Page 1

Manual

Programming Software ProCam 1.10

for Absolute Switching Cam Encoders

Baumer IVO GmbH & Co. KG

Dauchinger Strasse 58-62

DE-78056 Villingen-Schwenningen

Phone +49 (0)7720 942-0

Fax +49 (0)7720 942-900 05.11 · 174.02.034/3

info.de@baumerivo.com Subject to modification in technic and design.

www.baumer.com Errors and omissions excepted.

Page 2

Content

Introduction 4

1

1.1 Product assignment 4

2 General Information 5

2.1 System requirements 5

2.2 Installation 5

2.3 Software version 5

2.4 Information on commissioning 5

3 ProCam Program 6

3.1 Basics 6

3.2 Program procedure 6

3.2.1 Selecting encoder type 7

3.2.2 Encoder connected to PC - "Automatic selection" 8

3.2.3 Selecting encoder type from table - "Manual selection" 9

3.2.4 Starting encoder programming 10

4 Program Encoder 11

4.1 Menu and icon bar 12

4.1.1 File 12

4.1.2 Settings 13

4.1.3 Extras 14

4.1.4 Info 15

4.1.5 Reprogramming 15

4.1.6 Open file 15

4.1.7 Save file 15

4.1.8 Print 15

4.1.9 Request data from encoder 15

4.1.10 Send data to encoder (save) 15

4.1.11 Display position/activate cam program 15

4.2 "Resolution" programming mask 16

4.2.1 Code (steps) 17

4.2.2 Counting direction 17

4.2.3 Speed scaling 17

4.2.4 Revolutions 18

4.2.5 Steps/revolutions 18

4.2.6 Total resolution 18

4.2.7 Back to main menu 18

4.2.8 Dialog window 18

4.2.9 Display of encoder type 18

4.2.10 Read encoder data 19

4.2.11 Send encoder data 19

4.3 "Outputs" programming mask 20

4.3.1 Output 21

4.3.2 Data Valid 21

4.3.3 Speed 21

4.3.4 Still 21

4.3.5 Run Control 21

4.3.6 Inverted 21

Manual_ProCam_V1-10_EN.doc 2/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 3

4.3.7 Speed monitoring 21

4.4 "Program encoder" programming mask 22

4.4.1 Edit cam program 23

4.4.2 Send cam program 25

4.4.3 Activate cam program 25

4.4.4 Dialog window 25

4.4.5 Program status 25

4.5 "Cam" programming mask 26

4.5.1 Program 26

4.5.2 Cam memory 27

4.5.3 Cam No. 27

4.5.4 Output 27

4.5.5 Name 27

4.5.6 ON/OFF 27

4.5.7 DTC ON/DTC OFF 27

4.5.8 Lock 27

4.5.9 Status 28

4.5.10 Name outputs 28

4.5.11 Enter DTC values 29

4.5.12 Lock outputs 29

4.6 "Display position" and "Activate cam program" mask 30

4.7 "Set position" mask 32

5 Connecting Encoder 34

5.1 Connection between PC and encoder 34

5.1.1 Encoder programming connection 34

6 Index 35

Manual_ProCam_V1-10_EN.doc 3/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 4

1 Introduction

1.1 Product assignment

This ProCam software is suitable for the following types:

Hollow shaft encoders

Product Product Family interface

RXA1H Cam-operated switchgroup RS232 or RS485

Manual_ProCam_V1-10_EN.doc 4/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 5

2 General Information

2.1 System requirements

A PC with the operating system Windows 95/98/NT/2000/XP with one free RS232 serial port.

An RS485/RS232 interface converter with automatic directional switchover is required for

encoders with an RS485 interface.

2.2 Installation

The installation is menu-guided.

Please read the file "Readme.txt" on the included CD.

Note: Under Windows NT/2000 and Windows XP, the installation can only be carried out with

Administrator rights.

2.3 Software version

The version ProCam 1.10 replaces the earlier ProCam versions and is downward compatible.

2.4 Information on commissioning

- Wiring work on the encoder plug or in the switch cabinet may only be carried

out in the deenergized state. Do not connect or disconnect encoder plugs

while energized.

- Before switching on, please check and connect all connectors.

- Caution!

Incorrect encoder programming can lead to system failure.

Product information

The content or scope of this documentation can be changed at any time without prior notice.

The contents of this documentation does not represent the assurance of a certain property or

function by Baumer IVO GmbH & Co. KG.

Manual_ProCam_V1-10_EN.doc 5/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 6

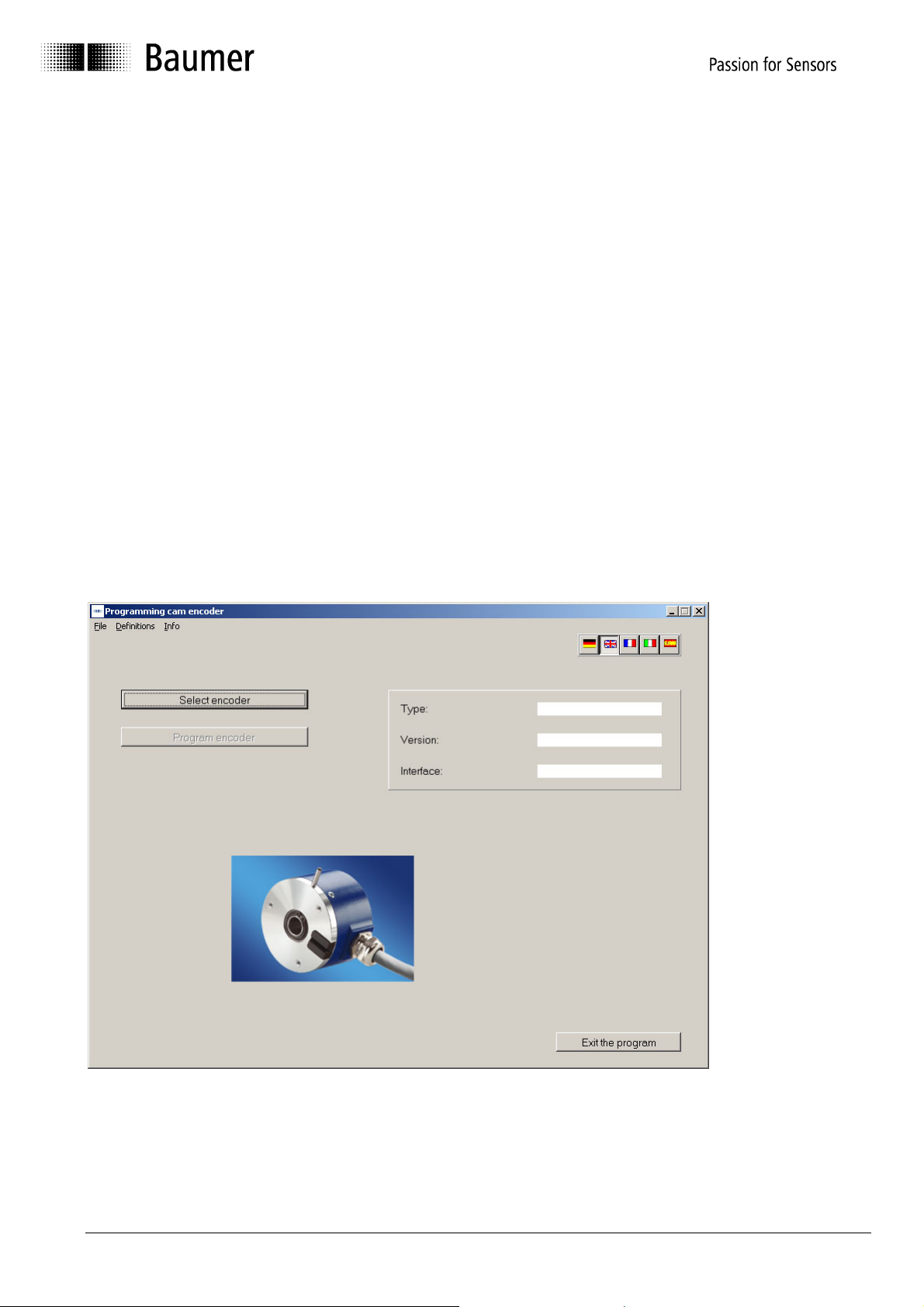

3 ProCam Program

3.1 Basics

The ProCam program is a software for programming Baumer IVO cam encoders. It can be

used to read out, change, program and display the encoder data. To make programming as

simple as possible, the user can select only the fields valid for the respective state. Fields

which cannot be selected in the current state have a gray background. Before the encoder can

be programmed, the encoder type must be selected. This results in a logical procedure

following the program start:

1. Step Select language with country flags

2. Step Select encoder type with "Select encoder" button

3. Step Programming can be started

If your encoder is not automatically detected, or is not contained in the selection list, please

contact Baumer IVO.

3.2 Program procedure

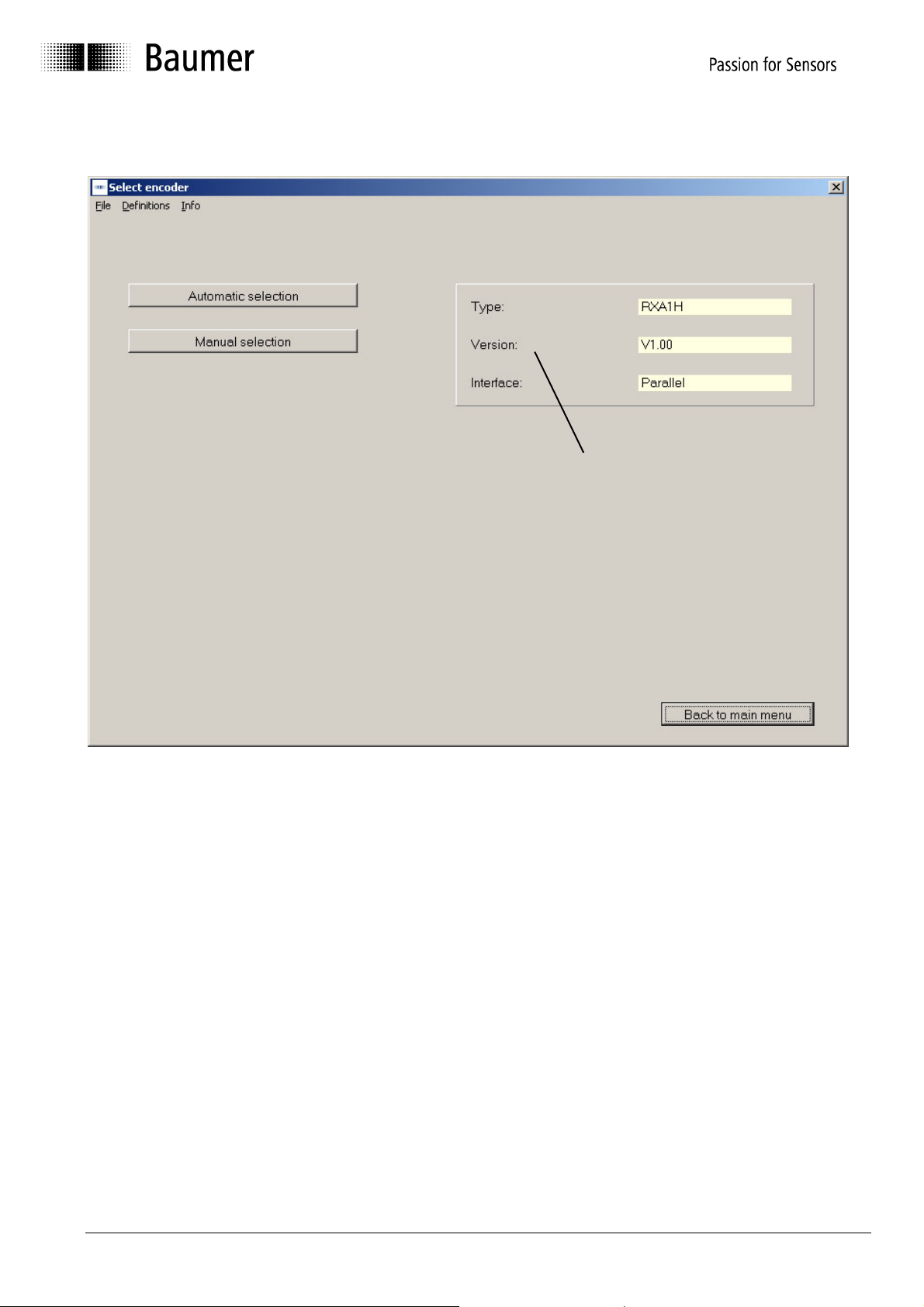

After the Start screen has run, the following mask appears:

Programming cannot begin until an encoder type has been selected.

Encoder selection is described in the chapters "Encoder connected to PC ⇒ Automatic

selection" and "Select encoder type from table ⇒ Manual selection".

Manual_ProCam_V1-10_EN.doc 6/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 7

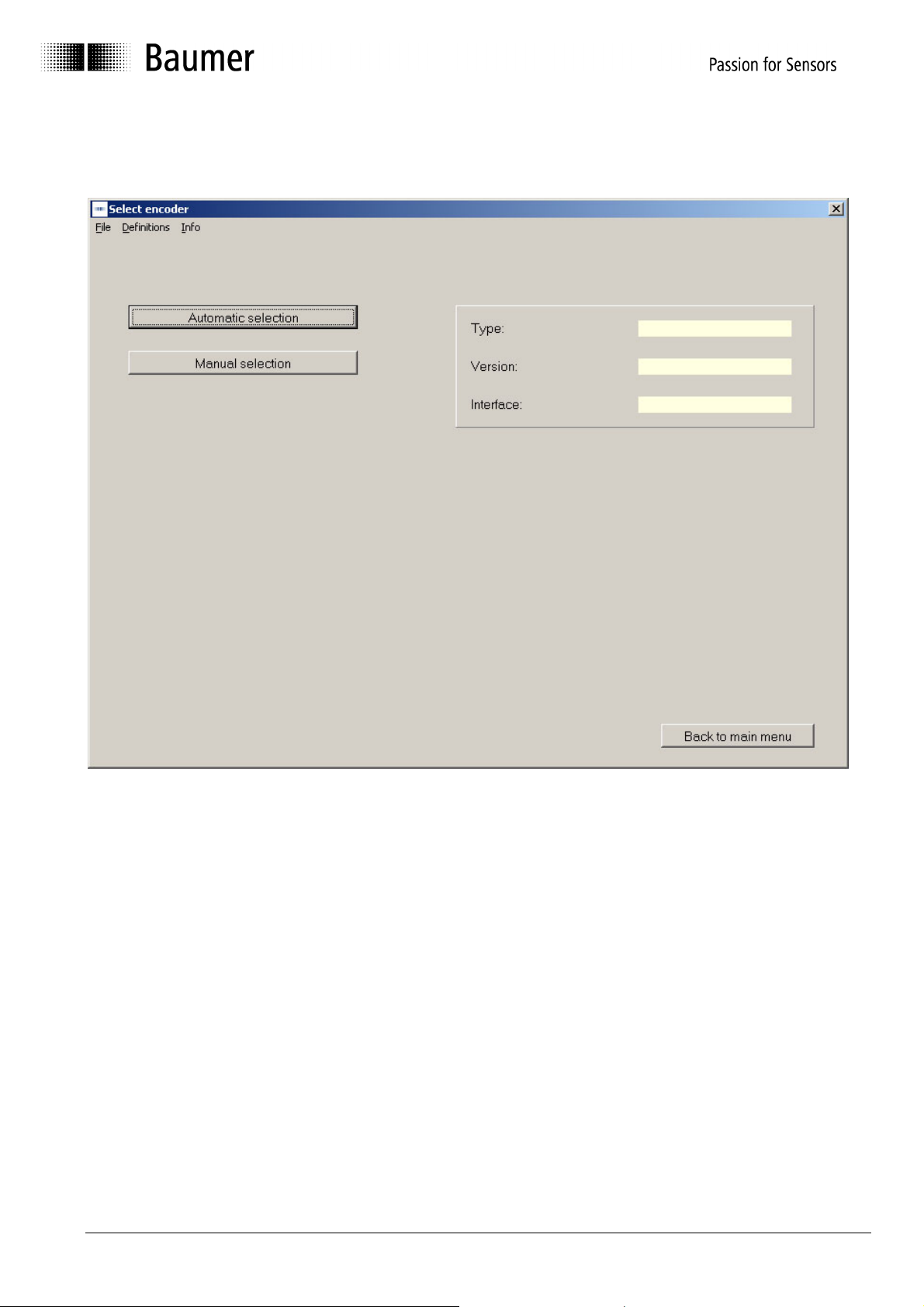

3.2.1 Selecting encoder type

The encoder can be selected in the first step.

The program offers automatic selection when an encoder is connected to the interface.

If there is no connection to the encoder, a desired encoder type can be selected from the list

with "Manual selection".

Manual_ProCam_V1-10_EN.doc 7/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 8

3.2.2 Encoder connected to PC - "Automatic selection"

A

utomatically

detected

encoder model

With an encoder selected, the encoder type can be read out (Automatic selection).

This information is necessary to provide the corresponding parameters for

programming. If the encoder or the cable connection is not properly connected, an

error message is displayed. If the automatically detected encoder does not match the

encoder rating plate, please contact Baumer IVO.

Manual_ProCam_V1-10_EN.doc 8/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 9

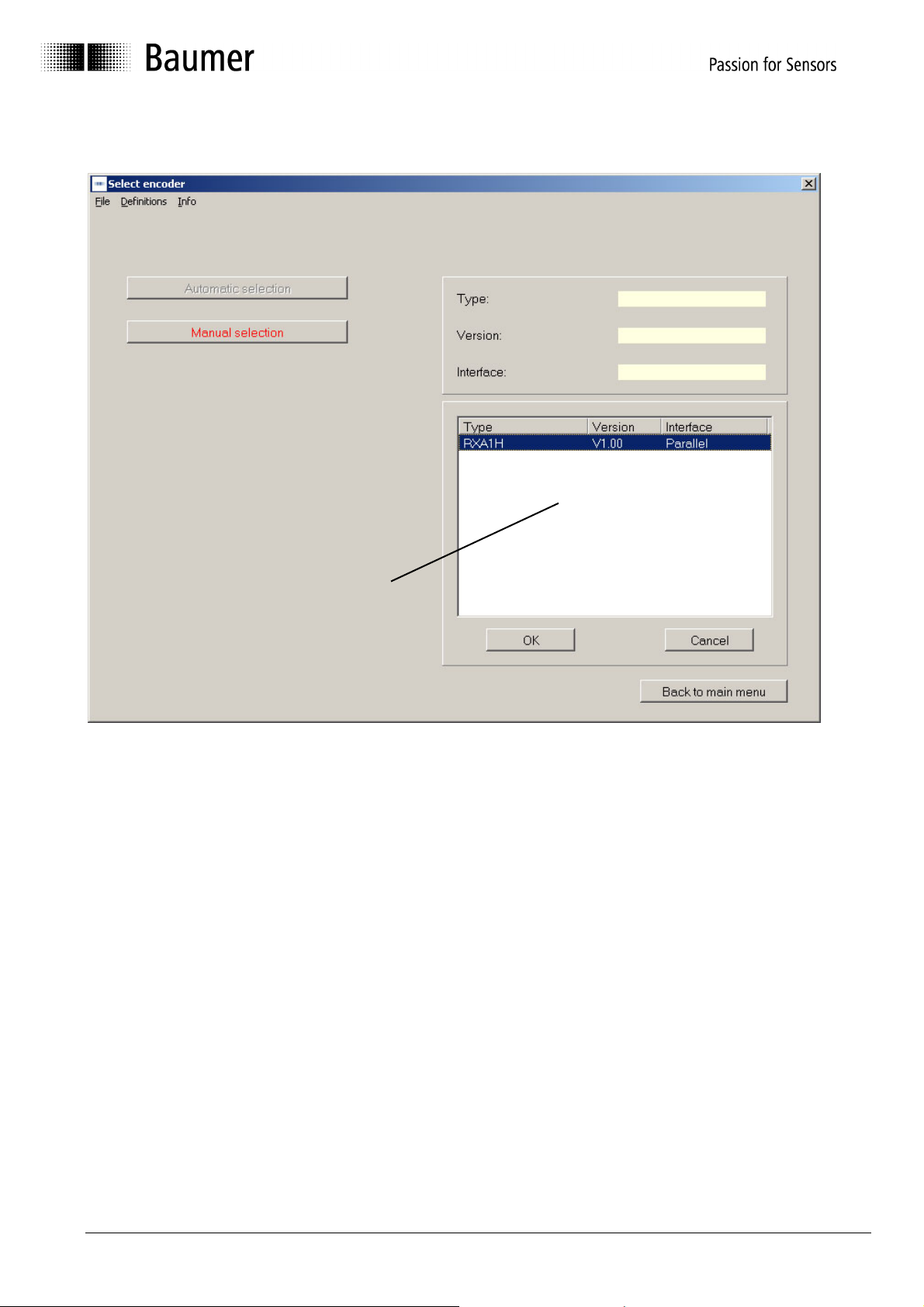

3.2.3 Selecting encoder type from table - "Manual selection"

Table for

selecting

encoder model

If no encoder is connected to the PC, the encoder type can be selected from the table

(Manual selection). The most common types are contained in the table. Not only the type,

but also the version is important. If your type is not included, please contact Baumer IVO.

The type and version can be read off the encoder rating plate.

Manual_ProCam_V1-10_EN.doc 9/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 10

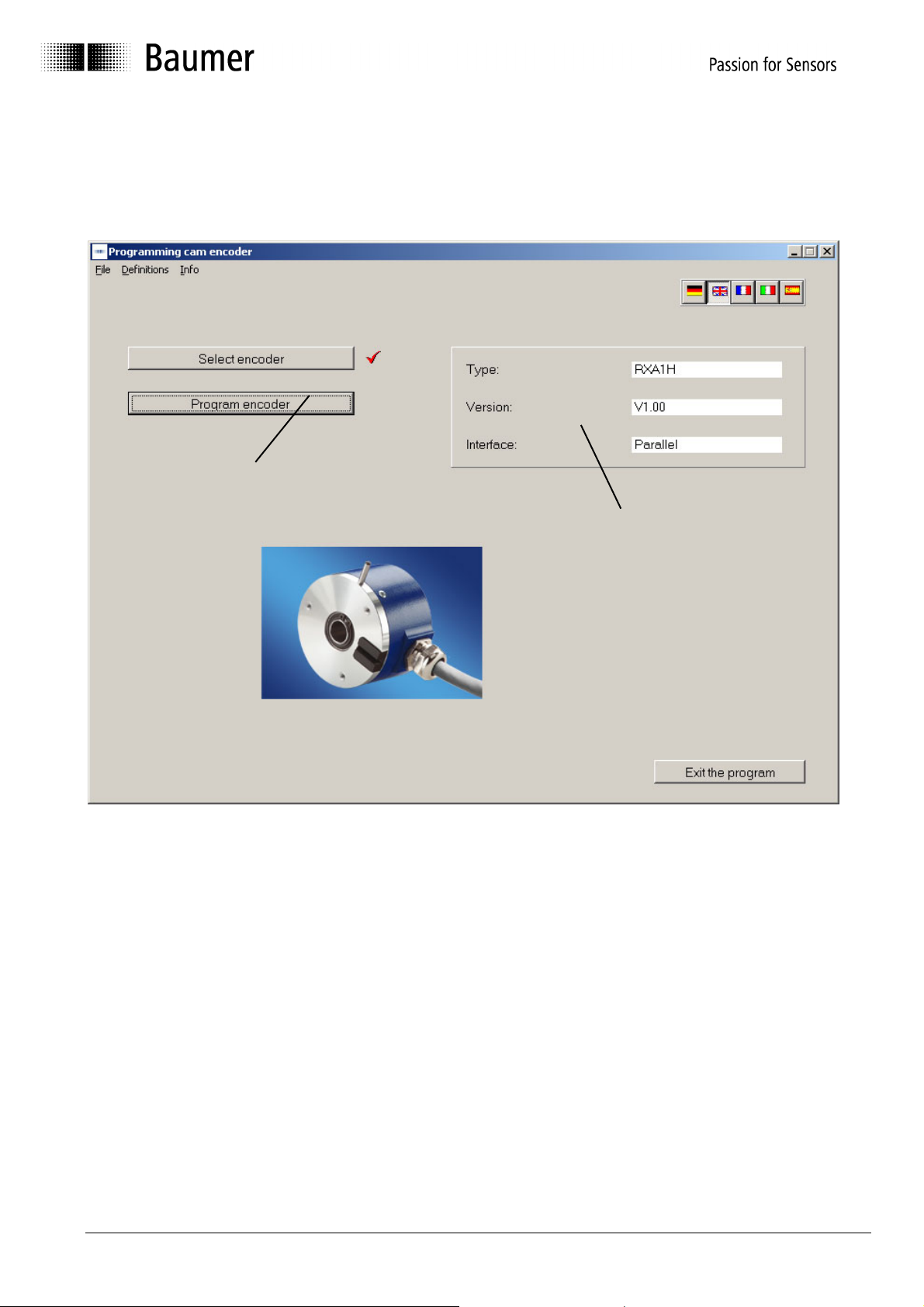

3.2.4 Starting encoder programming

After successfully selecting the encoder, programming can be started. The "Program

encoder" button is now active. The selected encoder is shown again in the right-hand

mask.

Encoder

programming

is active

Selected

encoder

Manual_ProCam_V1-10_EN.doc 10/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 11

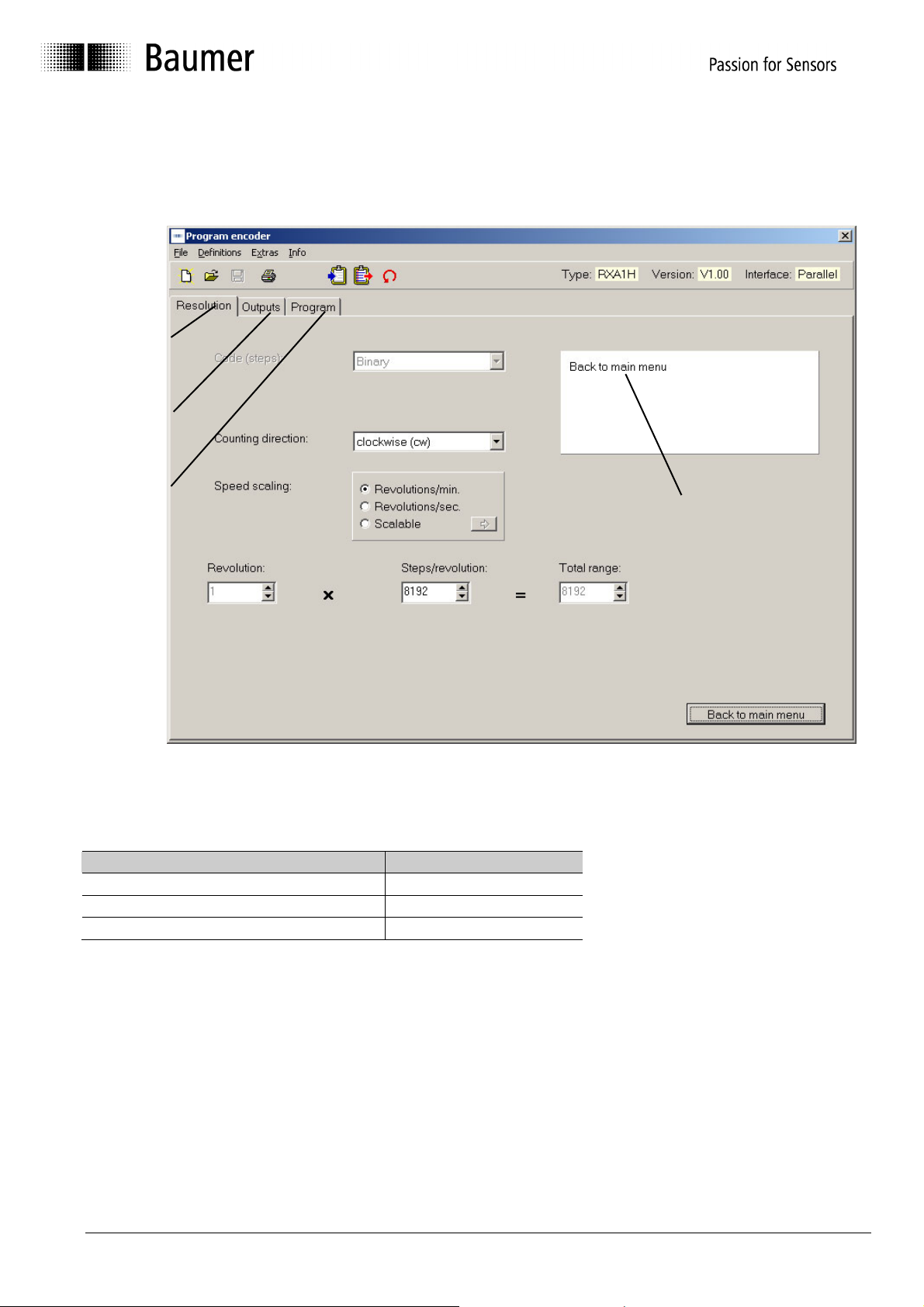

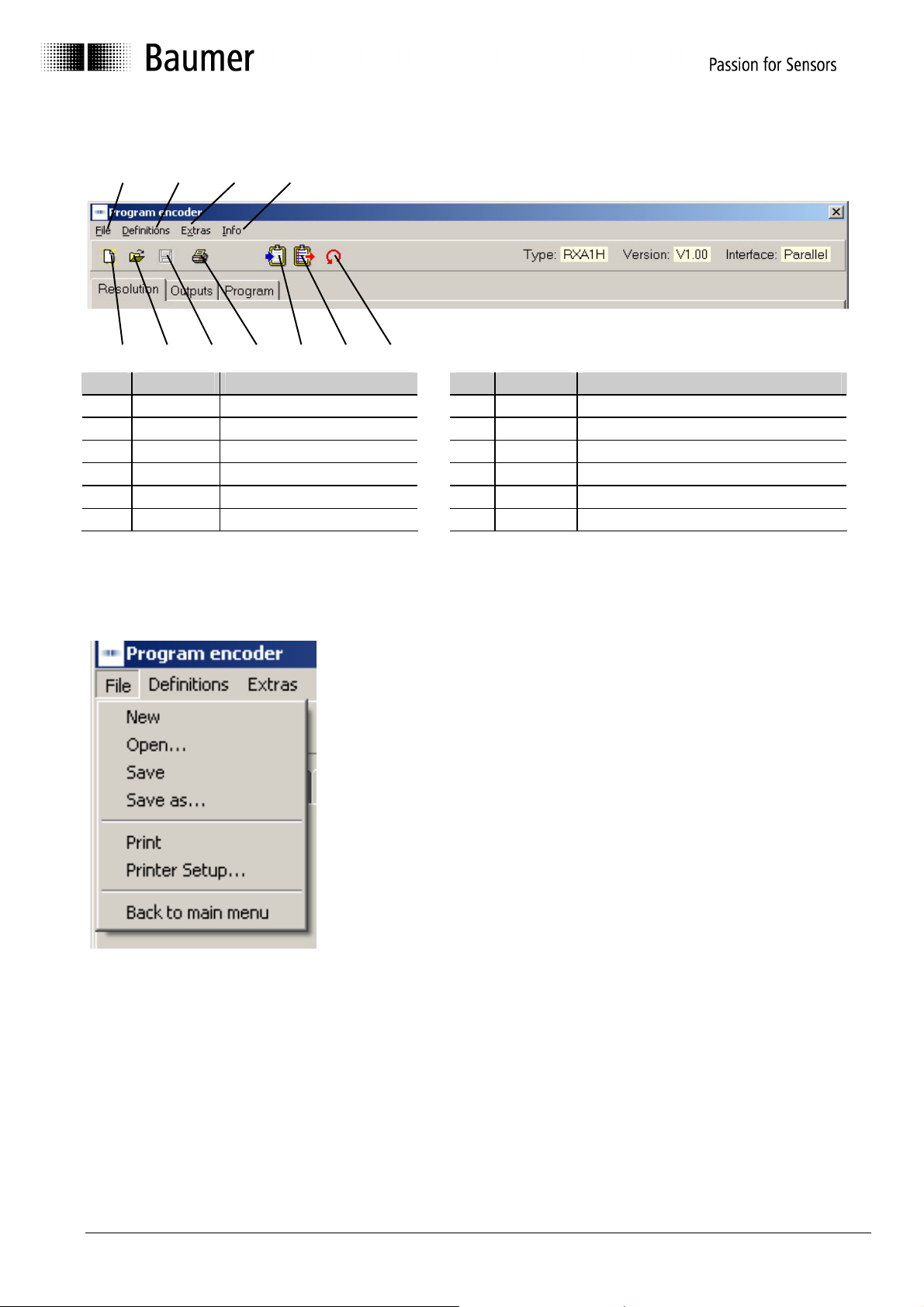

4 Program Encoder

The "Program encoder" mask now enables the programming of all parameters possible for this

encoder.

Resolution

tab

Outputs

tab

Program

Dialog window

tab

The parameters for the encoder can be set with the tabs "Resolution", "Outputs" and

"Program". The dialog window offers additional support and explanations for the selected

window.

Tab Explanations

"Resolution" tab See Chapter 4.2

"Outputs" tab See Chapter 4.3

"Program" tab See Chapter 4.4

Manual_ProCam_V1-10_EN.doc 11/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 12

4.1 Menu and icon bar

1

5

No. Chapter Buttons No. Chapter Buttons

1 4.1.1 File 7 4.1.7 Save file

2 4.1.2 Definitions 8 4.1.8 Print

3 4.1.3 Extras 9 4.1.9 Load data from encoder

4 4.1.4 Info 10 4.1.10 Save data in encoder

5 4.1.5 Reprogramming 11 4.1.11 Display position

6 4.1.6 Open file

2 3 4

6 7 8 9 10 11

4.1.1 File

In the "File" menu item the following items can be selected:

New: A programming mask with the

Open: A saved program can be loaded.

Save: The current data can be saved.

Save as: The current data can be saved

freely selectable directory.

Print: The current data can be printed for

Printer setup: A printer can be selected.

Back to main menu: The programming mask is exited.

basic setting is loaded.

under any desired name in a

archiving.

Manual_ProCam_V1-10_EN.doc 12/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 13

4.1.2 Settings

In the "Settings" menu item the COM 1 to COM 6 serial port

to which the encoder is connected can be selected. In

addition, the baud rate and the address of the encoder can be

set. The other parameters such as Parity, Stop bits and Data

bits can be checked here.

The port parameters are permanently set for the RXA1H series.

- Baud rate: 38400

- Parity: Even

- Stop bits: 1

- Data bits: 8

Manual_ProCam_V1-10_EN.doc 13/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 14

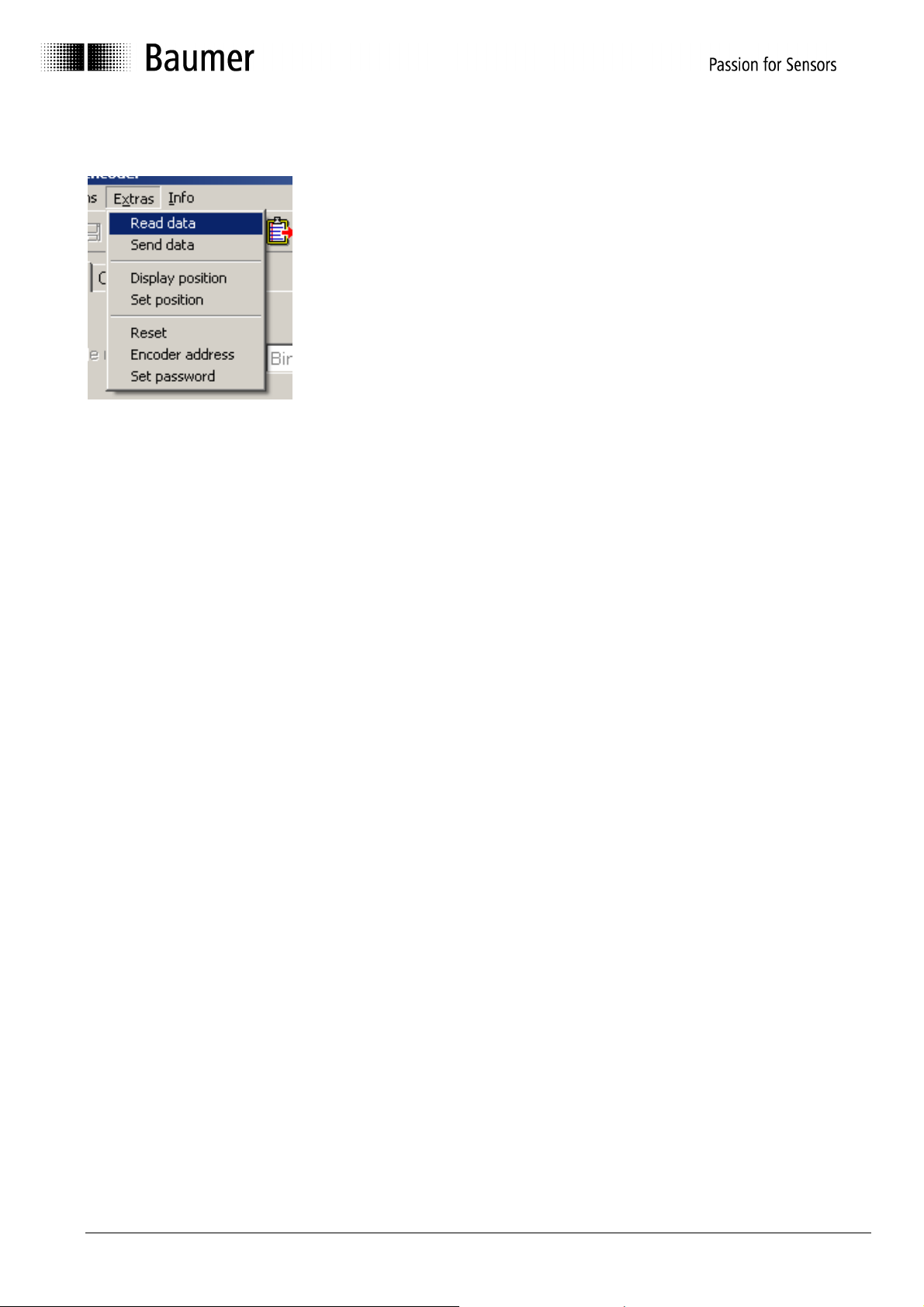

4.1.3 Extras

Read data: The data are requested from the connected encoder

Send data: The current programming is saved in the encoder

Display position: The "Display position" screen mask is opened (see Chapter 4.6)

Set position: The mask for assigning a position value is opened (see Chapter 4.7)

Reset: The encoder receives a reset command. The effect is identical to

switching the supply voltage off and then on again. No cam programs or

stored settings are deleted or changed.

Encoder address: The address set for the connected encoder can be requested or set.

Set password: A four-place password can be saved in the encoder. ProCam requests

the password during certain actions and compares it with the password

stored in the encoder. Among other things, this concerns the "locked

outputs" and prevents accidental changes. The default password on

delivery is "0000". Permissible characters are 0 - 9 and A - Z, as well as

blank spaces. It must especially be noted that a password can only be

deleted or changed when the password used up until that point is known.

Manual_ProCam_V1-10_EN.doc 14/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 15

4.1.4 Info

With Info the version of the ProCam and encoder software can be displayed.

4.1.5 Reprogramming

The display mask is reset to the basic setting. The same function can also be run

with "File ⇒ New".

4.1.6 Open file

Programming stored in the PC can be loaded. The same function can also be run

with "File ⇒ Open".

4.1.7 Save file

The current data are saved in the PC. The same function can also be run with "File

⇒ Save".

4.1.8 Print

The current encoder data are printed out. The printout can be used for archiving.

The same function can also be run with "File ⇒ Print".

4.1.9 Request data from encoder

The data are requested from the connected encoder. The same function can also be

run with "Extras ⇒ Read data".

4.1.10 Send data to encoder (save)

The current programming is saved in the encoder. The same function can also be

run with "Extras ⇒ Send data".

4.1.11 Display position/activate cam program

The current position and the status of the special outputs are shown. The same

function can also be run with "Extras ⇒ Display position".

Manual_ProCam_V1-10_EN.doc 15/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 16

4.2 "Resolution" programming mask

The resolution and other basic parameters of the encoder can be set with this programming

mask. The picture below shows the maximum possible settings. However, only those

parameters are shown which are supported by the selected encoder.

12

11 10

1

9

2

8

3

654

7

No. Chapter Field No. Chapter Field

1 4.2.1 Code (steps) 7 4.2.7 Back to main menu

2 4.2.2 Counting direction 8 4.2.8 Dialog window

3 4.2.3 Speed scaling 9 4.2.9 Display of encoder type

4 4.2.4 Revolutions 10 4.2.10 Read encoder data

5 4.2.5 Steps/revolution 11 4.2.11 Send encoder data

6 4.2.6 Total range 12 4.5 Display position

Manual_ProCam_V1-10_EN.doc 16/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 17

4.2.1 Code (steps)

The code (steps) is permanently set to binary.

4.2.2 Counting direction

With the counting direction it is possible to choose between "increasing clockwise"and

"decreasing clockwise". "Increasing clockwise" means that with clockwise rotation (looking

from the front at the encoder shaft), the position values increase, and with "decreasing

clockwise" these decrease accordingly.

4.2.3 Speed scaling

You can select from three settable functions (Revolutions/min, Revolutions/s or Scaleable) for

the display of the speed in the "Display position" window (Chapter 4.6).

Revolutions/min.

The display is shown in revolutions per minute.

Revolutions/sec.

The display is shown in revolutions per second.

Scaleable

Enter the value in the range from 1 - 6,5000 here which is to be

displayed at a speed of 6,000 revolutions/minute in the

"Display position" window (see Chapter 4.6).

Example:

The cam encoder is attached to a downstream gear unit that

reduces the motor speed in a ratio of 1:3. However, the motor

speed (in rpm) is to be displayed. Enter the value 18,000 in the

"Speed scaling" window. For an encoder shaft speed of 2,000

rpm, the display is now "6000".

Manual_ProCam_V1-10_EN.doc 17/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 18

4.2.4 Revolutions

With singleturn encoders, the value for the rotations cannot be set. It is always set to 1.

4.2.5 Steps/revolutions

Number of steps with which a rotation of the encoder axis is to be resolved. The possible value

range lies between 2 and 8192 steps/rotation.

4.2.6 Total resolution

The total resolution is the product of steps/rotation multiplied by the number of rotations.

Calculation formula for the total resolution:

1. Singleturn encoder

1 X Steps/revolutions = Total Resolution

2. Multiturn encoder

Revolutions X Steps/revolutions = Total Resolution

e.g. For 100 steps/rotation and a desired number of rotations of 10

the total resolution is 1000.

Depending on the encoder type, either the number of rotations or the total resolution can be

set. The other value is highlighted in gray, and can therefore not be changed. However, the

value is calculated and displayed.

Information:

This revolution can also be used for movements which run through the zero point several

times in the same direction (endless operation).

4.2.7 Back to main menu

The "Return to main menu" button exits the programming mask. If parameters have been

changed, these can still be saved.

4.2.8 Dialog window

Information texts on the parameter currently selected are shown in the dialog window.

The information texts describe the respective parameter with brief explanations.

4.2.9 Display of encoder type

The encoder which was selected manually or automatically after the program start is

permanently displayed in the programming mask. This makes it possible to monitor whether

the selected and the existing encoder are identical.

Manual_ProCam_V1-10_EN.doc 18/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 19

4.2.10 Read encoder data

The connected encoder is read out. Before the tabs "Resolution", "Outputs" and "Program" are

overwritten, they can be saved. If the connected encoder type does not match the one

selected, the following error message appears:

If the set encoder and connected encoder types are identical, the data are read in and

displayed.

4.2.11 Send encoder data

The encoder connected to the interface is programmed with the set parameters. If the

connected encoder type does not match the one selected, the following error message

appears:

During transfer the data in the encoder are saved in a non-volatile manner. The transfer can

take several seconds and is displayed as follows:

Manual_ProCam_V1-10_EN.doc 19/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 20

4.3 "Outputs" programming mask

Each of the 16 outputs can either switch cams or assume a special task as a special output.

This window controls the properties of each individual output. Each special function carried

out (No. 2 - 5) can be assigned to exactly one output. On the other hand, the property

"Inverted" (No. 6) can be assigned to any output, regardless of whether it is defined as a

cam output or as a special output.

1 72 3 4 5 6

No. Chapter Field

1 4.3.1 Output

2 4.3.2 Data Valid

3 4.3.3 Speed

4 4.3.4 Still

5 4.3.5 Run Control

6 4.3.6 Inverted

7 4.3.7 Speed monitoring

Manual_ProCam_V1-10_EN.doc 20/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 21

4.3.1 Output

The outputs are marked No.1 to No.16. This numbering cannot be changed. However, each

output can be assigned an additional plain text designation (see Section 4.6.10)

4.3.2 Data Valid

The output is assigned the special function "Data Valid". It becomes active when the

continuous internal self-monitoring function of the encoder has detected a problem, e.g. an

overloading of the output driver or an impermissible position value. The output remains active

as long as the problem continues, however for at least 2 seconds.

4.3.3 Speed

The output is assigned the special function "Speed monitoring". It becomes active when the

set upper speed limit is exceeded. See the explanation No. 7 for this window.

4.3.4 Still

The output is assigned the special function "Still display". It becomes active as soon as the

encoder speed has dropped below approx. 1 rotation/minute.

Attention:

No safety-relevant functions may be linked to this function, as the shaft

can also turn with the "Standstill display" signal active!

4.3.5 Run Control

The output is assigned the special function "Run Control". The output continuously outputs a

slow rectangular signal (approx. 1 Hz) which enables external monitoring of the cam encoder.

4.3.6 Inverted

The output outputs its signal inverted. In the active state, it is at Low level, in the inactive state

at High level.

4.3.7 Speed monitoring

Limit value for the output with the special function "Speed monitoring". An input in this window

is always made in rpm, regardless of a different scaling of the displayed speed which may be

selected. The permissible range for entry is product-specific and is specified in the

corresponding product information.

Manual_ProCam_V1-10_EN.doc 21/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 22

4.4 "Program encoder" programming mask

The programmable cam-operated switchgroup permits the execution of switching processes.

Here a total of 1,024 cam switching points distributed over a maximum of 16 cam programs

can be set. Each of the 1,024 cams can be assigned to one of the 16 switching outputs.

After the "Program encoder" tab is selected, the following window appears:

1

4

No. Chapter Field

1 4.4.1 Edit cam program

2 4.4.2 Send cam program

3 4.4.3 Activate cam program

4 4.4.4 Dialog window

5 4.4.5 Program status

5

2

3

Manual_ProCam_V1-10_EN.doc 22/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 23

4.4.1 Edit cam program

Create:

Clicking on the "Create" button starts the

entry of a new cam program in ProCam.

In the process, the next free program

number is automatically assigned.

Then the program name and the number

of cams can be entered.

"Continue" opens the "Edit cam program" mask (see Chapter 4.5).

Change:

By clicking the "Change" button, the data of the selected

cam program can be changed.

Clicking on "OK" opens the "Change cam program"

window. Here the program name and the number of cams

can be changed.

"Continue" opens the "Edit cam program" mask (see Chapter 4.5).

Manual_ProCam_V1-10_EN.doc 23/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 24

Copy:

Clicking on the "Copy" button copies the data of the

selected cam program to a new cam program to be

selected in ProCam.

The program automatically suggests the next free

Program No., whereby a free Program No. and a new

program name can also be assigned.

Information: It is not possible to overwrite an existing cam

program.

Delete:

.

By clicking on the "Delete" button, the data of the selected

cam program can be deleted in ProCam.

Manual_ProCam_V1-10_EN.doc 24/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 25

Save file:

The current data are saved in the PC. The same function can also be run with "File ⇒ Save".

Open file:

Programming stored in the PC can be loaded. The same function can also be run with "File ⇒

Open".

4.4.2 Send cam program

Send data

The current programming is saved in the encoder. The same function can also be run with

"Extras ⇒ Send data".

Request data

The data are requested from the connected encoder. The same function can also be run with

"Extras ⇒ Data".

4.4.3 Activate cam program

See Chapter 4.6

4.4.4 Dialog window

Information texts on the parameter currently selected are shown in the dialog window.

The information texts describe the respective parameter with brief explanations.

4.4.5 Program status

The current programs are displayed in this window.

Manual_ProCam_V1-10_EN.doc 25/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 26

4.5 "Cam" programming mask

After selection the following window appears:

1

3

4 6

5 7 8 9

10 11 12

2

No. Chapter Buttons No. Chapter Buttons

1 4.5.1 Program 7 4.5.7 DTC ON/DTC OFF

2 4.5.2 Cam memory 8 4.5.8 Lock

3 4.5.3 Cam No. 9 4.5.9 Status

4 4.5.4 Output 10 4.5.10 Name outputs

5 4.5.5 Name 11 4.5.11 Enter DTC values

6 4.5.6 ON/OFF 12 4.5.12 Lock outputs

Context messages appear on the mouse pointer which refer to the respective permissible

value range in the table column.

The fields with a colored background cannot be changed directly here. These fields are

automatically displayed depending on the programming of the outputs.

4.5.1 Program

The program number and, if set, the related program name is displayed via the cam table in

the "Program" information line.

Manual_ProCam_V1-10_EN.doc 26/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 27

4.5.2 Cam memory

The "Cam memory" display shows how many of the total number of available cams have

already been used for switching processes (in the picture 30 of 1,024).

4.5.3 Cam No.

The cam number is permanently specified in each case and cannot be changed.

4.5.4 Output

Enter the number of the output this cam is to act on here. The value range is 1 - 16. If you

enter a "0", the cam remains inactive.

4.5.5 Name

The field shows the plain text name of the output, provided one has been entered (see Section

4.5.10)

4.5.6 ON/OFF

The information in the fields "ON" and "OFF" determine the switching points of the cam.

The values are the position of the encoder in the previously selected resolution (also see the

"Resolution" tab).

If a time cam is to be programmed, the "OFF" field is the switching time of the time cam in ms

(1-65000 milliseconds).

4.5.7 DTC ON/DTC OFF

The fields "DTC ON" and "DTC OFF" show the programmed dead-time compensation for the

output this cam acts on. To program the dead time itself, see 4.5.11.

4.5.8 Lock

The "Locked" field indicates the locking status of the output on which this cam acts. To set or

delete the locking function itself, see 4.5.12.

Manual_ProCam_V1-10_EN.doc 27/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 28

4.5.9 Status

Input parameters for status:

0 = Default cam bidir (bidirectional, acting in both rotating directions)

1 = Time cam bidir (bidirectional, acting in both rotating directions)

2 = Default cam pos (only acting in the positive rotating direction)

3 = Default cam neg (only acting in the negative rotating direction)

4 = Time cam pos (only acting in the positive rotating direction)

5 = Time cam neg (only acting in the negative rotating direction)

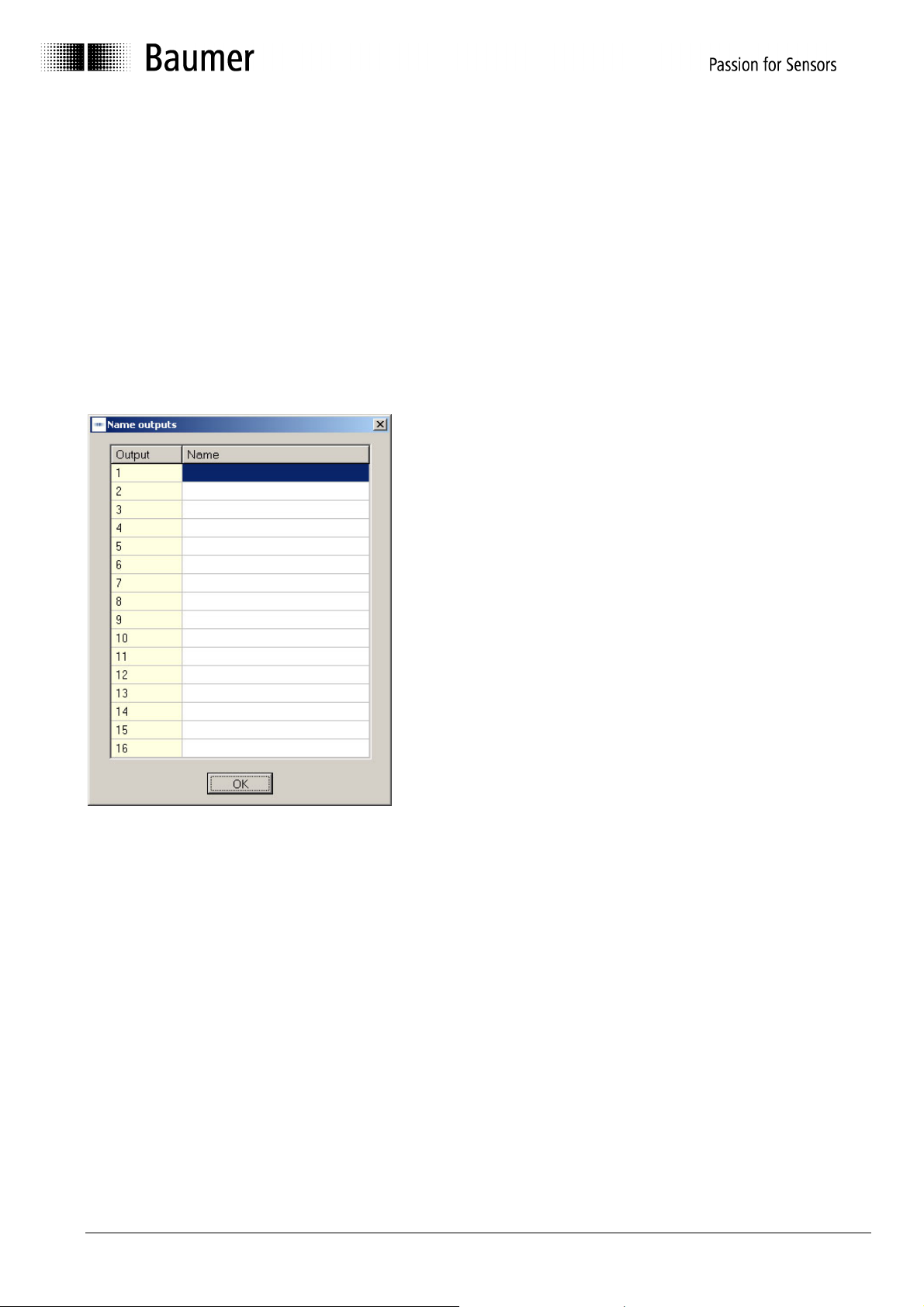

4.5.10 Name outputs

It is possible here to enter a name consisting of up to 16

characters for each output. The names are constantly

visible in the cam tables during programming and

simplify the entry of the switching points in this way.

As the names of the outputs are saved in the encoder

together with the cams, they are not only available on

the PC, but also on any connected display and operating

device.

Manual_ProCam_V1-10_EN.doc 28/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 29

4.5.11 Enter DTC values

Compensation times can be entered here to compensate

delay times with connected devices and processes.

Regardless of the current speed, the outputs are

switched earlier by the entered time.

The time unit in this window is milliseconds, and up to

1,000 ms are possible.

The entry is made separately for each output, i.e. always

"path-by-path". In addition, different values can be

specified for the switch-on and switch-off time.

4.5.12 Lock outputs

Each output can be locked individually, i.e. protected

against accidental changes.

If cams are entered which act on a locked output, the

password is requested. The password is also required to

release locked outputs for changes again later.

The password set at the factory is "0000" (also see

Chapter 4.1.3).

Permissible parameters for the entry are "0" (free) or

"1" (locked). During the entry of the cam tables, the

locking status is always visible as a lock symbol.

Manual_ProCam_V1-10_EN.doc 29/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 30

4.6 "Display position" and "Activate cam program" mask

The display module can display the position and the special outputs

of the connected encoder.

This can be selected under "Extras ⇒ Display position".

After the display module starts, the following mask appears.

4

1

2

5

3

7

6

No. Field

1 Total range

2 Total resolution bar display

3 Display of mechanical shaft position

4 Display of speed (scaled)

5 Display of switching state of outputs

6 Display of active program

7 Start or stop cam program

Manual_ProCam_V1-10_EN.doc 30/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 31

Start cam program

Clicking on the "Start" button starts the selected program. All

outputs programmed as cam outputs assume the state

corresponding to the cam position.

Time cams are treated as "Time

expired" during the program start.

Direction cams are set during the

program start with the encoder stopped

as if the encoder had last run in the

positive direction. Positive is the rotating

direction in which the position values

increase. (See Chapter 4.2.2 "Counting

direction" for setting).

Information window during

start

Stop cam program

Clicking on the "Stop" button stops the running program. All cam outputs assume the inactive

state. The inactive state is de-energized for non-inverted outputs, and +UB for inverted

outputs.

The outputs programmed with a special function (e.g. run control, speed monitoring) are

always active.

Manual_ProCam_V1-10_EN.doc 31/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 32

4.7 "Set position" mask

With this function the cam encoder is assigned a position value

("Preset value").

In the simplest case, the encoder could be set to "0000" in this way to calibrate the mechanical

zero position of the shaft with the display "0000". However, any other position value within the

set encoder resolution can also be transferred here.

To check this, the current position shown continually updated at the top of the window. After

the preset value is transferred with the "Assign position" button, this appears as the current

position at the top of the window.

Example: The encoder resolution has been set to 360 steps/revolution.

The permissible value range for the "Set position" function is 0 - 359 in this case.

Please observe the following note on dependence of the counting direction in the

"Set position" function.

Manual_ProCam_V1-10_EN.doc 32/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 33

Before assigning a position value, the encoder rotating direction (positive in

clockwise direction or opposite) must be specified and programmed in the encoder.

This information is transmitted to the encoder together with cam tables and other

data as part of the "Send data" function. The "Send data" function should therefore

be carried out once with the final rotating direction before the encoder is assigned a

position value.

The assignment of a position value may lead to a considerable position jump.

This position jump is not reported via the "Data Valid" special output, as it has been

purposely caused. Any running cam program also stops immediately for safety

reasons when a position value is assigned.

Manual_ProCam_V1-10_EN.doc 33/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 34

5 Connecting Encoder

5.1 Connection between PC and encoder

To realize the simplest possible connection to the PC, the encoder is equipped with an RS232

interface. With this the encoder can be connected directly to the PC. If the transfer distance is

greater than 30 m, it is advisable to use the RS485 interface. In this case an interface

converter with an automatic directional switchover function is required on the PC (not included

in the delivery scope).

5.1.1 Encoder programming connection

To program the encoder via a PC, the wires TxD, RxD and GND must be connected as

follows.

Connection assignment

Encoder

Function

UB Pin 36 RxD Pin 35 Pin 3

GND Pin 37 Pin 5

TxD Pin 34 Pin 2

Jumper 4-6 and

Jumper 7-8

The encoder must also be connected to the power supply (UB/red and GND/blue) via the

device plug.

Accessories: Z 139.009 Programming cable

ProCam programming software

Manual on CD

D-SUB connector,

37-pin

PC Connection

D-SUB, 9-pin

Manual_ProCam_V1-10_EN.doc 34/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Page 35

6 Index

Installation · 5

A

Automatic selection · 8

B

Back to main menu · 12

C

Code (steps) · 17

D

Decreasing clockwise · 17

Display module · 30

I

Increasing clockwise · 17

M

Manual selection · 9

N

New · 12

O

Open · 12

Operating system · 5

P

Print · 12

Print setup · 12

Programming mask · 16

R

Request data · 14

Reset · 14

RS232 · 34

RXD · 34

S

Save · 12

Save as · 12

Send data · 14

Steps · 18

T

Tabs · 11

Total resolution · 18

TxD · 34

Manual_ProCam_V1-10_EN.doc 35/35 Baumer IVO GmbH & Co. KG

10.05.11 Villingen-Schwenningen, Germany

Loading...

Loading...