SW4 40V Battery Powered

Chainsaw

User Manual

[Revision 1.0 April 2018]

READ THIS MANUAL CAREFULLY BEFORE USE – FAILURE TO DO SO MAY RESULT IN INJURY, PROPERTY

DAMAGE AND MAY VOID WARRANTY. • KEEP THIS MANUAL FOR FUTURE REFERENCE. • Products covered by

this manual may vary in appearance, assembly, inclusions, specifications, description and packaging.

E&OE ©2018 Bäumr-AG

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 2

Safety

Safety messages are designed to alert you to possible dangers or hazards that could cause death, injury or

equipment or property damage if not understood or followed. Safety messages have the following symbols:

You WILL be KILLED or

SERIOUSLY INJURED if you

do not follow instructions.

You CAN be KILLED or

SERIOUSLY INJURED if you

do not follow instructions.

You CAN be INJURED if you

do not follow instructions or

equipment damage may occur.

It is vital that you read and understand

this user manual before using the product,

including safety warnings, and any

assembly and operating instructions.

Keep the manual for future reference.

Safety precautions and recommendations

detailed here must be fully understood

and followed to reduce the risk of injury,

fire, explosion, electrical hazard, and/or

property damage.

Safety information presented here is

generic in nature – some advice may not

be applicable to every product. The term

"equipment" refers to the product, be it

electrical mains powered, battery powered

or combustion engine powered.

• Before Use - If you are not familiar with

the safe operation/handling of the

equipment, or are in any way unsure of

any aspect of suitability or correct use

for your application, you should

complete training conducted by a

person or organization qualified in safe

use and operation of this equipment,

including fuel/electrical handling/safety.

• Do NOT operate the equipment in

flammable or explosive environments,

such as in the presence of flammable

liquids, gases or dust. The equipment

may create sparks or heat that may

ignite flammable substances.

• Keep clear of moving parts.

• Equipment may be a potential source of

electric shock or injury if misused.

• Do NOT operate the equipment if it is

damaged, malfunctioning or is in an

excessively worn state.

• Do NOT allow others to use the

equipment unless they have read this

manual and are adequately trained.

• Keep packaging away from children risk of suffocation!

• Operators must use the equipment

correctly, consider conditions and pay

due care to persons and property.

• Ensure that any property that may be

damaged by equipment failure is not

within the work area / operating range.

General Work Area Safety

• Work areas should be clean and well it.

• Do not operate the equipment if

bystanders, animals etc are within

operating range of the equipment or the

general work area.

• If devices are provided for connecting

dust extraction / collection facilities,

ensure these are connected and used

properly. Dust collection can reduce

dust-related hazards.

General Personal Safety

• Wear appropriate protective equipment

when operating, servicing, or when in

the operating area of the equipment to

help protect from eye and ear injury,

poisoning, burns, cutting and crush

injuries. Protective equipment such as

safety goggles, respirators, non-slip

safety footwear, hard hat, hearing

protection etc should be used for

appropriate equipment / conditions.

Other people nearby should also wear

appropriate personal protective

equipment. Do not wear loose clothing

or jewellery, which can be caught in

moving parts. Keep hair and clothing

away from the equipment.

• Stay alert and use common sense

when operating the equipment. Do not

over-reach. Always maintain secure

footing and balance.

• Do not use the equipment if tired or

under the influence of drugs, alcohol or

medication.

• This equipment is not intended for use

by persons with reduced physical,

sensory or mental capabilities.

General Fuel Safety

• Petrol/fuel/gasoline is extremely

flammable – keep clear of naked

flames or other ignition sources.

• Do not spill fuel. If you spill fuel, wipe it

off the equipment immediately – if fuel

gets on your clothing, change clothing.

• Do NOT smoke near fuel or when

refuelling.

• Always shut off the engine before

refuelling.

• Do NOT refuel a hot engine.

• Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly.

• Always refuel in well ventilated areas.

• Always check for fuel leakage. If fuel

leakage is found, do not start or run the

engine until all leaks are fixed.

General Carbon-Monoxide Safety

• Using a combustion engine indoors

CAN KILL IN MINUTES. Engine

exhaust contains carbon-monoxide – a

poison you cannot smell or see.

• Use combustion engines OUTSIDE

only, and far away from windows, doors

and vents.

General Equipment Use and Care

• The equipment is designed for

domestic use only.

• Handle the equipment safely and

carefully.

• Before use, inspect the equipment for

misalignment or binding of moving

parts, loose components, damage or

any other condition that may affect its

operation. If damaged, have the

equipment repaired by an authorised

service centre or technician before use.

• Prevent unintentional starting of the

equipment - ensure equipment and

power switches are in the OFF position

before connecting or moving

equipment. Do not carry equipment

with hands or fingers touching any

controls. Remove any tools or other

items that are not a part of the

equipment from it before starting or

switching on.

• Do not force the equipment. Use the

correct equipment for your application.

Equipment will perform better and be

safer when used within its design and

usage parameters.

• Use the equipment and accessories

etc. in accordance with these

instructions, considering working

conditions and the work to be

performed. Using the equipment for

operations different from those

intended could result in hazardous

situations.

• Always keep equipment components

(engines, hoses, handles, controls,

frames, housings, guards etc) and

accessories (cutting tools, nozzles, bits

etc) properly maintained. Keep the

equipment clean and, where applicable,

properly lubricated.

• Store the equipment out of reach of

children or untrained persons. To avoid

burns or fire hazards, let the equipment

cool completely before transporting or

storing. Never place or store the

equipment near flammable materials,

combustible gases or liquids etc.

• The equipment is not weather-proof,

and should not be stored in direct

sunlight, at high ambient temperatures

or locations that are damp or humid.

• Do not clean equipment with solvents,

flammable liquids or harsh abrasives.

• For specific equipment safety use and

care, see Equipment Safety.

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 3

General Battery and Charging Safety

• Use only with the batteries and battery

charger specified by the manufacturer.

• When battery is charged, disconnect

the charger from the power supply and

remove the battery from the charger.

• Batteries can explode in the presence

of an ignition source, such as a pilot

light. To reduce the risk of serious

personal injury, never use any cordless

product in the presence of open flame.

Exploding batteries can propel debris

and chemicals.

• Do not use the charger in wet areas or

expose it to rain or water.

• Do not open the battery – danger of

short-circuiting and/or explosion.

• Do not attempt to destroy or

disassemble the battery pack or

remove any of its components.

• Do not touch the battery terminals with

metal objects and/or body parts as

short-circuit and/or personal injury may

result.

• Explosion hazard – protect the battery

against heat; for example, direct

sunlight and fire. Do not store batteries

in vehicles or locations subject to heat.

• Explosion hazard – do not open and/or

short-circuit the battery.

• Poison hazard – battery leakage (liquid

ejection). Under extreme conditions,

liquid may be ejected from the battery –

avoid contact. If contact accidentally

occurs, immediately seek medical

attention, and flush with water. If liquid

contacts eyes, immediately seek

medical attention, flush with clean

water for at least 10 minutes. Liquid

ejected from the battery may cause

irritation or burns.

• Ensure that the battery charger

electrical cord is not subjected to

damage or stress. Do not operate the

battery charger if it has a damaged

electrical cord or plug.

• For best results, charge batteries in

temperatures between 7°C (45°F) and

40°C (104°F).

• Dispose of non-serviceable batteries in

an environmentally responsible manner

and according to local regulations.

General Electrical Safety

• Inspect electrical equipment, extension

cords, power bars, and electrical fittings

for damage or wear before each use.

Repair or replace damaged equipment

immediately.

• Ensure all power sources conform to

equipment voltage requirements and

are disconnected before connecting or

disconnecting equipment.

• When wiring electrically powered

equipment, follow all electrical and

safety codes.

• Wherever possible, use a residual

current device (RCD).

• High voltage / high current power lines

may be present. Use extreme caution

to avoid contact or interference with

power lines. Electrical shock can be

fatal.

• Electrically grounded equipment must

have an approved cord and plug and

be connected to a grounded electrical

outlet.

• Do NOT bypass the ON/OFF switch

and operate equipment by connecting

and disconnecting the electrical cord.

• Do NOT use equipment that has

exposed wiring, damaged switches,

covers or guards.

• Do NOT use electrical equipment in wet

conditions or in damp locations.

• Do NOT use electrical cords to lift,

move or carry equipment.

• Do NOT coil or knot electrical cords,

and ensure electrical cords are not trip

hazards.

General Service Information

• The equipment must be serviced or

repaired at authorised service centres

by qualified personnel only.

• Replacement parts must be original

equipment manufacturer (OEM) to

ensure equipment safety is maintained.

• Do NOT attempt any maintenance or

repair work not described in this

manual.

• After use, the equipment and

components may still be hot – allow the

equipment to cool and disconnect spark

plugs and/or electrical power sources

and/or batteries from it before making

adjustments, changing accessories or

performing repair or maintenance.

• Do NOT make adjustments while the

equipment is running.

• Perform service related activities in

suitable conditions, such as a

workshop.

• Replace worn, damaged or missing

warning/safety labels immediately.

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 4

Safety Symbols

The product may have safety warning labels attached to it, explained below. Understand the symbols on

your product and their meanings. If any stickers become unreadable, unattached etc, replace them.

Flammable Material Hazard

Flammable liquids, gases or

substances etc may present.

Avoid ignition sources and

open flames. Danger of fire.

Read User Manual

Read and fully understand

product safety warnings,

operation, procedures etc

before using the product.

Use Hand Protection

Wear appropriate hand

protection and take due care

as the product or use of the

product may present hand

hazards.

Carbon-Monoxide Hazard

Do not use the product in

confined areas or without

adequate ventilation. Carbon-

monoxide poisoning can be

fatal.

Electrocution / Electrical

Shock Hazard

High voltage or high current

electricity may be present or

required by the product. Take

due care when handling

electrical products, cables,

plugs and leads. Electrical

shock can be fatal.

Toxic Fumes / Dust Hazard

Using the product or by-

products from use may

produce fumes, smoke or

particles that could be harmful

if inhaled. Wear appropriate

breathing protection and have

adequate ventilation.

Explosive Material Hazard

Combustible liquids, gases or

substances etc may be

present. Avoid ignition sources

and open flames. Danger of

explosion.

Cutting / Amputation Hazard

The product may have blades,

edges or mechanical devices

that can cause severe cut

injury to fingers, limbs etc.

Take due care when handling

and using the product.

Crush Hazard

The product may have blades,

edges or mechanical devices

that can cause severe crush

injury to fingers, limbs etc.

Take due care when handling

and using the product.

Single Operator Only

The product must be operated

by a single person only. More

than one person operating the

product may introduce

additional hazards.

Use Face Protection

Wear appropriate full-face

protection and take due care

as the product or use of the

product may present face and

eye hazards.

Use Foot Protection

Wear appropriate foot

protection and take due care

as the product or use of the

product may present foot

hazards.

Use Eye / Ear / Head

Protection

Wear appropriate eye and / or

ear and / or head protection

and take due care as the

product or use of the product

may present eye, hearing and

head hazards.

Running Hazard

Do not run on or near the

product as doing so may

present a fall hazard.

Diving Hazard

Do not dive into the product as

doing so may present a neck /

head injury hazard.

Adult Supervision Required

Always supervise children and

other users of a product to

prevent drowning or injury.

Skin Penetration / Puncture

Hazard

The product may produce

pressure, emit liquids or

objects that can cause severe

injury to fingers, limbs, blood

etc. Take due care when

handling and using the

product.

Hot Surface Hazard

Be aware that the product may

produce high temperatures

and hot surfaces that can

cause burn injuries.

Flying Debris Hazard

Be aware that the product or

use of the product may

present hazards produced by

flying debris. Wear appropriate

clothing and protectiove

devices.

Moving Parts Hazard

Be aware that the product

contains or uses mechanical

devices that move or rotate.

Always wait for moving parts

to stop fully before handling

the product, adjusting,

maintenence etc.

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 5

Carbon-Monoxide Hazard

Do not use the product in

confined areas or without

adequate ventilation. Carbon-

monoxide poisoning can be

fatal.

Pull Hazard

Be aware that the product

contains or uses mechanical

devices that can pull in objects

and can cause severe injury to

fingers, limbs etc. Take due

care when handling and using

the product.

Slope / Fall Injury Hazard

Be aware that using the

product on sloping surfaces or

in slippery conditions may

present additional dangers

from falls and contact with

blades, moving parts, hot

surfaces etc.

"Slam Dunk" Warning

Do NOT attempt "slam dunk"

maneouvres as this may result

in severe injury due to falling,

product breakage or collapse

etc.

Electrocution / Electrical

Shock Hazard - Outdoor

High voltage or high current

electricity may be present or

required by the product. Do

NOT use in rain, damp or wet

conditions. Electrical shock

can be fatal.

Electrocution / Electrical

Shock Hazard - Disconnect

High voltage or high current

electricity may be present or

required by the product.

Always disconnect the product

from the electrical supply

before handling the product,

adjusting, maintenence etc.

Power Line Electrocution

Hazard

High voltage / high current

power lines may be present.

Use extreme caution to avoid

contact or interference with

power lines. Electrical shock

can be fatal.

"Kick-Back" Hazard

High level of "kick-back"

hazard that can cause the

machine to suddenly rotate

towards operator. Kick-back

injury can be fatal.

Winch Operator Position

Hazard

Do NOT stand between winch

and load. Do NOT use winch

to move people.

Winch Lift Hazard

Do NOT LIFT load vertically.

Use machine to PULL only.

Cable Hazard

Ensure that load bearing cable

is not kinked or knotted.

Winch Cable Hazard

Ensure that there is a

minimum number of cable

coils on winching mechanism.

Winch Hook Hazard

Carry hook to load – do NOT

throw or run.

Flash / Blinding Hazard

Wear appropriate eye

protection for welding. Dorect

exposure to weld arcs may

cause permanent eye injury.

Laser Hazard

Laser may be in use – do NOT

look directly at laser, or allow

others to.

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 6

Equipment Safety

Chainsaws are high-speed, fast-cutting equipment with exposed blades that can cause

serious or fatal injury if not used correctly or without taking proper safety precautions. It is

extremely important that you read and fully understand the information in this section and all other

safety warnings / recommendations and usage instructions before using the equipment.

Operator

• If you are untrained in the use of a chainsaw, it is highly recommended that you be trained/instructed by

a suitably qualified or experienced chainsaw user before using the machine.

• Fully understand how to safely operate the machine and the sawing process to avoid "kick-back". See

Chainsaw Operation.

• You must be in good physical condition to use a chainsaw. NEVER operate the machine when tired, or

under the influence of any substance (medication, alcohol, drugs etc) that may impair your judgement,

alertness, physical strength, vision or dexterity.

• Maintain sure-footing and balance always when using or handling the chainsaw and have full awareness

of your surroundings and any possible hazards.

• Prolonged chainsaw use may lead to health complications, such as carpal tunnel syndrome, due to

vibration. To help reduce the possibility of such conditions, wear gloves, take breaks frequently, keep

fingers and hands warm, and maintain the equipment for optimal operation and minimal vibration. It is

recommended to seek medical advice if you feel numbness or burning sensations in fingers/hands.

Clothing and Protective Equipment – All Operators and Assistants

• Wear approved safety goggles, or safety glasses with adequate top and side protection. In addition to

eye protection, wearing a full-face shield is highly recommended.

• Wear suitable hearing protection.

• Wear an approved safety hard-hat.

• Wear heavy-duty, non-slip leather or protective gloves.

• Wear approved heavy-duty safety boots, with steel toe-caps and non-slip soles.

• Wear suitable overalls or work clothing that fits snugly, but does not restrict movement. It is highly

recommended to provide additional cut protection to legs, such as Kevlar chaps. Avoid loose fitting

clothing, scarves, jewellery etc and keep long hair contained to avoid getting caught or pulled by the

chainsaw or by tree branches etc.

Work Area Safety

• Use EXTREME CAUTION to avoid power lines – contact can be fatal. Do NOT cut branches touching

power lines or that may fall onto power lines when cut.

• To operate the chainsaw at height it is highly recommended to use a "scissor lift" or "cherry picker" and

ensure that the work platform is completely stable. Do NOT use ladders, ropes or tree branches.

• Ensure that any person other than the operator and any assistants is kept a minimum 25m (75') away

from where the equipment is being used or where there is any possibility of falling branches, trees etc.

Be aware of any property that may be affected by falling branches, trees etc.

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 7

Operational Safety

• Do NOT use the machine if the trigger or any safety guard or mechanism is not installed or is not

operating correctly – have the machine inspected and repaired at an authorised service centre before

using it again.

• Fully understand how to safely operate the machine and the sawing process to avoid "kick-back". See

Chainsaw Operation.

• Always hold the machine firmly with both hands during operation. Always use the machine handles.

• Do NOT use a ladder or tree branches as a platform when using the machine at height – always use a

stable, flat platform such as a cherry-picker or scissor-lift.

• Do NOT use the equipment for purposes it is not designed for, such as wood chipping.

• Before cutting any branch, limb, pruning or cross-cutting, ensure that none of the materials to be cut is

under tension that may be released unexpectedly during cutting.

• Tree felling should be performed by trained and experienced personnel only. If in any doubt, seek

assistance and advice.

Transportation Safety

• Always STOP the machine and remove the battery before putting

the machine down, transporting or working on it (adjusting etc).

• Fit the blade sheath whenever transporting or storing the machine.

• When walking with the machine, ensure the battery is removed, the

chain brake is engaged, and the blade sheath is installed. Hold the

machine by the upper handle, with the blade pointing backwards

from the body.

• When transporting the machine in a vehicle, ensure the battery is removed, the chain brake is engaged,

and the blade sheath is installed. Secure the machine in an upright position to prevent tip-over or

machine damage.

• Do NOT store batteries in direct sunlight or hot environments, such as vehicle interiors, for any period.

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 8

Table of Contents

Safety ............................................................................................................................................. 2

Safety Symbols ............................................................................................................................................ 4

Equipment Safety .......................................................................................................................... 6

Parts Identification ........................................................................................................................ 9

Batteries and Battery Charging ................................................................................................. 10

Charging ..................................................................................................................................................... 10

Before Use Checklist .................................................................................................................. 11

Assembly .................................................................................................................................................... 11

Saw Chain Lubricant .................................................................................................................................. 12

Saw Chain Tension .................................................................................................................................... 13

Checking Tension ................................................................................................................................ 13

Adjusting Tension ................................................................................................................................ 13

Chainsaw Operation ................................................................................................................... 14

Preparing the Chainsaw for Use ................................................................................................................ 14

Starting and Stopping the Motor ................................................................................................................ 14

Understanding and Avoiding "Kick-Back" and Other Reactionary Forces ................................................. 15

Using the Chain Brake ............................................................................................................................... 16

Basic Cutting Guidelines ............................................................................................................................ 17

Maintenance ................................................................................................................................ 18

Saw Chain and Chain Bar .......................................................................................................................... 19

Inspection and Cleaning ...................................................................................................................... 19

Chain Lubricant .......................................................................................................................................... 20

Cleaning Guidelines ................................................................................................................................... 21

Transportation and Storage ....................................................................................................... 21

Troubleshooting .......................................................................................................................... 22

Specifications ............................................................................................................................. 22

SW4 Battery Powered Chainsaw

No.

Name

No.

Name

1

Chain Bar

9

Trigger

2

Saw Chain

10

Battery

3

Upper Handle

11

Battery Release

4

Chain Lubricant Tank / Cap

12

Chain Tension Adjustment Ring

5

Rear Handle

13

Chain Bar Lock Nut

6

Chain Brake Handle

14

Chain Drive Cover

7

Speed Selection Controls

15

Log Spike

8

Trigger Safety Button

2 3 4 9 6 8 5

10

12 1 13

15

11

16

7

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Parts Identification

Chainsaws come with all parts required for normal domestic use. A basic toolkit may also be included. It is

strongly recommended that you familiarise yourself with all major components of the machine before using it

or performing any maintenance tasks.

Products detailed in this manual may vary in appearance, inclusions, description and packaging

from those shown or described. This section shows typical major components common to most 2-

stroke petrol powered chainsaws; the position of some components may also vary between models.

E&OE ©2018 Bäumr-AG 9

SW4 Battery Powered Chainsaw

C D E

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Batteries and Battery Charging

Batteries may come supplied in a low-charge condition for shipping reasons – charge before

use. • A battery that is new or has not been used for a long period does not charge to full

capacity until after approximately 5 charge/discharge cycles. • Do not recharge batteries after using them if

they are not to be used for an extended period. • Recharge batteries only as and when required. • If the

battery is warm after use, allow it to cool before charging, otherwise it may not fully charge. • Use only with

the batteries and battery charger specified by the manufacturer. • Batteries can explode in the presence of

an ignition source, such as a pilot light. Never use any cordless product in the presence of open flame.

Exploding batteries can propel debris and chemicals. • Do not use the charger in wet areas or expose it to

rain or water. • Ensure that the battery charger electrical cord is not subjected to damage or stress. Do not

operate the battery charger if it has a damaged electrical cord or plug. • Do not open the battery – danger of

short-circuiting and/or explosion. • Do not touch the battery terminals with metal objects and/or body parts as

short-circuit and/or personal injury may result. • For best results, charge batteries in temperatures between

7°C (45°F) and 40°C (104°F). • Dispose of non-serviceable batteries in an environmentally responsible

manner and according to local regulations. Charging time varies for different battery types depending on

battery capacity and charger output etc. • To prolong battery life, avoid leaving the battery pack on charge for

extended periods (over 30 days without use). • During charging, the battery may become warm and some

noise may be emitted – this is normal.

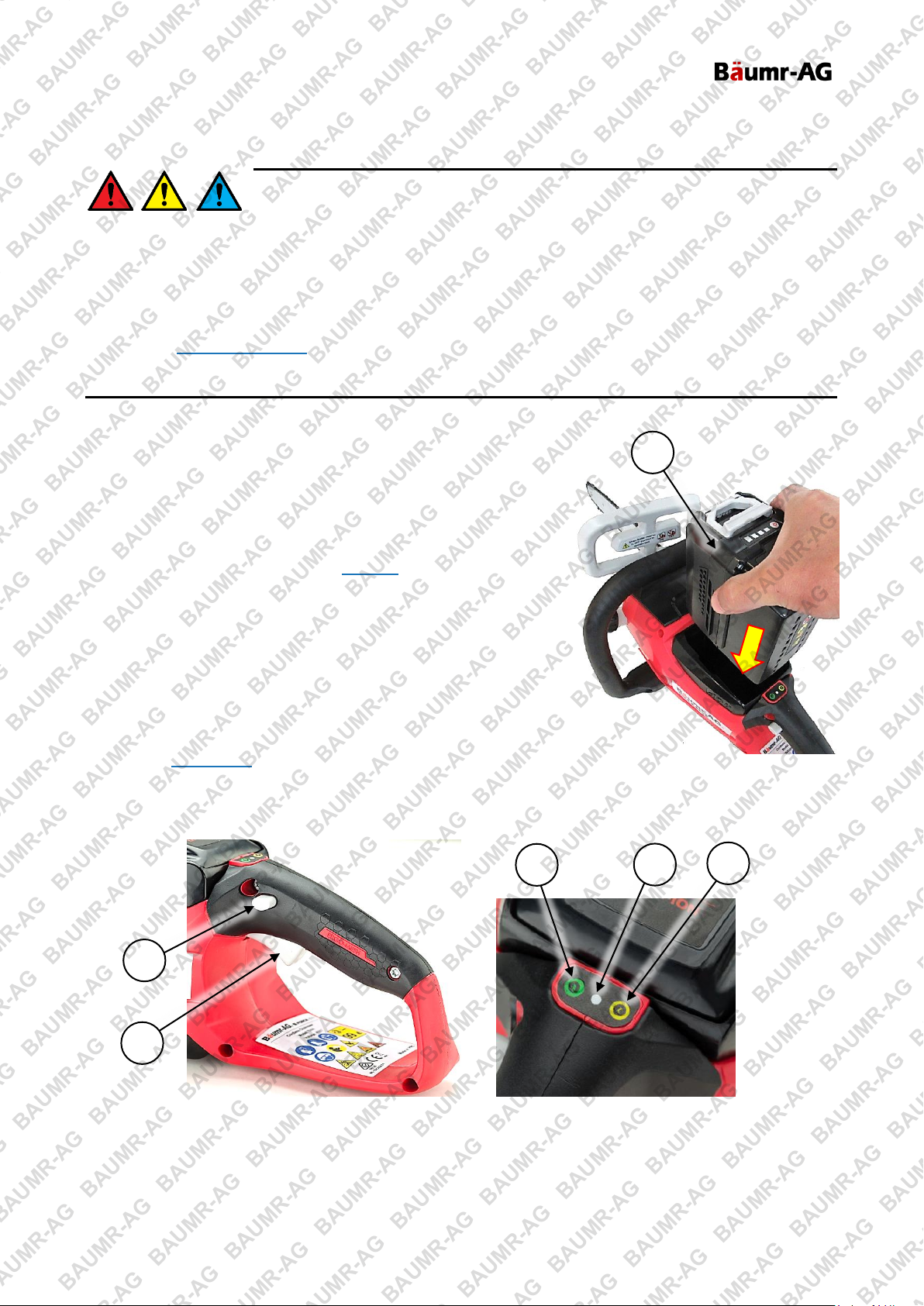

Charging

Generally, if the tool stops during use, the cutting power

reduces, or the motor slows considerably, it indicates

that the battery needs charging. To remove the battery

(A), lift the battery handle (B) until the battery releases,

then pull the battery from the tool.

Batteries for the SW4 have a display built-in that shows

current charge status. To use the functions, press button

(C) on the battery – charge capacity is shown as green

lamps for 25%, 50%, 75% and 100%.

The battery charger has charge status LED indicators

that illuminate and flash in various combinations:

• Green Flash – Charging.

• Green ON – Battery charged.

1. Plug the battery charger power supply (D) into a 240VAC mains electrical outlet and switch on.

2. Slide the battery fully into the battery charger connector (E). The battery charger indicator LEDs will

indicate battery charge status. Charging takes approximately 2.5 hours from fully discharged.

3. When the battery is fully charged, unplug the charger from power supply and disconnect the battery

charger connector from the battery pack.

E&OE ©2018 Bäumr-AG 10

SW4 Battery Powered Chainsaw

AA

C

D B A

E

F

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Before Use Checklist

Ensure that you carry out all procedures below before starting operating the equipment. All

procedures described are generic in nature and slight variations between different models may

exist. Failure to follow the checklist and carry out the procedures correctly may result in making the

product warranty void. • The saw chain cutters are very sharp – wear suitable protective gloves when

handling the saw chain.

Assembly

Typically, the equipment requires minimal assembly. Prior to

assembly, unpack all components and check that all items

have been received.

The adjacent image shows the chainsaw after unpacking,

including chainsaw body, chain bar, saw chain, battery,

battery charger, and chain sheath.

1. Remove the chain drive cover – lift the edge of the chain

bar lock nut (A) (this is the "unlock" position), then rotate

left (anti-clockwise) to unscrew it, then remove the chain

drive cover (B) from the chainsaw body.

2. On the chain bar (C), rotate the tensioning wheel (D) left

(anti-clockwise) until it stops – this is the least tension

position and helps with installing the chain and bar.

3. Place the saw chain (E) into position and engage it with the drive

sprocket (F). Ensure that the sharp edges of the saw chain cutters

(AA) are facing the correct direction.

4. Place the chain bar (C) into position so the chain bar stud (G)

protrudes through the hole in the chain bar tensioning wheel.

5. Wrap the chain around the chain bar so it is sitting in the chain bar

groove. Note that the chain is slack.

E&OE ©2018 Bäumr-AG 11

SW4 Battery Powered Chainsaw

G

BB

CC

D B A

DD

G

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

6. Rotate the tensioning wheel right (clockwise) so that the chain is no longer slack. Check that it is sitting

in the chain bar groove on both the top and bottom edges of the chain bar.

7. Bring the chain drive cover (B) into position, ensuring that alignment spigot (BB) and locating tab (CC)

engage with the applicable holes in the chainsaw body. When properly aligned, the nut (DD) will engage

with the chain bar stud (G).

8. Lift the edge of the chain bar lock nut (A) (this is the "unlock" position), then rotate right (clockwise) to

screw it onto the chain bar stud until the chain bar is just held firmly (do not fully tighten the lock nut),

then adjust chain tension.

Saw Chain Lubricant

The saw chain and drive system requires adequate lubricant of the correct type to operate safely and

efficiently. The machine is shipped without chain lubricant. Check the chain lubricant level and ensure that it

is at the recommended level. See Chain Lubricant.

E&OE ©2018 Bäumr-AG 12

SW4 Battery Powered Chainsaw

A

LOOSE

TIGHT

CORRECT

B

C

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Saw Chain Tension

Ensure that the saw chain is correctly tensioned and the chain bar lock nut is properly

tightened before use and during cutting. • The saw chain will "stretch" with use, so it is

important to check chain tension before and during use • The saw chain cutters are very sharp – wear

suitable protective gloves when handling the saw chain. • Do NOT check chain tension with the battery

installed in the tool. • Do NOT adjust chain tension with the battery installed in the tool.

Correct saw chain tension is extremely important in terms of both machine efficiency and operator safety.

Check chain tension before each use. Check chain tension frequently during use – whenever the machine is

put down (the battery MUST be removed first).

Checking Tension

1. Remove the battery from the tool.

2. The saw chain should fit snugly into the groove in the chain bar and it must be possible to pull the chain

along the bar by hand. You should be able to lift the saw chain just out of the chain bar groove without

excessive effort.

3. If the chain "sags" under the chain bar or can be lifted well out of the chain bar groove, it is too loose.

4. If the chain is snug in the chain bar groove but cannot be lifted out slightly or be pulled around the bar by

hand, it is too tight.

Adjusting Tension

1. Remove the battery from the tool.

2. Lift the edge of the chain bar lock nut (A) (this is the "unlock" position), then rotate left (anti-clockwise) to

loosen it just enough so you can lift the end of the chain bar (B) slightly.

3. Rotate the chain tension adjustment ring (C) to set the chain tension. Rotate right (clockwise) to increase

tension; rotate left (anti-clockwise) to reduce tension. If it is difficult to rotate the adjustment ring, check

that the chain cover lock nut is sufficiently loosened.

4. Check chain tension and re-adjust, if necessary.

5. Firmly tighten the chain bar lock nut by hand. You should not be able to move the end of the chain bar

up or down when properly tightened.

E&OE ©2018 Bäumr-AG 13

SW4 Battery Powered Chainsaw

A

C

B

F D E

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Chainsaw Operation

Chainsaws are high-speed, fast-cutting equipment with exposed blades that can

cause serious or fatal injury if not used correctly or without taking proper safety

precautions. It is extremely important that you read and fully understand the information in this

section and all other safety warnings / recommendations and usage instructions before using the

equipment. • Always wear suitable protective clothing and equipment when using the machine. • Inspect the

machine before each use and check for wear or damage. If the machine is damaged, have it inspected and

repaired at an authorised service centre before using it again. • If you experience excessive vibration from

the machine during operation, this may indicate wear or damage. It is recommended to have it inspected and

repaired before using it again. • Be aware that parts of the machine may be extremely hot. • Ensure that the

saw chain is correctly tensioned and the chain bar lock nut is properly tightened before use. • Always release

chain tension after finishing work to prevent damage through over-tension as the saw chain cools and

contracts.

Note the following recommendations:

• Operate the tool at full speed when cutting.

• Cut according to the recommended methods. If in doubt, do

NOT cut – seek professional advice.

Preparing the Chainsaw for Use

• Ensure the battery is adequately charged.

• Insert the battery (A) into the battery compartment. Batteries

can be inserted correctly in one direction only – ensure that the

battery is fully inserted.

Starting and Stopping the Motor

1. Remove the blade sheath.

2. Pull the chain brake handle to the "OFF" position.

3. Press and hold the trigger safety button (B), then squeeze the trigger (C) to start the tool – once running,

you can release the safety button. The tool will run at the last used speed setting. To change speed,

press (D) for low speed (the indicator (E) illuminates for low speed); press (F) for high speed.

To stop the tool, release the trigger, then push the chain brake handle forward to the "ON" position.

E&OE ©2018 Bäumr-AG 14

SW4 Battery Powered Chainsaw

NEVER ALLOW ANY OBJECT

TO COME INTO CONTACT

WITH THE KICK-BACK ZONE

Kick-Back

Zone

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

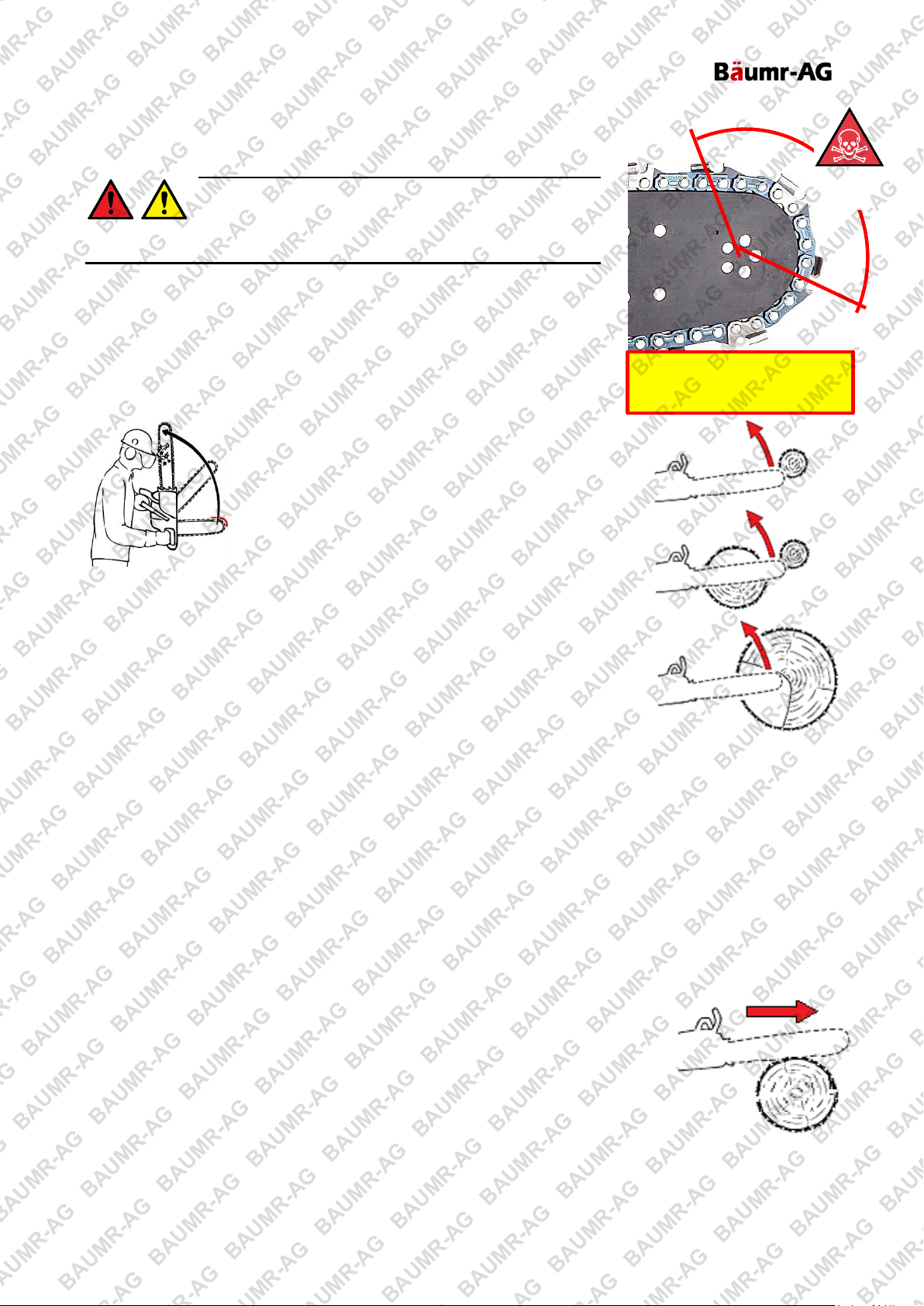

Understanding and Avoiding "Kick-Back"

and Other Reactionary Forces

Kick-back and other reactionary forces can cause

loss of control of the machine and can result in

serious, even fatal injury – use the chainsaw in ways to avoid kickback and other reactive forces at all times.

When the saw chain is rotating, many forces are created, such as the

ability to cut. The contact point between the chainsaw and object to cut is

critical. If the chainsaw is not used correctly, cutting forces may become

"reactionary", in that instead of the chain rotating, a reactionary force is

created. Many factors affect the occurrence and force of reaction, such as

saw chain speed, contact angle, and saw chain condition.

Kick-Back

"Kick-back" is a reactionary force that causes the chain

bar to rotate up and back, against the direction of cut.

Kick-back can also be thought of as the chain cutters at

the tip of the chain bar – the "kick-back zone", "digging

in" to the object to be cut and momentarily stopping or

significantly slowing rotation of the saw chain, which

causes the chainsaw to suddenly and quickly rotate

backwards towards the operator.

The chain brake handle is a safety device that is designed to apply the chain

brake if the handle is moved forward. During a "kick-back" event, the sudden

rotation upward of the chain bar will cause the chain brake handle to activate

through inertia or to contact the operator's hand or arm, therefore stopping the

tool. To avoid kick-back:

• Do NOT use the tip of the saw for cutting or allow it to make contact with

any object.

• Always hold the machine firmly by both front and rear handles when

operating.

• Maintain saw chain sharpness and the correct cutter shape and cutting depth.

• Do NOT use the machine above shoulder height or in any way where the machine cannot be securely

held with both hands or the entire machine is not visible to the operator.

• Cut one piece of timber at a time.

• Use extreme caution when inserting the saw into a previous cut.

• Be alert to log shifting or other forces that may close over or pinch the saw chain.

• Stand to the side of the saw chain cutting path.

• Use extreme caution when plunge cutting.

Pull-In

"Pull-in" is a reactionary force that causes the chainsaw to pull forward in the

direction of cut. Pull-in can also be thought of as the chain cutters at the bottom

of the chain bar being caught, pinched or "digging in" to the object to be cut and

momentarily stopping or significantly slowing rotation of the saw chain, which

causes the chainsaw to suddenly and quickly pull forward and away from the

operator. To avoid pull-in:

• Ensure that the log spike (if equipped) is making good contact with the log.

• Use wedges to help prevent cuts closing in over the saw chain.

E&OE ©2018 Bäumr-AG 15

SW4 Battery Powered Chainsaw

Chain Brake

OFF

Chain Brake

ON

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Push-Back

"Push-back" is a reactionary force that causes the chainsaw to push backward

against the direction of cut. Push-back can also be thought of as the chain cutters

at the top of the chain bar being caught, pinched or "digging in" to the object to be

cut and momentarily stopping or significantly slowing rotation of the saw chain,

which causes the chainsaw to suddenly and quickly push back towards the

operator. To avoid push-back:

• Cut one piece of timber at a time.

• Avoid twisting the saw chain when withdrawing the saw from cuts.

Using the Chain Brake

The chain brake prevents the tool from running. Engage the chain brake:

• In an emergency.

• When transporting or storing the machine.

To engage the chain brake, push the chain brake handle forward

until it "clicks" into position.

To release the chain brake, pull the chain brake handle backward until the

brake disengages. You must disengage the chain brake to run the tool.

Testing

To check operation of the chain brake, engage it, then attempt to

run the tool – it must not run. If the saw chain rotates at all during

the test, do NOT use the tool – have it serviced at an authorised

service centre.

E&OE ©2018 Bäumr-AG 16

SW4 Battery Powered Chainsaw

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Basic Cutting Guidelines

The following information are general guidelines to chainsaw use:

Removing Branches/Limbs from Fallen Trees (Limbing)

• Be alert to high kick-back dangers from other branches or tree trunk.

• Be alert to branches/limbs under tension that could move suddenly or launch when being cut.

• Do NOT stand on the log.

• Remove the thinner upper branches first, then move down the trunk to the lower larger branches.

Cutting Logs into Sections (Bucking)

• Ensure the log is stable and cannot move or roll.

• Do NOT stand on the log.

• Cut one piece of timber at a time.

• Do NOT permit another person to hold the log. Do NOT steady the log

with your legs or feet.

• When cutting logs under tension or strain, be alert to pinching the saw chain. Start by making a cut on

the compression side (1), then cut from the tension side (2).

Basic Tree Felling

• Be alert to any power lines, cable or structures.

• Maintain a minimum distance of 2.5 times the height of the tree being

felled to any other person.

• Always consider all conditions that may affect the fall direction of the

tree, including structures and/or other tress, tress condition and decay,

wind direction and speed, slope of the land etc.

• Establish escape paths (A) that can be used if the tree does not fall as

expected. The paths should be clear of obstacles, including equipment,

and be at 45° angles to the opposite direction of tree fall (B).

• Use extreme caution when felling trees that are decayed or rotten inside

or if the trunk is under tension due to tree weight etc.

• For large buttress roots, remove the roots before felling. When cutting into

buttress roots, cut vertically (1) first, then horizontally (2). Remove the

section of root.

• Cut the felling notch (C) perpendicular (90°) to the line of fall and as close to

ground level as practical. The angled cut (5) of the felling notch should be

cut first and at an approximate 45° to the trunk and should extend into the

trunk approximately 20 to 25% of the trunk diameter. Then, make the

horizontal cut (6) of the felling notch. Remove the section of trunk.

• Make the horizontal felling cut (7)

approximately 25 to 50mm (1 to 2")

above the centre of the felling notch, and

extend it into the trunk so that

approximately 10% of the trunk remains

uncut to create the "hinge" (E) – do NOT

cut through the hinge.

• To start and control direction of the fall,

drive wooden wedges into the felling cut

(7), as needed.

E&OE ©2018 Bäumr-AG 17

SW4 Battery Powered Chainsaw

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Maintenance

Do NOT perform and maintenance procedures with the battery installed in the tool. •

The machine should be cool enough to touch before performing maintenance activities. •

Some maintenance activities may be beyond the scope of some users. Do NOT attempt procedures that you

are not comfortable with, or do not have the necessary tools, experience or knowledge for – take the unit to

an authorised service centre or qualified technician for servicing. • Harsh operating environments such as

extreme temperatures, dust etc may necessitate more frequent maintenance. • Failure to follow the

maintenance schedule, using incorrect or non-compatible accessories or replacements parts, or

general negligence may result in making the product warranty void.

To keep the machine performing at optimal efficiency, regular checks and maintenance is required.

E&OE ©2018 Bäumr-AG 18

SW4 Battery Powered Chainsaw

H C A

D

G F E

B

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Saw Chain and Chain Bar

Ensure that the saw chain is correctly tensioned and the chain drive cover lock nut is

properly tightened before use. • The saw chain will "stretch" with use, so it is important to

check chain tension before and during use • The saw chain cutters are very sharp – wear suitable protective

gloves when handling the saw chain. • Use replacement parts from, or recommended by, the manufacturer. •

Always replace the saw chain and/or chain bar with replacements of the correct type (see Specifications). • It

is recommended to have saw chains sharpened professionally.

Inspection and Cleaning

It is essential for efficient operation and safety that the saw chain and chain bar are properly maintained.

Replace the saw chain if it:

• Shows signs of damage, such as broken or chipped cutters, damaged rivets, corrosion etc.

• Can no longer be properly tensioned due to "stretch".

• Can no longer be sharpened properly.

To clean the saw chain, soak it in a proprietary saw chain cleaning solution, solvent, or mixture of ammonia

and water for approximately 15 minutes to help remove dirt, grease and resin/sap. After soaking, brush the

saw chain thoroughly with a saw chain brush or stiff bristle wire brush to remove any stubborn particles, then

lubricate the chain.

Replace the chain bar if it:

• Shows signs of damage, such as bending, cracks, chips or corrosion.

• The top edges of the chain bar groove become worn unevenly.

• The depth of the saw chain groove is no longer deep enough for the saw chain to

seat correctly and run along the top edges of the chain bar groove.

To clean the chain bar, use a proprietary saw chain cleaning solution, solvent, or

mixture of ammonia and water to help remove dirt, grease and resin/sap, particularly

from within the saw chain groove (A), the lubricant inlet hole (B), and the tension

adjustment wheel (C). Use suitable tools or objects to help dislodge any stubborn

particles from within the saw chain groove.

To remove the saw chain and chain bar:

1. Remove the battery from the tool.

2. Loosen the chain drive cover lock nut (D) slightly, then rotate the tension adjustment ring (E) to slacken

the chain. Fully unscrew the nut and remove the cover (F). Be careful to prevent the chain bar falling out.

3. Carefully extract the saw chain (G) from the chain bar (H) groove and drive gear, then remove the chain

and chain bar.

4. Clean away any sawdust, wood particles, dirt etc from the chain drive cover, lock nut, tension adjustment

mechanism etc.

To install the saw chain, chain bar and chain drive cover, see here. To tension the saw chain, see here.

E&OE ©2018 Bäumr-AG 19

SW4 Battery Powered Chainsaw

A

B

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Chain Lubricant

Always check the chain lubricant level before using the machine and ensure it is at or close to the

recommended level. • Use a suitable chainsaw lubricant. • Do NOT operate the machine without

adequate chain lubricant – failure to do so will damage the saw chain, chain bar and/or other parts of

the machine, and is not covered under warranty.

To check chain lubricant level:

1. Place the machine on a flat and level surface.

2. Lubricant will be visible through the lubricant tank. There is a minimum level mark on the tank.

To add chain lubricant:

1. Remove (rotate left) the chain lubricant tank cap (A).

2. Using a funnel, carefully add chain lubricant to the tank (B) until its level is close to the filler hole.

3. When finished, re-install (rotate right) the chain lubricant tank cap until firm. Wipe off any residual oil from

the machine.

E&OE ©2018 Bäumr-AG 20

SW4 Battery Powered Chainsaw

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Cleaning Guidelines

Do NOT expose any part of the machine to water. Exposure to water may create an

electrical shock hazard and / or may damage the machine electronics. Exposing the

machine to water or other liquids may void any product warranty. • Remove the battery from the

machine before cleaning. • Do not use solvents, chemicals or abrasives when cleaning the machine, as

some surfaces may be damaged. • Wear gloves or use suitable tools to assist in cleaning – do not use bare

hands. • Clean the machine after every use to ensure best performance and longest service life. • Do NOT

store batteries in direct sunlight or hot environments, such as vehicle interiors, for any period.

• Use a slightly damp cloth and mild detergent for cleaning.

• Use a brush for parts that are difficult to reach.

• Ensure air vents and surfaces designed for heat dissipation are clean and free of obstructions or debris.

• Remove the drive chain cover and clean away any sawdust, wood particles, dirt etc from the tension

adjustment mechanism, chain bar and saw chain.

• It is recommended to lightly oil the saw chain after each use to help prevent corrosion.

• Ensure all guards and safety devices are clean and functioning correctly.

• Ensure that spring-loaded parts, such as the throttle, return to the normal position when released.

• Ensure that all control cables, levers, switches etc are clean and operate normally and smoothly.

Transportation and Storage

Always ensure that the machine is cool enough to touch before transporting or storing. •

Always transport and store the machine with the battery removed. • Do NOT store the

machine or battery in direct sunlight or

Preparing for Transport and Storage

• Clean the equipment before transport or storage.

• Ensure the battery is removed and the chain brake is engaged, and the blade sheath is installed.

• When transporting the machine in a vehicle, secure the machine in an upright position to prevent tip-over

or machine damage.

• Store the equipment in a dry, well-ventilated area that is not exposed to direct sunlight or excessive heat,

and out of the reach of children.

• Cover the equipment to protect it.

E&OE ©2018 Bäumr-AG 21

SW4 Battery Powered Chainsaw

Possible Fault

Action

Incorrect procedure

Ensure chain brake is in the "OFF" position, press the trigger safety button in and hold, then

squeeze the trigger.

No voltage

Ensure the battery is charged and is correctly inserted.

Saw chain obstructed / jammed

Remove the battery and remove any obstructions to the saw chain.

Battery or control switch faulty

Have battery and / or machine tested and repaired at an authorised service centre.

Possible Fault

Action

Blades dull or damaged

Sharpen or replace saw chain.

Possible Fault

Action

Blades dull or damaged

Sharpen or replace saw chain.

Chain bar loose or incorrectly

adjusted

Check chain bar lock nut for tightness. Ensure chain tension is correct

Battery Charger Electrical Requirements

240VAC / 50Hz

Battery Type

40V Lithium-Ion

Saw Chain and Chain Bar

3/8" pitch, 0.050" gauge, 52 links / 14" chain bar with sprocket nose

Weight

Approximately 6kg (with battery installed)

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG BAUMR-AG

Troubleshooting

Do NOT perform and maintenance or troubleshooting procedures with the battery

installed in the tool. • The machine should be cool enough to touch before performing

maintenance activities. • Some maintenance activities described may be beyond the scope of some users.

For procedures that you are not comfortable with or have the tools, knowledge or experience for, have the

unit serviced by a service centre or qualified technician.

The following information may assist in identifying a problem and rectifying it.

Difficulty starting the chainsaw.

Cutting is poor.

Excessive vibration.

Specifications

E&OE ©2018 Bäumr-AG 22

SW4 Battery Powered Chainsaw

E&OE ©2018 Bäumr-AG 23

Some experts believe the incorrect or prolonged use of almost any product could cause serious

injury or death. For information that may reduce your risk of serious injury or death, consult the

points below and additionally, the information available at www.datastreamserver.com/safety

• Consult all documentation, packaging and product

labelling before use. Note that some products feature

online documentation which should be printed and kept

with the product.

• Check product for loose / broken / damaged / missing

parts, wear or leaks (if applicable) before each use.

Never use a product with loose / broken / damaged /

missing parts, wear or leaks (if applicable).

• Products must be inspected and serviced (if applicable)

by a qualified specialist every 6 months assuming

average residential use by a person of average weight

and strength, above average technical aptitude, on a

property matching average metropolitan specification.

Intended use outside these guidelines could indicate

the product is not suitable for intended use or may

require more regular inspection or servicing.

• Ensure all possible users of the product have

completed an industry recognized training course

before being given access to the product.

• The product has been supplied by a general merchandise retailer that

may not be familiar with your specific application or your description

of the application. Be sure to attain third-party approval for your

application from a qualified specialist before use regardless of prior

assurances by the retailer or its representatives.

• This product is not intended for use where fail-safe operation is

required. As with any product (take an automobile, aircraft, computer

or ball point pen for example), there is always a small chance of

technical issues that needs to be repaired or may require replacement

of the product or a part. If the possibility of such failure and the

associated time it takes to rectify could in any situation inconvenience

the user, business or employee then the product is not suitable for

your requirements. This product is not for use where incorrect

operation or a failure of any kind, including but not limited to a

condition requiring product return, replacement, service by a

technician or replacement of parts could cause a financial loss, loss of

employee time or an inconvenience requiring compensation.

• If this item has been purchased in error after considering the points

above, simply contact the retailer directly for details of their returns

policy, if required.

©2018 Bäumr-AG. All rights reserved. No part of this document, including descriptive content, concepts,

ideas, diagrams or images may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, scanning or recording, or any information storage and retrieval system,

without express permission or consent from the publisher.

Loading...

Loading...