Baxi 35/80 IE, 60/100 IE Installation & Servicing Instructions Manual

Installation & Servicing Instructions

Page 1

Natural Gas

Baxi System

35/80 IE & 60/100 IE

Gas Fired Wall Mounted System Boiler

Please keep these instructions safe.

Should you move house, please hand

them over to the next occupier.

Baxi System 35/80 IE

Baxi System 60/100 IE

Baxi is one of the leading manufacturers of domestic heating products in the UK.

Our first priority is to give a high quality service to our customers. Quality is designed into

every Baxi p roduct - prod ucts which f ulfil the dema nds and needs of customers , offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have made a commitment to develop new ideas using

the latest technology - with the aim of continuing to make the products that customers want to

buy.

Everyone who works at Baxi has a commitment to quality because we know that satisfied

customers mean continued success.

We hope you get a satisfactory service from Baxi. If not, please let us know.

The boiler meets the requirements of Statutory Instrument " The Boiler (Efficiency)

Regulations 1993 No 3083" and is deemed to meet the requirements of Directive 92/42/EEC

on the energy efficiency requirements for new hot water boilers fired with liquid or gaseous

fuels:-

Type test for purpose of Regulation 5 certified by: Notified Body 0051.

Product/Production certified by: Notified Body 0051.

For IE only.

Baxi is a BS-EN ISO 9001

Accredited Company

Page 2

Contents

Section Page

1.0 Introduction

2.0 General Layout

3.0 Appliance Operation

4.0 Technical Data

5.0 Dimensions and Fixings

6.0 System Details

7.0 Site Requirements

8.0 Installation

9.0 Commissioning the Boiler

10.0 Completion

11.0 Servicing the Boiler

12.0 Changing Components

13.0 Illustrated Wiring Diagram

14.0 Fault Finding

15.0 Short Parts List

Page 3

40

4

5

6

7

9

10

12

17

26

28

29

31

39

43

1.0 Introduction

Baxi declare that no substances harmful to health are contained in the appliance or

used during appliance manufacture.

1.1 Description

1. The Baxi Sys tem 35/80 IE and 60/100 IE are fully automatic gas fired wall mounted system

boilers. They are room sealed and fan assisted.

2. The boilers are set to give a maximum output of 24.0kW (35/80 IE) or 29.3kW (60/100 IE).

3. They are designed for use on Natural Gas (G20) and can be converted to use Propane

(35/80 IE & 60/10 0 IE) or Butane (35/80 IE).

4. The boiler incorporat es a circulating pump and expansion vessel. It is suitable for use only

on fully pumped sealed s ystems.

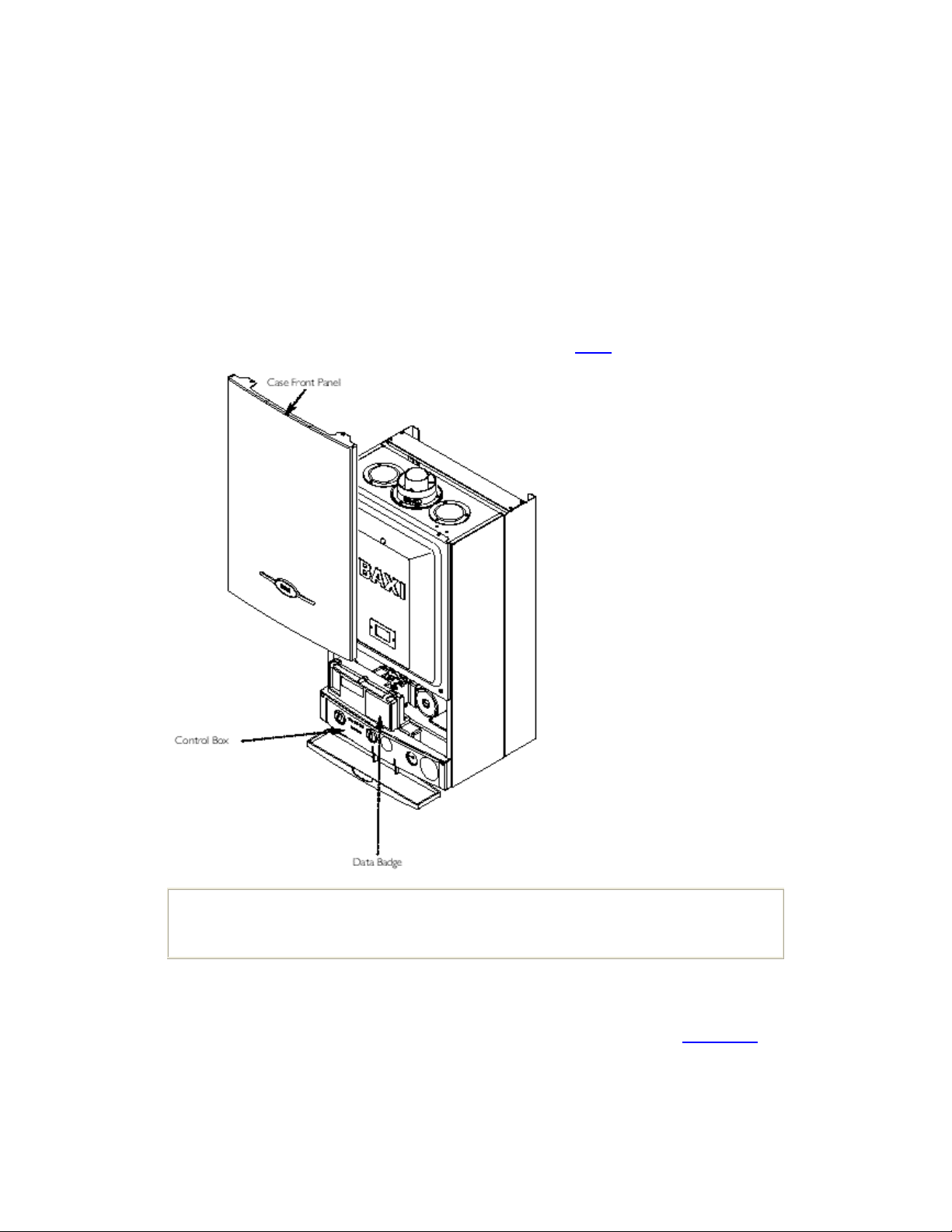

5. The boiler data badge gives details of the model and serial number and is situated on the

control box. It is visible when the case front panel is removed (Fig. 1

).

Fig. 1

NOTE:

This appliance must be installed in accordance with the manufacturer's

instructions and the regulations in force. Read the instructions fully before installing

or using the appliance.

6. The boiler is intended to be installed in residential / commercial / light industrial E.M.C.

environments on a governed meter supply only.

7. The boiler must be installed with one of the purpose designed flues such as the standard

horizontal flue kit, part no. 247719.

8. All systems must be thoroughly flushed and treated with inhibitor (see section 6.1

1.2 Installation

).

The installation must be carried out by a Competent Person and installed in accordance with

the current edition of I.S. 813 "Domestic Gas Installations", the current Building Regulations

and reference should be made to the current ETCI Rules for Electrical Installation.

1.3 Optional Extras

Various fl ue extensions, bends, vert ical flue kits ,control accessories etc. are available as

optional extras. These are detailed in a separate publication.

Page 4

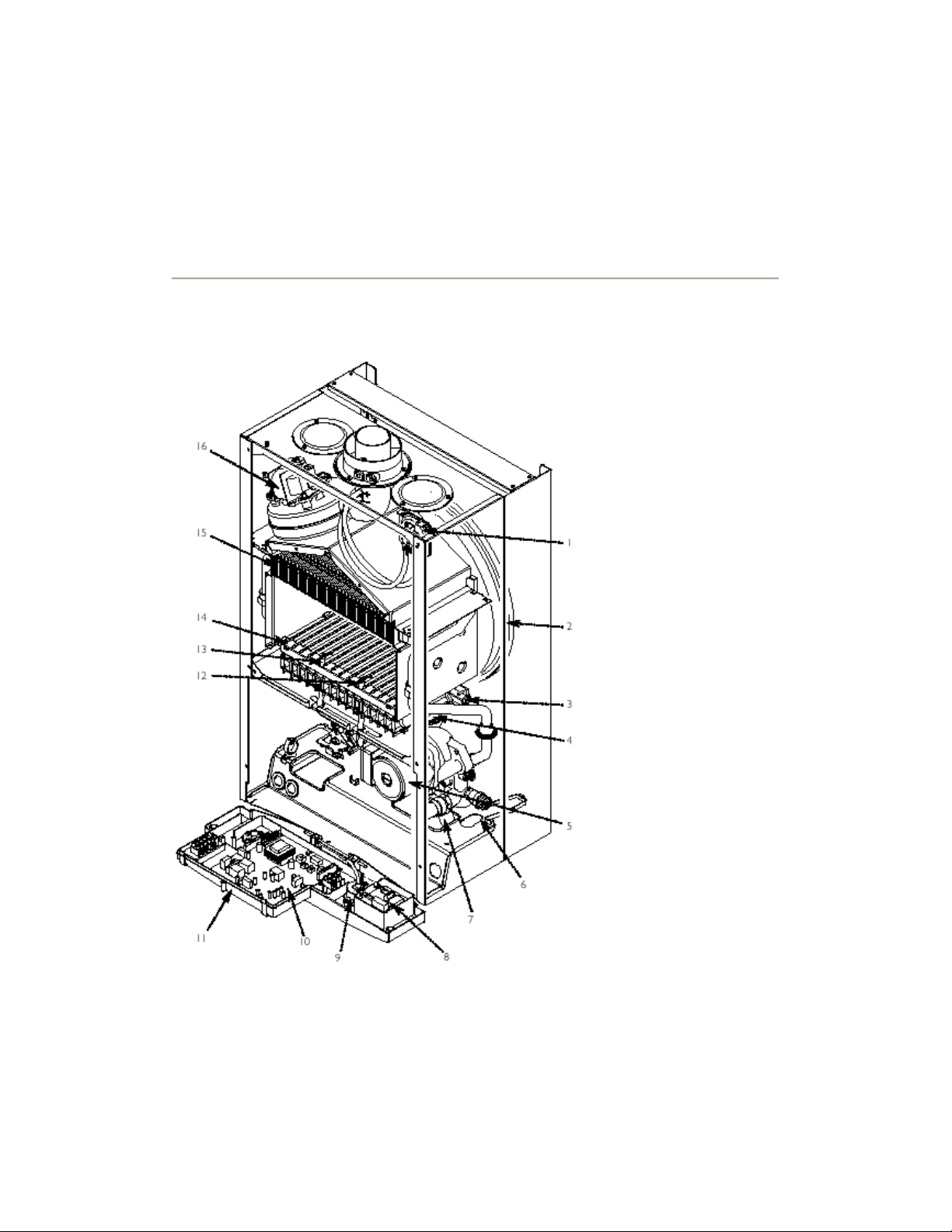

2.0 General Layout

2.1 Layout

1. Air Pressure Switch

2. Expansion Vessel

3. Burner Manifold

4. Automatic Air Vent

5. Circulation Pump

6. Drain Off Point

7. Pressure Relief Valve

8. DHW Relay PCB

9. System Pressure Gauge

10. PCB

11. Control Box

12. Flame Sensing Electrode

13. Spark Electrode

14. Burner

15. Primary Heat Exchanger

16. Fan Assembly

17. On/Off/Reset Selector Switch

18. Central Heating Temperature Control

19. F l am e Failure

20. Safety Thermostat

21. Fault on Fan or Flue

22. Fault on Pump or Low System Pressure

23. T em perature Indi c ation Only

24. Fault on Central Heating Sensor

25. Power On

26. Hot Water Mode

27. Central Heating Mode

28. Burner On

When neons 19 to 24 are constantly illuminated, they indicate the temperature of the central

heating water.

Page 5

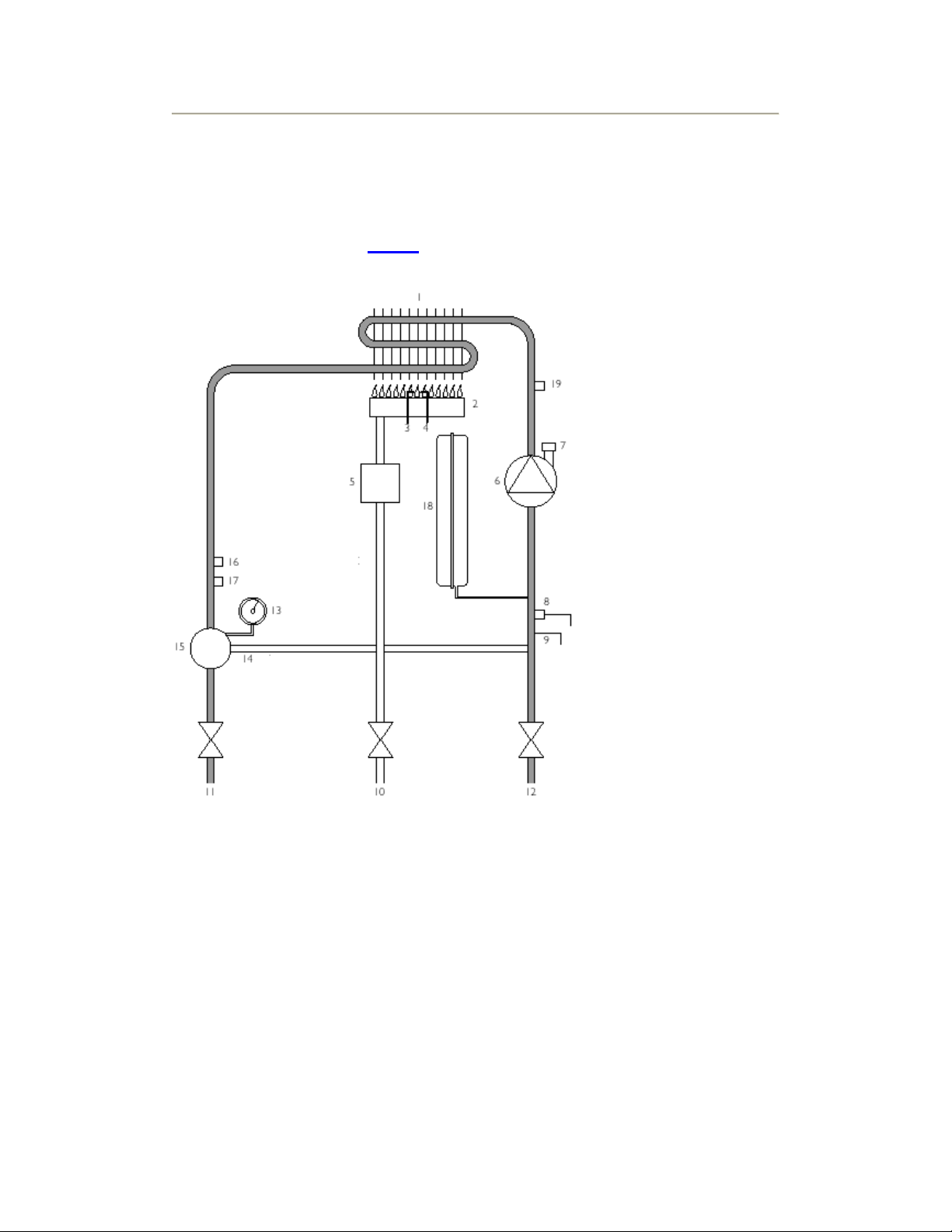

3.0 Appliance Operation

Boiler Prim ary Circuit

3.1 Operating Mode (Fig. 2)

Fig. 2

Key

1 Heat Exchanger

2 Burner

3 Ignition Electrode

4 Flame Sensing Electrode

5 Gas Valve

6 Pump

7 Automatic Air Vent

8 Pressure Relief Valve

9 Boiler Drain Point

10 Gas Inlet

11 Boiler Flow

12 Boiler Return

13 Pressure Gauge

14 Automatic By-Pass

15 Hydraulic Differential Pressure Sensor

16 Safety Thermostat

17 Central Heating Temperature Sensor

18 Expansion Vessel

19 Water Heating Sensor

1. With a demand for heating, the pump circulates water through the primary circuit. At a predetermined flow rate the hydraulic differential pressure switch operates, initiating the ignition

sequence.

2. The main burner ignites at low rate, then the gas valve controls the gas rate to maintain the

heating temperature measured by the temperature sensor.

3. When the flow temperature exceeds the setting temperature, a 3 minute delay occurs

before the burner relights automatically (anti-cycling). The pump continues to run during this

period.

4. When the demand is satisfied the burner is extinguished and the pump continues to run for

a period of 3 minutes (Pump Overrun).

IMPORTANT: When the selector switch is in the '0' (Off) position the electrical

supply to the boiler is isolated. The boiler will not operate.

3.2 Frost Protection Mode

1. The frost protection mode is integral to the appliance and functions only with the selector

switch (see Section 2.1

temperature falls below 5°C then the boiler will fire on its minimum setting until a flow

temperature of 30°C is reached. This will only protect the boiler, not the complete system.

Further protection can be incorporated by using a system frost thermostat.

) in the domestic hot water and central heating position. If the system

3.3 Pump Protection

1. With the selector switch (see Section 2.1) in either the central heating or central heating

and hot water position the pump will automatically operate for 1 minute in every 24 hours to

prevent stic king.

Page 6

4.0 Technical Data

4.1 System 35/80 IE

Appliance Type

Appliance Category

Heat Input (Gross)

C

C

12

CATⅡ

2H 3+

32

Max Min

kW 26.3 10.6

Btu/h 89,739 36,170

Heat Output

Max Min

kW 24.0 9.3

Btu/h 81,891 31,740

Max Gas Rate

m3/h 2.75

ft3/h 98.12

Burner Pressure

(Natural Gas - G20)

(After 10

Mins)

(Natural Gas - G20)

Max Rate Min Rate

mbar 12.2 ±0.5 2.5 ±0.5

in wg 4.88 ±0.2 1.0 ±0.2

Inlet Pressure

mbar 20

in wg 8

(Natural Gas - G20)

Burner Injector (Natural Gas - G20)

12 x 1.28mm Diameter

Electrical Supply

230V~ 50H

z

(Appliance must be connected to an earthed supply)

Power Consumption

External Fuse

Rating

170W

3A Maximum

Internal Fuse Rating

Fuse 2A Fast Blow to BS 4265

Electrical Protection

IPX5D

NOx

Class

3

Flue Terminal

Dimensions

Connections

Diameter 100mm

Projection 95mm

copper tails

Gas Supply - 3/4"

Central Heating Flow - 3/4"

- 3/4"

Return

Pressure Relief

Discharge

- 1/2"

Outercase Dimensions

Casing Height - 780mm

Overall Height Inc

Flue Elbow

- 980mm

Casing Width - 450mm

Casing Depth - 345mm

Clearances

Both Sides 5 mm Min

Above Casing 200 mm Min

Below Casing 200 mm Min

Front 450 mm Min (For Servicing)

Front 5 mm Min (In Operation)

Weights

Packaged Boiler

Carton

kg

45

Packaged Flue Kit 3

Installation Lift

Weight

37

Central Heating Primary Circuit Pressures

bar

Safety Discharge 3

Max Operating 2.5

Min Operating 0.2

Recommend Operating 1-2

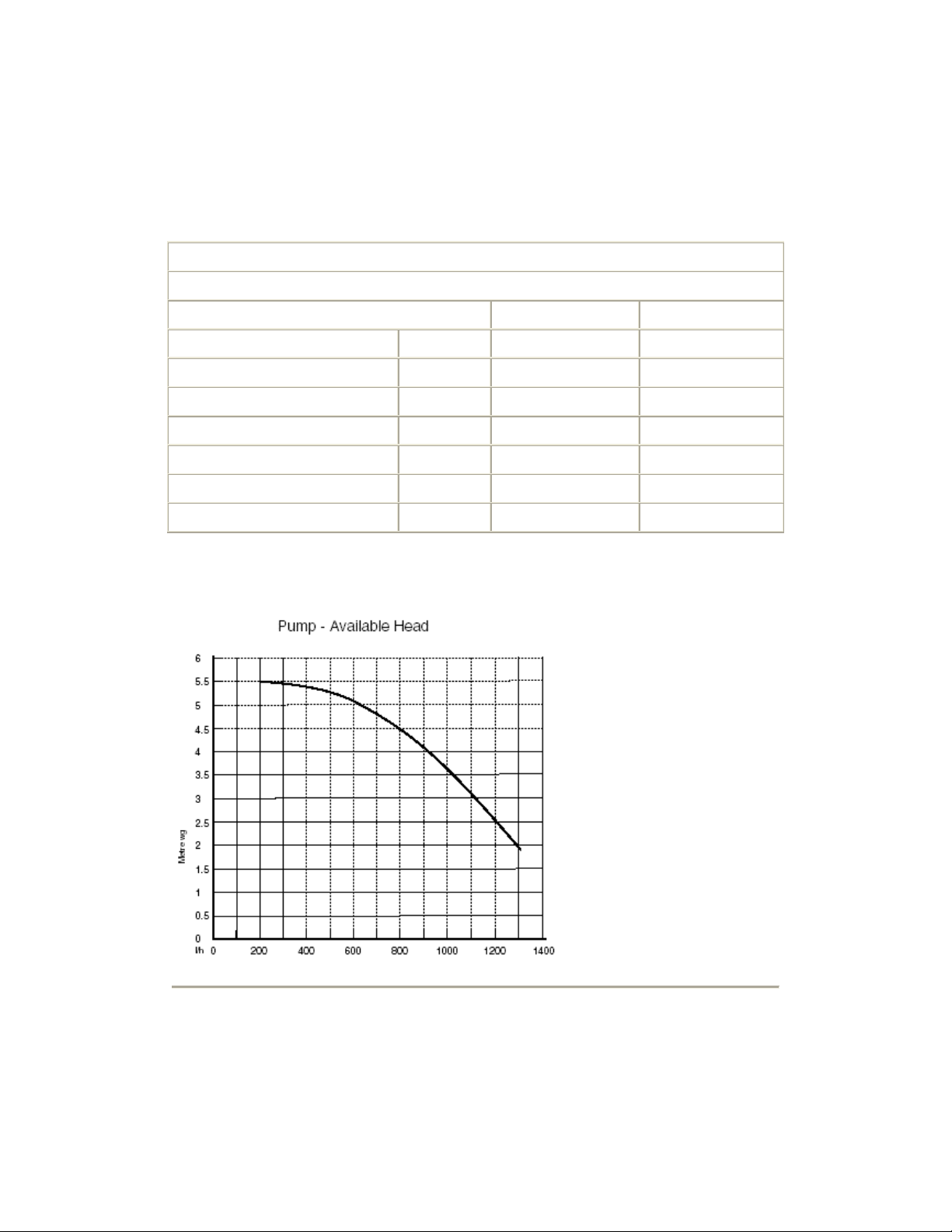

- Grundfos UP 15-60

Pump

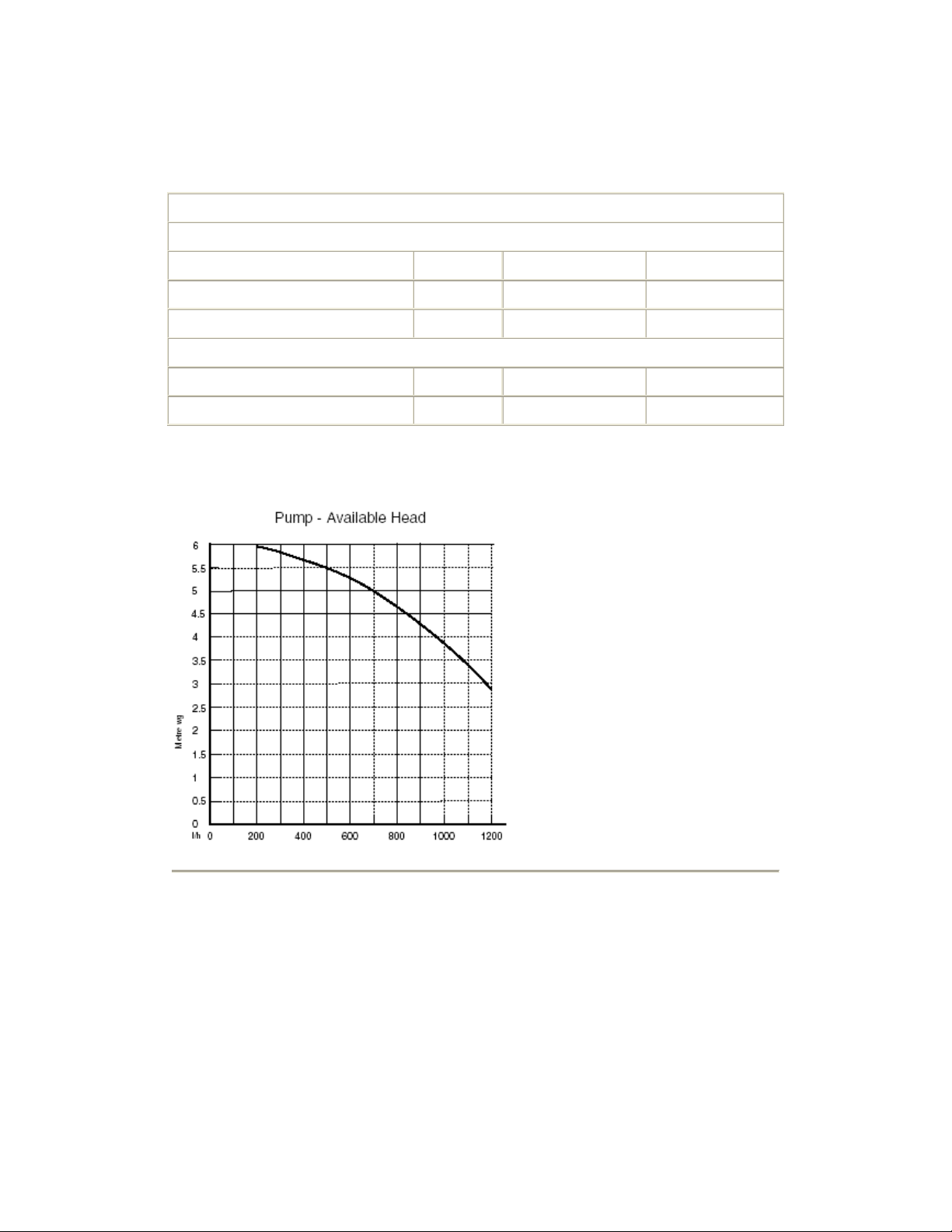

Available Head See graph below

Expansion Vessel

bar

Min Pre-charge

Pressure

litre

Max Capacity of

CH System

- (Integral with appliance)

0.5

125

1.0

Content of Boiler

(unpressurised)

Temperatures

C.H. Flow Temp (

adjustable)

35°C to 85°C

max (±5°C)

LPG Gases Propane - G31 and Butane - G30

Burner Injector 12 x 0.65mm diameter

Burner Pressure

Max Rate Min Rate

Propane mbar 36.2 ±0.5 10.8 ±0.5

in wg 14.5 ±0.2 4.3 ±0.2

Butane mbar 28.8 ±0.5 7.7 ±0.5

in wg 11.5 ±0.2 3.1 ±0.2

Inlet Pressures

Propane Butane

mbar 37 28/30

in wg 14.8 11.2

SEDBUK Declaration For System Boiler 35/80 IE

The seasonal efficiency (SEDBUK) is 78.6 %

This value is used in the UK Government's Standard Assessment Procedure (SAP) for

energy rating of dwellings. The test data from which it has been calculated have been certified

by 0051.

Page 7

C

Appliance Type

Appliance Category

C

12

CATⅡ

2H 3P

32

Heat Input (Gross)

Max Min

kW 32.6 11.9

Btu/h 111,250 40,610

Heat Output

Max Min

kW 29.4 10.4

Btu/h 100,330 35,490

Max Gas Rate

(Natural Gas - G20)

(After 10 Mins)

m

3

/h 3.45

ft3/h 122

Burner Pressure

(Natural Gas - G20)

Max Rate Min Rate

mbar 12.5 ±0.5 1.8 ±0.5

in wg 5.0 ±0.2 0.7 ±0.2

Inlet Pressure (Natural Gas - G20)

mbar 20

in wg 8

Burner Injector

(Natural Gas - G20)

15 x 1.28mm Diameter

Electrical Supply

(Appliance must be connected

to an earthed supply)

Power Consumption

External Fuse

Rating

230V~ 50H

190W

3A Maximum

Internal Fuse Rating

Fuse 2A Fast Blow to BS 4265

Electrical Protection

IPX5D

NOx

Class

3

Flue Terminal

Dimensions

Connections

Diameter 100mm

Projection 95mm

copper tails

Gas Supply - 3/4"

Central Heating Flow - 3/4"

z

- 3/4"

Return

Pressure Relief

Discharge

- 1/2"

Outercase Dimensions

Casing Height - 780mm

Overall Height Inc

Flue Elbow

- 980mm

Casing Width - 450mm

Casing Depth - 345mm

Clearances

Both Sides 5 mm Min

Above Casing 200 mm Min

Below Casing 200 mm Min

Front 450 mm Min (For Servicing)

Front 5 mm Min (In Operation)

Weights

Packaged Boiler

Carton

kg

47

Packaged Flue Kit 3

Installation Lift

Weight

Central Heating Primary Circuit Pressures

39

bar

Safety Discharge 3

Max Operating 2.5

Min Operating 0.2

Recommend Operating 1-2

Pump -

Grundfos UP 15-60

Available Head See graph below

Expansion Vessel

- (For Central Heating only. Integral with appliance)

bar

Min Pre-charge Pressure 0.5

litre

Max Capacity of CH System 125

Primary Water Content of

Boiler (unpressurised)

1.1

Temperatures

C.H. Flow Temp (

35°C to 85°C

LPG Gases Propane - G31

adjustable)

max (±5°C)

Burner Injector 15 x 0.77mm diameter

Burner Pressure

Max Rate Min Rate

Propane mbar 34.4 ±0.5 5.1 ±0.5

in wg 13.8 ±0.2 2.0 ±0.2

Inlet Pressures

mbar 37

in wg 14.8

SEDBUK Declaration For System Boiler 60/100 IE

The seasonal efficiency (SEDBUK) is 78.2 %

This value is used in the UK Government's Standard Assessment Procedure (SAP) for

energy rating of dwellings. The test data from which it has been calculated have been certified

by 0051.

Page 8

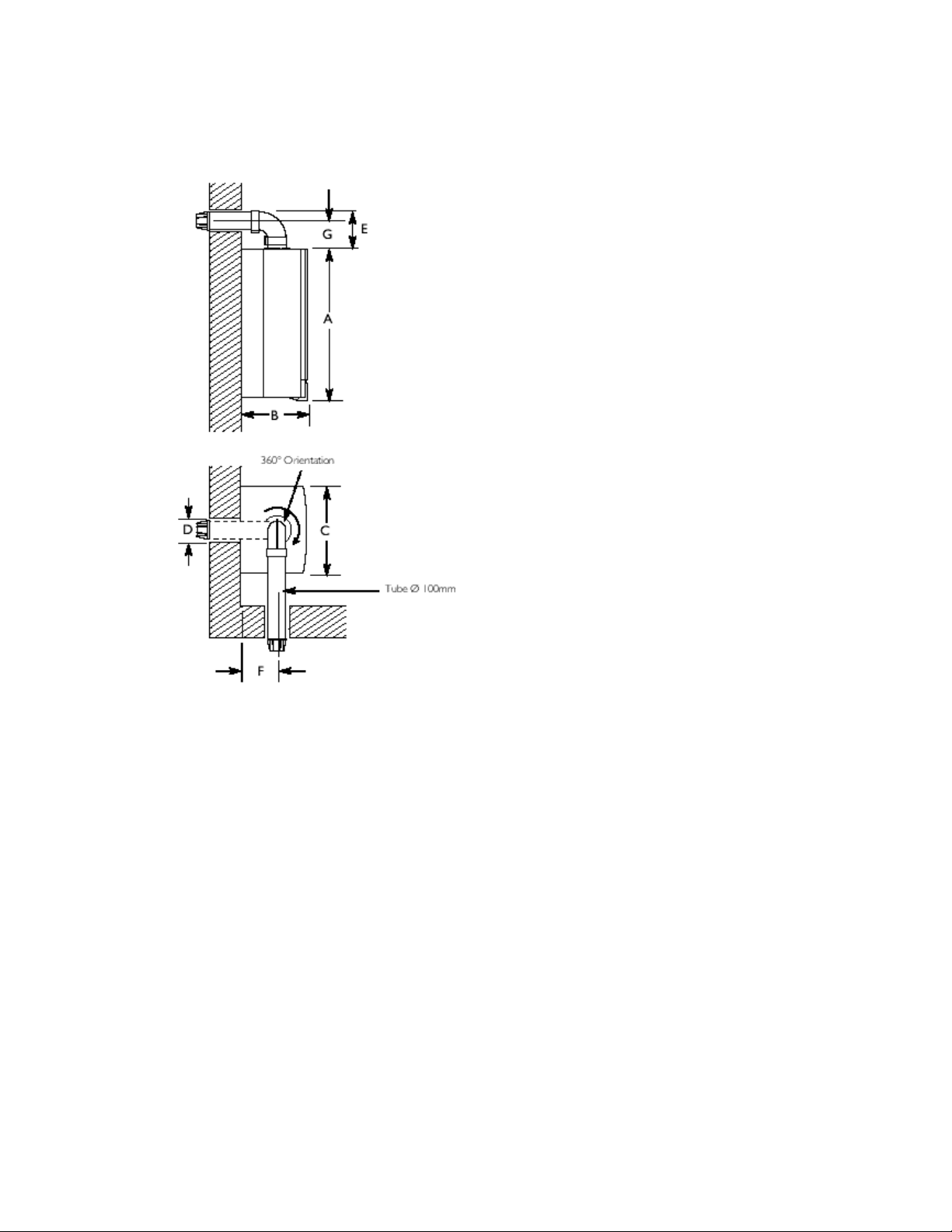

5.0 Dimensions and Fixings

Dimensions

780mm

A

345mm

B

450mm

C

107mm Ø Min.

D

200mm

E

F

G

190mm

143mm

Page 9

6.0 System Details

6.1 Central Heating Circuit

1. The appliance is suitable for fully pumped SEALED SYSTEMS ONLY.

Treatment of Water Circulating Systems

• All recirculatory water systems will be subject to corrosion unless an appropriate

water treatment is applied. This means that the efficiency of the system will

deteriorate as corrosion sludge accumulates within the system, risking damage to

pump and valves, boiler noise and circulation problems.

• For opt i mum performa nce after ins tallation this boiler and its associated central

heating system must be flushed. A means of achieving this is by following the

guidelines given in BS 7593 "Treatment of water in domestic hot water central

heating system s " .

• This must involve the use of a proprietary cleanser, such as BetzDearborn Sentinel

X300 or X400, or Fernox Superfloc. Full instructions are supplied with the product s,

but for immediate information please contact BetzDearborn (+44 151 420 9563) or

Fernox (+44 1799 550 811) directly.

• For long term protection against corrosion and scale, after flushing it is recommended

that an inhibitor such as BetzDearborn Sentinel X100, or Fernox MB-1 or Copal is

used. The correct dosing is obtained by following the guidelines given in BS 7593.

Failure to flush and add inhibitor to the system may invalidate the appliance

warranty.

• It is important to check the inhibitor concentration aft er installation, system

modification and at every service in accordance with the manufacturer's instructions.

(Test kits are available from inhibitor stockists.)

• For information or advice regarding any of the above contact Heatmerchants

Technical Enquiries on 090 - 6442303.

6.2 Bypass

1. The boiler is fitted with an automatic integral bypass.

6.3 System Control

1. The boiler is designed for use in a heating system that incorporates external controls, i.e. a

minimum of a time r device.

Page 10

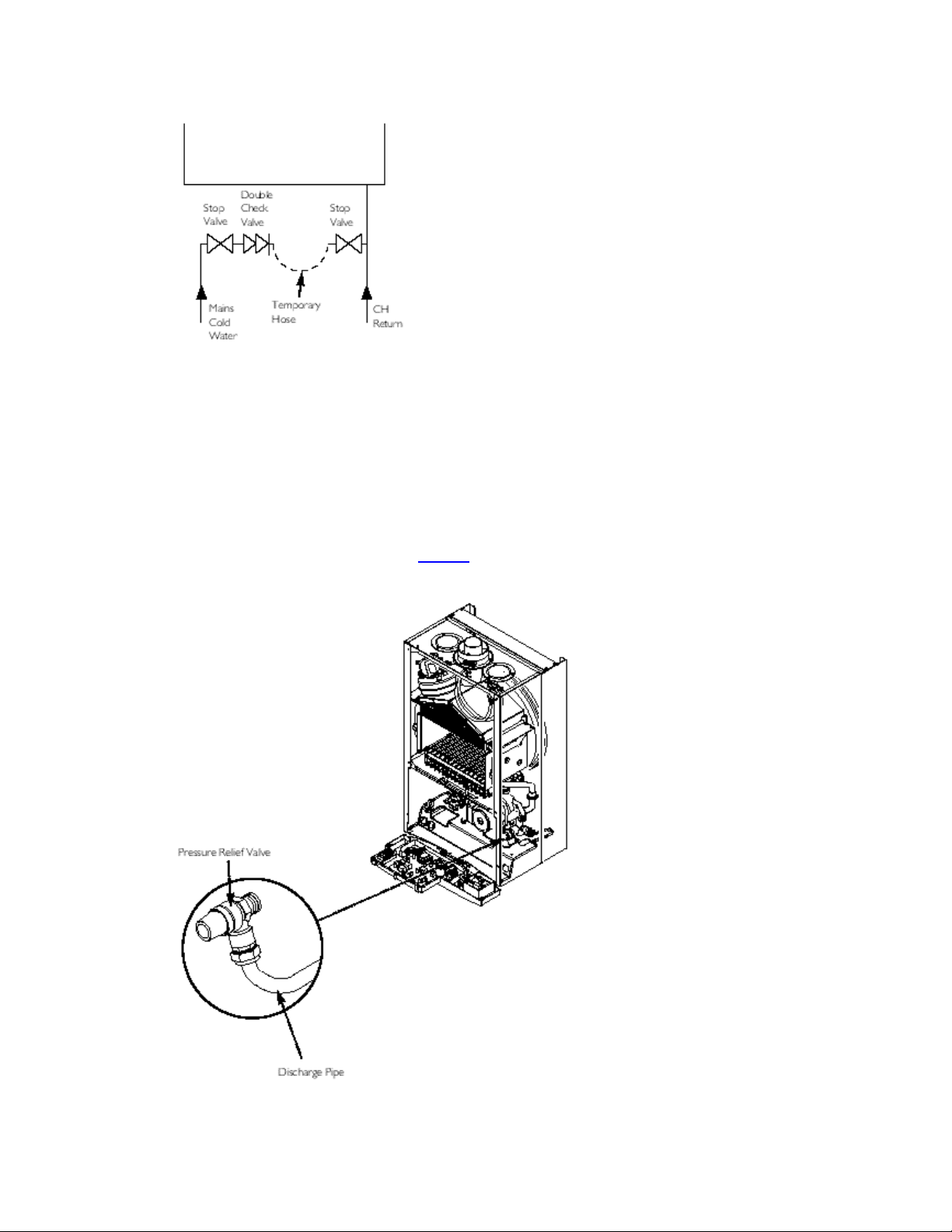

6.4 System Filling and Pressurising

1. A filling point connection on the central heating return pipework must be provided to

facilitate initial filling and pressurising and also any subsequent water loss

replacement/refilling.

2. The filling method adopted must be in accordance with the relevant Water Supply

regulations and use approved equipment. Your attention is also drawn to the current edition of

I.S. 813.

3. The sealed primary circuits may be filled or replenished by means of a temporary

connection between the primary circuit and a supply pipe provided a 'listed' double check

valve or some other no less effective backflow prevention device is permanently connected at

the inlet to the circuit and the temporary connection is removed after use (Fig. 3

).

Fig. 3

4. There are connection points on the mains cold water inlet and central heating return

isolating taps to which the optional filling loop can be assembled.

6.5 Expansion Vessel

1. The appliance expansion vessel is pre-charged to 0.5 bar. The vessel is suitable for correct

operation for system capacities up to 125 litres. For greater system capacities an additional

expansion vessel must be fitted -refer to the current edition of I.S. 813.

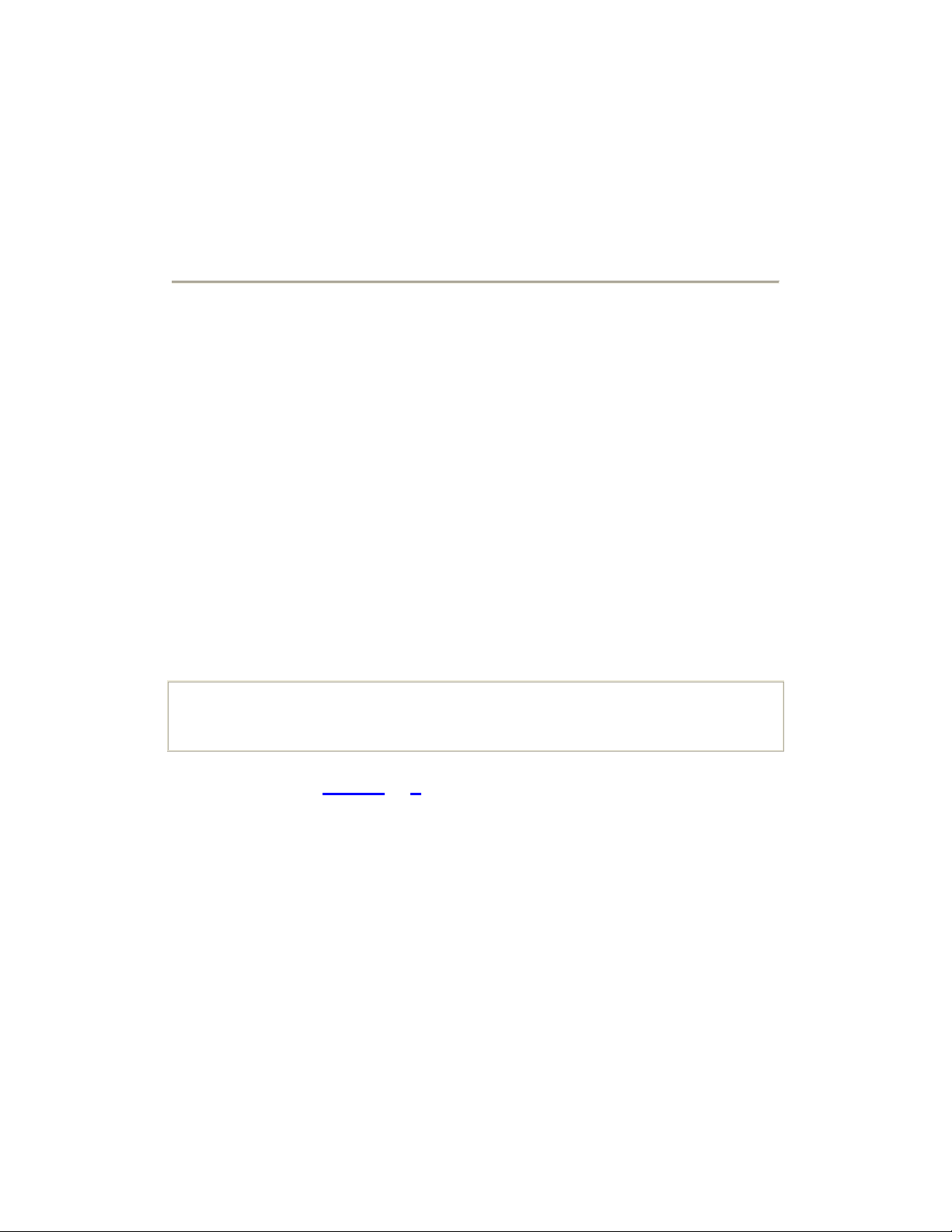

6.6 Pressure Relief Valve (Fig. 4)

Fig. 4

1. The press ure relief valve is set at 3 bar, therefore all pipework, fittings, etc. should be

suitable for pressures in excess of 3 bar.

2. The pressure relief discharge pipe should be not less than 1/2" dia, run continuously

downward, and discharge outside the building, preferably ov er a drain. It should be rout ed in

such a manner that no hazard occurs to occupants or causes damage to wiring or electrical

components. The end of the pipe should terminate facing down and towards the wall.

3. The discharge must not be above a window, entrance or other public access.

Consideration must be given to the possibility that boiling water/steam could discharge from

the pipe.

Page 11

7.0 Site Requirements

7.1 Information

The installation must be carried out by a Competent Person and installed in accordance with

the current edition of I.S. 813 "Domestic Gas Installations", the current Building Regulations

and reference should be made to the current ETCI Rules for Electrical Installation.

7.2 Codes of Practice

Standard Scope

I.S. 813 Domestic Gas Installations.

BS 5546 Installation of hot water supplies for domestic purposes.

BS 5449 Part 1 Forced circulation hot water systems.

BS 7074 Expansion vessels and ancillary equipment for sealed water systems.

BS 7593 Treatment of water in domestic hot water central heating systems.

WARNING - The addition of anything that may interfere with the normal operation

of the appliance without the express written permission from the manufacturer or his

agent could invalidate the appliance warranty.

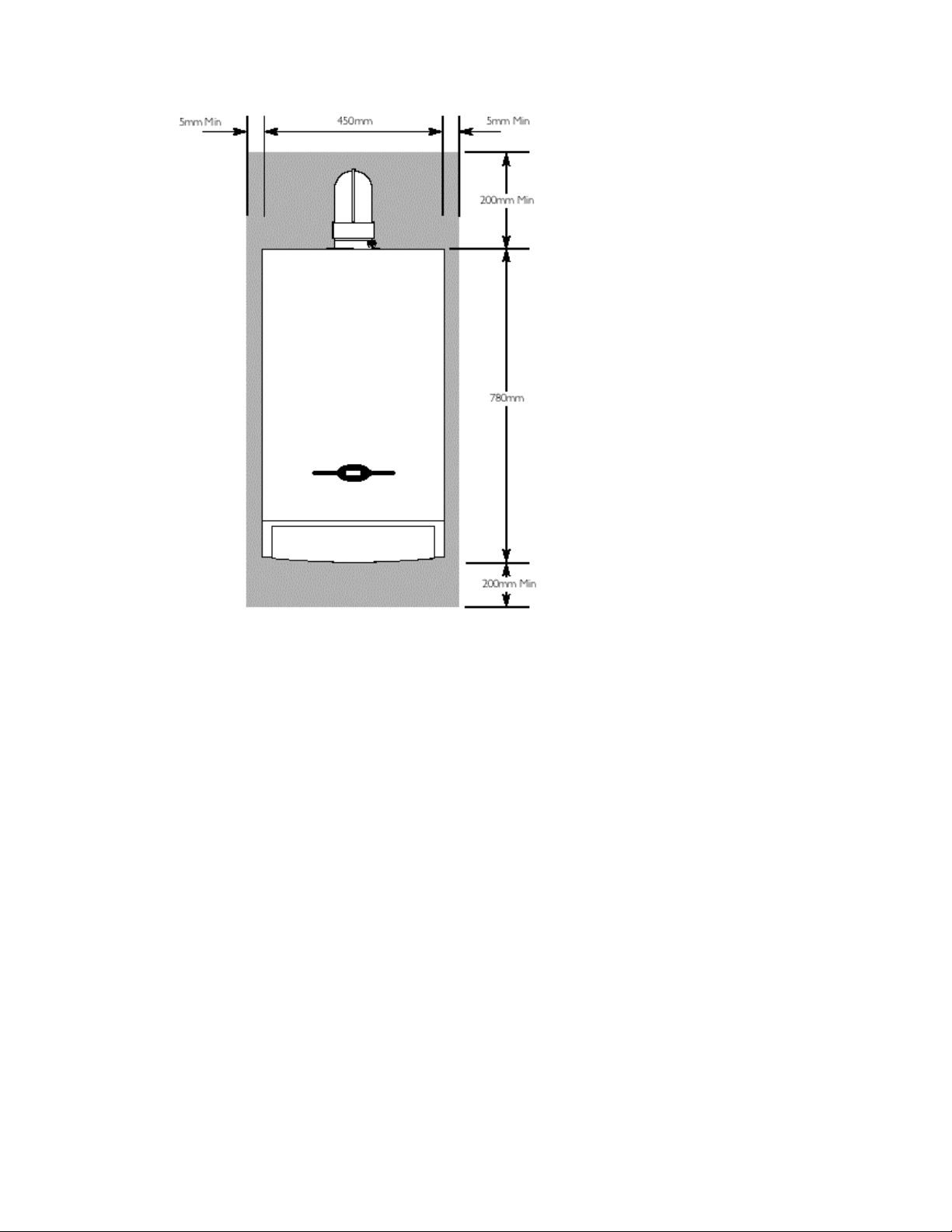

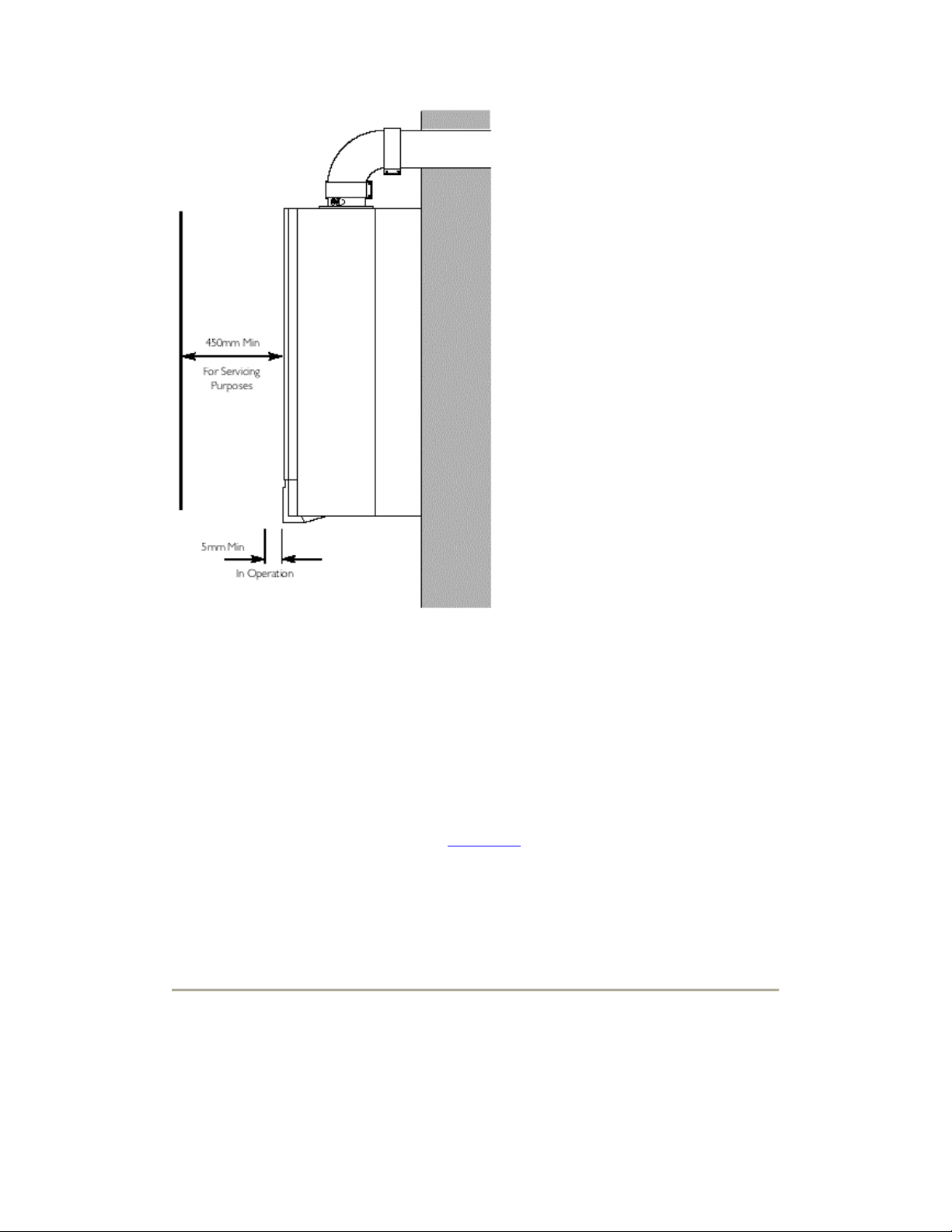

7.3 Clearances (Figs. 5 & 6)

Fig. 5

Fig. 6

1. A flat vertical area is required for the installation of the boiler.

2. These dimensions include the necessary clearances around the boiler for case removal,

spanner access and air movement. Additional clearances may be required for the passage of

pipes around local obstructions such as joists running parallel to the front face of the boiler.

7.4 Location

1. The boiler may be f it t e d to an y s uitable wall with the flue passing through an outside wall or

roof and discharging to atmosphere in a position permitting satisfactory removal of

combustion products and providing an adequate air supply. The boiler should be fitted within

the buildi ng unless otherwise protected by a sui table enclos ure i.e. gar age or outhouse. (The

boiler may be fitted inside a cupboard-see Section 7.5

2. If the boiler is sited in an unheated enclosure then it is recommended to leave the

On/Off/Reset Selector Switch in the domestic hot water and central heating position to give

frost protection.

3. If the boiler is fitted in a room containing a bath or shower reference must be made to the

current edition of I.S. 813 and the current ETCI Rules. If the boiler is to be fitted into a building

of timber frame construction then reference must be made to the current edition of Institution

of Gas Engineers Publication IGE/UP/7 (Gas Installations in Timber Framed Housing).

Page 12

).

7.5 Ventilation of Compartments

1. Where the appliance is installed in a cupboard or compartment, no air vents are required.

The appliance will run sufficiently cool without ventilation.

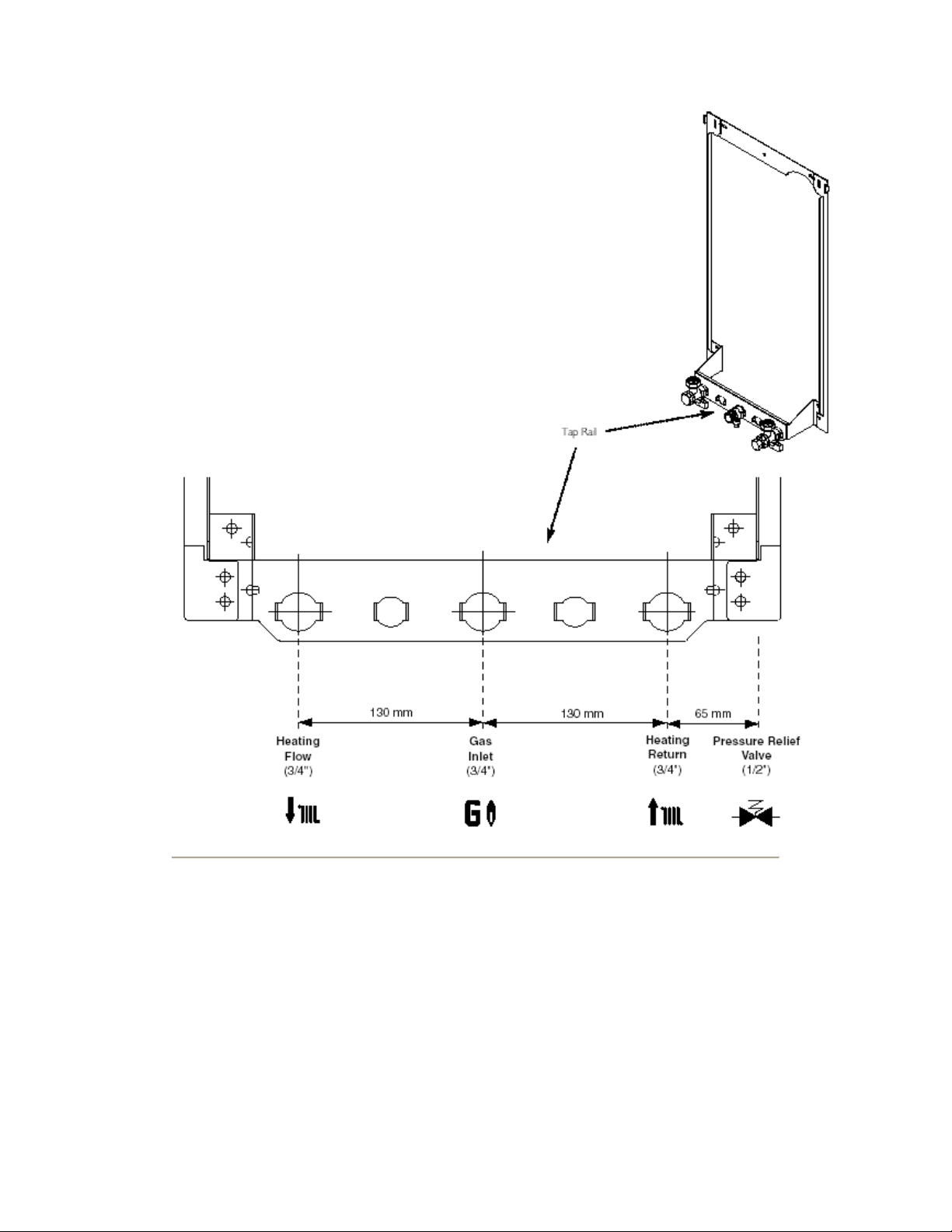

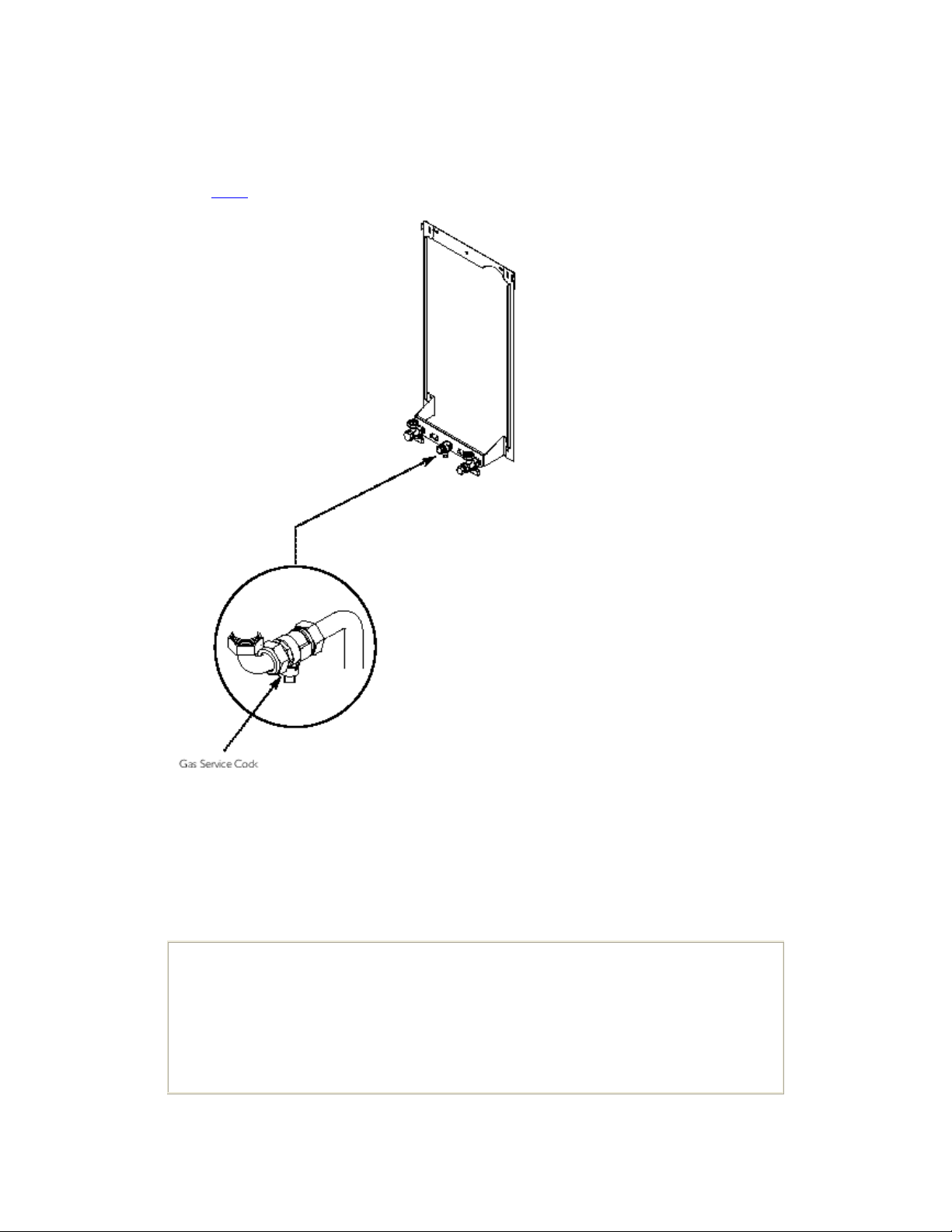

7.6 Gas Supply

1. The gas installation should be in accordance with the current edition of I.S. 813.

2. The connection to the appliance is a 3/4" copper tail located at the rear of the gas service

cock (Fig. 7

).

Fig. 7

3. Ensure that the pipework from the meter to the appliance is of adequate size. Do not use

pipes of a smaller diameter than the boiler gas connection (3/4").

7.7 Electrical Supply

1. External wiring must be correctly earthed, polarised and in accordance with current edition

of the ETCI Rules.

2. The mains supply must be 230V ~ 50H

NOTE: The method of connection to the electricity supply must facilitate

complete electrical isolation of the appliance.

Connection may be via a fused double-pole isolator with a contact separation

of at least 3mm in all poles and servicing the boiler and system controls only.

and fused at 3A maximum.

z

3. When the system includes an indirect domestic hot water cylinder it is recommended that a

cylinder thermostat is used in conjunction with a 3 port 2 position valve or 2 port zone valve.

4. A switched live feed should be taken from the cylinder thermostat to the boiler. This will

operate the boiler when there is a demand for domestic hot water (see Section 8.8

of suggested system wiring schemes).

Page 13

for details

7.8 Flue

1.

The flue terminal position must be in accordance with the recommendations given in

the current edition of I.S. 813.

2. The terminal shall be located in such a position that the wind can freely blow across it at all

times, that the products of combustion will not be blown into nearby air-entry grills or roof

spaces or cause discomfort to passers-by.

3. A suitable guard shall protect terminals located less than 2 m above any level, to which

people have normal access.

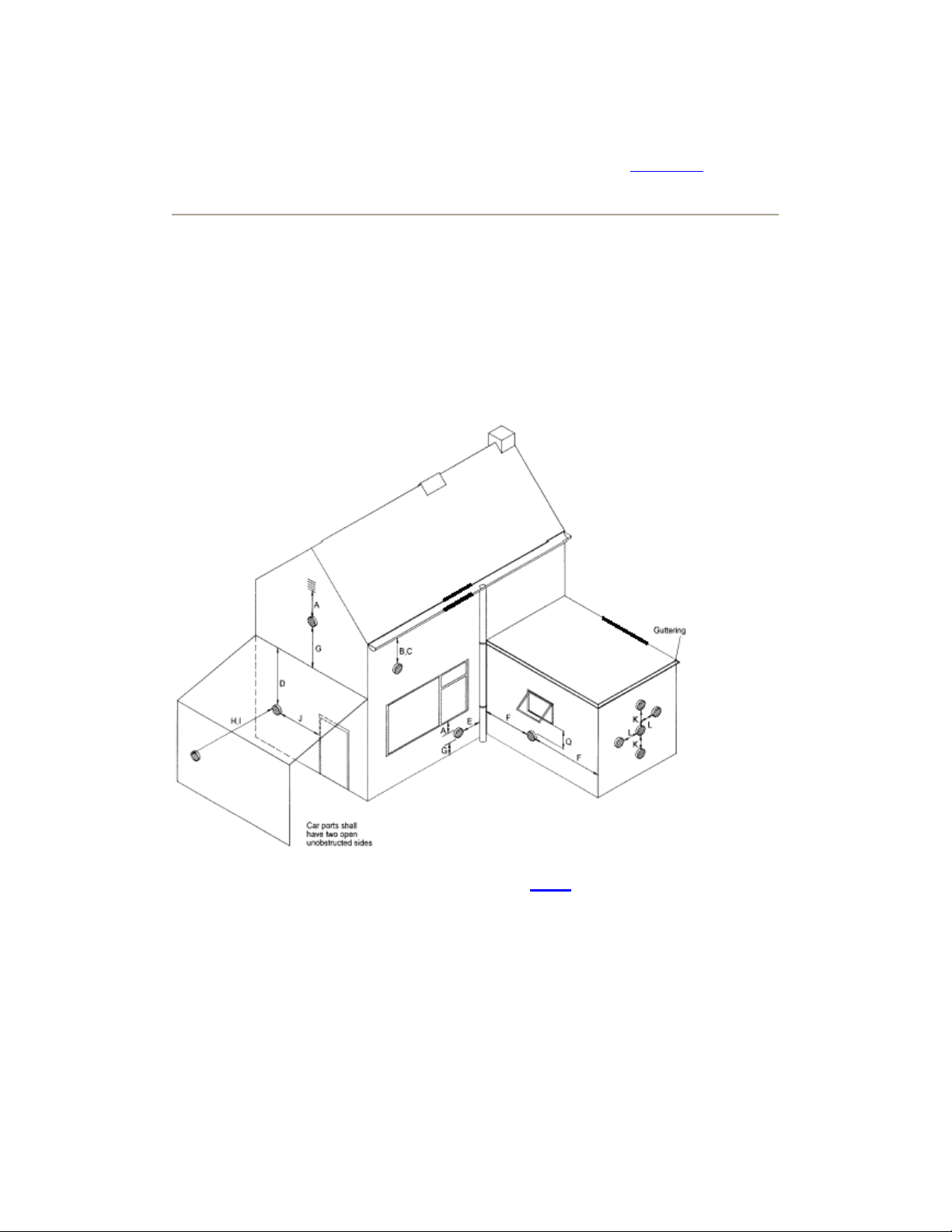

Fig. 9

Terminal Position with Minimum Distance (Fig. 9

)

(mm)

A Directly below opening vent, window, air brick etc. 300

B Below gutters, soil pipes. 25

C Below eaves. 25

D Below balconies/car port roof. 25

E From a vertical drain/soil pipe. 25

F From an internal/external corner. 25

G Above ground, roof or balcony level. 300

Loading...

Loading...