Page 1

© Baxi Heating UK 2012

Please read these instructions before installing or commissioning.

This Solar Thermal Domestic Hot Water System should only be

installed by a competent person.

PLEASE LEAVE THESE INSTRUCTIONS WITH THE

USER FOR SAFE KEEPING.

2nd Fix Solar Manual

Page 2

2

© Baxi Heating UK 2012

Index

© Baxi Heating UK Ltd 2012. All rights reserved. No part of this publication may be reproduced or

transmitted in any form or by any means, or stored in any retrieval system of any nature (including in

any database), in each case whether electronic, mechanical, recording or otherwise, without prior

written permission of the copyright owner, except for permitted fair dealing under Copyrights, Designs

and Patents Act 1988.

Applications for the copyright owner’s permission to reproduce or make other use of any part of this

publication should be made, giving any details of the proposed use to the following address:

The Company Secretary, Baxi Heating UK Ltd, Brooks House, Coventry Road, Warwick CV34 4LL.

Full acknowledgement of author and source must be given.

WARNING: Any person who does any unauthorised act in relation to a copyright work may be liable

to criminal prosecution and civil claims for damages.

2 Index

3 Introduction to Solar

4 Hydraulic station specifications

5 Differential temperature controller specifications

6 Ancillary components

Expansion vessel

Solar heat transfer fluid

7 Cylinder specifications

Unvented

Cistern-fed vented

9 Safety information

11 Installation of hydraulic station

Parts list

Identification of components

Pipework installation - general

Installing the hydraulic station - positioning

Installing the wall brackets and hydraulic station

Installing the safety group

Connecting the solar expansion vessel

Connecting pipework

17 Commissioning of system

Air test

Flushing and filling the pipework

19 Installation of solar controller

Appliance installation

Opening the controller

Electrical connection overview

230/240V~ connections

Solar gain measurement

Connection of temperature sensors

Control of auxiliary heat input

24 Commissioning of hydraulic station

Ensure the solar primary system is free from air

Setting the system pressure

25 Commissioning of solar controller

Main menu

Control button

Menu “info”

Menu “programming”

Menu “Manual operation”

Menu “Basic adjustment”

Overview of display and operating elements

Controller functions

General controller functions

Cylinder heating by solar primary system

Systems with two storage cylinders

Rotational speed regulation

Thermostat (heating)

Thermostat (cooling)

Tube collector

Sensor monitoring

Flow monitoring

System protection function

Frost protection

Energy productivity measurement

Operating hours meter

37 Setting the system flow rate

Checking and adjusting the flow rate

Installation of the thermal insulation

Commissioning record

41 Maintenance

Check heat transfer fluid

Maintenance of the collector

Cylinder

42 Fault Finding

Failures with error message

45 Spares

Spare parts and accessories

46 Warranty

Standard warranty terms & conditions

Page 3

3

© Baxi Heating UK 2012

1.0 Introduction to Solar

1.1 Description

1. Thank you for purchasing a high quality Solar Thermal

Domestic Hot Water System.

2. The sun is the ultimate source of most of our renewable

energy supplies. Energy from the sun is clean and abundant.

3. There is a widely held opinion that the UK does not have

enough sun to make solar systems worthwhile. In fact par ts of

the UK have annual solar radiation levels equal to 60% of those

experienced at the equator.

4. However, this energy is not received uniformly throughout the

year. Some 70% of UK annual radiation is received over the

period April to September and 25% is received in the months

of June and July.

5. Solar water heating technology captures energy from the sun

and transfers this to a water heater to raise the water

temperature therefore reducing the reliance on fossil fuel

energies such as gas, oil and electricity. Up to 60% of a dwelling’s

annual hot water requirement can be provided by a solar water

heating system. The balance is provided by traditional means via

a second heat exchanger connected to a fossil fuel boiler or

electrical heating by electric boiler or immersion heater.

6. The water heating system provides all the principal

components required for an efficient solar water heating system.

The sun’s energy is captured by a series of solar collector panels

through which a special heat transfer fluid is pumped. As the

fluid passes through the collector panels its temperature is

raised. The heated fluid is circulated through a heat exchanger

coil in the base of the solar storage cylinder transferring the

heat gained to the stored water, gradually raising its

temperature. The cooled fluid then returns to the collector

panel to be heated again. Heating by the solar coil is controlled

by a solar differential temperature controller that ensures the

system will only operate when there is useful solar heating gain

at the collector panel. As the sun’s energy input to the collector

panels is variable supplementary heating by a conventional boiler

or electric immersion heater should be provided. The optional

cylinders that can be supplied with the package provide a

supplementary heat exchanger coil and immersion heater as

standard.

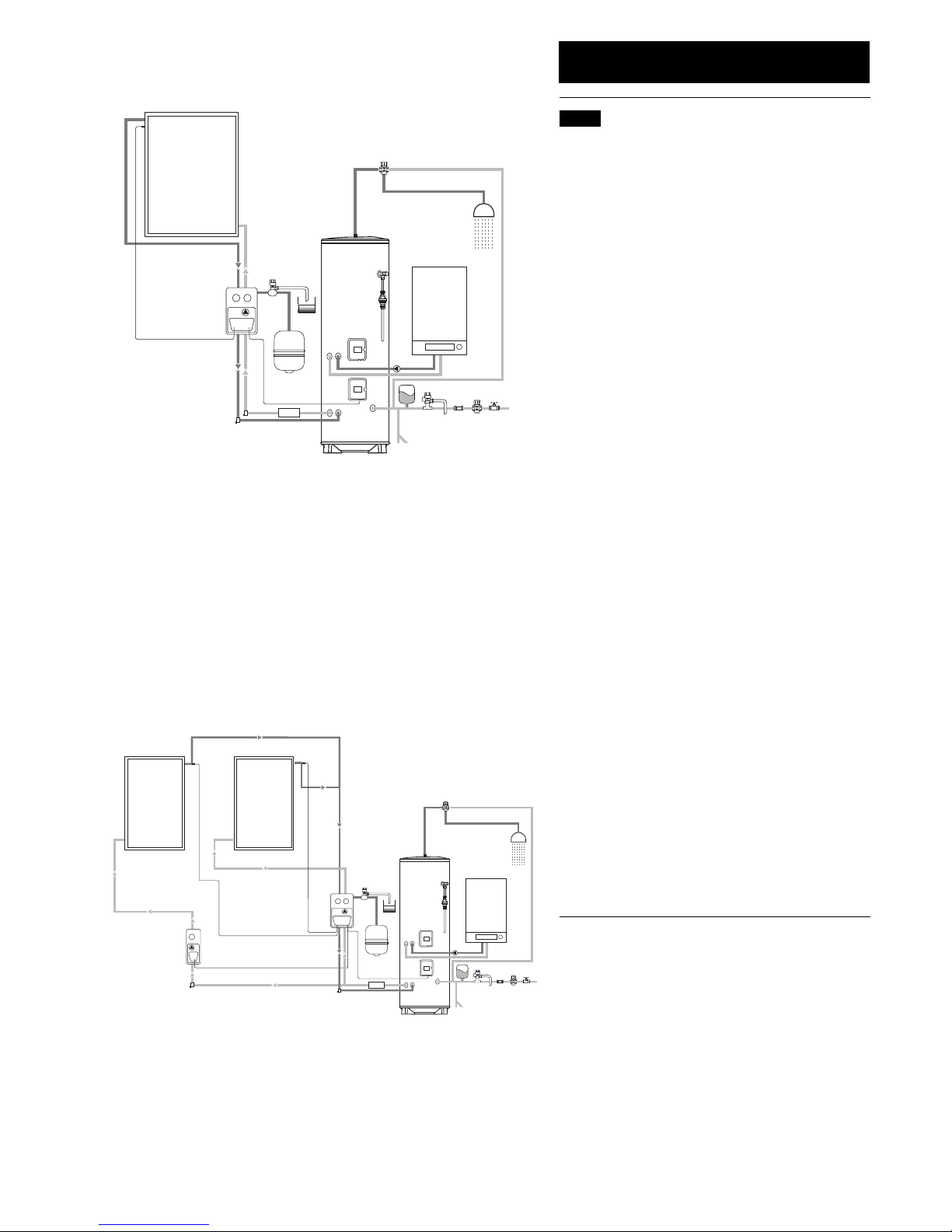

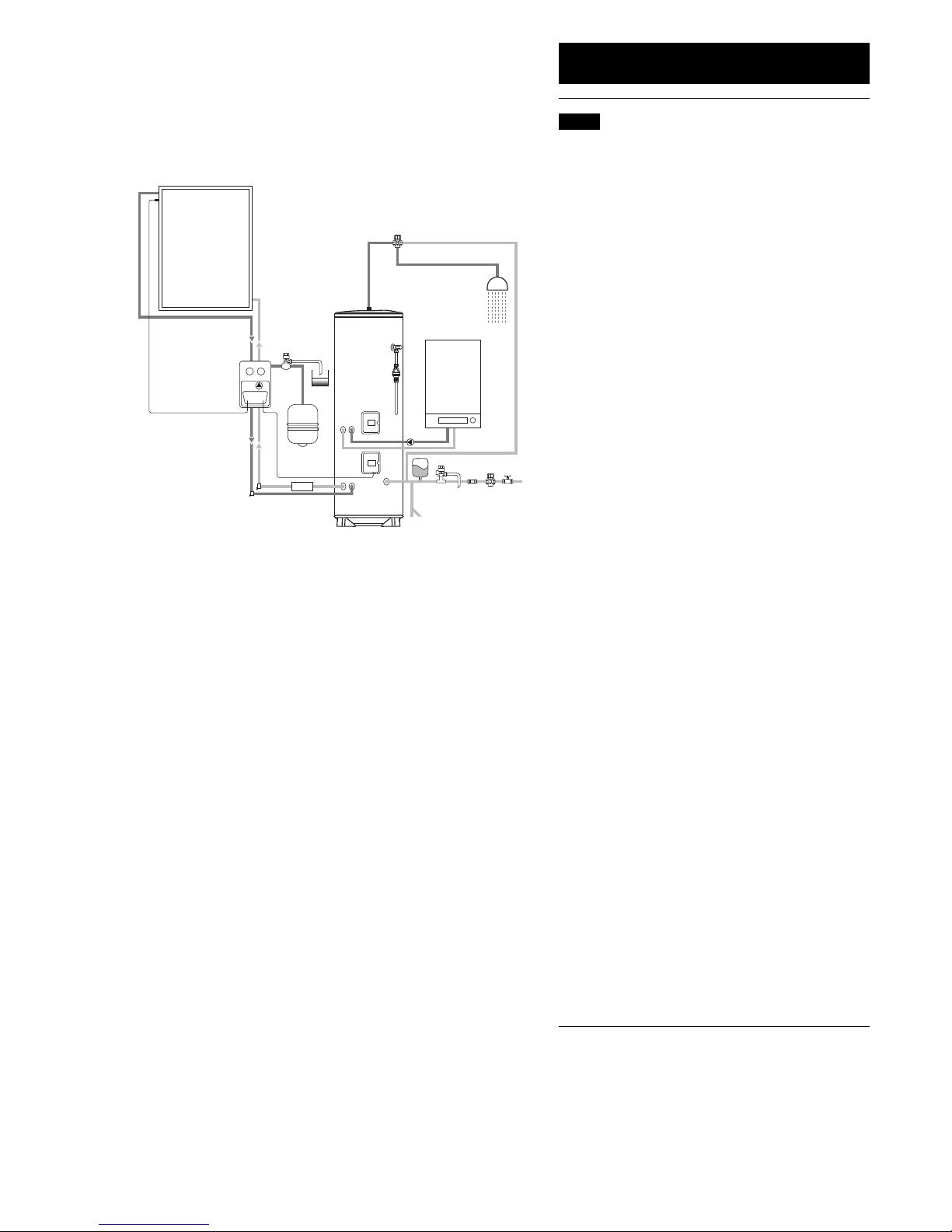

2

3

1

11

12

10

8

4

6

14

13

Cold Supply for Domestic Hot Water

Domestic Hot Water Outlet

Auxiliary Discharge Arrangement

Solar Collector 1

Solar Collector 2 (For East / West Array Installation)

Collector Sensor 1 (PT 1000)

Collector Sensor 2 (PT 1000)

Solar Pumping Station with Controller

Solar Pumping Station Cascade Module

Solar Expansion Vessel

Auxiliary Heat Source (Central Heating Boiler)

Flow Meter on a ‘COMMON’ Return (Accessory code 84515064)

4

5

6

7

9

2

3

1

11

12

10

8

14

13

Solar Fluid Discharge Vessel (Accessory code 720294601)

Thermostatic Blending Valve (Accessory code 720223301)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Fig. 1

Fig. 2

Page 4

4

© Baxi Heating UK 2012

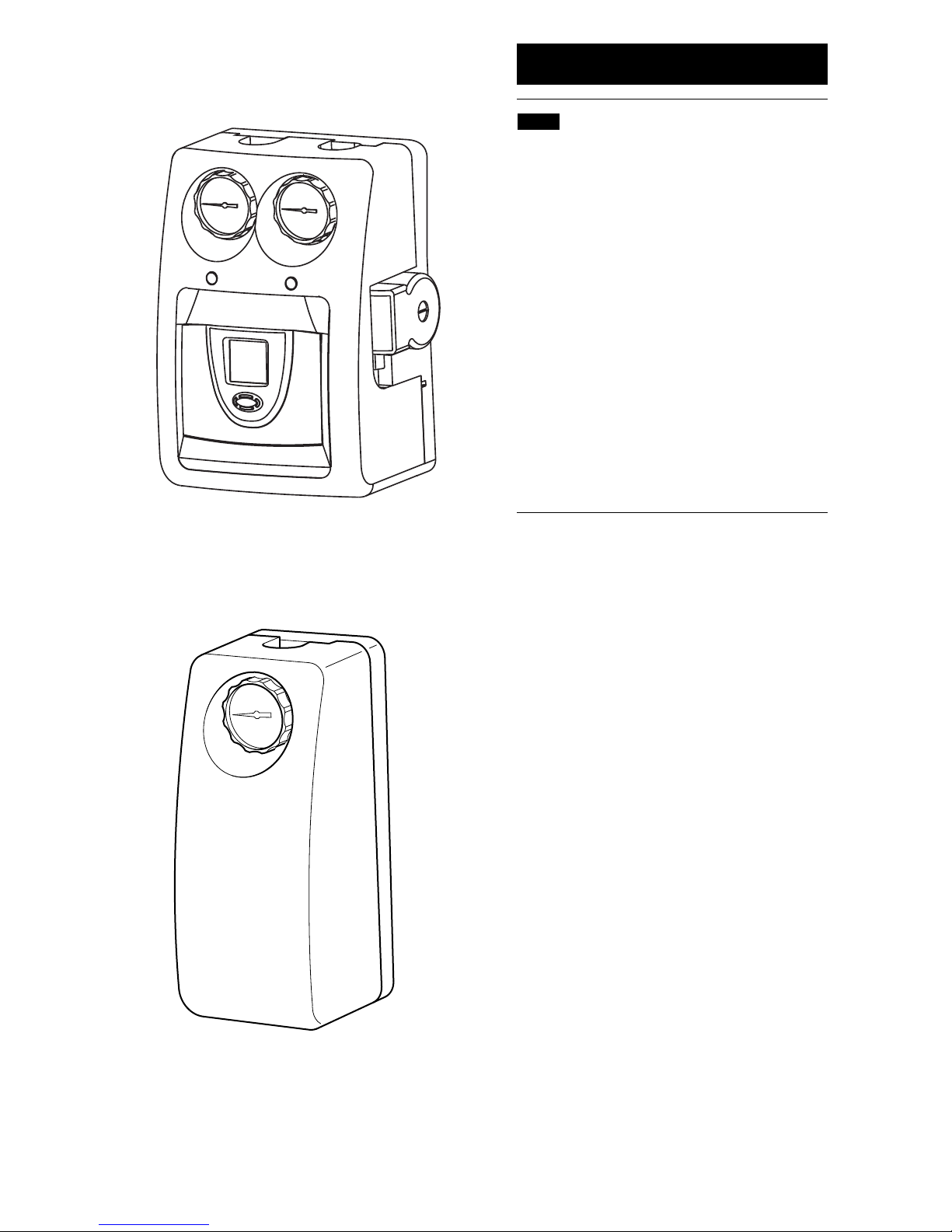

2.0 Hydraulic station specifications

2.1 Technical data

Dimensions (Height/Width/Depth)

System Module

Pump Station 375/250/190mm

Cascade Module

Pump Station 375/190/190mm

Flow and return connections

(compression fittings) 22mm

Maximum working temperature: 160°C

Maximum working pressure: 6 bar

Pressure Relief Valve setting: 6 bar

Circulating Pump: Baxi

Circulating Pump voltage: 230/240 V ~

Power consumption Setting 1: 45W / 45W

Setting 2: 68W / 65W

Setting 3: 90W / 85W

Maximum Pump Head: 6 metres

Maximum Pump Capacity: 4.5 m3/h / 3.5 m3/h

Flow meter scale: 2 to 15 l/min

Fig. 3 System Module

Fig. 4 Cascade Module

Page 5

5

© Baxi Heating UK 2012

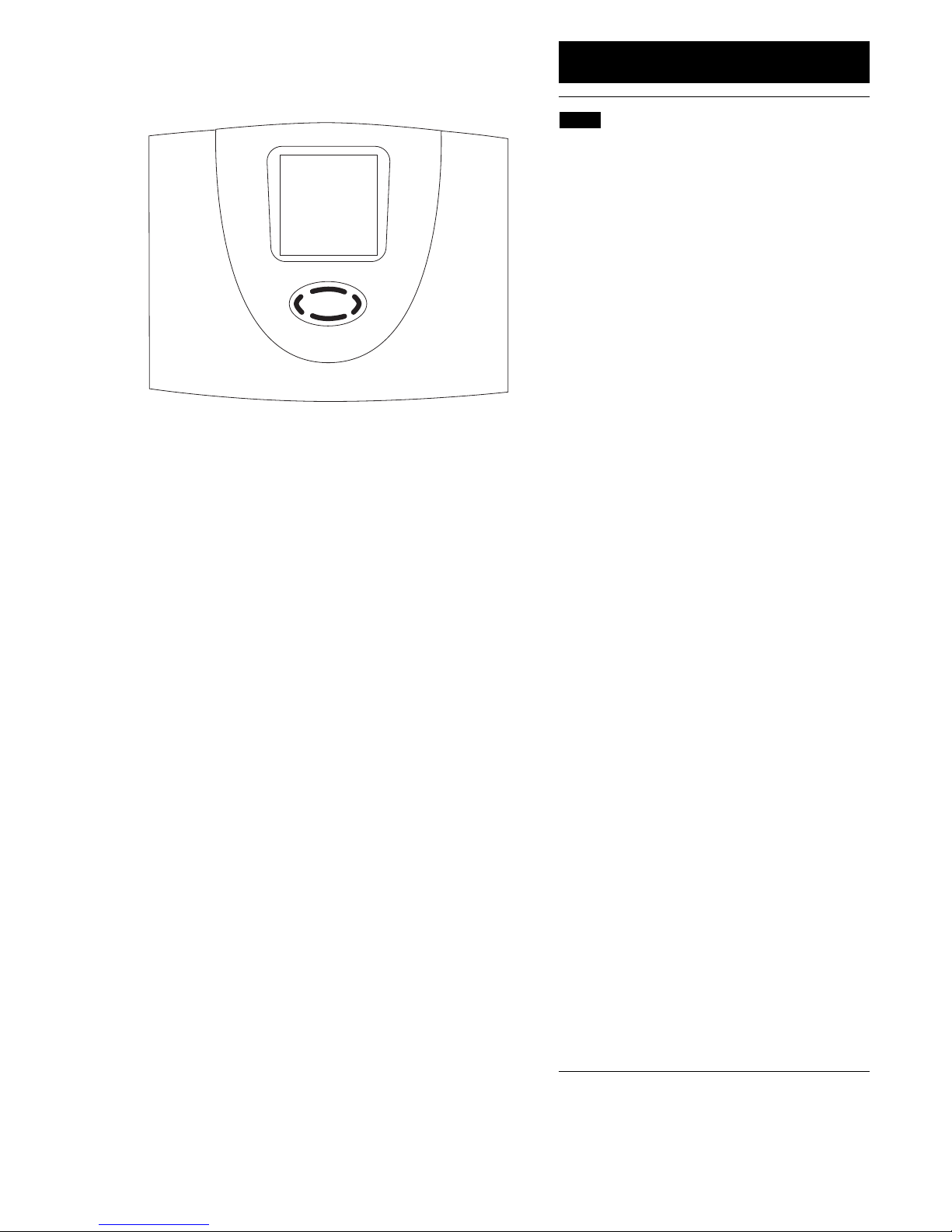

3.0 Differential temperature controller

3.1 Technical data

Housing

Material 100% recyclable ABS

Dimensions

L x W x D in mm 175 x 134 x 56

weight ca. 360 g

Ingress protection IP40 according to VDE 0470

Electrical values

Operating voltage 230/240V ~ 50 Hz

Interference grade N according to VDE 0875

Max. conductor

cross-section

240V-connections 2.5 mm2 fine-strand/single-wire

Temperature sensor /

temperature range PTF6 - 25°C to 200°C

PT1000, 1,000 kΩ at 0°C

Test voltage 4 kV 1 min according to

VDE 0631

Switching voltage 230V / 240V

Capability per one

switch output 1A / ca. 230VA for cos j = 0,7-1,0

Total capability of

all outputs 2A / ca. 460VA maximum

Fuse protection fine-wire fuse 5 x 20mm, 2A/T

(2 amperes, slow)

Features

Self explanatory, menu driven operation

Adjustable control values

System monitoring

Energy yield, (solar gain) measurement

Suitable for flat plate and evacuated tube type collectors

Reheat thermostat function

Can be used in a number of system configurations

Fig. 5

Page 6

6

© Baxi Heating UK 2012

4.0 Ancillary components

4.1 Expansion vessel

1. Membrane expansion tanks for solar primary heating

circuit. Manufactured according to the Directive PED 97/23/CE

(approved noZ-DDK-MUC-02-396876-04).

2. Butyl membrane suitable for solar primary heating fluid, DIN

4807-3 approval.

Maximum working temperature +110°C.

Maximum percentage of glycol 50%.

Connection: 3/4” BSP male parallel

3. Expansion vessel supplied with wall mounting bracket

and self sealing vessel connection that will allow removal of the

vessel for maintenance without losing solar heat transfer fluid.

4.2 Solar heat transfer fluid

1. The system uses a sealed system indirect solar primary circuit

which must be filled with the solar heat transfer fluid provided.

This is a Pre-mixed (40% glycol / 60% water) Solar thermal

transfer fluid, based on1,2 - propylene glycol with corrosion

inhibitors. It is Non-toxic, odourless, bio-degradable.

2. DO NOT mix the fluid with other types.

3. The use of chemical resistant gloves and suitable eye

protection is required when handling.

4. A full safety data sheet is available on request.

5. The system should be filled when there is no direct radiation

from the sun. If direct radiation occurs the collector panels

should be shaded by covering them during filling and flushing.

6. Although the solar heat transfer fluid is non corrosive and biodegradable appropriate precautions should be taken when

handling.

7. Wash with soap and water if the fluid comes into contact with

skin.

8. If fluid gets into eyes, immediately rinse with large quantities of

clear running water.

9. The solar heat transfer fluid must be pumped into the system.

The pump can be electric or manual but must be capable of

producing a pressure of at least 2 bar. The system should be

thoroughly flushed to remove any contaminants in the solar

primary circuit prior to filling with the heat transfer fluid

10. The fluid is supplied in 20litre container.

Weight of container full - 21kg.

11. Systems found to have low glycol concentrations will not be

covered by the warranty.

Ø300mm

392mm

3

/4”

Expansion vessel

Fig. 6

Page 7

7

© Baxi Heating UK 2012

5.0 Cylinder specifications

5.1 Unvented

Nominal capacities 210, 250 and 300 litre.

Rating Immersion heater(s) 1 x 3 kW (indirect models),

2 x 3kW (direct models) @ 240V~.

Outer casing White plastic coated corrosion proofed steel.

Thermal insulation CFC/HCFC-free (ODP zero) flame-

retardant expanded polyurethane (60mm thick). GWP 3.1

(Global Warming Potential).

Cylinder Duplex stainless steel.

Pressure testing To 15 bar.

Heat unit Titanium

element/s, incorporated into an easily removable heater plate,

should replacement be necessary. Rated 3.0kW @ 240V~.

Primary coil (for Auxiliary boiler heating) 22mm

diameter stainless steel. Coil in coil design for improved

performance

Solar coil 25mm diameter stainless steel. Coil in coil design

and large surface area for improved performance.

Thermostat

Direct models: Element thermostat adjustable from 10°C to

70°C.

Indirect models: Factory-fitted cylinder thermostat adjustable

to 70°C.

Solar: Factor y fitted control pocket suitable for

insertion of solar controller temperature probe.

Factory fitted safety features:

Direct models: Manually re-settable cut-out on heating

element operates at 85°C.

Indirect models: High limit thermal cut-out operates at 85°C.

Wired in series with two-port motorised valve (supplied) to

provide primary over temperature protection when using

auxiliary (boiler) coil.

All models: Temperature and Pressure Relief Valve,

factory set to operate at 10 bar and 90°C.

High limit thermal cut-out operating at 85°C at solar coil

position. Wired in series with the solar differential temperature

controller to provide over temperature protection if

overheating occurs from solar collector panels.

N.B. This must be used in an unvented installation to comply

with the requirements of Building Regulation G3.

Anode Not required.

For full technical and performance specification see

cylinder installation instructions.

The cylinders are unvented so installation must comply with

Building Regulation G3 and / or other local regulatory

requirements.

2

3

1

11

12

10

8

4

6

14

13

Unvented system - schematic diagram

Fig. 7

Note: Indirect twin coil unit shown.

Page 8

8

© Baxi Heating UK 2012

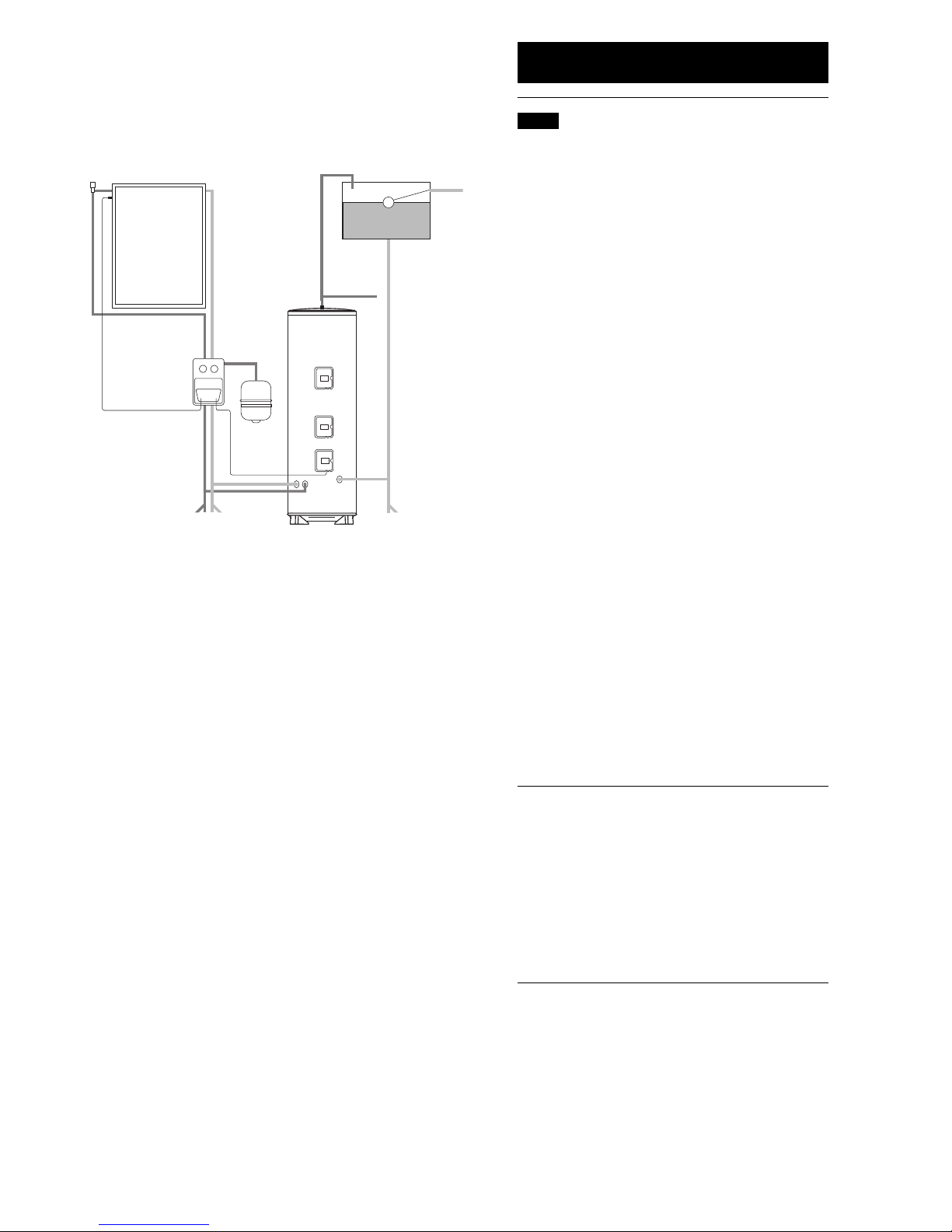

Vented system - schematic diagram

Fig. 8

Note: Direct unit shown. Auxiliary heating by immersion heater.

5.0 Cylinder specifications

5.2 Cistern-fed vented

Nominal capacities 210, 250 and 300 litre.

Rating Immersion heater(s) 1 x 3 kW (indirect models),

2 x 3kW (direct models) @ 240V~.

Outer casing White plastic coated corrosion proofed steel.

Thermal insulation CFC/HCFC-free (ODP zero) flame-

retardant expanded polyurethane (60mm thick). GWP 3.1

(Global Warming Potential).

Water container Duplex 2304 stainless steel. 40 metres

(4 bar) maximum working head.

Heat unit Titanium element/s, incorporated into an easily

removable heater plate, should replacement be necessary.

Rated 3.0kW @ 240V~.

Primary coil (for auxiliary boiler heating) 22mm

diameter stainless steel. Coil in coil design for improved

performance.

Solar coil 25mm diameter stainless steel. Coil in coil design

and large surface area for improved performance.

Thermostat

Direct models: Element thermostat adjustable from 10°C to

70°C.

Indirect models: Factory-fitted cylinder thermostat from 10°C

to 70°C.

Solar: Factor y fitted control pocket suitable for

insertion of solar controller temperature probe.

Safety features Thermostats with manually resettable thermal

cut-out.

High limit thermal cut-out operating at 85°C at solar coil

position. Wired in series with the solar differential temperature

controller to provide over temperature protection if

overheating occurs from solar collector panels.

Anode Not required.

For full technical and performance specification see

cylinder installation instructions.

Detailed installation and commissioning instructions are

supplied with the cylinders.

NOTE:The system is also compatible with cylinders configured

for solar DHW systems. For installation and specification details

refer to the manufacturers instructions supplied with the solar

cylinder.

Any system installed using an unvented cylinder must comply

with Building Regulations G3 and/or other Local Regulations.

Page 9

9

© Baxi Heating UK 2012

6.0 Safety Information

6.1 Safety

1. In order to reduce the number of deaths and major accidents

attributable to work at height, the Health and Safety Executive

has introduced comprehensive regulations and guidance that

should be followed by all businesses working at height.

2. We consider in the following paragraphs some of the main

features of the regulations and guidance. This is, however, only a

limited summary and it is recommended that all businesses

planning on undertaking solar water heating installations obtain

a copy of the regulations and guidance issued by the Health and

Safety Executive and carefully consider the contents.

3. The regulations and guidance state that you are required to

carry out a risk assessment for all work conducted at height and

to put in place arrangements for :

• Eliminating or minimising risks from work at height.

• Safe systems of work for organising and performing

work at height.

• Safe systems for selecting suitable work equipment.

• Safe systems for protecting people from the

consequences of work at height.

4. The regulations and guidance highlight a hierarchy for safe

work at height:

• Avoid the risk by not working at height if practicable.

• Prevent falls, where it is not reasonably practicable to

avoid work at height; you are required to take suitable

and sufficient steps to prevent the risk of a fall

including selecting the most suitable work equipment

(in accordance with the regulations).

• Mitigate the consequences of a fall; where the risk of

a person or object falling still remains, take suitable

and sufficient measures to minimise the distance and

consequences of any fall.

5. Collective protection measures, such as guard rails on scaffold,

should be given priority over personal protection measures,

such as safety harnesses.

6. Within the regulations’ framework, you are required to:

a) Assess the risk to help you decide how to work safely.

b) Follow the hierarchy for safe work at height (i.e. avoid,

prevent and mitigate).

c) Plan and organise your work properly, taking account of

weather conditions and the possibility of emergencies.

d) Make sure those working at height are competent.

e) Make use of appropriate work equipment.

f) Manage the risks from working on or around fragile surfaces

and from falling objects.

g) Inspect and maintain the work equipment to be used and

inspect the place where the work will be carried out

(including access and egress).

7. When preparing to install a solar water heating system, it is

required that you perform a risk assessment in relation to work

at height and plan how you will organise your work, taking into

account the site, the weather conditionsand the experience and

competence of colleagues or contractors who may be working

at height with you.

Page 10

10

© Baxi Heating UK 2012

6.0 Safety Information

6.1 Safety (cont)

Risk Assessments

8. The HSE has published a number of very useful free

publications that advise how to undertake risk assessments.

9. Two of these that you should obtain are:

Five Steps to Risk Assessment.

A Guide to Risk Assessment Requirements.

10. The five steps outlined in the HSE leaflet are:

Step 1: Look for the hazards, this will mean looking at the site

and identifying significant hazards. These could be features such

as a steep roof, a fragile surface where the collectors may be

mounted, uneven ground or obstructions where access to the

roof might be required.

Step 2: Decide who may be harmed and how, this might

mean considering the particular risks that young workers or

trainees might face and thinking about the residents of the

household or visitors who could be hurt by your activities.

Step 3: Evaluate the risks and decide which precautions

should be made, you should consider how likely it is that each

hazard will cause harm, decide which precautions you might

take and then assess, after you have taken those precautions,

whether the remaining risk will be high, medium or low. Where

you identify remaining risks, you should consider which fur ther

action you could take to control the risks so that harm is

unlikely.

Step 4: Record your findings, if you have fewer than five

employees you do not need to write anything down, though it

is useful to keep a written record of what you have done. If

you employ five or more people you must record the

significant findings of your assessment. You must also tell your

employees about your findings. You need to be able to show

that a proper check was made, that you considered who might

be affected, that you dealt with all the obvious significant

hazards, that the precautions you propose are reasonable and

that the remaining risk is low.

Step 5: Review your assessment if necessar y, each solar water

heating installation may bring its own challenges and present its

own particular hazards. You should therefore be careful not to

rely on a “standard” risk assessment for installing a solar water

heating system in a house, but review the particular hazards

for each new situation. The issue of work equipment must be

considered, but at the preparation stage you should consider

where scaffold or other access equipment might be positioned

and look out for any obvious obstacles to this, such as a

conservator y or porch. In addition to the risks associated with

work at height, you should also consider the risks associated

with lifting and carrying solar collectors, using electric drills and

using blow lamps or blow torches for soldering. This is not an

exclusive list and so you should consider all aspects of the

proposed installation to assess whether there are additional

risks that need to be taken into account.

Page 11

11

© Baxi Heating UK 2012

7.0 Installation of hydraulic station

7.1 Parts list

Before commencing the installation check all listed components

are contained in the following cartons.

Hydraulic Station carton:

1. Hydraulic pump station with insulation incorporating

wall mounting bracket.

2. Solar differential temperature controller.

3. Safety group, comprisingPressure relief valve, pressure gauge and fill &

drain valve.

4. 22mm compression fitting nut and olive(4 off).

5. Sensor extension cable (13m) (not shown).

Ancillary component carton:

6. Solar expansion vessel complete with mounting bracket

and strap assembly.

7. Expansion vessel connecting hose.

8. Expansion vessel self sealing connection.

1

2

3

4

Fig. 9 (Diagrams not to scale)

8

7

6

Page 12

12

© Baxi Heating UK 2012

7.0 Installation of hydraulic station

7.2 Identification of components

1. The main components of the hydraulic station are:

– Two isolating valves (Fig. 10, Item 1 & 2) with integral

thermometers which display the solar primar y flow

and return temperatures.

– A safety group (Fig. 10, Item 3, supplied unconnected),

which protects the solar primary circuit. The pressure

relief valve and pressure gauge are integrated in the

safety group.

– A non-return valve in both feed and return prevents

the possibility of gravity circulation in the solar

primary circuit.

– A solar circulation pump (Fig. 10, Item 4).

– A flow meter with fill & drain valve and shut-off valve

(Fig. 10, Item 5).

– An air separator.

2. The heat transfer fluid is circulated by the solar circulation

pump integrated in the hydraulic pump station (Fig. 10).

3. The hydraulic station has a solar differential temperature

controller (Fig. 10 Item 6) integrated into the front

insulation moulding. This is pre-wired to the solar pump.

Fig. 10

21

3

4

5

6

Page 13

13

© Baxi Heating UK 2012

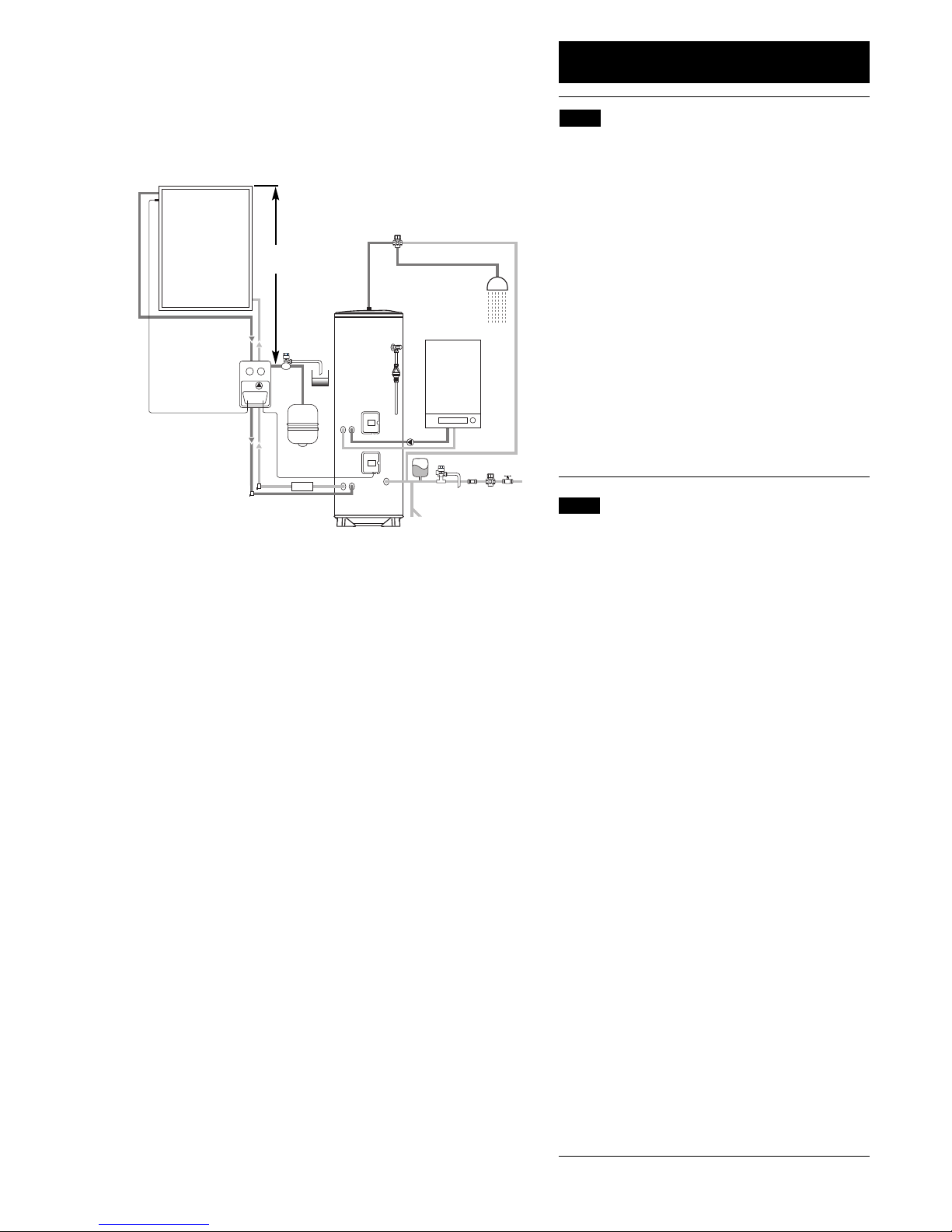

7.0 Installation of hydraulic station

7.3

See Fig. 11

1 Cold Supply for Domestic Hot Water

2 Domestic Hot Water Outlet

3 Auxiliary Discharge Arrangement

4 Solar Collector 1

5 Solar Collector 2 (For East / West Array Installation)

6 Collector Sensor 1 (PT 1000)

7 Collector Sensor 2 (PT 1000)

8 Solar Pumping Station with Controller

9 Solar Pumping Station Cascade Module

10 Solar Expansion Vessel

11 Auxiliary Heat Source (Central Heating Boiler)

12 Flow Meter on a ‘COMMON’ Return

(Accessory code 84515064)

13 Solar Fluid Discharge Vessel

(Accessory code 720294601)

14 Thermostatic Blending Valve

(Accessory code 720223301)

7.4 Pipework installation - general

1. In Solar Heating Systems, the collectors, the hydraulic station

and solar cylinder (Fig. 11, Item 1) must be connected with

brazed or silver soldered copper pipes, compression fittings or

the multifit accessory flexible steel tube and insulation. (See

brochure for details) N.B. Plastic pipes MUST NOT be used.

2. Connections supplied are suitable for pipe diameters of

22mm. However for short pipe runs (up to 10m flow and

return) the use of 15mm diameter pipe is acceptable.

3. All connections and joints must be resistant to temperatures

of up to 150°C and resistant to glycol.

4. If any pipe sealants are used these should be resistant to

glycol and be able to withstand temperatures of up to 150°C.

5. The difference in height between the highest point in the

pipework (collector) and the level of the hydraulic pump

station determines the static head for the system. The static

head is 0.1 bar times this height in metres. This static head is

used when setting the expansion vessel precharge pressure

and the system pressure.

6. If the static head is greater than 1.5 bar (15m) then a larger

expansion vessel may be required for larger collector arrays.

7. If the pipe runs between the solar collector and pump

station are short (<6m) then a protection vessel (Accessar y

No. 5131963) should be installed between the pump station

and expansion vessel.

8. Earthing pipework

All solar primary pipework between the solar collectors,

hydraulic station and solar cylinder should be earth bonded in

accordance with current IEE wiring regulations.;

Fig. 11

2

3

1

11

12

10

8

4

6

14

13

Static

Height (m)

Page 14

14

© Baxi Heating UK 2012

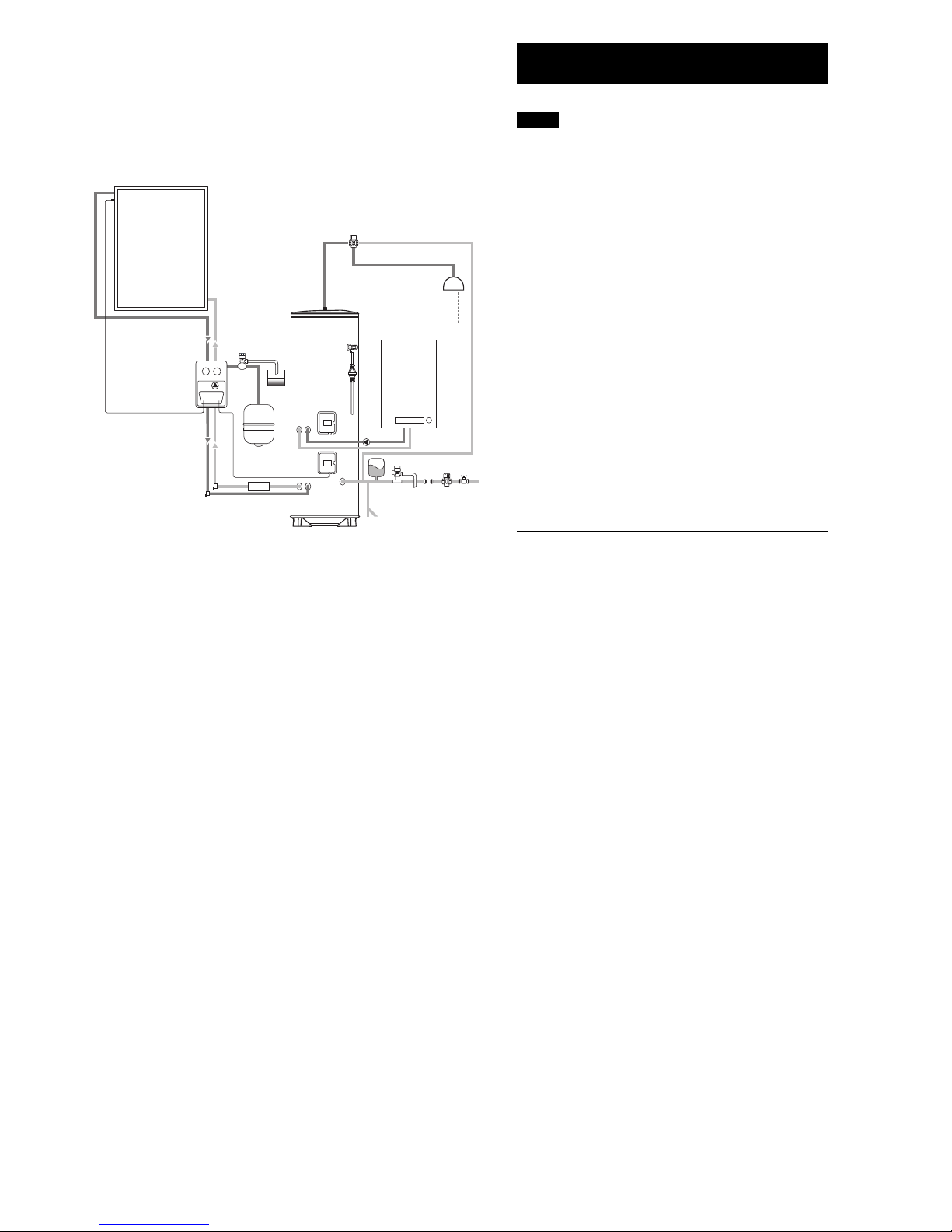

7.0 Installation of hydraulic station

7.4 Pipework installation - general (cont)

9. Venting the pipework

The hydraulic station the component includes an air

collector/separator and bleed point so an automatic air vent is

not necessary. Any section of solar pipework that falls and rises

again should be fitted with an additional air vent valve to relieve

any trapped air which may cause air locking in the system. The

automatic air vent and isolating valve used must be compatible

with solar primary systems, i.e. be resistant to glycol and

temperatures up to 180ºC.

10. Insulating the pipework

External pipework should be insulated with high temperature

resistant materials and be protected against UV degradation.

The insulation must be peck-proof and rodent-proof. Internal

pipework, especially through unheated spaces such as a loft

space, should also be insulated with high temperature resistant

materials. Mark the outside of any insulation to identify the flow

and return pipes. The collectors are supplied with 2x2m pre

insulated flexible stainless steel tubes. Additional lengths (30m)

of stainless steel flexible tubes and high temperature insulation

can be supplied.

Fig. 12

2

3

1

11

12

10

8

4

6

14

13

See Section 7.3 for Key

Page 15

15

© Baxi Heating UK 2012

7.0 Installation of hydraulic station

7.5 Installing the hydraulic station - positioning

1. It is usual to install the hydraulic station and solar differential

temperature controller near to the solar cylinder. However this

does not have to be the case, the hydraulic station can be

installed anywhere convenient on the solar primary pipework

although adequate access will be necessary for commissioning

and maintenance (See also comments regarding system static

head given in Section 7.4).

2. The solar differential controller should also be accessible for

system operational monitoring. If not in close proximity to the

solar cylinder it will be necessary to extend the solar cylinder

temperature sensor cable, refer to section 9.6 for details of how

to do this.

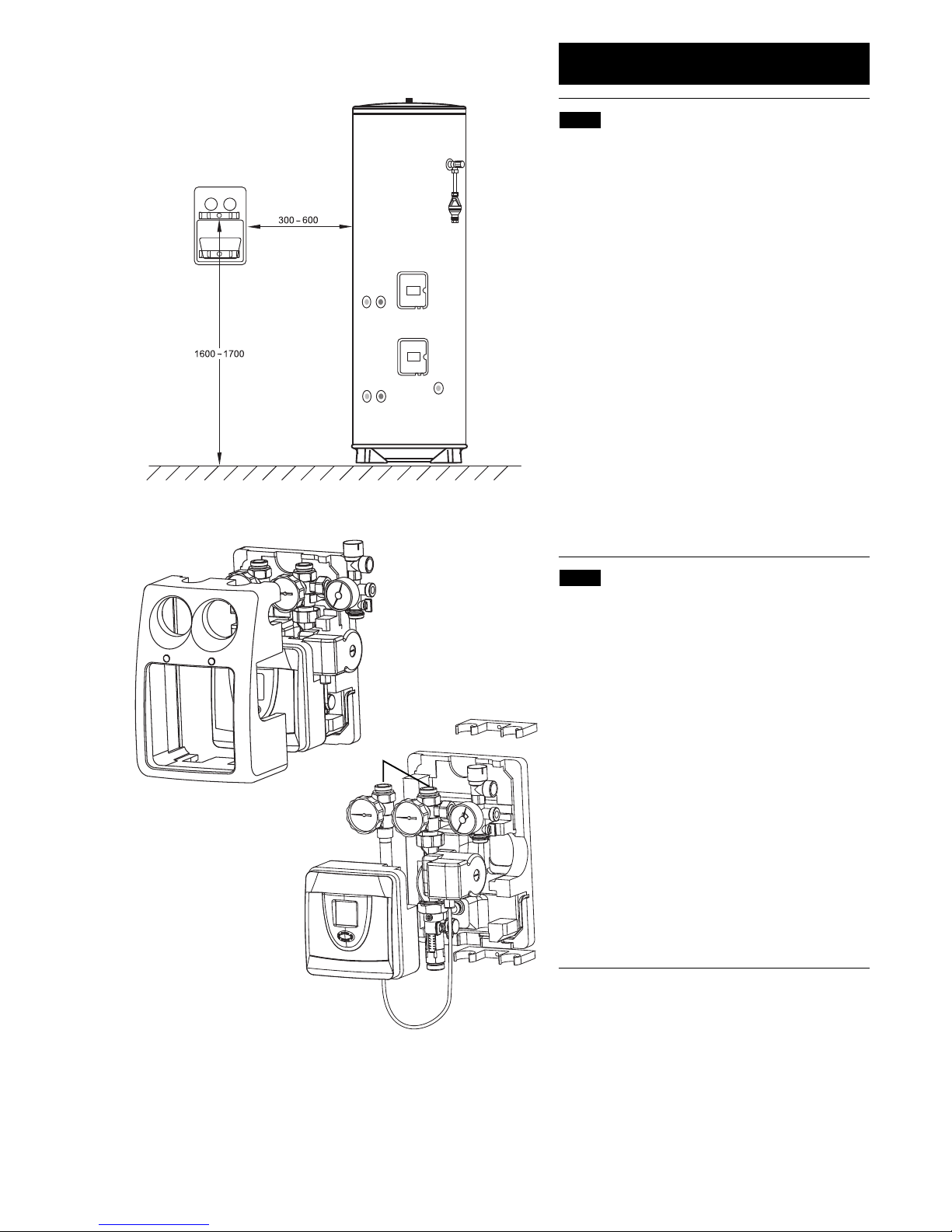

3.It is recommended that the upper mounting bracket

of the hydraulic station is positioned approx. 1600 to 1700mm

above the floor level for ease of access and operation of the

controls, see Fig. 13.

4. When choosing the site for the hydraulic station provision of a

discharge pipe from the safety group and the location of the

solar expansion vessel must be considered.

7.6 Installing the wall brackets and hydraulic station

1. Remove the front insulation moulding (Fig 14. Item 1) by

pulling forward whilst holding the solar differential controller

moulding (Fig 14. Item 2) in place, carefully remove the solar

differential controller mounting by pulling forward and

disconnect the pump cable connector (Fig 14. Item 3).

2. Place the hydraulic assembly on the wall at the desired

location and mark the fixing positions through the holes in the

mounting brackets.

3. Remove the hydraulic assembly from the mounting brackets

(Fig 14. Item 4) and remove rear insulation moulding (Fig 14.

Item 5).

4. Drill and plug the mounting positions and screw the mounting

brackets into position.

5. Push the rear insulation moulding over the wall brackets and

refit the hydraulic assembly (Fig 14. Item 6) to the mounting clips

on the wall brackets.

1

2

3

4

4

5

6

Fig. 13

Fig. 14

Page 16

16

© Baxi Heating UK 2012

7.0 Installation of hydraulic station

7.7 Installing the safety group

1. Connect the safety group (Fig 15 Item 1) to the connection

on the hydraulic station return isolating valve assembly (Fig 15

Item 3). Ensure that the pre-fitted gasket is securely in place on

the safety group prior to connection.

7.8 Connecting the solar expansion vessel

1. Mount the solar expansion vessel (Fig 16 Item 1) adjacent to

the hydraulic station (Fig 16 Item 2) so that the vessel can be

connected to the vessel connection of the safety group (Fig 16

Item 3) using the flexible pipe (Fig 16 Item 4) supplied. (Note:

Solar expansion vessel, mounting bracket, self sealing connection

and flexible pipe are supplied in the Ancillary Components kit).

2. The vessel must be mounted as shown (connection to top)

and securely supported using the wall bracket supplied. The self

sealing vessel connection should be screwed onto the vessel

connection before connecting the flexible pipe (Fig. 16 Item 5).

3. DO NOT replace the solar expansion vessel with either a

potable water expansion vessel or boiler sealed system vessel.

4. The charge pressure of the solar expansion vessel must be

adjusted (when the fluid circuit is empty or de-pressurised) to a

pressure equal to the static head + 0.4 bar, or a minimum of 1.2

bar. (NOTE: the static head is the height difference between the

highest point in the pipework (collector) and the hydraulic

station in metres x 0.1 bar. The charge pressure should not

normally exceed 1.9 bar - see also Section 7.4.

7.9 Connecting pipework

1. Connect the flow and return pipes to the pump station via

compression fittings (Fig 17 Item 1). Fittings are for 22mm o/dia

pipe. Support the hydraulic assembly when tightening

connections.

2. Installing a drain valve

It is recommended to install a device for draining the solar

heating system (tee piece with drain valve, Fig. 18) into the flow

and return at the lowest point in the solar heating system. The

drain and its rubber seal must be suitable for solar applications.

3. Connecting the solar cylinder

For detailed installation instructions refer to the

installation instructions supplied with the solar cylinder.

1

2

3

4

5

1

2

3

3

2

4

1

Flow

from

panel

Return

to

panel

Flow

to

cylinder

Return

from

cylinder

To a suitable container

(e.g. Solar fluid discharge vessel

Accessory No. 720294601)

Flow to cylinder

Return from cylinder

Return to hydraulic station

Fig. 15

Fig. 17

Fig. 18

Fig. 16

Page 17

17

© Baxi Heating UK 2012

8.0 Commissioning of system

8.1 Air Test

1. An air test may be used on the pipework to detect any gross

leakage prior to flushing and filling with solar heat transfer fluid.

Pressurise the system to a maximum of 1 bar to check for leaks.

2. Ensure that the solar expansion vessel pre-charge pressure

has been set prior to flushing and filling.

8.2 Flushing and Filling the pipework

1. Before the system is commissioned the pipework must be

flushed to remove any contaminants. This must be done using

the solar heat transfer fluid as it will be impossible to fully

drain all parts of the system.

2. Connect the flushing pipes to the fill & drain valve on the

safety group (Fig. 19 Item 1) and to the fill & drain valve on the

flow meter (Fig. 19 Item 2).

3. Open the fill & drain valves.

4. Turn the slot of the adjusting screw (Fig. 19 Item 3) in the

return so the slot is vertical to open the non-return valve.

5. Turn the left hand isolating valve with integral thermometer in

the flow (Fig. 19 Item 4) in the direction indicated by the arrow

(to a 45° position) to open the non-return valve.

6. Ensure that the right hand isolating valve with integral

thermometer in the return (Fig. 19 Item 5) is open indicated by

the dot on the thermometer bezel being at the top.

7. Turn the slot of the flow meter adjusting screw (Fig. 19 Item

6) in the return vertically to open the flow limiter (Fig. 19 Item

7).

8. Flush the solar primary pump by pumping the fluid into the

system via the fill and drain valve on the safety group (Fig. 19

Item 1).

9. Close right hand isolating valve (dot on thermometer bezel at

9 o’clock position). Flush solar primary pipework and collector

via the fill and drain valve on the safety group. If reusing flushed

fluid ensure this is filtered before re-introducing into the

system. (see Fig. 20). Use a suitable container of a large enough

volume to collect the fluid.

10. When satisfied that all pipework and component parts have

been thoroughly flushed, the system can be filled.

4

5

3

6

7

Fig. 19

Fig. 20

Fig. 21

Solar fluid

Filling pump

Filter

1

2

1

3

2

45°

Read at top

of float

Page 18

18

© Baxi Heating UK 2012

8.3 Flushing and Filling the pipework (cont)

11. Pour an amount of the solar heat transfer fluid into the filling

pump.

12. Close the fill and drain valve - safety group (Fig. 19 Item 1) and

the fill and drain valve - flow meter (Fig. 19 Item 2) and pressurise

the pump slightly prior to filling the system. If an electric pump is

being used follow the instructions with the pump.

13. Fully open the fill and drain valve on the safety group (Fig 19,

item 1) and pump fluid into the system. Whilst pumping, open the

flow meter drain valve (Fig 19, item 2) slightly to allow the air to

vent out of the system.

14. When the pump is down to approximately 1 litre isolate the

fill and drain valves. Vent the filling pump and refill with solar heat

transfer fluid.

15. Re-pressurise the filling pump and repeat steps 3 and 4 above

until fluid is seen discharging from the drain valve on the flow

meter. (Fig 19, item 2). Close the drain valve.

16. Continue filling at the fill and drain valve on the safety group

(Fig 19, item 1) until the system pressure reaches 2 bar.

17. At this point the circulation pump should be vented. If the

system pressure drops, repressurise using the procedure above.

18. After venting the pump and checking that the system pressure

is 2 bar, close the fill and drain valve on the safety group (Fig. 19

Item 1), and check the system for leaks.

19. Turn the left hand isolating valve (Fig 19, item 4) back 45°

clockwise until the dot on the bezel is back at 12 o’clock.

20. Turn the right hand isolating valve (Fig. 19 Item 5) back 90°

clockwise until the dot on the bezel is back at 12:00 O’clock.

21. Turn the slot of the adjusting screw (Fig. 19 Item 3) back to

the horizontal position.

8.0 Commissioning of system

Page 19

19

© Baxi Heating UK 2012

Pump

pre-wired

(mounted on

hydraulic station)

230V/240V~

Mains supply

L

N

E

Cylinder

sensor

Solar

differential

controller

Hydraulic Station

Solar panel

sensor

Terminal block

for extending

collector sensor

Double pole

isolating switch

Solar Coil

over-temp

cut-out

9.0 Installation of solar controller

9.1 Appliance installation

1. Always disconnect from the mains before opening the

controller cover. The solar differential temperature controller

is designed to be mounted on the front of the hydraulic

station. Alternatively it can be removed from the insulation and

be wall mounted (see panel below). In the case of wall

mounting the pump cable may need to be lengthened.

Alternative mounting option

In the case of wall installation proceed in the

following way:

Drill installation holes according to the dimensions

shown below. Screw in two upper screws up to 6 mm

distance. Open the appliance as described in section 10.2

and hang it onto two screws. Now two lower screws can be

mounted. Tighten all screws. Do not overtighten to avoid

damage to the controller backplate.

9.2 Opening the controller

1. Always disconnect from the mains before opening the

controller cover.

2. No tools are required to open the controller. The front of

the controller is secured by two latches which engage with the

controller backplate.

3. It can be opened by gently pulling the lower side edges

outwards and then hinging the front upwards.

126mm

118mm

84mm

Fig. 22

The collector panel temperature sensor should be installed in

the sensor pocket at the collector array flow connector as

part of the first fix process. Ensure that the cable from this

sensor can be identified for connection to the pump station

wiring centre. Use the 13m extension cable supplied if

required.

Page 20

© Baxi Heating UK 2012

20

F U S E

Fuse rating T 2A L 250V

A1

L

A2

A3

PEPE

PE

PE

NNNN

M1 M2 M3 M4 M5 M6 M7

T2 T6T5 T7

T1

T3 T4

Mains 230/240V connections

Low Voltage (SELV) connections

240 Volts

Terminal

Reference

Description

L 240V Supply Live

N 240V Supply Neutral

A1 Switched Output to Solar Pump

N Solar Pump Neutral

A2 Switched Output - Live 2 (For East West Array or Dual Tanks)

N Switched Output 2 Neutral

A3 Switched Output - Live 3 (For Auxiliary Heat Control)

N Switched Output 3 Neutral

PE Earth Connection

T1 & M1 Temperature Sensor Collector 1 (Tc1)

T2 & M2 Temperature Sensor Storage Tank 1 (Ts1)

T3 & M3 Temperature Sensor Collector 2/Storage Tank 2 (Tc2 / Ts2)

T4 & M4 Temperature Sensor Collector Return (Tret)

T5 & M5 Temperature Sensor for 2nd temperature differential controller (Tth)

T6 & M6 Frost Protection or 2nd temperature differential controller

Flow Meter (Optional)

T7 & M7

9.0 Installation of solar controller

9.3 Electrical connection overview

1. Always disconnect from the mains before opening the

controller cover. The electrical installation must conform to all

current Wiring Regulations and be carried out by a competent

electrician.

2. The connection of all electrical cables is to the terminal block

located on the backplate of the controller. The

terminals on the right side of the terminal block are for extra

low voltage connections (temperature sensors and flow

transmitters). The terminals on the left side of the

terminal block are for 230/240 V~ connections.

General connection guidelines.

3. In the case of all connecting wires the outer sheath should

be stripped back to 80mm. The individual conductor sleeving

should be stripped approx. 10mm.

4. Cables are inser ted in the controller through knockouts

provided in the controller backplate.

5. Flexible cables must be secured against straining by

suitable strain relief bushes or devices.

6. The controller must be earthed.

9.4 230/240V~ connections

1. For 230V connections you must follow the following points:

2. The mains supply to the controller should be via a suitable

double pole isolating switch with a contact separation of at

least 3mm in both poles. Additionally the controller should be

wired via the solar coil over temperature cutout such that

power is interrupted to the controller and hydraulic station in

the event of the cylinder overheating (see Fig. 24).

3. Controllers are intended for the operation in 230/240V~

/50Hz mains. Any motorised valves connected must be suitable

for this voltage.

4. All earth wires must be connected to terminals marked with

PE. Any bare wire earth conductors must be sleeved with

green/yellow sleeving.

5. The neutral terminals (N) are electrically connected and are

not switched.

6. All switch outputs (A1, A2 and A3) are 230/240V~ closers. If

potential-free contacts are needed, appropriate accessories are

required.

Fig. 23

230V/240V~

Mains supply

L

N

E

Solar

differential

controller

Hydraulic Station

Double pole

isolating switch

Solar coil

over-temp

cut-out

Fig. 24

Page 21

21

© Baxi Heating UK 2012

9.0 Installation of solar controller

9.5 Solar Gain measurement

1. For solar gain (energy productivity) measurement in System

type ‘0’, it is necessary to fit the collector return sensor as shown

in the diagram in Fig. 25. and input the correct flow value.

2. For System types 2 and 4, the collector return sensor must

be securely attached to the common return pipework using the

securing tiles supplied and then covered by insulation. Use cable

ties (not supplied) to ensure good attachment and accurate

readings.

3. The solar gain of the system is calculated on the basis of the

temperature difference between the collector flow and return

and the solar primary circulation flow rate.

4. The function is factory set-up as ‘on’ in the Solar Differential

Temperature Controller.

5. For System Type 2 the additional pump (P2) can be ordered

as an accessory, Par t No. 7202943 together with appropriate

sensor for cylinder 84515063.

6. For System type 4 use the East/West kit accessory as required

(See Sales Brochure).

NOTE: The solar gain flowmeter must be connected to sensor terminals marked T7 where fitted (see Fig. 23).

Collector

Type 0:

1 collector, 1 storage tank

Storage tank

Collector

Type 2:

1 collector, 2 storage tanks

with 2 pumps

Storage tank1 Storage tank2

Key Description

Tc1 Temperature Sensor - Collector 1

Tc2 Temperature Sensor - Collector 2

Tth Temperature Sensor - Thermostat

Ts1 Temperature Sensor - Storage 1

Ts2 Temperature Sensor - Storage 2

Tret Temperature Sensor - Collector Return

P1 Circulation Pump 1

P2 Circulation Pump 2

FM Flow Meter

Tfr * Temperature Sensor - Frost Protection

*

not shown

System

Type

System Description T1 T2 T3 T4 T5 T6 T7

0 1 collector array, 1 storage cylinder Tc1 Ts1

-

Tret Tth Tfr FM

2 1 collector array, 2 storage cylinders Tc1 Ts1 Ts2 Tret Tth Tfr FM

4 2 collector arrays, 1 storage cylinder Tc1 Ts1 Tc2 Tret Tth Tfr FM

Collector 1

Type 4:

2 collectors, 1 storage tank

with 2 pumps

Storage tank1

System type Output terminal designation (see Fig. 23)

Type Description A1 A2 A3

0 1 collector array, 1 storage cylinder P1 - Cooling or thermostat or diff. controller

2 1 collector array, 2 storage cylinder (pump-pump) P1 P2 Cooling or thermostat or diff. controller

4 2 collector array, 1 storage cylinder (pump-pump) P1 P2 Cooling or thermostat or diff. controller

Fig. 25

Tc1

Tc1

Tc2

Tc1

Tth

Ts1

Tr et

Tr et

Tr et

P1

P1

P2

P1

P2

Ts2

Ts1

Ts1

Tth

Tth

FM

FM

FM

Tret

Page 22

22

© Baxi Heating UK 2012

9.0 Installation of solar controller

9.6 Connection of temperature sensors

1. The controller uses precise platinum temperature sensors

type PT1000. The controller is supplied with 3 sensors ready

wired. The sensor with black silicone sheathing (supplied with

the first fix kit) must be used for the solar panel sensor.

2. Installation / cabling of temperature sensors:

a) Mount the sensors in the pockets provided in the collector

and storage tank. When installing into the collector panel

sensor pocket the sensor should be secured by sealing with

UV resistant High Temperature Silicone sealant.

b) The wires of the temperature sensors can be lengthened.

Up to 15m long you need a 2 x 0,5mm2 cross-section, up to

50m 2 x 0,75mm2. In the case of long connections (collector)

shielded extension lead must be used. DO NOT run sensor

leads adjacent to mains carrying voltage conductors (at least

50mm separation is recommended).

c)Temperature sensors are supplied connected to the

appropriate terminals, refer to Fig 26. The sensors are polarity

free.

d) Sensors MUST NOT be connected to the 230/240V~

terminals.

9.7 Control of Auxiliary heat input

1. When using the reheat function the operation of the

auxiliary heat input device can be controlled via output A3

from the controller (see fig. 23(c)).

2. The reheat sensor cable is connected to terminals T5 of the

solar controller (see page 20) and the sensor element be

inserted into the controls pocket at the auxiliar y heater level.

3. N.B. The maximum switching current of the controller

is 2A so if switching an electrical immersion heater this MUST

be done via a relay (see Fig. 26 Block Wiring Scheme C) order

accessory code No. 5122765.

4. If using a boiler for auxiliary input, the output from the

reheat function should be integrated into the boiler control

circuit.

3A Fused Supply

L

1

1

710 3

123E

2345678910Terminal Box (Not supplied)

23 4235 12376

NE PLLNESLLNE

DHW ON CH ON

Boiler Terminal Strip Programmer

1

Cylinder Auxiliary Controls

692

12N

Room Stat

1L

Solar

Controller

Boiler Immersion

3

12E

Solar O/Temp Cutout

322

PE L N

Solar Differential Controller

11A112

N

T1 T2A2 N T4 T7

423

LNE

CH Pump

A1 N PE

11 12 E

Solar Pump

A1 N PE

11 12 E

Solar Pump 2

3 2 10 1

G/Y BL BR GR

DHW 2 Port Valve

5

OR

3291

G/Y BL BR GR

CH 2 Port Valve

5

OR

See Fig. 23

3A Fused Supply

L

1

1

710 3

123E

2345678910Terminal Box (Not supplied)

23 4235 1216

NE PLNESL LN12

Boiler Terminal Strip Programmable Room Stat

1

L

Cylinder Auxiliary Controls

13

12E

Solar O/Temp Cutout

8

382

PE L N

Solar Differential Controller

11A112 7 2

N

A3 N T1 T2A2 N

A2 N

T4 T5 T7

423

LNE

CH Pump

A1 N PE

11 12 E

Solar Pump

A1 N PE

11 12 E

Solar Pump 2

3 2 10 1

G/Y BL BR GR

DHW 2 Port Valve

5

OR

3261

G/Y BL BR GR

CH 2 Port Valve

5

OR

See Fig. 23

3 Amp Fused Supply

L

1

12345678910Terminal Box (Not supplied)

23

NE

13 Amp Fused Supply

L

456

NE

183

12E

Solar O/Temp Cutout

756

LNE

Immersion Heater

A3 N 4

1 5 CoM

Auxiliary Immersion Heater Relay

7

No

382

PE L N

Solar Differential Controller

11A112

N

A3 N T1 T2 T4 T5 T7

A1 N PE

11 12 E

Solar Pump

See Fig. 23Relay

A1 N PE

11 12 E

Solar Pump 2

Fig. 26

Block Wiring Schemes

A. In conjunction with auxiliary heating by boiler - no reheat control

by solar controller.

B. In conjunction with auxiliary heating by boiler - reheat control

via solar controller.

Note: For Boilers without Pump over run CH Pump Live Supply to 5

C. Solar Cylinder with auxiliary heating by immersion heater.

Page 23

23

3A Fused Supply

L

1

1

85 3

123E

2345678910Terminal Box (Not supplied)

23 1423 12387

NE LPLNE

SL L N E

DHW ON DHW OFF

Boiler Terminal Strip Programmer

5

Cylinder Auxiliary Controls

7

692

12N

Room Stat

1L

Solar

Controller

3

12E

Solar O/Temp Cutout

32

PE L N

Solar Differential Controller

11A112

N

T1 T2 T4 T7

423

LNE

CH Pump

A1 N PE

11 12 E

Solar Pump

3 2 10 NOT USED

G/Y BL BR GR

2 Port Valve

OR

3297

G/Y BL WH GR

3 Port Mid Position Valve

5

OR

6

CH ON

See Fig. 23

3A Fused Supply

L

1

1

85 3

123E

2345678910Terminal Box (Not supplied)

23 1423 1219

NE LPLNE

SL L N 1 2

Boiler Terminal Strip Programmable Room Stat

5

Cylinder Auxiliary Controls

7

163

12E

Solar O/Temp Cutout

362

PE L N

Solar Differential Controller

11A112 8 2

NA3N

T1 T2 T4 T5 T7

423

LNE

CH Pump

A1 N PE

11 12 E

Solar Pump

3 2 5 NOT USED

G/Y BL BR GR

DHW 2 Port Valve

OR

3297

G/Y BL WH GR

3 Port Mid Position Valve

5

OR

See Fig. 23

A2

N

A1 N PE

11 12 E

Solar Pump 2

A2 N

A1 N PE

11 12 E

Solar Pump 2

D. Auxiliary heating by boiler with 3 port mid position valve system

- no reheat control by solar controller.

E. Auxiliary heating by boiler with 3 port mid position valve system

- reheat control by solar controller.

9.0 Installation of solar controller

9.8

1. Key to abbreviations:

L-Live

N - Neutral

E-Earth

PL - Pump Live

SL - Switched Live

G/Y - Green and Yellow

BL - Blue

BR - Brown

GR - Grey

OR - Orange

WH - White

2. The wiring schemes assume the use of an unvented Solar

DHW cylinders.

3. These diagrams are presented for guidance only, terminal

numbers may differ between different manufacturers

equipment.

4. Baxi accept no liability for any loss or damage arising from

any errors or omissions that may be inadvertently contained

within these diagrams.

5. The various ancillary equipment manufacturers should be

consulted to confirm the correct operation of their products

within the system.

6. The Warranty only applies to equipment and controls

supplied with the system.

© Baxi Heating UK 2012

Fig. 26

Page 24

24

© Baxi Heating UK 2012

10.0 Commissioning of hydraulic station

10.1 Ensure the solar primary system is free from air

1. Switch on the power supply to the solar differential

temperature controller.

2. Manually switch the circulation pump ON and OFF via the

solar differential temperature controller (see section 11.5) to

pump fluid around the solar primary system.

3. Turn the pump off and open the airbleed screw on the air

separator (Fig. 27 Item 1). Bleed any air from the air separator.

If the system pressure drops top up by opening the fill and

drain valve (Fig. 27 Item 2) on the safety group and pumping in

more solar fluid to restore the pressure. This must be repeated

until the pressure remains stable.

10.2 Setting the system pressure

1. During commissioning, the system pressure should be 0.7

bar above the static pressure (1 metre height differential

equals 0.1 bar). However, it must be at least 1.5 bar and no

higher than 2.2 bar.

2. Determine the system pressure when the system is cold

(20°C). This should be recorded on the Commissioning

Record Sheet.

3. If the pressure is too low you should pump additional heat

transfer fluid into the system; the fill & drain valve on the safety

group (Fig. 27 Item 2) needs to be opened for this purpose.

When system pressure is correctly set, ensure the fill and drain

valve is closed and remove filling hose from safety group.

Fig. 27

1

2

Page 25

25

© Baxi Heating UK 2012

1

2

4

35

11.0 Commissioning of solar controller

Main Menu

Display Screen

Control Button

Scroll upwards

Scroll downwards or select required main menu

Scroll left or exit to main menu

Scroll right or select to edit function

2

4

3

5

1

On completion of commissioning the Solar Controller, note all the

required information in the Solar Commissioning Record Sheet at

the end of Section 12.

11.1 Main Menu

To make the operation of the controller clear, operating and display

functions are divided into 4 main menus.

Info Indication of current measured values.

Indication of system condition.

Indication of error messages.

Indication of operating hours and energy

productivity (if installed).

Programming Changes to programmable values

(parameters).

Manual operation Switching on and off connected pumps

and auxiliary devices.

WARNING - During manual operation

there is no automatic regulation of the

system. Temperature control is isolated.

System temperature could be

extremely high.

Basic adjustment Information about basic adjustment for

system function. To carry out any

changes to this menu it must be

selected within the first minute after

switching the appliance on.

IMPORTANT: Adjustment and changes

in this menu must only be carried out

by a competent installer or service

engineer.

Each active menu is shown in the upper line of the display by its

corresponding icon.

11.2 Control Button

When in the Main Menu the control button functions are as follows:

Item 2 - Scroll upwards- no function in this menu

Item 3 - Scroll left - moves left through the main menu

options

Item 4 - Scroll down - selects the menu option currently

flashing and gives access to the submenu

Item 5 - Scroll right - moves right through the main menu

options

Once the sub-menu has been accessed, the flashing symbol

becomes static and the button functions are then as follows:

Item 2 - Scroll upwards- moves up through the available

functions of the sub-menu

Item 3 - Scroll left - return to main menu

Item 4 - Scroll down - moves down through the available

functions of the sub-menu

Item 5 - Scroll right - select to edit the function displayed.

The selected function will flash if it is

available for editing. Use 2 to increase the

required value and 4 to reduce it.

Use 5 to OK.

Sub-Menu

Diagram of all possible symbols

Example Screen - Programming Menu

Fig. 28

Page 26

26

© Baxi Heating UK 2012

11.0 Commissioning of solar controller

11.3 Menu “Info”

In this menu mode all measured values and operating states

are shown.

If the values are marked as “reset possible”, they may be reset

in the following way:

Choose the value with buttons and

Reset value by means of the button

Message “OK?” confirm with = no or = yes

Press or to scroll

up or down to the required sub function.

The icon will flash, press to

select the function. Reset by pressing

or for

increase/decrease values. Press

and appears,

press to confirm and

disappears.

ok?

ok?

75 °C

Indication of current collector(s)

temperature.

No

52 °C

Indication of current temperature storage

tank(s).

No

Temperature difference controller for heat

consumer

*

Only displayed if temperature sensor

fitted (not supplied as standard).

No

Displays current return temperature

No

60°C

Heating, Cooling, Temperature difference

controller T1…T6

*

Only displayed when activated

No

Yes

No

Yes

Indication of minimum temperature

storage tank(s).

Resettable to current temperature.

Antifreeze sensor

Indication of universal temperature

measuring points (T6).

* Only displayed if temperature sensor

fitted (not supplied as standard).

Yes

Yes

Yes

Operating hours for charging storage

tank(s).

Resettable to 0 h.

Energy productivity for storage tank(s).

Resettable to 0 h.

Yes

Reset

possible?

Indication of minimum collector(s)

temperature.

Resettable to current temperature.

Indication of maximum collector(s)

temperature.

Resettable to current temperature.

25 °C

Meaning

Indication of maximum temperature

storage tank(s).

Resettable to current temperature.

max

65°C

min

40°C

927 kWh

min

12°C

Indication

e.g.

max

105°C

1234 h

60°C

35°C

1

2

1

2

Fig. 29

Page 27

27

© Baxi Heating UK 2012

11.0 Commissioning of solar controller

11.4 Menu “Programming”

1.All adjustable parameters can be checked in this menu and, if

necessary, changed. The default factory setting will usually give

efficient and problem free operation. However Baxi recommend

the following parameters marked * must be left at the default

settings. Any change to the Baxi recommended settings will

invalidate the warranty.

2. For more information or guidance please contact the Technical

Enquiries.

Press or to scroll

up or down to the required sub function.

The icon will flash, press to

select the function. Reset by pressing

or for

increase/decrease values. Press

and appears,

press to confirm and

disappears.

ok?

ok?

13:21

Time

0:00 - 23:59 12:00

dT max

7K

Min

100

Storage tank 1 or 2

Maximum permissible

temperature

40 °C

Meaning

dT

10 K

3 - 40K

Temperature difference

controller. Hysteresis dT max

Storage tank 1 or 2:

switch-off differential (dToff)

2 - 35K

Adjustment of pump rotational

speed.

100% = rotational speed

regulation set to 'off'

7K

1 - 30K

Switch-on temperature for

Heating/Cooling function

Hysteresis for Heating/Cooling

function

10K

30% - 100%

Value range

20 - 90°C

Typical

adjustment

3 - 40K 7K

3K

15 - 65°C

(15 - 95°C

Tank 2)

Indication

dT min

3 K

dT max

7 K

max

65 °C

65°C*

MAX

Storage tank 1 or 2:

switch-on differential (dTon)

100%

40°C

2

2 - 35K 3K

min

00:00

1(2,3)

Timeframe 1(2,3): Start

0:00 - 23:59 00:00

dT min

3K

Temperature difference

controller.

Hysteresis dT min

Timeframe 1(2,3): Start for the

collector function

0:00 - 23:59 06:00

max

23:59

1(2,3)

Timeframe 1(2,3): Stop

0:00 - 23:59

20:00

max

20:00

4

Timeframe 1(2,3):

Stop for the collector function

0:00 - 23:59

23:59

min

06:00

4

Meaning Value range

Typical

adjustment

Indication

Fig. 30

Page 28

28

© Baxi Heating UK 2012

11.0 Commissioning of solar controller

11.5 Menu “Manual operation”

1. For commissioning, service and test purposes the solar primary

system can be manually operated. For this purpose the switch

outputs may be disconnected or connected.

WARNING - During manual operation there is no automatic

regulation of the system. Temperature control is isolated.

System temperature could be extremely high.

2. To avoid inadmissible operating states this mode of operation

changes into “Indication” after approximately 8 hours and the

automatic regulation is activated again.

NOTE: Exiting this menu will automatically return the system to

normal operation.

Press or to scroll

up or down to the required sub function.

The icon will flash, press to

select the function. Reset by pressing

or for

increase/decrease values. Press

and appears,

press to confirm and

disappears.

ok?

ok?

Switching on/off switch output A1 (solar

circulation pump) by hand.

0 = off

1 = on

Indication Meaning Value range

Switching on/off switch output A3 (cooling,

thermostat or 2

nd

temperature difference

controller function) by hand.

0 = off

1 = on

Switching on/off switch output A2

(pump2/valve1) by hand.

0 = off

1 = on

3

Fig. 31

Page 29

29

© Baxi Heating UK 2012

11.0 Commissioning of solar controller

0 Anro 6 Tyfocor L5.5 - supplied

1 IIexan E, Glythermin 7 Dowcal 10

2 Antifrogen L 8 Dowcal 20

3 Antifrogen N 9 Dowcal N

4 IIexan E 10 Tyfocor LS

5 IIexan P 11 Fernox S1

Press or to scroll

up or down to the required sub function.

The icon will flash, press to

select the function. Reset by pressing

or for

increase/decrease values. Press

and appears,

press to confirm and

disappears.

ok?

ok?

11.6 Menu “Basic adjustment”

1. Adjustment and changes in this menu must be carried out

only by a competent installer or service engineer.

Incorrect adjustments may adversely affect the function of

controller and solar primary system.

2. To avoid accidental changes in menu “Basic adjustment”, it is

not editable in normal functioning but has only a display

function. To be able to carry out any changes, this menu must

be chosen within the first minute after switching on the

appliance. The basic adjustment menu is ‘blocked’

automatically one minute after switching on if the menu is

not accessed.

For correct operation of the system, Baxi

recommend the settings shown above.

Indication

Collector protection function

110..150°C 120°C

Recooling storage tank temperature

30..90°C 40°C

Energy yield measurement 'Off'

0

Energy yield measurement

with flow meter

1

Energy yield measurement

without flow meter

2

Energy yield measurement sets glycol type

0…11

11

0 ... 100%

5% - steps

No value shown, when item 5 is set to 0

-----

Adjustment value when item 5 is set to 1

0.5 – 25Litres

per impulse

Adjustment value when item 5 is set to 2

0.1 – 75Litres

per minute

First priority storage tank selection

1 - 2 1

12 -- 6

Anti-freeze function.

Reference sensor selection

1 - 6 6

30 - 480

11 -- 0

Antifreeze function

0 = off

1 = on

0

10 -- 1

100

9 -- 240

Multiple tank storage systems.

Controller response time in seconds

240

8… 10

10

6 -- 11

7 -- 100

Energy yield measurement glycol mixture

5 -- 2

3 -- 40 °C

4 -- 0

Tube collector function - time-controlled

0

0 = off

1 = on

2

0 -- 0

0

1 -- 120 °C

2 -- 0

Recooling function

(only if the collector protection is on)

0

Collector protection function

0 = off

1 = on

0 = off

1 = on

Description Value range

Factory

set - up

Line / value

Note: This Solar Controller has

the ability to calculate the

energy yield without the use

of a ow meter. The Flow

Meter is now available as an

accessory - Code no. 5122979.

Anti-freeze function start temperature

-20 °C ... +7 °C

3

0 = off

1 = cooling

2 = thermostat

1 - 6 5

16 -- 0

System diagram

0 - 4 0

15 -- 5

Independent controller reference sensor

2

13 -- 3°C

14 -- 2

Independent controller function

Fig. 32

Page 30

30

© Baxi Heating UK 2012

11.0 Commissioning of solar controller

Graphic symbol Description Indication in operation

Measuring points assignment

Temperature measuring point collector array 1

Temperature measuring point collector array 2

Temperature measuring point storage tank 1 solar

(storage tank 1 charging)

Temperature measuring point storage tank solar

(storage tank 2 charging)

Temperature measuring point collector - return

Temperature measuring point storage tank

(auxiliary heating)

Antifreezing sensor or universal temperatures

measuring point (T6) (no sensor monitoring)

Auxiliary heating temperature

Operating hours, energy productivity measurement

Status indication

Solar circulation pump Symbol revolves when solar circulation pump is on

Switch output 1 is active Appears when switch output 1 is active (on)

Switch output 2 is active Appears when switch output 2 is active (on)

Switch output 3 is active Appears when switch output 3 is active (on)

Reference to system fault Display flashes when a fault occurs in the system

Safety query for value changes which are to be stored

Input value can be either

rejected or accepted

!

ok?

11.7 Overview of display and operating elements

Fig. 33

Page 31

31

© Baxi Heating UK 2012

Graphic symbol Description Indication in operation

Indicator values

dT Temperature difference

min Min value Appears when minimum values are indicated

max Max value Appears when maximum values are indicated

min Time period 1 start Appears when the differential controller is active

0:00 (timeframe 1-3) or tube collector is active (timeframe 4)

1

Max Time period 1 stop Appears when the differential controller is active

23:59 (timeframe 1-3) or tube collector is active (timeframe 4)

1

5 x 7 segment display. Display of all values, display flashes when

Presentation of figures 00000 to 99999 a value is changed

ºC Temperature in Celsius

K Temperature difference in Kelvin

h Operating hours

kWh Productivity indication in kWh

11.0 Commissioning of solar controller

11.8 Overview of display and operating elements

(cont)

Fig. 34

Page 32

32

© Baxi Heating UK 2012

11.0 Commissioning of solar controller

“Programming”

Maximum temperature

dT max (dT on)

Switch-on temperature difference

dT min (dT off)

Switch-off temperature difference

Corresponding values in menu

11.9 Controller functions

1. The differential temperature controller contains many

functions to regulate and monitor the solar primary system.

Including

- controller functions for heating the solar cylinder

- functions for system protection and system monitoring

- additional functions (other accessories may be required to

achieve these functions).

11.10 General controller functions

1. The controller collects the temperatures from various

measuring points and determines the right time to charge the

storage tank on account of programmed (additional) functions

and controller parameters.

11.11 Cylinder heating by solar primary system

1. Switching action can be adjusted through dTmax (dTon) and

dTmin (dToff). The solar cylinder is heated by operating the

solar pump on output A1 up to the set maximum storage

temperature (65°C). Pump operation starts when the

collector temperature exceeds the cylinder temperature by

more than dTon and continues while the collector

temperature is above cylinder temperature + dToff, as set in

the programming menu. dTon cannot be set lower than dToff

+ 1K.

11.12 Systems with two storage cylinders

1. For systems with more than one storage cylinder (System

Type 2) the cylinder heating can be optimised depending on

the energy supply. Usually the cylinder with lower priority will

have a lower temperature than that with the higher priority.

Re-directing the energy to the lower priority cylinder will

lower the temperature in the collector array.

2. To check the collector temperature the heating of the lower

priority cylinder will be interrupted for a short while at fixed

intervals. If the heating requirement for the higher priority

cylinder is fulfilled then the lower priority cylinder will be

heated.

3. The higher priority cylinder can be selected in the

“Basic Adjustment” menu point no. 10.

Page 33

33

© Baxi Heating UK 2012

“Basic adjustment” “Programming”

14 -- 1 Start temperature max ºC

15 -- 5 Hysteresis dT in K

Time period (1…3) Start: min time

Time period (1…3) Stop: max time

Corresponding values in menu

“Basic adjustment” “Programming”

14 -- 2 Start temperature max ºC

15 -- 5 Hysteresis dT in K

Time period (1…3) Start: min time

Time period (1…3) Stop: max time

Corresponding values in menu

“Basic adjustment” “Programming”

--- Rotational speed min <100%

Corresponding values in menu

Thermostat

(Storage top)

Heating on (A3)

T[ºC]

t

dT

10k

TTh

40ºC

on

A3

off

11.0 Commissioning of solar controller

11.13 Rotational speed regulation

1. The solar circulation pump on 230V-outputs A1 and A2 can

be operated either in switch-mode (two-point controller) or in

a rotational speed regulated way. If the rotational speed

regulation is activated the pump power is adjusted by a

controller so that switch-on temperature difference “Storage

tank dTmax” is kept constant as much as possible. At lower

deviation of “Storage tank dTmax” the pump is operated with

the lowest power till the switch-off wave is reached.

11.14 Thermostat (heating)

1. The thermostat is an independent control circuit from the

storage loading. Thus, auxiliar y heating of the top area of the

storage cylinder is made possible.

The output A3 will be:

• Switched on, when the temperature falls below the adjusted

start level.

• Switched off, when the temperature reaches the adjusted

start level + hysteresis.

11.15 Thermostat (cooling)

1. In order to optimise the energy yield, it could be useful to

“redirect” the solar energy, or to take it away from the storage

when the storage temperature reaches a pre-set level.

When the sensor reaches the start temperature, output A3

will be switched on. When the temperature level falls below

the start temperature hysteresis, the output A3 will be

switched off.

Fig. 35

Page 34

34

© Baxi Heating UK 2012

“Basic Setting” “Programming”

4 -- 1 Time period (4) Start: min time

Time period (4) Stop: max time

Corresponding values in menu

!

!

Short circuit on temperature sensor of the current measuring point

Break on temperature sensor of the current measuring point,

circulation error at activated energy productivity measurement

Indication Meaning

X

11.0 Commissioning of solar controller

11.16 Tube collector

1. The function “tube collector” can be switched off/on in the

“Basic setting” menu – point 4. Timeframe 4 in the “Program”

menu makes it possible to activate this function during certain

periods of the day. When activated, the solar pump will be

switched on every 30 minutes for a period of 30 seconds to

check for any heat gain in the collector.

11.17 Sensor monitoring

1. The sensors and their connecting cables are constantly

monitored for any break or short circuit. If a faulty sensor is

detected by the controller, the symbol is shown. By

scrolling up and down you can detect the source of the error.

The use of the wrong type of temperature sensors

can also give to an error message

Page 35

35

© Baxi Heating UK 2012

Indication Meaning

+ Fluid flow is above 90°C (indication) / Missing circulation in solar circuit

!

11.18 Flow monitoring

1. If during normal operation the flow temperature rises above

90°C a warning indication will be shown.

2. If the energy productivity measurement option is

deactivated, the temperature difference between collector and

storage tank is checked. If the temperature differential exceeds

60K + dTmax an error message will occur, as under normal

system operation where the pump is running, large

temperature differences would not normally be seen.

3. If the energy productivity measurement option is activated,

the flow rate is checked, if no flow is detected for 15 minutes

an error message will be seen (Applicable if Flow Meter

fitted).

NOTE: these error conditions will automatically reset after a

short period of operation once normal flow/temperature

conditions are restored.

11.19 System protection function

1. The system protection function switches the system off if the

“maximum collector temperature” is exceeded by 10K. As

soon as the temperature drops below the “maximum collector

temperature”, the system restarts. This function has priority