²) with a fill pressure indicator

must be fitted to the system, preferably at the same

point as the expansion vessel in an easily visible

position.

3. EXPANSION VESSEL - An expansion vessel

complying with the requirements of BS 4814 must be

fitted to the system by means of a connection close to

the inlet side of the circulating pump in accordance with

the manufacturers instructions, the connecting pipe

being unrestricted and not less than 15mm (½ in)

nominal size. The volume of the vessel should be

suitable for the system water content and the nitrogen

or air charge pressure should not be less than the

system static head (See Table. 1).

Table 1

NOTE

Where a vessel of the calculated size is not obtainable

then the next available larger size should be used.

Further details of sealed system design can be

obtained from BS 5449 and the British Gas publication

entitled Specifications for Domestic Wet Central

Heating Systems’.

4. FILLING POINT - A filling point and an approved stop

valve to BS 1010 must be fitted at low level and the

method used for filling the system should be approved

by the local water undertaking. For further details see

BS 6798.

5. MAKE UP SYSTEM - A method of replacing water lost

from the system should be provided either by means of

a make up vessel of not more than 3 litres (5 pints)

capacity, mounted above the highest point of the

system, or by re-pressurisation of the system.

6. VENTING - A method of venting the system during

filling and commissioning must be provided by fining

automatic air vents or by venting manually.

7. HOT WATER STORAGE - The hot water storage

vessel must be of the indirect coil type. All components

used in the system must be suitable for operation at

110ºC (230ºF) and at the pressure allowed by the

safety valve.

Page 12

7.0 Site Requirements – page 12

Fig. 12

7.1 Information

WARNING - Check the information on the data plate is compatible

with local supply conditions

1. The installation must be carried out by a CORGI Registered

Installer or other registered competent person and be in

accordance with the relevant requirements of the current GAS

SAFETY (Installation and Use) REGULATIONS, the

BUILDING REGULATIONS (Scotland)(Consolidation), the

LOCAL BUILDING REGULATIONS, the current I.E.E.

WIRING REGULATIONS and the bye laws of the LOCAL

WATER UNDERTAKING. Where no specific instruction is

given reference should be made to the relevant BRITISH

STANDARD CODES OF PRACTICE. For Ireland install in

accordance with IS 813 “INSTALLATION OF GAS

APPLIANCES”. Reference should also be made to BRITISH

GAS GUIDANCE NOTES FOR THE INSTALLATION OF

DOMESTIC GAS CONDENSING BOILERS.

7.2 B.S. Codes of Practice

Standard Scope

BS 6891 Gas Installation

BS 5546 Installation of hot water supplies for domestic

purposes.

BS 5449 Part 1 Forced circulation hot water systems

BS 6798 Installation of gas fired hot water boilers.

BS 5440 Part 1 Flues

BS 5440 Part 2 Ventilation

BS 7074 Expansion vessels and ancillary equipment for

sealed water systems.

BS 7593 Treatment of water in domestic hot water

central heating systems

Fig. 13

WARNING - The addition of anything that may interfere with the

normal operation of the appliance without the express written

permission of Baxi Limited could invalidate the appliance warranty

and infringe the GAS SAFETY (Installation and Use)

REGULATIONS.

7.3 Clearances (Figs. 12 &13)

1. A flat vertical area is required for the installation of the boiler.

2. These dimensions include the necessary clearances around

the boiler for case removal, spanner access and air movement.

Additional clearances may be required for the passage of pipes

around local obstructions such as joists running parallel to the

front face of the boiler.

7.4 Location

1. The boiler may be fitted to any suitable wall with the flue

passing through an outside wall or roof and discharging to

atmosphere in a position permitting satisfactory removal of

combustion products and providing an adequate air supply.

The boiler should be fitted within the building unless otherwise

protected by a suitable enclosure i.e. garage or outhouse. (The

boiler may be fitted inside a cupboard - see Section 7.5).

2. If the boiler is sited in an unheated enclosure then it is

recommended to incorporate an appropriate device for frost

protection in the system controls.

3. If the boiler is fitted in a room containing a bath or shower

reference must be made to the current I.E.E.WIRING

REGULATIONS and BUILDING REGULATIONS, If the boiler

is to be fitted into a building of timber frame construction then

reference must be made to the Institute of Gas Engineers

document UP 7.

Page 13

7.0 Site Requirements – page 13

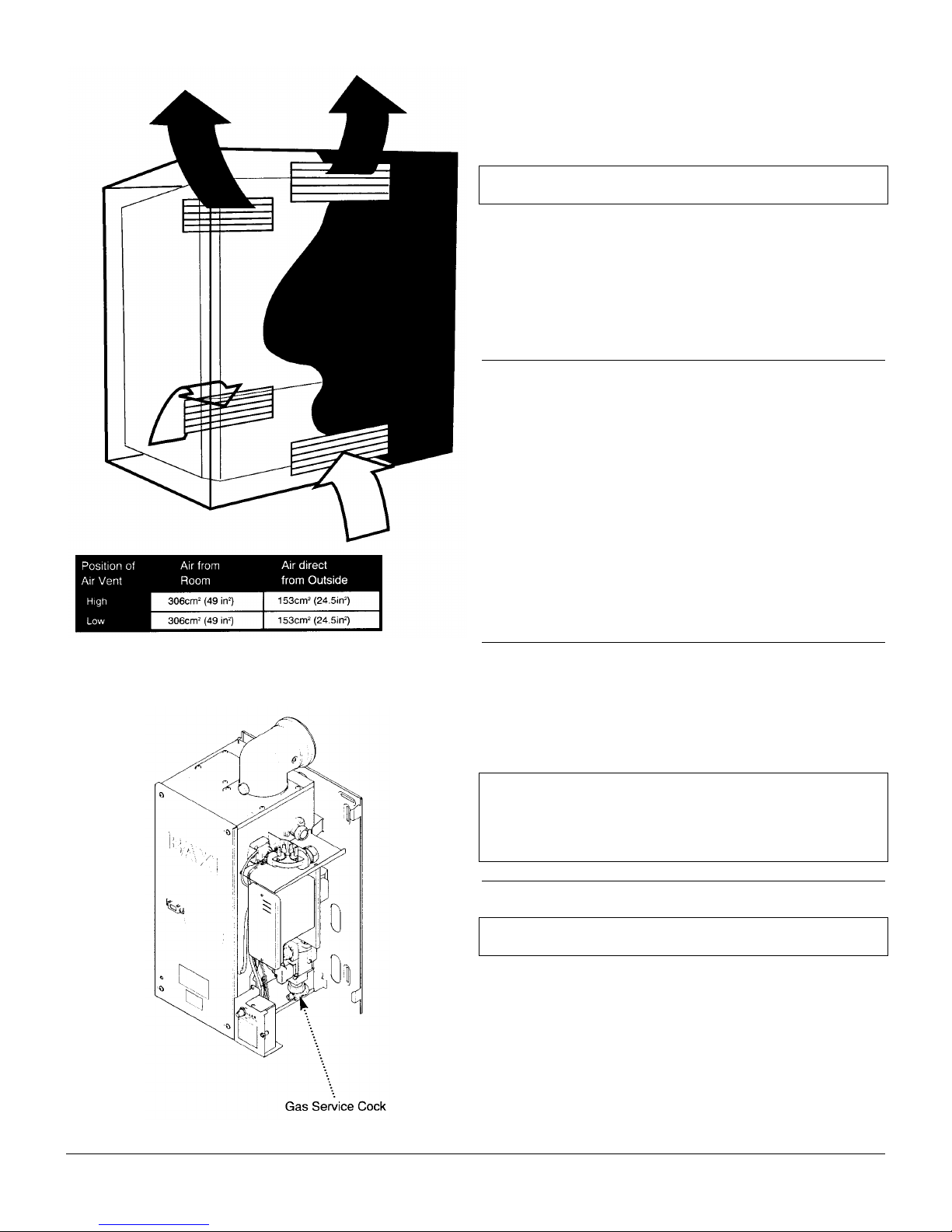

Fig14

7.5 Ventilation of Compartments (Fig. 14)

1. Where the boiler is installed in a cupboard or

compartment, air vents are required (for cooling

purposes) in the cupboard or compartment at high and

low level which may communicate with a room or direct

to outside air.

NOTE: Both air vents must communicate with the same

room or both be on the same wall to outside air

2. Detailed recommendations for air supply are given in

BS 5440: Part 2.

3. An existing cupboard or compartment may be used,

provided that it is modified for the purpose.

Recommendations for air supplies and details of

essential cupboard compartment design are given in

BS 5440: Part 2.

7.6 Gas Supply

1. The gas installation should be in accordance with

BS6891.

2. The connection to the appliance is a ½in BSPT internal

threaded connection located at the rear of the gas

service cock (Fig. 15).

3. Ensure that the pipework from the meter to the

appliance is of adequate size. (22mm pipework must be

connected to the appliance gas service cock. This

should extend for at least 3 meters back towards the

gas meter).

Do not use pipes of a smaller diameter than the

boiler gas connection.

Fig. 15

7.7 Electrical Supply

1. External wiring must be correctly earthed, polarised and

in accordance with current l.E.E. WIRING

REGULATIONS.

2. The mains supply is 230V ~ 50Hz fused at 3A.

NOTE: The method of connection to the electricity supply

must facilitate complete electrical isolation of the appliance.

Connection may be via a fused double-pole isolator with a

contact separation of at least 3mm in all poles and servicing

the boiler and system controls only.

7.8 Condensate Drain

NOTE: Ensure the discharge of condensate complies with

any national or local regulations in force.

1. The condensate outlet terminates in a 1” BSP nut and

seal for the connection of 21.5mm (¾in) plastic

overflow pipe which should generally discharge

internally into the household drainage system. If this is

not possible, discharge into an outside drain is

acceptable.

2. The pipe should run internally as much as possible and

with a 10º (1 in 6) fall to dispose of condensate quickly

to avoid freezing.

Page 14

7.0 Site Requirements – page 14

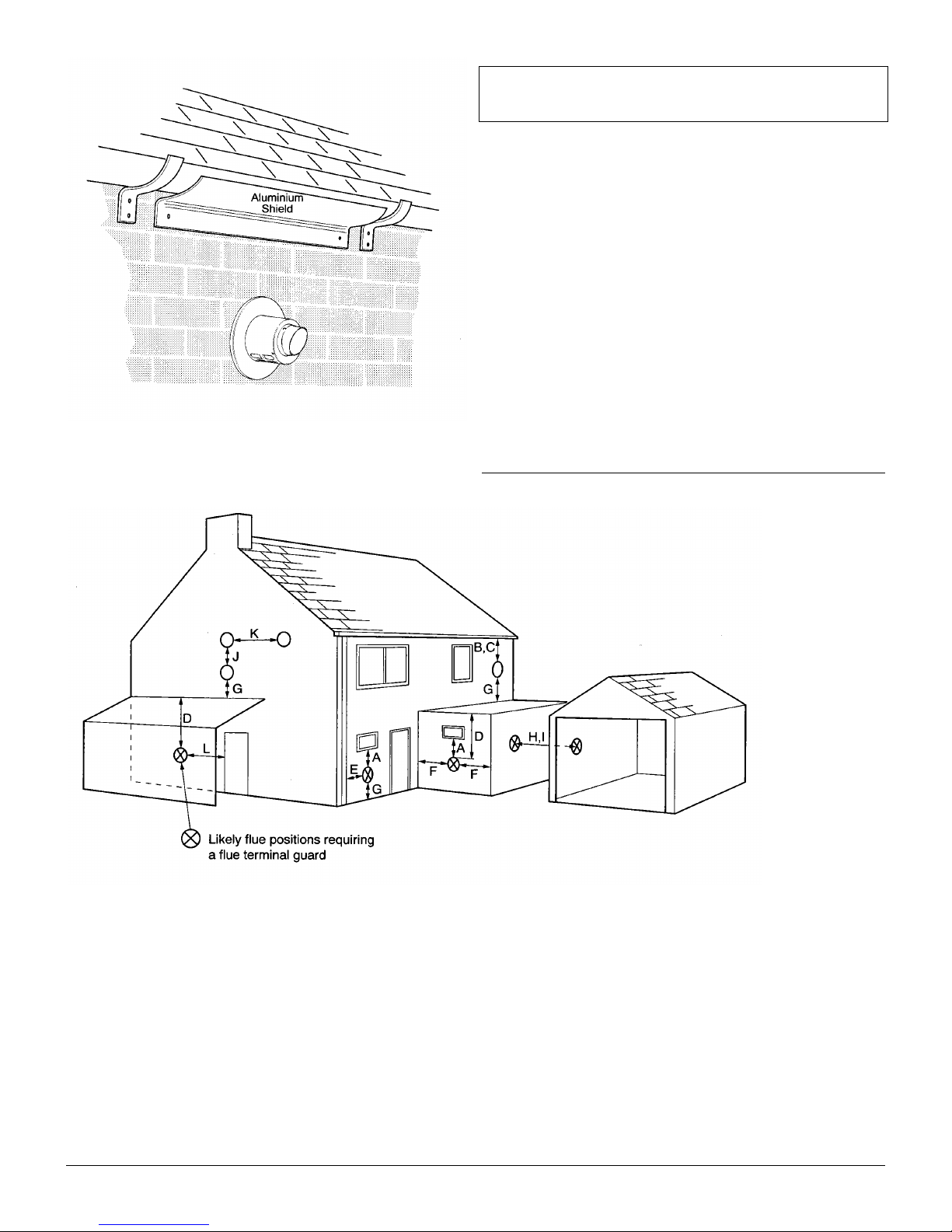

Fig. 16 7.9 Flue

Fig. 17

NOTE: Due to the nature of the boiler a plume of water

vapour will be discharged from the flue. This should be

taken into account when siting the flue terminal.

1. The following guidelines indicate the general

requirements for siting balanced flue terminals.

Recommendations for flues are given in BS 5440 Pt.1.

2. If the terminal is fitted within 1 metre (39 in) of a plastic

gutter, within 500mm (19½ in) of a painted eave or a

painted gutter, an aluminium shield of at least 1 metre

(39 in) long should be fitted to the underside of the

gutter or painted surface. An air space of 5mm (3/16 in)

should be left between shield and gutter (Fig. 16).

3. If the terminal discharges onto a pathway or

passageway, check that combustion products will not

cause a nuisance and that the terminal will not obstruct

the passageway.

4. Take into consideration the effect the plume of vapour

may have on neighbours when siting the flue.

5. If a terminal is less than 2 metres (78¾ in) above a

balcony, above ground or above a flat roof to which

people have access, then a suitable terminal guard

must be provided.

Terminal Position with Minimum Distance Fig 17 mm

A Directly below an openable window or other opening,

e.g. an air brick.

B Below gutters, soil pipes or drain pipes.

C Below eaves.

D Below balconies or car port roof.

E From vertical drain pipes and soil pipes.

F From internal or external corners.

G Above ground, roof or balcony level.

H From a surface facing a terminal.

I From a terminal facing a terminal.

J Vertically from a terminal on the same wall.

K Horizontally from a terminal on the same wall.

L For an opening in a car port (e.g. door, window) into a

dwelling.

300

75

200

200

75

300

300

600

1200

1500

300

1200

Page 15

7.0 Site Requirements – page 15

Fig. 18

7.10 Flue Dimensions

See Section 1.2. The standard horizontal flue kit allows for

flue lengths between 270mm (10 5/8”) and 800mm (32”)

from elbow to terminal

(Fig. 18).

The maximum permissible equivalent flue length is:

4 metres (Fig. 18a).

NOTE: Each additional 45º of flue bend will account for an

equivalent flue length of 0.5m

eg. 45º = m, 90º = 2 x 45º = 1m etc.

7.11 Terminal Guard (Fig. 19)

1. When codes of practice dictate the use of terminal

guards, they can be obtained from most Plumbers’ and

Builders’ Merchants.

2. When ordering a terminal guard, quote the appliance

model number.

Fig 18a

Pictorial examples of flue runs where EQUIVALENT flue

length equals 4m

Fig. 19

3. The guard manufacturers listed below can be contacted

for terminal sizes and guard model numbers.

Tower Flue Components Ltd.,

Tower House,

Vale Rise,

Tonbridge,

Kent.

Tel: 01732 351555.

Quinnell, Barrett & Quinnell,

884 Old Kent Road,

London,

SE15 1NL.

Tel: 0171 639 1357.

4. The flue terminal guard should be positioned centrally

over the terminal and fixed as illustrated

7.12 Vertical Flue

1. Only a flue approved with the Baxi Barcelona can be

used.

2. For information on vertical flues consult the Baxi

Barcelona Installer Guide or Notes for Guidance

supplied with the vertical flue pack.

Page 16

8.0 Installation – page 16

Fig. 20

Fig. 21

Check Site Requirements (section 7) before

commencing.

8.1 Initial Preparation

The gas supply, gas type and pressure must be checked

for suitability before connection (see Section 7.6).

NOTE: If the boiler wall plate is to be pre-hung, follow both

these instructions and those on the boiler pack.

1. Remove the fixing template (Fig. 20) from the carton.

2. After considering the site requirements (see Section 7.0

) position the template on the wall ensuring it is level

both horizontally and vertically.

3. Mark the position of the centre hole for the wall plate

(Fig. 20).

4. Mark the centre of the flue hole (rear exit). For side exit,

mark as shown (Fig. 21). If required, mark the position

of the gas and water pipes. Remove the template.

5. Cut the hole for the flue (minimum diameter 125mm,

see table for wall thicknesses and flue diameters).

Fig. 22

6. Drill and plug the wall as previously marked. Secure the

wall plate using the centre hole.

7. Ensuring the wall plate is level both horizontally and

vertically, drill and plug at least 4 securing positions at

the top and bottom through the wall plate. Utilising the

slots available ensure the wall plate is square and

secure to the wall (Fig. 22).

8. Loosely route the condensate discharge pipe to the

lower left hand side of the wall plate.

Page 17

8.0 Installation – page 17

Fig. 23

8.2 Preparing The Boiler

1. Remove the outer carton.

2. Remove the internal packaging.

3. Lift the outercase upwards and remove (Fig. 23).

Baxi Limited declare that no substances harmful to

health are contained in the appliance or used during

appliance manufacture.

Page 18

8.0 Installation – page 18

Fig. 24 8.3 Fitting The Boiler (Fig. 24)

1. Remove the screw and retaining bracket from the wall

plate spring clip.

2. Offer up the boiler to the wall plate and locate the rear

bottom edge onto the self locating support at the base

of the wall plate.

3. Rotate the boiler and engage into temporary spring

retaining latch.

4. Ensure the boiler is secured with the retaining

bracket and screw previously removed,

immediately.

5. Remove thread protection caps from the FLOW and

RETURN connections.

8.4 Making the Water Connections (Fig. 25)

1. The boiler has two side water connections, the front

connection being FLOW and the rear connection being

RETURN.

2. It is essential that Flow and Return pipes are connected

to the correct fittings. The flow connection incorporates

the boiler thermostats and a flow switch. To avoid

damage to the flow switch when tightening the flow

connection the use of two spanners is recommended.

3. A copper elbow, compression nut and olive are

provided in the kit for the return connection.

NOTE: Drain cocks should be fitted to all system’s low

points and vents to all high points.

4. Ensure that any pipework is routed so as to leave the

boiler via the spaces at the rear of the outer case,

either at the top or at the bottom.

Pipework within the confines of the outercase should

consist of solder fittings.

NOTE: It is important that the pipework does not interfere

with the correct fitting of the outer case and a space of 14

mm clearance must be left between any vertical pipes and

the outer edge of the wall plate.

8.5 Making the Condensate Drain Connection

1. Connect the condensate drain using the 1 “BSP nut

and seal supplied. (see section 7.8.).

NOTE: To ensure the correct operation and integrity of

the condensate drainage system

- Carefully pour approximately 1 cupful (250ml) of water into

the flue products exhaust, at the top of the heat exchanger

(Fig. 25a) to ensure a seal is made in the trap.

Page 19

8.0 Installation – page 19

Fig. 26

8.6 Making the Gas Connection

1. Connect the gas supply to the RC½ (½in BSPT

internal) gas tap located on the lower right side of the

boiler.

8.7 Fitting The Flue

Before fitting the flue, check the condensate drain

integrity (see section 8.5).

IMPORTANT: The flue should always be installed with a 3º

(1 in 20) fall from terminal to elbow, to allow condensate to

run back to the boiler.

HORIZONTAL FLUE

1. The standard flue is suitable for lengths 270mm

minimum to 800mm maximum (measured from the

edge of the flue elbow outlet).

Rear Flue: maximum wall thickness - 630mm

Side Flue: maximum wall thickness - 565mm (left or right)

2. For rear exit - measure the wall thickness (Fig. 26) and

to this dimension add 235mm. This dimension to be

known as (X).

i.e. (X) = wall thickness + 235

3. Take the flue and mark off (X) from the terminal end as

indicated in the diagram (Fig. 27).

Check your dimensions.

Fig. 27

Fig. 27a

The flue tubes are fixed together. Cut through both

tubes whilst resting the flue on the semicircular packing

pieces. Deburr both tube ends.

4. For side exit - measure the distance from the edge of

the wall plate to the inner face of the wall (Fig. 26) and

to this dimension add the wall thickness + 275mm. This

dimension to be known as (Z).

i.e. (Z) = wall plate to wall + wall thickness + 275

5. Take the flue and mark off (Z) from the terminal end as

indicated (Fig. 27).

Check your dimensions.

The flue tubes are fixed together. Cut through both

tubes whilst resting the flue on the semicircular packing

pieces. Deburr both tube ends.

IMPORTANT: Check all measurements before cutting

NOTE: When cutting ensure the cut does not interfere with

the inner flue support bracket (Fig. 27a).

Page 20

8.0 Installation – page 20

Fig 28

8.7 Fitting the Flue (Cont)

6. Ensure the inner flue support bracket is positioned in

the flue (Fig. 28).

7. Engage the flue into the flue elbow using soap solution

to ease the engagement ensuring the flue is assembled

as shown (Fig. 29).

8. Place the gasket over the flue exit on the boiler.

9. Slide the flue assembly through the hole in the wall.

10. Engage the elbow on to the flue connection on top of

the boiler. Secure with the four screws supplied in the

kit.

11. Make good between the wall and air duct outside the

building ensuring the 3º drop between the terminal and

elbow.

12. The flue trim should be fitted once the installation is

complete and the flue secure (Fig. 30). Apply a suitable

mastic to the inside of the trim and press against the

wall finish, making sure the brickwork is dust free and

dry.

13. If necessary fit a terminal guard (see Section 7.11).

VERTICAL FLUEING

1. Only a flue approved with the Baxi Barcelona can be

used.

2. For information on vertical flues consult the Baxi Gas

Central Heating Boilers Installer Guide or Notes for

Guidance supplied with the vertical flue pack.

Page 21

8.0 Installation – page 21

8.8 Making The Electrical Connections

WARNING: This appliance must be earthed

1. The electrical connections are on the right hand side of

the unit inside the electrical box.

2. Undo the two screws securing the electrical box cover

and remove the cover (Fig. 31).

3. Undo the two screws securing the SL, , N, PF cable

clamp and place to one side (Fig. 32).

4. If fitting an integral programmer kit please refer to kit

instructions at this stage.

5. If necessary the output of the boiler can be increased to

100,000 Btu/h.

a) Draw the control PCB forwards out of the electrical box

(the control PCB is the right hand board).

b) Pull off the two jumper connections at the top rear

corner of the PCB (Fig. 32a).

c) Replace the PCB and continue with the installation.

6. Route the incoming electrical cable/s through the

grommet in the support bracket. This will prevent

damage to the cable (Fig. 31a).

7. Lay the cable through the cable clamp to gauge the

length of cable required when it is connected to the 4way terminal block (Fig. 32).

8. Connect the (S/L), (N) and ( ) wires to the 4-way

terminal block and refit the cable clamp (Fig. 33).

9. The pump can be wired directly to the system controls

or to the P/F connector on the boiler. For full TRV

installation refer to section 6.1.

10. The P/F connection should only be used on a full TRV

system without a bypass.

11. Check the electrical installation for; earth continuity,

short circuits, resistance to earth, correct polarity and

fuse failure.

12. Replace the electrical box cover and secure.

Page 22

9.0 Electrical – page 22

9.1 Schematic Wiring Diagram

Page 23

9.0 Electrical – page 23

9.2 Illustrated Wiring Diagram

Page 24

10.0 Commissioning the Boiler – page 24

10.1 Commissioning the Boiler

1. Reference should be made to BS 5449 Section 5 when

commissioning the boiler.

2. Flush the whole system using a suitable flushing agent

(see Section 6.2) and vent the radiators. Check for

water leaks.

3. Refill the system with inhibitor following the inhibitor

manufacturer’s instructions and BS 7593 Code of

Practice for Treatment of Water in Domestic Hot Water

Central Heating Systems (see Section 6.2).

4. Turn the gas supply on and purge the system according

to BS 6891.

5. Turn the gas service cock anticlockwise to the ON

position and check for gas soundness up to the gas

valve (Fig. 34).

6. Turn the boiler control knob fully clockwise to ‘HIGH’

(Fig. 35) and run the system and check the boiler for

correct operation.

NOTE: The boiler is self-regulating and the gas rate will

modulate between inputs of 33.76kW and 10.2kW

dependent upon the system load. The input is factory set at

23.45kW and can be altered to 33.76kW - see section 8.8.

No adjustment of the gas valve is permissible.

7. With the system cold and all controls calling for heat

check the gas pressure at the inlet tapping of the gas

valve (Fig. 36). The pressure must be a minimum of

18.1 mbar.

Page 25

11.0 Fitting the Outer Case – page 25

Fig. 37

11.1 Fitting The Outer Case

1. Position the outercase over the boiler engaging the lugs

in the side flanges over the hooks on the wall plate (Fig.

37).

2. Using the two screws supplied in the kit, secure the

outercase to the combustion box (Fig. 37).

3. Replace the lower front door panel (Fig. 38).

4. Carefully read and complete all sections of the

“Benchmark” Installation, Commissioning and Service

Record Log Book that are relevant to the appliance and

installation. The details of the Log Book will be required

in the event of any warranty work. The Log Book must

be handed to the user for safe keeping and each

subsequent regular service visit recorded.

5. Instruct the user in the operation of the boiler controls.

Hand over the User’s Operating, Installation and

Servicing Instructions and the Log Book, giving advice

on the necessity of regular servicing.

6. Advise the user that a plume of vapour from the flue

terminal is normal, and that there is no need for

concern.

Fig. 38

IMPORTANT: This boiler is fitted with an aluminium alloy

heat exchanger. It is important that the system is thoroughly

flushed in accordance with BS 7593 and that one of the

following inhibitors is used:

BETZ DEARBORN SENTINEL X100

FERNOX COPAL

Refer to inhibitor manufacturer’s instructions for correct

use. Failure to comply with this requirement will invalidate

the appliance warranty.

It is also important to check the inhibitor concentration after

installation, system modification and at every service.

Date Boiler Installed ……./……./………

Inhibitor Used ………………………………

7. This label is located on the electrical box front cover on

the boiler. Detail of system treatment should be added

for future reference.

Page 26

12.0 Servicing the Boiler – page 26

12.1 Annual Servicing

IMPORTANT: When servicing ensure that both the gas and

electrical supplies to the boiler are isolated before any work

is started.

When the boiler control knob is switched off the control

PCB remains live. Therefore it is important to isolate the

electrical supply.

Hazardous materials are not used in the construction of

Baxi products, however reasonable care during service is

recommended.

When replacing the combustion box door after servicing it is

essential that the retaining screws are tightened fully.

1. For reasons of safety and economy, it is recommended

that the boiler is serviced annually. Before servicing

please read Section 1.2 Important Information.

2. After servicing, complete the relevant section of the

“Benchmark” Installation, Commissioning and Service

Record Log Book. This should be in the possession of

the user.

3. If it is intended to undertake a flue gas analysis as part

of the service, then whilst the boiler is running measure

the CO and CO2 content of the flue products, by

removing the sample point screw on the flue elbow

(Fig. 39) and inserting a suitable sampling probe. If the

CO/CO2 ratio is greater than 0.02 then a more

extensive service and investigation will be required. If

the CO/CO2 ratio is less than 0.02 proceed as follows:

4. Ensure that the boiler is cool.

5. Ensure that both the gas and electrical supplies to

the boiler are isolated.

6. Remove the outercase and lower door panel (see

Fitting the Outercase, Section 11.0).

7. Release the four ¼ turn screws securing the air box

door panel and remove the door (Fig. 40).

8. Disconnect the leads from the centre and right hand

terminals (earth and flame sensing probe). The spark

electrode lead is permanently fixed to the electrode.

Undo the re-usable cable tie and pull down the sleeving

to expose the joint in the electrode lead. Disconnect the

lead (Fig. 41a).

9. Undo the four screws securing the combustion box

door and remove the door (Fig. 41).

10. Visually check for debris/damage and clean or replace

if necessary the following:

a) Burner (Fragile - handle with care).

b) Heat exchanger fins.

c) Fan compartment (check also for condensate leaks)

d) Insulation

e) Door seals-Important: Pay particular attention to the

condition of the combustion box door seals.

f) Electrodes

g) Check condensate trap for debris. NOTE: If necessary

remove the trap drain plug and place a vessel

underneath to catch the condensate (care should be

taken as this could be hot). Clean the trap and refit the

drain plug.

h) Top of heat exchanger

Page 27

12.0 Servicing the Boiler – page 27

12.1 Annual Servicing (Cont)

NOTE: General cleaning can be undertaken using a

vacuum. However debris should only be gently blown

off the burner skin due to Its fragile nature.

11. If CO/CO2 ratio is greater than 0.02 then proceed as

follows to allow removal and cleaning of inner and rear

heat exchanger flueways:

a) Disconnect the electrical leads to the fan component

protection sensor (Fig. 42).

b) Loosen the screw retaining the gas injector pipe at the

venturi (Fig. 42).

c) Undo the two wing nuts to disconnect the fan (Fig. 42).

d) Remove the fan and disconnect the electrical supply to

it (Fig. 42).

e) Remove the gas injector pipe from the gas valve (push-

fit) (Fig. 42).

f) Undo the condensate trap securing nut, lock nut and

the condensate drain pipe. Remove the condensate

trap and disconnect the sensor leads (Fig. 43).

g) Remove the two screws securing the burner and

remove the burner. Visually inspect the internal burner

baffle for obstruction.

Fig 44

NOTE: The burner skin is fragile - handle with care. Clean

and if necessary replace the burner (Fig. 44) (see note

above).

h) Loosen the two screws retaining the heat exchanger

support bracket and slide to the left to remove (Fig. 44).

i) Remove the four screws securing the heat

exchanger/combustion box base and withdraw the

base.

j) Lower the central insulation panel and check condition

(Fig. 44). Replace the lower insulation pad if necessary.

k) Ensure the heat exchanger fins are clear of any

obstruction.

I) Check condition of all seals. Important: Pay particular

attention to the condition of the combustion box door

seals.

m) Reassemble in reverse order.

12. Complete the relevant section of the “Benchmark”

Installation, Commissioning and Service Record Log

Book and hand it back to the user.

Page 28

13.0 Changing Components – page 28

Fig. 45

13.1 Changing Components

IMPORTANT: When changing components ensure that

both the gas and electrical supplies to the boiler are

isolated before any work is started.

When the boiler control knob is switched off the control

PCB remains live. Therefore it is important to isolate the

electrical supply.

Hazardous materials are not used in the construction of

Baxi products, however reasonable care during service is

recommended.

When replacing the combustion box door after changing

components, it is essential that the retaining screws are

tightened fully.

1. Before changing any components please read Section

1.2 Important Information.

2. Remove the outer case and lower door panel (see

“Fitting the Outercase” Section 11.0).

3. Isolate the water circuit and drain the system as

necessary. A drain point is located on the heat

exchanger manifold at the right hand side of the boiler

(Fig. 45) to enable the heat exchanger to be drained.

4. Place a tube on the drain point to drain water away

from electrics. Turn anticlockwise to open (Fig. 45).

NOTE: When reassembling always fit new ‘O’ rings,

ensuring their correct location on the spigot. Green “O”

rings are used for gas joints and Black “O” rings for water

joints. Use Greasil 4000 (Approved Silicone Grease).

5. After changing a component re-commission the boiler

where appropriate and check the inhibitor concentration

(see Section 6.2 and 10.1).

The thermistor, safety thermostat, interface PCB and the

flow switch can be accessed after removal of the outer

case.

13.2 Flow Temperature Thermistor and Safety

Thermostat (Fig. 46).

1. The procedure is the same for both the thermistor and

the safety thermostat.

2. Remove the electrical connections from the sensor.

3. Unscrew the sensor from the pipe.

4. Fit the new thermistor or safety thermostat and

reassemble in reverse order.

Fig 46

Page 29

13.0 Changing Components – page 29

13.3 Interface PCB

1. Pull the control knob off the spindle and remove the

securing nut and washer (Fig. 47).

2. Release the electrical box securing screw and hinge

the electrical box down (Fig. 48).

3. Remove the two rear cover securing screws and

remove the rear cover (Fig. 49).

4. Lift the PCB from the electrical box and remove the

electrical connections (Fig. 49).

5. Fit the new PCB and reassemble in reverse order.

13.4 Flowswitch (Fig. 50)

1. Drain the boiler

(see Section 13.1 paragraph 2 & 3).

2. Disconnect pipework, loosen elbow locking nut and

undo screws on support bracket.

3. Remove the clip securing the flow pipe to the

flowswitch.

Fig. 50

4. Remove the two screws securing the flow switch to the

boiler.

5. Disconnect the inline electrical connection.

6. Remove the flowswitch.

7. Fit the new flowswitch and reassemble in reverse order.

8. Recommission the boiler and check the inhibitor

concentration (see Section 6.2 and 10.1).

Page 30

13.0 Changing Components – page 30

The control and ignition boards can be accessed on the

removal of the main electrical box cover.

1. Remove the two screws securing the main electrical

box cover (Fig. 51).

13.5 Control Board (Fig. 52)

1. Slide out the control board (right hand side) and

disconnect the electrical connections noting their

positions.

2. Check if the two jumper connections have been

removed from the board (see section 8.8), if so remove

the jumpers from the new control board.

2. Fit the new control board and reassemble in reverse

order.

13.6 Ignition Board (Fig. 53)

1. Remove the control board, (13.5) and slide out the

ignition board (left hand side) and disconnect the

electrical connections noting their positions.

2. Fit the new ignition board and reassemble in reverse

order.

13.7 Transformer (Fig. 54)

1. After the removal of the control and ignition boards the

transformer can be accessed. Loosen the two electrical

box mounting plate securing screws, remove the front

drip tray securing screw and lift the assembly to clear

the keyhole slots.

2. The transformer is mounted on the rear of the electrical

box mounting plate.

3. Remove the two transformer mounting screws and

remove the transformer.

4. Fit the new transformer and reassemble in reverse

order.

NOTE: Check the original board for the presence of input

jumpers - see section 8.8. Set the new board as the

original.

Page 31

13.0 Changing Components – page 31

The fan and venturi, gas valve, injector pipe, condensate

trap, fan protection sensor, spark and sensing

electrodes can be accessed and changed on the

removal of the airbox door panel.

1. Remove the airbox door panel by loosening the four ¼.

turn screws (Fig. 55).

13.8 Spark and Sensing Electrodes (Fig. 56)

1. Disconnect the leads from the centre and right hand

terminals (earth and flame sensing probe). The spark

electrode lead is permanently fixed to the electrode.

Undo the re-usable cable tie and pull down the sleeving

to expose the joint in the electrode lead. Disconnect the

lead.

Spark - Opaque cable

Earth - Black cable

Sensing - White cable

2. Remove the two screws securing each of the

electrodes to the combustion box door and remove the

electrodes.

3. Fit the new electrodes and reassemble in reverse

order.

NOTE: The spark electrode sleeve should always cover

the joint in the electrode lead to prevent tracking.

13.9 Fan (Fig. 57)

1. Loosen the screw holding the injector pipe into the

venturi.

2. Remove the electrical connections to the fan protection

sensor on the fan.

3. Remove the wing nuts securing the fan to the base of

the combustion box.

4. Lower the fan and remove.

5. Disconnect the electrical supply from the right hand

rear of the fan.

6. If changing the fan remove the screws securing the

venturi and fan protection sensor bracket, noting the

positions of the injector opening and sensor bracket, fix

them to the new fan.

7. Fit the new fan and reassemble in reverse order.

The injector pipe, condensate trap and gas valve can be

changed after the removal of the fan.

Page 32

13.0 Changing Components – page 32

Fig. 58

The removal of the fan is necessary to enable the

changing of the injector pipe, condensate trap and gas

valve (see section 13.9).

13.10 Injector Pipe (Fig. 58)

1. Remove the injector pipe by pulling out from the ‘O’ ring

joint in the gas valve.

2. Fit the new injector pipe and reassemble in reverse

order.

13.11 Gas Valve (Fig. 58)

1. Release user interface and pivot downward for better

access.

2. Disconnect the gas inlet union at the gas tap.

3. Undo the case pressure pipe from the gas valve.

4. Undo the screw and disconnect the electrical plug from

the gas valve.

5. Remove the two gas valve securing screws from inside

the air box holding the gas valve.

6. Remove the gas valve from the airbox side.

Fig. 59

7. Remove the nut union, aluminium spacer and its gasket

from the gas valve.

8. Fit the nut union, aluminium spacer and its gasket to

the new valve.

9. Fit the new gas valve and reassemble in reverse order.

13.12 Condensate Trap (Fig. 59)

1. Disconnect the condensate trap from the base of the

heat exchanger.

2. Disconnect the condensate drain (outside the boiler)

from the condensate trap.

3. Undo the condensate trap lock nut.

4. Remove the condensate trap from the boiler.

5. Disconnect the sensor leads.

Fit the new condensate trap and reassemble in reverse

order.

Page 33

13.0 Changing Components – page 33

The burner and heat exchanger can be changed after

removal of the combustion box door. To change the

heat exchanger, the fan and burner must be removed

first (see section 13.9).

1. Remove the combustion box door by removing the four

securing screws (Fig. 60).

IMPORTANT: On refitting the combustion box door check

the condition of the combustion box door seals.

13.13 Burner (Fig 61)

WARNING: The burner skin is fragile:

Handle with care

1. Remove the two screws securing the burner to the

base of the combustion box.

2. Remove the burner carefully from the combustion box

base.

3. Fit the new burner and reassemble in reverse order.

13.14 Heat Exchanger

1. Drain the boiler (see section 13.1 paragraph 2 & 3).

2. Remove all components in the base of the airbox.

3. Undo the screws on the support bracket. Remove the

screws securing the flow switch and return connections

and remove the connections (Fig. 64).

4. Remove the electrical connections from the P.C.B.s

(see section 13.5 & 13.6).

5. Loosen the two screws securing the electrical box

mounting plate and remove the assembly (Fig. 62).

6. Remove the screws securing the heat exchanger

manifold and remove the manifold (Fig. 63).

7. Lift the heat exchanger assembly and rotate the bottom

upwards whilst pulling it forwards out of the airbox.

8. Fit the new heat exchanger and reassemble in reverse

order.

9. Recommission the boiler and check the inhibitor

concentration (see Section 6.2 and 10.1).

Page 34

13.0 Changing Components – page 34

Fig. 65 13.15 Heat Exchanger Lower Insulation Pad (Fig. 65)

1. Remove all components in the base of the airbox.

2 Remove the burner (see section 13.13).

3. Remove the four bolts securing the combustion box

base.

4. Remove the combustion box base.

5 Pull the central insulation panel down from the centre

of the heat exchanger and remove the lower insulation

pad.

6. Fit the new insulation pad and reassemble in reverse

order.

13.16 Heat Exchanger Upper Insulation Pad

1. Remove all components in the base of the airbox.

2. Remove the burner (see section 13.13).

3. Remove the heat exchanger (see section 13.14).

4. Remove the four bolts securing the combustion box

base.

5. Remove the combustion box base.

6. Pull the central insulation panel down from the centre of

the heat exchanger.

7. Fit the new insulation pad and reassemble in reverse

order.

Page 35

14.0 Short Parts List – page 35

Short Parts List

Key G.C. Description Manufacturers

No. No. Part No.

1 E06 058 Flow Temperature

Thermistor (Red) 242458

2 E06 059 Flow Switch 242459

3 E06 060 Safety Thermostat

(Black) 242460

8 E06 064 Control PCB 242463

9 E06 065 Ignition PCB 242464

10 E06 066 Transformer 242465

21 E06 074 Fan 242472

23 E06 075 Gas valve 242473

28 E06 079 Interface PCB 242477

38 E06 085 Viewing window 242464

39 E06 086 Condensate Trap 242485

44 E06 091 Electrodes Kit 242490

46 E06 092 Fan Protection

Thermostat 242491

47 E06 093 Burner Assy 242492

52 E06 097 Heat Exchanger Assy 242497

Page 36

15.0 Fault Finding – page 36

Page 37

15.0 Fault Finding – page 37

Page 38

15.0 Fault Finding – page 38

Page 39

15.0 Fault Finding – page 39

Page 40

15.0 Fault Finding – page 40

Page 41

15.0 Fault Finding – page 41

Page 42

15.0 Fault Finding – page 42

Ignition Lockout

Page 43

15.0 Fault Finding – page 43

Page 44

The Baxi Helplines - page 44

Comp Nº 240818 - Iss 8 - 3/00

For General Enquiries

+44 (0)1772 695 555

For After Sales Service

+44 (0)1772 695 505

For Technical Enquiries

+44 (0)1772 695 504

BAXI

Baxi Limited

Brownedge Road

Bamber Bridge Preston

Lancashire

PR5 6SN

www. baxi.com

Loading...

Loading...