Page 1

SPECTRONIC

21

MV

SPECTROPHOTOMETER

WAVELENGTH

The

MV

model

Figure

wavelength

READOUT

The

linear

bance.

tance

tance.

devices

ACCESSORIES

The

2.

3.

4.

5.

6.

Wavelength

Wavelength

Wavelength

Wavelength

1,

uses

atungsten

range

54”

meter

in

transmittance,

The

meter

with

linear

An

analog

to

record

instrument

1.

Universal

Spare

One

Operator’s

Dust

Calibration

7.

Occluder

8.

Adapter

SPECIFICATIONS

Spectral

test

tungsten

dozen

10mm

manual

cover

screwdriver

block

for

Range

Accuracy

Readability

Repeatability

Slitwidth

RANGE

of

the

SPECTRONIC

lamp

of

340-1000nm.

is

mirrored

and

scale

reads

scale

divisions

output

results

SUPPLIED

is

supplied

tube

lamp

rectangular

permits

in

holder

pathlength

to

provide

to

prevent

is

also

from

00.0

at

the

percent

complete

test-tube

cuvettes

340-1000nm

Better

365nm

1.0nm

Better

10nm

21

series,

an

parallax

calibrated

to

every

use

transmittance.

with:

than

and

than

shown

uninterrupted

error,

in

absor-

100% transmit-

1%

transmit-

of

recording

cuvettes

2nm

at

546nm

Inm

in

is

Stray

Radiant

Photometric

Photometric

Photometric

Photometric

Photometric

Long-term

Zero

Accessory

Dispersing

Power

Voltage

Size

Weight

Drift

Drift

Output

Element

Consumption

Reguirements

Energy

Readout

Range

Noise

Linearity

Accuracy

0.05%

(typical)

5%”

meter,

linear

transmittance

non-linear

mirrored

0-100%T,

Less

Better

meter

Better

analog

Better

analog

0.003A

Less

Analog

(adjustable)

Reflection

lines

40

Watts

Selectable:

220V,

144" W x

(36.8em W x

21.6cm

Add

for

General

Sample

16

lbs.

Add

General

Compartment.

absorbance

scale

0-2A

than

0.1%T

than

1.0%T

than

0.2%T

output

than

0.3%T

output

per

hour

than

0.1%T

in

%T, 1 volt

grating,

/mm

100V,

240V;

50,

104"

H)

5%”’

(14cm)

Purpose

Compartment.

(7.3kg)

3%

lbs.

(1.6kg)

Purpose

at

340nm

(T),

(A),

near

100%T

at

at

at

per

day

1200

115V,

60

Hz

Dx

84"

26.7em D x

to

width

for

Sample

H

DSC

|

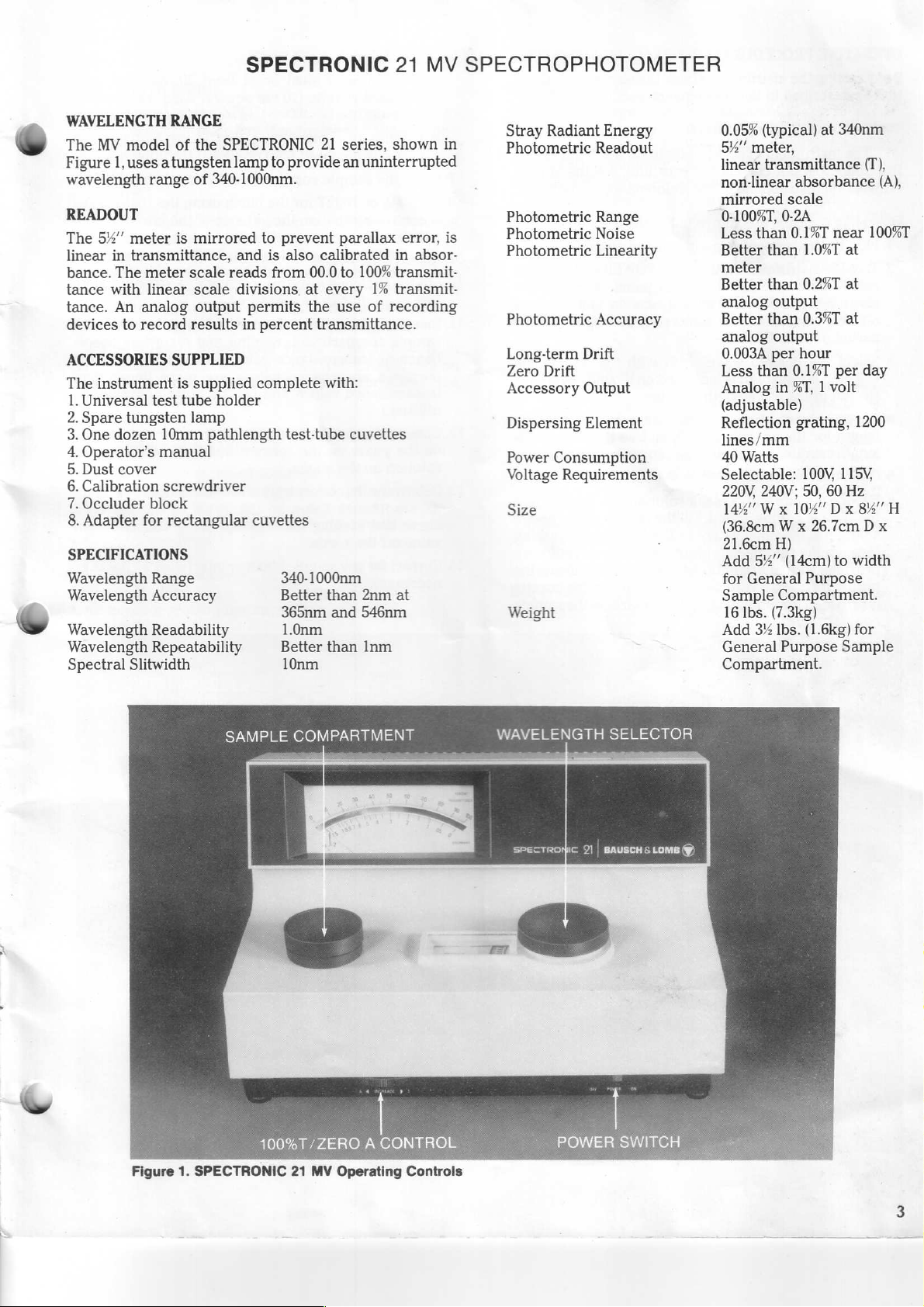

Figure

1.

SPECTRONIC

100%T/ZERO

21

MV

A

CONTROL

Operating

Controls

POWER

SWITCH

Page 2

Power

Consumption

Voltage

Requirements

Size

Weight

OPERATING

Before

tion

this

Conversion

Operating

using

as

described

The

voltage

1.

Plug

2.

Turn

right

instrument

on,

best

period

Display

instrument

controls

the

the

side

performance

of

characters

normal.

3.

Select

the

selector.

the

left

of

4.Choose

length

pathlength

for

samples.

5.

Open

the

6.

Fill

one

cuvette

sample

compartment.

solution

through

provided

proper

is

fill

provided

compartment.

a.

Solution

standard

adaptor).

b.

Solution

tube

cuvette

7.

Close

the

8.Select

bance,

9.

Set

lower

the

or

the

SENSITIVITY

control

45

Watts

Selectable:

240V;

14%" W x

(36.8cm x 26.7cm x 21.6cm)

Add

General

Compartment

16%

Add

Purpose

PROCEDURES

the

instrument,

in

the

check

Maintenance

NOTE

is

set

to

is

not

correct

instructions

are

instrument

instrument

of

the

can

be

15

to

30

for

in

the

shown

into a grounded

on

using

lower

control

used

almost

is

achieved

minutes.

NOTE

may

be

slow

to

turn

during

desired

Wavelength

the

matched

the

cuvettes

sample

first

minute

wavelength

is

indicated

wavelength

cuvettes

analytical

for

compartment

with a blank

Fill

to

completely

the

sample

cover

compartment.

with a horizontal

level. A vertical

for

alignment

with

NOTE

level

must

be

cuvette

level

sample

operating

concentration—using

(10

cm

must

be

(used

with

compartment

mode—transmittance,

at

switch

panel

to

LO.

100V,

50,

60

Hz

10%

5%’

(14cm)

Purpose

lbs.

(7.5kg)

3%

lbs.

(1.6kg)

Sample

the

section.

operate

on a 115VAC

your

line,

Maintenance

in

Figure

the

POWER

panel.

as

soon

following a warmup

on,

or

of

with

on

selector.

of

the

method.

all

blanks,

door.

solution and

the

cuvette

the

light

fiducial

fiducial

at

the

least

square;

least

32

mark

mark

mark

universal

cover.

the

located

115V,

220V,

Dx

8%

Η

to

width

Sample

for

General

Compartment

electronic

see

calibra-

the

Voltage

section.

2.

outlet.

switch

Although

as

it

is

may

have

unusual

operation.

the

wavelength

the

dial

located

appropriate

Use

the

sample

standards,

insert

with

enough

beam

passing

Some

cuvettes

to

indicate

on

the

cuvette

on

the

sample

20

mm

high

used

with

mm

high

in a test

test

tube

holder).

mode

selector.

in

the

center

for

line.

If

on

the

the

turned

This

is

to

path-

and

it

in

the

are

the

in

a

cuvette

absor-

of

the

10.SET

11.

12.

100%T,

100%T

/zero A control

lower

control

100%T,

000A

ITY

switch

position.

to

Any

acceptable.

adjustment

reset

the

100%T

reset

the

SENSITIVITY

Remove

Fill

solution

under

each

the

the

of

or

sample

heading

000A,

or

(The

for

blank.

the

using.

Absorbance

13.

Turn

tance

turn,

cording

most

linear

conveniently

14.

Construct a standard

on

solution

15.

Determine

the

and

the

16.

Correct

or

Transmittance

MODE

and

into

SELECTOR

insert

the

absorbance

analytical

than

transmittance

utilized.)

the

y-axis

on

the

the

absorbance

reading

the

x-axis.

for

any

necessary.

Concentration

standard

13.

Turn

standard

14.

Using

tion

value

with

other

CONC.

check

15.

Insert

results

16.

The

decimal

or O decimal

operates

trolled

of

the

Each

point

moves

the

zero

disappears).

turns

If

is

in

the

effect.

concentration

mal

setting

turned

to

the

Mode

curve

has

MODE

solution

the

CONC.

of

the

standard

FACTOR

and

record

samples

directly

select

places

in

the

by

the

digital

time

one

decimal

Pressing

the

decimal

the

pushbutton

transmittance

When

will

off,

turning

zero

decimal

or

000C

located

panel.

If

there

000C

on

the

the M (medium)

position

at

which

SENSITIVITY

the

100%T

/zero A control

switch.

matched

to

cuvettes

be

measured.

appropriate

to

each

sample

sample

purposes

compartment,

or

transmittance

absorbance

curve

vs.

the

concentration

x-axis.

concentration

or

transmittance

corresponding

sample

SELECTOR

blank

(use

be

verified).

in

the

ADJUST

standard

only

to

sample

on

solutions

CHECK

in

in

button

test

conditions

the

sample

concentration

feature

on

the

concentration

DECIMAL

SELECT

display:

the

pushbutton

place

to

the

place

is

reached

the

pushbutton

point

to

is

pressed

or

absorbance

the

instrument

mode,

the

still

be

it

back

previous

in

on

position

for

the

blank using

on

the

left

side

is

not

enough

blank,

move

or,

if

necessary,

100%T

switch

/zero A control.)

each

energy

the

can

is a coarse

time

with

the

SENSITIV-

Be

Proceed

to

the

mode

Mode

absorbance

or

standard

or

solution,

reading

values.

values

values

by

and

plotting

the

of

of

each

sample

value

concentration

or

interference

if

the

linearity

can

absorbance

each

by

on

the

concentration.

compartment.

control,

the

set

the

digital

display.

for

verification.

can

be

depressed

(see

Appendix

concentra-

compartment

units.

permits

digital-display.

selection

mode

only

The

and

pushbutton

is

right

the

pressed,

on

third

while

the

(the

decimal

once

place.

the

the

display

instrument

mode,

is

switched

effect.

resets

(no

point

concentration

If

back

the

instrument

the

decimal

visible).

the

of

the

to

set

to

the

HI

be

set

is

sure

to

that

you

standard

to

step

13

you

are

transmit-

in

the

re-

(For

are

more

be

more

standard

finding

y-axis

value

off

effects

of

the

Place

as

a

Repeat

The

to

A).

and

read

of

3,

2,

1,

feature

is

con-

at

the

left

decimal

until

point

more

re-

it

has

no

to

the

deci-

is

point

Page 3

yor

WAVELENGTH

The

UVD

Figure

tungsten

length

READOUT

The

modes:

three-position

control

For

digit

for

concentration

provides a readout

concentration

ACCESSORIES

The

1.

2.

3.

4.

5.

6.

7.

8.

SPECIFICATIONS

Wavelength

Wavelength

Wavelength

3,

range

digital

transmittance,

let

values

position

overrange.

The

instrument

Universal

Spare

One

dozen

Operator's

Dust

cover

Calibration

Occluder

Adapter

RANGE

model

has

and

concentration

tungsten

of

an

external

deuterium

of

200-1000nm.

display

SENSITIVITY

you

select

outside

will

units. A CONC.

mode.

SUPPLIED

is

test

tube

10mm

manual

screwdriver

block

for

rectangular

Range

Accuracy

Readability

SPECTRONIC

the

SPECTRONIC

lamp

house,

lamps which

lets

you

read

absorbance,

switch

the

desired

the

photometric

display a “u”

mode

of

the

concentration

supplied

lamp

pathlength

complete

holder

cuvettes

200-1000nm

Better

365nm,

Better

21

containing

in

any

of

or

and

instrument

range,

for

underrange

yields

FACTOR

test

tube

than

and

than

results

with:

21

UVD

series,

provide a wave-

concentration.

the

factor

2nm

three

operating

100%T

gain

the

directly

CHECK

when

cuvettes

at

546nm

1.0nm

shown

both

the

/zero

setting.

left-hand

or

an

“o”

button

in

the

254nm,

SPECTROPHOTOMETER

in

A

A

in

Spectral

Stray

Photometric

Photometric Range

Photometric

Photometric

Photometric

Long-term

Zero

Accessory

Monochromator

Dispersing

Power

Voltage

Size

Slitwidth

Radiant

Drift

Drift

in

Transmittance

Output

Element

Consumption

Requirements

Energy

Readout

Noise

Linearity

Accuracy

(T)

10nm

0.05%

(typical)

Digital

for

absorbance

concentration

A

(concentration

00.0-100.0

0.000-1.990

000-1990

Less

Better

0.4A)

Better

0.4A)

0.003A

Less

Analog

(adjustable),

Positive

Crossed

Reflection

lines

60

Selectable:

240V;

20°

(50.8cm x 26.7cm x 21.6cm).

Add

for

Sample

display,

transmittance

to C conversion

than

than

than

per

than

/mm

Watts

50,

Wx

54

General

at

340nm

selectable

(T),

(A),

or

(C),

and

factor

factor)

in

T

in

A

in

C

0.1

near

100%T

0.001

near

0.002

near

0.2%T

(0.002A

0.3%T

(0.003A

hour

0.1% per

in

%T, 1 Volt

True

Czerny-Turner

grating,

100V,

60

10%

(14cm)

Purpose

Compartment

BCD,

Logic

Hz

Dx

day

TTL

115V,

84

to

width

0.00A

1.00A

at

at

1200

220V,

Η

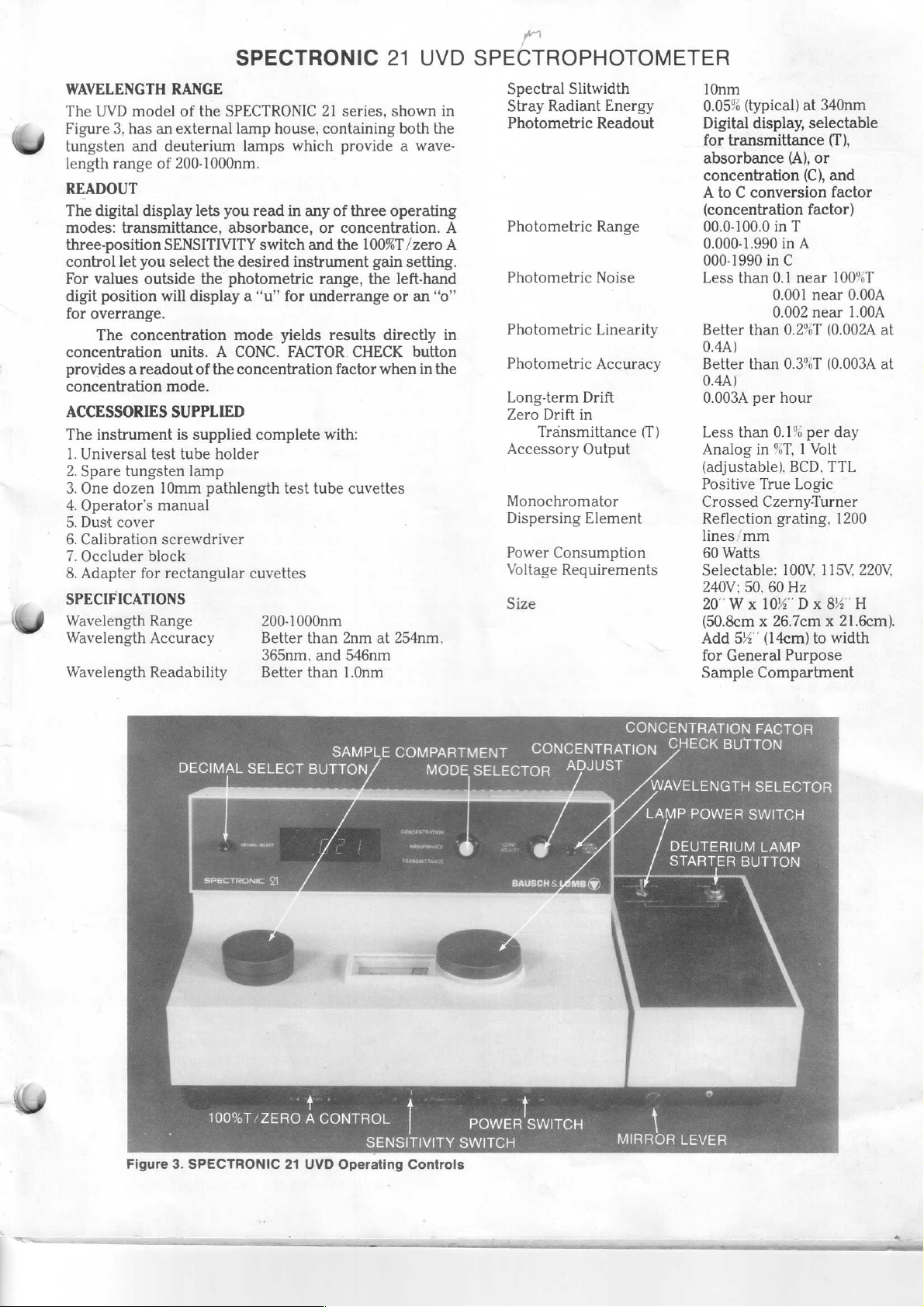

CONCENTRATION

SAMPLE

DECIMAL

Figure

3.

SPECTRONIC

SELECT

100%T/ZERO

BUTTON

+

A

21

UVD

CONTROL

Operating

COMPARTMENT

MODE

SENSITIVITY

Controls

SELECTOR

POWER

SWITCH

CONCENTRATION

ADJUST

WAVELENGTH

LAMP

>

У

SWITCH

—

7

MIRROR

CHECK

POWER

TERIUM

一

LEVER

FACTOR

BUTTON

SELECTOR

SWITCH

LAMP

一

Page 4

Se

™

Weight

OPERATING

—

”

Before

tion

this

Conversion

Operating

1.

Plug

2.

Turn

right

instrument

on,

of

3.

Select

selector.

the

set

4.

Adjust

pulling

lamp

the

5.

Choose

by

or

6.

Ignite

button

deuterium

minutes

stability

red

used.

blue

used.

alternate

which

when

7.Choose

length

length

ment

silica"

8.

Open

9.

Fill

sample

solution

through

provided

proper

is

compartment.

PROCEDURES

m

using

the

as

described

The

instrument

voltage

is

not

instructions

controls

the

instrument

the

instrument

side

of

can

best

performance

15

to

30

minutes.

the

desired

Wavelength

left

of

the

in

the

range

the

mirror

the

mirror

(UV)

and

tungsten

flipping

the

the

lamp

correct

DEUTERIUM-UV.

the

deuterium

for

approximately

lamp

before

takes

The

portion

line

indicates

The

portion

line

indicates

The

portion

red

provides

no

sample

matched

for

the

cuvettes

The

glass

are

usable

cuvettes

the

sample

one

cuvette

compartment.

to

completely

the

sample

with a horizontal

fill

level. A vertical

provided

for

22%

Ibs.

Add

3%

General

Compartment

instrument,

in

the

check

Maintenance

NOTE

is

set

to

operate

correct

are

the

be

for

in

the

shown

on,

lower

used

in

into a grounded

using

control

almost

is

achieved

wavelength

is

indicated

wavelength

selector.

200-1000nm.

position

lever

out

pushing

the

mirror

(VIS).

lamp

for

lamp

power

lamp

2seconds

requires a warm-up

readings

are

longer.

of

the

wavelength

that

the

of

the

wavelength

that

the

deuterium

of

the

wavelength

and

blue

marks

the

most

energy

is

in

place)

cuvettes

analytical

for

all

blanks,

method.

NOTE

test

tubes

supplied

only

above

must

be

used

compartment

with a blank

Fill

cover

compartment.

fiducial

fiducial

alignment

with

(10.2kg).

lbs.

(1.6kg)

Purpose

the

electronic

section.

on a 115

your

line,

see

Maintenance

Figure

the

3.

outlet.

POWER

panel.

as

soon

following a warm-up

with

the

on

the

dial

Wavelength

for

the

lamp

when

using

the

lever

in

the

selected

switch

by

tungsten

to

pushing

and

taken.

dial

dial

TUNGSTEN-VIS

releasing.

of

Maximum

marked

lamp

marked

lamp

dial

indicates

(gives

the

should

of

be

the

appropriate

Use

used.

the

standards,

with

325nm.

Quartz

below

325nm.

door.

solution and

the

cuvette

the

light

beam

Some

mark

mark

the

mark

on

for

Sample

calibra-

VAC

line.

the

Voltage

section.

switch

Although

as

it

on

is

turned

wavelength

located

may

required

deuterium

when

using

wavelength

the

STARTER

at

least

with

should

witha

should

marked

that

the

highest

same

path-

and

samples.

the

instru-

or

“fused

insert

it

in

with

enough

passing

cuvettes

to

indicate

on

the

cuvette

the

sample

If

the

the

to

be

by

The

10

lamp

a

be

be

with

lamp

%T

path-

the

are

the

a.

Solution

standard

adaptor).

b.

Solution

tube

10.

Close

11.

Select

bance,

12.

Setthe

lower

13.

Set

100%T

lower

100%T,

TIVITY

HI

position.

each

14.

Remove

15.Fill

each

solution

under

using.

Absorbance

16.

Turn

tance and

turn,

ing

absorbance

analytical

V

than

iently

17.

Construct a standard

on

the

solution

18.

Determine

its

absorbance

corresponding

19.

Correct

level

cuvette

the

sample

the

or

concentration—using

SENSITIVITY

control

100%T,

/zero A control

control

000A,

switch

time

that

the

of

or

sample

the

heading

or

MODE

insert

in

the

sample

values

transmittance

utilized.)

y-axis

on

the

for

any

necessary.

Concentration

the

standard

16.

Turn

standard

17.

Using

tion

this

CONC.

check

18.

Insert

results

19.

The

curve

MODE

solution

the

CONC.

value

of

step

with

FACTOR

and

samples

directly

decimal

record

or 0 decimal

operates

trolled

of

the

point

the

disappears).

by

digital

Each

moves

zero

in

the

time

decimal

NOTE

level

must

cuvette

(10

must

be

(used

with

compartment

operating

switch

panel

to

LO.

000A,

or

000C

located

panel.

If

there

or

000C

on

to

the M (medium)or,

Be

sure

to

reset

you

reset

blank.

the

matched

to

be

appropriate

Transmittance

SELECTOR

each

sample

compartment,

or

transmittance

absorbance

pui

values

Ex

curve

vs.

the

concentration

the

x-axis.

concentration

value

on

concentration

sample

mode

(to

has

blank

be

been

SELECTOR

in

the

ADJUST

the

standard

other

standards

CHECK

test

conditions

in

the

sample

in

concentration

select

feature

places

the

on

the

concentration

DECIMAL

display.

the

pushbutton

one

place

to

place

Pressing

the

be

at

least

20

mm

high

cm

square;

at

least

universal

used

32

mm

test

cover.

with

high

tube

mode—transmittance,

the

mode

selector.

located

for

is

the

the

the

SENSITIVITY

cuvettes

measured.

Mode

to

absorbance

and

by

of

the

used

in

the

the

blank

on

the

left

not

enough

blank,

move

if

necessary,

100%T

/zero A control

with

Proceed

to

the

mode

or

standard

reading

values.

values

plotting

y-axis

value

or

are

can

be

more

the

of

each

each

sample

and

off

interference

only

if

the

center

using

side

energy

the

switch.

the

to

or

solution,

and record-

(For

more

absorbance

by

reading

the

x-axis.

effects

linearity

verified).

to

concentration.

sample

on

button

compartment.

control,

the

digital

for

can

(see

set

verification.

be

Place

the

concentra-

display.

depressed

Appendix

compartment

units.

permits

digital

SELECT

the

is

reached

pushbutton

selection

display.

mode

pushbutton

is

pressed,

right

on

(the

The

only

the

the

display

decimal

once

and

at

in

a

cuvette

in a test

holder).

absor-

of

the

the

of

the

to

set

SENSI-

to

the

standard

step

16

you

are

transmit-

in

most

linear

conven-

standard

finding

the

as

of

the

Repeat

The

to

A).

and

read

of

3,

2,

1,

feature

is

con-

the

left

decimal

until

point

more

re-

Page 5

turns

the

If

is

in

the

effect.

decimal

the

pushbutton

point

transmittance

When

the

instrument

to

the

is

pressed

or

absorbance

is

third

place.

while

switched

the

instrument

mode,

back

it

has

to

no

the

concentration

mal

setting

turned

to

the

off,

zero

will

turning

decimal

mode,

still

the

previous

be

in

it

back

on

position

effect.

resets

(no

point

concentration

If

the

instrument

the

decimal

visible).

deci-

is

point

e

SCOPE

This

should

nance,

formed

OF

section

be

trouble-shooting,

only

Instrument

Cannot

sample

OPERATOR

describes

performed

by

an

Problem

inoperative.

set

100%T

in

sample

MAINTENANCE

all

maintenance

by

the

or

authorized

(.000A)

holder.

with

operator.

repair

tasks

service

no

MAINTENANCE

procedures

All

other

mainte-

should

representative.

Table

Line

Dead

Internal

Defective

Light

Wrong

wavelength

model).

Wrong

Source

model).

Source

Defective

be

1.

Operator

cord

power

fuse

beam

source

line

lamp

lamp

not

electronic

electronic

that

per-

Troubleshooting

Possible

connected

outlet.

blown.

blocked.

lamp

being

used

voltage.

not

adjusted

defective

TROUBLESHOOTING

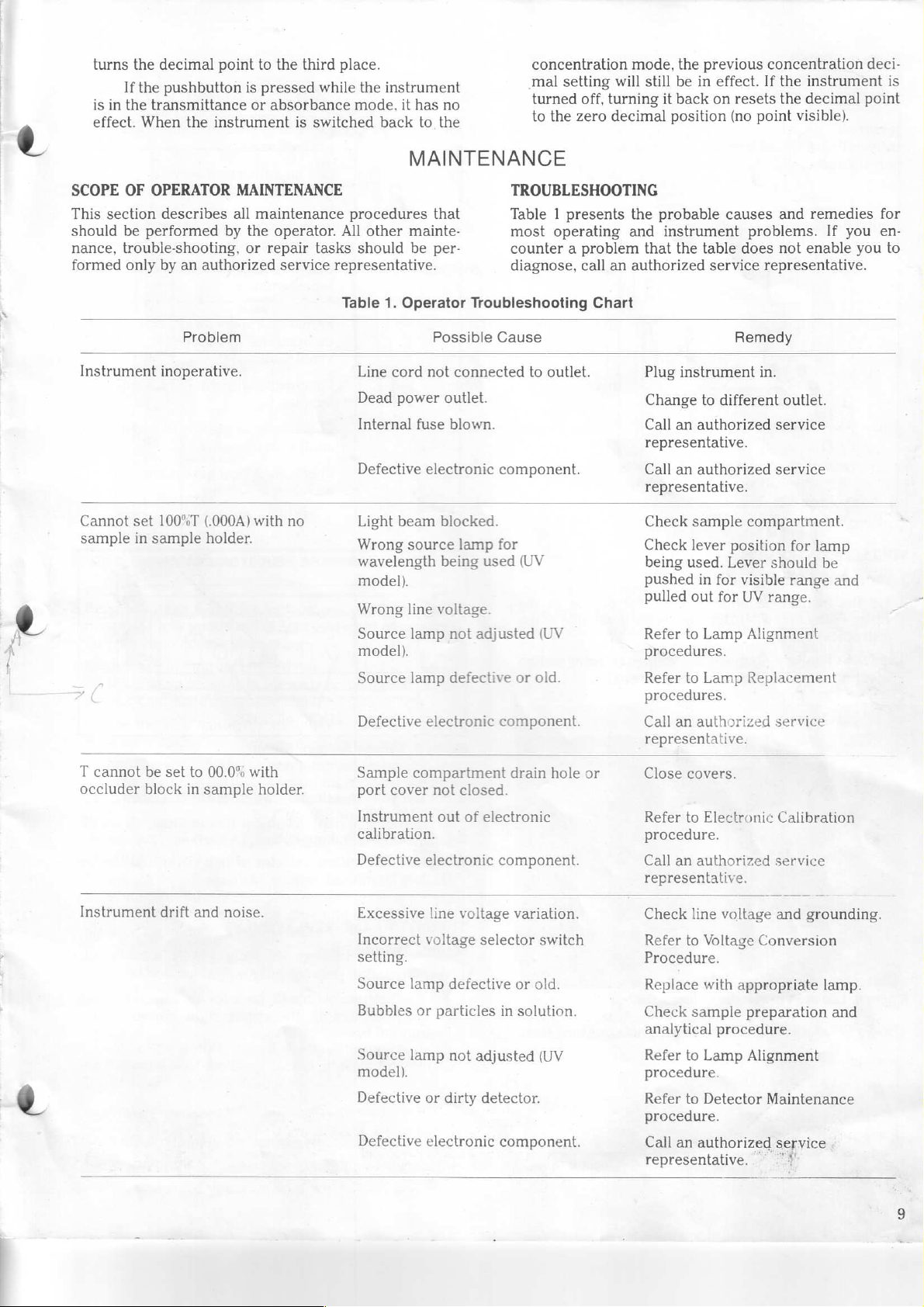

Table 1 presents

most

operating

counter a problem

diagnose,

Cause

to

component.

for

(UV

or

component.

call

Chart

outlet.

(UV

old.

the

probable

and

instrument

that

an

authorized

Plug

Change

Call

representative.

Call

representative.

Check

Check

being

pushed

pulled

Refer

procedures.

Refer

procedures.

Call

representative.

causes

the

table

service

Remedy

instrument

to

different

an

authorized

an

authorized

sample

lever

position

used.

Lever

in

for

out

for

to

Lamp

to

Lamp

an

authorized

and

remedies

problems.

does

not

enable

representative.

in.

outlet.

service

service

compartment.

for

lamp

should

visible

range

UV

range.

Alignment

Replacement

service

If

be

you

and

you

for

en-

to

T

cannot

occluder

Instrument

block

be

set

to

in

drift

00.0%

sample

and

with

holder.

noise.

Sample

port

Instrument

calibration.

Defective

Excessive

Incorrect

setting.

Source

Bubbles

Source

compartment

cover

not

electronic

line

voltage

lamp

or

lamp

model).

Defective

Defective

or

electronic

closed.

out

of

electronic

voltage

selector

defective

particles

not

adjusted

dirty

detector.

drain

hole

component.

variation.

switch

or

old.

in

solution.

(UV

component.

or

Close

covers.

Refer

to

Electronic

procedure.

Call

an

authorized

representative.

Check

Procedure.

Check

Refer

line

Refer

to

Voltage

Replace

analytical

Refer

procedure.

procedure.

Call

with

sample

to

Lamp

to

Detector

an

authorized

voltage

appropriate

preparation

procedure.

Alignment

representative.

Calibration

service

and

grounding.

Conversion

lamp.

Maintenance

service

‘7

and

Page 6

Table

1.

Incorrect

transmittance-to-absorbance

correlation.

Digital

regardless

Incorrect

(Con’t)

display

of

instrument

reading

does

Problem

not

obtained.

change

settings.

Instrument

calibration.

Defective

Instrument

Defective

Stray

Insufficient

Bubbles

Wrong

electronic

electronic

sample

or

wavelength

Possible

out

of

electronic

out

of

calibration.

preparation

sample

particles

setting.

Cause

component.

component.

vapors.

volume.

in

solution.

Remedy

Refer

to

Electronic

procedure.

Call

an

authorized

representative.

Refer

to

Electronic

procedure.

Call

an

authorized

representative.

Prepare

instruments;

ventilation.

Fill

volume.

Check

analytical

Check

wavelength

samples

cuvette

sample

analytical

use

with

procedure.

setting.

Calibration

service

Calibration

service

away

from

proper

greater

preparation

procedure

sample

C

«

and

and

VOLTAGE

1.

Turn

2.

Tilt

voltage

instrument

3.

Refer

cover

CONVERSION

off

and

the

instrument

selector

to

Figure

(mounted

VOLTAGE

unplug

switch,

base.

4.

with

SELECTOR

the

onto

located

Remove

two

SWITCH

instrument.

its

back

on

the

the

voltage

holding

screws).

COVER

for

access

underside

selector

to

the

of

the

switch

Figure

4.

Refer

4.

Location

to

Figure

of

Voltage

5.

Loosen

Selector

the

locking

Switch

nuts

one

turn

each.

ZA

=

LT

Figure

5.

5.

Set

the

(100,

115,

6.

Retighten

7.

Replace

the

two

TUNGSTEN

Models

1.

2.

MV

Turn

off

Tilt

the

housing,

instrument

VOLTAGE

Voltage

=

Selector

voltage

220,

or

the

locking

the

voltage

holding

LAMP

and

and

unplug

instrument

located

base.

DV

SELECTOR

su

001

o

N

\

LOCKING

selector

240

screws.

REPLACEMENT

onto

in

NUTS

Switch

switch

VAC).

nuts.

selector

the

instrument.

its

the

upper

000

Ove

DA

ya

ZÁ

switch

back

SWITCH

ZE

-

at

the

cover

for

access

right

ンク

desired

corner

and

to

the

voltage

tighten

lamp

of

the

10

(=>

Page 7

1.

PUSH

LAMP

MOUNT

2.

PRESS

LOCKING

|

REG

LAMP

DOWN

MOUNT

ON

TAB

INTO

SLOT

(©

IN

WHITE

@

SOCKET

{

Figure

6.

Exterior

3.

Refer

to

Figure

mount

Pull

4.

Grasp

its

lamp

5.

Check

necessary.

6.

Refer

housing

the

7.

Press

the

the

8.

To

inner

of

plate

9.

Insert

plate.

until

tab

the

lamp

the

edges

mount

the

to

Figure

and

socket

the

tab

until

walls

replace

surface

the

housing,

as far

the

Slide

the

(pry

access

lamp

are

aligned

out

new

Avoid

push

at

the

lamp

the

on

both

the

of

to

locking peg

the

peg

is

LAMP

of

Lamp

6.

Lift

gently

mount

through

lamp

touching

7.

Slide

the

rear

mount

front

sides.

access

the

access

and

the

right

peg

snug.

LAMP

ACCESS

MOUNT

Housing

the

with a screwdriver,

plate

tab

with

for

the

plated

of

tab

edge

plate,

press

into

down

TAB

locking

off.

and

the

slots

the

slots.

cleanliness

the

lamp

new

end

the

lamp

down,

of

the

hook

plate

the

plate

as

possible.

the

through

on

Model

peg

raise

in

lamp

of

the

housing.

then

mount

the tab

under

into

eye

on

the

PLATE

MV

out

of

if

the

lamp

the

base.

and

during

installation.

assembly

lamp

pull

is

tight

which

the

tab

place.

the

lamp

lamp

or

DV

the

lamp

necessary).

mount

wipe

mount

forward

at

Slide

mount

so

Pull

the

it

into the

into

on

against

is

on

the

the

top

the

access

tab

if

3.

PULL

IS

TIGHT

Figure

7.

Installation

front

of

lamp

housing

3.

Unscrew

the

tungsten

two

locating

mount

Do

to

not

KNURLED

OUT

the

and

remove

pull

ON

LAMP

AGAINST

of

lamp

housing

cover

remove

lamp

mount.

pins.

Grasp

the

on

the

wires.

THUMBSCREW

MOUNT

WALLS

Lamp

in

base

open.

the

knurled

Slide

the

old

lamp

CAUTION

TAB

ON

BOTH

Model MV

two

thumbscrew

the

lamp

socket

assembly.

LOCATING

LAMP

SO

or

full

and

PINS

MOUNT

SIDES

DV

turns.

Lift

securing

mount

pull

the

MOUNT

the

off

the

lamp

on

the

Model

1.

Turn

2.

Refer

When

the

plate

UVD

off

to

properly

outside

and

and

unplug

Figure

go

of

back

8.

NOTE

installed,

the

lamp

to

the

instrument.

Loosen

access

step

the

the

tip

plate.

5.

clamping

of

the

If

peg

is

not,

screw

visible

remove

on

the

Figure

8.

Tungsten

Mounting

in

SOCKET

Model

CLAMPING

UVD

SCREW

11

Page 8

4.

Check

sary.

5.

With

new

6.Slide

Replace

7.

Perform

this

8.

Close

screw.

the

new lamp

Avoid

touching

the

contact

lamp

into the

the

lamp

the

the

section.

the

lamp

PLATED

CONTACTS

aligned

socket.

mount

knurled

Tungsten

housing

for

cleanliness

the

lamp

during

as

shown

onto

the

thumbscrew.

Lamp

Alignment

cover

and

METAL

CONTACTS

and wipe

installation.

in

Figure

two

locating

procedure

tighten

the

if

neces-

9,

plus

pins.

clamping

the

in

bracket,

slot,

and

provided

8.

Replace

9.Place

10.Be

11.

LAMP

The

tometers

adjustment.

the

located

indicated

sure

Alignment

free

of

Close

the

screw.

ALIGNMENT

lamp

making

the

top

on

the

and

tighten

lamp

behind

on

the

the

lamp

procedure

dust

and

lamp

in

the

SPECTRONIC

is

self-aligning

sure

the

bottom

aligning

mounting

the

knurled

wires

over

the

mounting

label.

is

properly

in

this

fingerprints.

house

cover

(MODEL

post

plate.

plate,

section)

and

UVD

21

MV

and

aligning

is

through

thumbscrew.

the

spade

matching

aligned

and

tighten

ONLY)

and

DV

requires

post

is

in

the

hole

connectors

colors

(see

Lamp

completely

the

clamping

spectropho-

no

special

the

as

LAMP

COLLAR

DEUTERIUM

SØGE

lili

SOCKET

SKE

and

Socket

screw

full

turns

located

11).

in

Figure

the

adjusting

assembly.

on

in

the

and

10,

Figure

10.

Deuterium

Lamp

Mounting

Figure

9.

Model

DEUTERIUM

(MODEL

1.

2.Refer

3.

4.

Alignment

UVD

UVD

Turn

off

to

front

base

open

cover.

Pull the

behind

Unscrew

to

release

bracket

and

Figure

lamp

the

the

the

and

LAMP

ONLY)

unplug

of

the

wires

lamp

knurled

lamp

lift

out

LAMP

of

Tungsten

REPLACEMENT

the

instrument.

10.

Loosen

lamp house

off

the

mounting

thumbscrew,

mounting

the

lamp

MOUNT

Lamp

the

clamping

cover

spade

plate

plate

bracket

Mount

two

connectors

(see

Figure

shown

from

KNURLED

THUMBSCREW—

DEUTERIUM

LAMP

on

lamp

5.

Unscrew

assembly

6.

Place

plate

7.

Place

12

Do

the

not

lamp

or

the

and

the

touch

should

they

the

from

new

secure

lamp

the

will

be

lamp

the

lamp

with

mounting

CAUTION

lamp

be

removed

baked

collar

screws

mounting

assembly

the

lamp

envelope.

before

on.

to

plate.

on

collar

plate

against

Any

remove

the

fingerprints

ignition

the

lamp

mounting

screws.

the

adjusting

of

lamp

the

a

Figure

11.

Deuterium

Lamp

Spade

Connectors

Page 9

DEUTERIUM

HORIZONTAL

TUNGSTEN

VERTICAL

ADJUST

Figure

12.

Lamp

In a Model

be

done

when a lamp

also

be

checked

excess

adjustments.

Tungsten

1.

2.

3.

Turn

Set

Push

noise.

Lamp

the

the

the

range.

4,

Loosen

lamp

house

5.

Using

the

450nm.

6.

Set

the

7.

Close

the

8.

Rotate

transmittance

9.Using

the

the

adjusting

obtain a maximum

By

turning

vertically

out.

By

assembly

tance

readout.

10.

Repeat

imum

necessary

100%T

observable

11.

Close

transmittance

/zero A control

the

screw.

DEUTERIUM

VERTICAL

LAMP—

ADJUST

LAMP—

TUNGSTEN

HORIZONTAL

Alignment

UVM

ADJUST

LAMP—

ADJUST

or

LAMP—

UVD,

Adjustments

lamp

assembly

in

Refer

Alignment

instrument

lamp

power

mirror

the

clamping

cover

wavelength

mode

selector

sample

cases

lever

of

to

Figure

on.

switch

all

screw

two

full

selector,

to

TRANSMITTANCE.

compartment

100%T/zero A control

reading

eccentric

bracket,

the

to

obtain a maximum

turning

horizontally

left

and

right

during

transmittance

lamp

house

around

screws

adjust

transmittance

left

screw,

the

right

to

obtain a maximum

screw

value

this

(step

cover

aligment

is

replaced,

reduced

12

to

TUNGSTEN-VIS.

the

way

on

the

turns

and

set

covers.

to

50%T.

on

the

the

position

reading

move

transmittance

screw,

adjustments

is

obtained.

procedure

8)

to

reset a convenient,

reading.

and

tighten

must

always

and

should

lamp energy

for

location

in

for

the

visible

front

base

of

open

the

cover.

the

wavelength

set a convenient

tungsten

of

the

lamp

move

to

until a max-

the

the

lamp

as

follows:

assembly

the

transmit-

It

may

adjust

clamping

lamp

read-

lamp

or

of

the

to

to

be

the

Deuterium

There

ment.

should

remain

Use

deuterium

When

be

on.

Lamp

are

the

used

safety

lamp

result.

1.

Turn

the

instrument

2.

Set

the

lamp

3.

Ignite

the

button

4.

Set

5.

Loosen

lamp

6.

Using

240nm.

7.

Set

8.

Close

9.

Rotate

transmittance

10.

Using

adjusting

the

house

the

the

the

the

for

mirror

the

mode

the

obtain a maximum

Adjust

12.

By

turning

assembly

tance

readout.

lamp

assembly

transmittance

11.

Repeat

maximum

necessary

100%T

observable

12.

Close

upper

/zero A control

the

screw.

DETECTOR

Low

energy

indicate

1.

Turn

2.

Tilt

MAINTENANCE

or

the

need

off

and

the

instrument

bottom.

Alignment

WARNING

dangerous

lamp house

in

this

procedure

high

cover

voltages

WARNING

glasses.

during

power

deuterium

approximately

lever

clamping

cover

wavelength

selector

sample

100%T/zero A control

reading

eccentric

bracket,

the

screws

vertically

By

readout.

and

transmittance

during

transmittance

lamp

house

the

for

unplug

Do

not

operation.

on.

switch

to

lamp

the

to

by

two

UV

screw

two

full

turns

selector,

to

TRANSMITTANCE.

compartment

around

screws

adjust

the

transmittance

to

the

the

upper

to

obtain a maximum

turning

horizontally

lower

the

the

screw

value

procedure

(Step

reading.

cover

inability

cleaning

to

the

instrument.

onto

its

or

on

on

position

screw,

9) to

and

set

is

removed,

since

look

Eye

within

this

utmost

the

power

directly

damage

DEUTERIUM-UV.

depressing

seconds.

position.

the

and

set

the

cover.

to

50%T.

the

position

value

lower

to

obtain a maximum

the

front

base

open

cover.

wavelength

set a convenient

deuterium

of

the

as

follows:

shown

move

screw,

in

the

transmit-

move

adjustments

is

obtained.

to

It

adjust

reset a convenient,

tighten

100%T

replacing

back

for

the

clamping

or

zero A may

the

detector.

access

equip-

care

must

at

the

may

starter

of

the

lamp

lamp

Figure

lamp

the

until

may

the

to

the

to

to

a

be

13

Page 10

On

digital

DETECTOR

ACCESS

PLATE

following

the

meter

can

and

models

calibration

model

should

(MV)

be

used.

(DV

or

UVD)

procedures

only

the

0%T Calibration

perform

in

the

order

all

three

given.

procedure

of

the

On

Absorbance-to-Transmittance

(Digital

1.

2.Turn

Figure

13.

3.

Remove

by

removing

left.

4.Grasp

through

directly

board

components.

5.

Inspect

necessary,

been

dipped

6.

Insert

grasping

the

aligning

silicon

the

white

tors

located

7.

Replace

holding

Location

the

the

the

below

on

the

the

the

the

detector

plastic

the

screw.

of

detector

the

holding

detector

aligning

the

socket

very

edge

silicon chip

clean

gently

in

methyl

cleaned

detector

mounting

slot

(as

faces

terminal

in

the

instrument.

detector

Detector

access

screw

mounting

slots.

and

to

avoid

for

with a cotton

alcohol.

board

shown

toward

properly

access

Access

plate

(shown

and

lifting

board

If

pliers

only

contact

damaging

dirt

and

or

insert a new

and

inserting

in

Figure

the

light

engages

plate

and

Plate

in

the tab

and

pull

are

used,

the

metal

fingerprints.

swab

which

detector

14).

Be

source

the

secure

Figure

on

the

it

out

pull

mounting

runs

has

it

through

sure

the

and

that

connec-

with

the

13)

or

If

by

Models

Set

the

the

mode

100%T/zero

display

of

the

screwdriver

the

spectrophotometer

calibration

display

Only)

wavelength

selector

A

to

read

39.9.

SENSITIVITY

the

mode

to

pry

adjustment

reads

.399.

dial

to

control,

(If

switch.)

selector

off

the

*

Calibration

to

approximately

TRANSMITTANCE.

set

the

spectrophotometer

necessary,

to

small

control

(shown

change

ABSORBANCE.

access

panel.

in

Figure

340nm.

With

the

plate on

Turn

15)

until

Set

the

setting

Use

a

top

of

the

A

the

Figure

ELECTRONIC

The

does

be

performed

necessary.

.

is

adequate

and

14.

Detector

spectrophotometer

not

require

In

the

following

Before

let

it

warm

Replacement

CALIBRATION

periodic

only

when

for

most

calibrating,

up

for

has

been

calibration.

results

procedures,

applications.

turn

the

at

least

30

factory-calibrated

Calibration

lead

you

to

believe

an

accuracy

spectrophotometer

minutes.

of

+1

and

should

it

is

digit

on

ari.

Figure

15.

Calibration

3.

Switch

should

4.

If

necessary,

reading

disagreement

sorbance

most

a.

In

step

absorbance

calibration

reading

b.Reset

step

c.

Continue

reached

5.

Turn

the

100.0

6.

Turn

the

the

readout.

Location

Adjustments

back

still

read

in

step 3 is

readings,

rapidly

2,

note

difference

the

1.

to

as

mode

with

the

mode

of

Absorbance-to-Transmittance

to

the

transmittance

39.9.

repeat

steps 1 through 3 until the

obtained.

between

the

bring

the

the

amount

and

transmittance

adjustment

by

correct

repeat

in

steps a and b until

step

3.

selector

100%T

/zero A control.

selector

readings

half.

transmittance

to

to

If

the

transmittance

following

of

difference

to

reduce

TRANSMITTANCE

ABSORBANCE

mode.

there

is

procedure

into

agreement.

readings.

the

reading

The

display

correct

substantial

and

between

Turn

the

absorbance

as

agreement

and

and

observe

ab-

will

the

A

in

is

set

14

Page 11

7.

Turn

the

15)

until

(u)

was

clockwise

8.

Repeat

and

100%T = .000A,

9.Turn

SENSITIVITY

10.

With

the

ance

beyond

wavelength

detected

readout.

11.

Switch

calibration

display

01.0

while

correct

0%T

Calibration

1.

Set

the

mode

the

100%T

2.

Install

cover.

3.

Turn

the

16)

until

4.

Remove

A/T

calibration

the

display reads

displayed

steps 1 through 7 to

the

mode

100%T

readout

1.990

energy

back

reads

setting

wavelength

/zero A control,

the

occluder

0%T

the

the

in

step

to

obtain

dial

to

adjustment

you

selector

calibration

display

occluder.

the

then

selector

switch

and

to

/zero A control,

to

overrange

equals

lower

and

the

transmittance

01.0.

(The

turn

the

is

the

(All

Models)

dial

to

in

reads

thus

midpoint

to

set

the

adjustment

.000.

6,

turn

.000

readout.

ensure

proceed

to

ABSORBANCE.

LO.

Observe

.000

2.000A).

than

340nm

increase

(shown

display

adjustment

450nm.

TRANSMITTANCE.

the

display

sample

adjustment

exactly

(shown

If

the

underrange

the

calibration

that

39.9%T = .399A

with

the

increase

(which

If

necessary,

to

the

mode.

in

Figure

will

continue

about % turn.

of

this

range.)

On

digital

to

well

(shown

00.0.

in

control

step

9.

Set

display.

the

absorb-

occurs

turn

decrease

absorbance

Turn

the

15)

until

to

models,

With

read

100.0.

and

close

in

Figure

sign

the

just

the

the

ZERO

the

read

The

set

the

the

Figure

2.While

locate

behind

screwdriver,

pressing

the

exactly

the

CONC.

concentration-factor-check

the

third

vent

turn

the

.100.

slot

screw

FACTOR

shown

until

CHECK

calibration

in

Figure

the

display

button,

screw

17.

With

a

reads

Concentration-Factor-Check

(Digital

1.

Set

the

Models

the

mode

CONC.

Only)

selector

FACTOR

to

CHECK

WARNING

This

inside

Within

the

adjustment

procedure

the

instrument

the

chassis.

involves a screwdriver

chassis.

Do

not

screw.

τὰ

Calibration

ABSORBANCE.

button.

High

insert

the

Press

and

adjustment

voltages

screwdriver

are

fl

“fi

hold

present

beyond

ーー

Figure

17.

Location

Calibration

Adjustment

of

Concentration-Factor-Check

SN

a

fe

~

<P

a

€

Page 12

ACCESSORIES

READOUT

Bausch & Lomb

115V,

220V,

Provides a permanent

obtained

ing a changing

patch

Houston

A;onC:

Digital-to-Analog

For use

Provides

tration

SAMPLE-HANDLING

Liquicell,

An

aqueous

or

DV

can

length

such

General

Cat. No.

For

use

system

(Cat.

UVD

requires

DEVICES

10”

Cat.

No.

39-11-20;

Cat.

No.

39-11-30

during

Strip

cord

Log-linear

Instrument

with

modes.

spectrophotometer.

be

adjusted

is

as

found

Purpose

33-22-44

outside

and

No.

33-22-42)

(Cat.

the

value

Chart

to

connect

model

linear

Cat.

liquid

3mm

for

in

multiple

No.

33-22-43)

Cat.

sample

as

Recorder

recorders

Co.

Converter,

DV

analog

ACCESSORIES

No.

33-22-70

sampling

within

analysis

the

soft

Sample

the

main

sample

and

No.

33-22-29

Strip

Chart

record

analysis.

in

time-rate

requires

the

recorder

NOTE

such

will

permit

or

UVD

output

system

Standard

the

range

of

drink

Compartment,

instrument;

holder.

DV

(Cat.

model,

Recorder,

of

photometric

Also

enzyme

the

to

as

those

direct

Cat.

No.

and

strip

in

absorbance

for

sample

of

high

absorbance

industry.

For

No.

33-22-41).

the

sample

optical

rail

useful

for

procedures.

Cat.

No.

the

instrument.

available

recording

33-22-46

chart

and

use

with

volume

3-25ml.

comes

use

with

For

compartment

assembly.

values

monitor-

39-20-11

from

in

T,

recorder.

concen-

model

MV

of

5ml

Cell

path-

samples,

with

lens

the

MV

use with

For

Use

with

General

SEMI-MICRO/FLOW-THRU

CAT.

NO.

33-22-33

Required

flow-thru

THERMO-REGULATED

CAT.

Water-jacketed

thermo-block

perature

being

environment.

For

CUVETTE

Required

SAMPLE

For

SPACER,

For

SPACER,

For

Replacement

Cat.

Selected,

SPECTRONIC*

SPECTRONIC

performance

ratory

loading a cuvette

radiant

cal

certified

ever

for

cuvettes

NO.

33-20-14

between 5 and

made

on

Use

with

ADAPTER,

for

COMPARTMENT

test

tubes

CAT.

use

with

2mm

CAT.

use

with

5mm

No.

33-17-75

10mm

quality

energy,

alignment.

by

Bausch & Lomb

applicable.

using

45

to

multiple

maintains

sample

Main

Instrument

short

cuvettes,

or

cuvettes

NO.

33-17-98

pathlength

NO.

33-17-97

pathlength

Test

Tube

pathlength,

STANDARDS,

standards

quickly,

control

to

check

photometric

The

standards

CAT.

Purpose

10mm

48mm

CUVETTE

sample

10mm

55C

requiring a temperature-controlled

COVER,

up

Cuvettes

let

accurately,

program.

0%T,

Sample

CUVETTE

pathlength

tall.

HOLDER,

holder

square

while

Sample

NO.

33-22-08

45

to

to

102mm

cuvettes,

cuvettes,

optical

CAT.

you

check

as

They

wavelength

accuracy

are

individually

and

traceable

Compartment

HOLDER,

semi-micro

with

three-position

cuvettes

measurements

Compartment

48mm

CAT.

tall.

NO.

33-22-07

tall.

45mm

45mm

glass,

NO.

33-31-50

spectrophotometer

part

make

/linearity,

tall.

tall.

box

of

of

normal

it

as

accuracy,

tested

to

NBS

at

12.

easy

and

or

tem-

are

labo-

as

stray

opti-

and

wher-

16

Page 13

APPENDIX

A

TRANSMITTANCE

All

SPECTRONIC

relative

transmittance.

calibration,

Furthermore,

with

the

to

unknown

logarithmic

on

standard

drawn

known

concentration

transmittance

amount

stray

greater

transmittance

set

A

the

sensitivity

100%T,

samples

standard

paper

logarithmic

solutions

through

samples

ABSORBANCE

Usually,

direct

abc.

absorbance

conversion

in

known

is

the

correlation

Results

tables

absorbance

standards

drawn

through

operator

in

values

curve.

The

concentration

mined

tion

unknown.

instrument

to

values

ator

values

sion

ance

and

in

concentration

and

standard

studies and

by

locating

value

which

To

eliminate T to A calculations,

provides

absorbance:

Model

may

The

the

absorbance.

Absorbance

MV

corresponding

simply

to

construct a standard

digital

of

transmittance

mode

is

used,

results

pathlength

curve

for

MODE

21

of

light

The

radiant

very

low

mode

and

the

are

curve

by

axis

on

these

may

value

of

the

MODE

to

percent

by

or

may

be

on

rectilinear

these

on

corresponds

has

an

read

models

the

for

standards

Results

by

Beer’s

are

as

described

measurements

reaction

CHOOSING

spectrophotometers

transmitted,

transmittance

energy

concentrations

in

the

is

used,

results

obtained

may

plotting

vs.

the

the

linear

points.

then

be

which

unknown

by

conversion

corresponds

desires

concentration

transmittance

use

of

the

formula A =

plotted

points

of

unknowns

the

standard

absorbance

to

percent

the

absorbance

offer

to

absorbance.

reference

and

in

absorbance

Law, A =

known,

systems

mode

tests,

transmittance

the

reagent

for

standard

as

percent

be

constructed

the

percent

concentration

axis.

The

concentration

determined

on

the

results

by

can

transmittance-absorbance

against

the

graph

to

construct a standard

curve

to

the

of

transmittance

scale

transmittance.

scale

curve

as

precise

blank

unknowns

abc,

or

by

above.

are

which

measure

yielding

and

can

results

is

useful

filter

be

measured

mode.

blank

solutions

transmittance.

on

transmittance

of

The

best

by

locating

to

the

standard

in

Beer’s

paper.

can

absorbance

each

described

electronic

When

is

used

may

if

construction

useful

do

curves.

absorbance

Law, A =

be

converted

-logyT.

concentration

The

best

then

be

the

concentra-

model

marked

The

and

use

the

to

set

are

obtained

be

related

the

absorptivity

for

not

obey

A

the

in

for

studies.

When

is

used

and

semi-

known

line

is

of

un-

the

percent

for

to

Results

of

line

deter-

of

the

of

the

values

with

oper-

these

above.

conver-

absorb-

.000A,

to

of

a

kinetic

Beer’s

READOUT

Law

and

MODE

therefore

CONCENTRATION

The

digital

tometer

tion

mode,

ing a standard

converts

multiplying

standard

can

be

been

conditions

interest,

Furthermore,

the

standard

increases

When

instrument

blank,

alone,

introduce

concentration, c =

It

because

the

concentration

display

Operating

models

offer a more

which

results

the

curve

used

only

verified

include

cuvette

curve

with

using

in

the

set

000C.

should

the

is

not

actually

this

factor

to

read

Instructions

curve.

in

absorbance

(1/ab).

if

for

pathlength,

the

concentration

concentration).

the

absorbance

(A

be

used.)

1/ab

the

CONCENTRATION-FACTOR-CHECK

To

verify

that

operating

reagent batches

tion-factor-check

tion

mode

the

CONC.

factor.

standard

new

press

factor

of

conditions.

used

choose,

then

FACTOR

may

instrument.

given

reagent

the

on

A

change

the

standard

to

switch

be

FACTOR

solutions

the

set

however,

CHECK

used

or

has

been

on

batch

CONC.

digital

in

the

It is

recommended

the

concentration

to

the

button

to

Standards

feature

have

non-linear

MODE

of

the

SPECTRONIC

convenient

eliminates

absorbance

the

the

wavelength,

has a positive

concentration

true

factor

l/abx

the

The

value

Note

that

linearity

test

conditions

mode

reagent

Using

which

A.

NOTE

necessary

is

introduced

adjust

control

concentration

for

detailed

conditions

from

day

as

follows:

set

up

with

CHECK

the

are

FACTOR

curve

to

concentration

button

digital

used

for

or

when

setting

CHECK

display.

factor

indicates a change

due

set the

pressed,

set

the

pre-recorded

should

standard

21

readout,

necessity

instrument

to

concentration

the

of

the

concentration

and

analytical

mode

slope

and,

blank,

known

converts

to

know

into

is

used

of

the

by

the

concentration

standard

used.

can

be

(i.e.,

mode,

using

not

standard

absorbance

the 1 ab

the

instrument

to

the

standard.

instructions.)

FEATURE

do

not

to

day,

use

the

After

the

standard

and

display.

the

to

variation

that a standard

mode.

blank

mode.