Operating Instructions

Language English

Translation

Document-No. 5.08009.05

Part No. 422585

Status 11.03.2015

E

5.08009.05

b maXX

Safety I/O Terminals

SI4000 / SO4000

Read the Operating Instructions before beginning

®

Systems

Baumüller Nürnberg GmbH

Ostendstr. 80 - 90

90482 Nürnberg

Germany

Tel. +49 9 11 5432 - 0

Fax: +49 9 11 54 32 - 1 30

E-Mail: mail@baumueller.de

Internet: www.baumueller.de

Table of Contents

1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Information on the Operation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Preliminary information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.6 Further applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7 Replacement parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9 Warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.10 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.11 Terms used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.12 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.12.1 Approvals, directives and standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Use of this handbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Contents of the Operation Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Alterations and rebuilding of the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Operator responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6 Personnel training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.7 Personnel protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.8 Special dangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.9 Firefighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.10 Electric safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.10.1 Notice on power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.11 Safety equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.12 Conduct in the event of danger and accidents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.13 Signage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Functional Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Safety-related parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Lifetime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Using of the terminals with b maXX safe PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Description of the Safety I/O Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1.1 SI4000 4-channel safety digital input terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1.2 SO4000 4-channel safety digital output terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.1 SI4000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.2 SO4000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 Assembly and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operating Instructions Safety I/O Terminals SI4000 / SO4000

Dokument-Nr.: 5.08009.05

3

of 82

Inhaltsverzeichnis

6.2 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3 Installation of Bus Terminals on C mounting rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.1 Control cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.2 Mounting rail installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4 Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.1 Connections within a bus terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.2 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.3 Mechanical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.5 SI4000 pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.6 SO4000 pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.7 Address settings on the safety terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.1.8 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2 Diagnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2.1 Diagnostic LEDs SI4000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2.2 Diagnostic LEDs SO4000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4.2 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8 System validation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1 Function test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9 Dismantling, storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.1 Safety regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2 Requirements of the personnel carrying out work . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.3 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.4 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.5 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.6 Recommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix A - Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix B - Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

B.1 List of all accessory items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix C - Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C.1 Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C.2 Commissioning and validation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Appendix D - Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

D.1 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

D.2 Connection values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

D.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4

of 82

Appendix E - Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

E.1 What is an EC directive? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

E.2 What the CE symbol indicates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Operating Instructions Safety I/O Terminals SI4000 / SO4000

Dokument-Nr.: 5.08009.05 Baumüller Nürnberg GmbH

Inhaltsverzeichnis

E.3 Definition of the term Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

E.4 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Operating Instructions Safety I/O Terminals SI4000 / SO4000

Dokument-Nr.: 5.08009.05

5

of 82

6

of 82

Operating Instructions Safety I/O Terminals SI4000 / SO4000

Dokument-Nr.: 5.08009.05 Baumüller Nürnberg GmbH

1.1 Information on the Operation Manual

This Operation Manual provides important information on handling the device. Compliance with all safety instructions operation instructions specified is a prerequisite for work

safety.

Furthermore, it is also necessary to comply with the local accident prevention legislation

and general safety regulations applying to the device’s field of application.

Read the Operation Manual completely, in particular the chapter on safety instructions,

before beginning any work on the device. The Operation Manual is a component of the

product and must be kept accessible to personnel in the immediate vicinity of the device

at all times.

1PREFACE

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

7

of 82

1.2

Legend

1.2 Legend

Warning notices

Warning notices are indicated by symbols in this Op

troduced by signal words which express the extent of the hazard.

Comply with the notices under all circumstances an

accidents, personal injury and property damage.

DANGER!

eration Manual. The notices are in-

d act with caution in order to avoid

....notifies of an imminent dangerous

juries if not avoided.

WARNING!

....notifies of a potentially dangerous situation which can lead to death or serious in-

juries if not avoided.

CAUTION!

....notifies of a potentially dangerous situation which can lead to minor or slight inju-

ries if not avoided.

NOTE!

....notifies of a potentially dangerous situation which can lead to property damage if

not avoided.

situation which will lead to death or serious in-

Recommendations

8

of 82

NOTICE!

....draws attention to useful tips and recommendations as well as information for effi-

cient and trouble-free operation.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

1.3 Limitation of liability

All statements and instructions in this Operation Manual have been compiled in compliance with the applicable standards and legislation w

nology and our long-term experience an

The manufacturer assumes

m failure to observe the Operation Manual

m application for purposes other than those intended

m use by untrained personnel

hile taking the current level of tech-

d findings into account.

no liability for damages resulting from:

Preface

1

The actual scope of materials delivered may v

described here in cases involving custom designs or the use of additional ordering options, or as a result of the most recent changes in technology.

The user assumes the responsibility

accordance with the safety regulations of the applicable standards and all other relevant

national or regional legislation relating to conductor dimensioning and protection, grounding, circuit breakers, ove

The person who conducted the assembly or installation shall be accountable for damages

ring during assembly or connection.

occur

1.4 Preliminary information

CAUTION!

The following shall apply if the document you are reading is designated as preliminary

information:

This version pertains to preliminary technic

scribed devices and functions should receive ahead of time, in order to be able to adjust to potential changes and/or

This information is to be considered preliminary since it has not yet been subjected

the Baumüller internal review process. In particular, this information is still subject

to

to changes, meaning that this preliminary information cannot be construed as legally

binding. Baumüller assumes no liability for damages resulting from this potentially incorrect or incomplete version.

Should you detect or suspect content-related and/or serious formal errors in this preliminary information, please contact the contact person assigned to you and inform

us of your

tially incorporated during the transition from

(reviewed by Baumüller) information. The obligations specified in the following section under “Obligations” do not apply to preliminary information.

findings and comments, so that they can be taken into account and poten-

ary from the explanations and illustrations

of conducting maintenance and commissioning in

rvoltage protection, etc.

al information which the user of the de-

functional expansions.

the preliminary information to the final

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

9

of 82

1.5

Copyright

1.5 Copyright

Treat the Operation Manual as confidential. It is intended exclusively for those working

with the device. It is not permissible to transfer the Operation Manual to third parties without the written approval of the manufacturer.

NOTICE!

The content-related statements, texts, diagrams, images and

copyright protected and subject to industrial property rights. Any improper use is liable to prosecution.

b maXX

®

is a registered trademark of Baumüller Nürnberg GmbH

1.6 Further applicable documents

Components from other manufacturers are built into the device. Hazard evaluations for

these bought-in parts have been conducted by the applicable manufacturers. The conformity of the designs with the applicable Eur

clared by the respective comp

1.7 Replacement parts

WARNING!

Improper or defective replacement parts can

failure as well as jeopardize safety.

Therefore:

m Only use original replacement parts from the manufacturer

other illustrations are

opean and national legislation has been de-

onent manufacturers.

lead to damage, malfunctions or total

1.8 Disposal

10

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

Procure replacement parts from authorized dealers or directly from the manufacturer.

See also ZAppendix

If no return or disposal agreement has been made, dismantled components can be taken

for recycling after proper disassembly.

See also ZDisposal – o

B - Accessories– from page 65 onward.

n page 62.

1.9 Warranty conditions

The warranty conditions can be found as a separate document in the sales documentation.

The operation of the devices described here in accordance with the specified methods/

procedures/requirements is permissible. Everything else, even the operation of devices

in installation positions not depicted here, for instance, is not permissible and must be

clarified with the factor on a case-by-case basis. The warranty will be rendered null and

void if the devices are operated differently than described here.

1.10 Customer service

Our customer service is available for technical support.

Information on the contact person responsible can be found at any time via telephone,

fax, E-mail or over the internet (www.baumueller.de).

1.11 Terms used

Preface

1

1.12 Certification

The terms “SI4000” (for input terminal) or “SO4000” (for output terminal) are also used for

the product “Safety I/O Terminals.”

A list of the abbreviations used can be found in ZAppendix A - Abbreviations– from page

63 onward.

The safety I/O Terminals are a component part of a system composed of b maXX safe

PLC, power supply and other system modules.

The safety I/O Terminals have been developed in accordance with the standards specified in ZChapter 1.12.1– and certified by TÜV Süd.

SI4000:

Approval no. Z10 15 03 75013 001

Test report: BV82168T

SO4000:

Approval no. Z10 15 03 75013 003

Test report: BV82168T

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

11

of 82

1.12

1.12.1 Approvals, directives and standards

Certification

Safety engineering standards and directives

EN 61508, Parts 1-3 Functional safety of security-

DIN EN ISO 13849-1 Safety-related components of

Additional standards Area of application

2006/42/EC machinery directive

DIN EN 81-1 to the extent to which

EN 13243 to the extent to which

DIN EN 61000-6-2

DIN EN 61000-6-4

Area of application Approvals

up to SIL 3

related electric, electronic and

programmable electronic systems

up to performance

control units

e (category 4)

level

they may be applica-

ble

they may be applica-

ble

12

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

2USE OF THIS HANDBOOK

This safety handbook contains information on the intended use of the Baumüller safety

I/O terminals.

Knowledge of regulations and proper technical implementation of the safety instructions

in this handbook by qualified personnel are prerequisites for the safe installation, commis

sioning and safety during the operation and maintenance of the Baumüller safety I/O terminals. Unqualified interventions in the devices, during shutdown or use of the safety

functions or failure to comply with the instructions of this handbook can lead to serious

personal injury, property damage or environmental harm, for which Baumüller assumes

no liability.

Baumüller control devices are developed, manufactured and tested in compliance with

the applicable safety standards. They may only be used under the specified environmen

tal conductions and only in connection with approved external devices.

The Operation Manual contains safety instructions, descriptions of the interfaces and information on the phases of the product’s life cycle:

n Installation/Assembly

n Commissioning

n Operation

n Troubleshooting

n Maintenance/repair

n Disassembly

-

-

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

13

of 82

14

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

This section provides an overview of all important safety aspects for the optimum protection of the personnel as well as for safe and trouble-free operation.

3.1 Contents of the Operation Manual

All persons assigned to work on or with the device must have read and understood that

Operation Manual before beginning work with the device. This also applies if the person

concerned has already worked with such a device or similar device or has been trained

by the manufacturer.

3.2 Alterations and rebuilding of the device

In order to avoid hazards and ensure optimum performance, neither alterations, additions

nor rebuilding work may be conducted on the device unless explicitly authorized by the

manufacturer.

3SAFETY

3.3 Appropriate use

WARNING!

Caution - Risk of injury

Safety terminals may only be used for the purposes described below!

The safety terminals expand the application range of Baumüller bus terminals with functions that enable them to be used for machine safety applications. The safety terminals

e designed for machine safety functions and directly associated industrial automation

ar

tasks. They are therefore only approved for applications with a defined fail-safe state.This

safe state is the wattless state. Fail-safety according to the relevant standards is required.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

15

of 82

3.3

Appropriate use

The safety terminals enable connection of:

m 24 V

emergency stop push buttons, pu

switches, safety mats, light curtains, light barriers, laser scanners etc.

m 24 V

contactors, protection door switches with tumble

NOTICE!

Test pulses

When selecting actuators please ensure that the SO4000 test pulses do not lead to

tuator switching or diagnostic message from the SO4000. The test pulses of the

ac

SO4000 terminal outputs are not configurable and cannot be switched off.

sensors (SI4000) such as

DC

actuators (SO4000) such as

DC

ll cord switches, position switches, two-hand

r, signal lamps, servo drives etc.

The following modules were developed f

m The SI4000 terminal is an input module with digital inputs.

m The SO4000 terminal is an output module with digital outputs.

These modules are suitable for operation with

m Baumüller b maXX safe PLC

m Baumüller ECK000 series bus coupler

Your use of the device is considered to be comp

all instructions and information in this Operation Manual.

WARNING!

Follow the machinery directive

The safety terminals may only be used in machines according to the Machinery Directive.

WARNING!

Ensure traceability

The buyer has to ensure the traceability

or these tasks:

liant with its intended use if you have read

of the device via the serial number.

16

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

WARNING!

Danger due to use other than intended!

Safety

3

Any use of the device different from and/o

ed use can lead to dangerous situations.

Therefore:

m Only use the device as intended.

m Follow all specifications of this

m Ensure that exclusively qualified per

m Take care in project planning to see that the device i

ifications.

m The device and/or mounting rail is mounted on a w

m Ensure that the power supply meets the

m Only operate the device if it is in technically faultless condition.

m Only use the device in combination with co

berg GmbH.

3.4 Operator responsibility

The device is implemented in an industrial zone. The operator of the device is thus subject to the legal work safety obligations

In addition to the work safety in

prevention and environmental protection regulations applicable to the area of application

of this device must also be complied with. In doing so, the following applies in particular:

m The operator must inform himself of the applicab

tionally ascertain hazards arise through the special w

of the device in a risk assessment. The operator must implement this in the form of operation instructions for the operation of the device.

m This Operation Manual must be kept in the

cessible to persons working on and with the device at all times.

m The statements of the Operation Manual are to b

m The device may only be operated in technically fau

operation.

r exceeding beyond the scope of the intend-

Operation Manual.

sonnel work on or with this device.

s always used within its spec-

all which is sufficiently sturdy.

required specifications.

mponents approved by Baumüller Nürn-

.

structions in this Operation Manual, the safety, accident

le work safety regulations and addi-

ork conditions at the place of use

immediate vicinity of the device and be ac-

e followed completely and absolutely!

ltless condition and must be safe for

3.5 Protective equipment

Protection category

All SI4000 and SO4000 devices with the couple stations (b maXX safe PLC or bus coupler) must be built into a suitable electrical cabinet in order to comply with the protective

catego

ries (IP54) required in EN 60529.

SI4000 IP 20

SO4000 IP 20

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

17

of 82

3.6

Personnel training

DANGER!

Life-threatening danger through electric current!

Immediate life-threatening danger is present if

Therefore:

m Operate the device in an electrical cabinet which p

contact with the devices and meets at least the protective categories (IP54) of

EN 60529.

3.6 Personnel training

WARNING!

Risk of injury if operated by insufficiently qualified persons!

Improper handling can lead to severe personal injury and property damage.

contact with live parts is made.

rovides protection from direct

Therefore:

m Only allow certain activities to be conducted b

chapters of this Operation Manual.

The following qualifications for various areas o

Manual:

m Operating personnel

The drive system may only be operated by p

and authorized to do so.

Troubleshooting, repairs, cleaning, maintena

ed by trained or instructed pers

tion Manual and act according to it.

Commissioning and instruction may only b

m Qualified personnel

Electrical engineers and specialist electricians of

authorized by Baumüller Anlagen-Systemtechnik GmbH & Co. KG, trained and certified in the installation and commissioning of Baumüller drive systems and commissioning, grounding and designating electrical systems and devices in ac

safety engineering standards.

Qualified personnel is educated or trained in

ty equipment in accordance with the respective

onnel. These persons must be familiar with the Opera-

y persons specified in the respective

f operation are specified in the Operation

ersons who have been trained, instructed

nce and exchange may only be conduct-

e conducted by qualified personnel.

the customer or a third party who are

cordance with the

the maintenance and use of suitable safe-

local safety engineering standards.

18

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

3.7 Personnel protective equipment

Wearing the appropriate personal protective equipment when working is required in order

to minimize hazards to the health.

m Always wear the respective protective equipment r

working.

m Observe signs on personal safety in the work area!

Protective work clothes

denotes tight-fitting work clothing with low tea

truding parts. It primarily serves in protecting from...

Do not wear any rings and necklaces.

Protective helmet

for protection from falling and flying

parts.

Safety

equired for the respective task when

r resistance, tight sleeves and no pro-

3

To be worn during

ecial work

sp

Safety shoes

for protection from heavy

Safety gloves

to protect the hands from friction, abrasions, pr

as from contact with hot objects.

Protective glasses

to protect the eyes from flying parts and spraying liquids

falling parts.

ick wounds or deeper injuries as well

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

19

of 82

3.8

Special dangers

3.8 Special dangers

The residual risks arising as a result of the hazard analysis will be specified in the following section.

Observe the safety instructions described here

chapters in order to reduce health hazards and avoid dangerous situations.

Electric current

DANGER!

Live-threatening danger from electric current!

Immediate life-threatening danger is present

age to the insulation or individual comp

Therefore:

m Shut down immediately if the insulation on the power supply is damaged.

m Only allow the work to be co

nel.

m Turn the current off when conducting any work on the electrical system and secure

it befo

and the warning notices in the following

if contact with live parts is made. Dam-

onent can be life-threatening.

nducted on the electrical system by qualified person-

re turning it back on.

Dangers from residual energy

DANGER!

Live-threatening danger from electric current!

After the device has been disconnected from

nectors may only be touched once the cap

charged.

Therefore:

m Take the capacitors’ discharge time into account and do not touch live parts be-

forehand.

m Follow commensurate instructions on the device.

m If you have connected additional capacitors to the

take considerably longer for the intermediate circuit to discharge. In such case, you

will have to establish the necessary waiting period yourself or measure whether

the device has been de-energized.

the mains, live parts such as line con-

acitors in the device have been dis-

intermediate circuit, it can also

20

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

Moving parts

3.9 Firefighting

Safety

WARNING!

Risk of energy from moving parts!

Rotating and/or linear moving parts can cause severe injuries.

Therefore:

m Do not interfere with moving parts during operation.

m Do not open covers during operation.

m The mechanical residual energy depends on the applic

also keep rotating/moving for a certain time after the power supply has been shut

off. Make sure to provide suitable safety equipment.

ation. Powered parts will

3

DANGER!

Live-threatening danger from electric current!

Electric shock can occur if a conductive

Therefore:

m Use the following fire extinguishing medium:

ABC powder/CO2

fire extinguishing medium is used.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

21

of 82

3.10

Electric safety

3.10 Electric safety

The safety control is designed for contamination level 2 in accordance with EN 50178.

This means that only non-conductive contamination may appear during operating time.

Short-term conductivity from condensation is only permissible if the control is not in operation.

WARNING!

Risk of injury from conductive contaminants!

No conductive contaminants may appear during operating time.

Therefore:

m Before installing the system, check that contamination degree 2 is not exceeded,

nd ensure so by additional measures, if necessary.

a

3.10.1 Notice on power supply

WARNING!

Risk of injury from electric current!

Only devices which have a safe disconnection

ed to the control.

The power supply for generation the 24-volt su

PELV in accordance with EN 50178.

3.11 Safety equipment

WARNING!

Live-threatening danger from inoperable safety equipment!

Safety equipment provides a maximum of safety d

equipment may make work processes more complicated, they may not be put out of

operation under any circumstances. Safety is only ensured if the safety equipment is

intact.

to the 230 volt mains may be connect-

pply must meet the requirements for

uring operation. Even if the safety

22

of 82

Therefore:

m Check to make sure that the safety equipment is functional and installed properly

efore beginning work.

b

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

3.12 Conduct in the event of danger and accidents

Safety

3

Preventative measures

In case of emergency: Act properly

m Always be prepared for accidents or fire!

m Keep first aid equipment (first aid kits, blankets, etc.) and fire extinguishers readily

available.

m Instruct personnel in accident reporting, first aid and rescue equipment.

m Put the device out of operation immediately with the EMERGENCY STOP.

m Introduce first aid measures.

m Keep people out of the danger zone.

m Inform the supervisors at the site.

m Notify a doctor and/or fire department.

m Clear access routes for rescue vehicles.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

23

of 82

3.13

Signage

3.13 Signage

The following symbols and notification signs are found in the work area. They relate to the

immediate environment in which they are placed.

WARNING!

Live-threatening danger from electric current!

In the course of time, stickers and symbols on the device can become dirty or otherwise illegible.

Therefore:

m Keep all safety, warning and operation signs on

tion at all times.

the device in easily legible condi-

Electric current

Only qualified personnel may work in work spaces with this marking.

Unauthorized persons may not touch work equipment bearing this marking.

DANGER!

Live-threatening danger from electric current!

Discharge time > 1 minute

Saved electric charge.

Therefore:

m Keep the discharge time of the capacitors in min

forehand.

m Follow the commensurate instructions on the device.

m If you have connected additional capacitors to the

take considerably longer for the intermediate circuit to discharge. In such case, you

will have to establish the necessary waiting period yourself or measure whether

the device has been de-energized.

d and do not touch live parts be-

intermediate circuit, it can also

24

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

This chapter describes parameters in relation to functional safety. First of all, in accordance with IEC 61508, safety means that a syste

al safety is the part of the o

to its input conditions is free of errors. Internal safety-related device errors must be detected and brought into a safe condition in the process.

4.1 Safety-related parameters

The safety-related parameters of the safety I/O Terminals will be described in the following Safety-related parameters of b maXX safe PLC and decentral components can be

d in the applicable documentation. The values specified here relate exclusively to the

foun

safety I/O Terminals.

4FUNCTIONAL SAFETY

m is free of unwarranted risks. Function-

verall safety, which ensures that a safety system’s response

Parameters in accordance with

Meaning

IEC 61508

PFH = 2.30 * 10-9/h for SI4000

-9

PFH = 1.73 * 10

PFD

= 1.81 * 10-4 for SI4000

avg

/h for SO4000

Probability of Failure per Hour

Probability of Failure on Demand

= mean residual error probability of a dangerous

PFD

= 1.42 * 10-4 for SO4000

avg

error on demand

Lifetime [a] = 20 years

Safety Integrity Level = SIL 3

Classification element *) type A

HFT 1 Hardware Failure Tolerance

*) Classification according to IEC 61508-2:2010 (see chapter 7.4.4.1.2 and

7.4.4.1.3 in IEC 61508-2)

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

25

of 82

4.2

Lifetime

4.2 Lifetime

Parameters in accordance with

DIN EN ISO 13849

MTTFd > 100 years Mean Time To Failure

DC > 99% (high) Diagnostic Coverage

Performance level = e

Category = 4

The interval for the repeat test (proof test interval) is set for 20 years. The repeat test

serves to detect failures which could not be detected by the diagnostic coverage during

the operating time. It is necessary to detect all dangerous failures so that the repeat test

will be fully effective and “like new” condition can be established for the system.

CAUTION!

To ensure the safety-related

to be decommissioned and sent back to the manufacturer within not more than 20

years.

parameters specified above, the safety control will have

Meaning

The safety terminal are designed for a service life of 20 years.

Due to the high diagnostic coverage within the

quired.

The terminals have a date code which corresponds to the following glossary:

Date code: WW YY SW HW

WW calendar week of production

YY year of production

SW software version (hex)

HW hardware version (hex)

Example: Date code: 17 11 05 00

calendar week of production 17

year of production 2011

software version 05

hardware version 00

Additionally the terminals have a unique serial number.

lifecycle no special proof tests are re-

26

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

NOTICE!

Declaration of the version

All changes both of the hardware and of the firmware lead to a change of the version.

All cha

this manual.

nges which impact security-relevant properties of the terminals are denoted in

4.3 Using of the terminals with b maXX safe PLC

The tests of the b maXX safe PLC are carried out with the following terminal versions.

Functional Safety

4

Test Version input

termial SI4000

Module test FSoE 1701 1404

Module test Motion Control 1701 1404

Environmental test 1701 1404

EMC test 1701 1404

System test 1701 1405 / 1406

The results only apply for the current terminal hard

tests were carried out in a laboratory environment.

Version output

terminal SO4000

ware version at the time of testing. The

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

27

of 82

4.3

Using of the terminals with b maXX safe PLC

28

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

5DESCRIPTION OF THE SAFETY I/O

This chapter describes the safety I/O Terminals and the type code applied to the module.

5.1 General description

5.1.1 SI4000 4-channel safety digital input terminal

The SI4000 is a digital input terminal for sensors with floating contacts for 24 VDC. The

bus terminal has 4 fail-safe inputs.

With two-channel connection, the SI4000 meets the requirements of IEC 61508:2010

SIL3, DIN

The bus terminal has the standard design of a Baumueller Bus Terminal.

EN ISO 13849-1:2008 (Cat 4, PL e) and UL 508.

TERMINALS

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

29

of 82

5.1

General description

Figure 1: SI4000 safety input terminal

5.1.2 SO4000 4-channel safety digital output terminal

The SO4000 is a safe output terminal with digital outputs for connecting actuators (contactors, relays, etc.) with a maximum current 0.5 A (24 V

safe outputs.

The SO4000 meets the requirements of IEC 61508:2010 SIL3,

DIN EN ISO 13849-1:2008 (Cat 4, PL e) and UL 508.

The bus terminal has the standard design of a Baumueller Bus Terminal.

). The bus terminal has 4 fail-

DC

30

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

Description of the Safety I/O Terminals

5

Figure 2: SO4000 safety output terminal

5.2 Appropriate use

DANGER!

The safety I/O terminals may only be used for the purposes described in

ZAppr

5.3 Technical data

See ZAppendix D - Technical Data– from page 71 onward.

opriate use – from page 15 onward.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

31

of 82

5.4

Dimensions

5.4 Dimensions

5.4.1 SI4000

Figure 3: Dimensions of SI4000

Width: 12 mm (side-by-side installation)

Height: 100 mm

Depth: 68 mm

32

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

5.4.2 SO4000

Description of the Safety I/O Terminals

5

Figure 4: Dimensions of SO4000

Width: 24 mm (side-by-side installation)

Height 100 mm

Depth 68 mm

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

33

of 82

5.4

Dimensions

34

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

6.1 Safety instructions

Before installing and commissioning the safety I/O terminals please read the chapter

ZSafety

– from page 15 onward.

CAUTION!

The "Installation checklist" reproduced in Appendix ZC.1– o

used during the assembly and installation phase.

m Make sure that the installation process is carried out entirely in accordance with

the installation and

m Conduct a visual inspection and check all system components for visible damage.

m Check the system for wiring errors.

m Inspect the tightening torque and make sure tha

interrupted by insulation material.

m Inspect the tensile-load capacity of

m Make sure that the installation and cable r

applicable standards and guidelines.

m Make sure that the system’s environmental pr

ZD.3.1– on pa

m Make sure that the design of the system’s type

m Make sure that the safety system is not

area surrounding the installed safety components.

m Make sure that the system components do not come int

substances (such as acids, bases, transmission oil).

6ASSEMBLY AND INSTALLATION

n page 67 should be

wiring plan.

t the electrical connection is not

the electrical terminal and screw connections.

outing are carried out in accordance with

operties specified in Appendix

ge 74 are not exceeded.

of protection is sufficient.

damaged by moving parts or work in the

o contact with aggressive

6.2 Transport and storage

Use the original packaging for transporting or storing the digital safety I/O terminals.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

35

of 82

6.3

Installation of Bus Terminals on C mounting rails

CAUTION!

Note the specified environmental conditions

Please ensure that the digital safety I/O terminals are only transported and stored under the specified environmenta

page 71 onward).

l conditions (see ZAppendix D - Technical Data– from

6.3 Installation of Bus Terminals on C mounting rails

DANGER!

Danger from electricity

Set the bus system into a safe, powered down state

assembly or wiring of th

6.3.1 Control cabinet

The safety I/O terminals must be installed in a control cabinet or terminal box with IP54

protection class according to IEC 60529 as a minimum.

6.3.2 Mounting rail installation

The Bus Coupler and Bus Terminals are attached to commercially available 35 mm

C mounting rails (according to EN 50022) by applying slight pressure:

before starting installation, dis-

e Bus Terminals!

36

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

Assembly and Installation

6

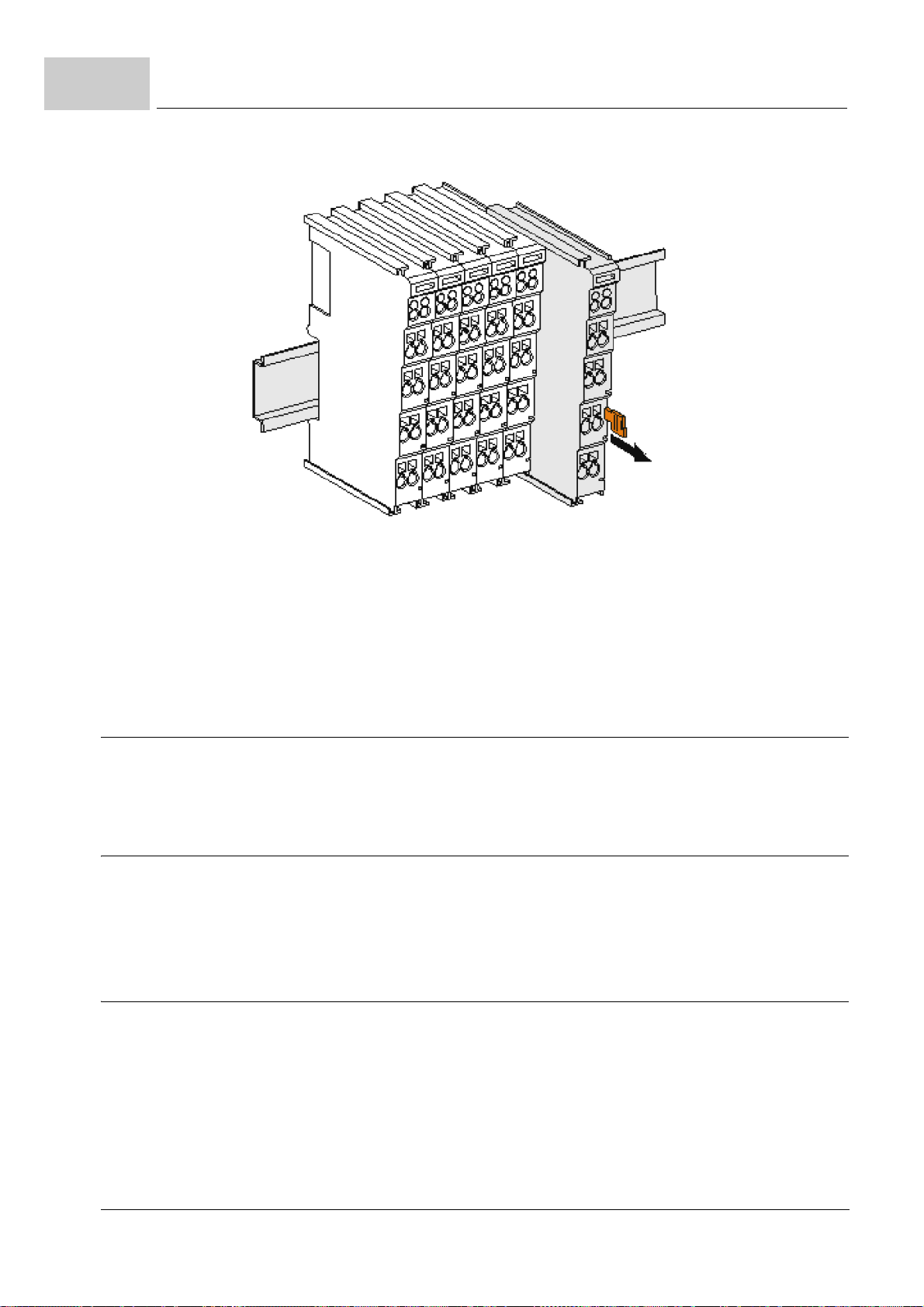

Figure 5: Assembly of the terminals

1 First attach the Fieldbus Coupler to the mounting rail.

2 Th

e Bus Terminals are now attached on the right-hand side of the Fieldbus Coupler.

Join the components with slot and key and push the terminals against the mounting

rail, until the lock clicks onto the mounting rail.

If the Terminals are clipped onto the mounting rail first and then pushed together without slot and key, the c

significant gap should be visible between the housings.

During the installation of the Bus Terminals, the lo

not come into conflict with the fixing bolts of the mounting rail.

onnection will not be operational! When correctly assembled, no

6.4 Electrical installation

6.4.1 Connections within a bus terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realised by joining the components:

m The six spring contacts of the I/O-Bus deal with the transfer of the data and the supply

e Bus Terminal electronics.

of th

cking mechanism of the terminals must

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

37

of 82

6.4

Electrical installation

NOTICE!

Note the maximum I/O bus current!

Observe the maximum current that your Bus Coupler can supply to the I/O bus!

m The power contacts deal with the supply for the field electronics and thus represent a

supply rail within the bus terminal block. The power contacts are supplied via terminals

on the Bus Coupler.

NOTICE!

Note the pin assignment of the power contacts!

During the design of a bus terminal block, the pin assignment of the individual Bus

rminals must be taken account of, since some types (e.g. analog Bus Terminals or

Te

digital 4-channel Bus Terminals) do not or not fully loop through the power contacts.

Power Feed Terminals (ES0000) interrupt the power contacts and thus represent the

t of a new supply rail.

star

PE power contact

The power contact labeled PE can be used as a protective earth. For safety reasons this

ntact mates first when plugging together, and can ground short-circuit currents of up to

co

125 A.

CAUTION!

Danger from damage of the terminal

Note that, for reasons of elec

tatively coupled to the mounting rail. This may

tion testing or to damage on the terminal (e.g. disruptive discharge to the PE line

uring insulation testing of a consumer with a nominal voltage of 230 V).

d

Therefore:

m For insulation testing, disconnect the PE supply line at the Bus Coupler or the Pow-

er Feed Terminal! In order to decouple further feed points for testing, these Power

eed Terminals can be released and pulled at least 10 mm from the group of ter-

F

minals.

tromagnetic compatibility, the PE contacts are capaci-

lead to incorrect results during insula-

38

of 82

DANGER!

Serious risk of injury!

The PE power contact must not be used for other potentials!

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

6.4.2 Wiring

Assembly and Installation

6

Figure 6: Wiring

Up to eight connections enable the connection of solid or finely stranded cables to the Bus

Terminals. The terminals are implemented in spring force technology. Connect the cables

as follows:

1 Op

2 T

3 Th

Wire cross-section 0.08 bis 2.5 mm²

Strip length 8 mm

6.5 Power supply

The supply connections Vk for the module electronics (I/O bus) and supply connections

for the field devices (power contacts) of a terminal block are galvanically separated from

each other and can be supplied via separate 24 V

lation is required between I/O bus and field d

devices can be supplied from a single voltage source.

en a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the

square opening above the terminal.

he wire can now be inserted into the round terminal opening without any force.

e terminal closes automatically when the pressure is released, holding the wire securely and permanently.

voltage sources. If no electrical iso-

DC

evices, the module electronics and the field

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

39

of 82

6.5

Power supply

NOTICE!

For the trouble-free operation of an I/O bus extension system, the ground connection

of

each other via a low-impedance connection (see Figure). This also includes the

ground connection of the I/O bus power supply of the higher-level Fieldbus Coupler!

the I/O bus power supplies (V

0 V) of all terminal blocks must be connected with

k

40

of 82

Figure 7: Power supply of the terminal blocks

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

7COMMISSIONING

Please ensure that the safety I/O terminals are only transported, stored and operated under the specified conditions (see ZAp

CAUTION!

The ZCommis

Appendix should be used during the commissioning phase.

Therefore:

m Make sure that the system is commissio

m Make sure that there are no people in the danger zone during the initial commis-

sioning. Always anticipate that a machine, system or safety device may not behave

as it is

m Never leave the system unsupervised during

variables in debug mode (forcing). The important safety functions may not be active in this form of operation. Make sure that no one enters the danger zone.

m If changes or expansions are conducted dur

fects on the behavior of the sy

necessary to process the checklists for the planning and installation phase again.

sioning and validation checklist – on page 69 reproduced in the

intended to.

pendix D - Technical Data– from page 71 onward).

ned exclusively by qualified personnel.

commissioning with manually set

ing the commissioning process, the ef-

stem will have to be inspected. To do this, it will be

DANGER!

Risk of injury!

The safety I/O terminals must not be used

m under the influence of ionising radiation

m in corrosive environments

m in an environment that leads to unacce

Operation Manual Safety I/O Terminals SI4000 / SO4000

under the following operating conditions:

ptable soiling of the bus terminal

Document no.: 5.08009.05

41

of 82

7.1

Installation

7.1 Installation

7.1.1 Safety instructions

Before installing and commissioning the safety I/O terminals please read the chapter

fety– from page 15 onward.

ZSa

7.1.2 Transport and storage

Use the original packaging for transporting or storing the digital safety I/O terminals.

CAUTION!

Note the specified environmental conditions

Please ensure that the digital safety I/O terminals are only transported and stored under the specified environmenta

page 71 onward).

l conditions (see ZAppendix D - Technical Data– from

7.1.3 Mechanical installation

DANGER!

Danger from electricity

Set the bus system into a safe, powered down state

assembly or wiring of th

7.1.3.1 Control cabinet

The safety I/O terminals must be installed in a control cabinet or terminal box with IP54

protection class according to IEC 60529 as a minimum.

7.1.3.2 Installation of Bus Terminals on C mounting rails

See ZMounting rail installation– from page 36 onward.

7.1.4 Electrical installation

See ZElectrical installation– from page 37 onward.

e Bus Terminals!

before starting installation, dis-

42

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

7.1.5 SI4000 pin assignment

Commissioning

7

Figure 8: SI4000

Clamping point Input Signal

1 1 Input 1+

2 Input 1-

3 3 Input 3+

4 Input 3-

5 2 Input 2+

6 Input 2-

7 4 Input 4+

8 Input 4-

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

43

of 82

7.1

Installation

NOTICE!

Configurable inputs

The inputs 1 to 4 can be occupied as you wan

sponding analysis is carried out in the b maXX safe PLC.

7.1.5.1 Tested devices

The following list contains devices that were tested together with the SI4000 terminal. The

results only apply for the current device hardware version at the time of testing. The tests

were carried out in a laboratory environment. Modifications of these products cannot be

considered here. If you are unsure please test the hardware together with the safety terminal.

Manufacturer Type Comment

SICK C4000 Safety light curtain

Wenglor SG2-141S045C1 Safety light grids

Leuze lumiflex ROBUST 42/43/44 Safety light barriers

Schmersal BNS250-11ZG Safety switch

ifm GM701S Inductive safety sensor

t with N/C or N/O contacts. The corre-

The tests were carried out as function tests o

tive manufaturer documentation remains valid.

nly. The information provided in the respec-

44

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

7.1.6 SO4000 pin assignment

Commissioning

7

Figure 9: SO4000

Clamping point Input Signal

1 not used, no function

2 positive power contact

3 negative power contact

4 not used, no function

5 not used, no function

6 positive power contact

7 negative power contact

8 not used, no function

1’ 1 Output 1+

2’ Output 1-

3’ 3 Output 3+

4’ Output 3-

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

45

of 82

7.1

Installation

Clamping point Input Signal

5’ 2 Output 2+

6’ Output 2-

7’ 4 Output 4+

8’ Output 4-

NOTICE!

Test pulses

When selecting actuators please ensure that the SO4000 test pulses do not lead to

ctuator switching or diagnostic message from the SO4000.

a

The test pulses of the SO4000 terminal outputs are not configurable and cannot be

ed off.

switch

7.1.6.1 Tested devices

The following list contains devices that were tested together with the SO4000 terminal.

The results only apply for the current device hardware version at the time of testing. The

tests were carried out in a laboratory environment. Modifications of these products cannot

be considered here. If you are unsure please test the hardware together with the safety

terminal.

Manufacturer Type Comment

Beckhoff AX5801 TwinSAFE Drive option card: safe restart lock

Beckhoff AX2000 AS option Safe restart lock

Beckhoff KL2964 Three-channel contact extension with feedback

Siemens SIRIUS series S00

Telemecanique LP1K09 Contactor

Dold LG5929.54/100 Extension module with floating contacts

The tests were carried out as function tests o

tive manufaturer documentation remains valid.

Contactor

3RT1016-1BB42

nly. The information provided in the respec-

46

of 82

NOTICE!

Recommended protective circuits

We recommend R/C or diode-based protective circuits for these devices. Varistor-

sed protective circuits should not be used.

ba

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

7.1.7 Address setting s on th e sa fe t y te rminals

Commissioning

7

Figure 10: Address setting

The address of the terminal is set via the 10-way Dip switch on the left-hand side of the

safety terminal. Addresses between 1 and 1023 are available.

Dip switch

1 2 3 4 5 6 7 8 9 10

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF 0

ON OFF OFF OFF OFF OFF OFF OFF OFF OFF 1

OFF ON OFF OFF OFF OFF OFF OFF OFF OFF 2

ON ON OFF OFF OFF OFF OFF OFF OFF OFF 3

OFF OFF ON OFF OFF OFF OFF OFF OFF OFF 4

ON OFF ON OFF OFF OFF OFF OFF OFF OFF 5

OFF ON ON OFF OFF OFF OFF OFF OFF OFF 6

Address

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

47

of 82

7.1

Installation

Dip switch

1 2 3 4 5 6 7 8 9 10

ON ON ON OFF OFF OFF OFF OFF OFF OFF 7

... ... ... ... ... ... ... ... ... ... ...

ON ON ON ON ON ON ON ON ON ON 1023

WARNING!

Unique safety address

Each address may only be used once within a network!

Address

7.1.8 Parameterization

7.1.8.1 SI4000 parameter overview

PrmName Meaning Values

S_Address Dip switch address 1 to 1023

Channel 1 Activation of channel 1 active/not active

Channel 2 Activation of channel 2 active/not active

Channel 3 Activation of channel 3 active/not active

Channel 4 Activation of channel 4 active/not active

Sensor test

channel 1

Sensor test

channel 2

Sensor test

channel 3

Sensor test

channel 4

The clock signal for connection Input1+

is checked at connection Input1-

The clock signal for connection Input2+

is checked at connection Input2-

The clock signal for connection Input3+

is checked at connection Input3-

The clock signal for connection Input4+

is checked at connection Input4-

active/not active

active/not active

active/not active

active/not active

48

of 82

Channel 1 and 2For two-channel evaluation, inputs 1 and 2

must have the same signal states

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

single-channel evaluation/two-channel evaluation

Commissioning

PrmName Meaning Values

7

Channel 3 and 4For two-channel evaluation, inputs 3 and 4

must have the same signal states

Ambivalence

channel 1 and 2

Ambivalence

channel 3 and 4

7.1.8.2 SI4000 configuration for light barriers, light grids, light curtains etc.

The SI4000 also supports direct connection of contact-free protective eqipment with two

self-testing outputs such as light barriers, light grids, light curtains, laser scanner etc.

CAUTION!

Sensors with self-testing outputs

Only sensors with self-testing outputs and a

350 µs may be connected to the SI4000.

If active, inputs 1 and 2 must have different

signal states

If active, inputs 3 and 4 must have different

signal states

maximum sensor self-test duration of

single-channel evaluation/two-channel evaluation

not active/active

not active/active

Parameter

To connect these sensors please set the follo

ProMaster:

m Connect the two sensor signals either to channels 1 and 2 or channels 3 and 4 and

te the two-channel evaluation for the two inputs used.

activa

m Set the SI4000 sensor test for the two inputs used to not

Operation Manual Safety I/O Terminals SI4000 / SO4000

wing parameters for the SI4000 in

active.

Document no.: 5.08009.05

49

of 82

7.1

Installation

CAUTION!

No simultaneous sensor self-test

The sensor self-test must not set the two ch

simultaneously.

with two-channel evaluation

annels for two-channel evaluation to LOW

7.1.8.3 SO4000 parameter overview

PrmName Meaning Values

S_Address Dip switch address 1 to 1023

Channel 1 Activation of channel 1 active/not active

Channel 2 Activation of channel 2 active/not active

Channel 3 Activation of channel 3 active/not active

Channel 4 Activation of channel 4 active/not active

50

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

7.1.8.4 Configuration of the safety SI4000 Parameter in ProSafety

Commissioning

7

Figure 11: ProSafety

h Switch to „Bus Configuration“ with the mouse

and mark the „Local I/O module / SI4000“.

=> The field „Safety parameter“ will be opened.

Here you can configure the SI40

such as „Watchdog time“, „Activation test pulse“, and so on.

Operation Manual Safety I/O Terminals SI4000 / SO4000

00 specific safety parameter

Document no.: 5.08009.05

51

of 82

7.1

7.1.8.5 Configuration of the safety SO4000 Parameter in ProSafety

Installation

Figure 12: ProSafety

52

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

h Switch to „Bus Configuration“ with the mouse

and mark the „Local I/O module / SO4000“.

=> The field „Safety parameter“ will

Here you can configure the SO4000 specific safety parameter

„Watchdog time“.

be opened.

7.1.8.6 Meaning of the SI4000 and SO4000 diagnostic variables

Variable Value / Bit Meaning

w_LM*_SDx_Diag_01 Bit 0 0: Configuration data of the safety device is

invalid

1: Configuration data of the safety device is

valid

Bit 1 0: Safety communication has not yet started

running to the safety device

1: Safety communication has started running to

the safety device (display saved)

Bit 2 0: An error has not occurred

1: An error related to the safety device has

occurred (saved display)

Bit 3 0: An error has not occurred

1: An error related to the safety device has

occurred (current display)

Commissioning

7

Bit 4 0: Safe parameter download to the safety

device not active

1: Safe parameter download to the safety

device active

Bit 5 0: Safety communication in another status

1: Safety communication running to the safety

device in “FailSafeData” status

Bit 6 0: Safety communication in another status

1: Safety communication is running t

device in “ProcessData” status (normal operation status)

Bit 7 0: No error reported by safety device

1: Safety device is reporting an error (FailSafeData)

Bit 8 – 15 Reserved

x stands for I with the input module and for O with the output module

o the safety

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

53

of 82

7.2

Diagnostic

7.2 Diagnostic

7.2.1 Diagnostic LEDs SI4000

Figure 13: Diagnostic LEDs SI4000

7.2.1.1 Diag 1 (green)

The Diag 1 LED indicates the state of the FSoE interface.

Flashing Code Meaning

LED illuminated continuously normal operation:

FSoE communication OK

rapid flickering, alternating with 1 flash

pulse

rapid flickering, alternating with 2 flash

pulses

rapid flickering, alternating with 3 flash

pulses

rapid flickering, alternating with 4 flash

pulses

rapid flickering, alternating with 5 flash

pulses

rapid flickering, alternating with 6 flash

pulses

rapid flickering, alternating with 7 flash

pulses

rapid flickering, alternating with 8 flash

pulses

Error in S parameter (Failsafe parameter

Error in I parameter (Individual parameter

Waiting for S and I parameter

S- and I-parameter correct:

Waiting for first host message

Watchdog error

CRC error

Sequence number error

Intermediate state in a sensor

7.2.1.2 Diag 2 (red)

54

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

The Diag 2 LED illuminates red if the terminal detects an external supply or cross-circuit.

Once the error has been rectified the LED goes out.

7.2.1.3 Diag 3 (red) and Dia g 4 (red)

The Diag 3 and Diag 4 LEDs indicate internal terminal errors.

NOTICE!

Returning the terminal

These errors lead to shutdown of the termin

mueller Anlagen-Systemtechnik GmbH

Diag 3 LED (red) Diag 4 LED (red) Source of error

Commissioning

al. The terminal must be checked by Bau-

& Co. KG.

7

Lit flashes (see below for

flashing codes)

Lit off µC2

In the event of a fault the Diag 4 LED indicates the

The flashing codes are structured as follows:

Flashing sequence Meaning

Rapid flickering Start of flashing code

First slow sequence Error code

Second slow sequence Error code argument

Figure 14: Blinking sequence

µC1

type of error through flashing codes.

Count the number of flash pulses after the rapid flickering sequence

m during the first slow sequence in order to ascertain the error code

m during the second slow sequence in order to ascertain the error argument

The flashing code is repeated after the seco

ing.

Operation Manual Safety I/O Terminals SI4000 / SO4000

nd slow sequence, followed by rapid flicker-

Document no.: 5.08009.05

55

of 82

7.2

7.2.2 Diagnostic LEDs SO4000

7.2.2.1 Diag 1 (green)

Diagnostic

Figure 15: LEDs SO4000

The Diag 1 LED indicates the state of the FSoE interface.

7.2.2.2 Diag 2 (red)

Flashing Code Meaning

LED illuminated continuously normal operation:

FSoE communication OK

rapid flickering, alternating with 1 flash

pulse

rapid flickering, alternating with 3 flash

pulses

The Diag 2 LED indicates the state of the digital outputs.

Flashing Code Meaning

rapid flickering, alternating with 1 flash

pulse

rapid flickering, alternating with 2 flash

pulses

Communication error: The connection is

not in „Run“ State

Communication error: The connection is

not in „Run“ State

Output 1: Open load or current below minimum value of 20 mA or current above

ximum value of 500

ma

Output 2: Open load or current below minimum value of 20 mA or current above

ximum value of 500

ma

mA

mA

56

of 82

rapid flickering, alternating with 3 flash

pulses

rapid flickering, alternating with 4 flash

pulses

rapid flickering, alternating with 5 flash

pulses

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

Output 3: Open load or current below minimum value of 20 mA or current above

ximum value of 500

ma

Output 4: Open load or current below minimum value of 20 mA or current above

ximum value of 500

ma

field potential too low

mA

mA

Flashing Code Meaning

Commissioning

7

rapid flickering, alternating with 6 flash

pulses

rapid flickering, alternating with 7 flash

pulses

rapid flickering, alternating with 8 flash

pulses

rapid flickering, alternating with 9 flash

pulses

rapid flickering, alternating with 10 flash

pulses

These errors can only be reset by switching the power supply for the safety terminal off

and back again.

7.2.2.3 Diag 3 (red) and Dia g 4 (red)

See ZDiag 3 (red) and Diag 4 (red)– from page 55 onward.

7.3 Troubleshooting

field potential too high

terminal temperature too low

terminal temperature too high

Temperature difference error

error in output circuit through Open Load,

external supply or cross-circuit

m Check wiring, check 24 V supply

m SO4000: Pay attention to minimum current of 20 mA

m The SAF module for the b maXX 5000, which is directly controlled via SO4000 must

cope with this ("Separate Grounds" of the type: BM5-O-SAF-002-001-xxx-#01 or

BM5-O-SAF-003-001-xxx-#01 and the adapter for the safety-I/O-terminal).

m FSoE communication problems:

n Checking the address setting on the safety terminals (may be assigned once only)

n Check if EtherCAT bus is running synchronously

m The setting of the cycle time in the ring must be the same all over

m The user must activate the bus synchronization in all b maXX 5000 controllers

(there is no automatic setting, as the EtherCAT slave is permanently integrated in

the controller. The device is delivered as single device without a configured bus

connection)

m Check grounding at the machine

m Regard EtherCAT cabling sequence by starting from the EtherCat master (for ex-

ample, if b maXX 5000 controllers are integrated):

Cable of EtherCAT master → Connection at (input) terminal “X3” (of the b maXX

5000), of (output) terminal “X4” → go to the next EtherCAT slave

n Incorrect mapping of the FSoE participants in the configuration software

n Mapped participants are missing at the EtherCAT bus

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05

57

of 82

7.4

Maintenance

7.4 Maintenance

The digital safety input terminal SI4000 and the digital safety output terminal SO4000 are

maintenance free!

WARNING!

Observe the specified environmental conditions!

Please ensure that the safety terminals are only stored and operated under the specified conditions (see ZAppendix

D - Technical Data– from page 71 onward).

7.4.1 Cleaning

7.4.2 Service life

If the terminal is operated outside the permitted temperature range it will sw

fault state.

Protect the safety terminal from unacceptable soiling during operation and storage!

If the safety terminals were subjected to unacc

erated!

WARNING!

Have soiled terminals checked!

Cleaning of the safety terminal by the user

Please send soiled terminals to the manufacturer for inspection and cleaning!

The safety terminals are designed for a service life of 20 years.

Due to the high diagnostic coverage within the

quired.

eptable soiling they may no longer be op-

is not permitted!

lifecycle no special proof tests are re-

itch to global

58

of 82

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05 Baumüller Nürnberg GmbH

8SYSTEM VALIDATION

All safety functions as well as the trouble-free functioning of the installed and programmed system must be tested with the initial o

be documented.

WARNING!

Danger during commissioning!

peration. The testing of the system must

8.1 Function test

The function test is a major part of the validation of the entire system. The function test is

used to determine the trouble-free allocation of the network safety components and the

programmed logic of the system.

Use the project documentation printed out by ProSafety to conduct the function test. The

instru

handbook.

The control system may only be put into commission aft

by a technical expert

Therefore:

m Conduct a complete function test. In doing so, check the correct allocation of the

nnected safety components.

co

m A checklist for the commissioning and valida

pendix ZC.2 Commission

validation of the system in accordance with this checklist and document the procedure accordingly.

m Make sure that operating personnel has been instru

trol system.

ctions on handling the project documentation can be found in the programming

ing and validation checklist– on page 69. Conduct the

tion of the system is reproduced in Ap-

er being tested successfully

cted in the handling of the con-

Depending on the complexity of the logic circuit of

ed to conduct the function tests in steps.

Operation Manual Safety I/O Terminals SI4000 / SO4000

Document no.: 5.08009.05