Page 1

Operators instructions

CombiPress™, type PFMx

CombiPress™ PFMx high end pressure transmitter is made for

measuring pressure in all gaseous and liquid processes, within

ranges from full vacuum (-1 bar) to 400 bar gauge.

Safety instructions

This instrument is built and tested according to the current EUdirectives and packed in a technically safe condition. In order to maintain this condition and to ensure safe operation, the user must follow the

hints and warnings given in this instruction.

During the installation the valid national rules have to be observed. Ignoring the warnings may lead to severe personal injury or substantial

damage to property.

The product must be operated by trained staff. Correct and safe operation of this equipment is dependent on proper transport, storage, installation and operation.

All electrical wiring must conform to local standards. In order to prevent

stray electrical radiation, we recommend twisted and shielded input

cables, as also to keep power supply cables separated from the input

cables. The connection must be made according to the connection diagrams.

Before switching on or off the power supply take care that other equipment is not effected. Ensure that the supply voltage and the conditions

in the environment comply with the specification of the device.

Description

The CombiPress™ PFMN industrial and PFMH hygienic version pressure transmitter is a high end programmable instrument for

measuring pressure from full vacuum to 400 bar gauge pressure or 0 to 400 bar absolute pressure.

CombiPress™ series are supplied to industrial applications with threaded connections or with hygienic connections for hygienic

applications. All wetted parts are in stainless steel AISI 316L (or better). The connection can be mounted as bottom connection or

as rear connection.

PFMx is powered by a 10…35 VDC power supply, featuring an analogue 4...20 mA output signal. A version with 4...20 mA signal

with HART® and an ATEX-version is available.

The CombiPress™ can be mounted with or without a display. The version with display utilizes the Baumer CombiView™ DFON

display, which is connected to the transmitter via the internal UnitCom ribbon cable. The DFON is supplied with power and a digital

signal for measured value, programming etc., which is more reliable and with better accuracy, than using a 4…20 mA loop. In

instruments with UnitCom both the transmitter and display can be programmed at the same time or separate programming of each

device can be selected.

The DFON has a unique background colour setting. Three colours are available – White / Red / Green and further the red and

green colour can be set as flashing as a warning.

The DFON has two integrated galvanic separated relays. The instrument can be delivered with or without activated relays. If supplied without activated relays, those can be activated by purchasing a license code from Baumer. By entering the code to the instrument via the FlexProgrammer the relays are enabled.

The DFON can be programmed by the touch screen on the display or by the FlexProgrammer 9701 Baumer programming unit with

the Baumer FlexProgram installed on a PC.

www.baumer.com

Operators instructions: 11120948 PFMx Page 1 / 12

EN/20131117 Design and specifications subject to change without notice

Page 2

Operators instructions

CombiPress™, type PFMx

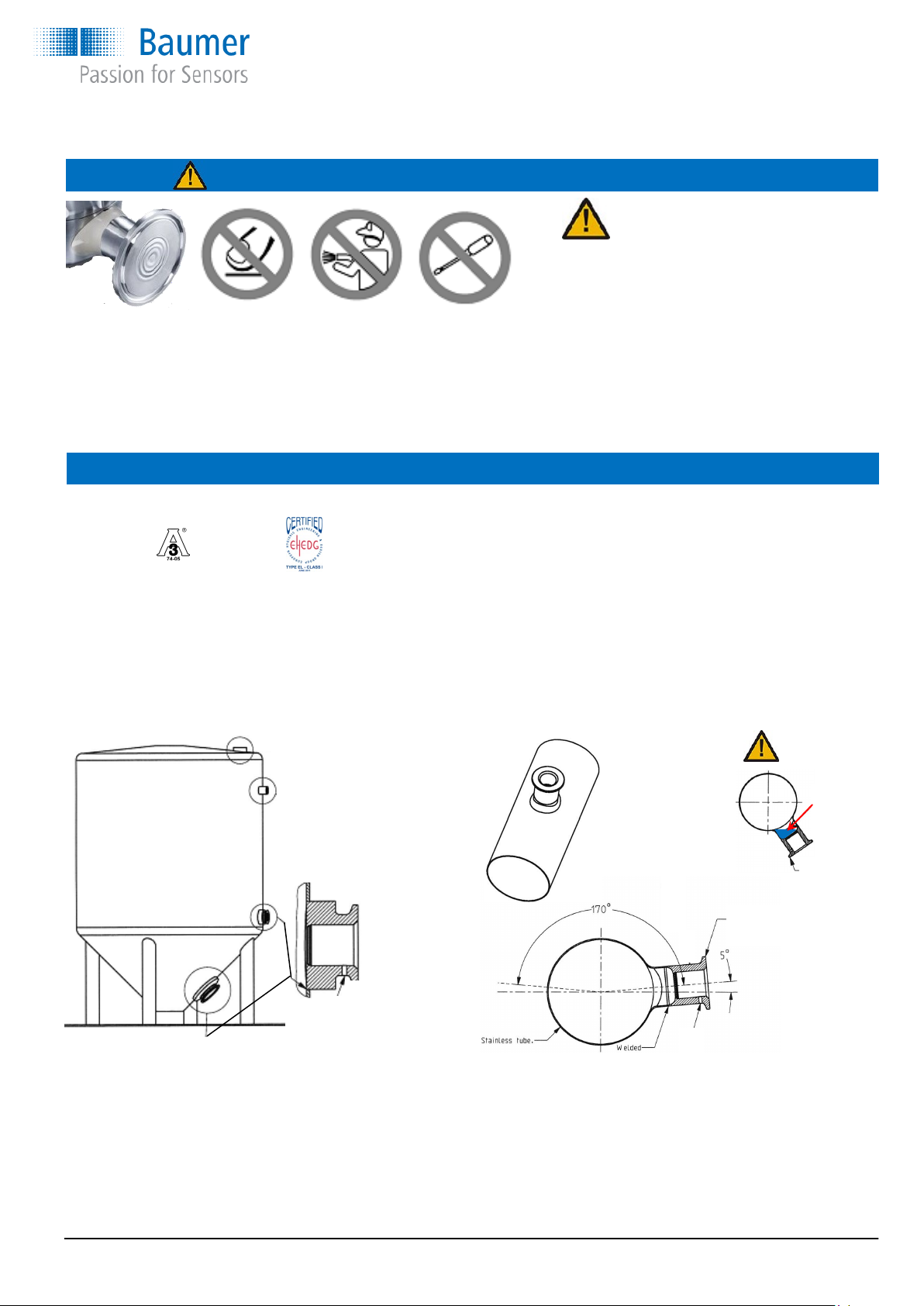

Warning

The diaphragm Don’t No high Use no

is very sensible toutch pressure tools

and easy to destroy cleaning

Mounting

Factory guarantee is void on mechanical damage

of the diaphragm

Don’t touch the diaphragm

Always put on the protection cap if removing

the instrument from the application

Don’t use a high pressure cleaner on the dia-

phragm

Don’t use any tools on the diaphragm, only a

soft brush may be used.

Installation of 3A approved and EHEDG certified products:

1) Use only a 3A approved counter part.

2) The inspection hole should be visible and drained.

3) Mount the instrument in a self drained position.

4) Level the inner surface of the pipe with the counter part.

5) Welding's should be grinded to Ra= 0.8

Tighten the connection with a torque of:

PFMN G½A/G1A 20 Nm

WARNING

Cannot be

drained

Fitted

incorrect

Example

with 8126928

Example

with 8126916

After installation and configuration

Check the leak tightness between the welding

sleeve and the instrument

Check the tightness of glands or M12 plugs.

Check the tightness of the instrument cover

www.baumer.com

Leakage indication hole

must be placed downwards

Operators instructions: 11120948 PFMx Page 2 / 12

Page 3

Operators instructions

CombiPress™, type PFMx

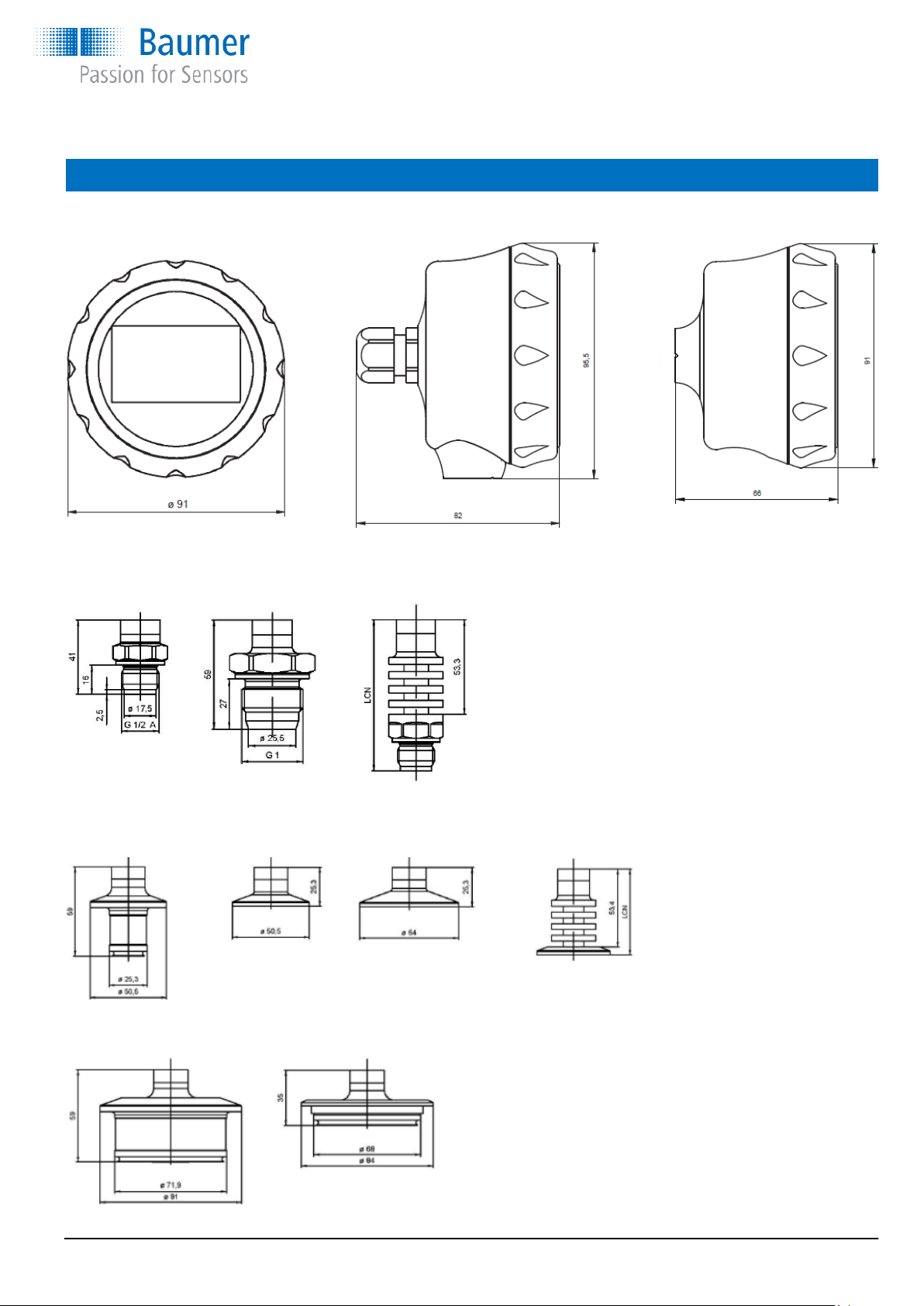

Dimensions

Housing Housing Housing

Diameter Bottom connection Rear connection

Connections for industrial pressure transmitter PFMN

Connection 41 Connection 44 Connection with

G½A G1 conical cooling neck

High temperature types

Standard High temp. LCN:

Code 41 → Code 71 77 mm

Code 44 → Code 74 89 mm

Connections for hygienic pressure transmitter PFMH

Connection 50 Connection 51 Connection 54 Connection with

3A DN 38 ISO 2852 DN 38 ISO 2852 DN 51 cooling neck

High temperature types

Standard High temp. LCN:

Code 51 → Code 81 51 mm

Code 54 → Code 84 51 mm

Connection 56 Connection 61

3A DN 76 Variline® type N

www.baumer.com

Operators instructions: 11120948 PFMx Page 3 / 12

Page 4

Installation

Operators instructions

CombiPress™, type PFMx

If the transmitter is visibly damaged, it should not be put into

operation.

The pressure diaphragm must not be touched during installation. Cleaning with high pressure cleaners and tools may damage the diaphragm.

If the transmitter has a G½A connection, check before mounting that the depth of the hole is at least 20 mm.

For correct installation in 3A connections please see page 2.

Mounting the pressure transmitter in a closed system (e.g. a

valve) may create overpressure higher than permitted, which

can deform and damage the diaphragm.

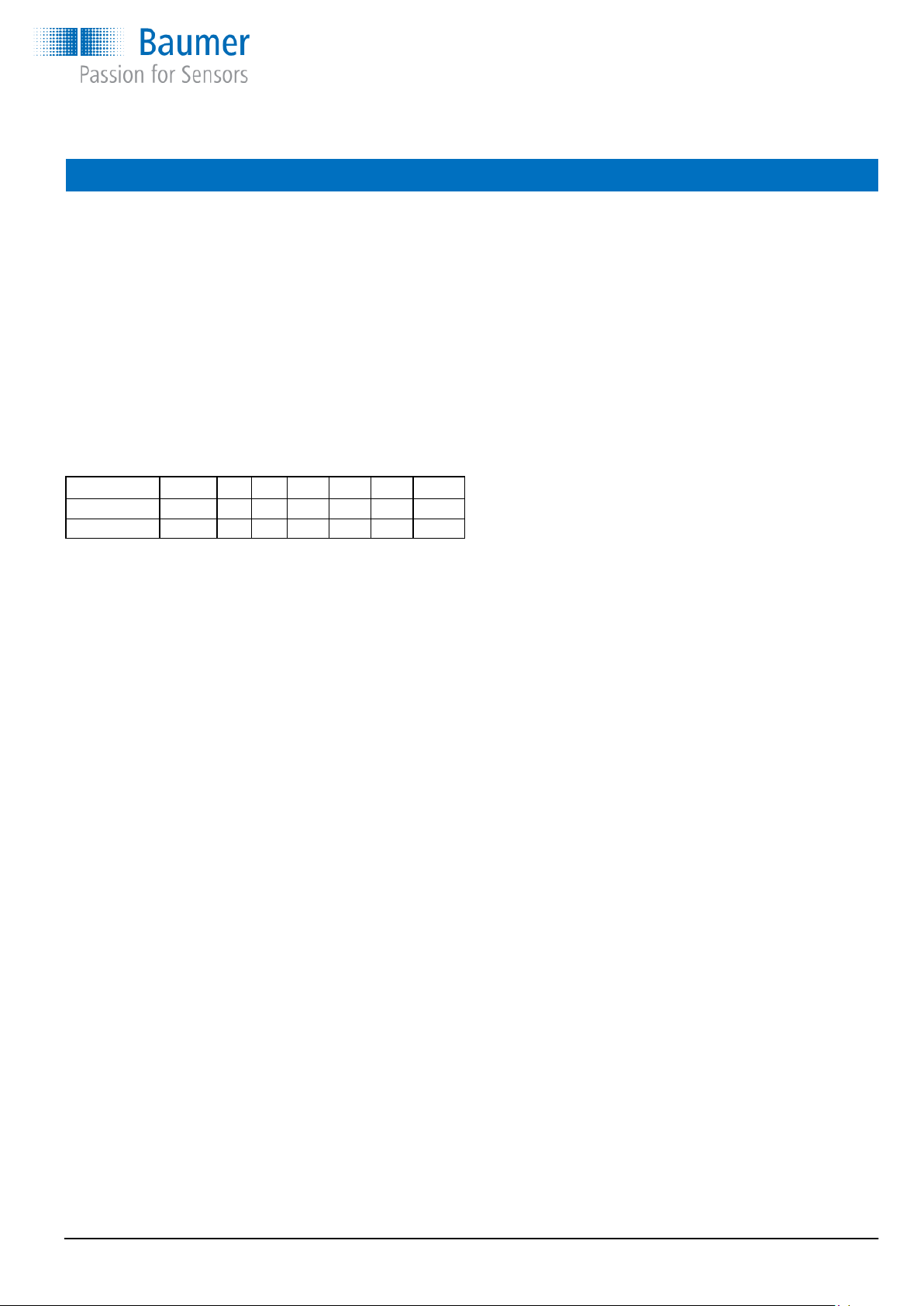

Measuring ranges and over pressure safety

Cell range, bar 0...0,345 -1...1 -1...5 -1...20 -1...34 -1...68 -1...400

Over pressure 1 3 15 60 70 135 690

Burst pressure 2 6 30 120 170 270 1.350

The freezing point of the filling liquid must not be exceeded

White oil -10°C

Silicone oil -40°C

The maximum temperature for the filling liquid is 200°C.

Though the maximum temperature is limited by the mechanical

construction for standard connection to 125°C.

During CIP the temperature may reach 150°C for max. 1 hour.

Installation procedure

The pressure transmitter can change zero point slightly, owing to

mechanical tension and the fitting direction selected for the pressure diaphragm. Optimal results are therefore achieved if the

zero point is adjusted after the pressure transmitter has been

mounted in place in the application.

Electrical installation

Suitable cables should be used to secure maximum tightness in

the gland. For models having a plug for electrical connection the

inner part of the plug must be oriented in a way so that the opening is turning downwards.

To avoid measuring errors resulting from insufficient supply voltage, the transmitter must be supplied with min. 10 VDC at 23

mA. When mounted with DFON display the minimum voltage will

be 14,5 or 16,5 VDC, depending on the setting of the background light.

The transmitter has a high immunity against high-frequency interference. In environments with a high radiation it is recommended to use screened and twisted cable.

Accuracy, turn down

The specifications for accuracy apply to full scale (FS). at 20°C

However the below results are tested and will under normal conditions apply

Accuracy: 0,10%/FS@20°C will apply for up to 2:1 turn down

0,25%/FS@20°C will apply for up to 4:1 turn down

a) Remove protection-cap.

b) Install CombiPress™ in the application

c) Connect the power supply

d) If needed, configure span by the touch screen, FlexPro-

grammer or a HART configurator.

e) If needed, configure the 0-point (4 mA) by pressing the

0-botton for about 5 second (slow blinking diode in app.

5 sec after which the diode will blink fast and the 0-point is

set) or use the facility in the FlexProgrammer or the HART

configurator.

The electronic zero point can be adjusted from -10...10% of the

measuring range.

The correct zero point pressure must be established prior to

adjusting the zero point. Tank and pressure transmitter must

have the same temperature. If the pressure transmitter has a

relative measuring cell from 0 bar, the zero point pressure is the

same as the atmospheric pressure or the level in a tank selected as zero point level. A pressure transmitter measuring absolute pressure has a zero point lower than 1 mbar abs.

You can revert to the factory set zero point correction by recon-

figuring the CombiPress™ with the FlexProgrammer and select-

ing factory setting.

www.baumer.com

Operators instructions: 11120948 PFMx Page 4 / 12

Page 5

Operators instructions

CombiPress™, type PFMx

CombiView™ DFON display

There are 9 different display modes available

Digital Analogue Bar graph Tank

small analogue horizontal tank illustration

large same w. bar graph vertical bottle illustration

same w. value

Electrical connection

Electrical connection

M12, 5-wire M12, 8-wire

1 + supply, 4...20 mA 1 n.c.

2 Common for relays 2 + supply, 4...20 mA

3 - supply, 4...20 mA 3 Relay 1

4 Relay 1 4 Relay 1

5 Relay 2 5 Relay 2

6 Relay 2

7 - supply, 4...20 mA

8 n.c.

Electrical connection

Pin 1 + 4…20 mA (not connected)

Pin 2 - 4…20 mA (not connected)

Pin 3 Relay 1

Pin 4 Relay 1

Pin 5 Relay 2

Pin 6 Relay 2

Com 1 FlexProgrammer ① red

Com 2 FlexProgrammer ② black

The PFMx with DFON display is delivered with terminal 1 and 2 not connected. The DFON is powered and will have data direct

through a special ribbon cable (UnitCom). Via UnitCom the DFON and PFMx transmitter can be programmed together when connecting the FlexProgrammer to Com 1 and COM 2 on the back of the display.

Cable gland

Transmitter

- - supply, 4...20 mA

+ + supply, 4...20 mA

Com 1 Red clip (FlexProgrammer)

Com 2 Black clip (FlexProgrammer)

Display

1 n.c.

2 n.c.

3 Relay 1

4 Relay 1

5 Relay 2

6 Relay 2

Com 1 Red clip (FlexProgrammer)

Com 2 Black clip (FlexProgrammer)

UnitCom

Pin 3 and 5 can be jumpered together if common supply is used for the two relays, e.g. via a M12 5-pin connector. Two galvanic

separated relay outputs will require a 8-pin M12 connector if plug connection is required. If cable glands is used the terminals 4...6

is connected via the screw terminals.

www.baumer.com

Operators instructions: 11120948 PFMx Page 5 / 12

Page 6

Operators instructions

CombiPress™, type PFMx

Touch screen programming the CombiView™, type DFON

Programming CombiView™, type DFON using the touch screen on the display

Tap on the display screen and the button will appear in the bottom.

Press and the display will start with the below menu.

With a transmitter communicating with the DFON via UnitCom ribbon cable

Instrument name menu

transmitter will automatically be uploaded in the display.

Display menu

in the display and also if a level measurement is wanted e.g. a volume or weight acc. to the pressure.

Data display mode

In this mode the display will communicate directly with the transmitter digitally, which is more accurate than using

the 4…20 mA communication.

For programming configuration please see page ?

For programming Display setup and Diagnostics please see page ?

MENU

Display menu

Enabling to the user to programme the connected transmitter through the DFON display. All data programmed into the

Enabling to the user to programme the DFON display only. This is necessary for programming the ColourView and relays

Enabling to the user to programme the connected transmitter and the programmed values will also be valid for the DFON

display. (Ignoring whatever setup already set on the display)

Only programming of background colours and relays must be done under “Display menu” / “Configuration”.

Instrument name menu

MENU

Display setup

Data display mode

Instrument name menu

Instrument name menu

Instrument name menu

Instrument name menu

Instrument name menu

Programming the PFMx/DFON mounted on the application on site using either the touch screen or the FlexProgrammer .

If mounted with DFON the ribbon cable (UnitCom) must not be disconnected after installation and power up of the PFMx. If this

happens the transmitter cannot “see” the display. To enable the PFMx to “see” the DFON again, please disconnect the power

supply to the transmitter, reconnect the ribbon cable (UnitCom) and connect the power supply again.

Programming the CombiPress™, type PFMx with the FlexProgram and FlexProgrammer

Guidance on programming of CombiPress™ PFMx with the DFON display using FlexProgram on your PC and the FlexProgram-

mer hardware tool will not be described here. A full manual for this is available on Baumer home page.

Please see or download the instruction from below internet address:

www.baumer.com → download → product documentation → assembly instructions/Operation instructions/Manuals → Programming the DFON

www.baumer.com

Operators instructions: 11120948 PFMx Page 6 / 12

Page 7

Operators instructions

CombiPress™, type PFMx

Touch screen programming the CombiView™, type DFON

Identification

TAG No. / Serial No. / Date / Prod. date

Display menu

Configuration

Input

Display output

Error/warning

Relay setup

Input 100%

Input 0%

Damping

Linearization

Display 100%

Display 0%

Decimals

Units

Rel. / Abs.

High error

High warning

Low error

Low warning

Relay 1 mode

Rel. 1 set point

Rel. 1 reset point

Relay 1 mode

Rel. 1 set point

Rel. 1 reset point

This menu section is only available when the relays are activated

Current at 100% (20 mA)

Current at 0% (4 mA)

0 = off / 1...30 sec.

Enable / Disable

Display value at 100%

Display value at 0%

Number of digits point

Select from list

Select CUSTOM / create

Select, when pressure

High error limit

High error indication

High error back light

See High error

See High error

See High error

AO / AC / NO / NC

Point at relay ON

Point at relay OFF

AO / AC / NO / NC

Point at relay ON

Point at relay OFF

Display setup

Diagnostics

www.baumer.com

Screen layout

Back light

Password

Attached

Statistics

Demo setup

Standard screen

Specific screen

This menu section is only available when synchronized via UnitCom

Colour

Intensity

Password enable

New password

Attached instr.

Att. Instr. menu

Min. / Max. value

High / Low errors

Demo mode Disabled / Static / Cyclic

Static value

Factory setting

Service menu

Operators instructions: 11120948 PFMx Page 7 / 12

Select display design

Select display design

Point at relay OFF

Point at relay OFF

Enable / Disable

Create new password

Display name of A.I.

Instr. Specific menu

Insert value

Load factory setting

For service personnel

Page 8

Operators instructions

CombiPress™, type PFMx

CombiPresS™ w./w.o. DFON - ATEX specifications and instruction

PFMx Zone 0 Gas: II 1 G, Ex ia IIC T5 Ga

Zone 20 Dust: II 1D, Ex ia IIIC T100°C Da

Zone 2 Gas: II 3G, Ex nA II T5

Please ensure that special requirements for installation in the specific environment is followed, as described below.

Safety instructions

This instrument is constructed and tested according to the current EU directives and packed in a technically safe condition. In

order to ensure safe conditions and operation, the user must follow the instructions and warnings given in this instruction and the

standard operation instruction.

During the installation the valid national rules have to be observed. Ignoring the instructions may lead to severe personal injury or

substantial damage to property.

The product must be installed and operated by trained staff. Correct and safe operation of this equipment is dependent on proper

installation and operation.

All electrical wiring must conform to local standards and the connection must be made according to the connection diagrams on

the following pages.

Before switching on the power supply take care that other equipment is not affected. Ensure that the supply voltage and conditions in the environment comply with the specification of the device.

Before switching off the supply voltage check the possible effects on other equipment and processing system.

To obtain the specified ingress protection degree, the CombiPress™, type PFMx must be mounted with a compliant cable.

Warning

This product is allowed to be operated in an explosion hazardous atmosphere of zone 0 only if atmospheric conditions exists

(temperature –20°C…+60°C and pressure from 0,8...1,1 bar). Under other atmospheric conditions the certificate may be used as a

guide.

Use of FlexProgrammer 9701 is only allowed in the safe area, not in the hazardous area.

Impact test of the display cover is performed according to EN 60079-0, with low impact energy of 2J and does not create a crack or

other intrusion into the housing. However the display, which is mounted close to the front cover may be damaged, but this will not

create any external sparking. The housing is impact texted also according to EN 60079-0, with low impact energy of 4J on housing,

connectors and cable gland.

This product contains no replaceable parts. In case of malfunction the products must be shipped to Baumer for repair.

www.baumer.com

Operators instructions: 11120948 PFMx Page 8 / 12

Page 9

Operators instructions

CombiPress™, type PFMx

ATEX Gas ia and for ATEX Dust ia

For ATEX ia Gas zone 0 and ATEX ia Dust zone 20 a zener barrier must separate the hazardous and safe area and must be installed in accordance with prevailing guidelines for zone 0 / zone 20.

ATEX ia Gas / Dust data:

Approval: Gas Zone 0/1 II 1 G, Ex ia IIC T5 Ga

Dust Zone 20/21 II 1 D, Ex ia IIIC T100°C Da

Voltage drop U

Temperature class T1…T5 Zone 0 and 20 -20°C…60°C

Zone 1/2 and 21/22 -40°C…65°C

Internal inductivity Li <10 µH

Internal capacity Ci <15 nF

Barrier data Ui <30 VDC

Ii <0,1 A

Pi <0,75 W

Suitable barrier e.g.: Pepperl+Fuchs, Z728

4,5 or 6,5 VDC

Disp

The display is supplied via the UnitCom from the transmitter. However to make the transmitter/display intrinsic safe a zener barrier

must be inserted before the PFMx/DFON. As the CombiView™, type DFON is attached to a Baumer PFMx transmitter using the

UnitCom ribbon cable, it is considered to be an integrated part of the instrument.

If the relays are enabled, each relay must be protected by a zener barrier. Use a barrier for each relay or a barrier with multiple

channels. However the two relays must have each a barrier.

Barrier data U <30 VDC

I <75 mA

P <0,75 W

Suitable barrier e.g.: Pepperl+Fuchs, Z779

Electrical connection

PFMx without relay output PFMx with relay output

1 +

1 +

2 -

Zener

barrier

15…30 VDC

2 -

3

Relay 1

4

5

Relay 2

6

Zener

barrier

Zener

barrier

Zener

barrier

15…30 VDC

0…30 VDC

75 mA

0…30 VDC

75 mA

www.baumer.com

Operators instructions: 11120948 PFMx Page 9 / 12

Page 10

Operators instructions

CombiPress™, type PFMx

ATEX Gas nA

For ATEX nA zone 2 is approved without using zener barrier to separate the hazardous and safe area and must be installed in

accordance with prevailing guidelines for zone 0.

ATEX data:

Approval: Gas Zone 2 II 3 G, Ex nA II T5

Voltage drop U

Temperature class T1…T5 -30 < T

4,5 or 6,5 VDC

Disp

amb

<65°C

Internal inductivity Li <10 µH

Internal capacity Ci <15 nF

Maximum voltage U

Maximum current I

Display without relay output Display with relay output

<35 VDC

max

<0,1 A

max

1 +

2 -

4…20 mA

1 +

2 -

3

4

5

4…20 mA

Relay 1

Relay 2

6

Programming the CombiPress™ w./w.o. DFON in ATEX area

Programming the CombiPress™ and the CombiView™, in hazardous area with the FlexProgrammer is not allowed, as the FlexProgrammer (and/or the PC) is not ATEX approved for use in hazardous area.

Follow below procedure to programme the instrument:

a Disconnect mains from the 4…20 mA loop circuit

b Disconnect the instrument from the circuit within the hazardous area

c Uninstall the instrument and bring it to safe area

d Connect the FlexProgrammer and perform the configuration session.

e Re-install the instrument in the hazardous area

f Connect the instrument to the circuit

g Connect mains from the 4…20 mA loop circuit

www.baumer.com

Operators instructions: 11120948 PFMx Page 10 / 12

Page 11

Operators instructions

CombiPress™, type PFMx

www.baumer.com

Operators instructions: 11120948 PFMx Page 11 / 12

Page 12

Operators instructions

CombiPress™, type PFMx

Baumer AG

Hummelstrasse 17

8501 Frauenfeld

Switzerland

+41 51 / 75 81 122

+41 52 / 72 81 144

sales.ch@baumer.com

www.baumer.com

Baumer A/S

Runetoften 19

8210 Aarhus V

Denmark

+45 8931 7611

+45 8931 7610

sales.cc-lct@baumer.com

Contact your local Baumer company

or Baumer distributor.

Please see:

www.baumer.com/worldwide

Select your country

Select your contact

Operators instructions: 11120948 PFMx Page 12 / 12

Loading...

Loading...