baxi 224 Combi User guide

These instructions include the Benchmark Commissioning Checklist and should be left with the

user for safe keeping.They must be read in conjunction with the Flue Installation Guide.

United Kingdom

en

Installation and Service Manual

High Efficiency Wall Hung Condensing Gas Boiler

Baxi Combi

224 — 228 — 424 — 428

Dear Customer,

Thank you very much for buying this appliance.

Please read through the manual carefully before using the product, and keep it in a safe place for later reference. In order to

ensure continued safe and efficient operation we recommend that the product is serviced regularly. Our service and customer

service organisation can assist with this.

We hope you enjoy years of problem-free operation with the product.

Contents

7661586 - 2 - 12072016 3

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Benchmark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 Building Regulations and the Benchmark Commissioning Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1.2 The Benchmark Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.3 Installer Notification Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Specific safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.5 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Abbreviations/Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.1.2 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Gas category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.4 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2.1 Technical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2.2 Technical parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Dimensions and connections/clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.1 Air-gas adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.2.2 Combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.3 Heating and domestic hot water production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4.1 Description of the keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4.2 Description of the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.5 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.5.1 Contents of the carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6.1 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2.1 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2.2 Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2.3 Hard water area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2.4 Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2.5 System control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.2.6 Treatment of water circulating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.7 Showers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.2.8 Expansion vessel (CH only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.2.9 Pump available head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.10 Safety pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.1 Location of the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.2 Data plate and service label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Contents

4 7661586 - 2 - 12072016

5.3.3 Bath and shower rooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.3.4 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.5 Condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.6 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5.3.7 Flue/chimney location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.8 Horizontal flue/chimney systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.9 Flue/chimney trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.10 Terminal guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.11 Flue/chimney deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.12 Flue/chimney accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.5 Unpacking & initial preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.2 Initial preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.6 Connecting diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.6.1 Filling information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5.6.2 Domestic hot water circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.2.1 Fitting the pressure relief discharge pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.2.2 Connecting the condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4 Air supply/flue gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.1 Connecting the flue/chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5.1 Panel removal to make electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5.2 Electrical connections of the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.5.3 Connecting a room thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6 Filling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.6.1 Flushing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.6.2 Filling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2 Checklist before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.1 Preliminary electrical checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.2 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.3 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.1 De-Aeration function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4.1 Check the operational (working gas inlet pressure and gas rate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4.2 Checking combustion - chimney sweep mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.5 Configuring the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.5.1 System draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.6 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.6.1 Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

8.1 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1.1 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.4 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.2 Information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.2 Periodic check and maintenance procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10.2.1 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.2.2 Checking the expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.2.3 Checking the automatic air vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Contents

7661586 - 2 - 12072016 5

10.2.4 Checking the burner and cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.3 Specific maintenance instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

10.3.1 Detection/spark ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.3.2 NTC flue sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

10.3.3 Flow and return sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.3.4 Safety overheat thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.3.5 HMI control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.3.6 Burner/combustion chamber door assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.3.7 Air/gas unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

10.3.8 Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.9 Heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.4 Hydraulics maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.4.1 Expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

10.4.2 Pump - complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.4.3 Auto air vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.4.4 Plate heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.4.5 Hydraulic pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.4.6 DHW flow sensor (hall effect sensor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.4.7 DHW flow regulator and filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

10.4.8 Diverter valve motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10.4.9 Diverter valve cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.4.10 Pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

11.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.2 Fault finding — temporary faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.3 Fault finding - permanent faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.4 Accessing the information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

11.5 Reading out operating parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.6 Statuses and sub-statuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12.1 Decommissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

13 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.1 Short parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

14.1 Combustion check on small heating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

14.2 Benchmark commissioning checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

14.3 Service records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

AD-3000725-01

1 Safety

6 7661586 - 2 - 12072016

1 Safety

1.1 Benchmark

1.1.1 Building Regulations and the Benchmark Commissioning Checklist

Building Regulations (England & Wales) require notification of the installa

tion of a heating appliance to the relevant Local Authority Building Control

Department. This can be achieved via a Competent Persons Self Certifica

tion Scheme as an option to notifying the Local Authority directly.

The Health & Safety Executive operates the ’Gas Safe Register’, a selfcer

tification scheme for gas heating appliances.

This company is a member of the Benchmark initiative and fully supports

the aims of the programme. Its aim is to improve the standards of installa

tion and commissioning of central heating systems in the UK and to en

courage the regular servicing of all central heating systems to ensure safe

ty and efficiency.

Building Regulations require that installations should comply with manu

facturer’s instructions. It is therefore important that the commissioning

checklist is completed by the installer. The relevant section of Building

Regulations only relates to dwellings. Therefore the checklist only applies

if the appliance is being installed in a dwelling or some related structure.

The flowchart opposite gives guidance for installers on the process neces

sary to ensure compliance with Building Regulations.

Fig.1

Benchmark

1.1.2 The Benchmark Scheme

Benchmark places responsibilities on both manufacturers and installers.

The purpose is to ensure that customers are provided with the correct

equipment for their needs, that it is installed, commissioned and serviced

in accordance with the manufacturer’s instructions by competent persons

and that it meets the requirements of the appropriate Building Regulations.

The Benchmark Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the customer for future ref

erence.

Installers are required to carry out installation, commissioning and servic

ing work in accordance with the Benchmark Code of Practice which is

available from the Heating and Hotwater Industry Council who manage

and promote the Scheme. Visit www.centralheating.co.uk for more infor

mation.

Fig.2 Installer Notification Guidelines

AD-3000696-01

Choose Building

Regulations Notification

Route

Contact your relevant Local

Authority Building Control

(LABC) who will arrange

an inspection or contact

a government approved

inspector

LABC will record the data

and will issue a

certificate of compliance

‘Gas Safe Register’ will issue a

Building Regulations Compliance

Certificate to the property owner

and inform the relevant LABC

You must ensure that the

certificate number issued by

the ‘Gas Safe Register’ is written

onto the Benchmark Checklist

Scheme Members only

Call ‘Gas Safe Register’ on:

0800 408 5577

or log onto:

www.gassaferegister.co.uk

within 10 days

If you notify via the ‘Gas Safe

Register’, the register will issue

the Building Regulations

certificate on members’ behalf

Complete the

Benchmark Checklist

Install and Commission this

appliance to manufacturer's

instructions

Competent Person's

Self Certification Scheme

Building Control

Complete the

Benchmark Checklist

Install and Commission this

appliance to manufacturer's

instructions

7661586 - 2 - 12072016 7

1 Safety

1.1.3 Installer Notification Guidelines

1 Safety

8 7661586 - 2 - 12072016

1.2 General safety instructions

Danger

This boiler can be used by children aged 8 years and above and

by persons with reduced physical, sensory or mental capabilities

or lack of experience and knowledge when they have been given

supervision or instruction concerning the safe use of the device

and understand the resulting risks. Children must not be allowed

to play with the appliance. Cleaning and user maintenance must

not be carried out by children without supervision.

Danger

If you smell gas:

1. Do not use a naked flame, do not smoke, do not operate elec

trical contacts or switches (doorbell, light, motor, lift, etc.).

2. Shut off gas supply.

3. Open the windows.

4. Trace possible leaks and seal them immediately.

5. If the gas leak is before the gas meter, contact the supplier

6. Telephone the National Gas Emergency Service on:- 0800

111 999.

Danger

If you smell flue gases:

1. Switch off the boiler.

2. Open the windows.

3. Trace possible leaks and seal them immediately.

Warning

Do not touch the flue gas pipes. Depending on the boiler settings,

o

the temperature of the flue gas pipes may exceed 60

C.

Warning

Do not touch the radiators for long periods. Depending on the boil

er settings, the temperature of the radiators may exceed 60oC.

Warning

Take precautions with the domestic hot water. Depending on the

boiler settings, the domestic hot water temperature may exceed

o

C.

65

Danger

Before any work, switch off the mains supply to the boiler.

Caution

After maintenance or repair work, check the entire heating installa

tion to ensure that there are no leaks.

1.3 Recommendations

7661586 - 2 - 12072016 9

1 Safety

Warning

Installation and maintenance of the boiler must be carried out by a

qualified installer in accordance with local and national regula

tions.

Warning

If the mains lead is damaged, it must be replaced by the original

manufacturer, the manufacturer's dealer or another suitably skilled

person to prevent hazardous situations from arising.

Warning

Always disconnect the mains supply and close the main gas tap

when working on the boiler.

Caution

Make sure the boiler can be reached at all times.

The boiler must be installed in a frost-free area.

In the case of a fixed connection to the power cord, you must al

ways install a main bipolar switch with an opening gap of at

least 3 mm (EN 60335-1).

Drain the boiler and central heating system if you are not going

to use your home for a long time and there is a chance of frost.

The frost protection does not work if the boiler is out of opera

tion.

The boiler protection only protects the boiler, not the system.

Check the water pressure in the system regularly. If the water

pressure is lower than 0.8 bar, the system must be topped up

(recommended water pressure between 1 and 2 bar).

1.4

Note

Keep this document near to the boiler.

Note

Casing panels may only be removed for maintenance and servic

ing purposes. Refit all panels when maintenance work and servic

ing are complete.

Note

Instruction and warning labels must never be removed or covered

and must be clearly legible throughout the entire service life of the

boiler. Replace damaged or illegible instruction and warning labels

immediately.

Note

The boiler must not be modified in any way.

Specific safety instructions

1.4.1 Handling

General

The following advice should be adhered to, from when first handling the

boiler to the final stages of installation, and also during maintenance.

Most injuries as a result of inappropriate handling and lifting are to the

back, but all other parts of the body are vulnerable, particularly should

ers, arms and hands. Health & Safety is the responsibility of EVERY

ONE.

There is no "safe" limit for one man - each person has different capabili

ties. The boiler should be handled and lifted by TWO PEOPLE.

Do not handle or lift unless you feel physically able.

Wear appropriate Personal Protection Equipment e.g. protective gloves,

safety footwear etc.

1 Safety

10 7661586 - 2 - 12072016

Preparation

Co-ordinate movements - know where, and when, you are both going.

Minimise the number of times needed to move the boiler - plan ahead.

Always ensure when handling or lifting the route is clear and unobstruc

ted. If possible avoid steps, wet or slippery surfaces, unlit areas etc. and

take special care on ladders/into lofts.

Technique

When handling or lifting always use safe techniques - keep your back

straight, bend your knees. Don’t twist - move your feet, avoid bending

forwards and sideways and keep the load as close to your body as pos

sible.

Where possible transport the boiler using a sack truck or other suitable

trolley.

Always grip the boiler firmly, and before lifting feel where the weight is

concentrated to establish the centre of gravity, repositioning yourself as

necessary. See the "Installation" section of these instructions for recom

mended lift points.

Remember

The circumstances of each installation are different. Always assess the

risks associated with handling and lifting according to the individual con

ditions.

If at any time when installing the boiler you feel that you may have in

jured yourself STOP !! DO NOT "work through" the pain - you may

cause further injury.

IF IN ANY DOUBT DO NO HANDLE OR LIFT THE BOILER — OBTAIN

ADVICE OR ASSISTANCE BEFORE PROCEEDING !

1.5 Liabilities

1.5.1 Manufacturer's liability

Our products are manufactured in compliance with the requirements of the

various Directives applicable. They are therefore delivered with the

marking and any documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We therefore reserve

the right to modify the specifications given in this document.

Our liability as manufacturer may not be invoked in the following cases:

Failure to abide by the instructions on installing the appliance.

Failure to abide by the instructions on using the appliance.

Faulty or insufficient maintenance of the appliance.

1.5.2 Installer's liability

The installer is responsible for the installation and initial commissioning of

the appliance. The installer must abide by the following instructions:

Read and follow the instructions given in the manuals provided with the

appliance.

Install the appliance in compliance with prevailing legislation and stand

ards.

Carry out initial commissioning and any checks necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the obligation to check the

appliance and keep it in good working order.

Give all the instruction manuals to the user.

1.5.3 User's liability

To guarantee optimum operation of the system, you must abide by the fol

lowing instructions:

Read and follow the instructions given in the manuals provided with the

appliance.

Call on a qualified professional to carry out installation and initial com

missioning.

1 Safety

7661586 - 2 - 12072016 11

Get your installer to explain your installation to you.

Have the required inspections and maintenance carried out by a quali

fied installer.

Keep the instruction manuals in good condition close to the appliance.

2 About this manual

12 7661586 - 2 - 12072016

2 About this manual

2.1 General

This manual is intended for the installer of a Baxi Combi boiler.

2.2

2.3

Additional documentation

Symbols used

These Installation & Service Instructions must be read in conjunction with

the Flue Installation Guide supplied in the Literature Pack.

Various timers, external controls, etc. are available as optional extras. Full

details are contained in the relevant sales literature.

2.3.1

This manual uses various danger levels to draw attention to special in

structions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Symbols used in the manual

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal in

jury.

2.4

Caution

Risk of material damage.

Note

Please note: important information.

See

Reference to other manuals or pages in this manual.

Abbreviations/Glossary

Enter your glossary term here.

BS British Standard

CH Central heating

DHW Domestic hot water

GB Great Britain

HHIC Heating and Hotwater Industry Council

Hi Lower heating value (LHV)

Hs Higher heating value (HHV)

IE Ireland

PCU PCB for managing burner operation

Pn Nominal output

Pnc Condensing output

PWM Pulse wide modulation

SU Safety PCB

3 Technical specifications

7661586 - 2 - 12072016 13

3.1 Homologations

3 Technical specifications

3.1.1 Directives

Our company declares that these products are provided with the CE mark

ing in compliance with the essential requirements of the following direc

tives:

Gas Directive 2009/142/EC;

Electromagnetic Compatibility Directive 2014/30/EU General standards:

EN 61000-6-3, EN 61000-6-1 Standard in reference to: EN 55014;

Electromagnetic Compatibility Directive 2014/30/EU General standards:

EN 61000-6-3, EN 61000-6-1 Standard in reference to: EN 55014.

For appliances connected to the electricity network: Comply with the

prevailing provisions for low-voltage electrical equipment;

Low Voltage Directive 2014/35/EU General standard: EN 60335–1

Standard in reference to: EN 60335–2-102;

Efficiency Directive 92/42/EC

Ecodesign Directive 2009/125/EC;

Directive on energy consumption 2010/30/EC; Regulation (EU) No.

813/2013 and 814/2013.

Energy Labelling Directive 2010/30/EU: Regulation 811/2013 and

812/2013

In addition to the provisions and legal directives, also the complementary

directives described in these instructions must be observed. All the sup

plements and additional requirements are applicable at the moment of in

stallation.

3.1.2 Certifications

Tab.1 Certifications

CE certificate number 0085CQ0192

NOx class 5 (EN 15502)

Boiler type C13, C

33

3.1.3 Gas category

Tab.2 Gas category, type and supply pressure

Gas category Gas type Supply pressure (mbar)

I

2H

G20 20

3.1.4 Standards

Codes of Practice — refer to the most recent version

Tab.3 In GB the following Codes of Practice apply:

Standard Scope

BS 6891 Gas Installation.

BS 5546 Installation of hot water supplies for domestic purposes.

BS EN

12828

BS EN

12831

Heating systems in buildings.

Heating systems in buildings — Calculation of load.

3 Technical specifications

14 7661586 - 2 - 12072016

Standard Scope

BS EN

14336

BS 6798 Installation of gas fired hot water boilers.

BS 5440

Part 1

BS 5440

Part 2

BS 7074 Expansion vessels and ancillary equipment for sealed wa

BS 7593 Treatment of water in domestic hot water central heating

BS 4814 Specification for Expansion Vessels using an internal dia

IGE/UP/

7/1998

Tab.4 In IE the following Code of Practice apply:

Standard Scope

IS 813 Domestic Gas Installations.

The following standards give valuable additional information:

BS 5546 Installation of hot water supplies for domestic purposes.

BS EN

12828

BS EN

12831

BS EN

14336

BS 7074 Expansion vessels and ancillary equipment for sealed wa

BS 7593 Treatment of water in domestic hot water central heating

Installation & commissioning of water based heating sys

tems.

Flues.

Ventilation.

ter systems.

systems.

phragm, for sealed hot water systems.

Guide for gas installations in timber framed housing.

Heating systems in buildings.

Heating systems in buildings — Calculation of load.

Installation & commissioning of water based heating sys

tems.

ter systems.

systems.

3.2 Technical data

3.2.1 Technical information

Note

All data in these sections are nominal and subject to normal pro

duction tolerances.

Tab.5 General

Baxi Combi 224 228 424 428

Gas Council Numbers 47–077–21 47–077–22 47–077–23 47–077–24

Nominal heat input Domes

tic Hot Water — Maximum

Rate

Nominal Heat Input Central

Heating — Maximum Rate

Nett (Qn

Hi)

Gross

(Qn Hs)

Nett (Qn

Hi)

Gross

(Qn Hs)

kW 24.7 28.9 24.7 28.9

kW 27.4 32.1 27.4 32.1

kW 20.6 24.7 20.6 24.7

kW 22.9 27.4 22.9 27.4

3 Technical specifications

7661586 - 2 - 12072016 15

Baxi Combi 224 228 424 428

Nominal Heat Input — Min

imum Rate

Nett (Qn

Hi)

Gross

kW 4.9 4.9 4.9 4.9

kW 5.4 5.4 5.4 5.4

(Qn Hs)

Nominal heat output

Pn kW 24.0 28.0 24.0 28.0

80/60°C — Domestic Hot

Water — Maximum Rate

Nominal heat output

Pn kW 20.0 24.0 20.0 24.0

80/60°C — Central Heating

— Maximum Rate

Nominal heat output

Pn kW 20.0 20.0 20.0 20.0

80/60°C — Central Heating

— Factory Setting

Nominal heat output

Pn kW 4.8 4.8 4.8 4.8

80/60°C — Minimum Rate

Nominal heat output

Pnc kW 21.8 26.1 21.8 26.1

50/30°C — Central Heating

— Maximum Rate

Nominal heat output

Pnc kW 5.2 5.2 5.2 5.2

50/30°C — Central Heating

— Minimum Rate

Tab.6 Central heating circuit specifications

Baxi Combi 224 228 424 428

Maximum pressure bar 3 3 3 3

Minimum pressure bar 0.5 0.5 0.5 0.5

Central heating temperature adjust

°C 25/80 25/80 25/80 25/80

ment ±5°C

Expansion vessel water capacity litres 7.0 7.0 7.0 7.0

Expansion vessel pre charge pres

bar 1.0 1.0 1.0 1.0

sure

Maximum capacity of central heat

litres 120 120 120 120

ing system

Primary water content of boiler (un

litres 2.5 2.5 2.5 2.5

pressurised)

Tab.7 Domestic hot water circuit specifications

Baxi Combi 224 228 424 428

Maximum pressure bar 8.0 8.0 8.0 8.0

Dynamic minimum pressure bar 0.5 0.5 0.5 0.5

Minimum working water flow rate l/min 2.0 2.0 2.0 2.0

Specific flow rate (D) l/min 11.5 13.4 11.5 13.4

Domestic hot water temperature

°C 35/60 35/60 35/60 35/60

range adjustment ±5°C

Production of domestic water with

l/min 13.8 16.1 13.8 16.1

ΔT = 25°C

Production of domestic water with

l/min 9.8 11.5 9.8 11.5

ΔT = 35°C

Where low flow taps or fittings are intended to be used in the DHW system connected to the boiler, it is strongly recommended

that the DHW flow rate DOES NOT fall below 2.5 l/min. This will ensure reliable operation of the DHW function.

3 Technical specifications

16 7661586 - 2 - 12072016

Tab.8 Characteristics of combustion

Baxi Combi 224 228 424 428

Natural gas rate (G20) Qmax

Natural gas rate (G20) Qmin

Diameter of coaxial discharge

m3/h

m3/h

mm 60/100 & 80/125 60/100 & 80/125 60/100 & 80/125 60/100 & 80/125

2.61 3.06 2.61 3.06

0.52 0.52 0.52 0.52

pipes

Note

Dynamic (nominal) inlet pressure (Natural gas — G20) 20mbar

with a CV of 37.78 MJ/m

3

Tab.9 Electrical specifications

Baxi Combi 224 228 424 428

Nominal electrical power supply

V 230 230 230 230

voltage

Nominal electrical power supply

Hz 50 50 50 50

frequency

Nominal power consumption when

W 84 94 84 94

firing

External fuse rating Amp 3 3 3 3

F2 Internal fuse rating — Connec

Amp 0.5 0.5 0.5 0.5

tion board ’B’

F1 Internal fuse rating — Main PCB

Amp 1.6 1.6 1.6 1.6

board ‘A’

Note

Boiler must be connected to an earth supply.

Tab.10 Other specifications

Baxi Combi 224 228 424 428

Degree of protection against hu

IP IPX5D IPX5D IPX5D IPX5D

midity (EN 60529) without plug-in

timer / receiver fitted

Degree of protection against hu

IP IPXO IPXO IPXO IPXO

midity (EN 60529) with plug-in tim

er / receiver fitted

Dimensions (height/width/depth) mm 700/395/279 700/395/279 700/395/279 700/395/279

Tab.11 Connections (copper tails)

Baxi Combi 224 228 424 428

Gas inlet mm 22 22 22 22

Heating flow mm 22 22 22 22

Heating return mm 22 22 22 22

Cold water inlet mm 15 15 15 15

Hot water outlet mm 15 15 15 15

Pressure relief discharge mm 15 15 15 15

Condensate discharge drain plastic

mm 21.5 21.5 21.5 21.5

waste pipe

3 Technical specifications

7661586 - 2 - 12072016 17

Tab.12 Clearances

Baxi Combi 224 228 424 428

Above casing mm 178 178 178 178

Below casing (min)

Below casing (recommended)

Front — for servicing (min)

Front — for servicing (recommen

mmmm200

250

mmmm450

1000

200

250

450

1000

200

250

450

1000

200

250

450

1000

ded)

Front — for operation mm 6 6 6 6

Sides LH mm 5 5 5 5

Sides RH mm 5 5 5 5

Tab.13 Weights

Baxi Combi 224 228 424 428

Packaged boiler kg 30.0 30.0 30.5 30.5

Boiler lift weight (dry) kg 26.0 26.0 26.0 26.0

Installed weight (dry) kg 28.0 28.0 28.5 28.5

Installed weight when filled with wa

kg 30.5 30.5 31.0 31.0

ter

3.2.2 Technical parameters

Tab.14 Technical parameters for boiler combination heaters

Baxi Combi 224 228 424 428

Condensing boiler Yes Yes Yes Yes

Low-temperature boiler

(1)

B1 boiler No No No No

Cogeneration space heater No No No No

Combination heater Yes Yes Yes Yes

Rated heat output

Useful heat output at rated heat output

and high temperature regime

(2)

Useful heat output at 30% of rated heat

output and low temperature regime

Seasonal space heating energy efficiency

Useful efficiency at rated heat output and

high temperature regime

Useful efficiency at 30% of rated heat

output and low temperature regime

Auxiliary electricity consumption

Full load

Part load

Standby mode

Other items

Standby heat loss

Ignition burner power consumption

Annual energy consumption

No No No No

Prated

P

4

P

1

ƞ

s

ƞ

4

ƞ

1

elmax

elmin

P

SB

P

stby

P

ign

Q

HE

kW 20 24 20 24

kW 20.0 24.0 20.0 24.0

kW 6.7 8.0 6.7 8.0

% 93 93 93 93

% 88.1 88.0 88.1 88.0

% 97.8 97.8 97.8 97.8

kW 0.028 0.038 0.028 0.038

kW 0.011 0.011 0.011 0.011

kW 0.003 0.003 0.003 0.003

kW 0.069 0.069 0.069 0.069

kW 0.000 0.000 0.000 0.000

GJ 62 74 62 74

1

2

3

4

5 6 7

8

700

279

395

PN-0000264

A

*

5.0

6

B*

285

700

3

95

PN-0000205

5.0

178

3 Technical specifications

18 7661586 - 2 - 12072016

Baxi Combi 224 228 424 428

Sound power level, indoors

Emissions of nitrogen oxides NO

L

WA

X

dB 48 50 48 50

mg/kWh 38 40 38 40

Domestic hot water parameters

Declared load profile XL XL XL XL

Daily electricity consumption

Annual electricity consumption

Water heating energy efficiency

Daily fuel consumption

Annual fuel consumption

(1) Low temperature means for condensing boilers 30°C, for low temperature boilers 37°C and for other heaters 50°C return temperature (at

heater inlet).

(2) High temperature regime means 60°C return temperature at heater inlet and 80°C feed temperature at heater outlet.

Q

elec

AEC

ƞ

wh

Q

fuel

AFC

kWh 0.151 0.151 0.151 0.151

kWh 33 33 33 33

% 86 85 86 85

kWh 22.770 22.930 22.770 22.939

GJ 17 17 17 17

See

The back cover for contact details.

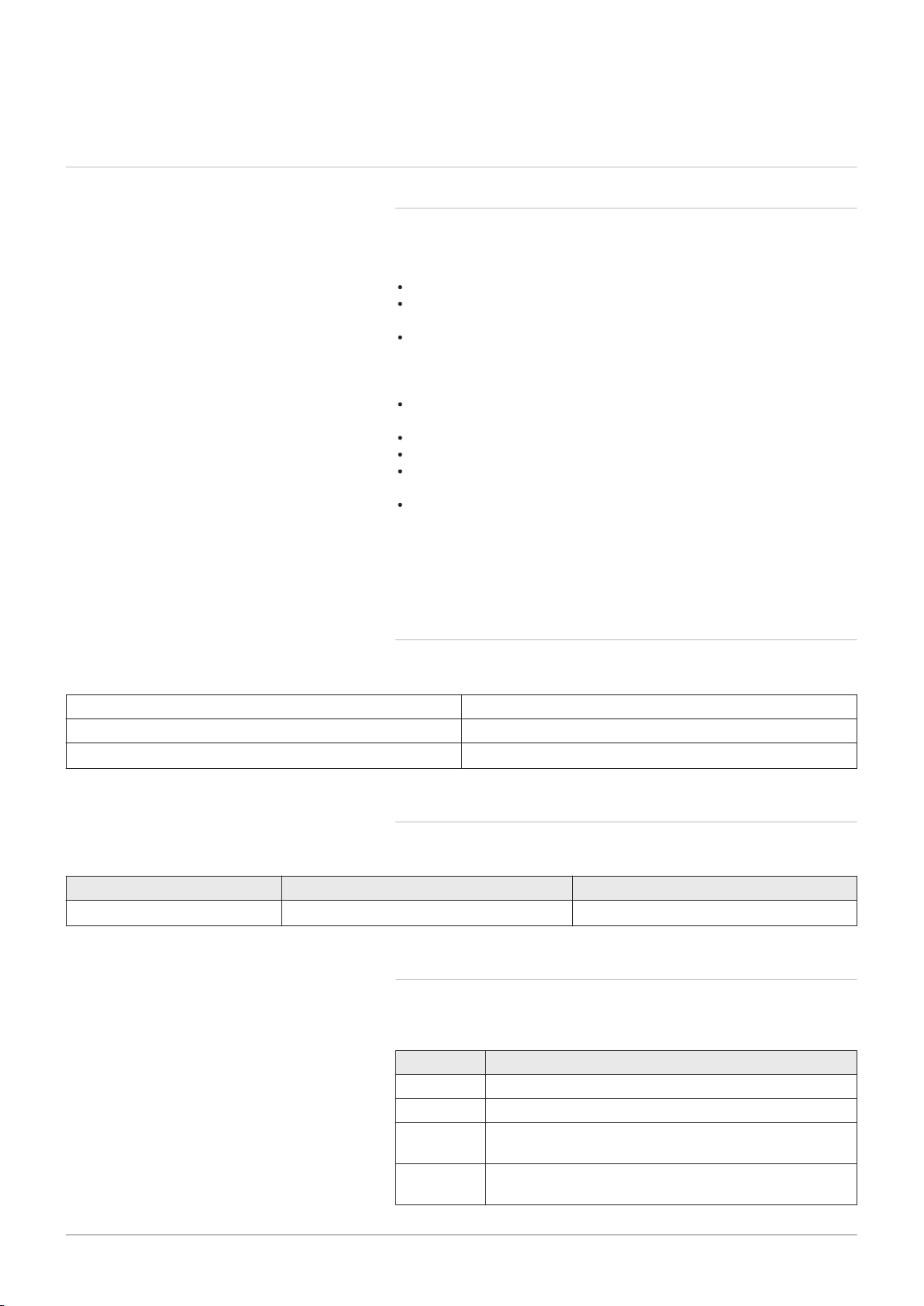

3.3

Fig.3

Fig.4

Dimensions and connections/clearances

Dimensions and connections

Clearances

1

2

3

4

5

6

7

8

Safety valve

Heating circuit water flow

Condensate discharge

Heating system/boiler drain tap

Domestic hot water outlet

Gas inlet

Mains cold water inlet

Heating circuit water return

The clearances shown in the diagram are minimum requirements to allow

for case removal, spanner access and air movement. These should be ob

served at all times and kept clear of obstructions.

A* Clearance below boiler— Minimum 200mm, Recommended

250mm

B* Clearance in front of boiler— Minimum 450mm, Recommended

1000mm

Fig.5 Paper template

Ø 8

34 33.5 65 65 65 65 67.5

198 198

50 MIN

82.5

32

116 Dia Minimum

Aperture For

Flue Tube

Vertical Flue

Centre Line

Ø 22

Heating

Return

(22mm)

Heating

Flow

(22mm)

Hot Water

Outlet

(15mm)

Combi Only

Not System

Cold Water

Inlet

(15mm)

Combi Only

Not System

Side Clearance 5Side Clearance 5

Clearance below 250

Clearance above 178

Wall

View from under boiler

PN-0000223

7661586 - 2 - 12072016 19

3 Technical specifications

HMI

1

1

1

GND

1

1

PWM - P

L-BUS

E

1

1

1

L

N

G/Y

G/Y

W

Br

Bl

DV

PN-0000268

Bl

Br

Bl

Br

P

230V - 50Hz

Gy

R

W

Bk

Vt

Br

Bl

13

R

R

R

R

Gn

W

Br

R Bl Gn

Br

Bl

Y

Bk

Bk

R

R

Vt

Vt

Vt

Vt

Br

Br

Br

Br

R R

Bk

Bk

W

Br

123 4 5 123 4 5 67

1

2 1

123

Br

Br

Bl

Bk

Bk

Gy

Bl

W

Gy

Vt

Br

BkWGn

Br

R

Bl

R

L-BUS

Bk

R

W

Gn

Gn

Wk

Bk

Br

R

16

F1

F1 (1,6A)

L

N

L(CH)

L(DW)

N

GV

W8-1

W8-2

W8-4

W8-3

ST

HS

WPS

DS RS

FS

X6-A

X9-1

X14-A

X4-A

W8

X5-A

X1-A

X3-A

X2-A

A

JP1

G/Y

G/Y

Circuit Board

‘A’

Connection Board

‘B’

SERVICE

X7 X6

F2

0.5A

X14

OS

X13

J

X9

L-BUS

3

On

B

X12

X11 X10

X3

TIMER

X2

X5

Off

230V - 50Hz

LN

2

1

X1 MAINS

X4

RT

X8

OT

Gn

Bk

Br Brown

Bl Blue

Bk Black

G/Y Green/Yellow

R Red

Gn Green

Gy Grey

W White

Vt Violet

Mains 230V

W4

W3

+

C2

C1

SIG

W2

W1

W5

F

3 Technical specifications

20 7661586 - 2 - 12072016

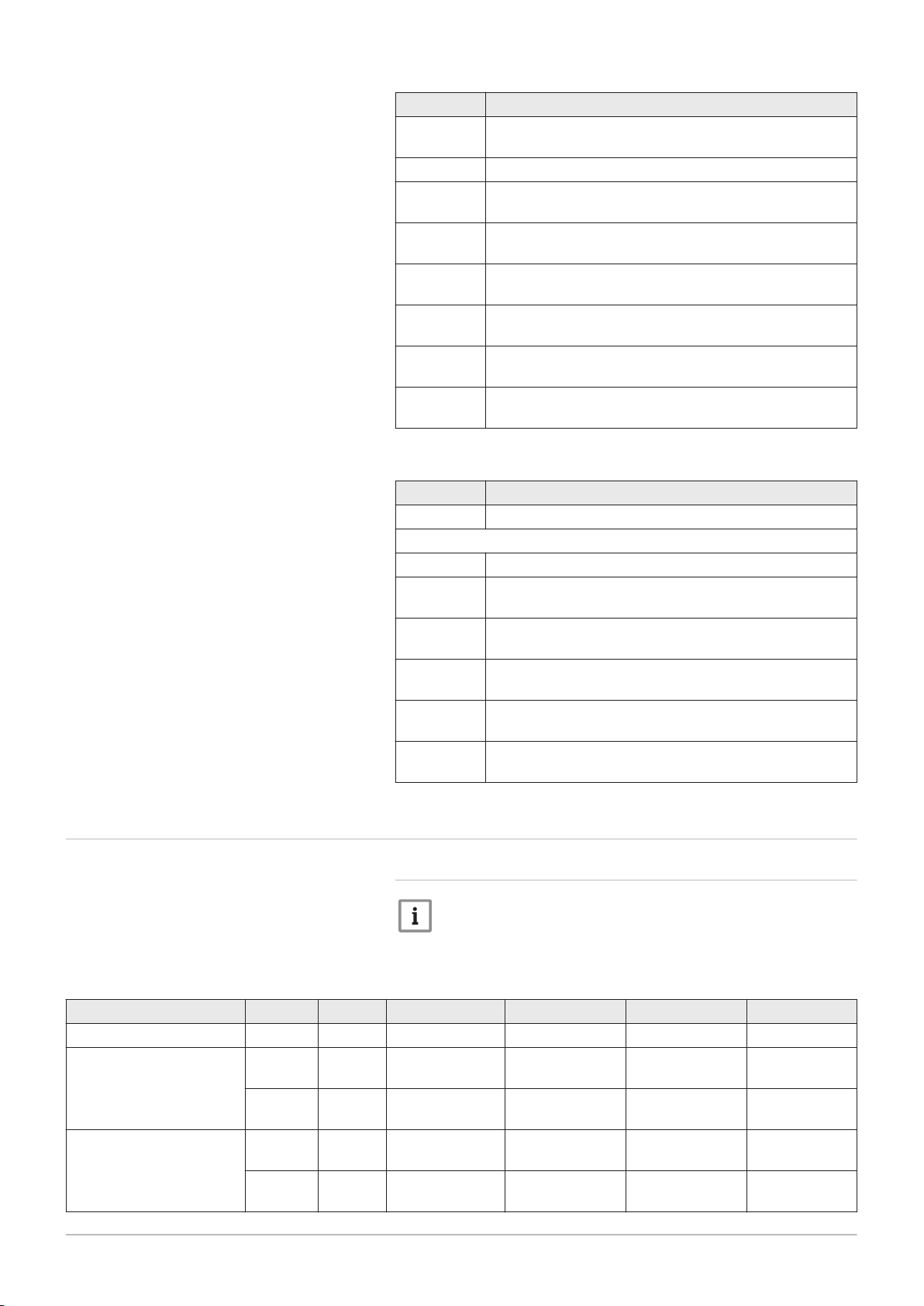

3.4 Electrical diagram

Fig.6 Electrical diagram

Tab.15 Electrical connections inside the boiler (A)

7661586 - 2 - 12072016 21

Electrical power supply 230 V — 50 Hz

X1–A

1: Earthing connector

2: L (230 V)

3: N

Pump

X2–A

1: Earth connection

2: L (230 V)

3: N

3-way valve

X3–A

1: L (CH) 230 V — Heating circuit opening command

2: L (DW) 230 V — Domestic water circuit opening command

3: N — Common

X4–A Pump PWM signal

Sensor connection

HS: domestic water request

RS: heating circuit water return

X5–A

DS: heating circuit water flow

FS: flue gas

WPS: hydraulic pressure switch

ST: safety thermostat

X6–A Boiler PCB and control panel connection (electrical connection board)

X13–A Not used

X14–A Connection L-BUS

3 Technical specifications

Tab.16 Electrical connections to be made to the boiler (B)

Electrical power supply 230 V — 50 Hz

X1–B

1: N

2: L (230 V)

3: Earthing connector

X4–B Room thermostat/timer (230V)

X6–B Not used

X7–B Solar probe connection

X8–B On-Off/R-Bus - Room thermostat connection (the jumper must be REMOVED to connect a device)

X9–B Service connection (SERVICE)

X13–B Connection L-BUS

X14–B Outside sensor connection (OS)

Dip-Switch

J

1: Maximum heating temperature OFF = 80°C - ON = 45°C (floor system)

2: OFF = Maximum output (heating) - ON = Boiler output 50% (heating)

3: DO NOT ADJUST

4 Description of the product

22 7661586 - 2 - 12072016

4 Description of the product

4.1 General description

The Baxi Combi condensing boiler is a gas-fuelled boiler. The purpose of

this boiler is to heat water to a temperature that is lower than boiling point

at atmospheric pressure. It must be connected to a heating installation and

to a domestic hot water distribution system that is compatible with its pow

er and performance ratings. Features of this boiler:

Low pollutant emissions.

High-efficiency heating.

Combustion products discharged through a coaxial connector.

Front control panel with display.

Lightweight and compact.

4.2

Operating principle

4.2.1

The air is drawn in by the fan and gas injected directly at the top of the

mixer valve. The fan rotation speed is regulated automatically by the elec

tronic board based on temperature adjustment and other parameters. The

gas and air are mixed in the manifold. The gas/air ratio ensures that the

quantity of gas and air are adjusted correctly to always obtain optimal

combustion. The gas/air mixture is fed into the burner at the front of the

heat exchanger. The mixture is ignited by the spark electrode.

Air-gas adjustment

4.2.2 Combustion

The burner heats the heating water circulating in the heat exchanger.

When the temperature of the combustion gas is lower than the dew point

(around 55 °C), the water vapour contained in the combustion gas con

denses in the flue gas side of the heat exchanger. The heat recovered

during this condensation process (the latent heat or condensing heat) is

also transferred to the heating water. Once cooled, the combustion gases

are discharged through the flue exhaust. The condensed water is dis

charged through a trap.

4.3 Main components

1

3

2

4

5

6

7

8

9

10

12

13

11

21

22

23

25

26

24

28

27

15

16

17181920

14

PN-0000286

PN-0000266

PN-0000267

7661586 - 2 - 12072016 23

4 Description of the product

4.2.3 Heating and domestic hot water production

Fig.7

Component description

1 Boiler case

2 Mounting slots for wall bracket

3 Flue adaptor

4 Expansion vessel air control/filling valve

5 Expansion vessel

6 Burner door

7 Detection/ignition electrode

8 Water circuit-expansion vessel connection pipe

9 Air-gas assembly (control board, fan, mixer valve)

10 Automatic air vent

11 Gas valve

12 Pump

13 3-way valve

14 Pressure gauge (fitted on the panel)

15 Domestic hot water priority sensor

16 Boiler electrical connection board

17 Domestic hot water plate heat exchanger fastening screws

18 Domestic hot water plate heat exchanger

19 Pressure relief valve

20 Condensate trap

21 Hydraulic pressure sensor

22 Silencer

23 Trap quick connection (with gaskets)

24 Heating circuit water flow sensor

25 Overheat safety thermostat

26 Heating circuit water return sensor (behind the silencer)

27 Heat exchanger

28 Flue gas temperature sensor

4.4 Control panel description

Fig.8 Control panel

Fig.9 Display screen

4.4.1 Description of the keys

Heating temperature control knob

Level access button: Information, Installer or Chimney Sweep

Manual reset button

4.4.2 Description of the display

Domestic hot water temperature control knob

Hour run meter

Malfunction

Maintenance

Reset necessary

Burner status

Heating mode

Outside temperature sensor

Domestic hot water mode

4 Description of the product

24 7661586 - 2 - 12072016

4.5 Standard delivery

4.5.1 Contents of the carton

The boiler is delivered in a carton comprising:

a wall-hung gas boiler;

a bracket for fastening the boiler to the wall;

a paper template;

an installation and service manual;

a user manual.

a fitting kit, including taps and tail pipes.

4.6

Accessories and options

4.6.1 Optional accessories

The table below shows the accessories available for this boiler range.

Tab.17 Optional accessories

Part number Accessory

7658276 Baxi plug-in 24 hr mechanical timer combi - RH

7658523 Baxi plug-in 7 day digital timer combi - RH

7658781 Baxi plug-in receiver 24 hr RF programmable mech room

thermostat-combi

7658789 Baxi plug-in receiver 7 day RF digital programmable room

thermostat-combi

7212438 Baxi single channel wired programmable room thermostat

7212444 Baxi single channel wired timer

720971601 Baxi room thermostat

720330001 Baxi wired weather sensor

720648301 Multifit condensate & PRV combined pump

720644401 Multifit 1m condensate drain pipe 'trace heating' element

720664101 Multifit 2m Condensate drain pipe 'trace heating' element

720664201 Multifit 3m condensate drain pipe 'trace Heating' element

720664401 Multifit 5m condensate drain pipe 'trace heating' element

7659335 Baxi 200-400 stand off kit

5121379 Multifit remote secondary PRV kit

248221 Multifit filling loop (Not required for 424 and 428 models)

For Flue Accessories (elbows, extensions, clamps etc.) refer to the Flue

Installation Guide supplied in the literature pack.

Any of the above MUST be fitted ONLY by a qualified competent person.

Further details can be found in the relevant sales literature and at

www.baxi.co.uk

Loading...

Loading...