Parameter manual

Language English

Translation

Document No. 5.12001.07

Part No. 442290

Status 15.11.2017

E

5.12001.07

b maXX BM3000 /

BM2500

Parameter manual

Version 01.13

Read the Operating Manual before starting any work!

Copyright The owner may produce an unrestricted num ber of copies of this Parameter manua l solely

for internal use. This Parameter manual may not be copied or reproduced, even in extract

form, for any other purpose.

Use and disclosure of the contents of this Parameter manual are not permitted.

Names or company symbols in this Parameter manual can be trademarks, the use of which

by third parties for their own purposes may infringe the rights of the owners.

Preliminary informationCaution: The following applie s if this document is identified as preliminary information:

This version contains preliminary technical information which the users of the devices an d

functions described are intended to receive in advance, in order to be able to make arrangements for any changes or functional enhancements that may be required.

This information should be considered to be provisional , as it has not yet been subjected to

the final Baumüller internal review process. In particular this information i s still subject to

change, so that no legal obligation can be deduced on the basis of this preliminary information. Baumüller accepts no liability for damages that may arise from this possibly erroneous

or incomplete version.

Should you detect or suspect errors of content and/or serious technical errors in this preliminary information, we ask you to contact the Baumüller support pe rson responsible for you

and inform us of your findings and comments so that they might be considered and possibly

incorporated when the preliminary information becomes finalized (reviewed by Baumüller).

The conditions noted in the following section under "Liability" do not apply in the case of preliminary information.

Obligation This Parameter manual is a part of the device/machine. This Parameter manual must be ac-

cessible to the operator at all times and be in a legible condition . Whe n the d evice/machine

is sold/relocated, this Parameter manual must be passed on together with the device/ma

chine by the owner.

After the device/machine is sold, this original and all copies must be handed over to the purchaser. After disposal or other end of service life, this original and all copies must be destroyed.

When this Parameter manual is handed over, the corresponding Operating Manuals with earlier issue dates become invalid.

Please note that specifications/data/information are the current values on the date of print-

ing. These specifications are not legally binding for measuring, computation and costing.

Baumüller Nürnberg GmbH reserves the right to change the technical data and operation of

Baumüller products within the framework of its own further development of the products.

However no guarantee can be provided regarding the freedom from errors of this Parameter

manual, unless otherwise described in the General Conditions for Sales and Supply.

-

Baumüller Nürnberg GmbH

Ostendstr. 80 - 90

90482 Nürnberg

Deutschland

Tel. +49 9 11 54 32 - 0

Fax: +49 9 11 54 32 - 1 30

E-Mail: mail@baumueller.de

Internet: www.baumueller.de

Table of Contents

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Information about the Parameter Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Other Applicable Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.6 Guarantee Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.7 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.8 Terms used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Commissioning BM25xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Voltage test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Requirements for the electrical supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Communication via EtherCAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.6 Switch-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7 Performing the commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 Commissioning BM3xxx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2 Voltage test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.3 Requirements for the electrical supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.4 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.4.1 Communication via the service cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.4.2 Communication via EtherCAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.5 Switch-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.6 Performing the commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 Description of the Software Modules and Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.1 Cycle times of the software modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.2 Structure of the parameter overviews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.3 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.3.1 System control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.3.1.1 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.3.1.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3.2.1 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3.2.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.4.1 Power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.4.1.1 ProDrive Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4.1.2 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4.1.3 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.4.2 Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4.4.2.1 Motor Identification Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4.4.2.2 Torque limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4.4.2.3 Torque monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Parameter manual b maXX BM3000

Document no.: 5.12001.07

3

of 820

Table of Contents

4.4.2.4 Torque Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

4.4.2.5 Maximum permissible speed (electrical conditioned). . . . . . . . . . . . . . . . . . . . . . . 114

4.4.2.6 ProDrive Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

4.4.2.7 Parameter overview motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

4.4.2.8 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4.4.3 Synchronous Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

4.4.3.1 ProDrive Synchronous Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

4.4.4 Asynchronous Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.4.4.1 ProDrive Asynchronous Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.4.4.2 Lh-characteristic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.4.4.3 ProDrive Lh-characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

4.4.4.4 Parameter overview Lh-characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

4.4.4.5 Description of the Lh-characteristic parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 152

4.4.5 Synchronous motor with interior permanent magnet. . . . . . . . . . . . . . . . . . . . . . . . 153

4.4.5.1 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4.4.5.2 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

4.4.5.3 Identification of the nonlinear parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.4.5.4 Field weakening at IPMSM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.4.5.5 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

4.4.5.6 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

4.4.6 Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

4.4.6.1 Encoder monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

4.4.6.2 ProDrive Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

4.4.6.3 Encoder optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

4.4.6.4 Encoder correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

4.4.6.5 Encoder accuracy and excentricity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

4.4.6.6 Resolver synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

4.4.6.7 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

4.4.6.8 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

4.4.7 Autotuning of Current controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

4.4.7.1 ProDrive Autotuning of the Current controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

4.4.7.2 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

4.4.7.3 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

4.4.8 Autotuning of position / speed controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

4.4.8.1 Ks Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

4.4.8.2 ProDrive Ks Determination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

4.4.8.3 Parameter overview Ks measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

4.4.8.4 Description of the Ks measurement parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 211

4.4.9 Autotuning Asynchronous Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.4.9.1 Identification Lh characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.4.10 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.4.10.1 ProDrive Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.4.10.2 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

4.4.10.3 Parameter description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

4.4.11 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

4.4.11.1 ProDrive Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

4.4.11.2 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

4.4.11.3 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.4.12 Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

4.4.12.1 Description of the Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

4.4.12.2 ProDrive analog input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

4.4.12.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

4.4.12.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

4

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Table of Contents

4.4.13 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

4.4.13.1 Description of the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

4.4.13.2 ProDrive Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

4.4.13.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

4.4.13.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

4.4.14 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

4.4.14.1 ProDrive filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

4.4.14.2 ProDrive Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

4.4.14.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

4.4.14.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

4.4.15 Fieldbus communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

4.4.15.1 Parameter IDs for the Real Time Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

4.4.15.2 Access Counter for each Real Time List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

4.4.15.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

4.4.15.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

4.4.16 Measuring encoder function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

4.4.16.1 ProDrive Measuring Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

4.4.16.2 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

4.4.16.3 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

4.4.17 Freely programmable PID controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

4.4.17.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

4.4.17.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

4.4.18 Master-Slave Torque Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

4.4.18.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

4.4.18.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

4.4.19 Friction compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

4.4.19.1 Description of the friction compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

4.4.19.2 Identification of the friction torque curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

4.4.19.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

4.4.19.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

4.4.20 Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

4.4.20.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

4.4.20.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

4.4.21 Configurable status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

4.4.21.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

4.4.21.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

4.4.22 SoftDrivePLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

4.4.22.1 Overview SoftDrivePLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

4.4.22.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

4.4.22.3 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

4.4.22.4 Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

4.4.22.5 Programming interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

4.4.22.6 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

4.4.22.7 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

4.4.23 DS402 Factor Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

4.4.23.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

4.4.23.2 ProDrive DS402 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

4.4.23.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

4.4.23.4 Description of the Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

4.5 Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

4.5.1 Drive management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

4.5.1.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

4.5.1.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Parameter manual b maXX BM3000

Document no.: 5.12001.07

5

of 820

Table of Contents

4.5.2 Data Set Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

4.5.2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

4.5.2.2 Command interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

4.5.2.3 Organization of the parameters in the data sets . . . . . . . . . . . . . . . . . . . . . . . . . . 363

4.5.2.4 Delivered state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

4.5.2.5 Switch-On behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

4.5.2.6 Changing, loading, copying and storing parameters . . . . . . . . . . . . . . . . . . . . . . . 364

4.5.2.7 Identification of parameter set and data sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

4.5.2.8 Functions of the Data Set Management System . . . . . . . . . . . . . . . . . . . . . . . . . . 365

4.5.2.9 Data Set Commands and Possible Error Messages . . . . . . . . . . . . . . . . . . . . . . . 366

4.5.2.10 Changeover to Data Set 1 to 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

4.5.2.11 Overview of the Data Set Management Commands . . . . . . . . . . . . . . . . . . . . . . . 368

4.5.2.12 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

4.5.2.13 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

4.5.3 Brake management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

4.5.3.1 Description of the Brake Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

4.5.3.2 Brake watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

4.5.3.3 ProDrive Brake Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

4.5.3.4 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

4.5.3.5 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

4.5.4 Error Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

4.5.4.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

4.5.4.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

4.5.5 Signal Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

4.5.5.1 Messages on the Signal Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

4.5.5.2 Supply Ready for use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

4.5.5.3 Chopper Resistor On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

4.5.5.4 ProDrive Signal bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

4.5.5.5 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

4.5.5.6 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

4.5.6 Set Value Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

4.5.6.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

4.5.6.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

4.6 Set Value Generators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

4.6.1 Ramp function generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

4.6.1.1 Optional interpolation of the ramp function generator input set value . . . . . . . . . . 403

4.6.1.2 ProDrive Ramp Function Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

4.6.1.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

4.6.1.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

4.6.2 Set Value Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

4.6.2.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

4.6.2.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 418

4.6.3 Error reaction controlled stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

4.6.4 Error Reaction Return Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

4.6.4.1 Parameter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

4.6.4.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

4.6.5 Cam generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

4.6.5.1 Time control via the table index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

4.6.5.2 Time control with virtual master axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

4.6.5.3 Parameter-controlled processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

4.6.5.4 Setting options of cam generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

4.6.5.5 State machine of the cam generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

4.6.5.6 Limiting of output value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

6

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Table of Contents

4.6.5.7 Handling the cam data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

4.6.5.8 Parameter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

4.6.5.9 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

4.6.6 Motor potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

4.6.6.1 Parameter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

4.6.6.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

4.7 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

4.7.1 Position / Speed Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

4.7.1.1 The factor Ks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 446

4.7.1.2 Position / speed controller adaption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

4.7.1.3 Cyclical Ks adaption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

4.7.1.4 ProDrive Position / Speed Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

4.7.1.5 Parameter Overview of Position / Speed Controller . . . . . . . . . . . . . . . . . . . . . . . 451

4.7.1.6 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

4.7.2 Current Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

4.7.2.1 Current Prediction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

4.7.2.2 Dead Time Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

4.7.2.3 Torque Current Limiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 470

4.7.2.4 Feedforward. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

4.7.2.5 Current controller adaption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

4.7.2.6 Pulse Width Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

4.7.2.7 ProDrive Current Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

4.7.2.8 Overview of Current Controller Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

4.7.2.9 Description of Current Controller Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 482

4.7.3 DC link controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

4.7.3.1 Description of the DC link controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

4.7.3.2 ProDrive DC link controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

4.7.3.3 Reactive current brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

4.7.3.4 Short circuit brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

4.7.3.5 Parameter Overview of the DC link controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

4.7.3.6 Description of the DC link controller parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . 492

4.7.4 Field weakening controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

4.7.4.1 Breakdown torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

4.7.4.2 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

4.7.4.3 Description of the Field Weakening parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 502

4.7.5 Two-level controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

4.7.5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

4.7.5.2 Two-level controller with absolute thre sh old s . . . . . . . . . . . . . . . . . . . . . . . . . . . . 507

4.7.5.3 Two-level controller with relative thre sh old s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

4.7.5.4 Combination of the operating modes absolute and relative thresholds. . . . . . . . . 508

4.7.5.5 Sign-independent monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 510

4.7.5.6 Linking of the controller output with the target parameter . . . . . . . . . . . . . . . . . . . 510

4.7.5.7 Parameter Overview of the Two-level Controller. . . . . . . . . . . . . . . . . . . . . . . . . . 511

4.7.5.8 Description of the Two-level Controller Parameter with absolute Thresholds. . . . 512

4.7.5.9 Description of the Two-level Controller Parameter with relative and absolute Thresholds

514

4.7.6 Flux controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

4.7.6.1 ProDrive Flux controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

4.7.6.2 Parameter Overview of the Flux Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

4.7.6.3 Description of the Flux Controller parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

4.7.7 Controller adaptations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 520

4.7.7.1 Parameter Overview of the Controller Adaptations. . . . . . . . . . . . . . . . . . . . . . . . 521

4.7.7.2 Description of the Controller Adaptations parameters. . . . . . . . . . . . . . . . . . . . . . 521

4.7.7.3 Adaption EMF feed forward. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 523

Parameter manual b maXX BM3000

Document no.: 5.12001.07

7

of 820

Table of Contents

4.7.7.4 Adaption torque monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 524

4.7.7.5 Ks adaption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 525

4.7.7.6 Adaption of the Saturation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 526

4.7.7.7 Compensation dead time voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

4.7.7.8 Temperature adaption motor resistances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

4.7.7.9 Temperature adaption slip frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

4.8 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

4.8.1 Operating Modes general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

4.8.1.1 Moving to positive stop command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

4.8.1.2 ProDrive general parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

4.8.1.3 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

4.8.1.4 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

4.8.2 Target Position Setting (Positioning) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 549

4.8.2.1 Controlling the Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 549

4.8.2.2 Positioning Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

4.8.2.3 Bits in the Control Word / Status Word. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

4.8.2.4 Actions on the Rising Edge of "New Set Value". . . . . . . . . . . . . . . . . . . . . . . . . . . 552

4.8.2.5 Sequence of Events for Positioning Handshake with "Single Set Value". . . . . . . . 552

4.8.2.6 Sequence of Events for Handshake with “Set of Set Values” . . . . . . . . . . . . . . . . 554

4.8.2.7 Hardware limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 555

4.8.2.8 Software Limit Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 557

4.8.2.9 Target Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 557

4.8.2.10 Change of Operating Mode to Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

4.8.2.11 Halting a Running Positioning Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

4.8.2.12 Aborting a Running Positioning Task. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 559

4.8.2.13 Set Value Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 559

4.8.2.14 Comparison of Motion Profiles for Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 560

4.8.2.15 Control by Means of the "Start Positioning" Method . . . . . . . . . . . . . . . . . . . . . . . 562

4.8.2.16 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

4.8.2.17 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 567

4.8.3 Operating mode Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

4.8.3.1 Procedure of a homing under consideration of Zero pulse or Zero angle . . . . . . . 583

4.8.3.2 Shifting the zero angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 584

4.8.3.3 Maximum distance for zero pulse detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 584

4.8.3.4 Procedure of a Homing to switch only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 584

4.8.3.5 Homing without setting the home position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 585

4.8.3.6 Automatic setting of the absolute value offset at homing. . . . . . . . . . . . . . . . . . . . 586

4.8.3.7 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 586

4.8.3.8 Homing Method 1 (neg. limit switch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 587

4.8.3.9 Homing Method 2 (pos. limit switch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 587

4.8.3.10 Homing Methods 3 and 4 (pos. zero point changeover switch). . . . . . . . . . . . . . . 588

4.8.3.11 Homing Methods 5 and 6 (neg. zero point changeover switch). . . . . . . . . . . . . . . 589

4.8.3.12 Homing Methods 7 to 14 (Reference Switch). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 590

4.8.3.13 Homing Methods 15 and 16 (reserved) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 591

4.8.3.14 Homing Methods 17 to 30 (without zero pulse or zero angle) . . . . . . . . . . . . . . . . 591

4.8.3.15 Homing Methods 31 and 32 (reserved) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 592

4.8.3.16 Homing Methods 33 and 34 (zero pulse only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 592

4.8.3.17 Homing Method 35 (set home position only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 593

4.8.3.18 Manufacturer specific homing methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 593

4.8.3.19 Command set home position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 594

4.8.3.20 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 594

4.8.3.21 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 595

4.8.4 Manual drive operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603

4.8.4.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

8

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Table of Contents

4.8.4.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

4.8.5 Operation mode spindle positioning (M19 command). . . . . . . . . . . . . . . . . . . . . . . 607

4.8.5.1 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 611

4.8.5.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612

4.8.6 Position control with synchronous set value specification. . . . . . . . . . . . . . . . . . . . 616

4.8.6.1 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 617

4.8.6.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 618

4.8.7 Operating mode synchronous operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 627

4.8.7.1 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 629

4.8.7.2 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 630

4.8.8 Operating mode Notch position search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 639

4.8.8.1 ProDrive Notch Position Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 641

4.8.8.2 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 641

4.8.8.3 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 642

4.8.9 Notch position search with the injection method. . . . . . . . . . . . . . . . . . . . . . . . . . . 645

4.8.9.1 Parameter survey and parameter description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 645

4.8.9.2 Error response at notch position search 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 645

4.8.10 Sensorless control for synchronous machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 646

4.8.10.1 General constraints of sensorless control with the injection procedure. . . . . . . . . 647

4.8.10.2 Commissioning at the sensorless operation of the synchronous machine . . . . . . 647

4.8.10.3 Vibration damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 648

4.8.10.4 Motor diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 648

4.8.10.5 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 649

4.8.10.6 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650

4.8.11 Sensorless control for asynchronous motors (open loop). . . . . . . . . . . . . . . . . . . . 655

4.8.11.1 Sensorless control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655

4.8.11.2 Catch on Fly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 656

4.8.11.3 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 657

4.8.11.4 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 658

4.8.12 Operating Mode U-f Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 660

4.8.12.1 Compensating controller for acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 661

4.8.12.2 Current control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 662

4.8.12.3 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 662

4.8.12.4 Description of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 664

4.8.13 Operation mode coupled operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 669

4.8.13.1 Transmission of master axis position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 671

4.8.13.2 Transmission of the curve data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 672

4.8.13.3 Changing the chaining sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 673

4.8.13.4 Definition of the starting segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 674

4.8.13.5 Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 674

4.8.13.6 Use of the output-sided gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 676

4.8.13.7 Overlaying using an additional movement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 676

4.8.13.8 Intermediate buffering of curve segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 677

4.8.13.9 Real master axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 679

4.8.13.10 Flexible segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 680

4.8.13.11 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 680

4.8.13.12 Description of the Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 682

4.9 Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 690

4.9.1 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 690

4.9.1.1 Parameter overview Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 690

4.9.1.2 Description of the diagnosis parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 691

4.9.2 Oscilloscope function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

4.9.2.1 Parameter overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

4.9.3 Software function FFT analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 707

Parameter manual b maXX BM3000

Document no.: 5.12001.07

9

of 820

Table of Contents

4.9.3.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 707

4.9.3.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 708

4.10 Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 714

4.10.1 Automatic controller and filter setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 714

4.10.2 Torque ripple compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 715

4.10.2.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 715

4.10.2.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 716

4.11 Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 717

4.11.1 Field angle monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 717

4.11.1.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 717

4.11.1.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 717

4.11.2 Position Error monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 719

4.11.2.1 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 719

4.11.2.2 Description of the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 720

4.11.3 Overload monitoring of the power unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 723

4.11.3.1 Ixt model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 723

4.11.3.2 Temperature model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 727

4.11.3.3 Real power limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 730

4.11.4 Temperature monitoring of the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 731

4.11.5 Overload monitoring of the motor (I2t) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 731

4.11.5.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 731

4.11.5.2 Speed variable l2t overload monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 735

4.11.5.3 Monitoring of the single phases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 738

5 Error messages and troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 741

5.1 Behavior in case of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 741

5.2 Monitoring functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 742

5.2.1 Monitoring function - explanations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 744

5.3 Error detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 746

5.4 Error handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 746

5.4.1 Error reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 746

5.5 Error descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 747

6 Summary of all Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 771

Anhang A - Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 807

Table of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 815

Overview of Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 819

10

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

1.1 Information about the Parameter Manual

The Operating Manual for the b maXX 3000 (5.11018) provides important information regarding handling the device. A prerequisite for safe working is compliance with all specified safety information and handling instructions.

Furthermore, the local accident prevention regulations and general safety requirements

applicable to the area of application of the device must be observed.

Before starting any work on the device, completely read through the Operating Manual,

in particular the chapter on safety information. The Operating Manual is an integral part

of the product and must be kept in the immediate vicinity of the device in order to be ac

cessible to personnel at all times.

The Parameter Manual provides information abo ut the par amete rs for the b m aXX 3000 ,

for

controller firmware from Version 01.13

The parameters are used to influence the behavior of the drive controller.

The controller controls the behavior of the power unit and the connected motor.

1GENERAL

-

Parameter manual b maXX BM3000

Document no.: 5.12001.07

11

of 820

1.2

Explanation of Symbols

1.2 Explanation of Symbols

Warnings

Warnings are identified by symbols in this Parameter Manual. The notices are introduced

by signal words which express the magnitude of the danger.

Observe the notices without exception and exercise caution to prevent accidents, perso nal injury and damage to property.

DANGER!

....warns of an imminently dangerous situation which will result in death or serious in-

jury if not avoided.

WARNING!

....warns of a potentially dangerous situation which may result in death or serious in-

jury if not avoided.

Recommendations

CAUTION!

....warns of a potentially dangerous situation which may result in minor or slight injury

if not avoided.

NOTICE!

....warns of a potentially dangerous situation which may result in material damage if

not avoided.

NOTE!

....points out useful tips and recommend ations, as well as information for efficient,

trouble-free operation.

12

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

1.3 Limitation of Liability

All specifications and information have been compiled taking account of the applicable

standards and regulations, the state of the art and also our many years of expertise and

experience.

The manufacturer accepts no liability for damage resulting from:

m Non-compliance with the Operating Manual

m Non-compliance with the Parameter Manual

m Non-intended use

m Use of untrained personnel

The product actually supplied may deviate from the versions and illustrations described

here in the case of special versions, the use of additional ordering options or as a result

of the latest technical changes.

The user is responsible for carrying out serv icing and maintenance in accordance with the

safety regulations in the applicable standards and all other relevant national or local reg

ulations concerning conductor dimensioning and protection, grounding, isolation switches, overcurrent protection, etc.

The person who carried out the assembly or installation is liable for d amage arising during

assembly or upon connection.

General

1

-

1.4 Copyright

Treat the Parameter Manual confidentially. It is intended exclusively for persons involved

with the device. It must not be made available to third parties without the written permis

sion of the manufacturer.

NOTE!

The details, text, drawings, pictures and other illustrations contained within are copyright protected and are subject to industrial property rights. Any imprope r exploitation

is liable to prosecution.

CiA® and

CANopen

®

EnDat

EtherCAT

Hiperface

PROFINET

Sercos

SinCos

®

®

Windows®

b maXX

®

®

®

is a registered trademark of CAN in Automation e.V.

90429 Nürnberg, Germany

is a registered trademark of Dr. Johannes Heidenhain GmbH,

83301 Traunreut, Germany

is a registered trademark of Beckhoff Automation GmbH,

33415 Verl, Germany

is a registered trademark of SICK STEGMANN GmbH,

78166 Donaueschingen, Germany

®

is a registered trademark of PROFIBUS International

is a registered trademark of Sercos international e.V.

is a registered trademark of SICK STEGMANN GmbH,

78166 Donaueschingen, Germany

is a registered trademark of Microsoft Corporation, USA

is a registered trademark of Baumüller Nürnberg GmbH,

90482 Nürnberg, Germany

-

Parameter manual b maXX BM3000

Document no.: 5.12001.07

13

of 820

1.5

Other Applicable Documents

NOTE!

Please note, that BAUMÜLLER is not responsible to examine whether any (industrial

property) rights of third parties are infringed by the application-specific use of the

BAUMÜLLER products/components or the execution.

1.5 Other Applicable Documents

Name Contents

Operating Manual for b maXX

BM3000 (5.11018)

Components from other manufacturers are installed in the device. Hazard assessments

for these purchased parts have been performed by the respective manufacturers. The

compliance of the designs with the applicable Eu ropean and national regulations has

been declared by the respective manufacturers of the components.

1.6 Guarantee Conditions

The guarantee conditions are located as a separate document in the sales documents.

Operation of the devices describe d here in accordan ce with the stated me thods/ proce -

dures / requirements is permissible. Anything else, e.g. even the operation of devices in

installed positions that are not shown here, is not permissible and must be checked with

the factory in each individual case. If the devices are operated differently than described

here, any guarantee will be invalidated.

1.7 Customer service

Our customer service department is available for technical information.

Description, installation and safety information

1.8 Terms used

14

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Information concerning the responsible contact person can be obtained at any time by

telephone, fax, e-mail or over the internet.

In this documentation, the term "device" is also used for the "b maXX" Baumüller product.

For abbreviations used, see

ZAppendix A - Abbreviations– from Page 807.

2COMMISSIONING BM25XX

This chapter describes a specimen commissioning of a decentralized drive b maXX

BM2500. An axis unit, a controller part and a motor are integrated in one housing.

Perform the commissioning to satisfy yourself that the supplied device is functioning properly.

This commissioning does not constitute a complete set-up of the device for your application.

Before the commissioning, make sure that the technical requirements are met:

1 All points, including the installation, in the b maXX® 2500 Operating Manual

(5.16020) have been followed.

2 Check of the requirements for the electrical supply.

3 Check of the requirements for the electrical cables and provision of appropriate ca-

bles.

4 Check of the characteristics of the connections and manufacture of the appropriate

cables.

®

Parameter manual b maXX BM3000

Document no.: 5.12001.07

15

of 820

2.1

Safety information

2.1 Safety information

NOTE!

The installation and initial commissioning are carried out exclusively by the manufacturer's employees or by qualified personn el.

Qualified personnel are persons who, due to their training, experience, instruction

and knowledge of the relevant standards and specifications, accident preventio n reg

ulations and operating condition s of the person responsible for the safety of the installation have been authorized to carr y out the activities required in each case and

in so doing are able to recognize and avoid potential dangers. The qualifications re

quired for working on the unit are, for example:

m Training or instruction or authorization to commission, ground and characterize

power circuits and devices in accordance with safety engineering standards.

m Training or instruction in accordance with safety engineering standar ds in the care

and use of appropriate safety equipment.

-

-

WARNING!

Danger due to incorrect installation and initial commissioning!

Installation and initial commissioning require qualified personnel with adequate expe-

rience. Errors during installation can lead to life-threatening situations or result in significant material damage.

Therefore:

m Have the installation and initial commissioning carried out exclusively by the man-

ufacturer's employees or by qualified personnel.

DANGER!

Danger to life from electric current!

When this electrical unit is operated, certain parts of the unit are of necessity at a haz-

ardous voltage.

Therefore:

m Pay attention to the areas on the device that could be dangerous during the elec-

trical installation.

16

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

2.2 Voltage test

DANGER!

Risk of fatal injury from electrical current!

During the routine test of these devices, a voltage test is performed by Baumüller

Nürnberg GmbH in accordance with EN

essary for the customer to do this.

Therefore:

m Subsequent tests of the devices using high voltages may only be performed by

Baumüller Nürnberg GmbH.

m Disconnect the converter from the system during high-voltage testin g!

2.3 Requirements for the electrical supply

Commissioning BM25xx

61800-5-1, Section 5.2.3.2. It is thus unnec-

2

For all important data, see the Operating Manual for the b maXX 2500.

Small deviations in the electrical supply from the requirements can result in malfunctions

of the device. If the supply deviates greatly from the requirements, the device could be

destroyed.

The device may only be operated in environments of the second type (industrial environment).

The destruction of the device can cause personal injury.

DANGER!

Danger to life from electric current!

If the requirements for the electrical supply are not complied with, the de vice may be

damaged/destroyed and consequently present a significant danger to persons.

Therefore:

m Before installation, make sure that the requirements for the electrical supply are

met.

Parameter manual b maXX BM3000

Document no.: 5.12001.07

17

of 820

2.4

Preparations

2.4 Preparations

Specimen installation of a decentralized drive BM25xx.

The prerequisite for the commissioning is that assembly and installation have been car-

ried out correctly.

1 Make sure that the assembly is carried out correctly and, in particular, that all safety

2 Make sure that the installation is carried out correctly and, in particular, that all safety

regulations have been observed (see Assembly in the Operating Manual for the

b

maXX® 2500 basic unit).

NOTE

Pictures for the next work steps can be found in the Operating Manual for the

b

maXX® 2500 basic unit.

regulations have been observed (see Installation in the Operating Manual for the

b

maXX® 2500 basic unit).

Motor data

(Identification

plate)

3 ProDrive must be installed on the PC/Laptop.

During commissioning you can, among other things, enter motor and en coder data in

the operating software or correct incorrect values. So that you can perform the com

missioning efficiently, it is advantageous to have all the data at hand for the comm issioning. Data for Baumüller motors are available in the form of a "Motor Database"

within the operating software.

4 Make sure that all the necessary data are at hand.

These data can be found, e.g., on the identification plate for the motor that you are using

for the commissioning.

Name Value, e.g. Used for entering in the parameter list /parame-

Motor type, designation DSD Parameter list/Motor configuration

Nominal voltage U

Nominal current I

Nominal speed n

N

N

N

330 V Parameter list/Motor configuration

4,0 A Parameter list/Motor configuration

3000 rpm Parameter list/Motor configuration

ter

Z107.2– Motor type

Z107.8– Motor nominal voltage

Z107.9– Motor nominal current

Z107.7– Motor nominal speed

The motor database is used in this example; the values in the table are provided only for

checking purposes.

-

18

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Commissioning BM25xx

2

Motor data

(Data sheet)

Encoder data

(Data sheet)

These data can be found on the data sheet for the motor that you are using for the commissioning.

Name Value, e.g. Used for entering in the parameter list /parame-

ter

Max. current I

Number of pole pairs 3 Parameter list/Motor configuration

Max. speed n

Notch angle, if specified

1)

You can also have ProDrive determine the notch angle (see ZSearching for the notch position– on page 40).

mot,max

max.

1)

14,3 A Parameter list/Motor configuration

Z107.21– Maximum drive current

Z107.19– Pole pairs

6000 Parameter list/Motor configuration

Z107.26– Maximum speed mechanical

240° Parameter list/Motor configuration

Z127.8– Encoder Offset el.

These data can be found on the data sheet for the encoder that you are using for the commissioning.

Name Value, e.g. Used for entering in the parameter list /parame-

ter

Encoder type Stegmann SRS

50/60 SinCos

encoder

Number of pulses 1024 Parameter list/Encoder configuration/

With sine-cosine encoders with HIPERFACE® interface, the encoder type is read in automatically via

the HIPERFACE

Z137.1– Number of pulses

®

interface

5 Make sure that the motor meets the following conditions:

m provided with a suitable encoder, in this example: SRS50 SinCos encoder

m connected to b maXX® 2500

m ready for operation

m properly secured

m can rotate freely during commissioning

6 Make sure that switching elements for pulse enabling are connecte d to the b maXX

®

2500 (e.g. in a patch panel) and are functioning. Make sure that the switch is in the

rest position (inactive).

7 Make sure that all safety devices are connected on the supply and motor sides and

are ready for operation.

8 Make sure that the encoder for motor control (sine-cosine encoder) is connected to

the encoder evaluation module with the appropriate encoder cable.

9 Make sure that the PC/Laptop is connected to the controller.

Parameter manual b maXX BM3000

Document no.: 5.12001.07

19

of 820

2.5

Communication via EtherCAT

2.5 Communication via EtherCAT

BM2500 with EtherCAT® CoE profile with the following type code is required:

BM25XX-XXX1-...

For the communication via EtherCAT the following is required:

m EtherCAT Master BMC-M-ECT-02

m Controller BMC-M-PLC-02

m Power supply unit BMC-M-PSB-01

m Engineering Framework ProMaster

n Leave the base address on the EtherCAT Master un changed (192.168.1.1).

h Set the desired IP address on the BM2500 controller (here 192.168.1.2).

You will find further information about this in the b maXX BM2500, 5.16020 Operating

Manual, Art. No. 441838. and in the EtherCAT

440084).

®

, 5.10030 Application Manual, Art. No.

h Set a fixed IP address on the PC or use a second network card:

System Control Network Connections LAN Connection Properties

Internet Protocol (TCP/IP) Properties Assign fixed IP address

from the same address space (here, e.g. 192.168.1.254).

20

of 820

Figure 1: Setting fixed IP addresses

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Commissioning BM25xx

n Start ProMaster.

n Select b maXX controller PLC with EtherCAT Master from the catalog.

n Select b maXX 2500 Drive from the catalog.

n Open/activate the Workspace window.

n Click the Controller PLC in ProMaster.

n Click EtherCAT Master Configure Master Bus (ProEtherCAT) in the Worksp ace win-

dow.

n The window will open:

2

Figure 2: ProEtherCAT

n Click on Connect.

n Select the tab Download Update list Download

Figure 3: ProEtherCAT Download

n Click on Close.

n Select the tab Bus control click on Operational.

Parameter manual b maXX BM3000

Document no.: 5.12001.07

21

of 820

2.5

Communication via EtherCAT

n Start ProDrive and select "Find device".

Figure 4: ProDrive: Find device

n The PLC will appear here with 192.168.1.1 and the controller with 192.168.1.2.

n Click on OK

22

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Commissioning BM25xx

n Select the device: Button SELECT DEVICE

n Select the device type for which parameters are to be set: Button TYPE

(here: b maXX 2500 Drive)

n Select the communication: Button TYPE (here: TCP/IP)

2

Figure 5: ProDrive: Device select with EtherCAT communication

10 Start the graphical user interface by clicking on "OK".

Parameter manual b maXX BM3000

Document no.: 5.12001.07

23

of 820

2.5

Communication via EtherCAT

11 Wait until the ProDrive start window appears.

Figure 6: Pro Drive: Start window

12 Then press

"Connect".

13 This concludes the preparations. The remainder of the commissioning is described in

ZPerforming the commissioning– on page 26.

24

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

2.6 Switch-on sequence

The following overview shows the commissioning schematically. You will find the individual steps of the commissioning described in detail in ZPerforming the commissioning–

from page 26.

Commissioning BM25xx

2

Figure 7: Switch-on sequence

Parameter manual b maXX BM3000

Document no.: 5.12001.07

25

of 820

2.7

Performing the commissioning

2.7 Performing the commissioning

Begin the commissioning after you have completed the preparations.

1 Connect the power supplies to the b maXX®

(main power supply + control voltage).

The device then starts up.

2 Establish communication as described in ZPreparations– on page 18.

3 Start the ProDrive program (if it is not already running).

4 Then click on auf "Drive Manager" in ProDrive

Acknowledging

warnings/errors

Figure 8: ProDrive: Navigation Drive manager

5 "Acknowledge" any warnings/errors that may be present in the "Drive manager" win-

dow (press the "Reset errors" button several times if necessary).

NOTE

Any queued error messages may result from the as yet incomplete parameter setting.

These errors cannot be acknowledged.

26

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Commissioning BM25xx

.

2

Figure 9: ProDrive: Drive Manager

NOTE

Due to the numerous possible combinations of motors and encoders, it is only possible to give an example here. Enter your own motor and encoder data!

Parameter manual b maXX BM3000

Document no.: 5.12001.07

27

of 820

2.7

Performing the commissioning

6 Click on "Power unit".

Figure 10: ProDrive: Navigation for Power unit

28

of 820

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

Commissioning BM25xx

7 In the "Maximum drive current" box, enter the cu rrent req uired for your application, at

most the limiting current of the motor (according to th e data sheet): 1.5 A, at wh ich

you wish to operate the motor and the power unit.

2

Figure 11: ProDrive: Power unit

Parameter manual b maXX BM3000

Document no.: 5.12001.07

29

of 820

2.7

Performing the commissioning

Setting encoder

parameters

The parameters for the encoder still have to be entered.

8 Go back to the navigation.

9 Click on „Scaling“

Figure 12: ProDrive: Navigation Scaling

The „Scaling“ window opens:

30

of 820

Figure 13: ProDrive: Scaling

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

10 Click on % at speed

11 Go back to the navigation.

12 Click on "Encoder 1".

Commissioning BM25xx

2

Figure 14: ProDrive: Navigation Encoder

Parameter manual b maXX BM3000

Document no.: 5.12001.07

31

of 820

2.7

Performing the commissioning

The "Encoder 1 Configuration" window opens.

32

of 820

Figure 15: ProDrive: Encoder 1 configuration

13 Enter data when using a sine-cosine encoder without a HIPERFACE® interface. With

a sine-cosine encoder with a HIPERFACE

matically over the HIPERFACE® interface - do not alter the data.

m Sine-cosine without HIPERFACE® e.g. Number of Pulses = 512

m Sine-cosine without HIPERFACE® e.g. Revolutions = 1

14 Enter the overspeed limit manually in the parameter list in the diagnostic block

[FB:006]:

Parameter number 006.005 and 006.007: enter the value 115%,

Parameter number 006.006 and 006.008: enter the value -115%

Parameter manual b maXX BM3000

Document no.: 5.12001.07 Baumüller Nürnberg GmbH

®

interface, the data are transferred auto-

Commissioning BM25xx

15 Change back to the navigation and click on "Motor general".

2

Using the motor

database

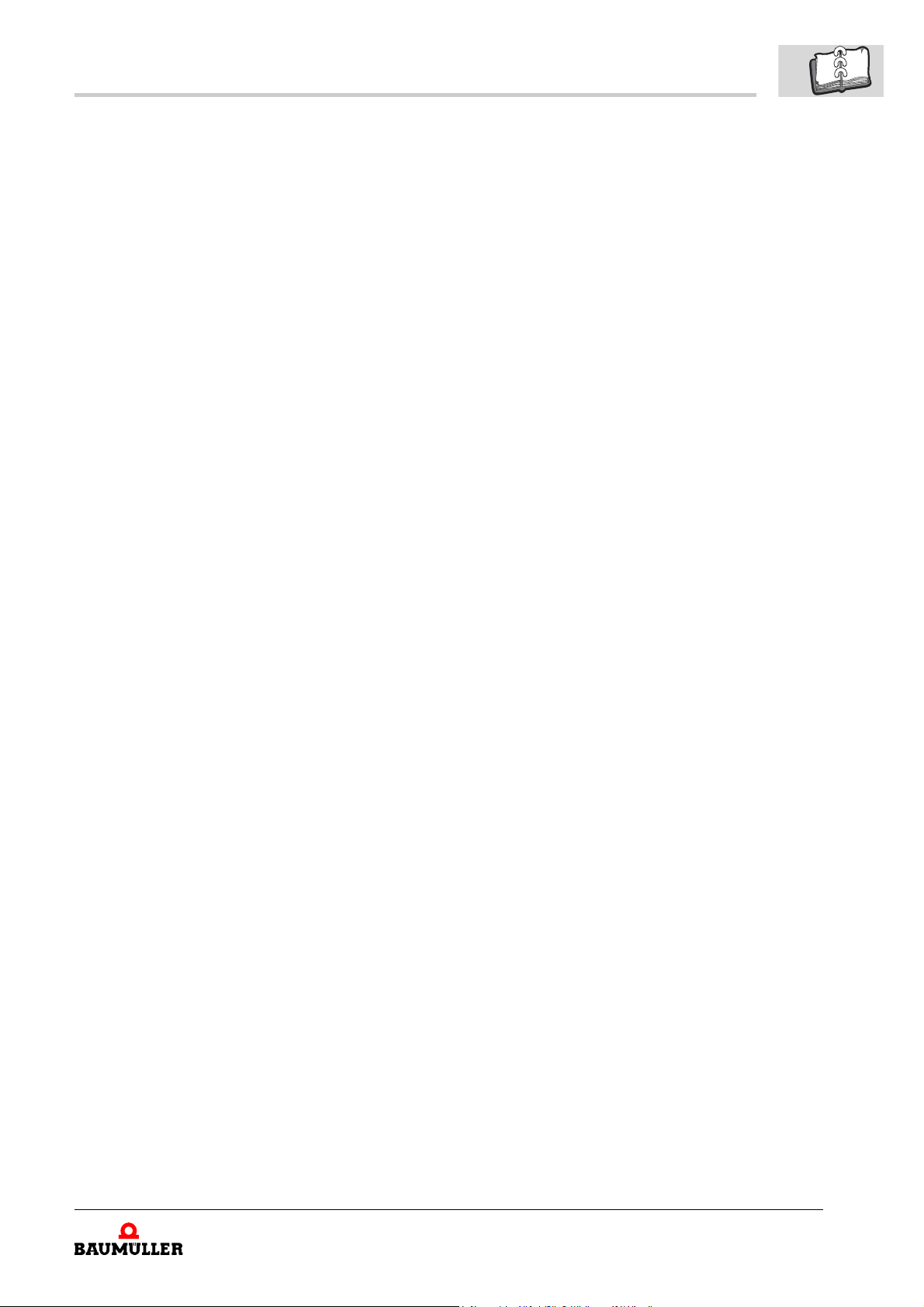

Figure 16: ProDrive: Navigation Motor general

16 Click on the "Motor database" button in the icon bar in the Motor window.

Figure 17: ProDrive: Motor database

17 The following window appears.

Parameter manual b maXX BM3000

Document no.: 5.12001.07

33

of 820

2.7

Performing the commissioning

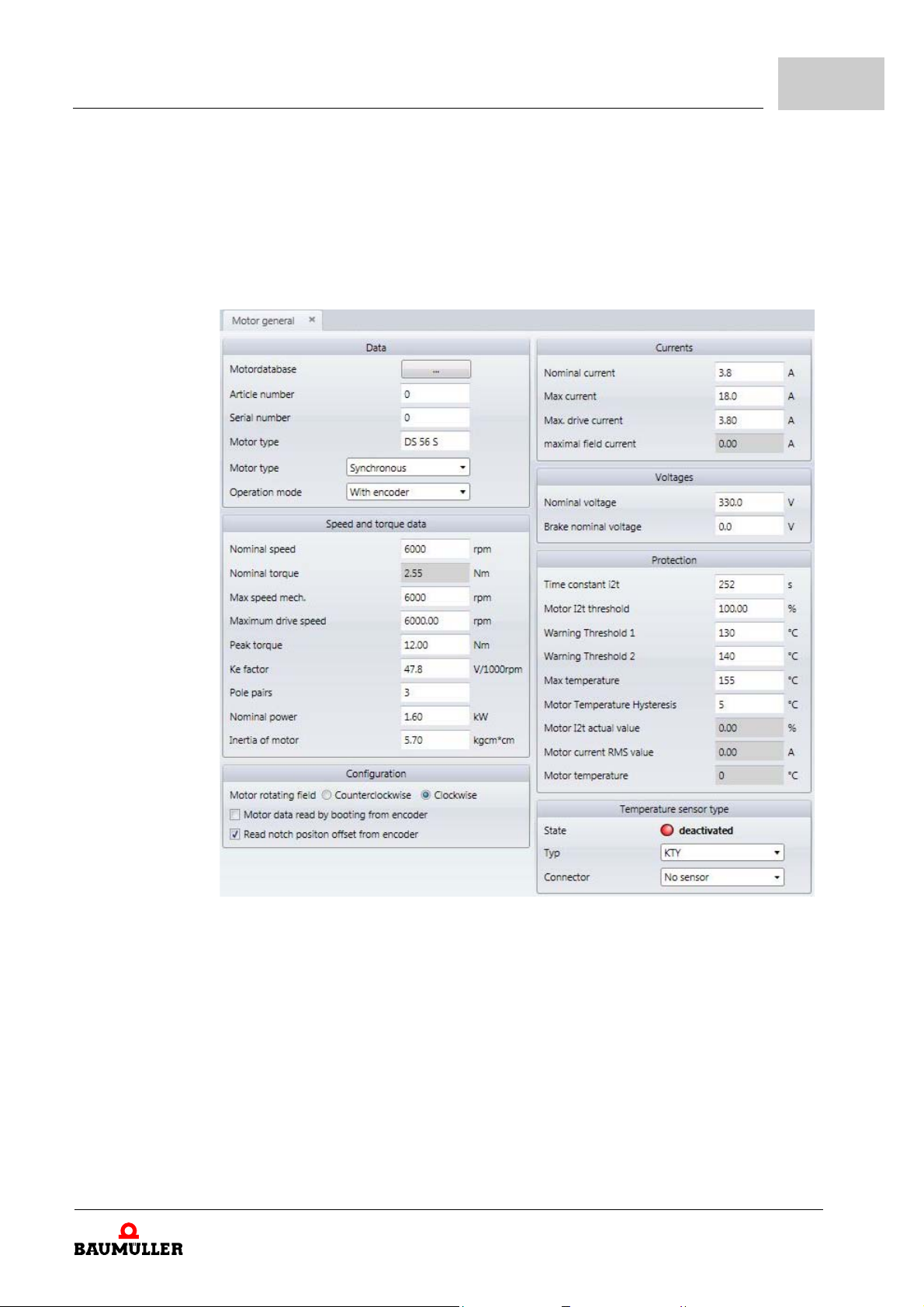

Figure 18: ProDrive: Selecting the motor

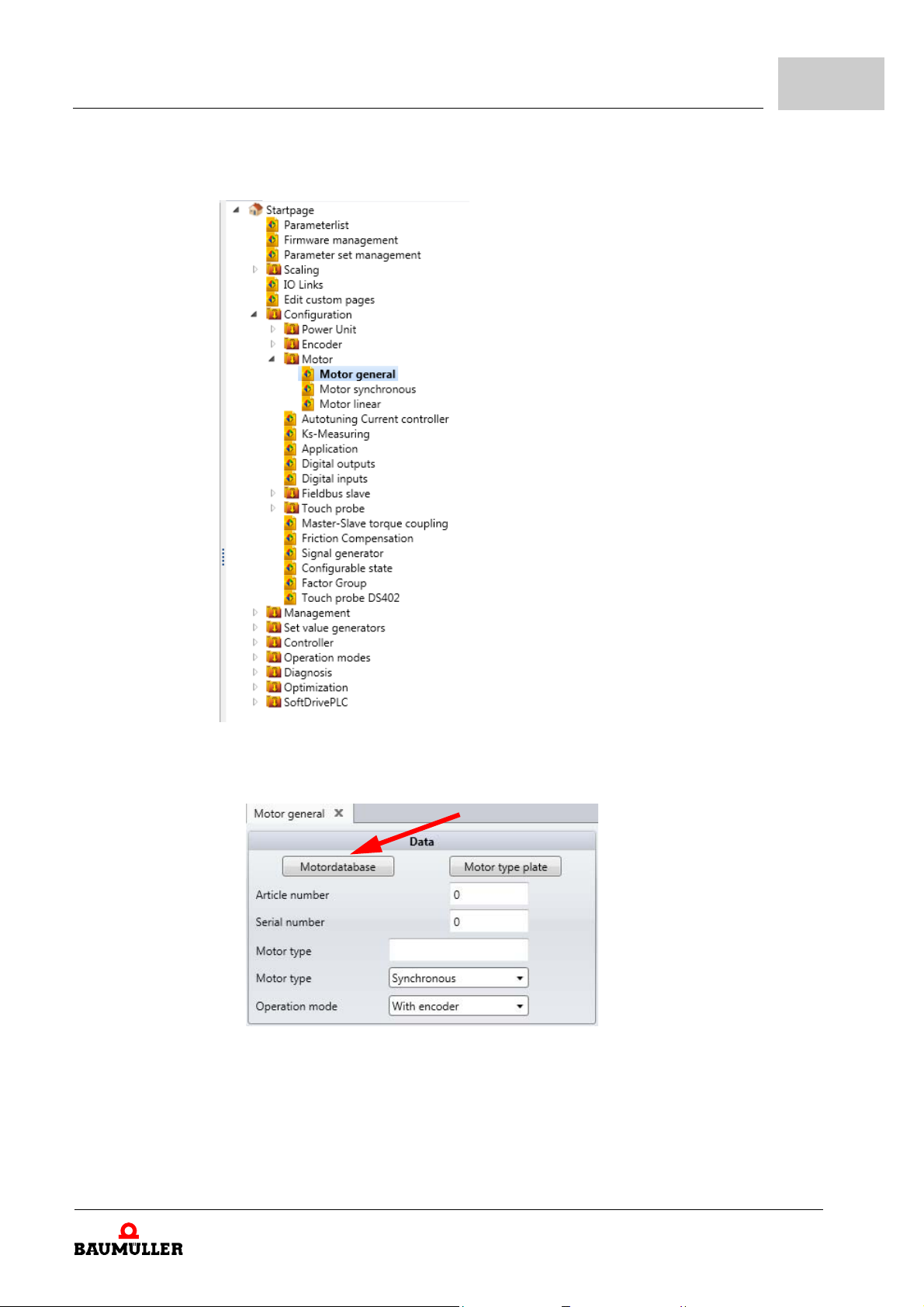

18 Select the synchron motor "DS 56-S" with the following parameter in this window:

m the nominal voltage for the motor DC link: "540 V"